Patents

Literature

452results about How to "Increase the diffusion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-situ remediation method of heavy metal-organic combined pollution soil

InactiveCN106269843ATo achieve an organic combinationAchieve migrationContaminated soil reclamationEngineeringAlternating current

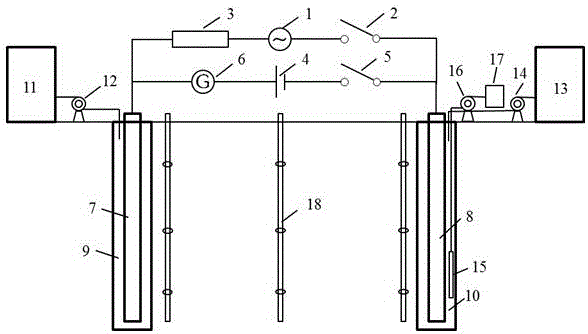

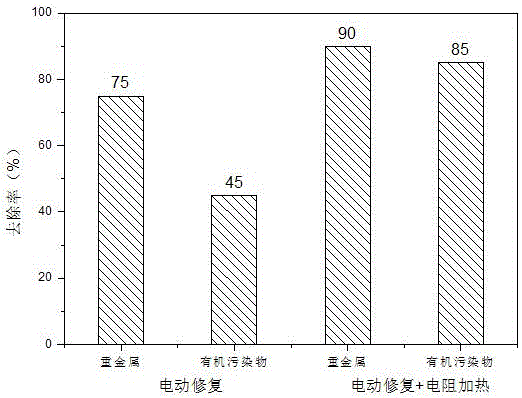

The invention relates to an in-situ remediation method of heavy metal-organic combined pollution soil. According to the method, a set of electrokinetic remediation device is added with a power switching system, an electrode heating technology is combined with the electrokinetic remediation and chemical oxidization technology, namely, the direct current power is utilized firstly, sodium persulfate used as the oxidizing agent is migrated to soil through electric process, meanwhile, migration and removal of heavy metal ion in the soil are realized. Then the alternating current power is switched, and soil is heated to a certain temperature through the electrode heating method so as to activate the sodium persulfate migrated to soil, and thereby realizing the in-situ degradation of organic pollutant in the soil. The method applies electrode to the electrode heating system and the electrokinetic remediation device at the same time, simplifies the remediation device and saves the system energy consumption while solves the difficulty that oxidant cannot migrate and activate in the soil and improves the remediation efficiency; the method is a combined soil remediation technology with prospect of application and promotion.

Owner:中建中环新能源有限公司 +1

Methods and apparatus for improved administration of testosterone pharmaceuticals

InactiveUS6726673B1Improve breathabilityImprove performanceElectrotherapyMedical devicesControl releaseDose rate

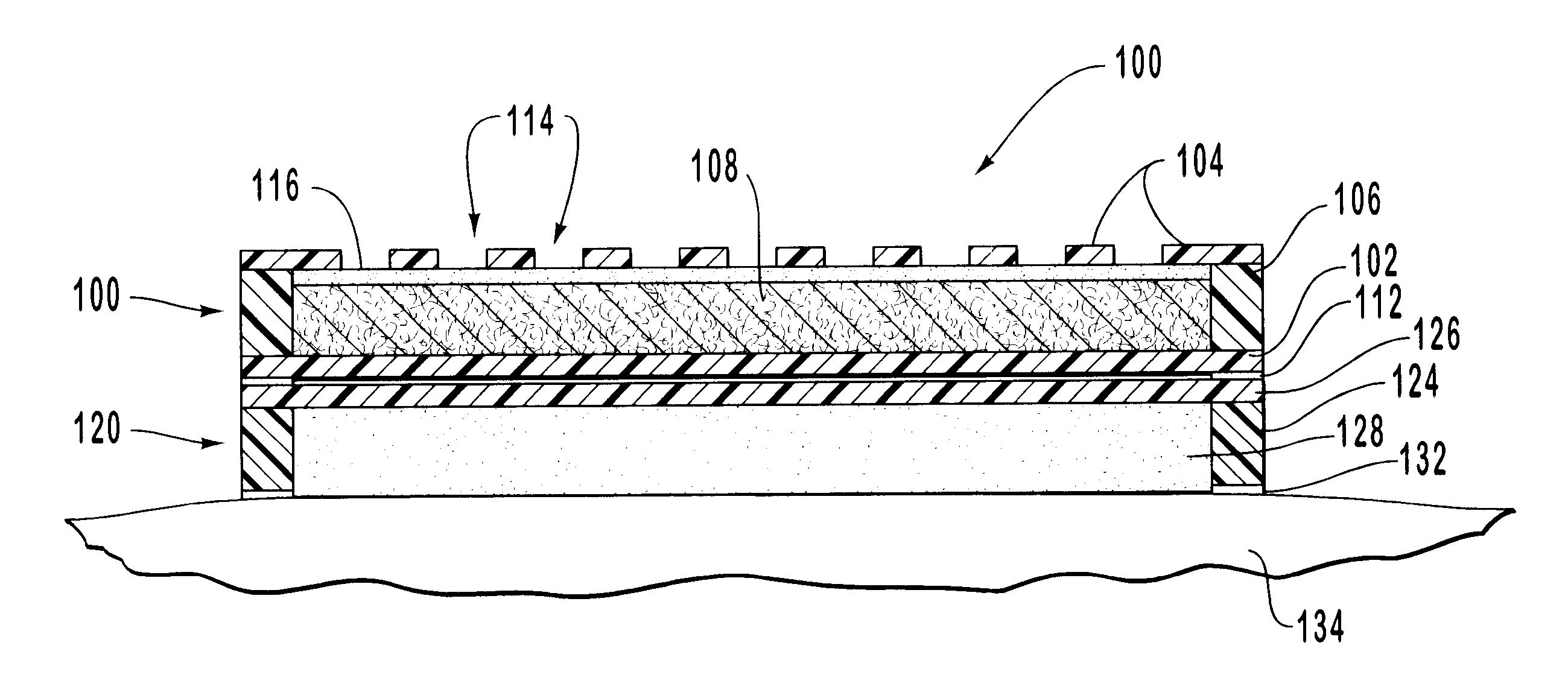

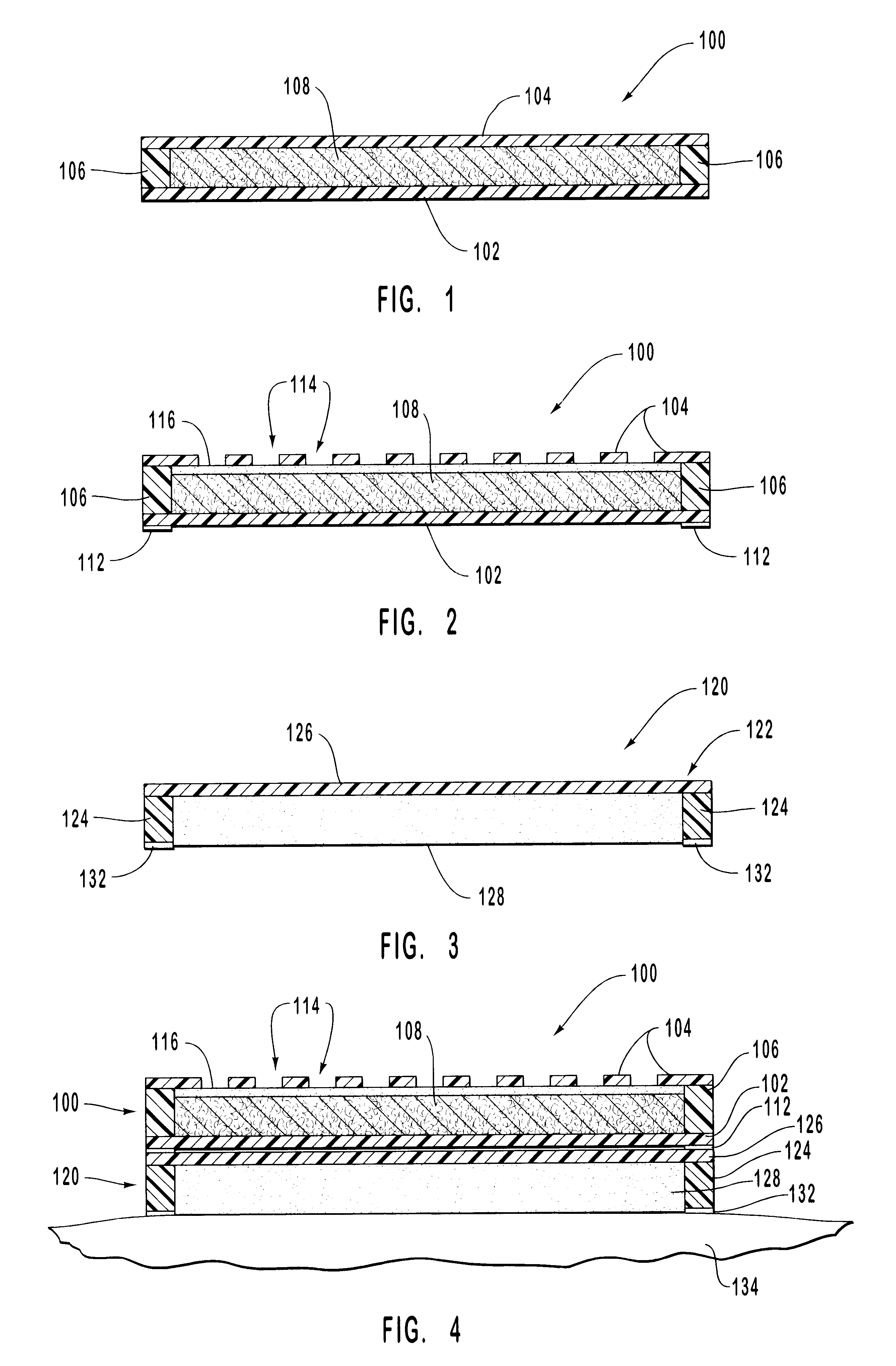

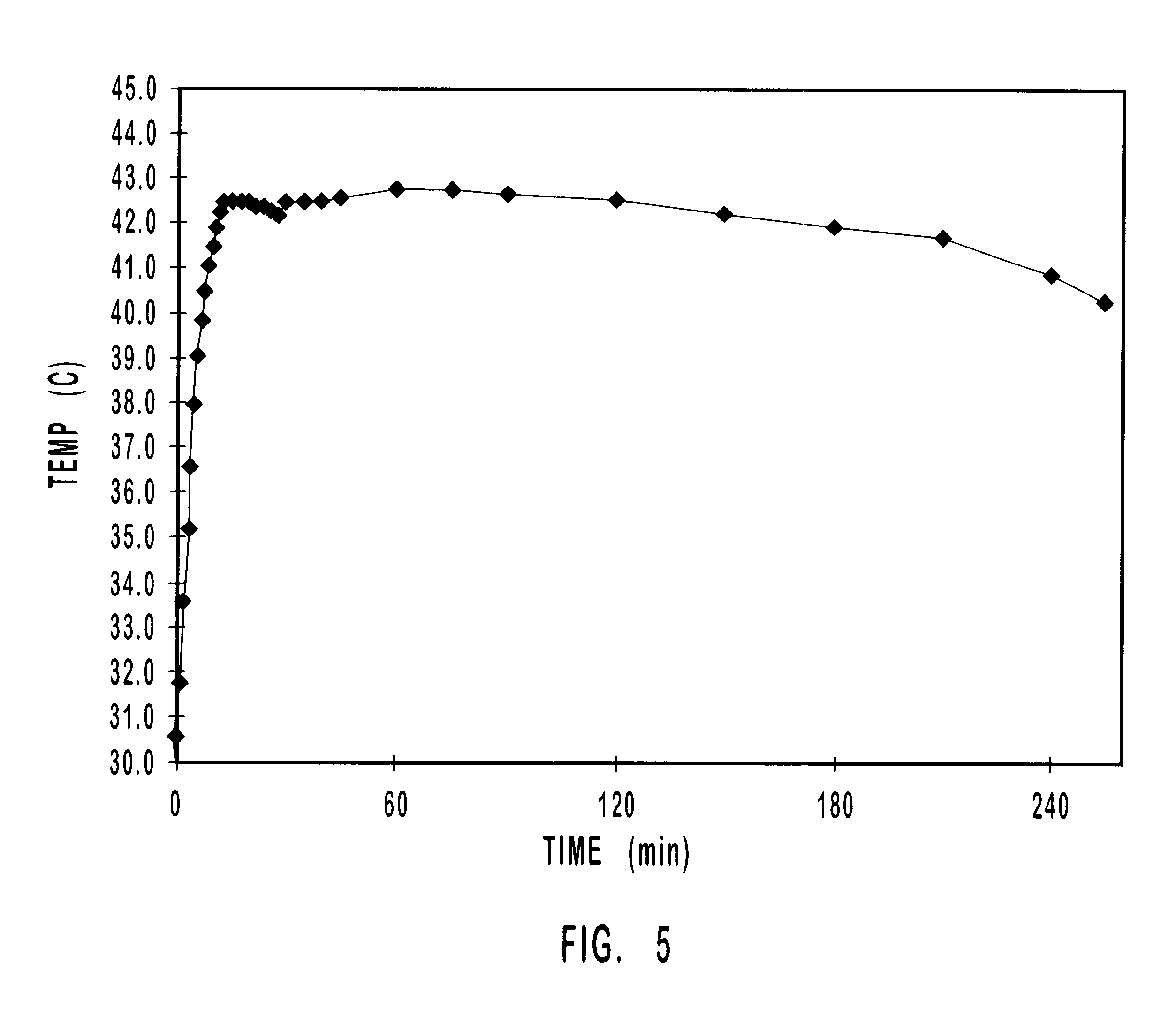

The present invention relates to a method and apparatus for increasing the delivery rate of an androgen transdermal therapeutic system through the skin. An androgen transdermal therapeutic system can be applied to a patient's skin for delivery of the androgen. A temperature modification apparatus which is capable of generating controlled heat is applied approximate to the androgen transdermal therapeutic system. The heating from the temperature modification apparatus raises the temperature of the androgen transdermal therapeutic system and raises the temperature of the patient's skin to achieve an increased rate of delivery of androgen through the skin. The controlled heat can also be used to adjust dosage rates of the androgen transdermal therapeutic system and to mimic natural circadian patterns. The controlled heating may also be used to improve or regulate the release of androgen from injected / implanted extended / controlled release systems.

