Patents

Literature

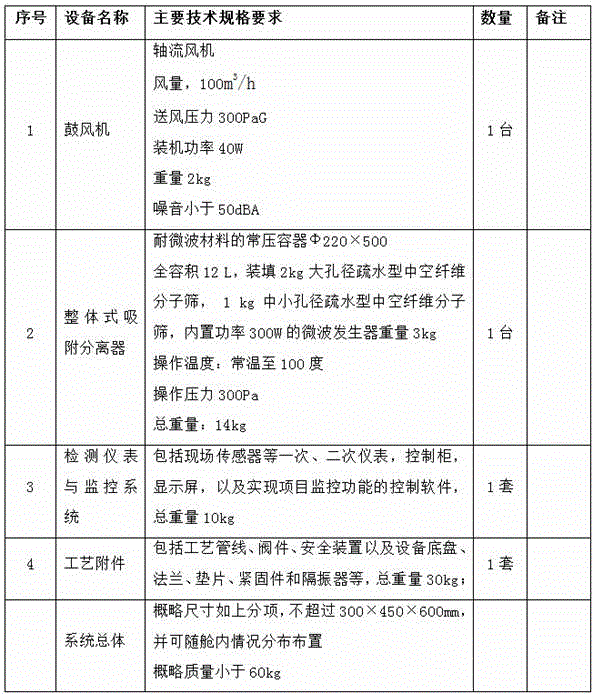

38results about How to "Increase desorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

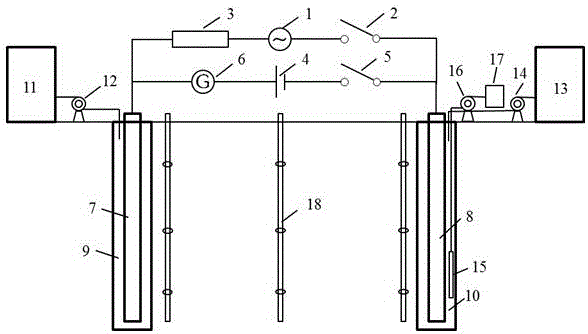

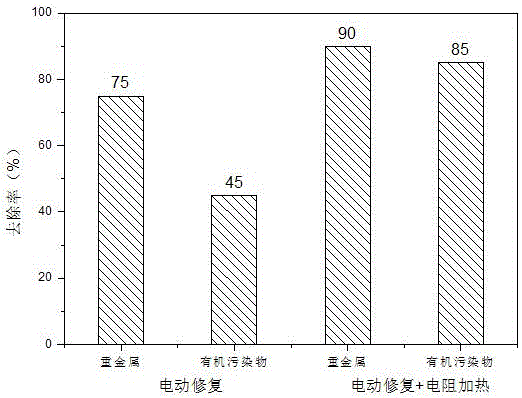

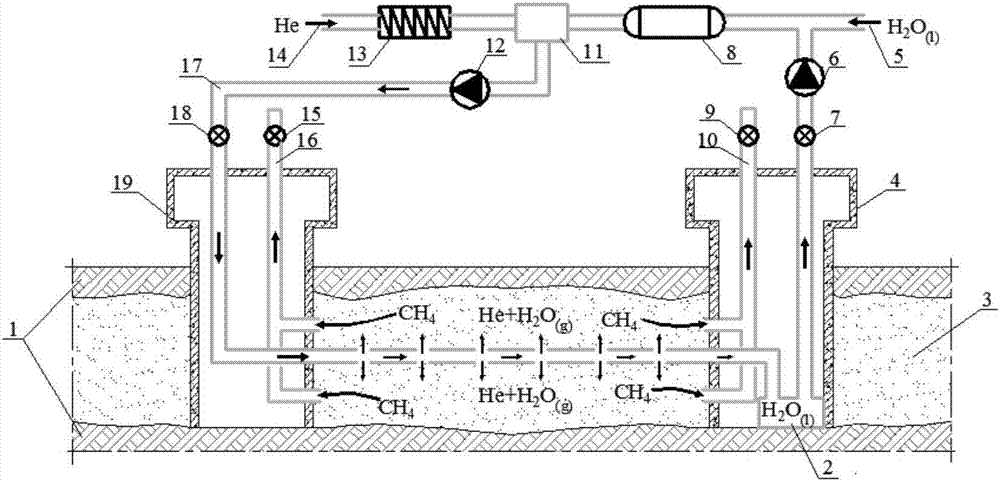

In-situ remediation method of heavy metal-organic combined pollution soil

InactiveCN106269843ATo achieve an organic combinationAchieve migrationContaminated soil reclamationEngineeringAlternating current

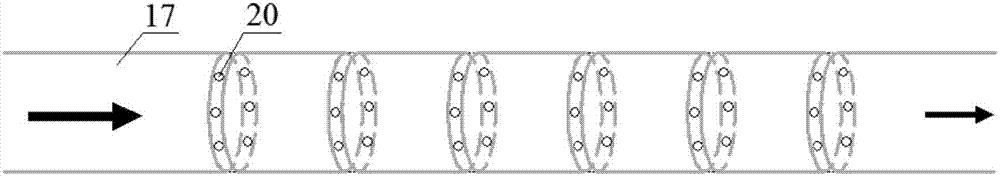

The invention relates to an in-situ remediation method of heavy metal-organic combined pollution soil. According to the method, a set of electrokinetic remediation device is added with a power switching system, an electrode heating technology is combined with the electrokinetic remediation and chemical oxidization technology, namely, the direct current power is utilized firstly, sodium persulfate used as the oxidizing agent is migrated to soil through electric process, meanwhile, migration and removal of heavy metal ion in the soil are realized. Then the alternating current power is switched, and soil is heated to a certain temperature through the electrode heating method so as to activate the sodium persulfate migrated to soil, and thereby realizing the in-situ degradation of organic pollutant in the soil. The method applies electrode to the electrode heating system and the electrokinetic remediation device at the same time, simplifies the remediation device and saves the system energy consumption while solves the difficulty that oxidant cannot migrate and activate in the soil and improves the remediation efficiency; the method is a combined soil remediation technology with prospect of application and promotion.

Owner:中建中环新能源有限公司 +1

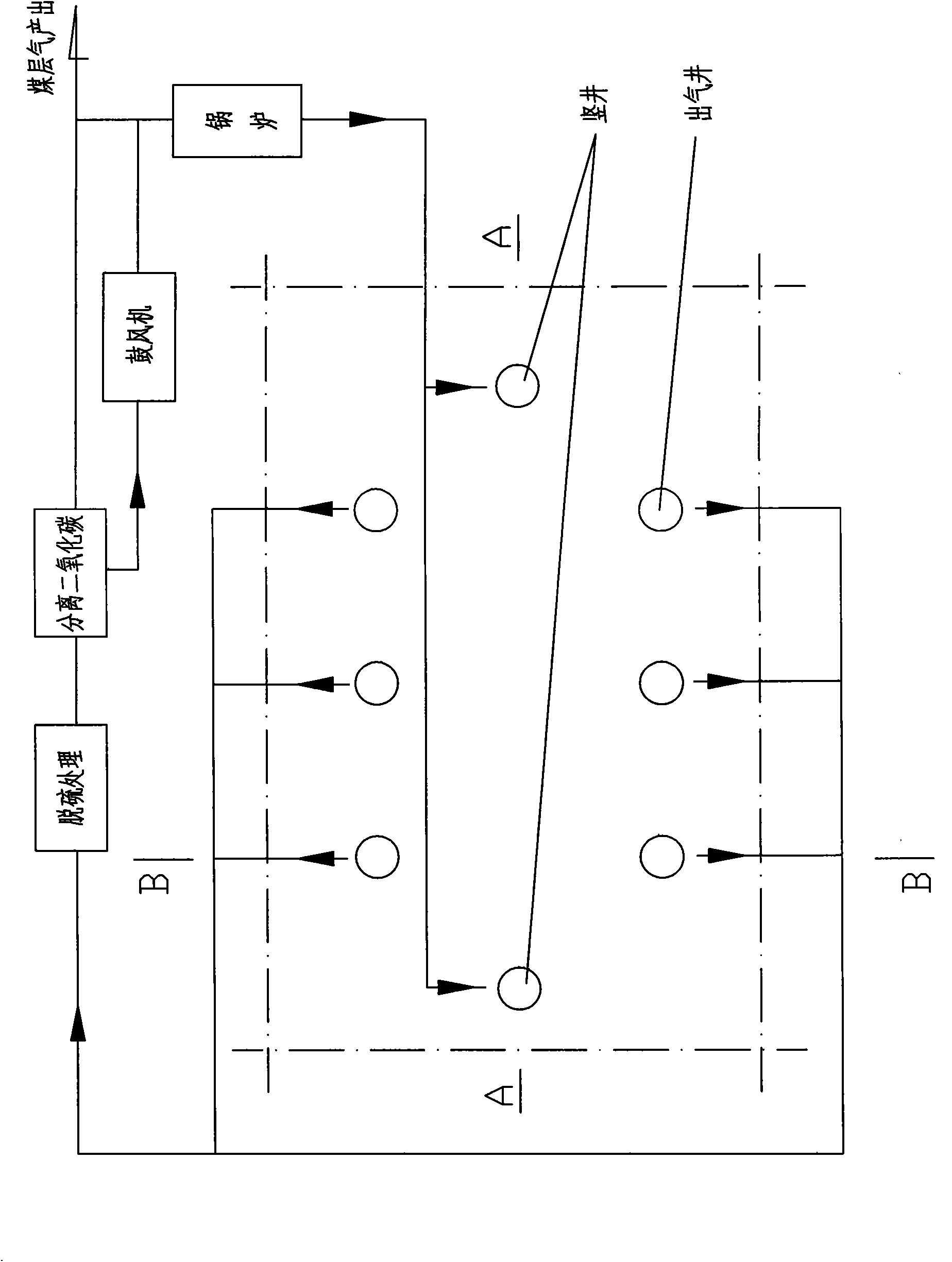

Method for coal bed methane mining by multi-element thermal fluid foam displacement

ActiveCN103061730AImprove permeabilityHard to getOther gas emission reduction technologiesFluid removalHigh pressure waterHigh pressure

The invention discloses a method for coal bed methane mining by multi-element thermal fluid foam displacement. Multi-element thermal fluid is injected into a coal bed of an injection-production well group through an injection well, and foaming agent is injected at intervals. A multi-element thermal fluid foam slug is formed in the coal bed to displace the coal bed methane in order to improve the recovery efficiency of the coal bed methane. The method specifically includes that extracted coal bed methane is compressed and mixed with compressed air, and then the mixture is injected into a multi-element thermal fluid generation device for ignition, extracted processed ground water is mixed to produce the multi-element thermal fluid mainly with high-temperature and high-pressure water vapor and mixed gas of carbon dioxide and nitrogen, the produced multi-element thermal fluid is injected into the underground coal bed through the injection well, a foaming system composed of preferred alkyl ether sulfonate and corrosion inhibitor is injected from an oil jacket annulus at intervals, the multi-element thermal fluid foam slug is formed under the ground to displace the coal bed methane, and water is drained and gas is recovered from a production well. The method has the advantages that fuel is easy to obtain, principles are clear and distinct, and the like, and can provide guidance for implementation of well stimulation of the coal bed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