Owner:NUVO RES

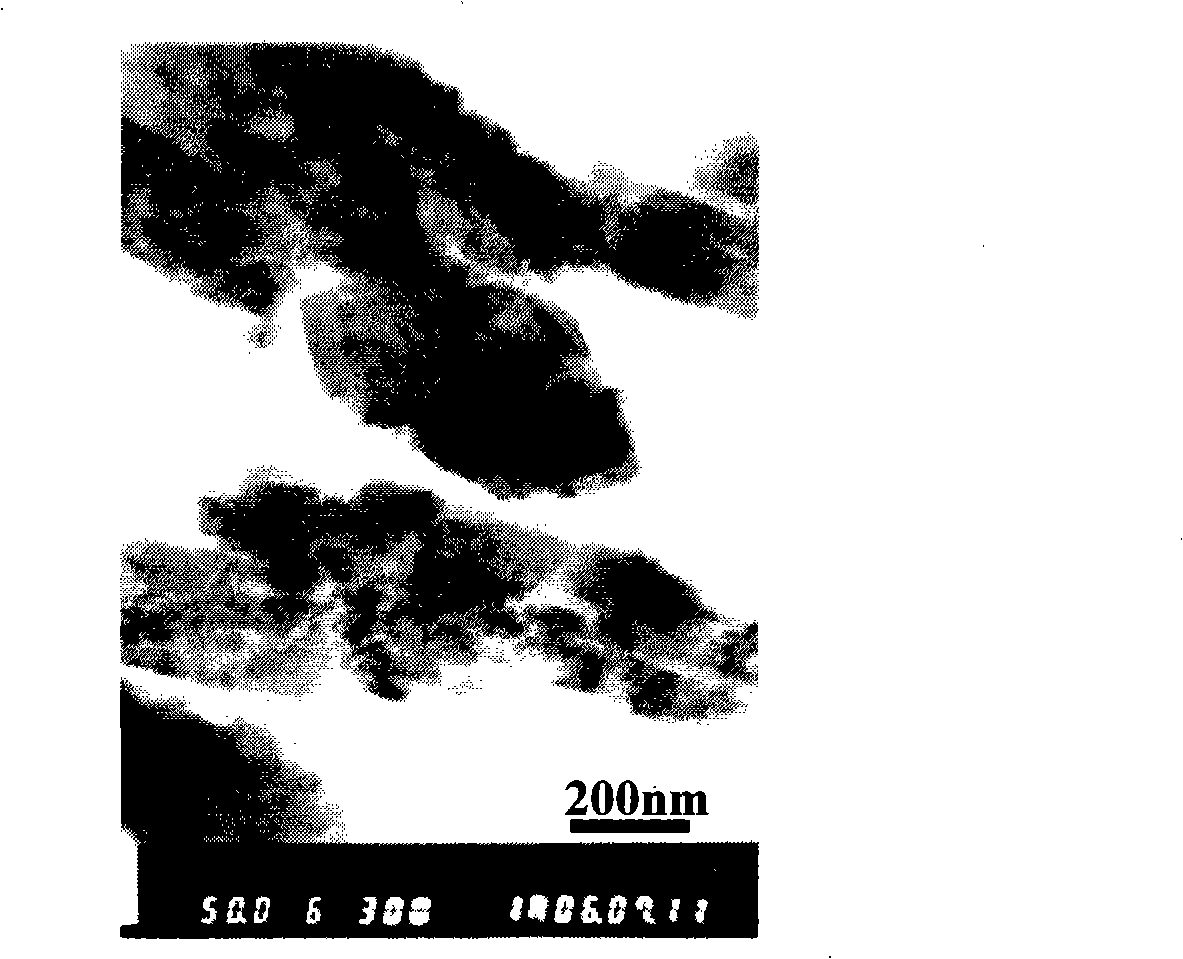

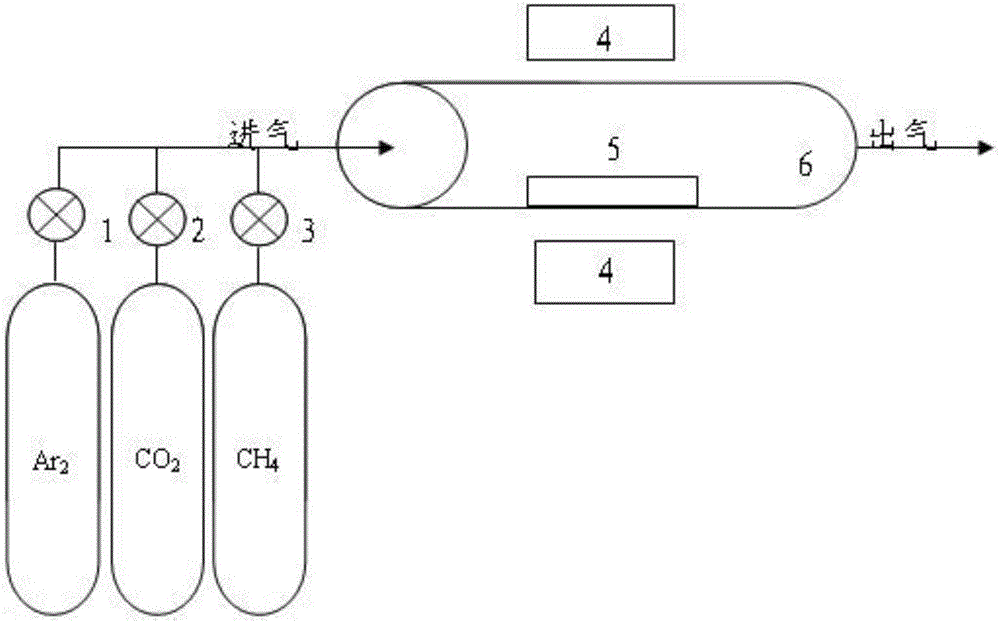

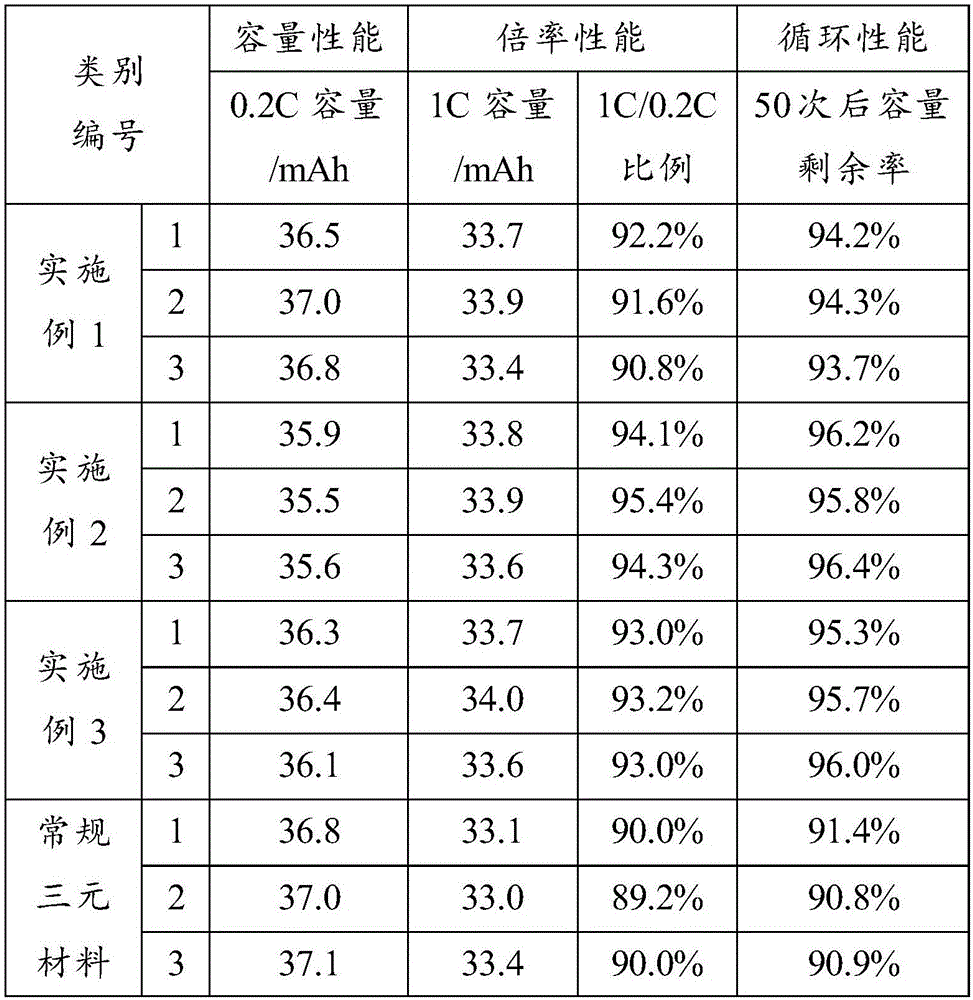

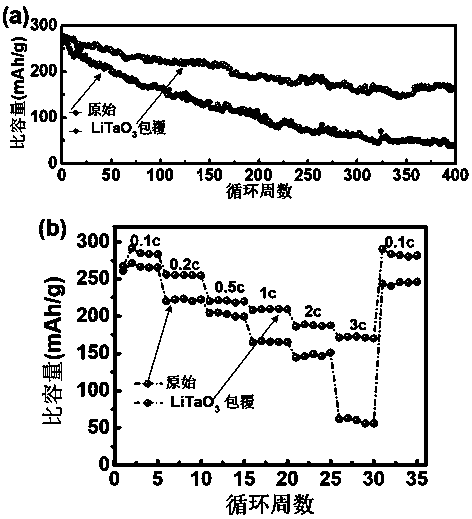

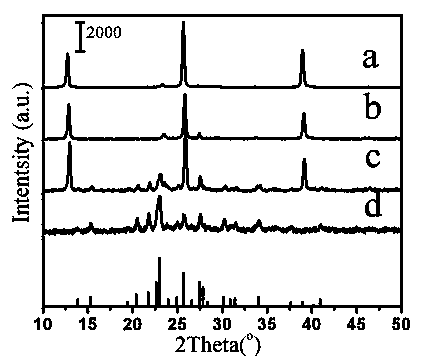

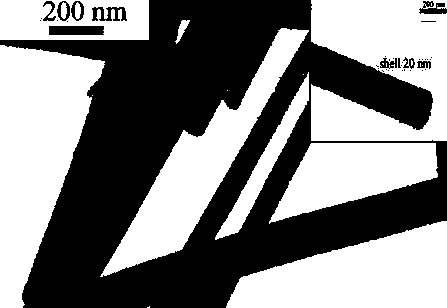

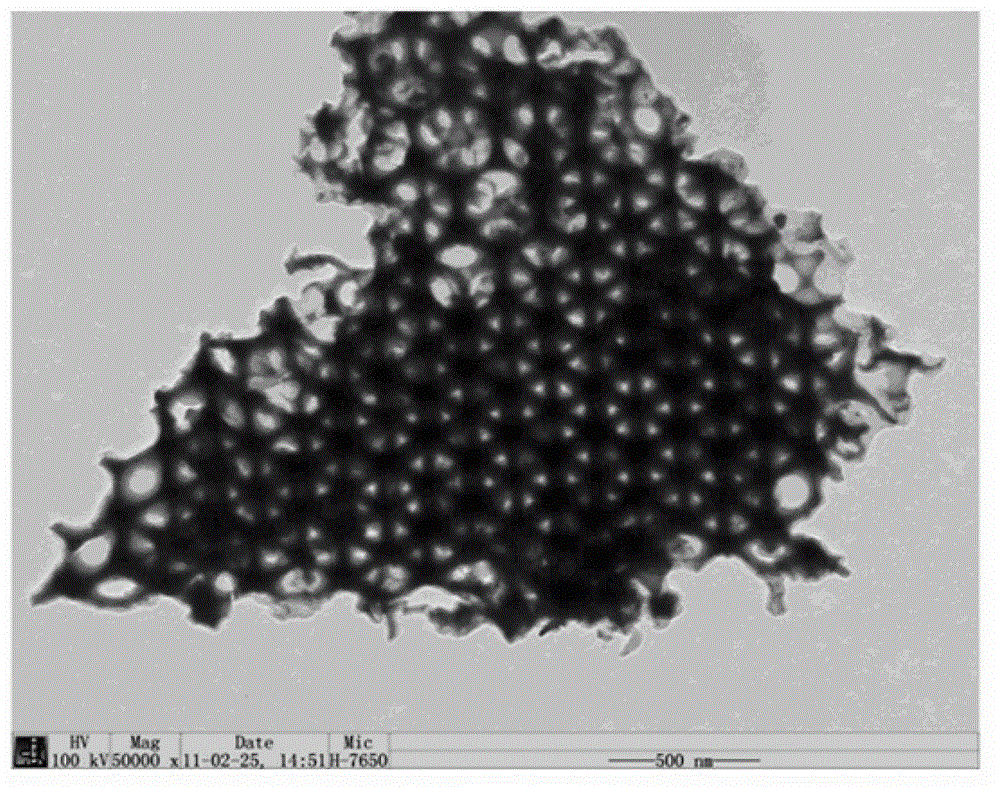

Coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material and preparation method thereof

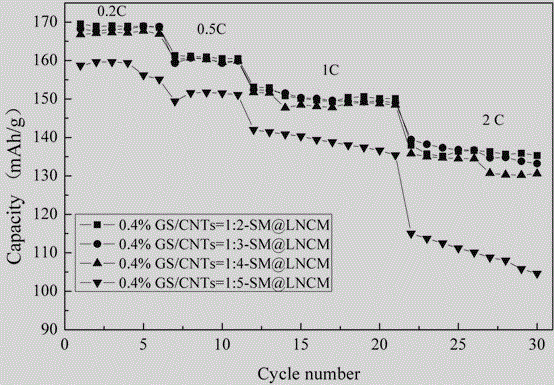

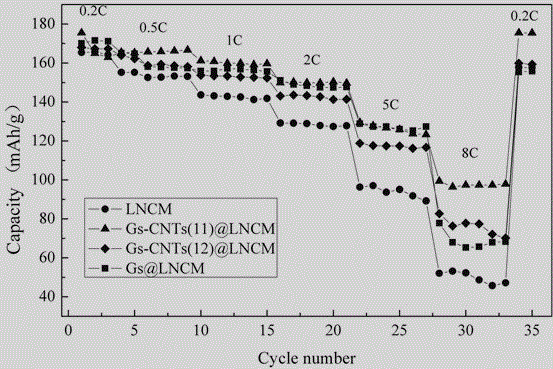

ActiveCN105070888AImprove conductivityIncrease the diffusion coefficientMaterial nanotechnologyCell electrodesManganeseCarbon nanotube

The invention relates to the technical field of battery materials, in particular to a coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material and a preparation method thereof. According to the coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material, a nickel-cobalt-manganese ternary material, carbon nano tubes and graphene are taken as raw materials; and the ternary material is characterized by being prepared by the following steps: with polyvinyl pyrrolidone as a dispersing agent, through a liquid-phase self-assembling method, simultaneously connecting the graphene and the carbon nano tubes with a silane coupling agent to form a three-dimensional network structure; and evenly dispersing the coupled carbon nano tube-graphene composite material and the nickel-cobalt-manganese ternary material through a physical method, coating the surface of the nickel-cobalt-manganese ternary material, and sintering the nickel-cobalt-manganese ternary material in an inert atmosphere, so as to obtain the evenly coated product. The product provided by the invention has the advantages of high specific discharge capacity, long cycle life and simplicity in preparation process; and large-scale production is easy to realize.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

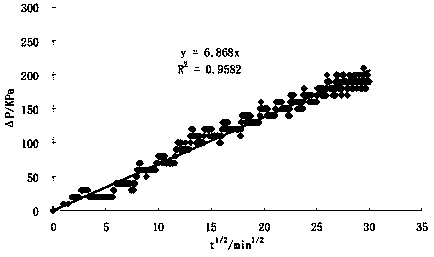

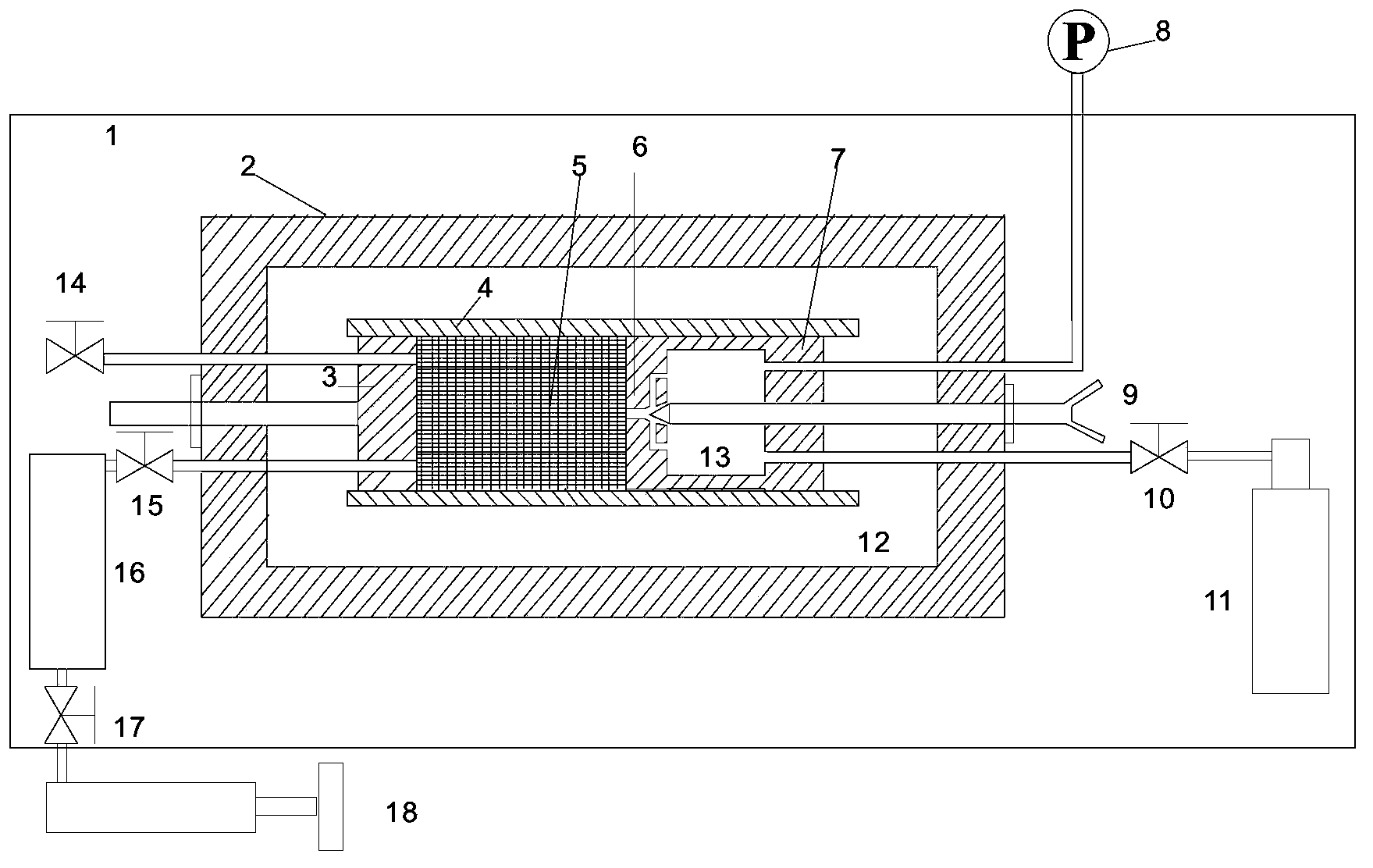

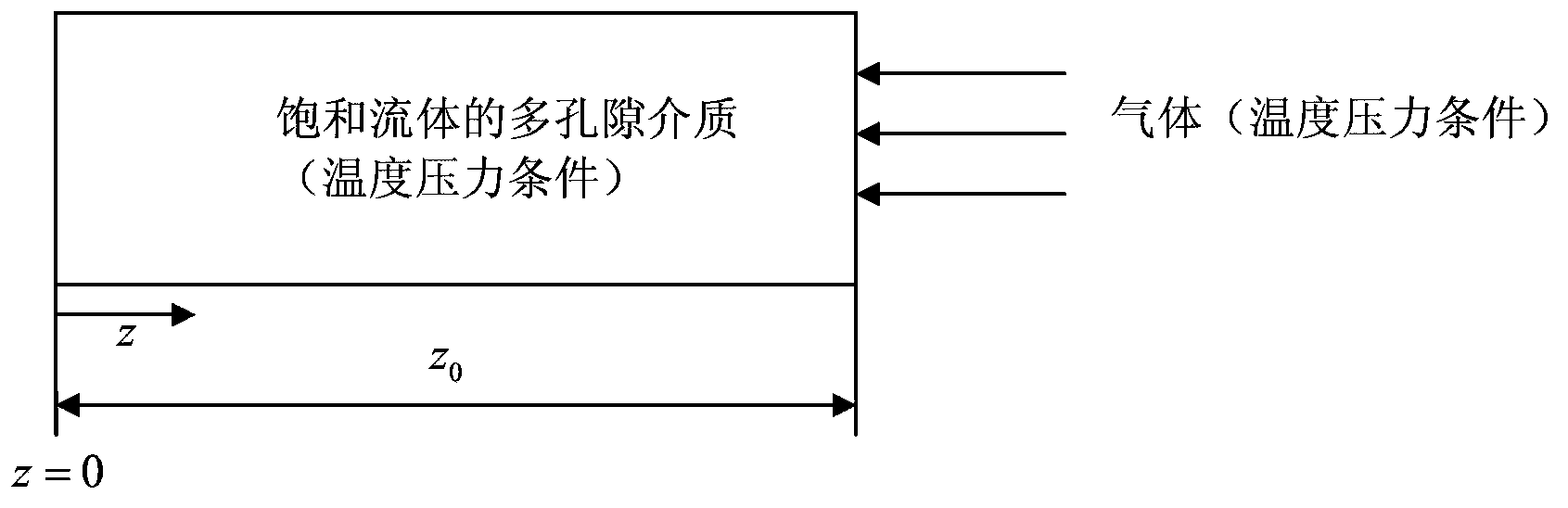

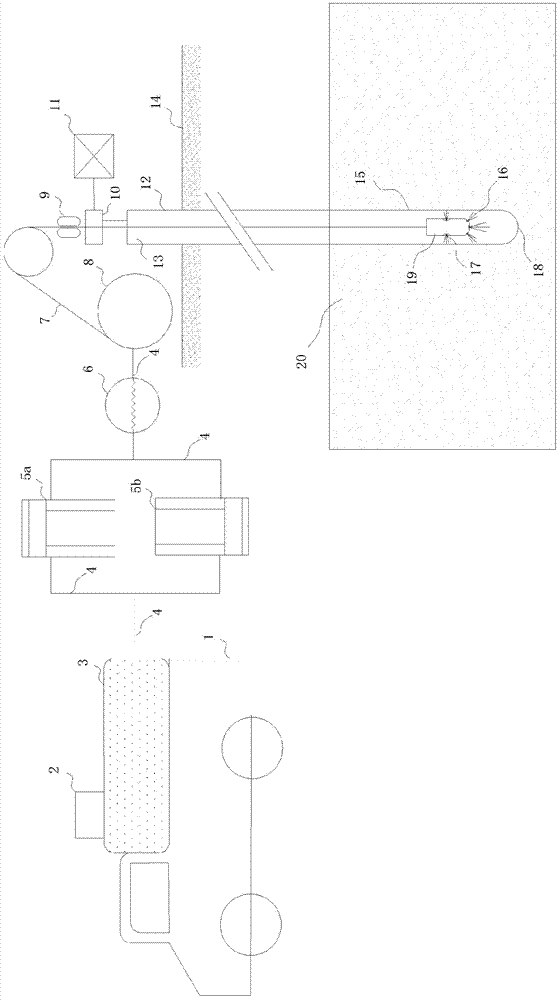

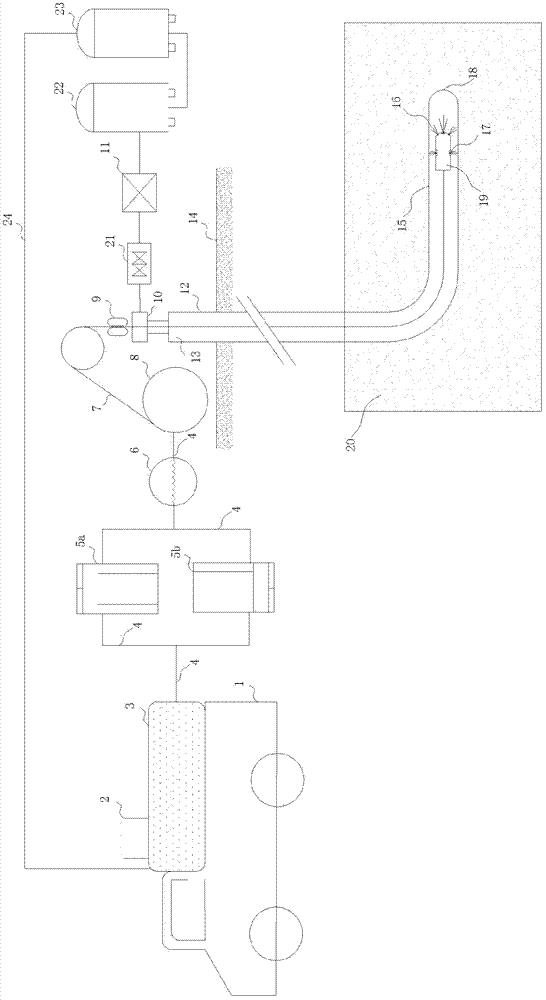

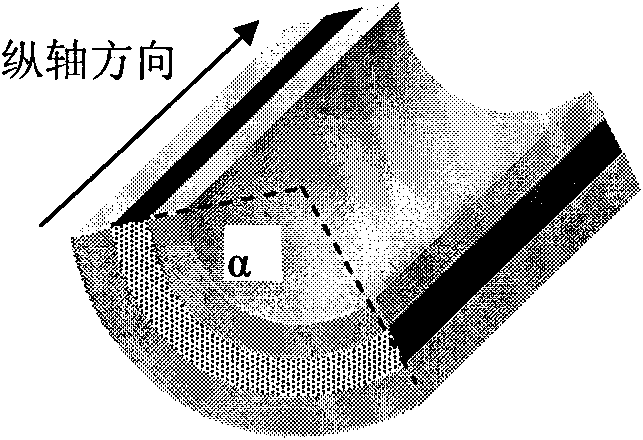

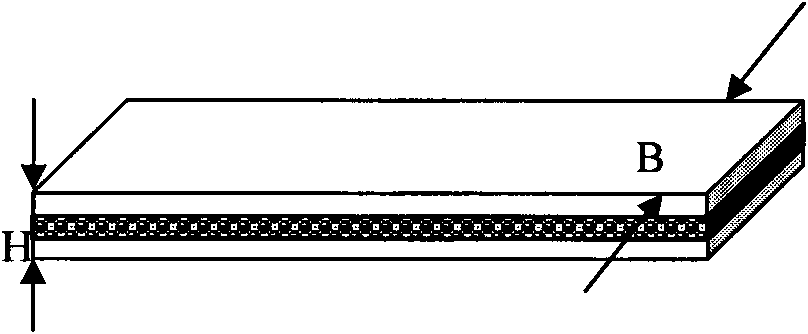

Device and method for measuring axial diffusion coefficient of gas in porous medium

ActiveCN103674799AAvoid expansion lossImprove experimental accuracySurface/boundary effectPermeability/surface area analysisGas cylinderPorous medium

The invention provides a device and a method for measuring an axial diffusion coefficient of gas in a porous medium and belongs to the field of oil-gas field development. The device comprises a constant temperature oil bath (1), and a holder (2), a container (16) and a high pressure gas cylinder (11) which are arranged in the constant temperature oil bath (1), wherein a lead sleeve (4) is arranged in the holder (2) and is in a cylindrical structure of which two ends are open; a plug (3) is arranged at one end of the lead sleeve (4), and a plug (7) with a valve is arranged at the other end of the lead sleeve (4); an outer cylindrical surface of the plug (3) and an outer cylindrical surface of the plug (7) with the valve are in sealing contact with an inner surface of the lead sleeve (4); a sample cavity is formed in an inner cavity of the lead sleeve (4) between the plug (3) and the plug (7) with the valve; a porous medium (5) is arranged in the sample cavity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method combining coiled tubing with supercritical CO2 for jet-flow sand washing plugging removal

The invention relates to a method combining coiled tubing with supercritical CO2 for jet-flow sand washing plugging removal. The method uses the supercritical CO2 as flushing fluid to carry out jet-flow sand washing plugging removal for a shaft or an oil casing. When a supercritical CO2 jet-flow is combined with the coiled tubing to carry out supercritical CO2 jet-flow sand washing plugging removal, pressure relief is not needed in the trip process, the coiled tubing can directly work with pressure, and the working procedure and the time are saved. The fluid viscosity of the supercritical CO2 is low, the surface tension of the supercritical CO2 is close to zero, and the diffusion coefficient of the supercritical CO2 is large, so that the supercritical CO2 can easily enter into tiny pores and cracks to dissolve polymer organic matters and other impurities, and the cleaning is more thorough. And, above all, the supercritical CO2 does not have any pollution to a reservoir, the viscosity of crude oil can also be reduced after the supercritical CO2 enters into the reservoir, the permeability of the reservoir is increased, and the yield and the recovery ratio are increased. Thus, the supercritical CO2 is especially suitable for downhole plugging removal working of unconventional oil-gas reservoirs such as low permeability oil-gas reservoirs, pressure-depleted oil-gas reservoirs, coal gas reservoirs, shale gas reservoirs, tight sandstone gas reservoirs, heavy oil reservoirs and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of graphene quantum dot/nanometer silicon negative electrode material for lithium-ion battery

InactiveCN105742586ASimple methodLow costMaterial nanotechnologyCell electrodesCvd grapheneCapacitance

The invention provides a preparation method of a graphene quantum dot / nanometer silicon negative electrode material for a lithium-ion battery. Amino acid functional graphene quantum dots are prepared by high-temperature pyrolysis of a mixture of a citric acid and an amino acid as a carbon source; and then a graphene quantum dot / nanometer silicon compound is obtained by coating the graphene quantum dots on the surface of nanometer silicon particles. A research shows that the electron / ion conductivity of a silicon negative electrode is improved by introduction of the graphene quantum dots; and the compound has significantly improved specific capacitance and high rate capability and cycling stability as the negative electrode material for the lithium-ion battery. The preparation method can be widely applied to various high-capacity lithium-ion batteries.