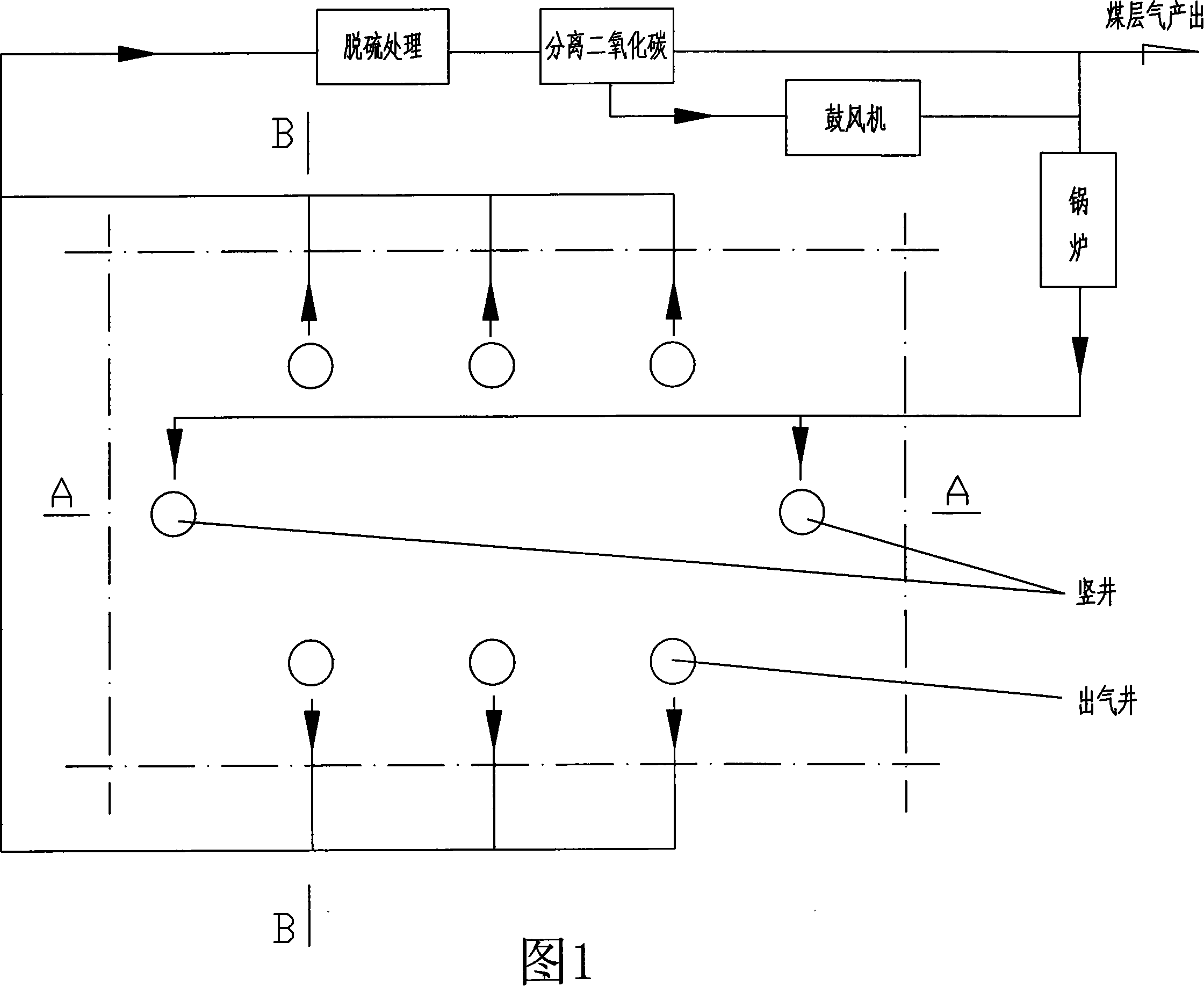

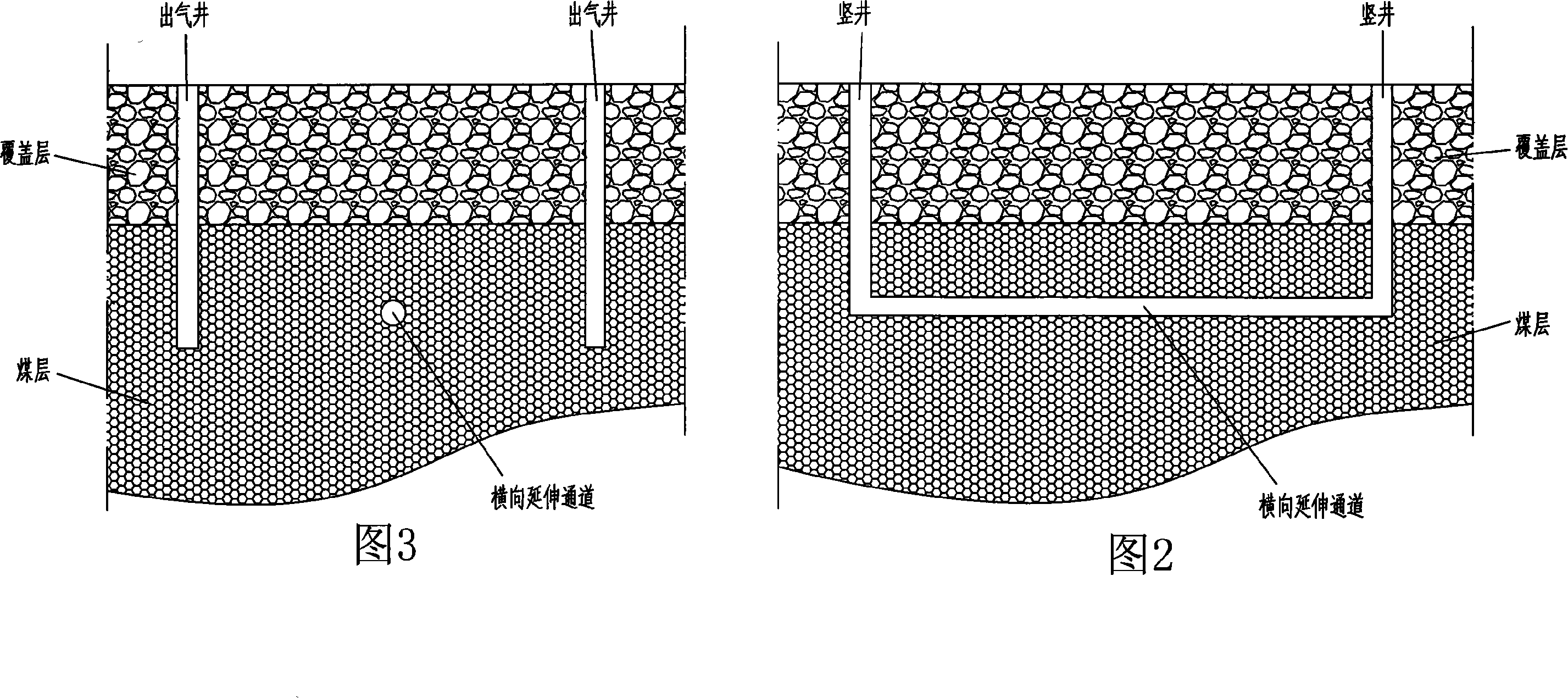

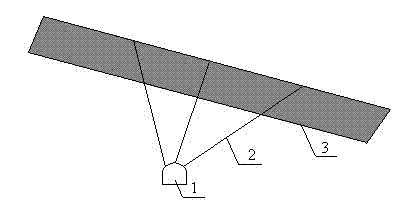

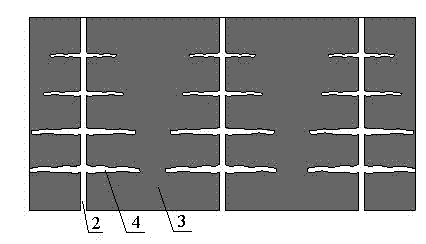

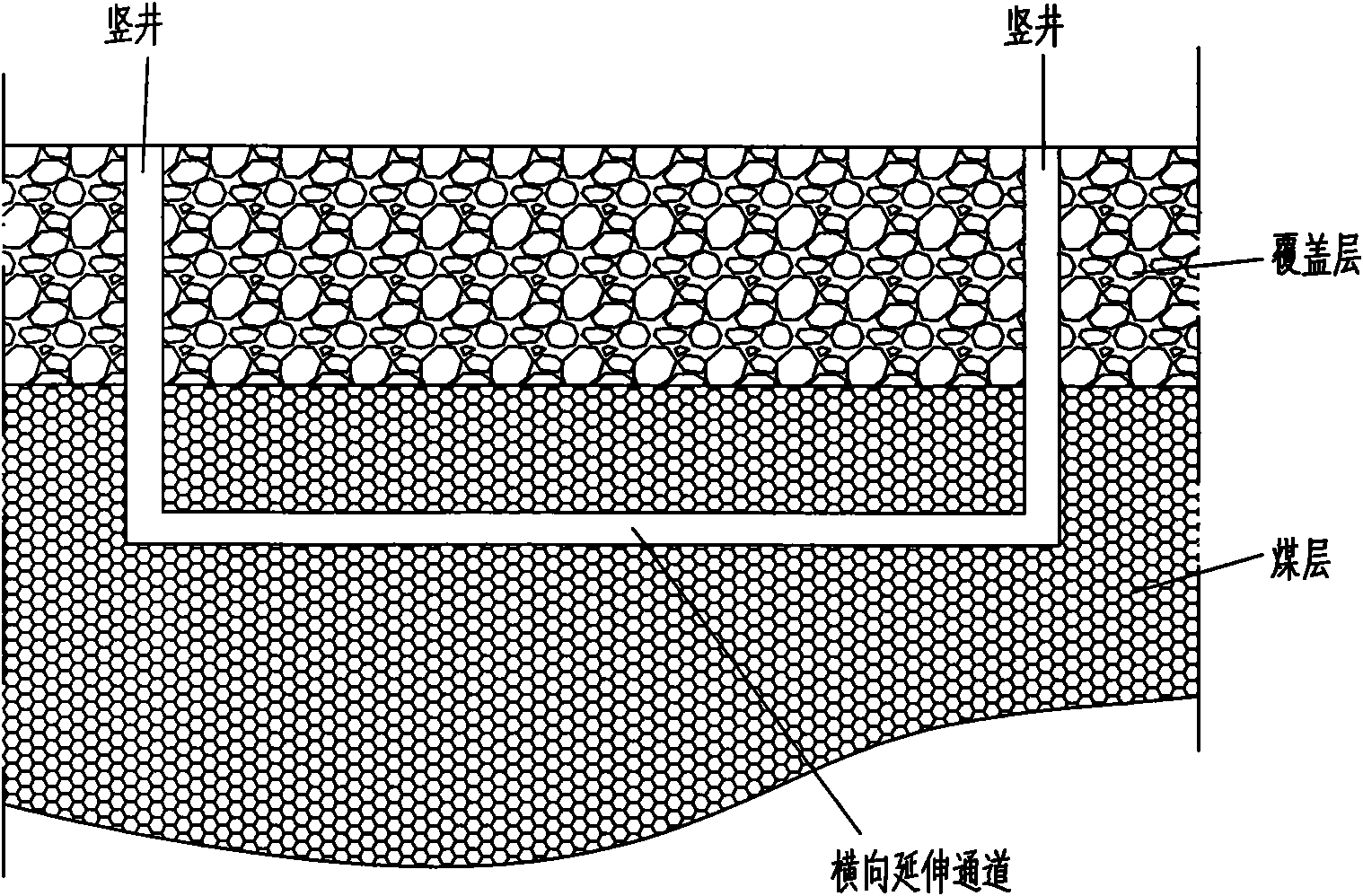

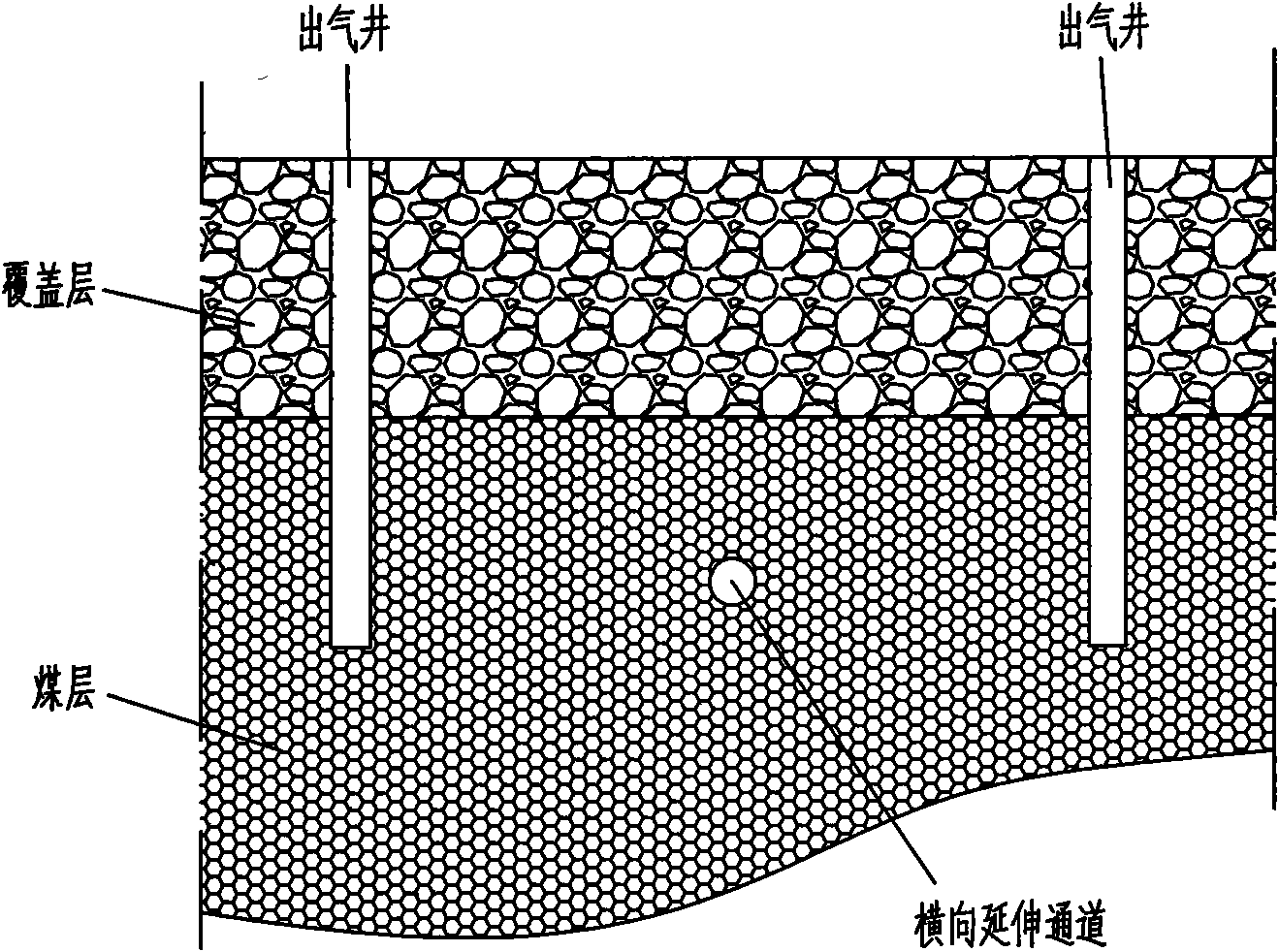

Coal bed gas mining novel technology

The invention discloses a new coal-bed methane exploitation technology and is divided into the following steps. (1) A gas intake mine comprising a vertical shaft and a passage extending transversely is arranged. (2) Then one side or both sides of the passage extending transversely is provided with an air outtake mine. (3) Fracturing treatment is done through high-pressure fluid with the prior art. (4) A coal bed at the bottom of the air outtake mine is burnt, meanwhile, the high-pressure air or oxygen is injected to the air intake mine. Thereby an air passage formed by cracks of coal bed is established between the air intake mine and the air outtake mine by making use of pressure difference between the air intake mine and the air outtake mine and the characteristics that water and oxygen in the coal mine tend to get close to the burning point at the air outtake mine. (5) Mixed gas discharged from the air outtake mine is collected and treated and then the coal-bed methane is obtained. Part of the obtained coal-bed methane is taken to be burnt completely and thermal smoke from burning is reinjected to the air intake mine to ensure a stable gas supply from the air outtake mine. The invention overcomes the effects caused by unfavorable factors such as low permeability, low pressure and low saturation and realizes commercial production of coal-bed methane.

Owner:ENN SCI & TECH DEV

Slotting induced-flow pressure-relief anti-reflection method for complicated seam

ActiveCN102966372AAchieving safe miningImprove extraction efficiencyFluid removalGas removalSocial benefitsDesorption

A slotting induced-flow pressure-relief anti-reflection method for a complicated seam is suitable for gas control of high-gas high-ground-stress complicated seam regions, can improve the gas permeability and gas desorption rate of coal, solves the difficult problems of low exhausting and mining efficiencies of coal-bed gas, high drilling construction load and the like, and realizes efficient gas exhausting and mining as well as fast outburst elimination of the complicated seam. High-pressure water is jetted into drilled holes to cut and destroy the coal in a rotary manner, and the coal in the radial direction of the drilled holes is destroyed and disturbed, so that buckling failures of the coal are induced and the coal and the gas are enabled to be spouted out of the drilled holes, as a result, the gas expansion energy of the coal is released, coal cracks are expanded and the exposure surface area of the coal is increased. therefore, the gas exhausting and mining efficiencies of coal are improved, coal and gas burst risks are eliminated, the effective influence range of drilling gas exhausting and mining is improved by 1-3 times, the air permeability coefficient of coal around the drilled holes is improved by 100-200 times, the drilling methane gas exhausting and mining quantity is improved by 2-5 times within hundreds of meters, and the outburst elimination time of the coal bed is shortened by 30-50 percent. The slotting induced-flow pressure-relief anti-reflection method for the complicated seam has very good field application value and social benefits.

Owner:CHINA UNIV OF MINING & TECH

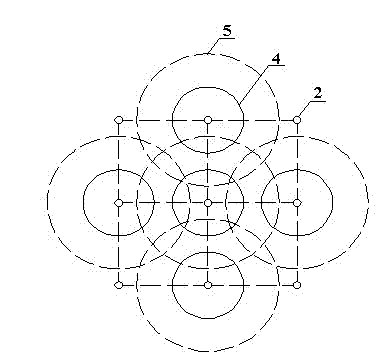

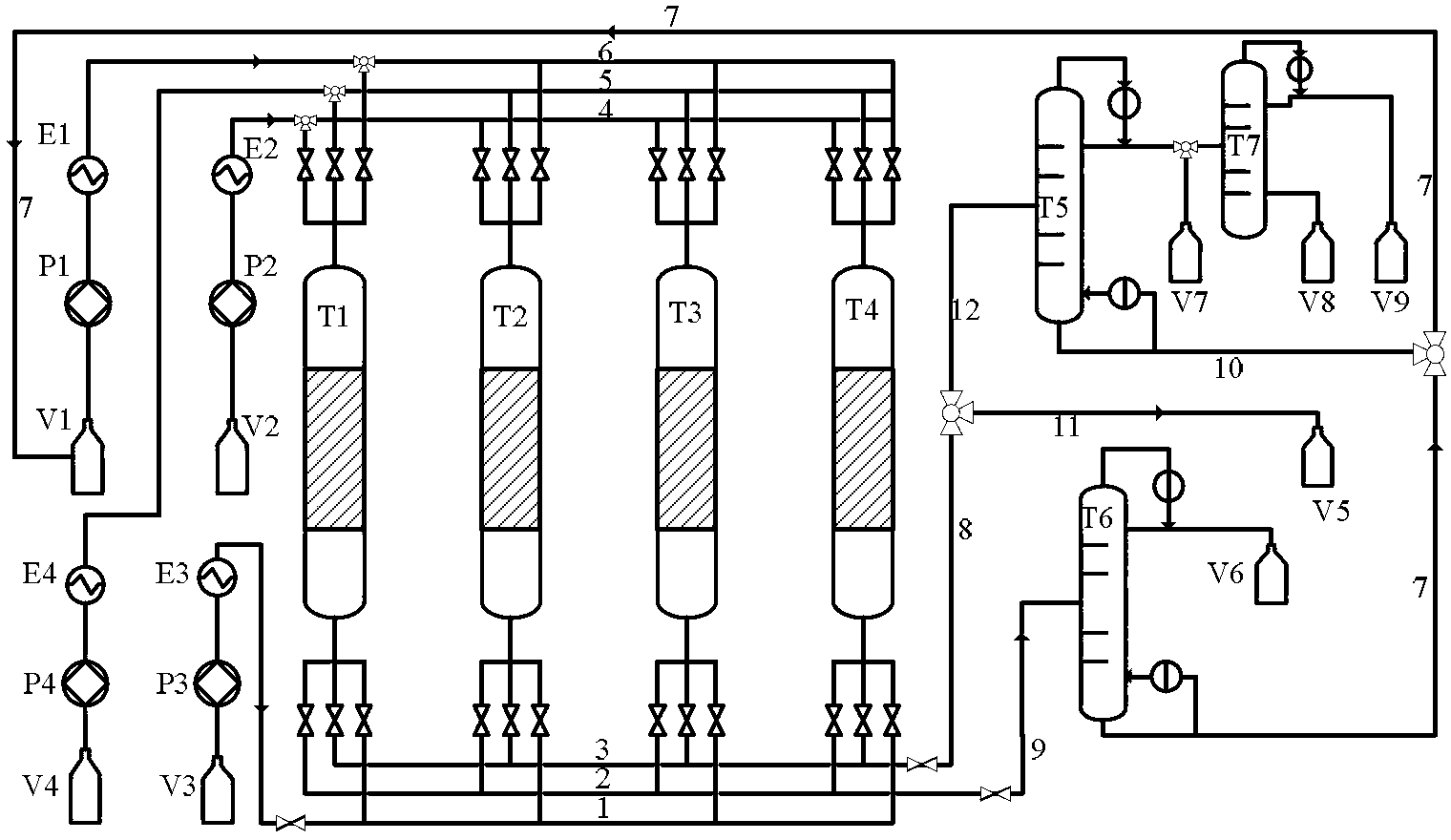

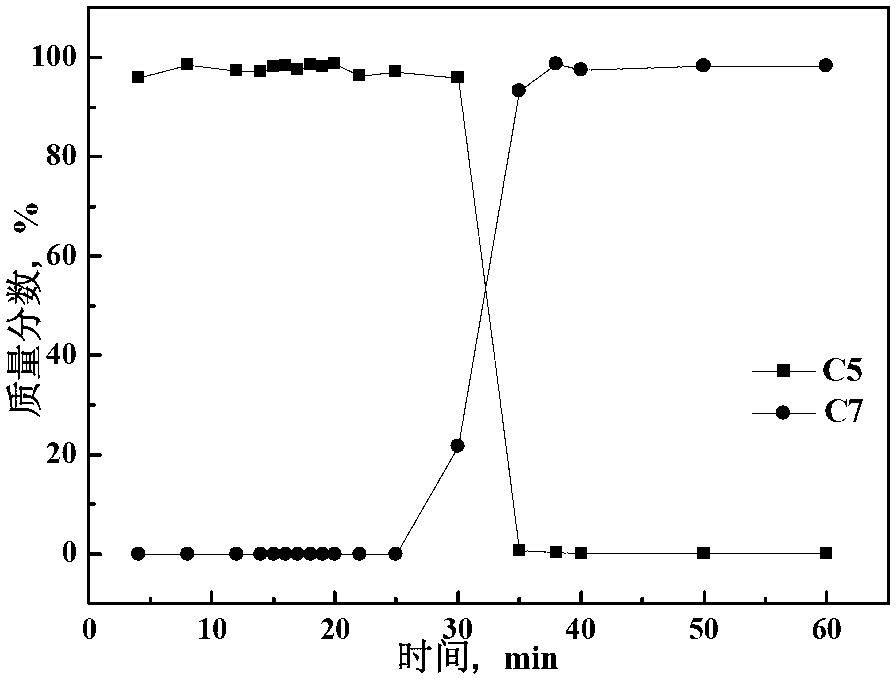

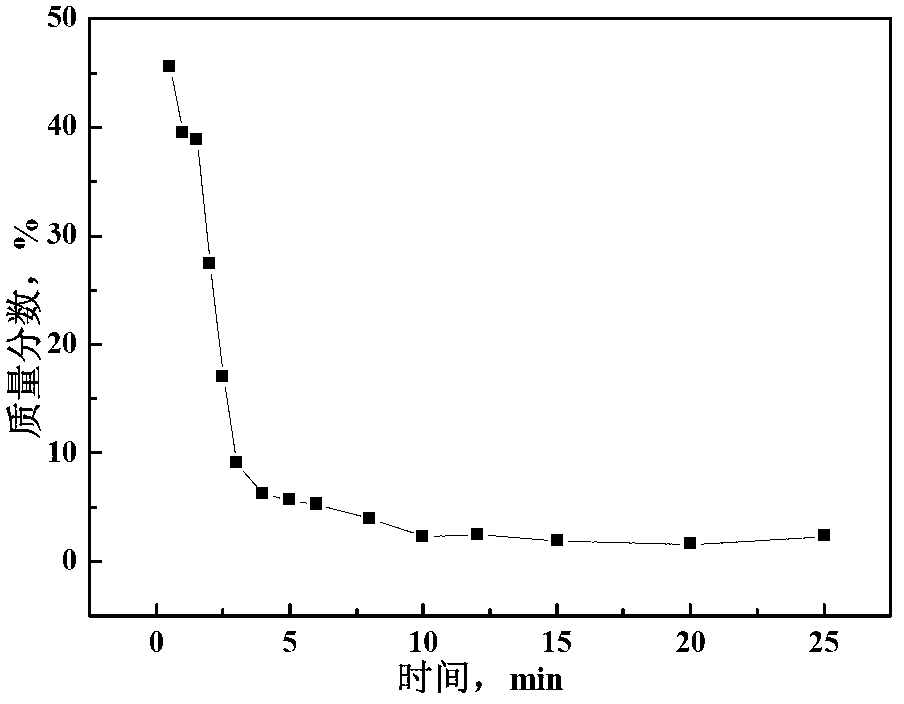

Process for extracting C4-C6 normal paraffins and coproducing isopentane and heterogeneous hexane cooperatively produced from light naphtha

InactiveCN103254932AEasy to separateAdsorption and separation energy consumption is reducedDistillation purification/separationAdsorption purification/separation2-methylbutaneDesorption

The invention relates to a chemical separation process and in particular relates to a process for extracting C4-C6 normal paraffins and coproducing isopentane and heterogeneous hexane from light naphtha. A multi-tower variable pressure adsorption and distillation separation coupling process is adopted by the invention. The process comprises the following steps of: introducing mixed gaseous C4-C6 normal paraffins and isohydrocarbons serving as raw materials into an adsorption tower for adsorption and separation; desorbing a bed by taking gaseous C7-C9 normal paraffins as a desorption reagent after the adsorption ends; introducing the desorbed material into a rectifying tower to separate out the product C4-C6 normal paraffins and the desorption reagent C7-C9 normal paraffins; recycling the desorption reagent; then regenerating the adsorption tower which absorbs the C7-C9 normal paraffins by using the un-adsorbed C4-C6 isohydrocarbons; and rectifying and separating the regenerated material twice to obtain high-purity desorption reagent C7-C9 normal paraffins, high-purity isopentane and high-purity heterogeneous hexane. By adopting the process disclosed by the invention, normal paraffins and isohydrocarbons can be effectively separated; the adsorbent is easy to regenerate; the process flow is simple and economic benefit is high; and the energy consumption in the process disclosed by the invention is greatly reduced in comparison with the energy consumption in other desorption processes.