Owner:JIANGNAN UNIV

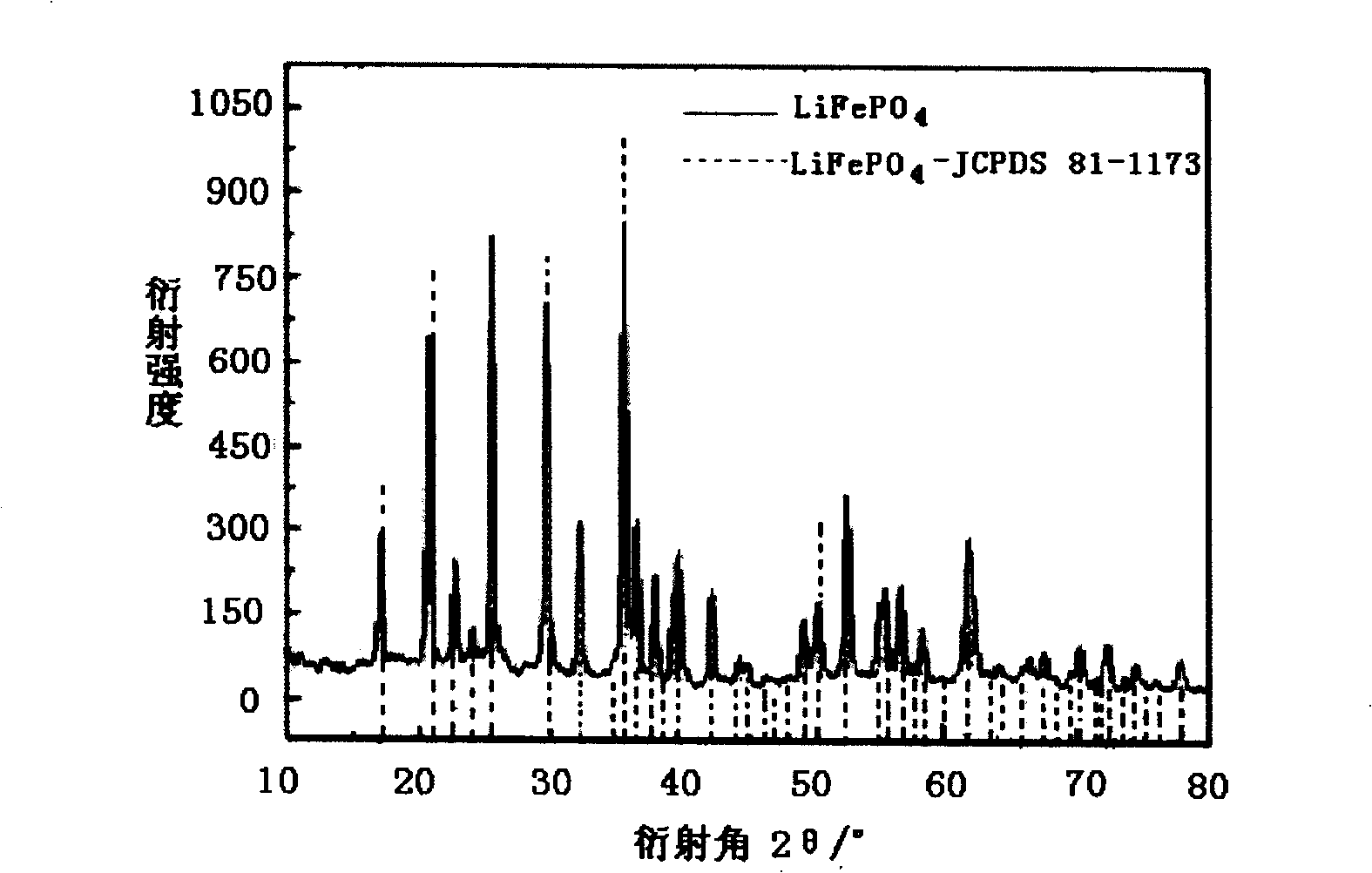

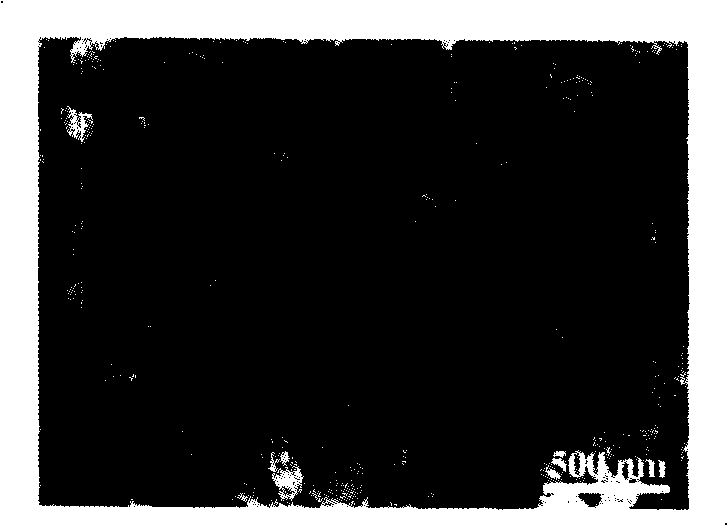

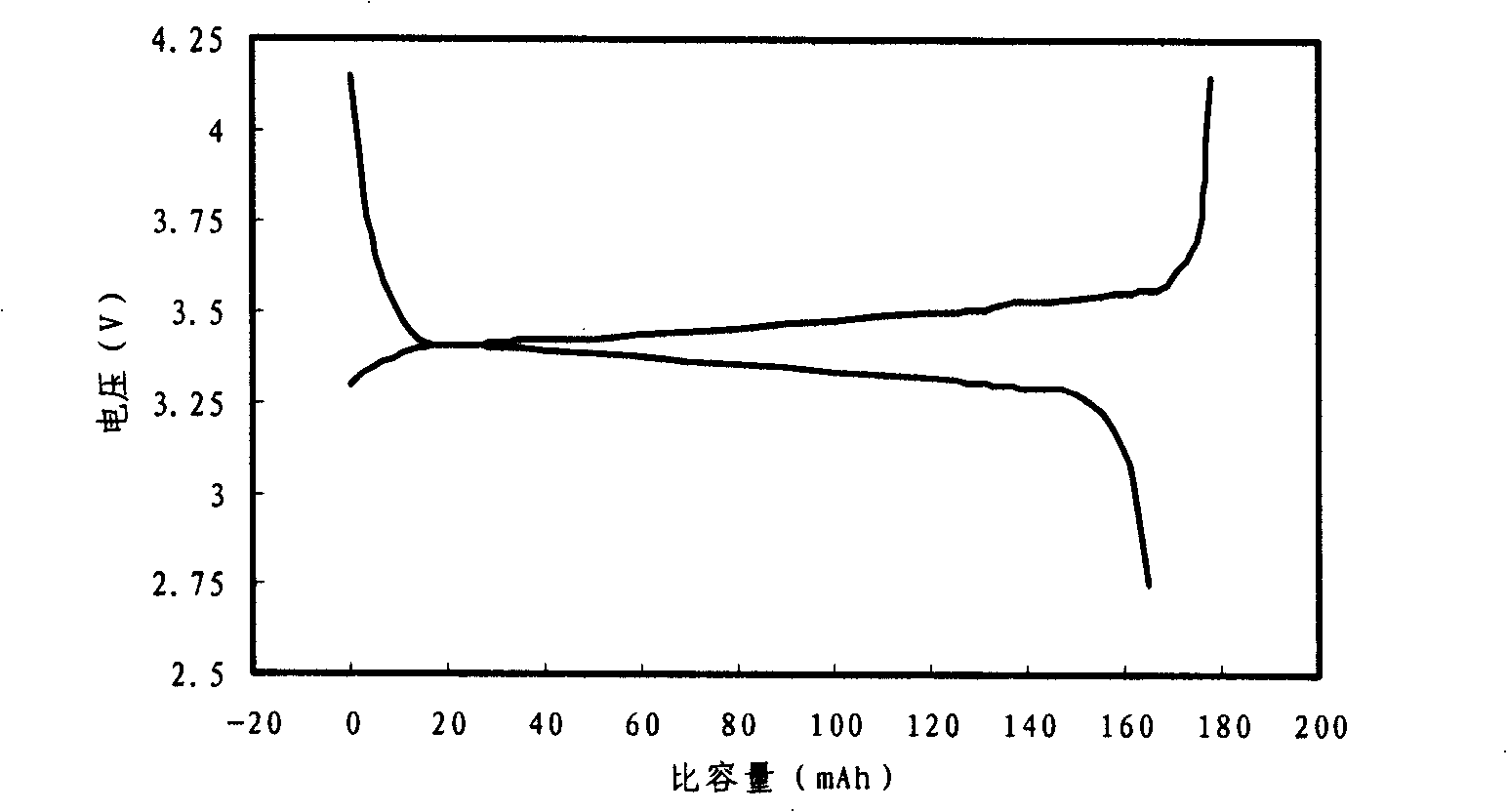

Positive electrode material of lithium ion cell and its preparation method

InactiveCN101339988ASolve the control puzzleWell mixedElectrode manufacturing processesPhosphorus compoundsPhosphateCopper nitrate

The invention discloses an electrode material of a lithium-ion battery and a preparation method thereof. The electrode material is lithium iron phosphate (LiFePO4) with the surface coated with nano-copper and is prepared by using the following method: water solution of ferrous phosphate and lithium phosphate is evenly mixed according to a chemical formula, and is added with a stabilizer OP-10 water solution for mixing and stirring, the mixed solution is controlled at a certain temperature for precipitation, and then the precipitate is filtered, rinsed and aired. Heat treatment is carried out for an aired precursor obtained from the previous step at high temperature, therefore a lithium iron phosphate semi-finished product is obtained. The problem of the imperfect particle size of the lithium iron phosphate is solved by controlling the process conditions. Copper nitrate solution is mixed with the lithium iron phosphate semi-finished product and is added with vitamin C for reducing to obtain the copper; metal copper is evenly clad on the surface of the lithium iron phosphate particles. The preparation method has simple operational procedure; the lithium-ion battery anode material of the prepared lithium-ion battery electrode material has high ionic conductivity and electron conductivity, the 1C initial specific capacity is not less than 162mAh / g and the lC tap density is not less than 1.5g / cm<3>.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

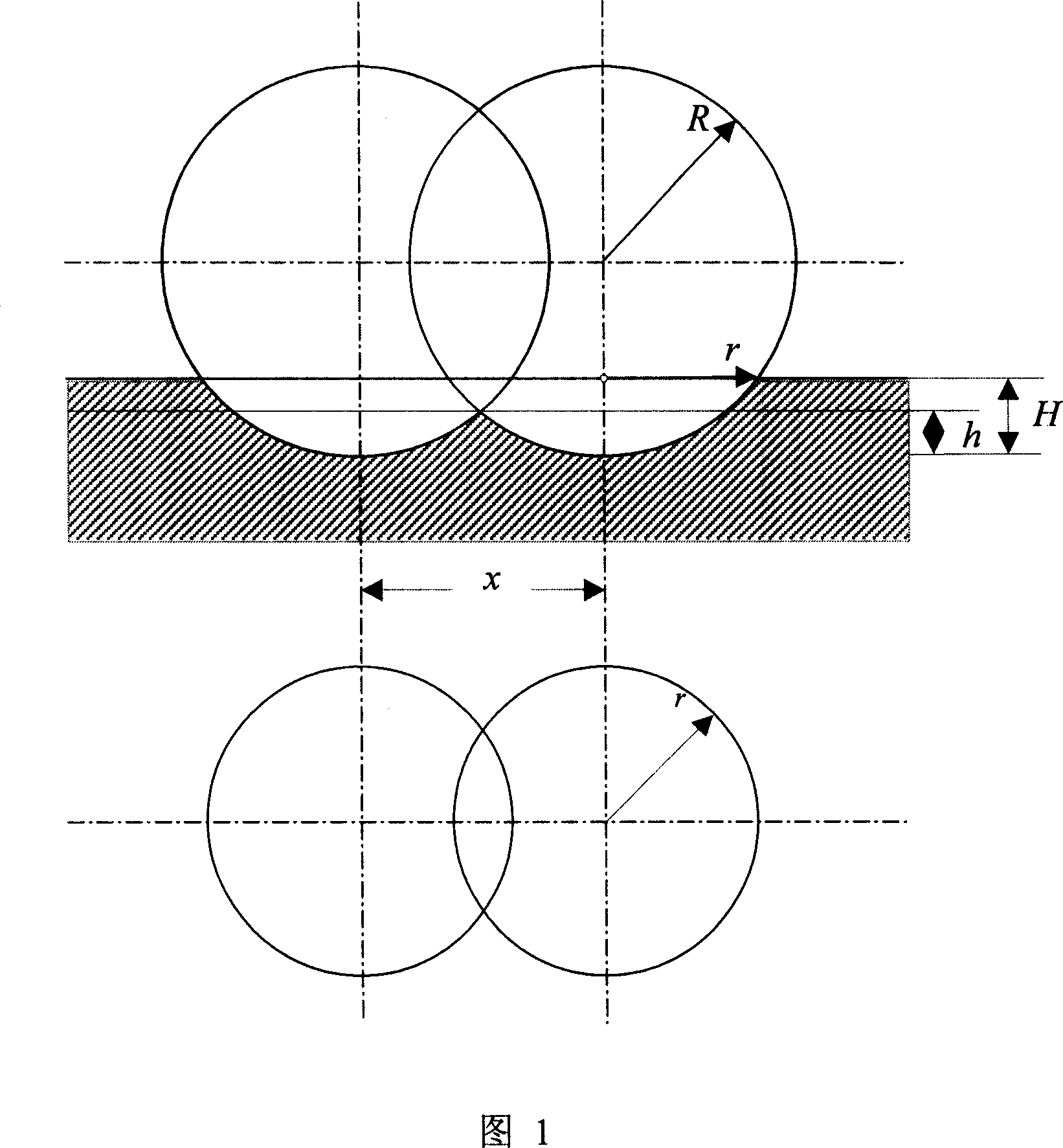

Metal surface nanolizing method of supersonic wave high-energy surface machinery processing

the invention discloses a realizing method of nanometer metal non-coating surface through ultrasonic mechanic manufacturing, which is characterized by the following: contacting plunger chip on the ultrasonic energy exchanger with metal sample directly; controlling the relative position, relative moving pattern and speed of ultrasonic exchanger and metal sample; selecting or controlling the geometrical shape, amplitude, ultrasonic frequency and power of plunger chip; inputting the ultrasonic vibrating energy into the metal piece; deforming local metal surface to obtain the product.

Owner:BAOSHAN IRON & STEEL CO LTD

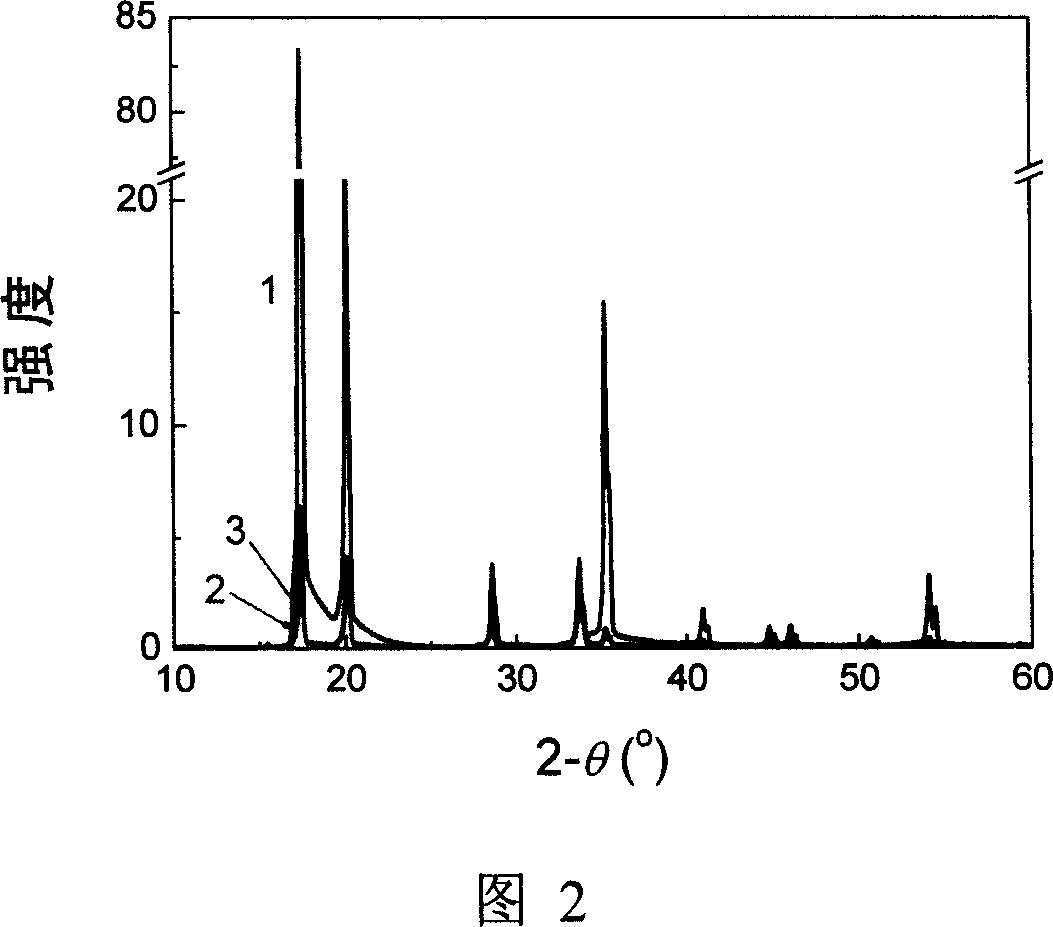

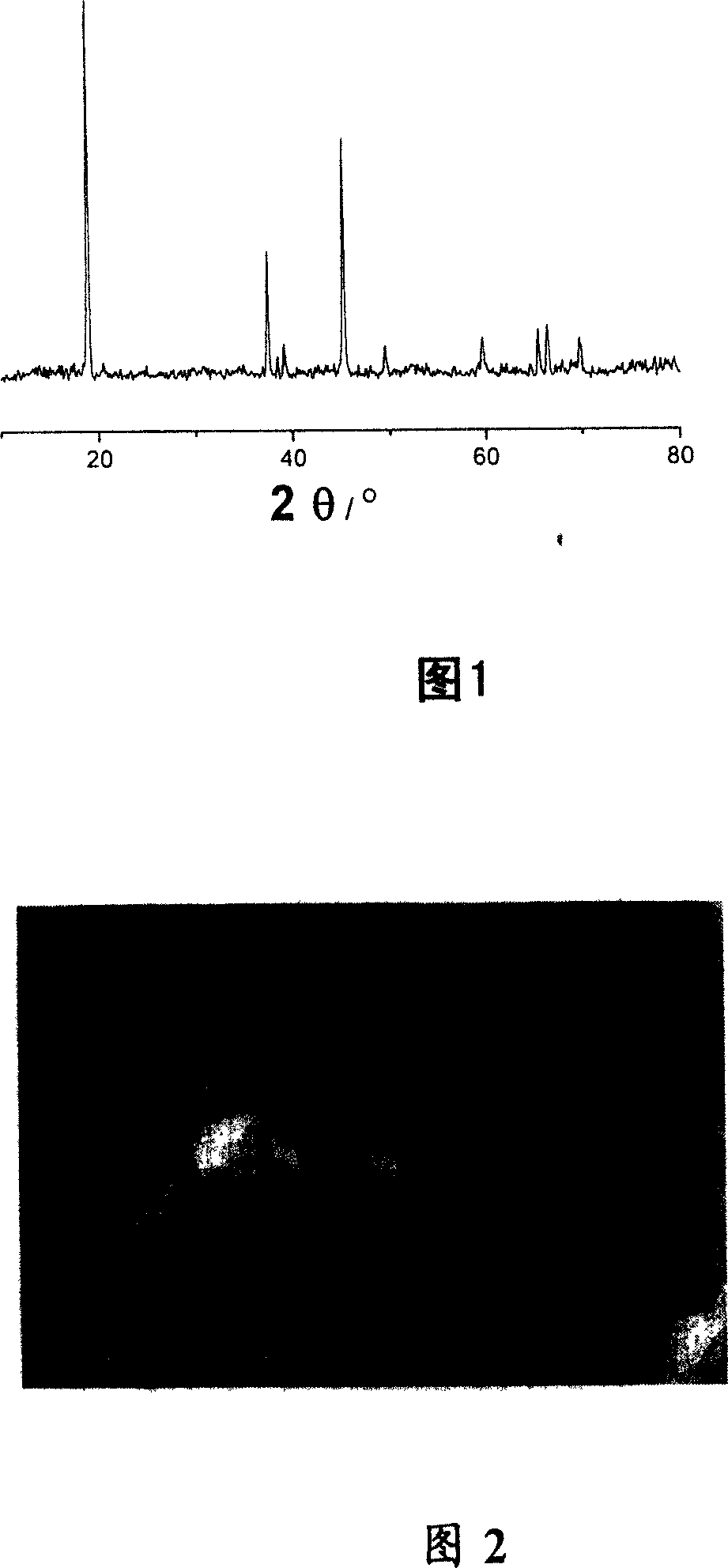

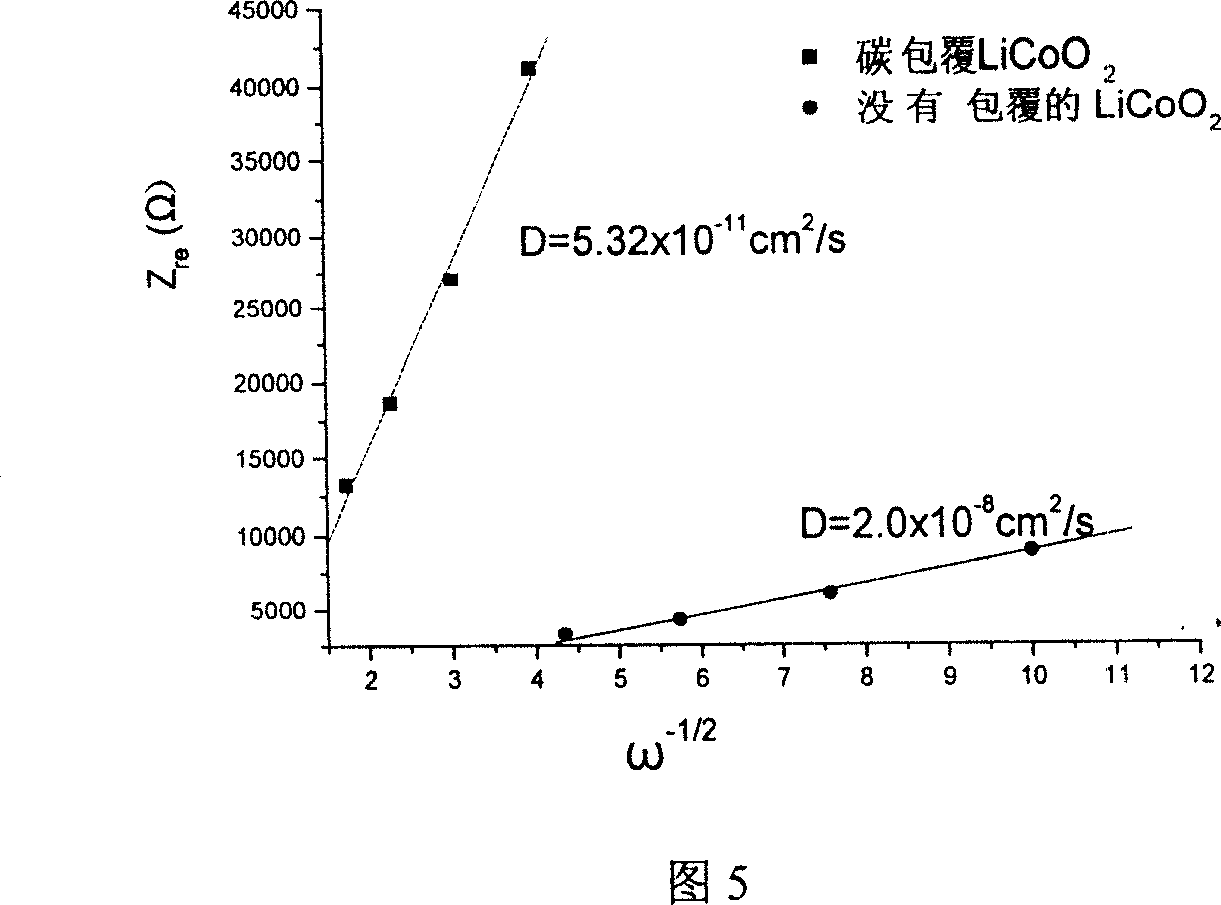

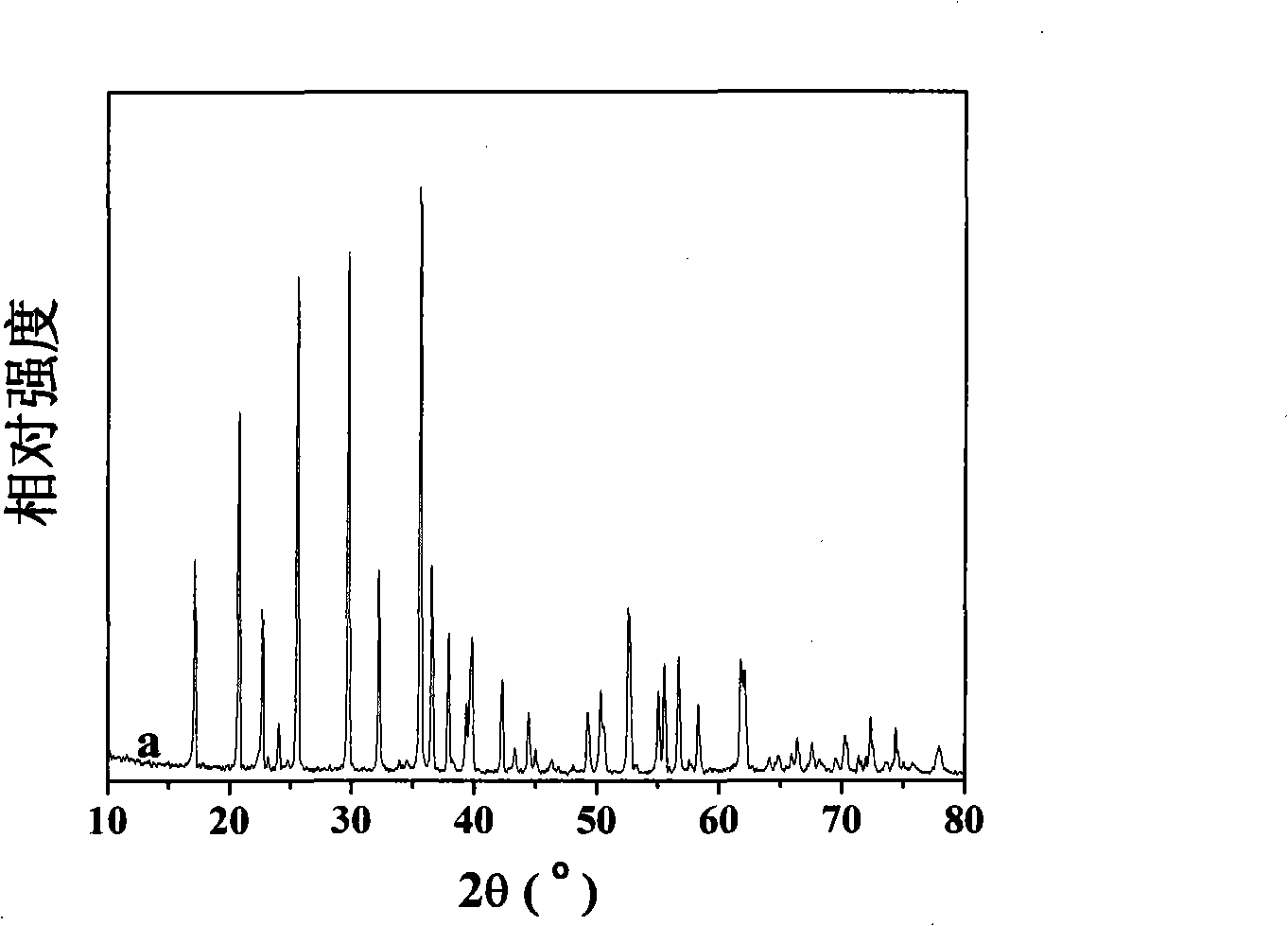

Carbon coated nano LiCoO2 material and its preparing method and application

InactiveCN1986429AIncrease the diffusion coefficientCell electrodesCobalt compoundsCarbon coatedEmulsion polymerization

The present invention belongs to the field of electrochemical technology, and is especially carbon coated nanometer LiCoO2 material and its emulsion polymerization preparation process and application. The carbon coated nanometer LiCoO2 material has homogeneous grains and 3 magnitude orders raised lithium ion diffusion coefficient. The process of the present invention has high operability, high repeatability and capacity of obtaining stable quality product.

Owner:FUDAN UNIV

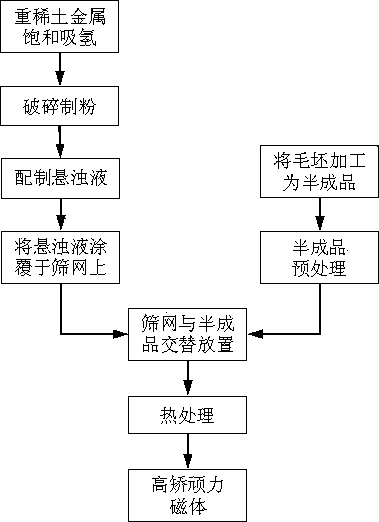

Heavy rare earth element attachment method for sintered NdFeB magnetic body

InactiveCN104299744AIncrease the diffusion coefficientImprove coercive forceInorganic material magnetismRare-earth elementIsolation layer

The invention discloses a heavy rare earth element attachment method for a sintered NdFeB magnetic body. The heavy rare earth element attachment method for the sintered NdFeB magnetic body includes that enabling two surfaces of a pre-processed sintered NdFeB magnetic body to stay close to an isolating layer coated with powder with heavy rare earth hydride, performing diffusing heat treatment, and enabling the heavy rare earth hydride to enter the magnetic body through grain boundary diffusion after dehydrogenation so as to effectively improve the coercive force of the magnetic body. The heavy rare earth element attachment method for the sintered NdFeB magnetic body is simple in technique, low in equipment requirement, suitable for industrial production and worthy of popularization.

Owner:许用华

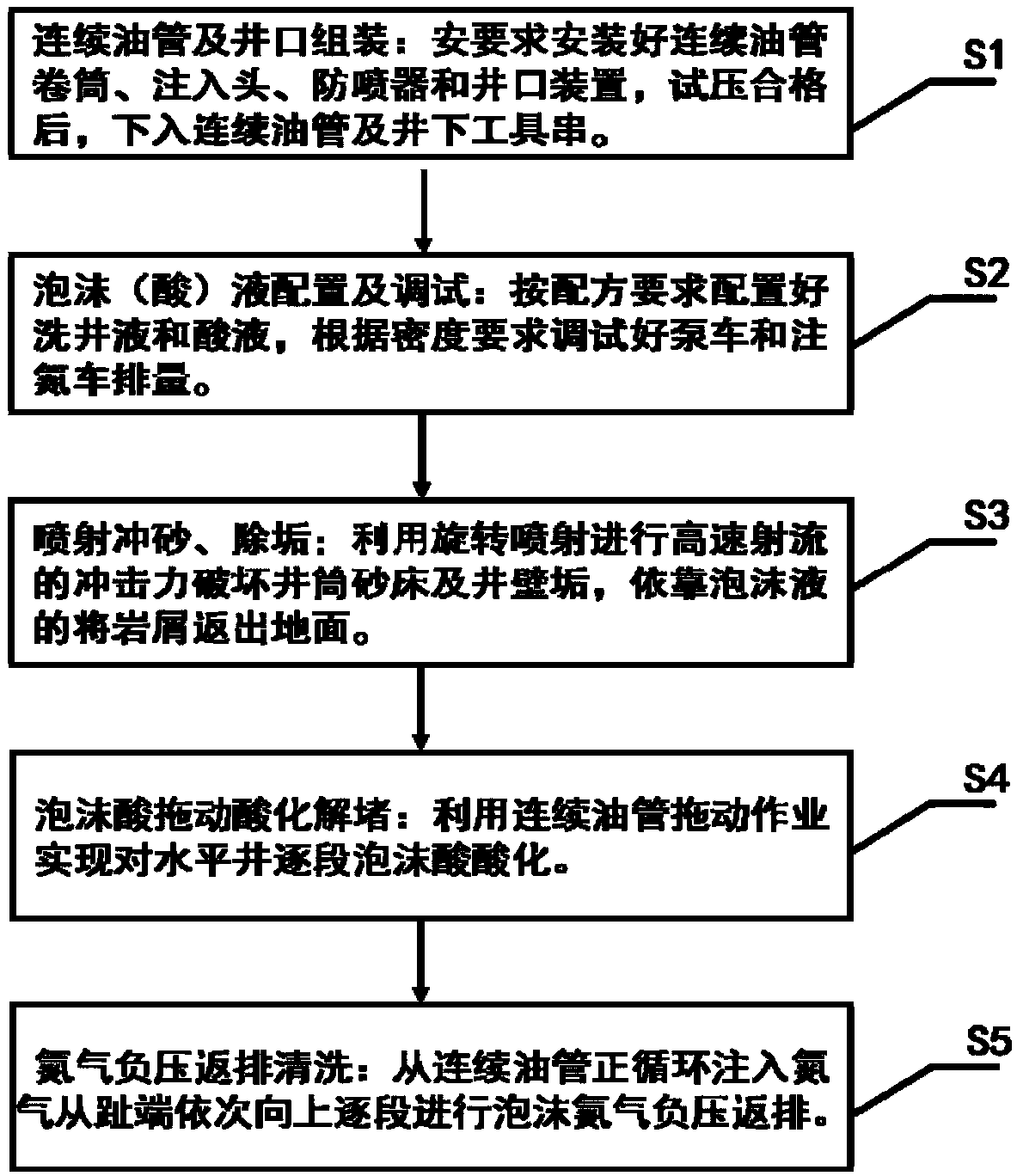

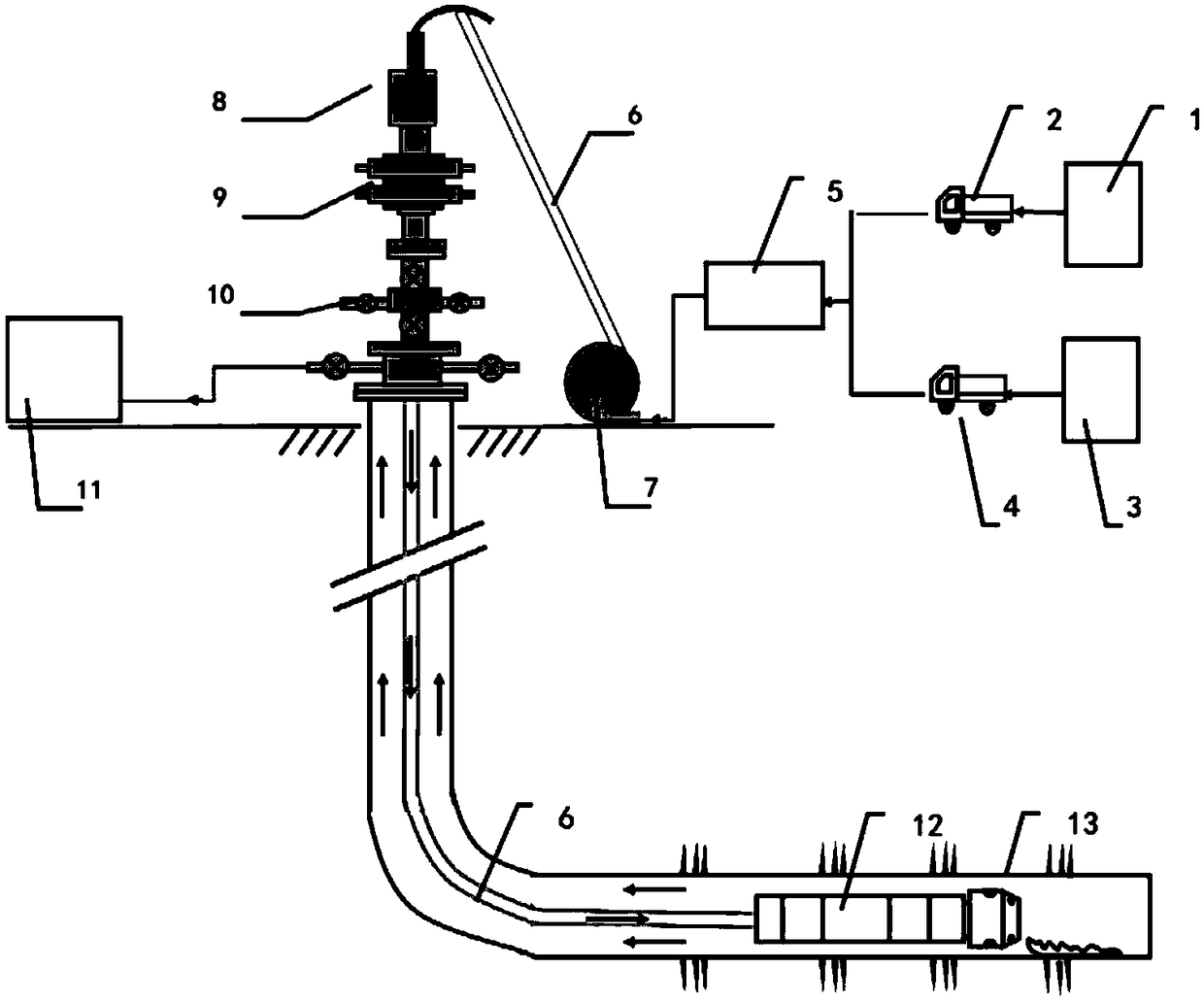

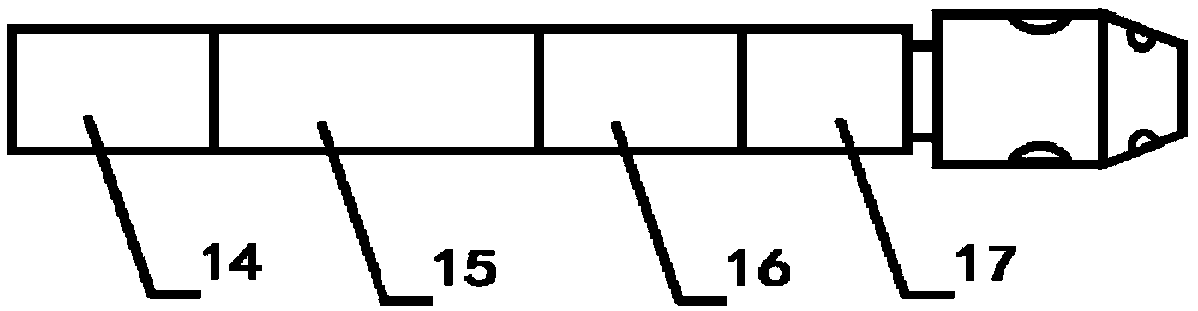

Combined unclogging method for coiled tubes of horizontal well

InactiveCN109083621AWide range of blockingGood plugging effectCleaning apparatusCoiled tubingNitrogen

The invention discloses a combined unclogging method for coiled tubes of a horizontal well. According to the method, the coiled tubes are adopted, the impact force of a rotary ejection tool is utilized to crush a shaft casting bed and well wall dirt, a nitrogen foam acid is adopted for dissolving obstructions near the well, flowback for unclogging an oil flow passage is achieved through the negative pressure of the foam, and other approaches similar to the approaches above are also used for combined unclogging. The method includes the steps of 1, installation of the coiled tubes and underground tool strings; 2, foam (acid) liquid preparation and debugging; 3, ejection on shafts for removing sand and dirt; 4, acidization and unclogging through dragging of the foam acid; 5, flowback for cleaning through the negative pressure of the foam. Combined unclogging is carried out to recover the productivity of the oil well. A rotary ejection crushing mode is adopted, the impact is strong, the acidization and unclogging effect of the foam is great, flowback based on the negative pressure is carried out thoroughly, the operation is convenient, and the construction cycle is short.

Owner:PETROCHINA CO LTD

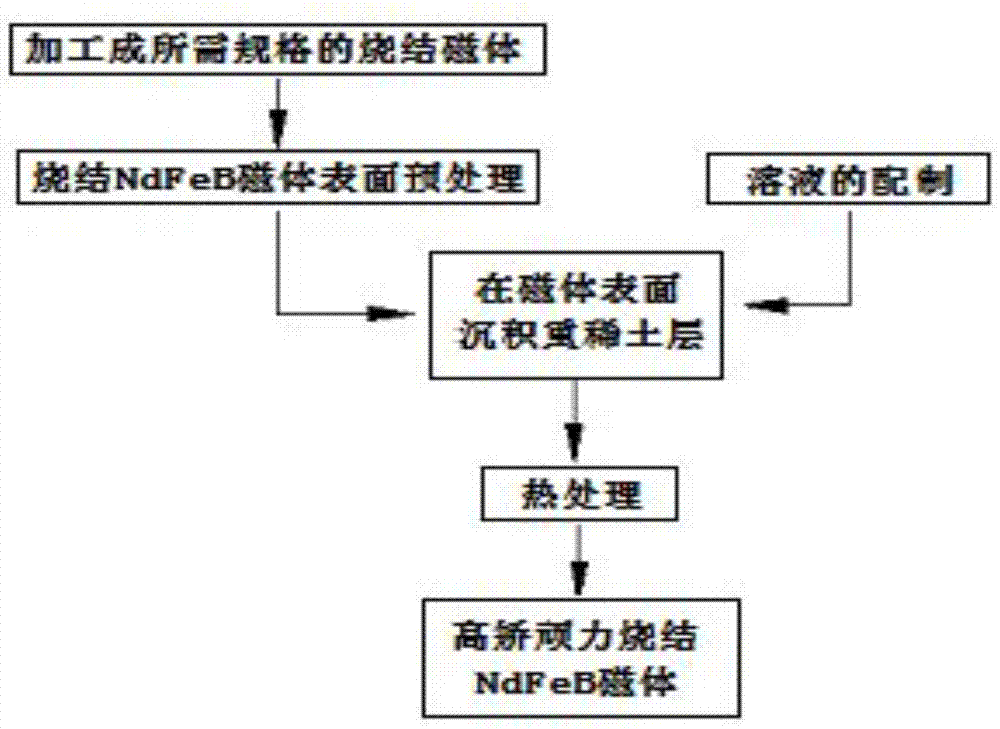

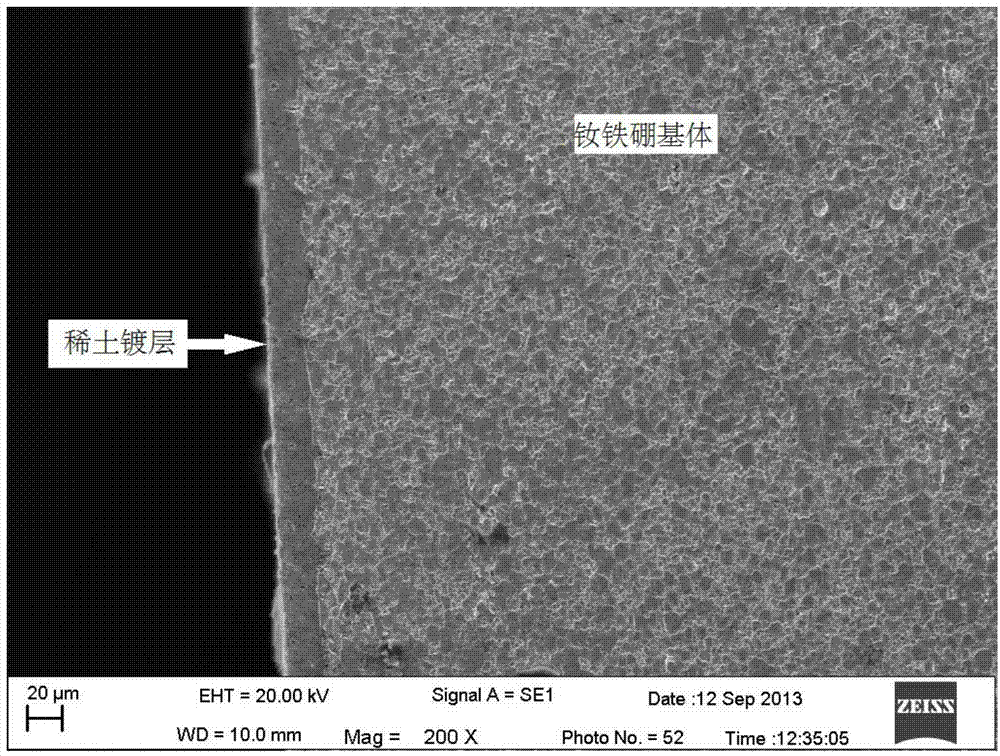

Heavy rear earth adhering method of sintered NdFeB magnet

InactiveCN103617884AImprove coercive forceIncrease the diffusion coefficientInorganic material magnetismInductances/transformers/magnets manufactureMischmetalRemanence

The invention provides a heavy rear earth adhering method of a sintered NdFeB magnet, and belongs to the technical field of rear earth magnetic functional materials and preparation. The preparation technology particularly includes the steps that the sintered NdFeB magnet after surface pretreatment is placed in a heavy rear earth salt organic solution, under the action of currents, heavy rear earth elements are deposited on the surface of the sintered NdFeB magnet and form a dense heavy rear earth metal thin layer, and then the heavy rear earth elements in a heavy rear earth metal film diffuse into the magnet through grain boundaries in the process of high temperature diffusion treatment or high temperature diffusion and low temperature tempering two-stage thermal treatment. Coercivity of a sintered NdFeB rear earth permanent magnetic material prepared through the method is remarkably improved, remanence is not obviously reduced, heavy rear earth consumption is small, the process is simple and controllable, efficiency is high, and the method is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