Owner:NANJING UNIV OF TECH

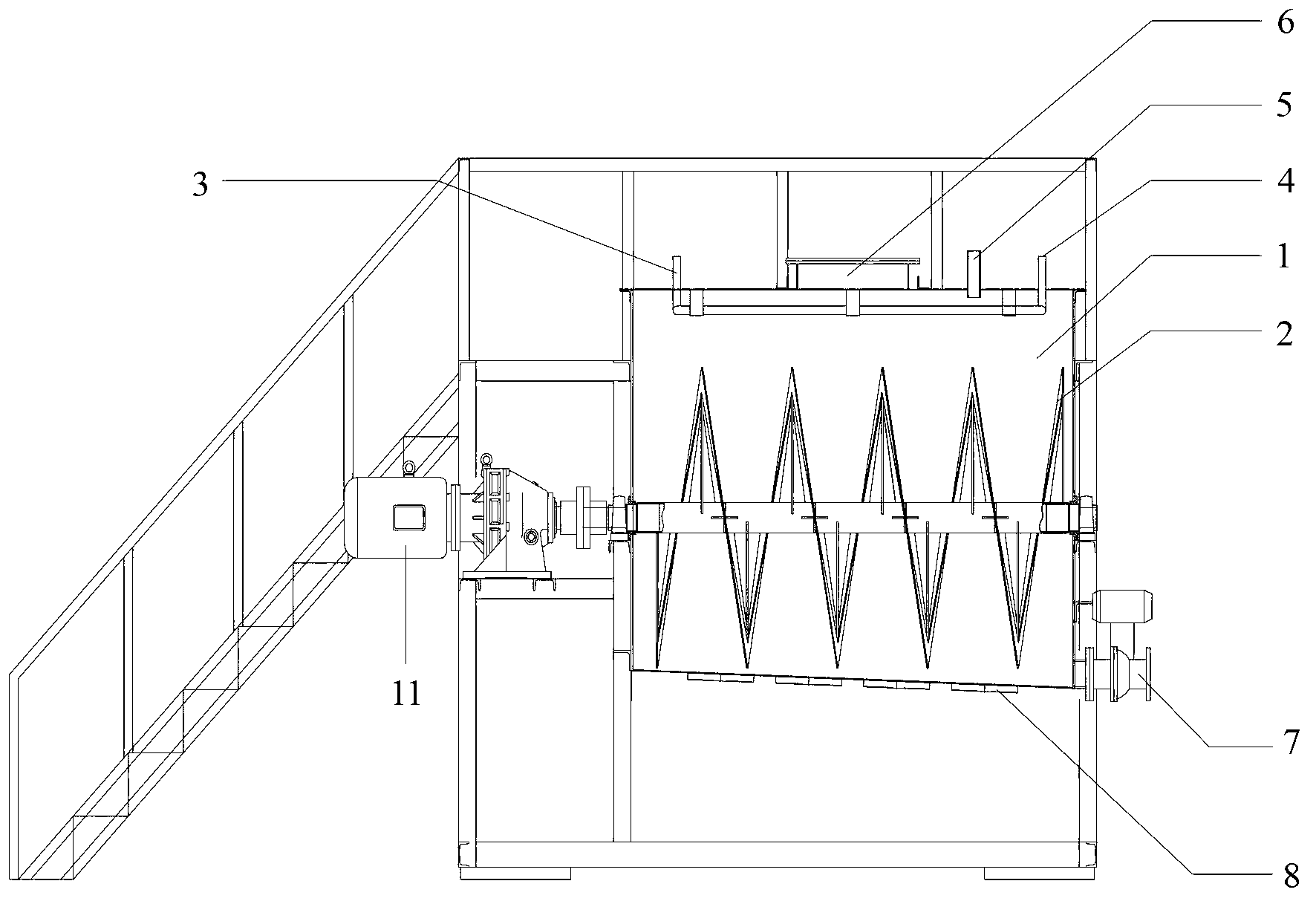

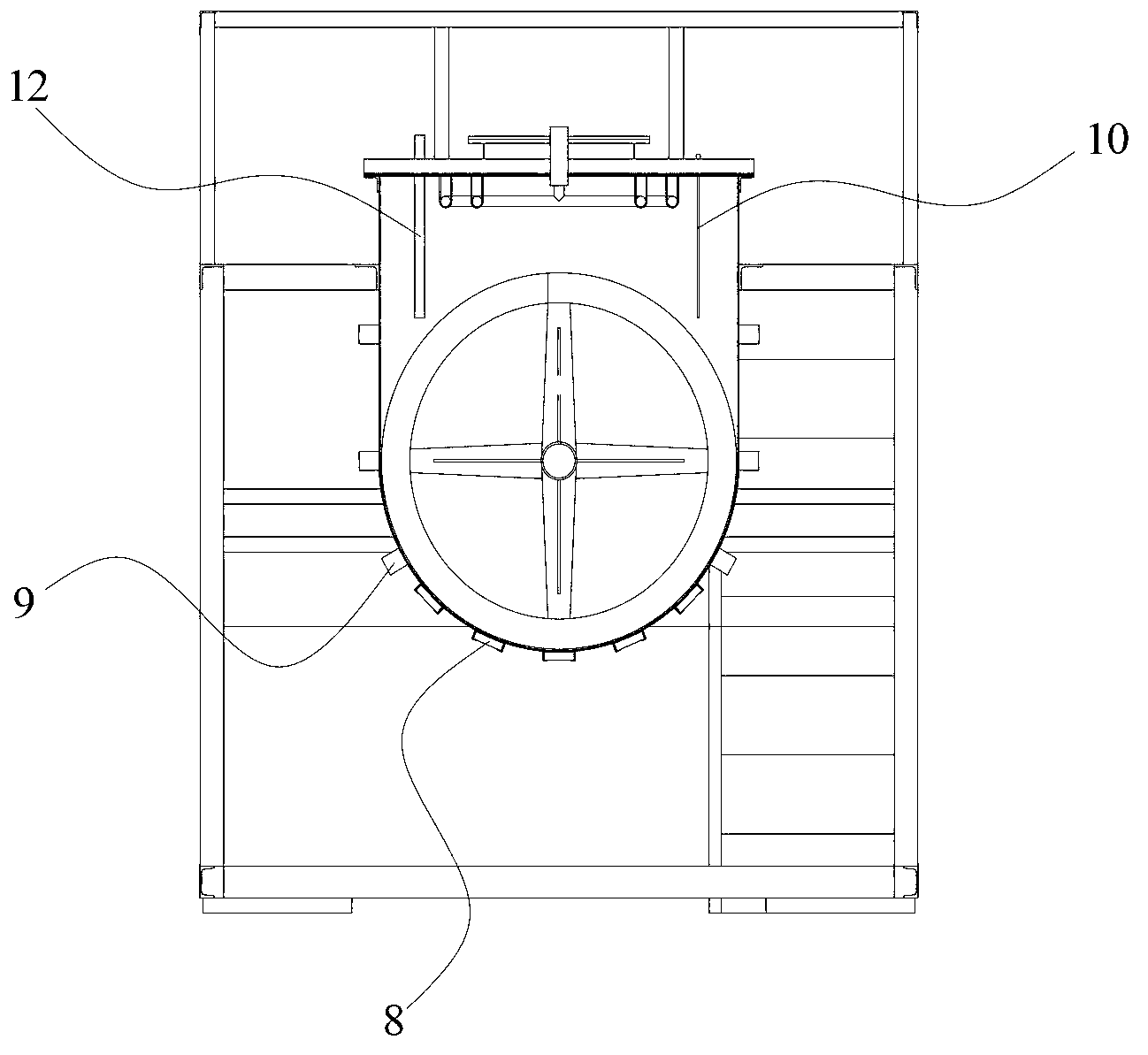

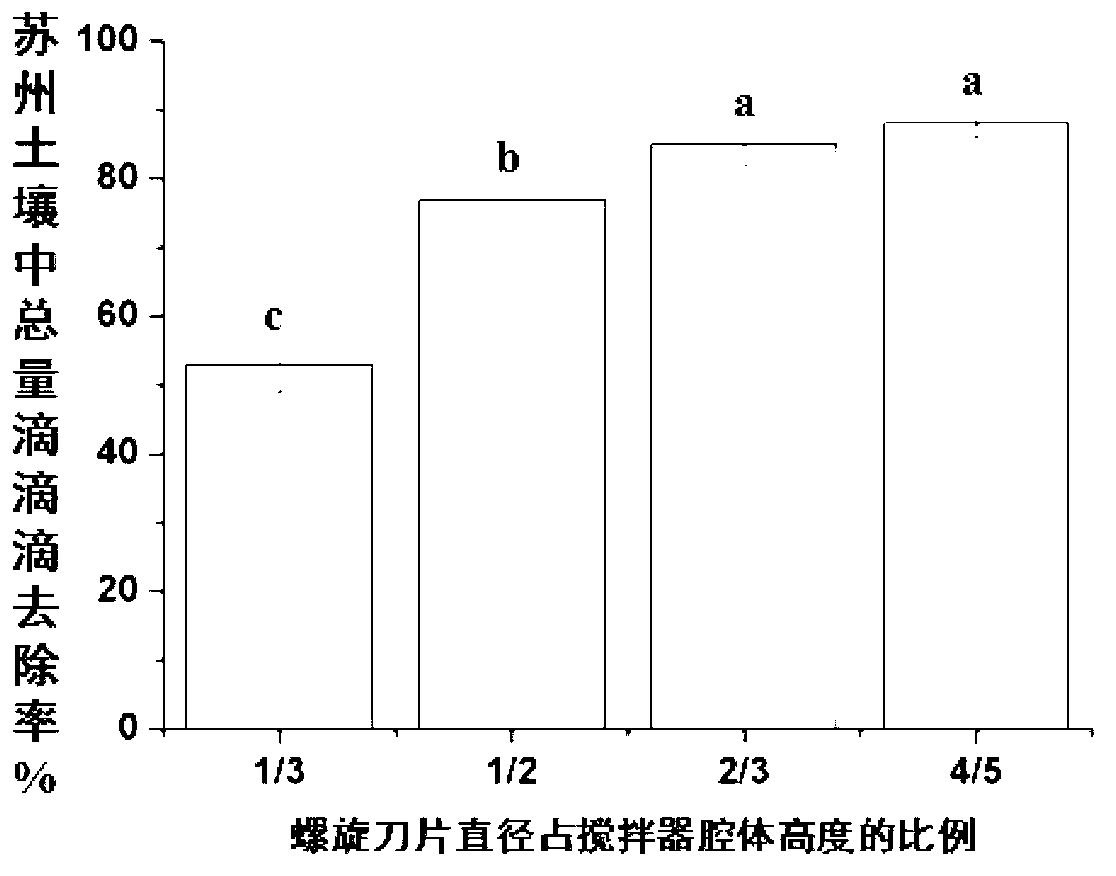

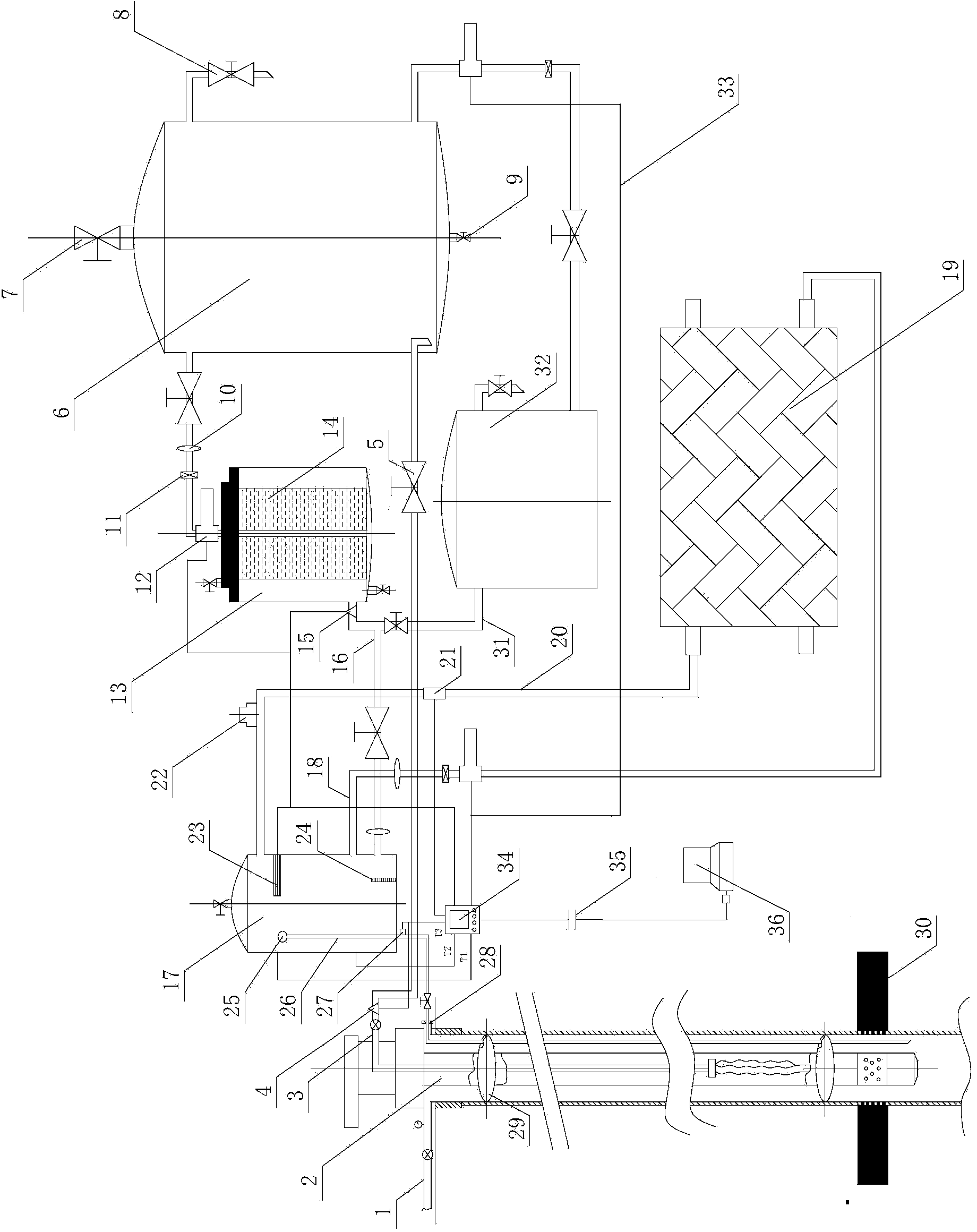

Multielement ex-situ remediation equipment and method used for organo-chlorine pesticide contaminated soil

InactiveCN103182394AWell mixedUniform heating effectContaminated soil reclamationSoil organic matterElution

The invention discloses multielement ex-situ remediation equipment and method used for organo-chlorine pesticide contaminated soil, belongs to the technical field of materializing remediation equipment for contaminated sites. The equipment comprises a stirring device, an eluent injecting device, an eluent recovery device, an ultrasonic generator and a heater. The equipment has extremely strong remediation broad-spectrum performance for organo-chlorine pesticide site soil with different characteristics such as organo-chlorine pesticide substance types, soil contamination incidents, soil contamination concentration, soil organic matter content, soil texture and the like, and a removal rate by single or repeated continuous elution is higher (larger than or equal to 85%); the equipment can form a good matching technology with a patent eluent (ZL201010547630.2), and is developed specially aiming at solving actual contamination situation of organo-chlorine pesticide sites in our country; and during a process of manufacturing the equipment, on the basis of synergistic effects generated by multielement strengthening components such as stirring, ultrasonic, heating and the like, the parameter condition design is optimized, the distribution is scientific and reasonable, and the optimal integration of multielement strengthening components is reflected.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

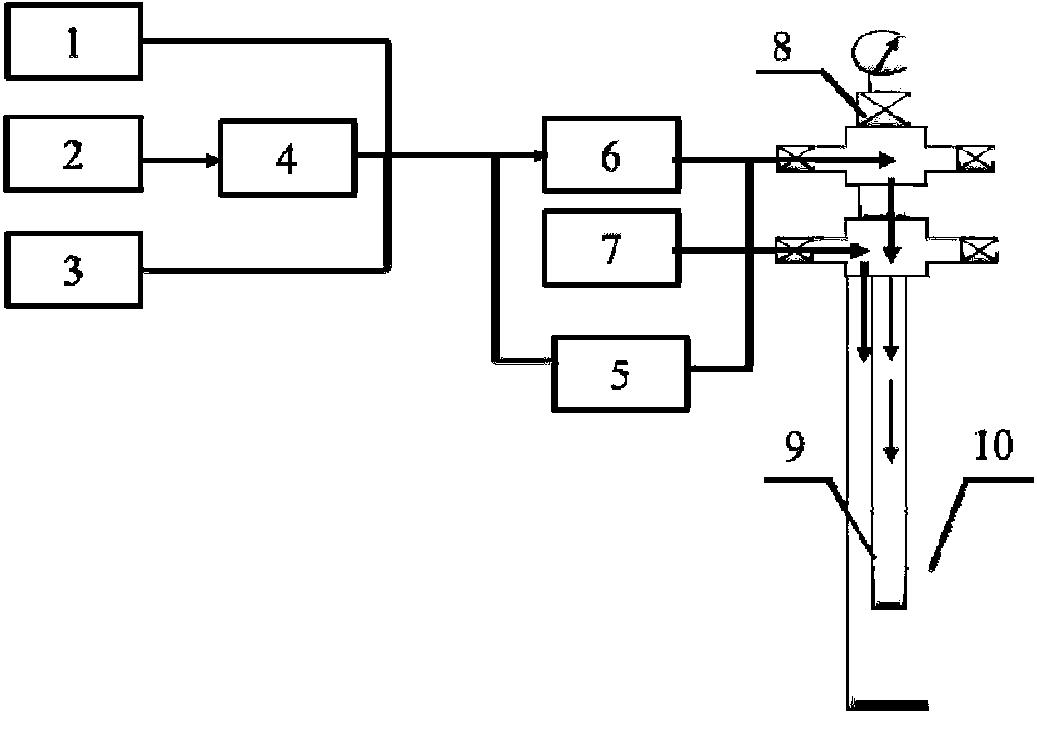

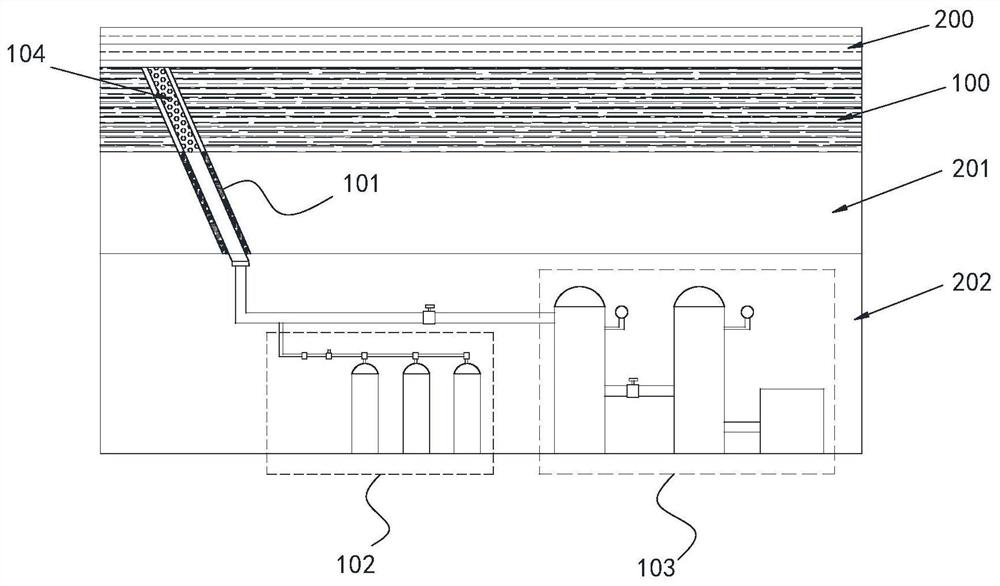

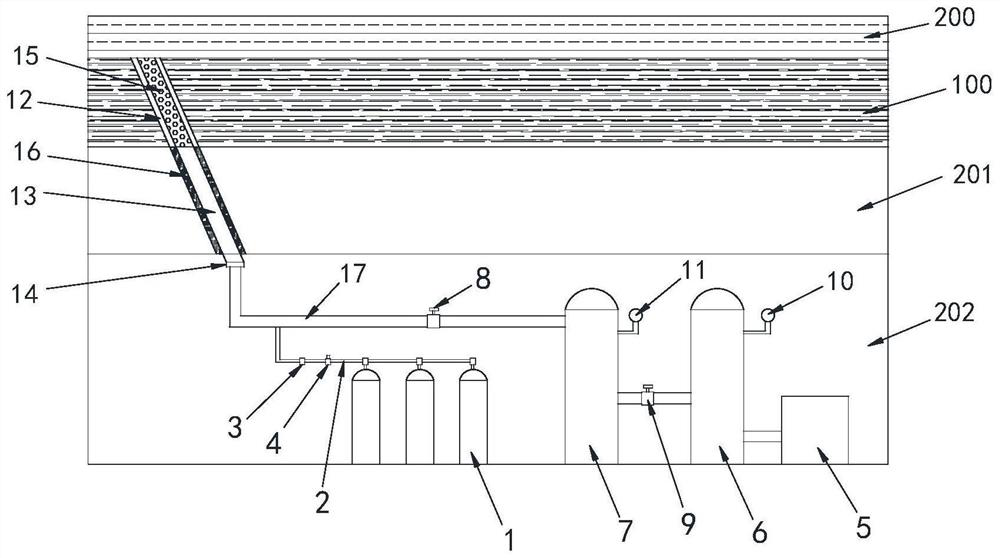

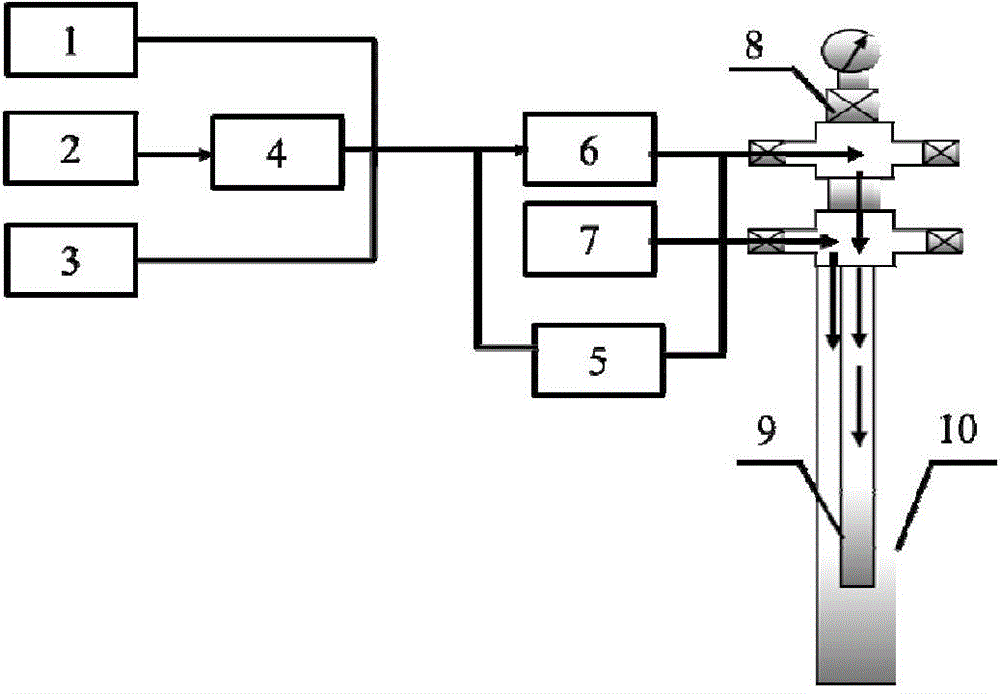

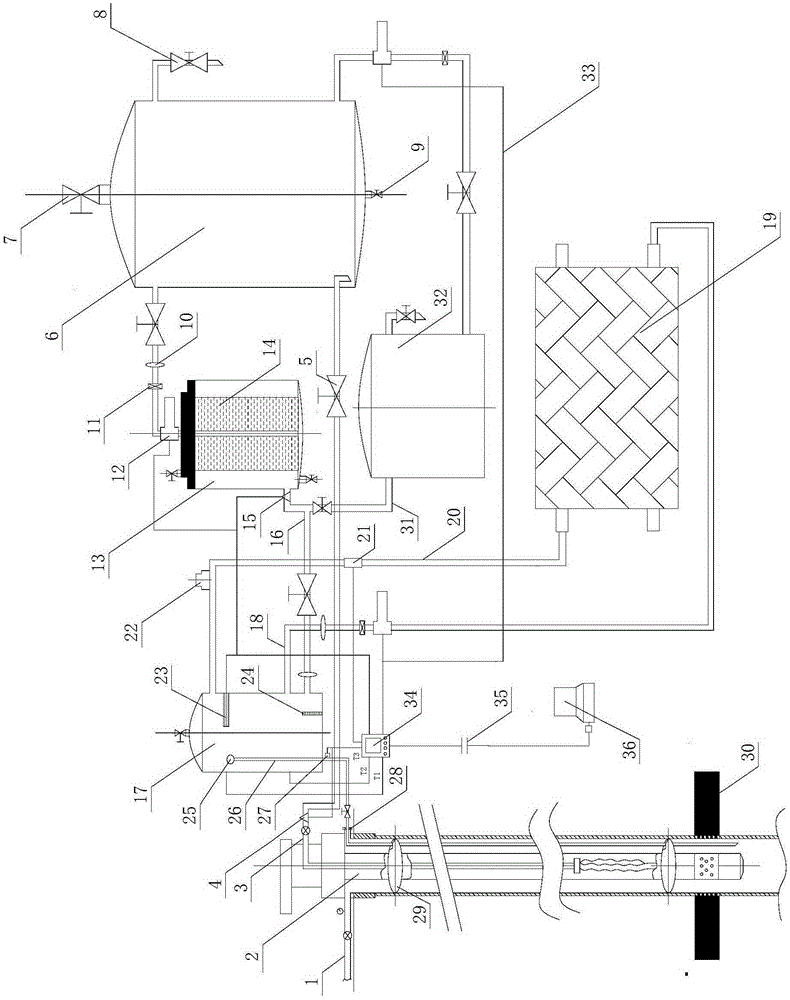

Thermal exploiting system and method for coalbed methane

InactiveCN107387045AImprove thermal conductivityIncrease desorption rateFluid removalFree energiesGas heater

The invention provides a thermal exploiting system and method for coalbed methane. The thermal exploiting system for the coalbed methane comprises a set of gas injecting system and a set of gas exploiting system; the gas injecting system comprises a gas heater, a booster pump, a high-temperature steam generator, a gas mixing box, two valves, a water storage tank, a water pumping pump and a ventilating pipeline; and the gas exploiting system comprises two gas exploiting pipelines and two valves. High temperature mixed gas is injected through the gas injecting system, heat is transferred to a coalbed, so that the temperature of the coalbed is increased to 50-80 DEG C, free energy of coalbed methane is improved and acting force between molecules is destroyed, the gas absorbed in a coalbed gap and on the surface of coal is desorbed, and the coalbed methane is obtained.