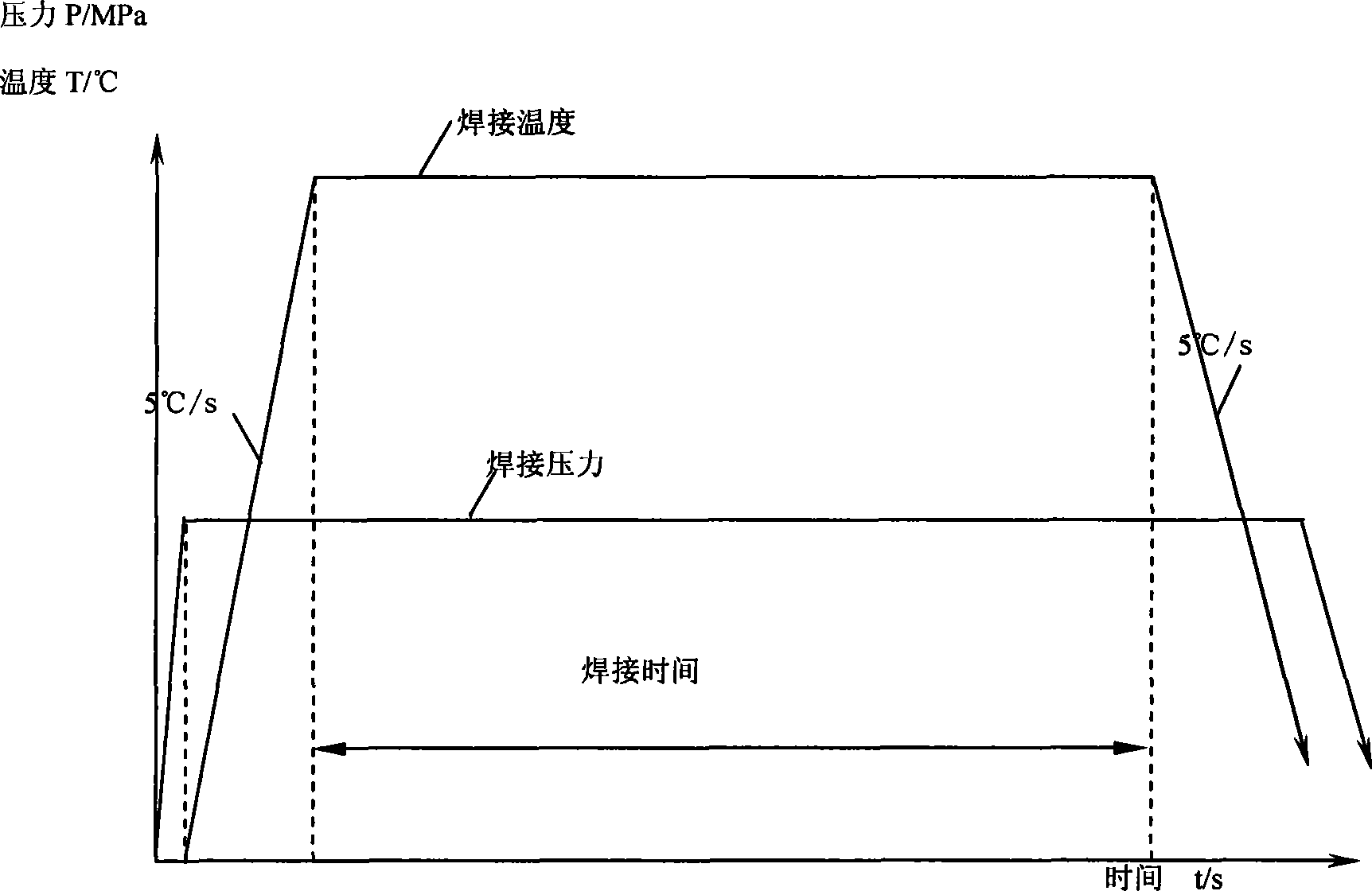

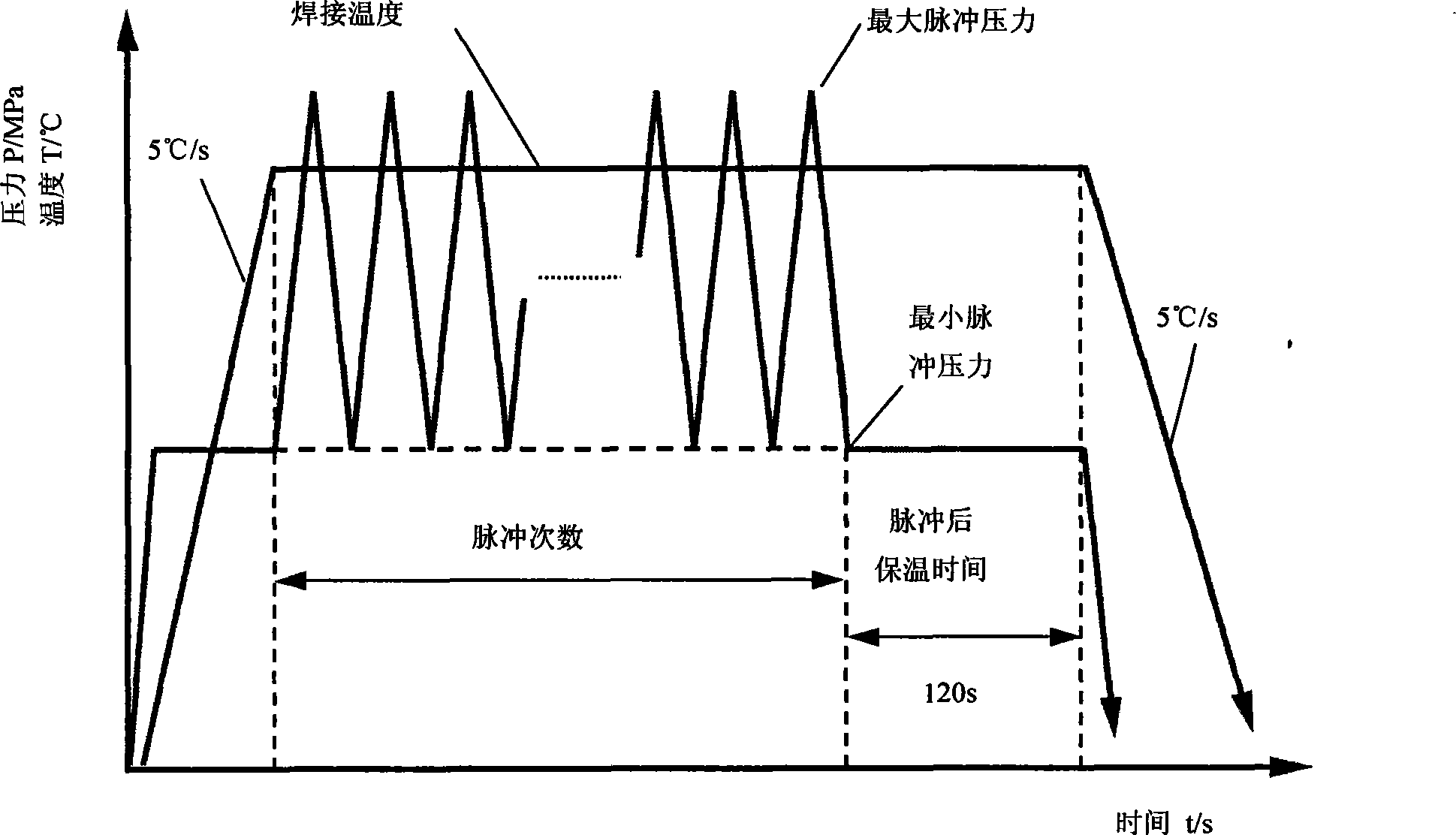

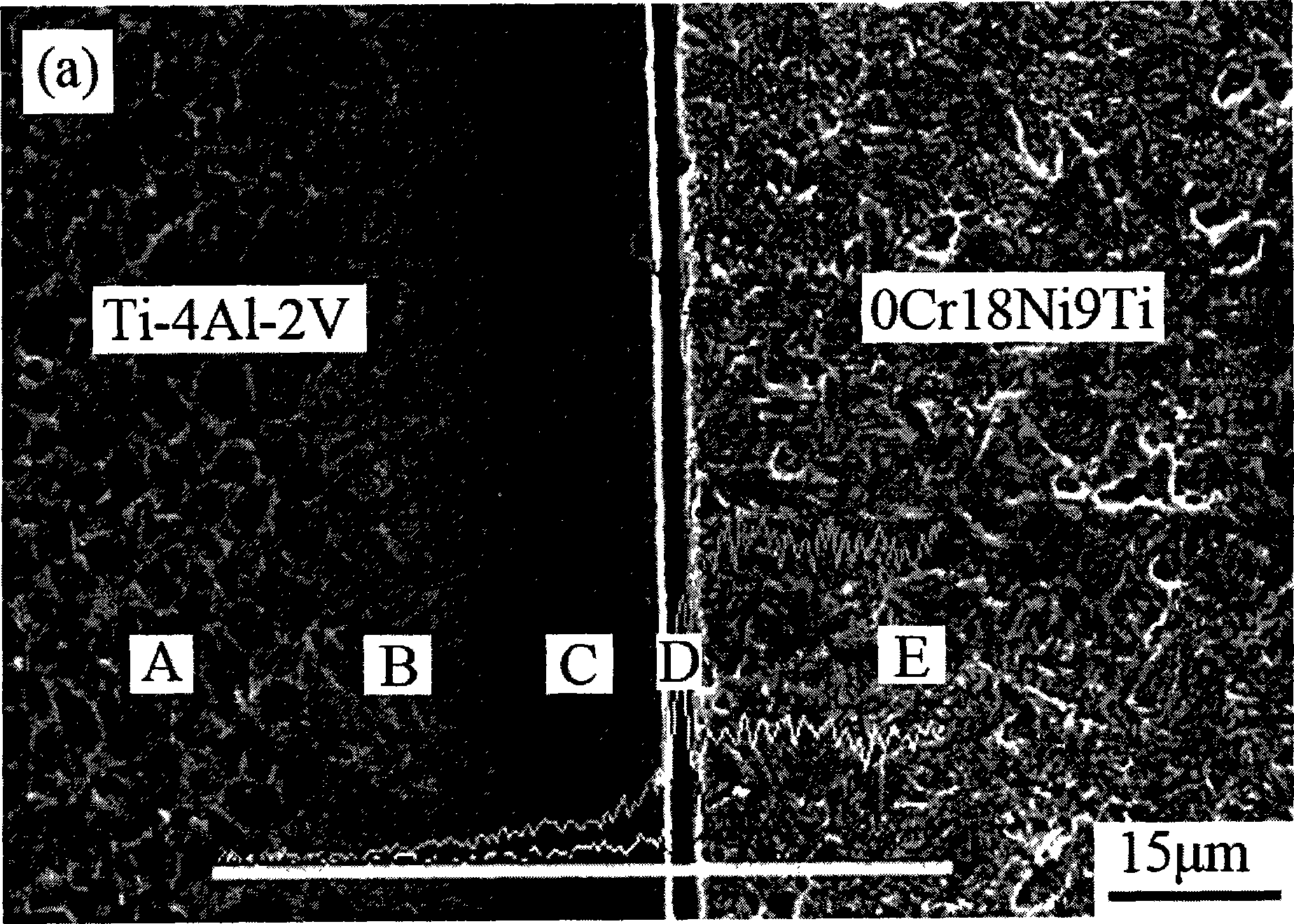

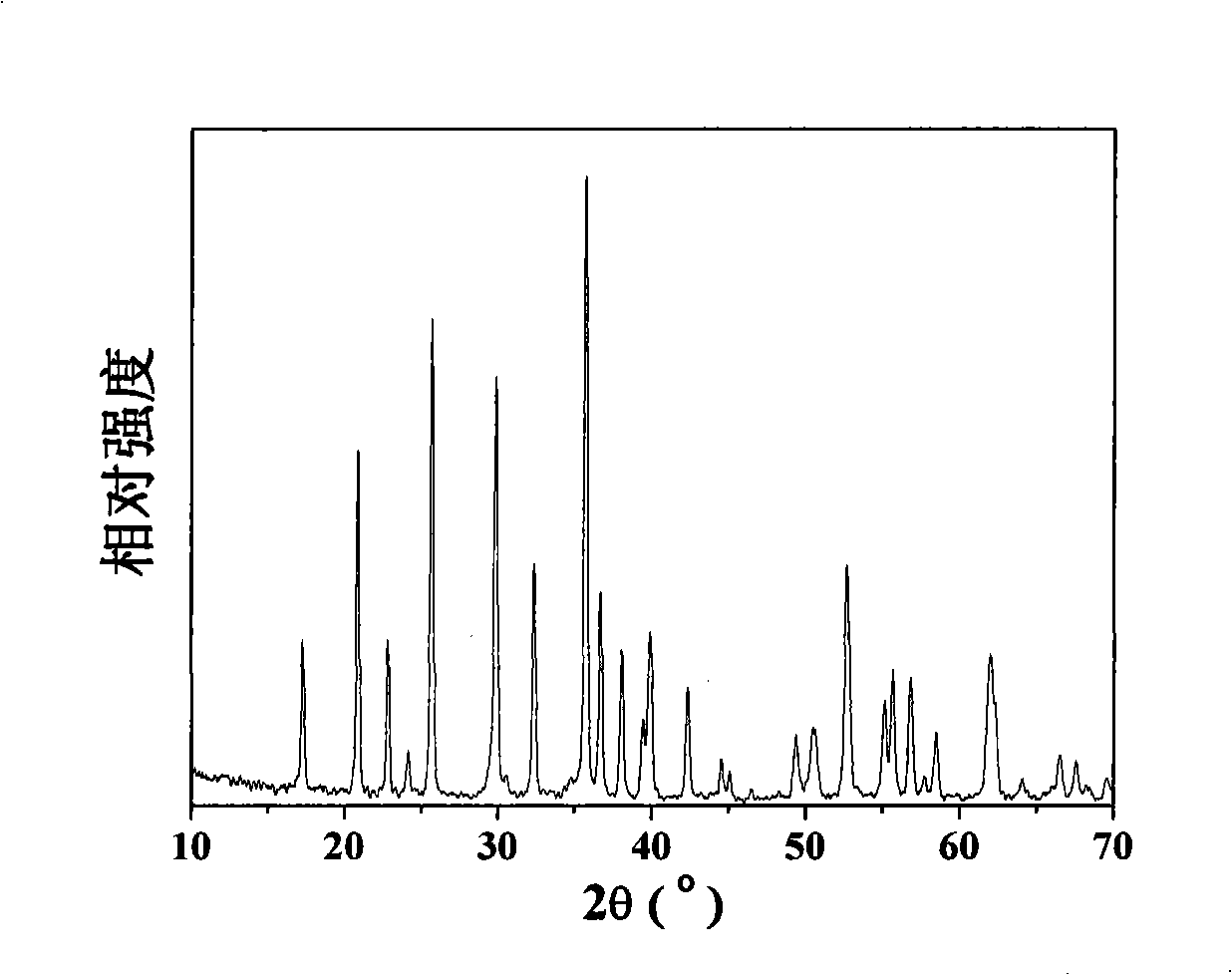

Self-nano-structure diffusion welding technique for titanium alloy and stainless steel surface

InactiveCN101244483AIncrease the diffusion coefficientImprove mechanical propertiesPolishing machinesNon-electric welding apparatusNano structuringTitanium alloy

The invention discloses a titanium alloy and stainless steel surface self-nanocrystallization diffusion welding craft; wherein, the same diameter titanium alloy and stainless steel rod are selected; the surface self-nanocrystallization of the end face of the welding terminal is processed; the constant temperature and constant pressure diffusion welding or the impact pressurizing diffusion welding are processed. The titanium alloy and stainless steel surface self-nanocrystallization diffusion welding craft has the advantages of raising the diffusion coefficient of the titanium alloy and stainless steel in the process of diffusion welding, shortening the welding time, raising the welding efficiency, reducing the thickness of intermetallic compounds layer, refining the joint crystalline grain, and raising the mechanical property of the diffusion welding joint of titanium alloy and stainless steel.

Owner:CHONGQING UNIV

Paper deacidification method

ActiveCN101538816ALow viscosityIncrease the diffusion coefficientOld paper after-treatmentOrganic solventPulp and paper industry

The invention discloses a paper deacidification method by using a supercritical fluid technology. The method comprises the following steps: placing paper (particularly ancient books) in a supercritical CO2 treatment device, extracting and purifying before adding a deacidification agent and an entrainer for treatment so that the paper approaches to neutral. The invention applies the supercritical fluid technology to the paper deacidification method to save time and labor and avoid organic solvent pollution, and the treated paper is not bent and deformed and has no phenomena, such as color diffusion, ink diffusion, conglutination, and the like.

Owner:GUANGDONG UNIV OF TECH +1

Lithium iron phosphate anode material for lithium ion battery and modification method

InactiveCN101315981AUniform structureEasy to processElectrode manufacturing processesChemical/physical/physico-chemical processesSolid state reaction methodLithium-ion battery

The invention provides a lithium iron phosphate anode material used for lithium ion batteries; the lithium iron phosphate which is prepared by a water heating method is taken as a precursor which is then uniformly mixed with a conductive matter precursor and metal ion salt, and finally baked in inert gas to obtain the lithium iron phosphate anode material which is coated by the conductive matter and doped by the metal ions. Compared with a pure solid phase reaction method, the method of the invention has small energy dissipation, the chemical uniformity of the synchronized outcome is good, the dimension and the appearance of the outcome are uniform, and the electromechanical performance and the processing performance have good stability and repeatability. Compared with the a pure water heating method, as the coating of the conductive matter, the doping and modifying performance of the metal ions are added during the anaphase, the electric conductivity of the material is greatly improved, and the high magnification electromechanical performance of the material is excellent; wherein, under the 10C discharging magnification, the discharging content of the lithium iron phosphate anode material with the copper ion doped is kept at 107mAh / g. After circulation for 50 times, the discharging content of the material is kept unchangeable basically, which can certify that the material has good circulation performance.

Owner:HEFEI UNIV OF TECH

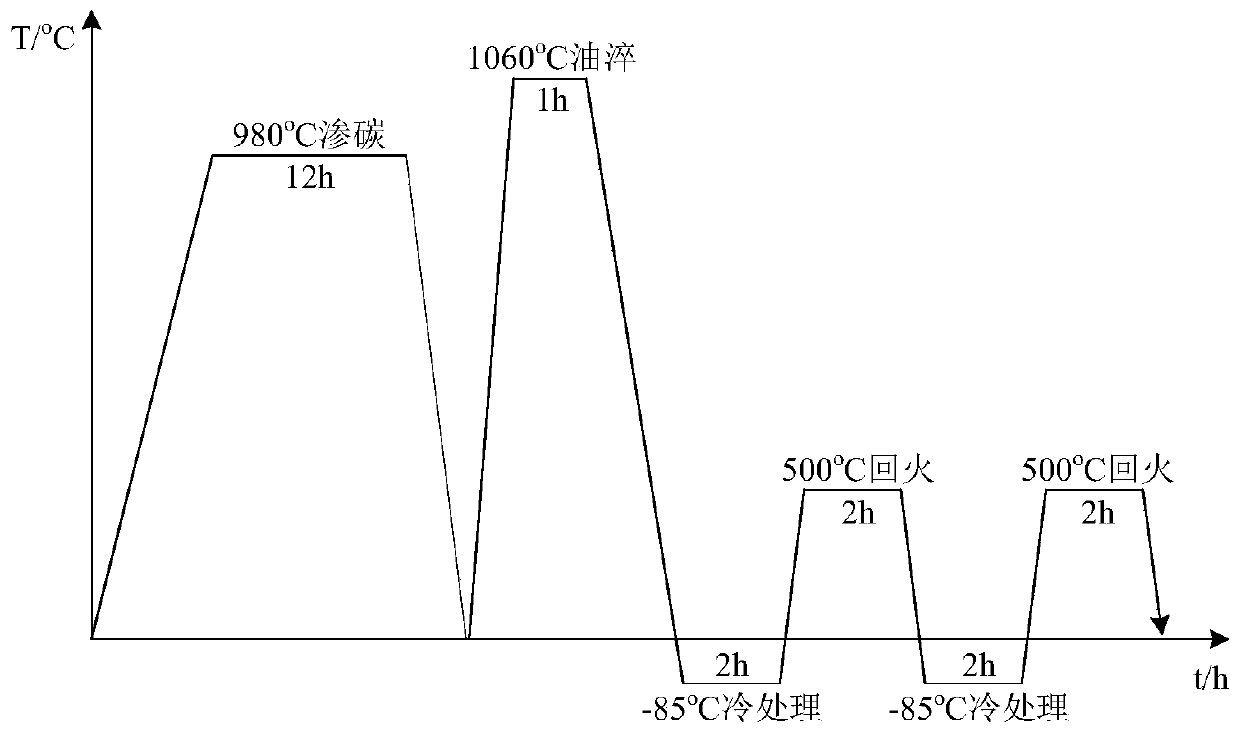

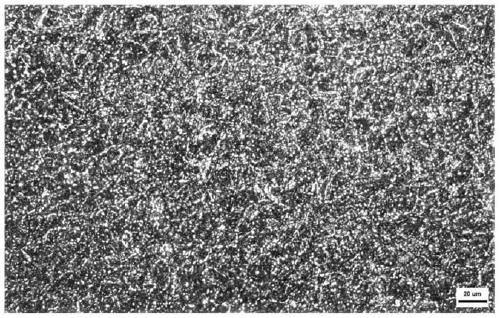

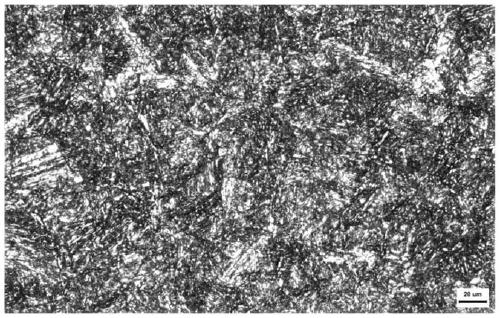

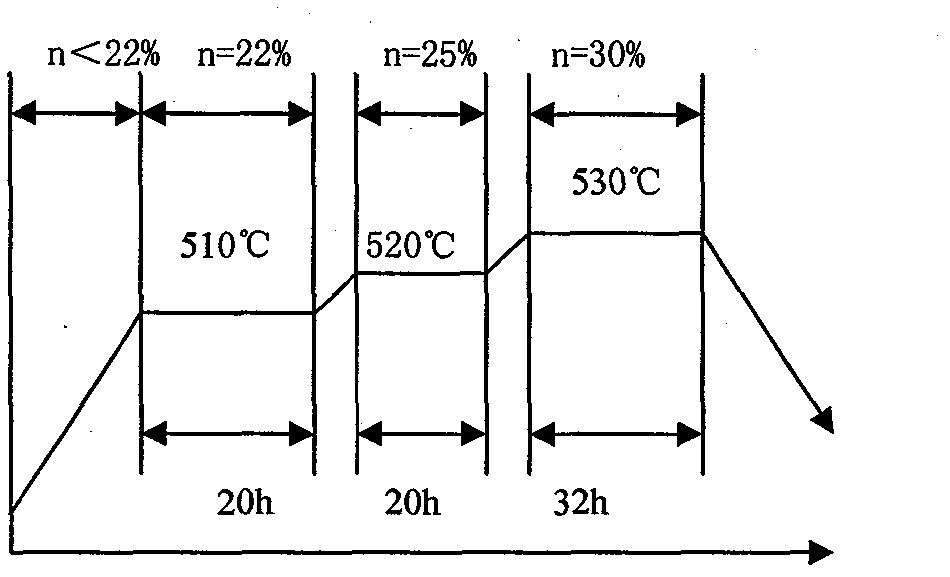

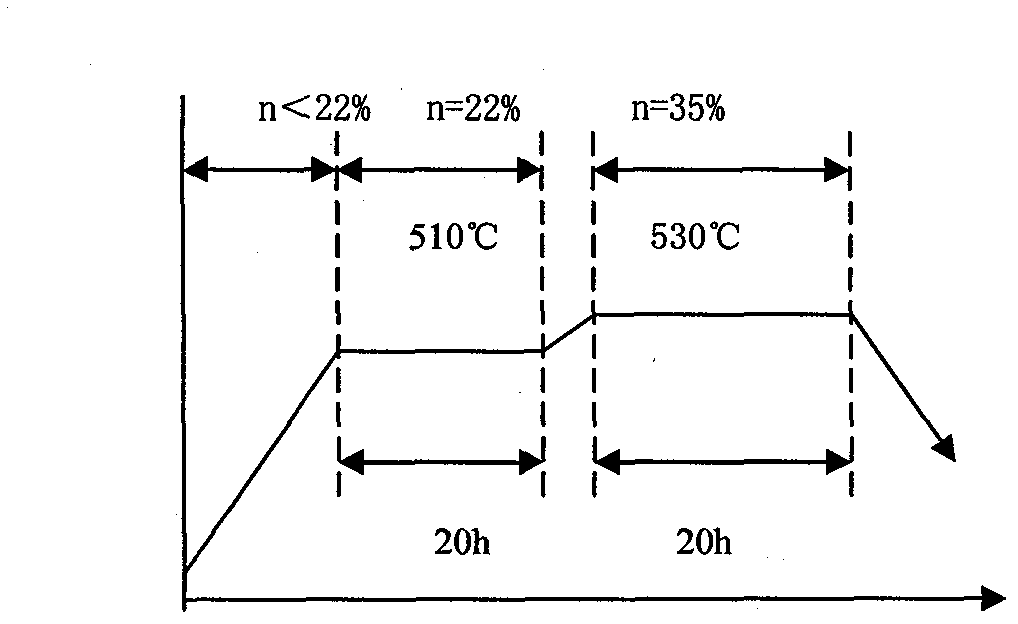

Low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel

ActiveCN109735794ASolve pollutionHigh fatigueSolid state diffusion coatingQuenchingPrepared Material

The invention relates to a low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel. The method comprises the treatment steps of low-pressure vacuum carbonizing, quenching, deep cooling and high-temperature tempering; and the steps can be repeatedly performed. The low-pressure vacuum carbonizing process uses a saturated value adjusting method for multi-section pulse carbonizing; a carbonizing agent adopts acetylene gas; the carbonizing temperature is 850-1050 DEG C; the carbonizing pressure is 100-2000 Pa; and the powerful seepage and dispersion circulating period is 20-70 times. The treatment method is safe, energy-saved and environment-friendly, can eliminate intergranular oxidation, realizes precise control of the seepage layer depth, and canguarantee excellent service performances of prepared materials above 400 DEG C.

Owner:NORTHEASTERN UNIV

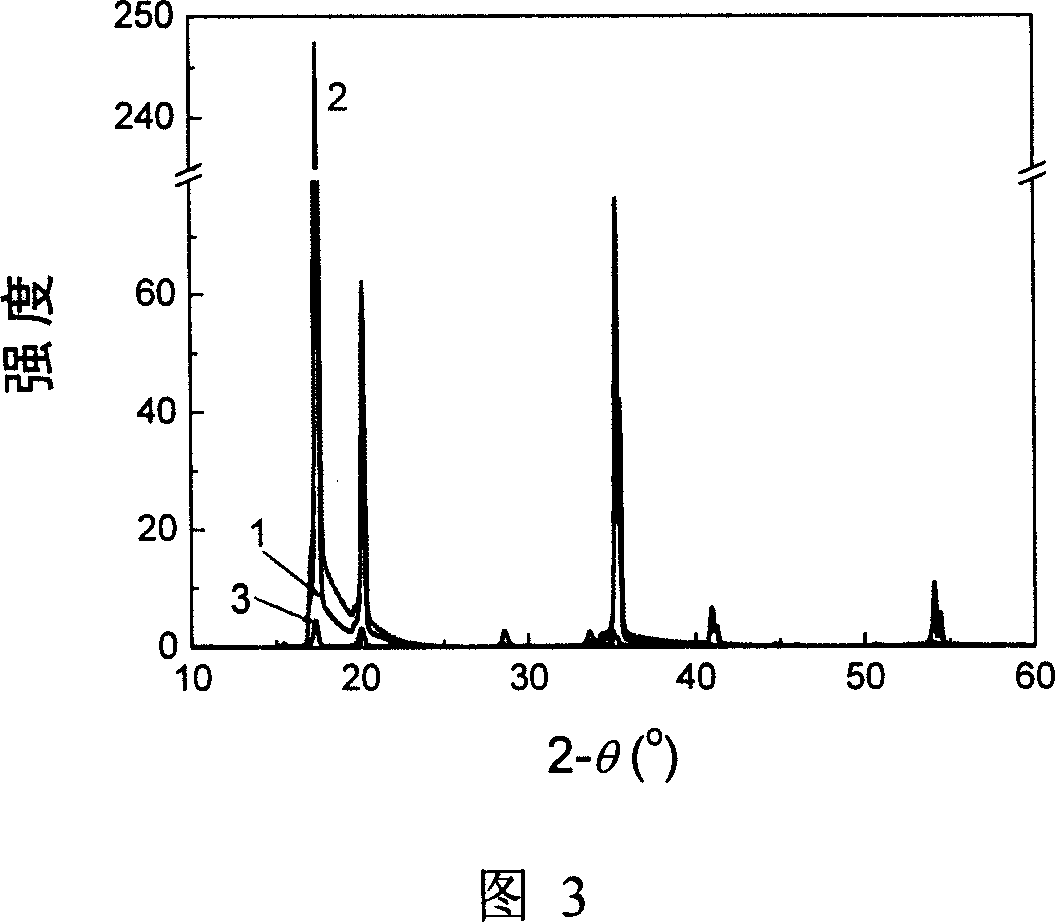

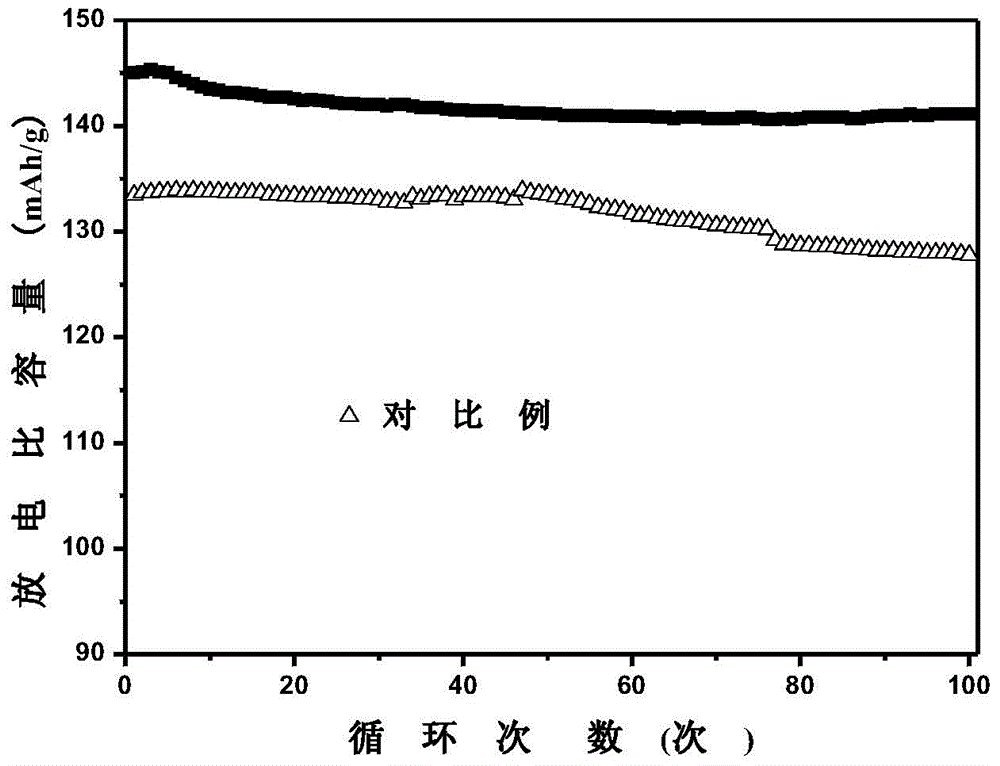

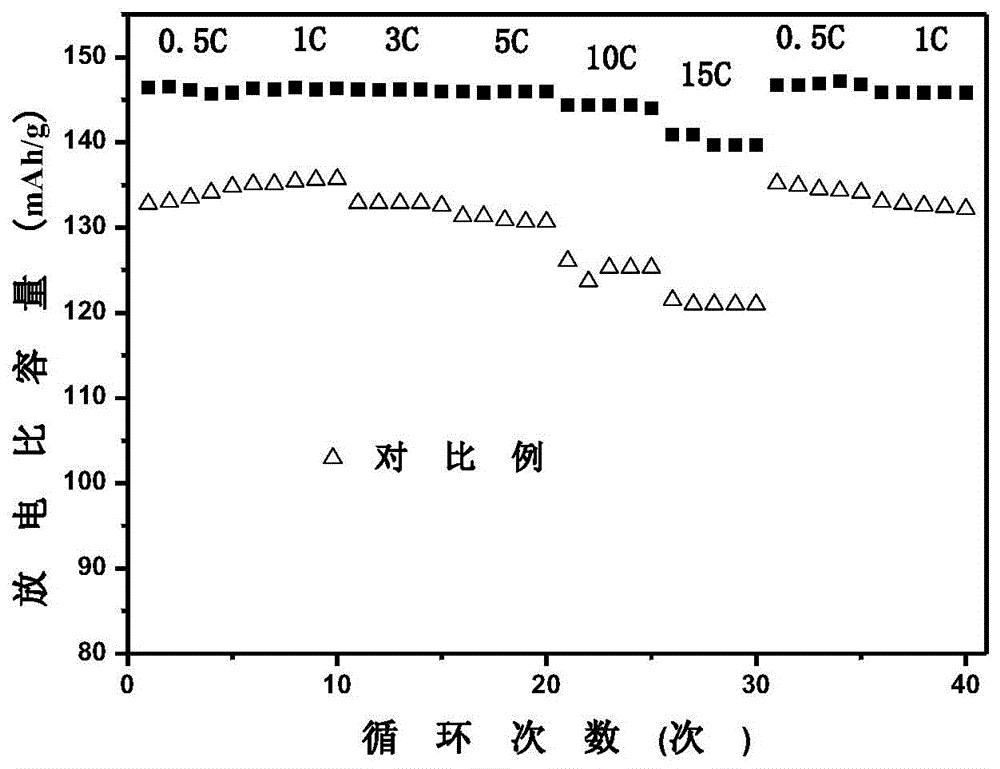

Modification method of lithium nickelate, cobaltate and manganate ternary material

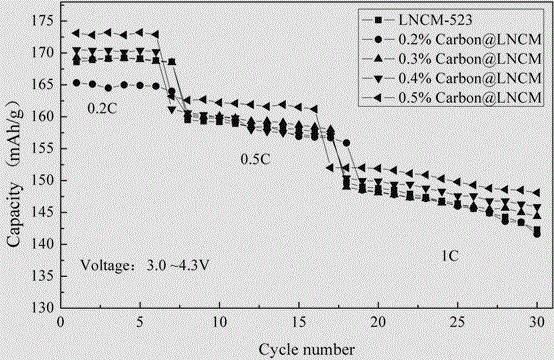

ActiveCN106450217ASimple processReduce shufflingCell electrodesSecondary cellsCarbon coatingCarbon source

The invention provides a modification method of a lithium nickelate, cobaltate and manganate ternary material. The method comprises the step that after a lithium nickelate, cobaltate and manganate material is subjected to vapor phase deposition under the conditions of carbon source gas and protective gas, a carbon-coated modified lithium nickelate, cobaltate and manganate material is obtained. The modification method provided by the invention has the benefits that carbon deposits on the surface of the lithium nickelate, cobaltate and manganate ternary material through a vapor phase deposition method, so that carbon coating is realized; by adopting simpler processes, with the aid of the protective gas, the ternary material is carbon-coated, so that the problem of lithium nickelate reduction in the coating process of a traditional ternary material is effectively solved, and the coating of a carbon layer on the surface of the ternary material is realized; through the lithium nickelate, cobaltate and manganate ternary material coating carbon, the first-time charging and discharging efficiencies are improved, the lithium ion diffusion coefficients and the electronic conductivity of the material are improved, and the electrochemical performance of the NCM material is improved. According to the modification method provided by the invention, equipment is relatively simple, the process is less, and the structure is controllable; the material has higher battery capacity, cycle performance and rate capability.

Owner:GREE ELECTRIC APPLIANCES INC

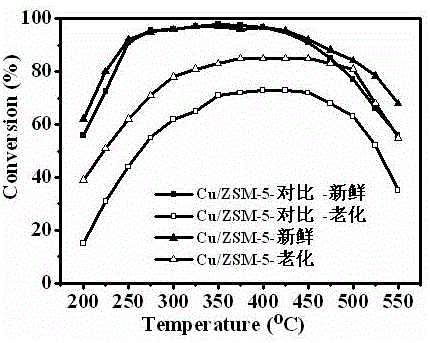

Copper-based molecular sieve catalyst as well as preparation method and application thereof

ActiveCN105772064AImprove activity stabilityHigh hydrothermal stabilityGas treatmentInternal combustion piston enginesMolecular sieveFreeze-drying

The invention discloses a copper-based molecular sieve catalyst, as well as a preparation method and application of the copper-based molecular sieve catalyst for purifying catalyst oxynitride in a post-treatment Urea-SCR system on a diesel vehicle. The preparation method comprises the following steps: firstly performing ultrasonic impregnating and then performing freeze-drying treatment, so that the catalytic activity and the hydrothermal stability of the copper-based molecular sieve catalyst are effectively improved.

Owner:DONGFENG COMML VEHICLE CO LTD

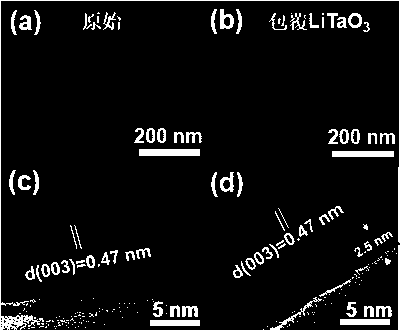

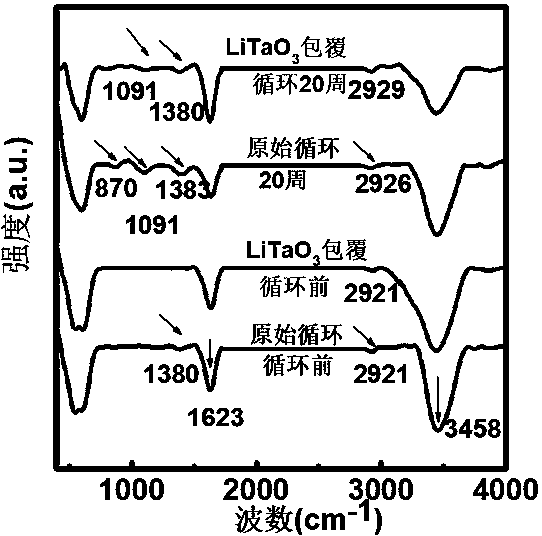

Lithium ion battery anode material coated with piezoelectric material on surface and preparation method thereof

PendingCN109921000AEasy to operateGood repeatabilityCell electrodesSecondary cellsBarium titanatePotassium

The invention provides a lithium ion battery anode material coated with piezoelectric material on the surface and a preparation method thereof. The surface of the battery anode material is coated witha layer of piezoelectric material with piezoelectric effect; the piezoelectric material comprises any one or more of barium titanate, lithium niobate, sodium niobate, lithium tantalite, sodium-potassium metaniobate and barium-strontium metaniobate with piezoelectric effect. The piezoelectric characteristic of the piezoelectric material is utilized to realize a coating modification function for the anode active materials so as to ensure that the volume phase structures of the anode active materials are not influenced and damaged, the growth of solid-electrolyte interface membranes is suppressed, and the diffusion speeds of active material-coating layer interface lithium ions are improved, thereby effectively improving the structure stability and electrochemical cycle performance of the lithium ion battery anode material, improving the pyrolysis temperature of the anode material and then enhancing the safety performance of the lithium ion batteries in the using process.

Owner:HENAN UNIVERSITY

Molybdate and preparation method thereof

InactiveCN103663560ALarge specific surface areaMany interface atomsMaterial nanotechnologyMolybdeum compoundsMolybdateHydrothermal synthesis

The invention relates to molybdate and a preparation method thereof. The technical scheme of the preparation method comprises the following steps: 1) hydrothermal synthesis of monocrystalline molybdenum oxide nano tetragonal rods; 2) preparation of a MoO3 / MOx one-dimensional core-shell structure through surface hydrolysis and deposition; and 3) preparation of molybdate Mx(MoO4)y having a nano hollow structure through static air heat treatment. Thus, the molybdate having a nano hollow structure is synthesized; and the invention can be used for industrial production of molybdate having a nano hollow structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

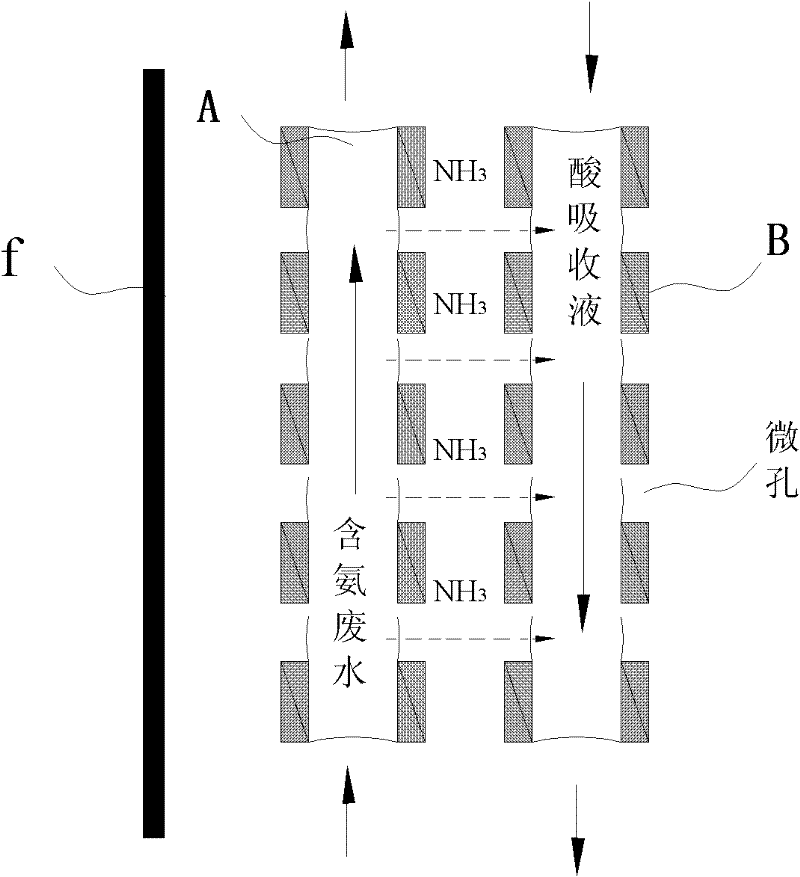

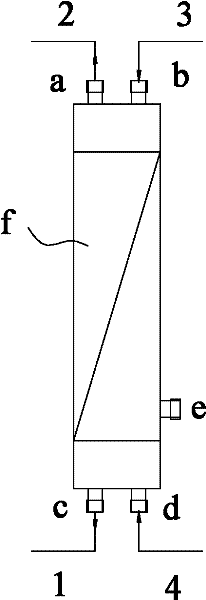

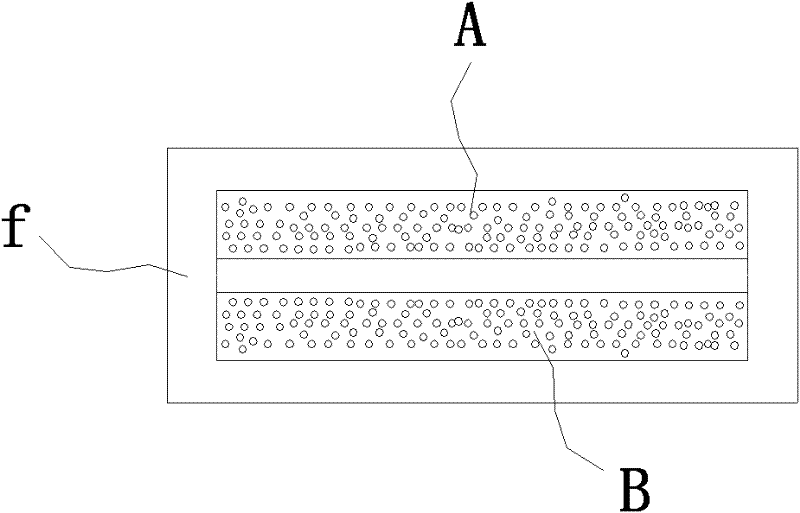

Stable gas membrane and method used for removing, recovering, and gathering ammonia or organic amine from dosage liquor or wastewater

The invention relates to a stable gas membrane used for removing, recovering, and gathering ammonia or organic amine from dosage liquor or wastewater. The gas membrane comprises a membrane shell, hollow fibrous membranes (A) and hollow fibrous membranes (B). A cavity is provided in the middle of the membrane shell. An inlet and an outlet are respectively arranged on each of the two ends of the membrane shell. The hollow fibrous membranes (A) and the hollow fibrous membranes (B) are positioned in the cavity of the membrane shell. A shell pass outlet communicating with the atmosphere is arranged on a lower end of the membrane shell. The hollow fibrous membranes (A) and the hollow fibrous membranes (B) are uniformly arranged in the membrane shell with regular spaces. Dosage liquor or wastewater containing ammonia or organic amine is delivered through the tube pass of the hollow fibrous membranes (A), and absorption liquid is delivered through the tube pass of the hollow fibrous membranes(B). With the gas membrane provided by the invention, problems of traditional gas membranes of leakage and low service life are overcome; dilution of a byproduct ammonium salt solution caused by a concomitant osmotic distillation phenomenon can be effectively inhibited; ammonium salt concentration of the byproduct ammonium salt solution can be increased from 10-20% to 20-40%; mass transfer coefficient at the acid absorption liquid side can be substantially improved; the ammonia removing efficiency is high; the ammonia removing effect is stable for a long-term; and the service life of membranesets can be improved by 3-10 times than common gas membranes.

Owner:天津凯铂能膜工程技术有限公司

Preparation method of electrochromic film having photonic crystal structure

ActiveCN102978674AHigh densityImprove coloring efficiencyNon-linear opticsElectrolytic organic material coatingSolar absorptancePhotonic crystal structure

The invention relates a preparation method of an electrochromic film having a photonic crystal structure. The preparation method solves the problem that the existing electrochromic material has irreversibility so that material reflectivity is not improved and solar absorptance is not reduced. The preparation method of the electrochromic film having a photonic crystal structure comprises the following steps of 1, base material surface treatment, 2, colloidal solution preparation, 3, film-type colloidal crystal template preparation, 4, solution preparation, 5, electrode preparation and 6, film electrochemical preparation. A polyaniline photonic crystal film having an inverse opal structure and prepared by the preparation method has excellent electrochromism response performances. The preparation method can be used for the field of preparation and production of the electrochromic film having a photonic crystal structure.