Owner:SUZHOU UNIV

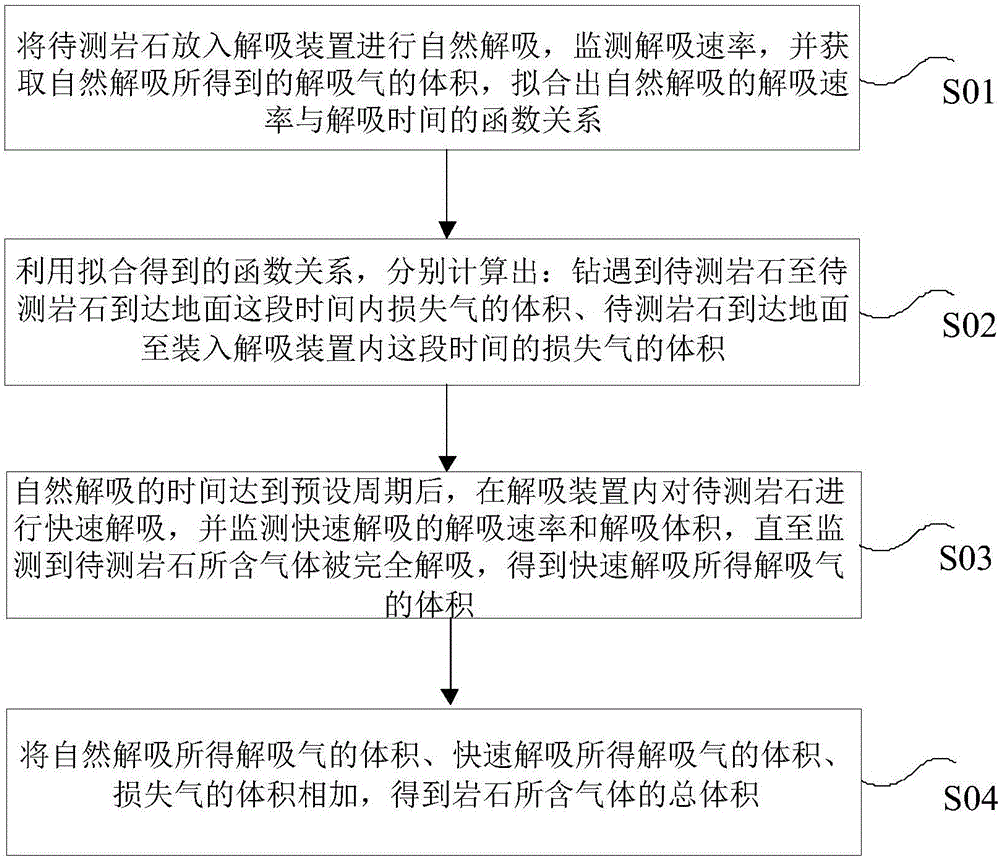

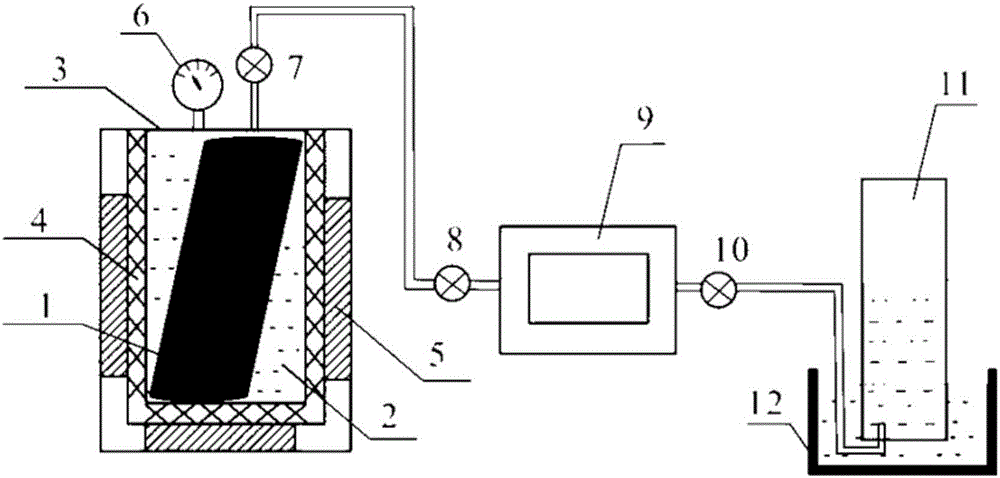

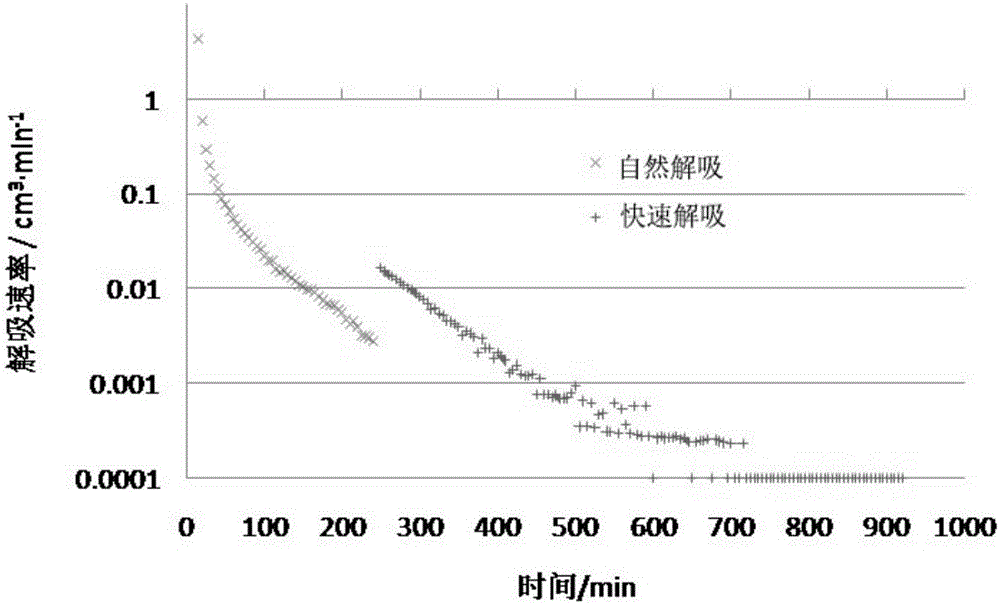

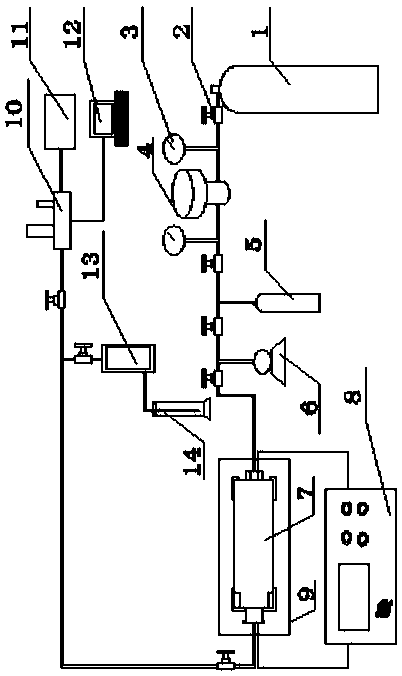

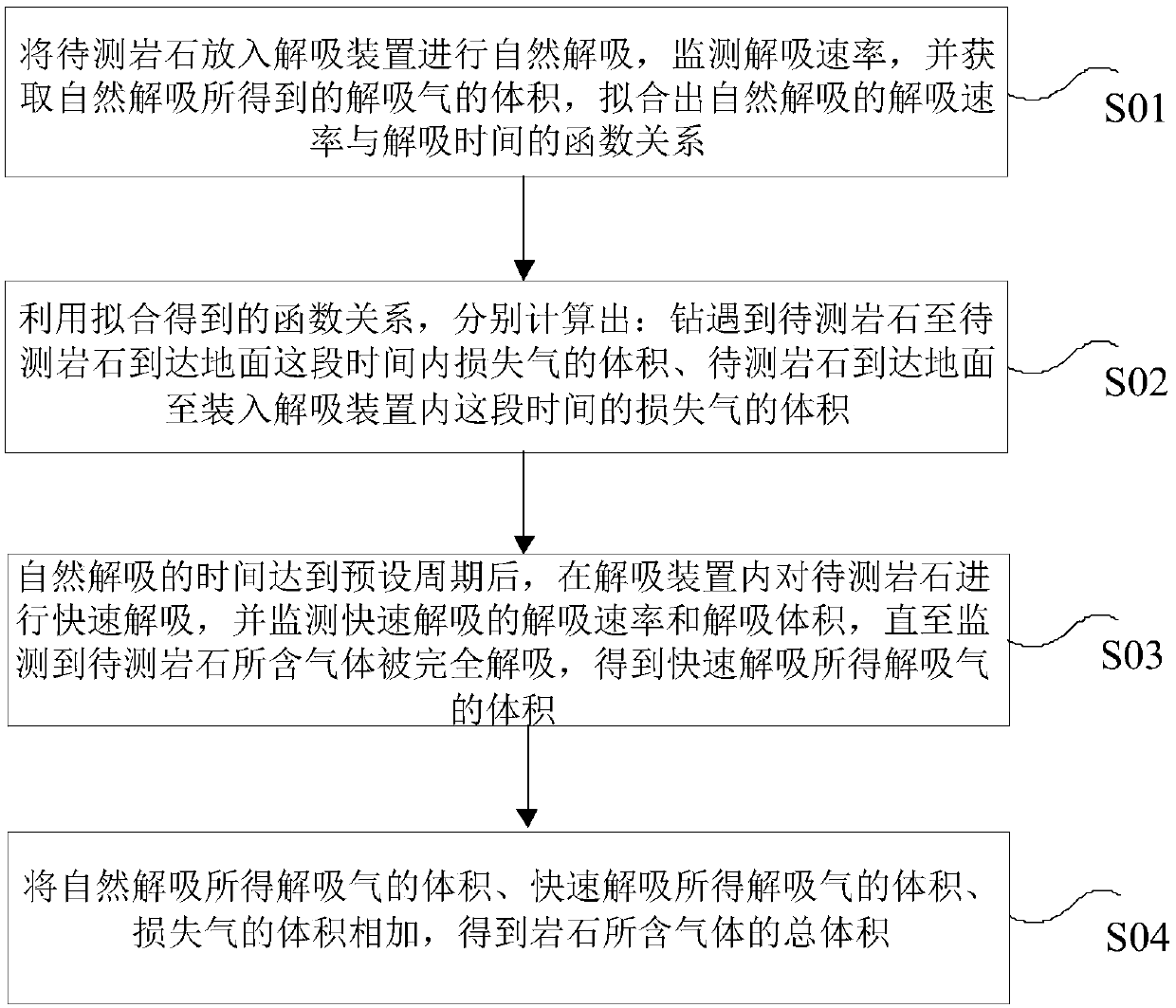

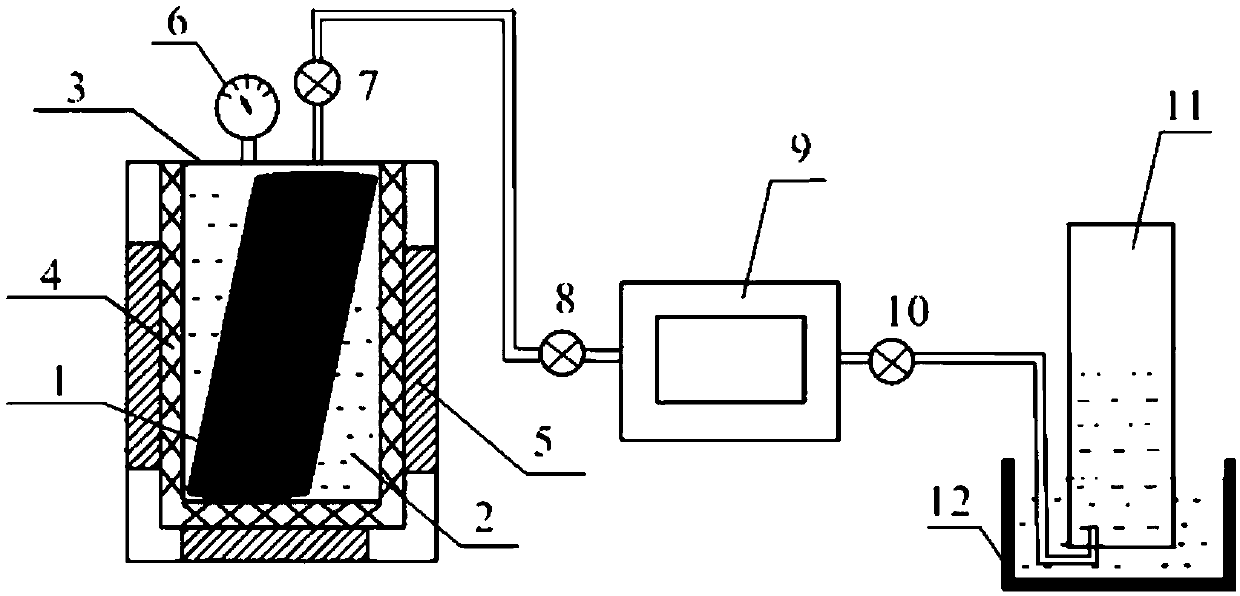

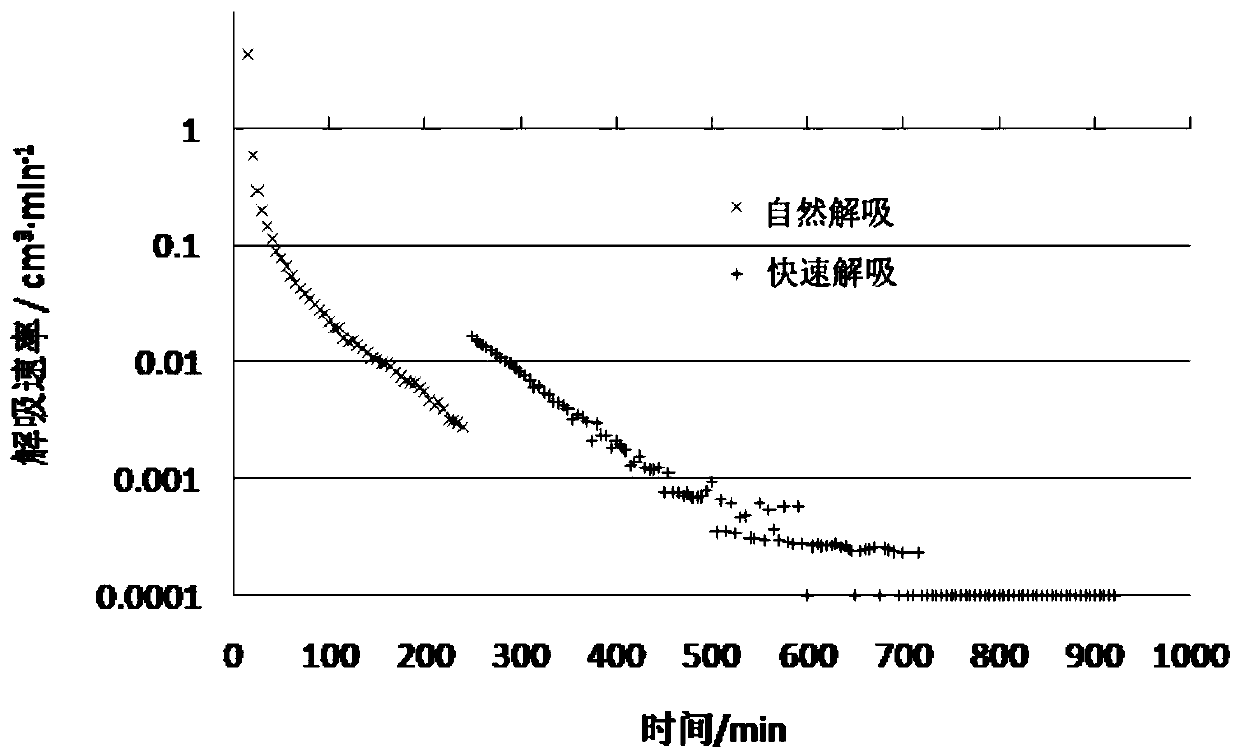

Method and device for testing gas containing data of rock

ActiveCN106290058AIncrease desorption rateImprove accuracyMaterial analysisDesorptionEnvironmental geology

The embodiment of the invention discloses a method and device for testing gas containing data of rock. The method comprises the steps of placing the rock to be tested into a desorption device for natural desorption, and monitoring desorption rate; obtaining the function relationship between the desorption rate and desorption time through fitting, and calculating the volume of lost gas according to the function relationship; conducting natural desorption till it is monitored that gas in the rock to be tested is completely desorbed, and measuring the volume of desorbed gas obtained from natural desorption and fast desorption; adding the volume of the lost gas and the volume of the desorbed gas together to obtain total volume, and then obtaining the gas content of the rock to be tested through calculation. By the adoption of the embodiments of the invention, testing processes can be effectively simplified, and the accuracy of a test result is improved.