Owner:HARBIN INST OF TECH

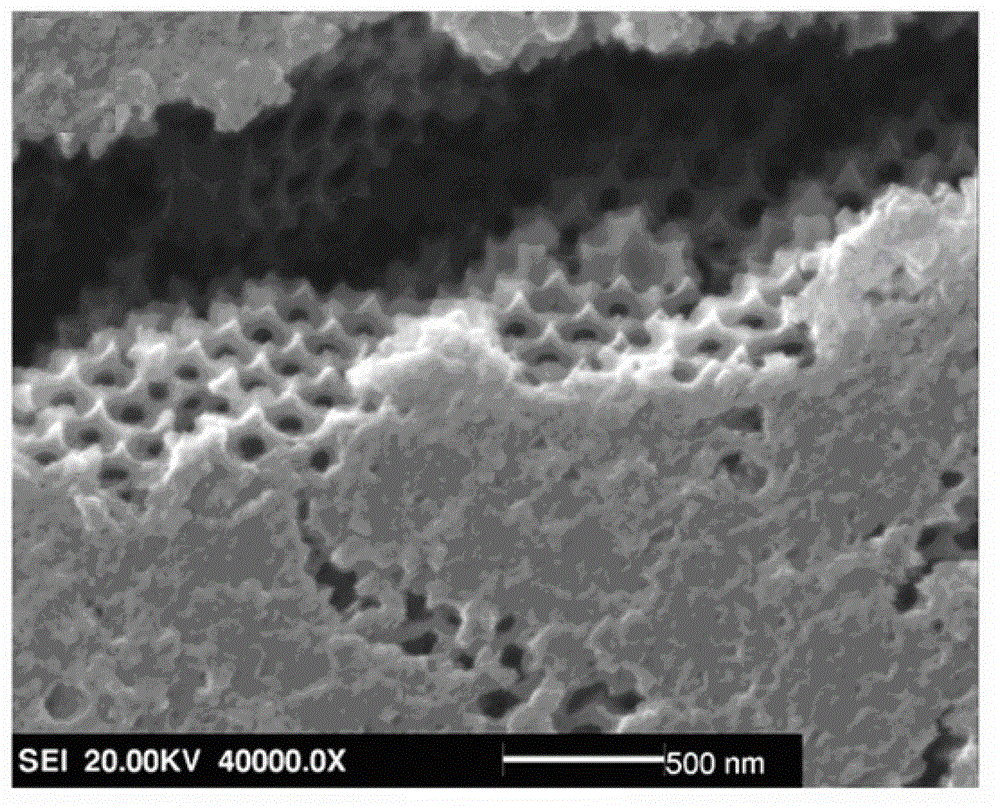

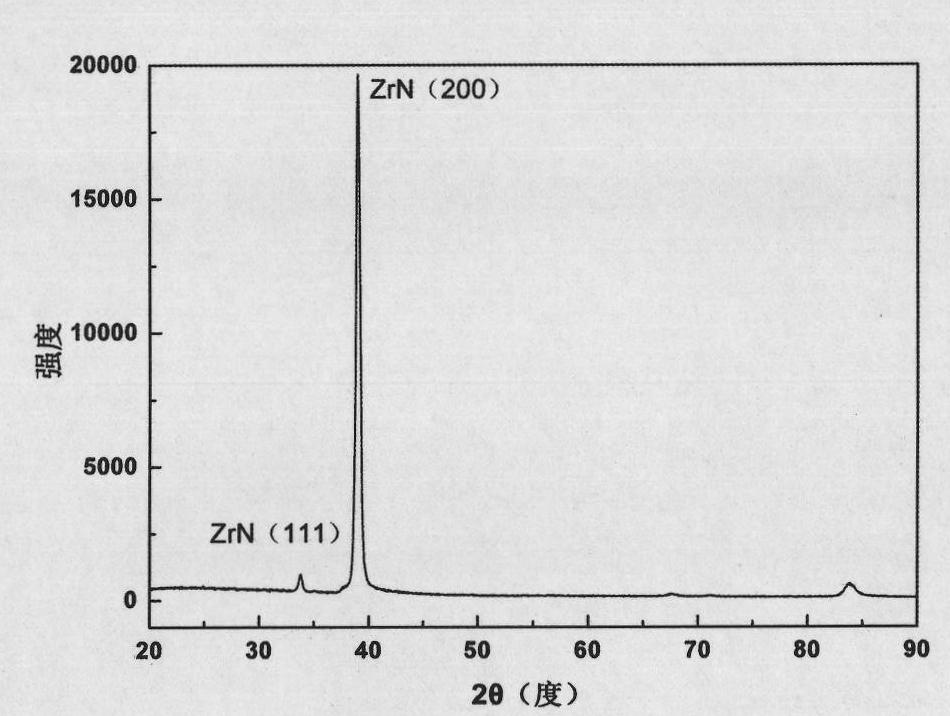

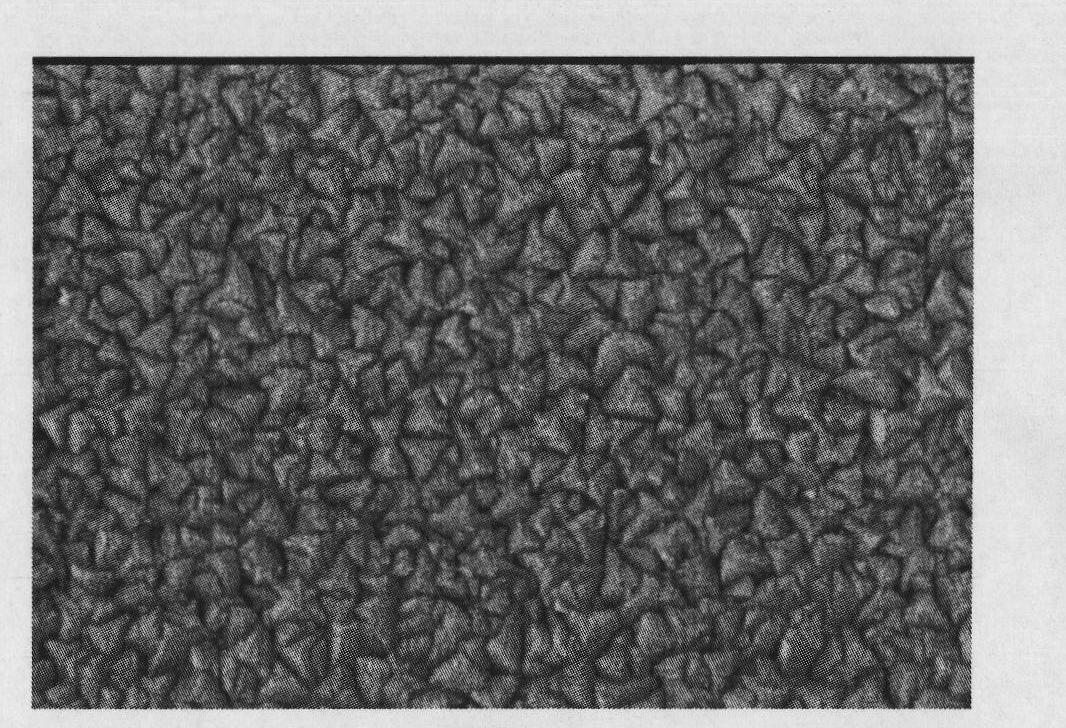

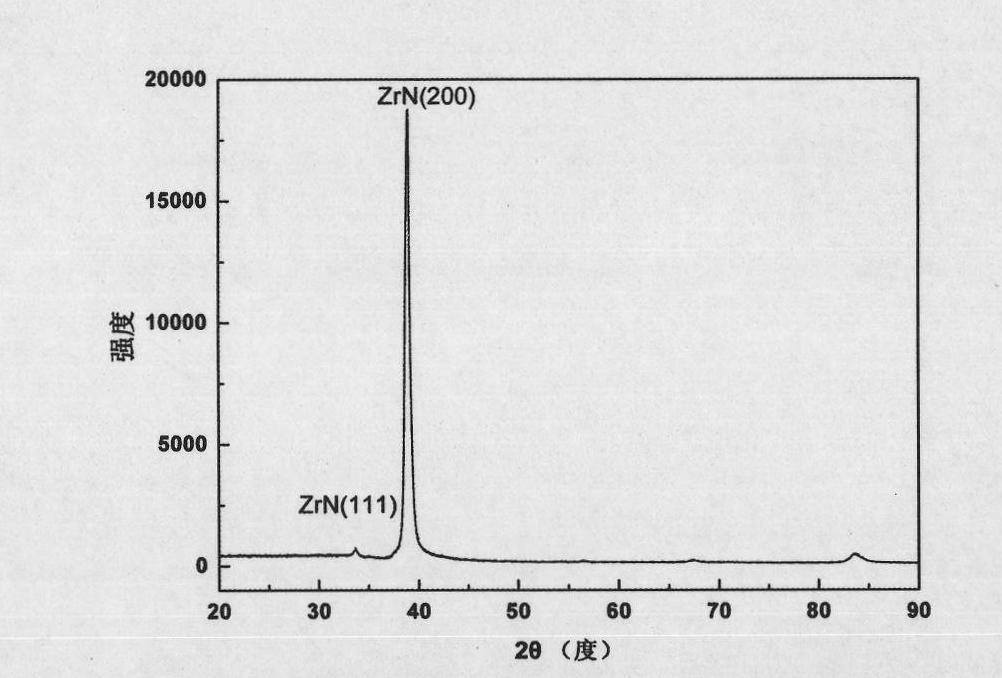

Preparation method of high hardness zirconium nitride hard coat

InactiveCN101775585AHigh hardnessHigh crystallinityVacuum evaporation coatingSputtering coatingNitrogenAlloy

The invention discloses a preparation method of a high hardness zirconium nitride hard coat and relates to a preparation method of a hard coat, which comprises the following steps: matrix pretreatment: hard alloy matrix is washed and dried after being ground and polished; and the sputter deposition is carried out after the pre-sputtering is performed. A method by adopting magnetic control sputtering method to control the process conditions such as the atmosphere, the matrix temperature, the matrix bias and the like of the sputter deposition so as to prepare the zirconium nitride hard coat on the surface of the hard alloy matrix is adopted to improve the hardness of the zirconium nitride coat. DC power is adopted to perform the magnetic control sputter deposition on the surface of the hard alloy matrix which is mechanically polished, washed by ultrasonic and washed and processed by ion source, the total pressure is controlled at 0.3 to 0.5 Pa, the flow rate of the nitrogen is 15 to 20 percent, DC power of the Zr target is 250 to 300W, the matrix temperature is 300 to 450 DEG C, the matrix bias voltage is minus 50 to 100V, the deposition time is 90 to 120 minutes, and the coat has high hardness of more than 30 GPa.