Owner:PETROCHINA CO LTD

Automatic reinjection water heating production increasing process of coal-bed gas well

The invention relates to an automatic reinjection water heating production increasing process of a coal-bed gas well. The process comprises the following steps: A, performing precipitation and filtration treatment on produced liquid once or for more times to remove more than 95 percent of solid particles; B, heating the treated clear liquid through solar energy to increase the water temperature to 60-90 DEG C; C, injecting hot water into a shaft through a hot water reinjection pipeline, extending the hot water reinjection pipeline to the space below a coal bed through an oil sleeve annulus and increasing the temperature of the original shaft liquid to over 20 percent; D, circularly performing the steps. The process has the advantages that the heat energy is injected into the shaft liquid in a hot water injection mode and the brownian motion of coal dust in the shaft liquid is increased so as to increase the divergence of the coal dust in the water, favorably reduce the concentration of the coal dust and discharge the coal dust, besides a part of heat energy is transferred to a coal-bed gas storage layer of an immediate vicinity of a wellbore, so that the free energy of the coal-bed gas can be increased to increase the desorption rate of the coal-bed gas, and meanwhile the gas is expanded on heating, so that a seepage passage can be expanded, the permeability of a reservoir stratum is improved and the production increase of the coal-bed gas is realized.

Owner:CNOOC ENERGY TECH & SERVICES

Coal reservoir water locking damage control method

The invention relates to a coal reservoir water locking damage control method, which comprises the following steps that:1, a ground coal-bed gas well subjected to fracturing transformation is selected; 2, reservoir coal samples are collected on sites, and the contact angle of water on the coal sample surface is tested in an indoor position; 3, quickly penetrating agents T and chlorine dioxides are added into fracturing fluid, the concentration of the quickly penetrating agents T is selected according to the contact angle of the water on the coal sample surface, and the concentration of the chlorine dioxide is selected according to the coal rank of the coal samples (the metamorphism degree of the coal samples); 4, after the quickly penetrating agents T and the chlorine dioxides are added, the uniformly stirred fracturing fluid can be used as ahead fluid, or is used as sand-carrying fluid to be subjected to joint hydraulic fracturing with non-active water fracturing fluid, and 20 to 30 cubic meters of active water fracturing fluid needs to be pumped between the ahead fluid and the sand-carrying fluid for isolation; and 5, the fracturing fluid return and discharging can start only after at least 3 hours from the hydraulic fracturing completion. The coal reservoir water locking damage control method has the advantages that the capillary resistance and the surface tension of a coal-bed gas reservoir layer are reduced; the reservoir layer water locking damage is reduced; the coal-bed gas reservoir layer is favorably protected; and the coal-bed gas recovery rate is favorably improved.

Owner:HENAN POLYTECHNIC UNIV

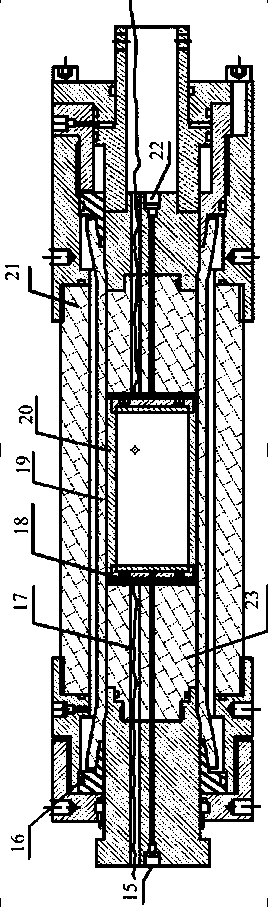

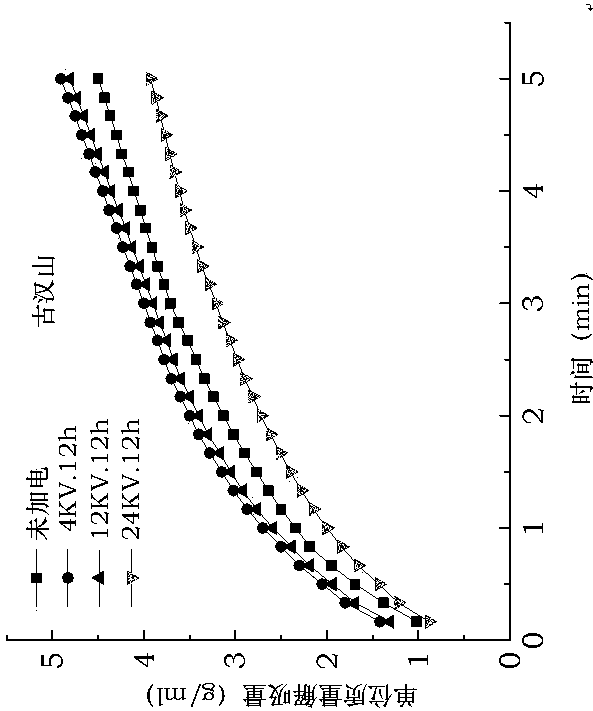

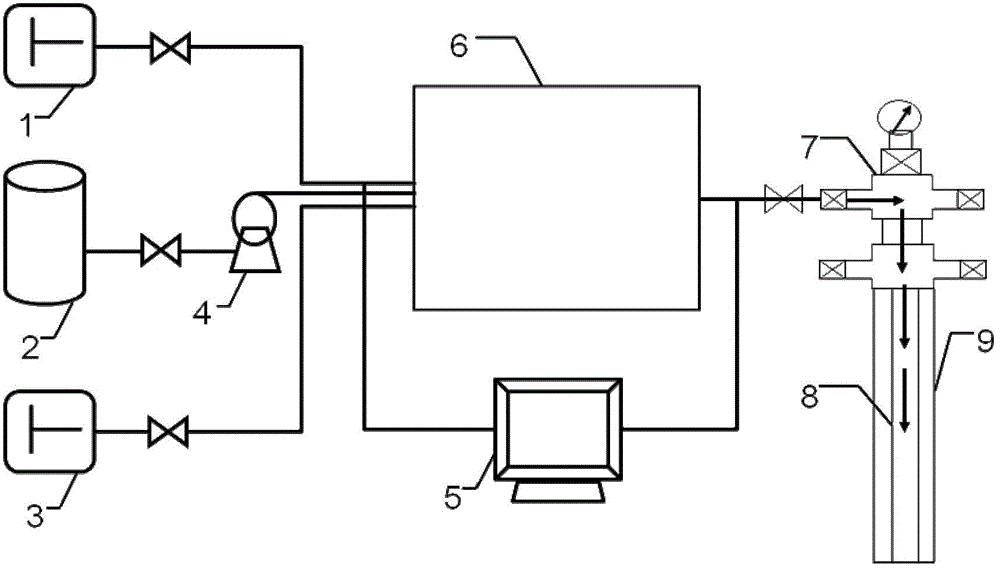

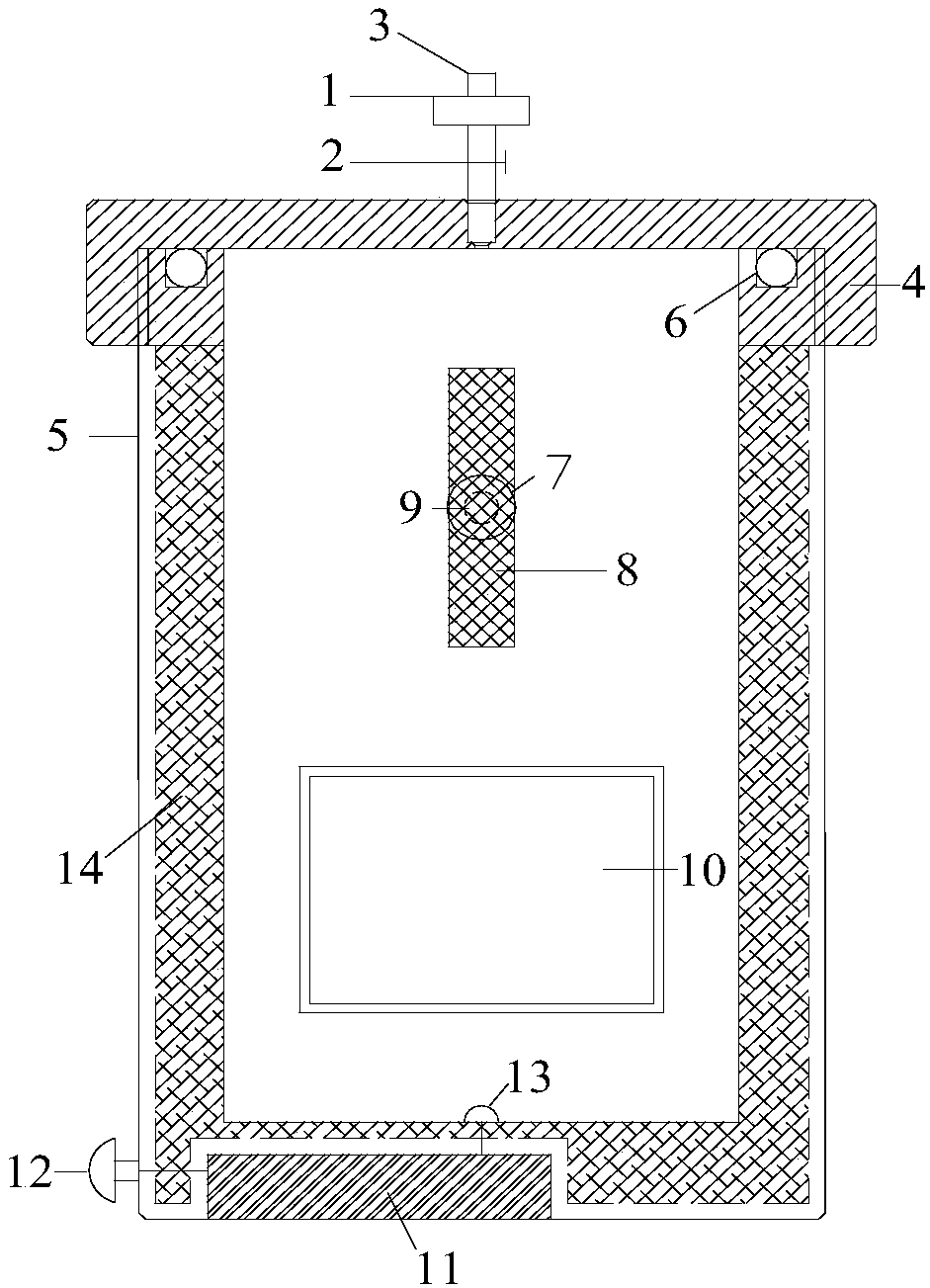

System and method for judging competitive field intensity of gas adsorption and desorption

PendingCN108593492AIncrease desorption rateIncrease desorptionMaterial analysisWater bathsDesorption

The invention relates to a system and a method for judging competitive field intensity of gas adsorption and desorption. The system comprises a methane tank, a valve, a pressure gauge, a pressure regulating valve, a reference cylinder, a vacuum pump, a clamp device, a high-voltage power source, a constant-temperature water bath box, a flow rate sensor, a gas collecting box, a computer and a gas water drain device, wherein the clamp device comprises a cylinder body, and a coal sample cylinder is arranged in the cylinder body; a left electrode plate and a right electrode plate are arranged at both ends of the coal sample cylinder, and are respectively connected with an anode and a cathode of the high-voltage power source; the methane tank is connected with a gas inlet of the clamp device; agas outlet of the clamp device is connected with a gas exhaust pipeline, and the tail end of the gas exhaust pipeline is connected with the gas collecting box; the gas water drain device comprises a first metering cylinder and a second metering cylinder; the first metering cylinder is connected with the gas outlet of the clamp device, and the first metering cylinder is connected with the second metering cylinder. The system and the method have the advantage that the gas adsorption and desorption are measured by externally adding different electric fields, so as to obtain the gas adsorption anddesorption rule, find the competitive field intensity of gas extraction rate, and provide powerful experiment support for the recovery of coal beds.

Owner:HENAN POLYTECHNIC UNIV

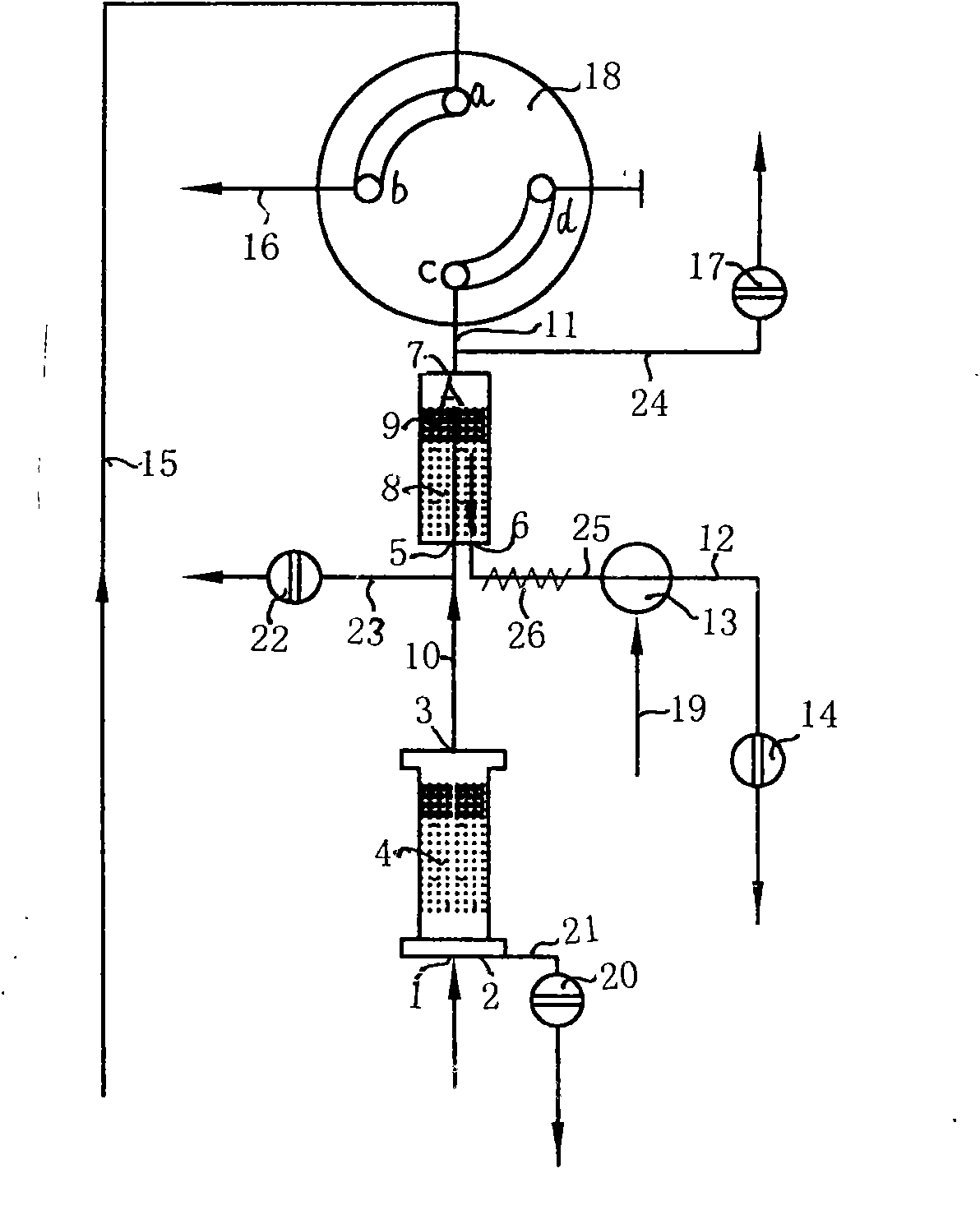

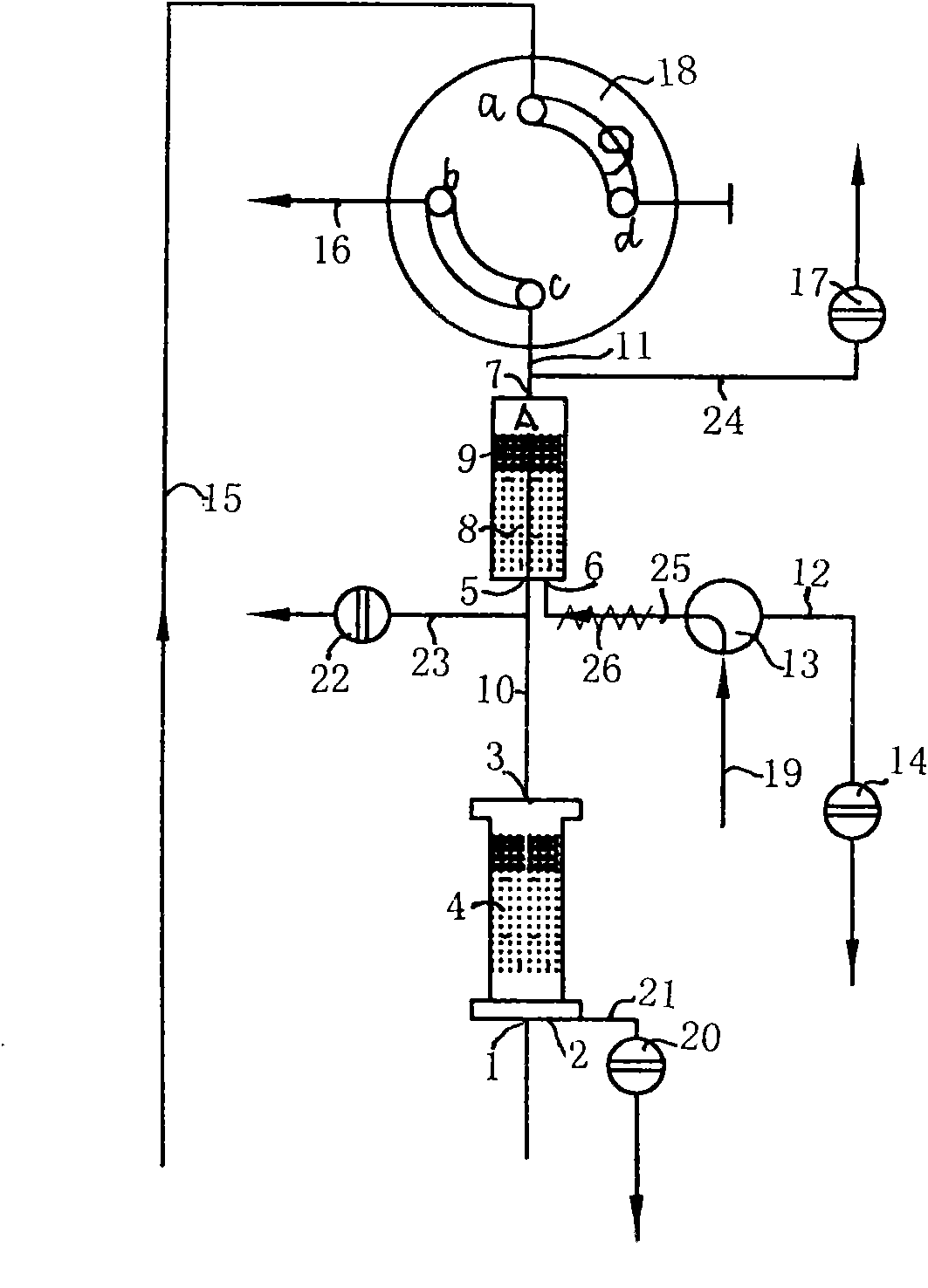

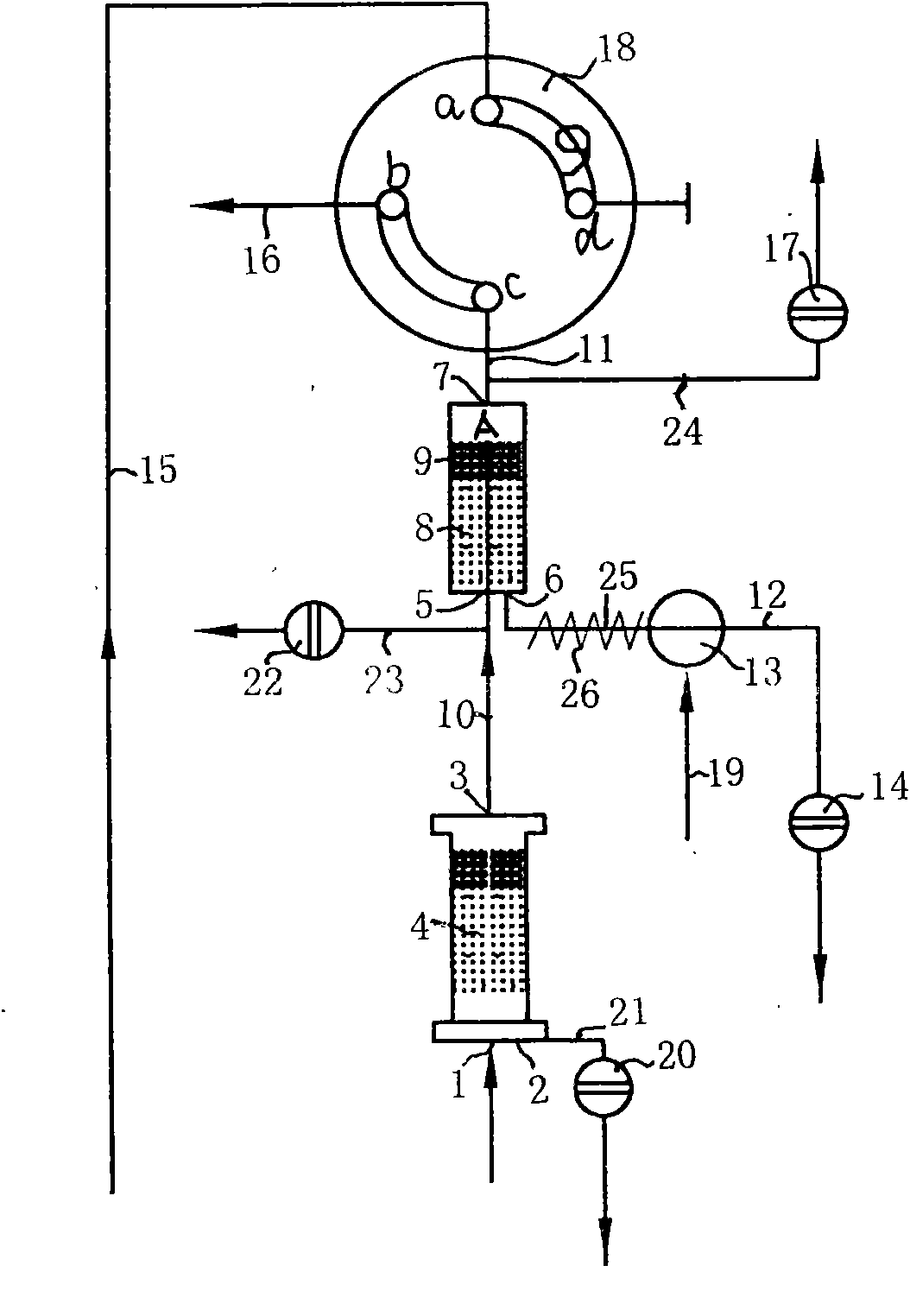

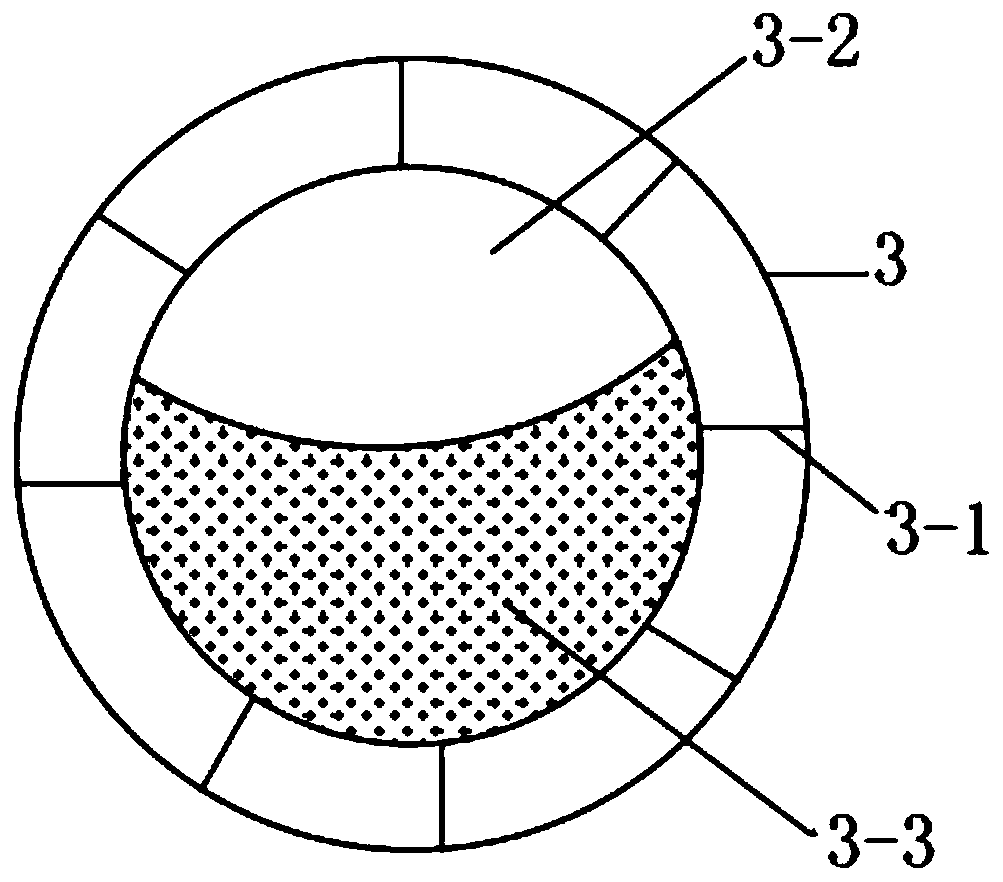

Automatic thermal desorption instrument based on thermal gas desorption

InactiveCN102004134AImprove the desorption effectIncrease desorption rateComponent separationVapor phase chromatographyControl valves

The invention relates to an automatic thermal desorption instrument based on thermal gas desorption. The auotomatic thermal desorption instrument comprises a sample pipe provided with a first desorption sample outlet and a condensing adsorption pipe which is provided with a desorption sample inlet, an adsorption / desorption inlet / outlet and a second desorption sample outlet and is filled with adsorbent, wherein a first end of a first sample output pipe is communicated with the desorption sample outlets, and a second end of the first sample output pipe extends out of the end surface of the adsorbent after penetrating through the condensing adsorption tube and the adsorbent; a first end of a second sample output pipe is communicated with the second desorption sample outlet; a preheated carrier gas conveyer pipe the first end of which is communicated with the adsorption / desorption inlet / outlet is provided with a heater, and a second end of the preheated carrier gas conveyer pipe is provided with a first control valve; a desorption exhaust pipe connected with the first control valve is provided with a second control valve; and a second carrier gas conveyer pipe is connected with the first control valve. Besides, the desorption instrument also comprises a first carrier gas conveyer pipe, a transfer pipe the first end of which is communicated with a gas chromatograph and a changeover valve. By adopting the invention, the secondary desorption rate can be improved, the chromatographic peak is sharpened and simultaneously the desorption efficiency is improved.

Owner:CHENGDU COLIN TECH

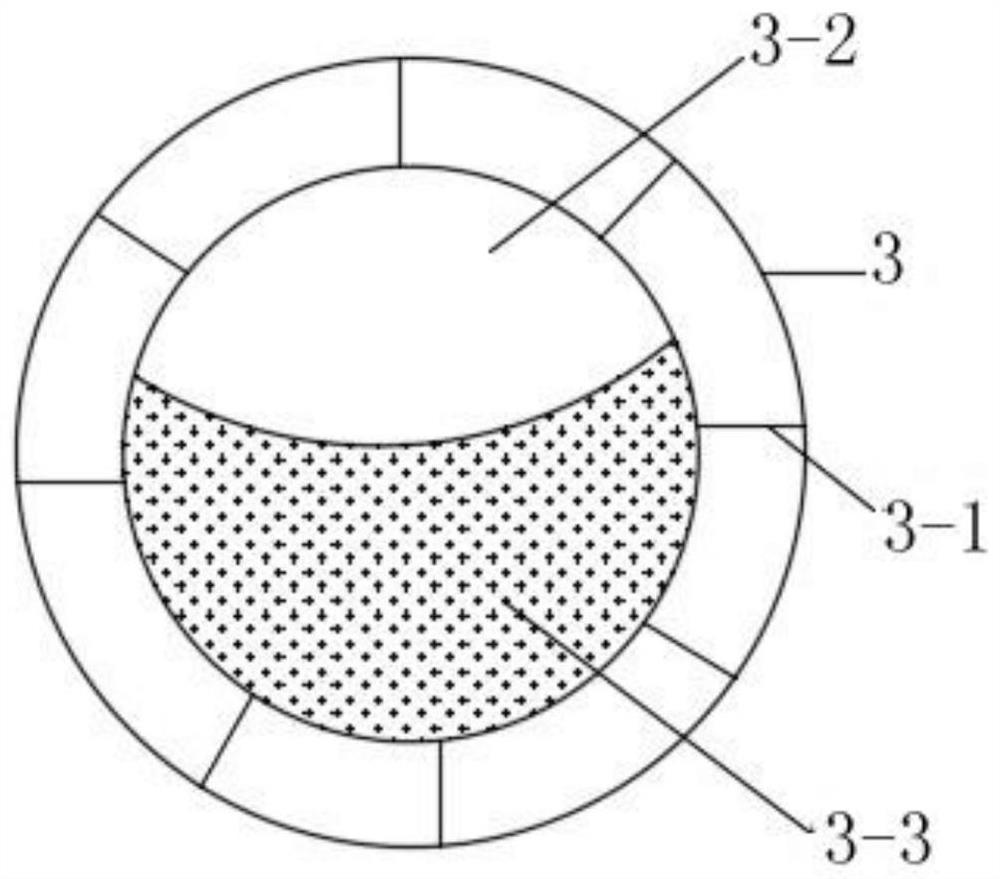

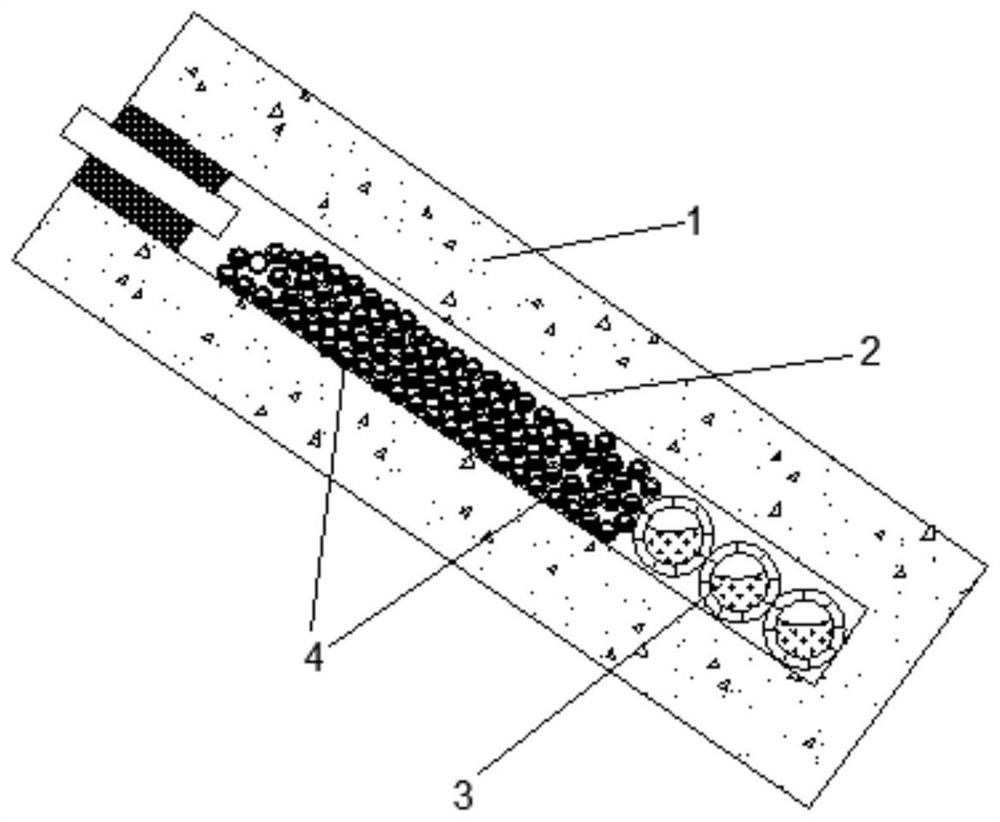

Method for both protecting soft coal seam borehole and improving gas drainage efficiency