Owner:XIAMEN UNIV

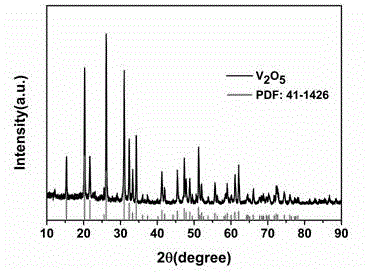

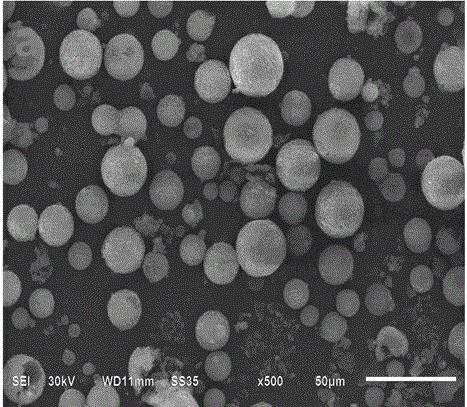

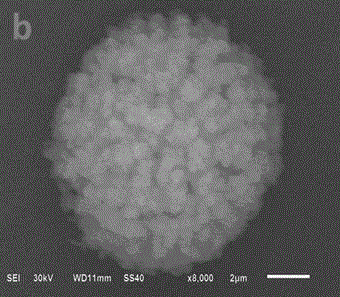

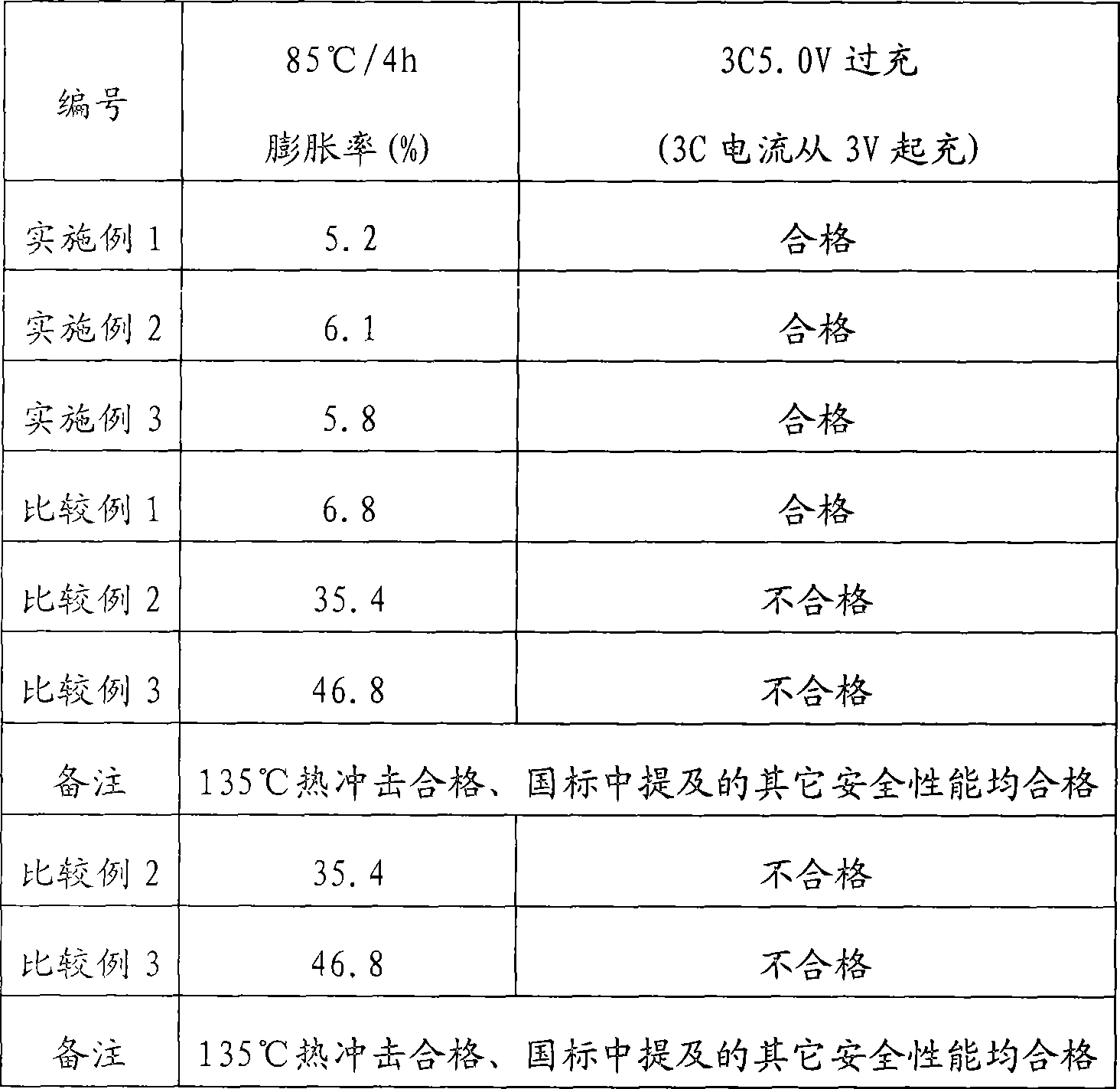

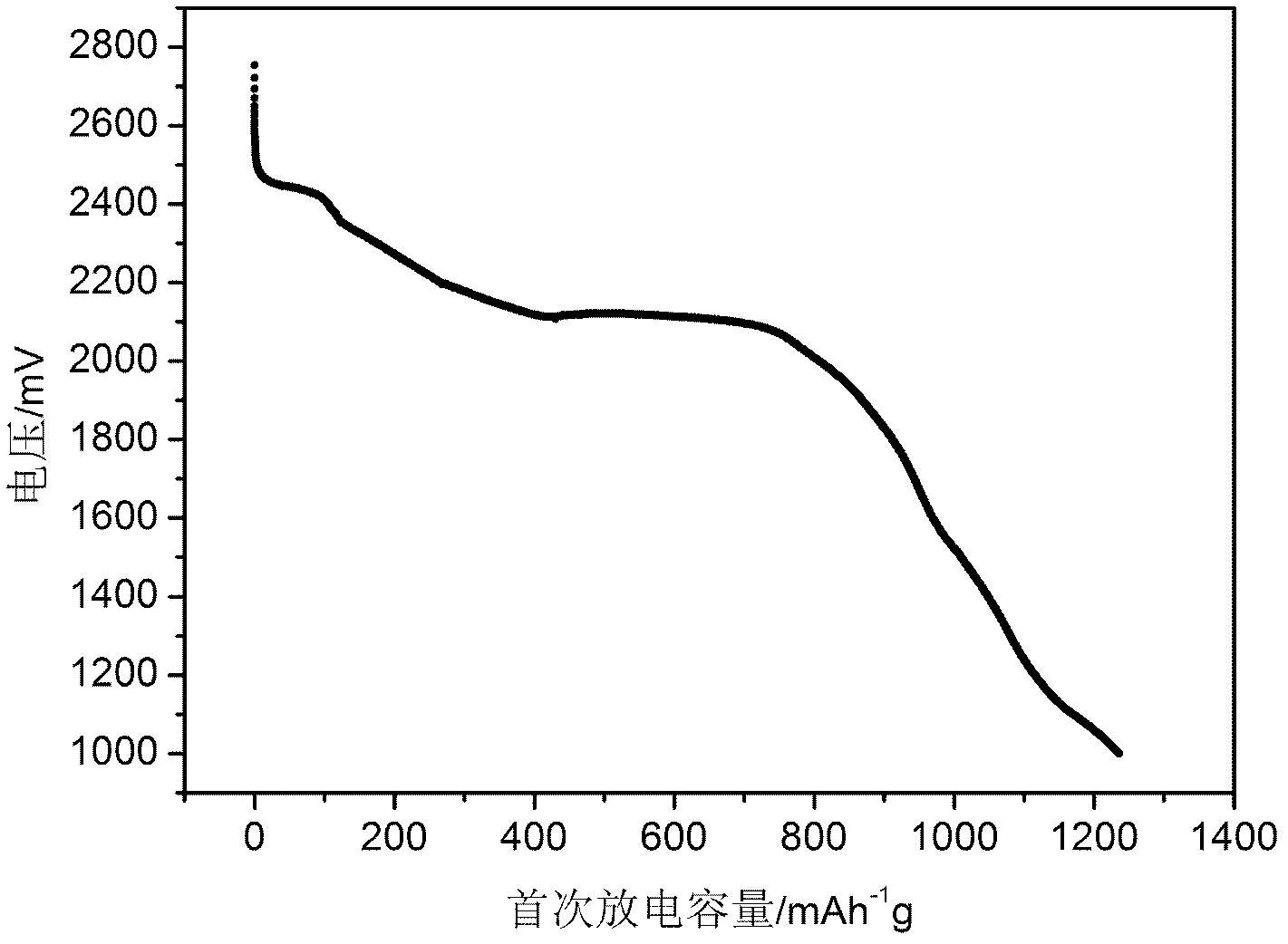

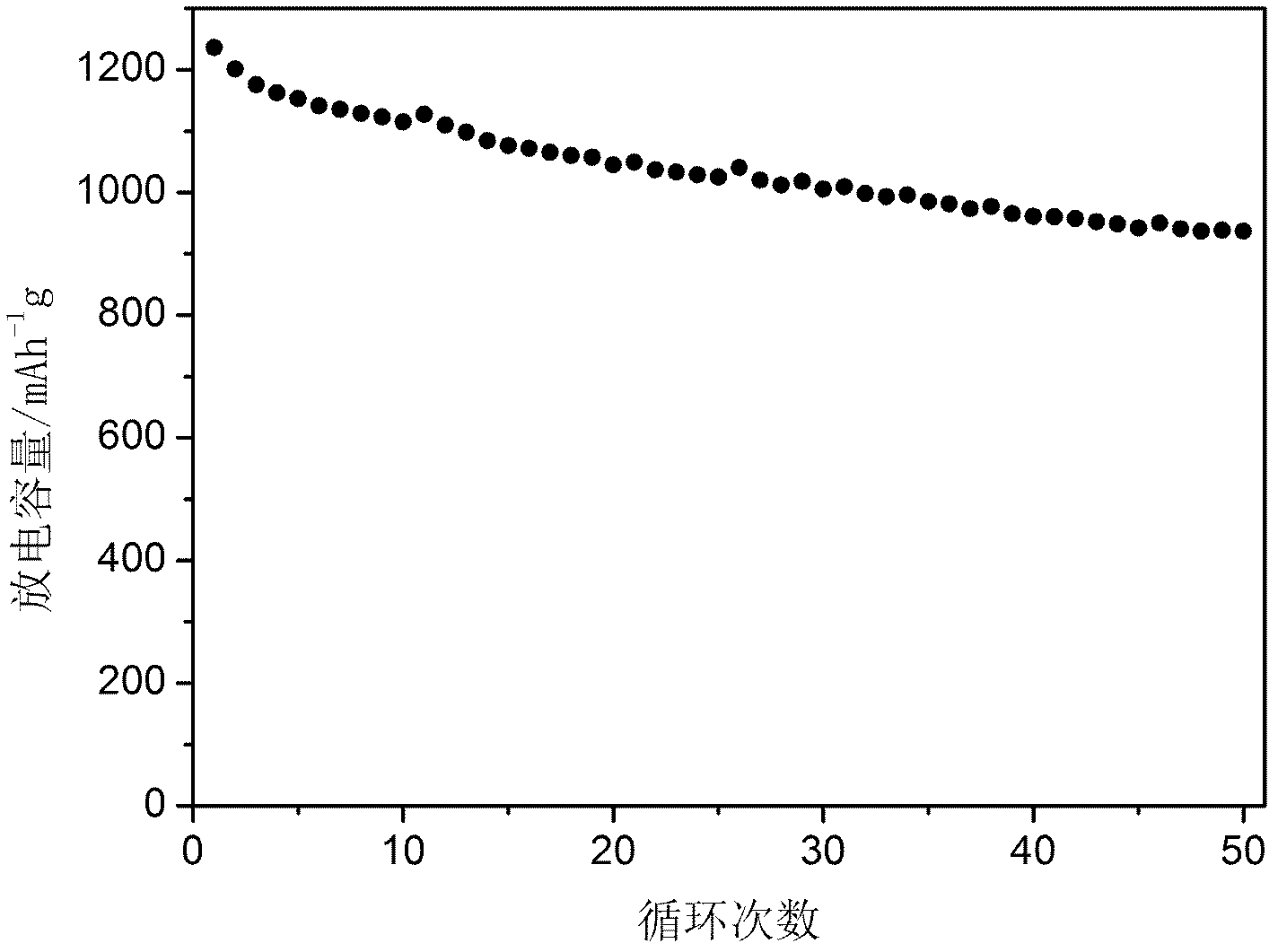

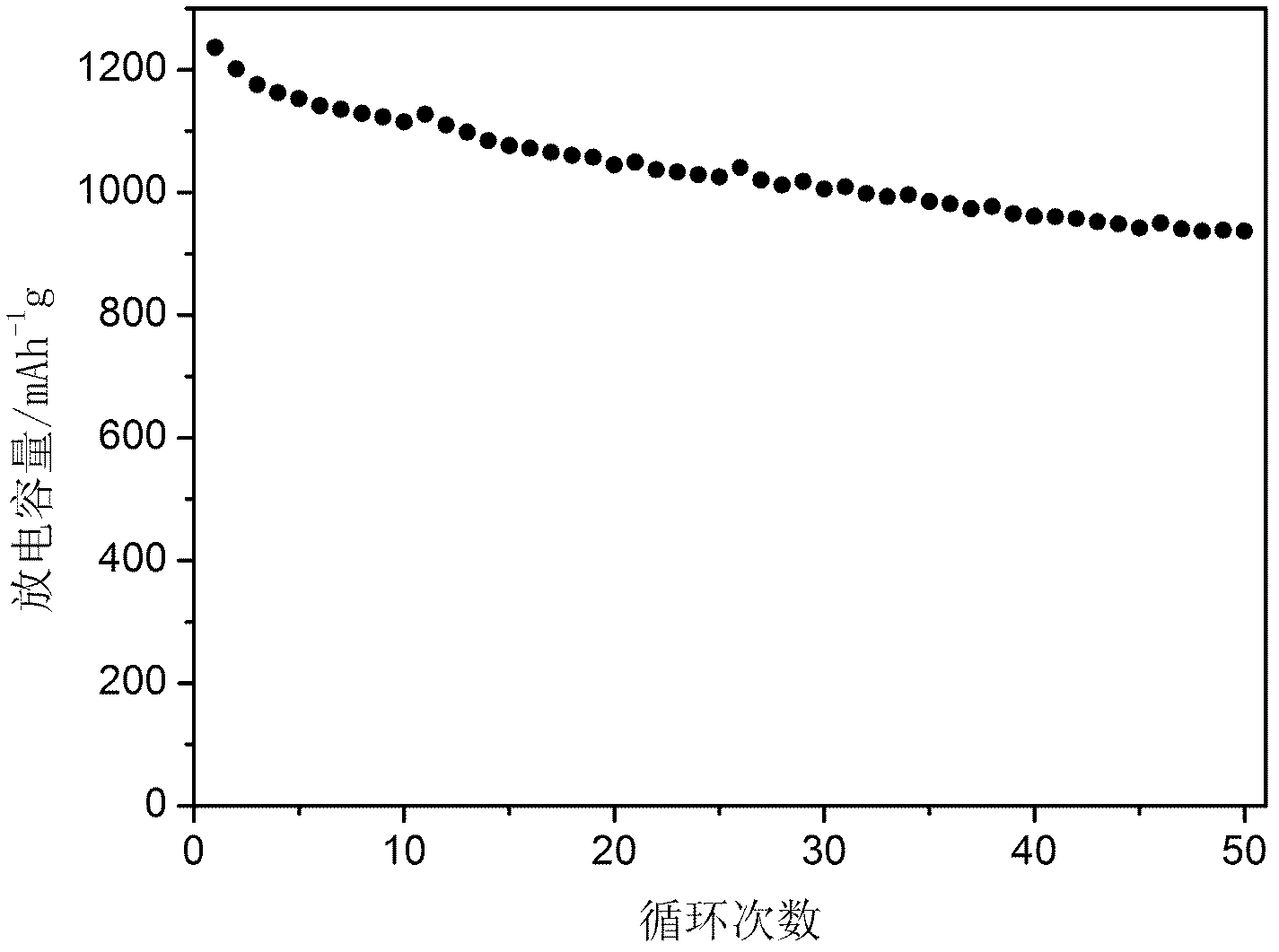

Porous V2O5/C composite microspheres of lithium secondary battery positive electrode material and preparation method of porous V2O5/C composite microspheres

InactiveCN104466102AEffective control of particle sizeEffective control of morphologyCell electrodesMicrospherePolymethyl methacrylate

The invention discloses porous V2O5 / C composite microspheres of a lithium secondary battery positive electrode material and a preparation method of the porous V2O5 / C composite microspheres. The porous V2O5 / C composite microspheres are formed by clustering carbon coated V2O5 nano composite particles with the particle sizes of 5-30 mirons, and the porous V2O5 / C composite microspheres are internally provided with porous structures. The preparation method comprises the following steps of synthesizing crosslinked polymethyl methacrylate PMMA microgel spheres, hydrolyzing partially so as to act as a mold plate for synthesizing the porous V2O5 / C composite microspheres; adsorbing VO<2+> to three-dimensional meshes of the PMMA mold plate, changing the pH value of an adsorption solution, hydrolyzing the VO<2+> to generate V2O5 nano particles, and filling the three-dimensional meshes in situ with the V2O5 nano particles so as to obtain a V2O5 / PMMA precursor; and forging the precursor so as to obtain the porous V2O5 / C composite microspheres. The composite microsphere has the beneficial effects of improving the multiplying performance and the cycle performance and the like; the preparation method is simple in technology, and is suitable for being used in large-scale industrial production.

Owner:XIANGTAN UNIV

Anode material of lithium ion cell and preparation method thereof

ActiveCN101436666AImprove distributionEvenly distributedElectrode manufacturing processesCobalt compoundsLithium carbonatePhysical chemistry

The invention discloses a method for preparing lithium cobaltate positive pole material for a lithium ion cell and the obtained lithium cobaltate positive pole material. The method comprises the following steps: adopting a multiple-step synthesizing process; in a first synthesis, adopting excessive lithium so as to obtain larger lithium cobaltate particles at lower temperature; and before a second synthesis, adhering mixed powder of cobalt carbonate and lithium carbonate with small particle size and larger specific surface area to the one-step synthesized lithium cobaltate large particles through a mechanical granulation mode. The method can effectively improve the particle size and the tap density of the lithium cobaltate positive pole material so as to improve the compacted density and the volume specific capacity of the positive pole material.

Owner:广东风华新能源股份有限公司

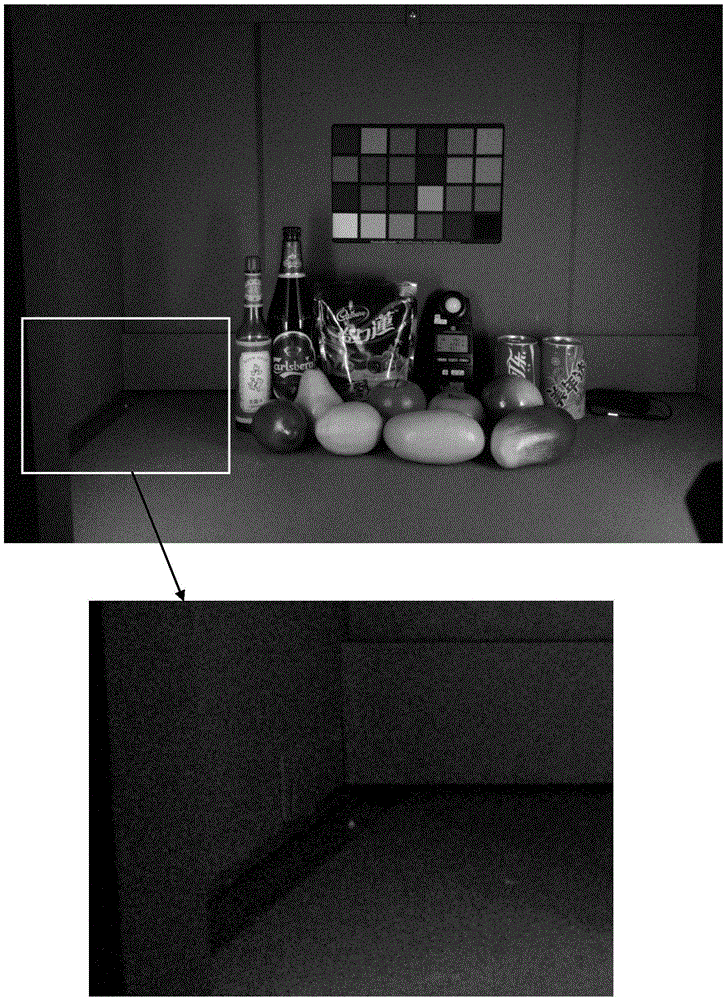

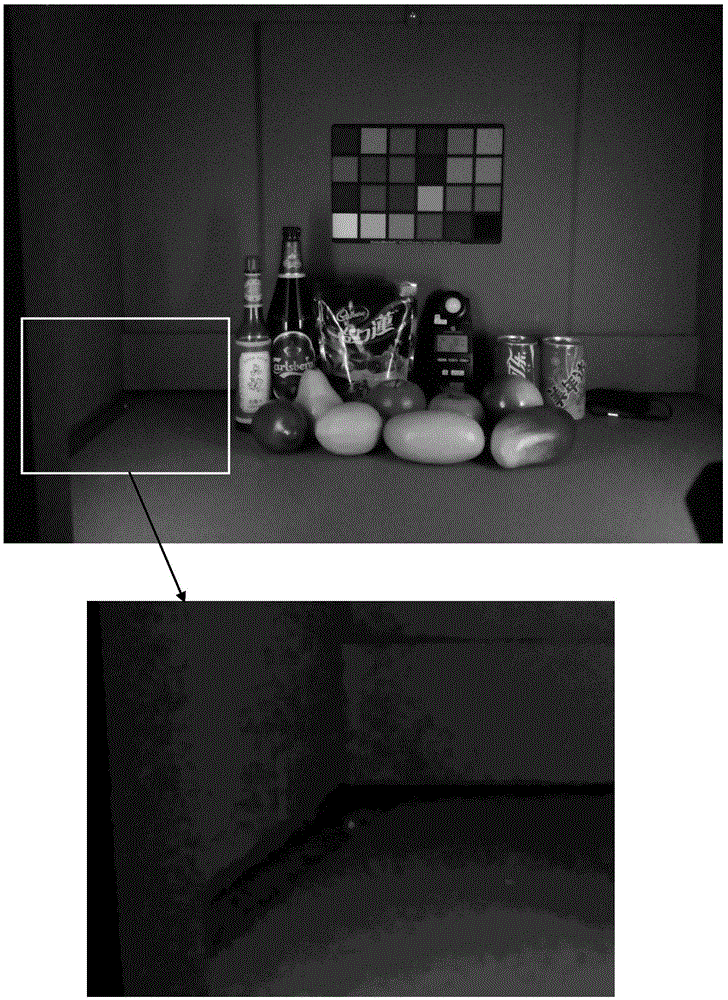

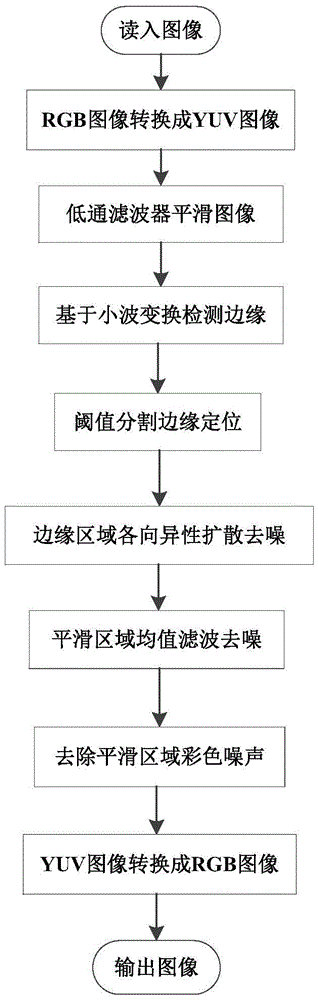

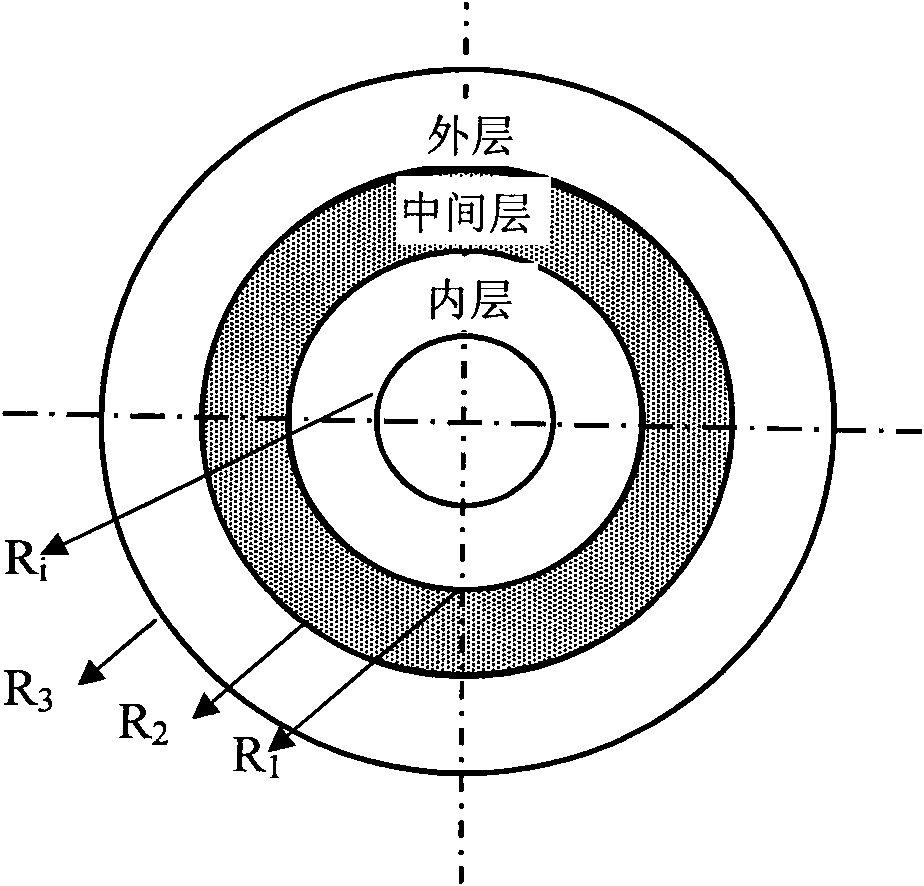

Mobile phone image denoising method based on wavelet transform edge detection

ActiveCN105654445AHigh precisionReduce misjudgmentImage enhancementImage analysisPattern recognitionImage denoising

The invention discloses a mobile phone image denoising method based on wavelet transform edge detection. The mobile phone image denoising method disclosed by the invention can be used for effectively smoothing noise, reserving image edge details and removing colour noise at the same time, so that an ideal denoising effect is obtained. The mobile phone image denoising method disclosed by the invention comprises the following steps: firstly, reading a colour noise image, and converting an input image into a YUV colour space from an RGB colour space; secondly, smoothing the image by adopting a Gaussian filter, and carrying out lowpass filtering on a Y channel image three times; thirdly, detecting the edge of the image by utilizing a wavelet transform algorithm; fourthly, obtaining a binary image of the edge by carrying out threshold segmentation; fifthly, smoothing noise by carrying out anisotropic diffusion at the edge region of the image; sixthly, carrying out mean filtering in a smooth region of the image for denoising; seventhly, further removing the colour noise from the image in the smooth region; and eighthly, converting the image into the RGB colour space from the YUV colour space to obtain a final denoised image.

Owner:SOUTHEAST UNIV

Short-flow production method of high-boron stainless steel plate

InactiveCN101875069AImprove plasticitySimple processRoll force/gap control deviceTemperature control deviceMaterials preparationMetallic materials

The invention discloses a short-flow production method of a high-boron stainless steel plate, which belongs to the field of metal material preparation and is used for manufacturing a high-boron austenitic stainless steel plate with a boron content of 0.5-3% and a thickness of 1-10mm. The method comprises the following main process: using three layers of austenitic stainless steel composite tube blanks which have different boron contents as raw materials, wherein the boron content of the intermediate layer is 2-10%, and the boron content of the austenitic stainless steel at the inner and outer layers is 0-0.1%; splitting the austenitic stainless steel into 3-10 parts of which the cross sections are fan-shaped in the axial direction; carrying out hot rolling on the split composite plate blanks, wherein the total deformation is 50-90%, the austenitic stainless steel of the intermediate layer fragments in the rolling process, and the boron elements are subject to preliminary diffusion; carrying out thermal diffusion annealing to uniformly distribute the boron elements by diffusion; and using a cold rolling process to improve the surface quality and the dimensional accuracy of the plates. Based on the characteristic that the plasticity of austenitic stainless steel is poor at high temperature when the boron content is high, the method produces the high-boron stainless steel plate by using the conventional hot rolling process, and has the advantages of short process flow and simple operation of equipment.

Owner:UNIV OF SCI & TECH BEIJING

All-solid-state polymer electrolyte used for lithium-sulfur secondary battery and its preparation method

InactiveCN102496736ALow costShort production processSecondary cellsCell component detailsPolymer electrolytesAll solid state

Belonging to the technical field of lithium-sulfur secondary battery preparation, the invention relates to an all-solid-state polymer electrolyte used for a lithium-sulfur secondary battery and its preparation method. Directed at the current situation that a metal lithium negative electrode is likely to generate a dendrite which can break a diaphragm so as to cause a short circuit when the liquid electrolyte or gel polymer electrolyte of a lithium-sulfur secondary battery matches with metal lithium, the invention provides an all-solid-state polymer electrolyte used for a lithium-sulfur secondary battery. The electrolyte comprises PEO (polyethylene oxide), a Li4Ti5O12 particle and a lithium salt, which can be LiClO4, LiPF6, LiBF4, LiCF3SO3 or LiTFSI. At a temperature of 30DEG C, the electrolyte has electric conductivity greater than 10<-4>S / cm, which is far higher than the electric conductivity of 10<-6>-10<-7>S / cm of PEO / a lithium salt at a temperature of 30DEG C. In a lithium-sulfur secondary battery, the electrolyte can serve both as an electrolyte and a diaphragm, and the double functions can substantially enhance the utilization rate and circulation stability of a positive active material.

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU

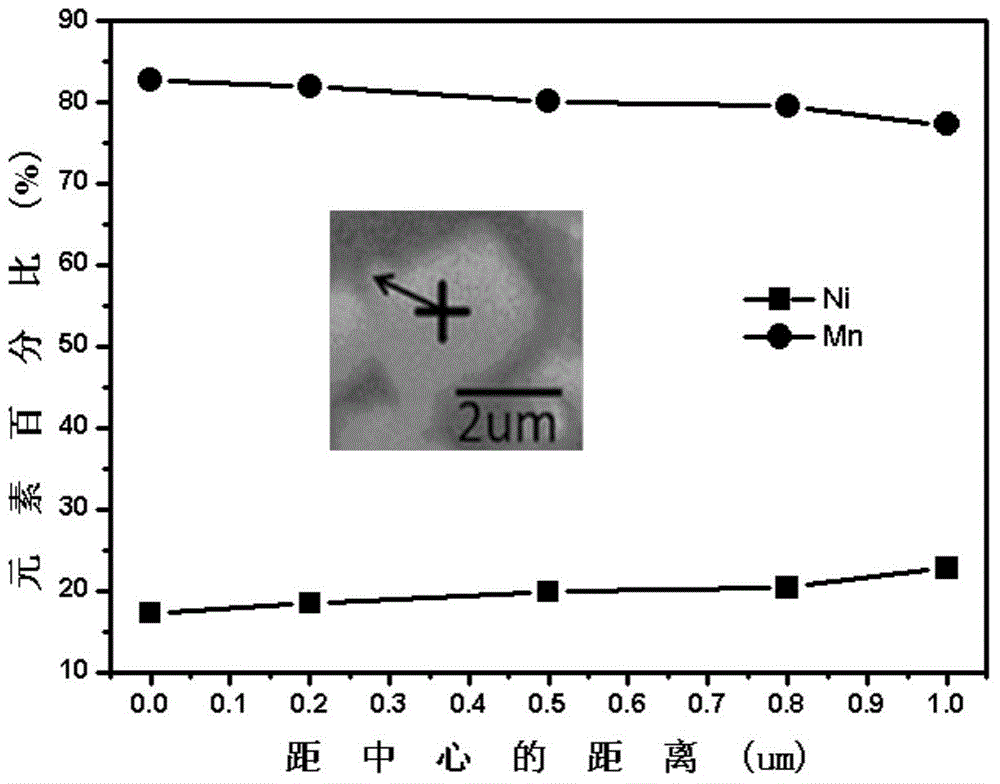

Lithium manganese nickel oxide cathode material having nickel manganese concentration gradient and preparation method thereof

ActiveCN105226270AHigh chemical stabilityEliminate Volume Change MismatchesCell electrodesSecondary cellsChemical compositionRoasting

The invention discloses a lithium manganese nickel oxide cathode material having nickel manganese concentration gradient and a preparation method thereof. The average chemical composition of the lithium manganese nickel oxide cathode material can be shown as a molecular formula of LiNi<0.5-x>Mn<1.5+x>O<4>, wherein x is more than or equal to 0.1 and less than or equal to 0.35, the concentration of Ni is gradually reduced in a gradient distribution manner from the particle center to the particle surface of the lithium manganese nickel oxide cathode material, and the concentration of Mn is gradually reduced in a gradient distribution manner from the particle center to the particle surface of the lithium manganese nickel oxide cathode material. The preparation method comprises the following steps of firstly, synthesizing a spherical-like particle having a core-shell structure by a co-precipitation process; and finally, preparing the lithium manganese nickel oxide cathode material with change on the nickel and manganese concentration by element diffusion during the high-temperature roasting process. The cathode material disclosed by the invention has excellent high-temperature cycle stability and rate performance, high reversible capacity, high chemical stability, long cycle life, and excellent comprehensive electrochemical performance.

Owner:UNIV OF SCI & TECH BEIJING

Solid Rare Earth Nitriding Catalyst

InactiveCN102268632AFast nitridingIncrease the diffusion coefficientSolid state diffusion coatingWaxAmmonium chloride mixture

The invention is a solid rare earth nitriding infiltration accelerator, which is composed of the following ingredients uniformly mixed by weight percentage: 50-90% of rare earth chloride, 5-30% of ammonium chloride and 5-20% of urea. The rare earth permeation agent is a paste solid, packed in a wax-sealed carton with a plastic film, and then put into an iron can and put into a gas nitriding furnace together with the nitriding workpiece for use. The permeation accelerator of the invention has the advantages of simple preparation, convenient use, 30-60% increase in nitriding speed, energy saving, and increased workpiece surface hardness HV50-150.

Owner:哈尔滨意锋稀土材料开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com