ActiveCN111287709ASmooth extractionFacilitate desorptionFluid removalGas removalMining engineeringPetroleum engineering

The invention discloses a method for both protecting soft coal seam borehole and improving gas drainage efficiency. A method that large plastic balls with holes and small plastic balls with holes aresequentially filled is adopted, the two types of plastic balls with holes can play a protective supporting role for a gas drainage borehole after the borehole is filled, and the possibility of collapse and deformation of the borehole is reduced; a formed gas drainage channel is kept smooth; and with the decrease of the gas drainage concentration, water is injected into the borehole, and the waterneutralizes with quicklime to accelerate the gas desorption after a coal body is heated, so that the efficiency of the gas drainage is improved. By injecting of the water many times, the reaction of calcium oxide and the water can be effectively utilized to release heat, and the efficiency of the gas drainage can be gradually improved. The method integrates borehole protection and improvement of the gas desorption rate, the gas drainage efficiency is high, the effect is good, and the smooth gas drainage channel can be ensured without special installation equipment, so that the whole implementation process is convenient and easy, the method is convenient for field use, and the practicability is wide.

Owner:XUZHOU UNIV OF TECH

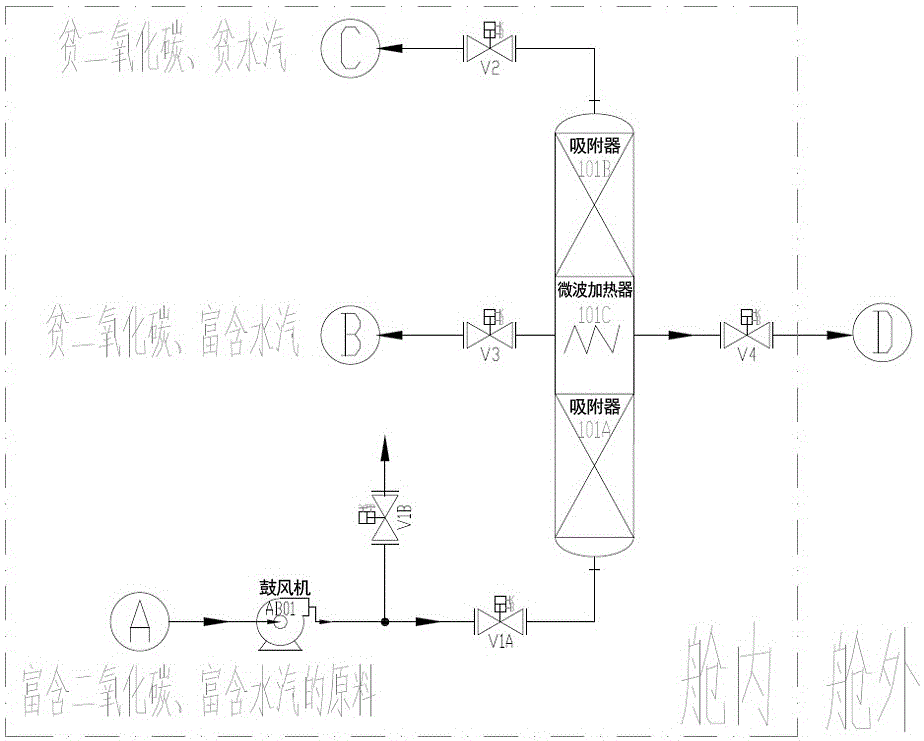

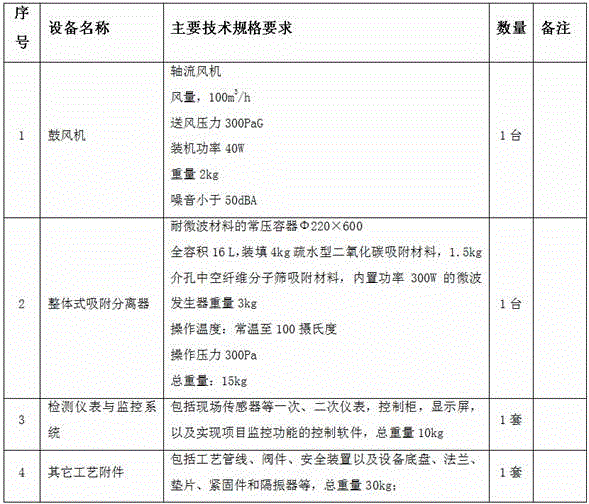

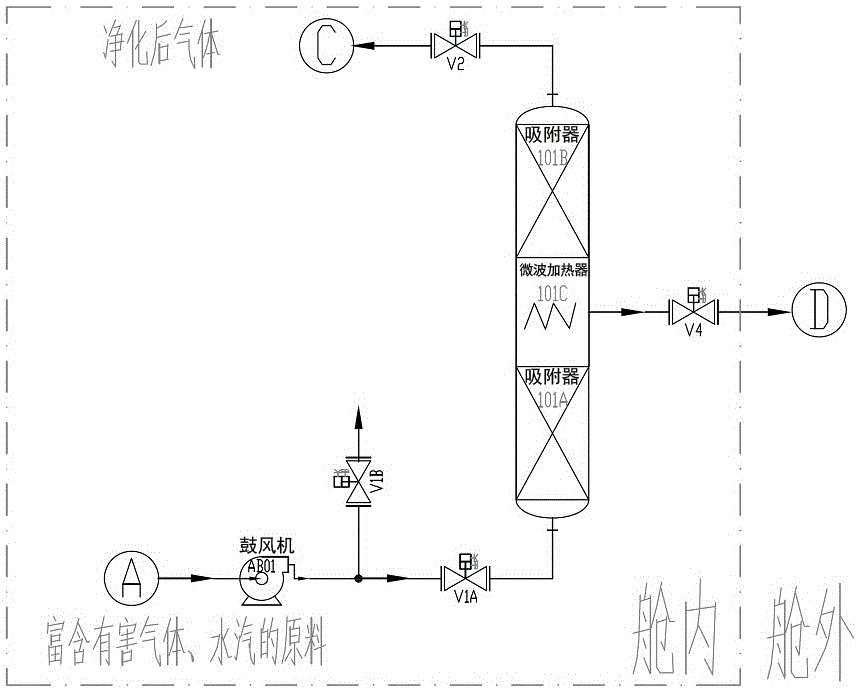

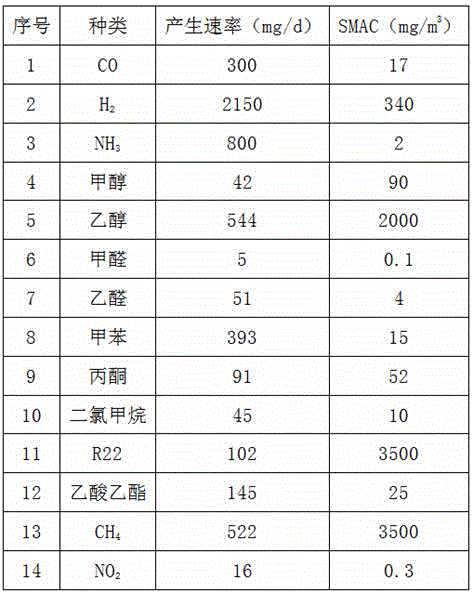

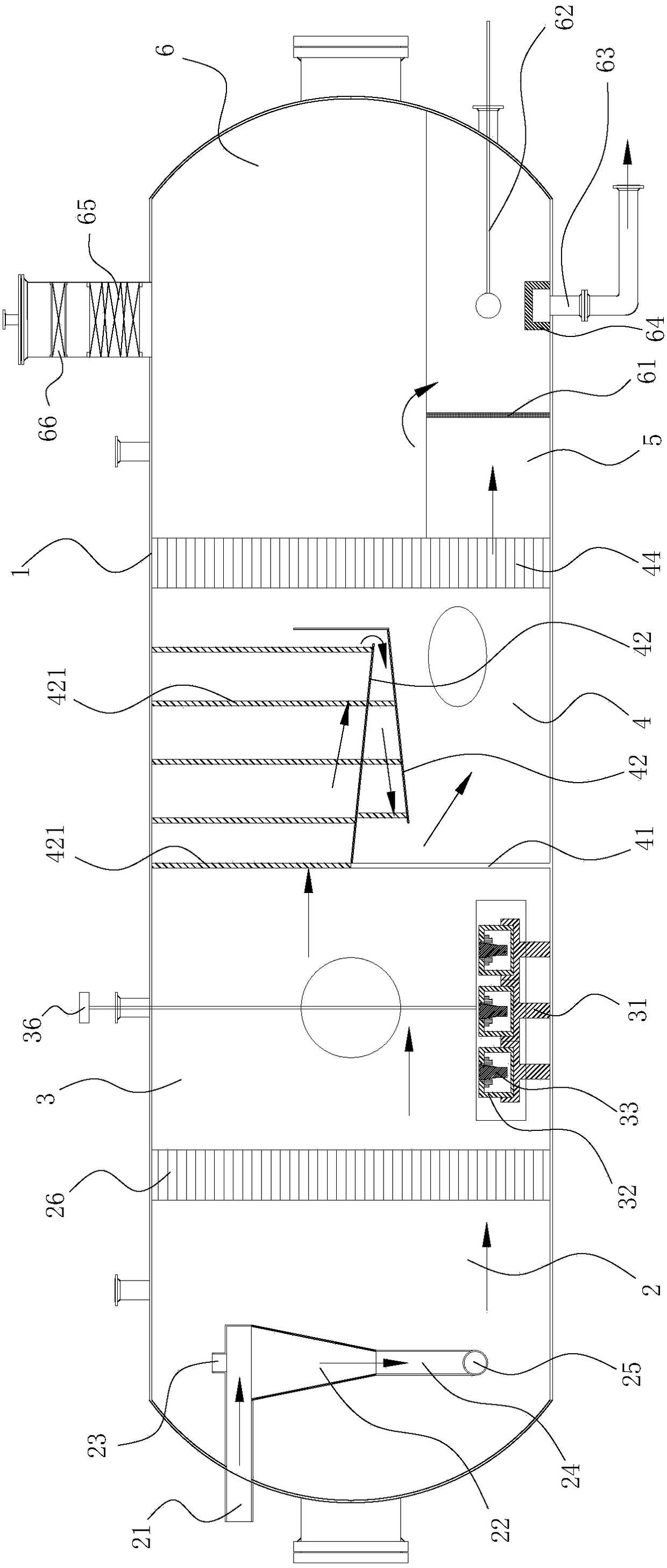

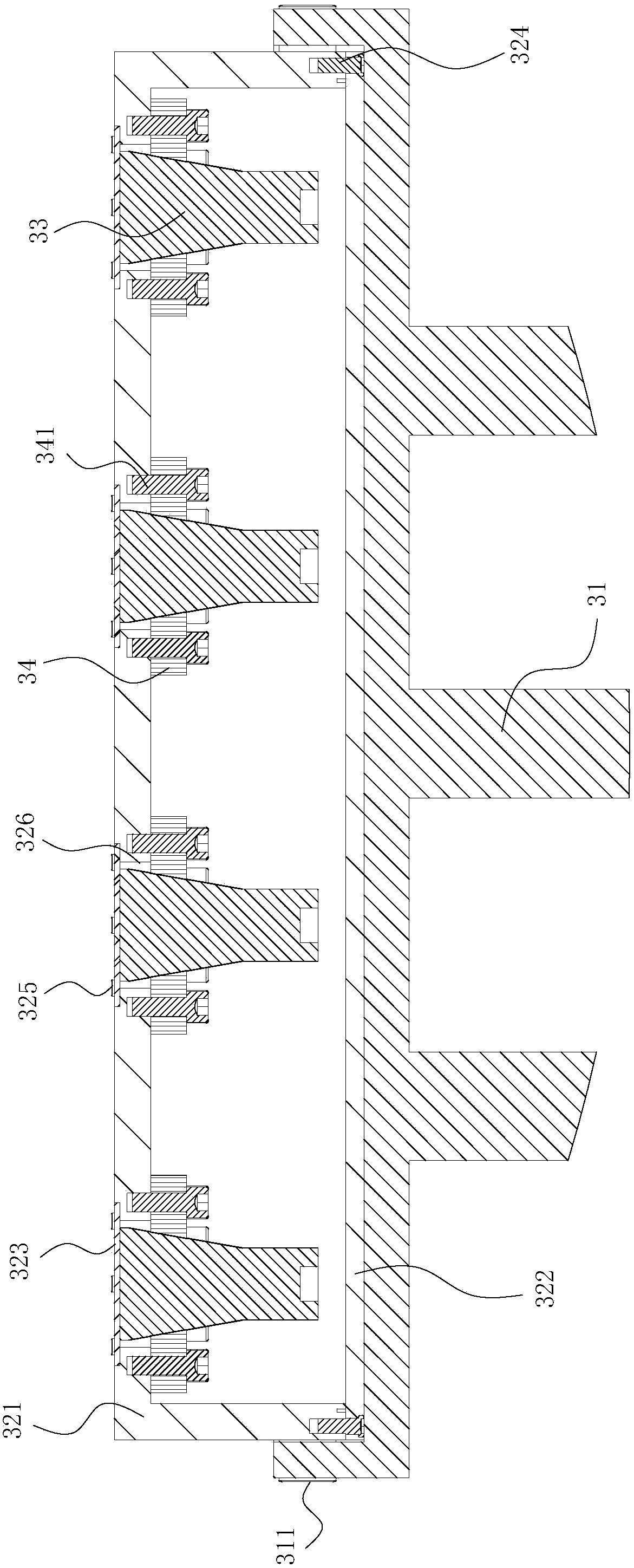

Integrated treatment device and method for non-consumption type carbon dioxide and water

InactiveCN106178828AGuaranteed long-term cycle lifeReduced weight and volume requirementsGas treatmentDispersed particle separationMolecular sieveCarbon dioxide

The invention belongs to the technical field of space flight and aviation life support and environmental control, particularly relates to an integrated combined treatment device and method for non-consumption type carbon dioxide and water. The device comprises an air supply unit, an adsorption and desorption unit, and necessary control valves, connection pipelines and control systems, wherein the adsorption and desorption unit is an integrated separator and is divided into a lower adsorber and an upper adsorber; a hydrophobic carbon dioxide hollow fiber molecular sieve in the lower adsorber is used as an adsorbent and is used for adsorbing the carbon dioxide in gas; a mesoporous zeolite hollow fiber molecular sieve in the upper adsorber is used as an adsorbent and is used for adsorbing the water in the gas; a desorption device is arranged between the lower adsorber and the upper adsorber and is used for performing heating and regeneration on the used adsorbent. A plurality of integrated separators can be provided, which are connected in parallel or series to operate. The device can effectively realize integrated treatment of the carbon dioxide and the water in a cabin, and can reduce the weight and the power consumption of a system and the consumable supply demand.

Owner:上海穗杉实业股份有限公司

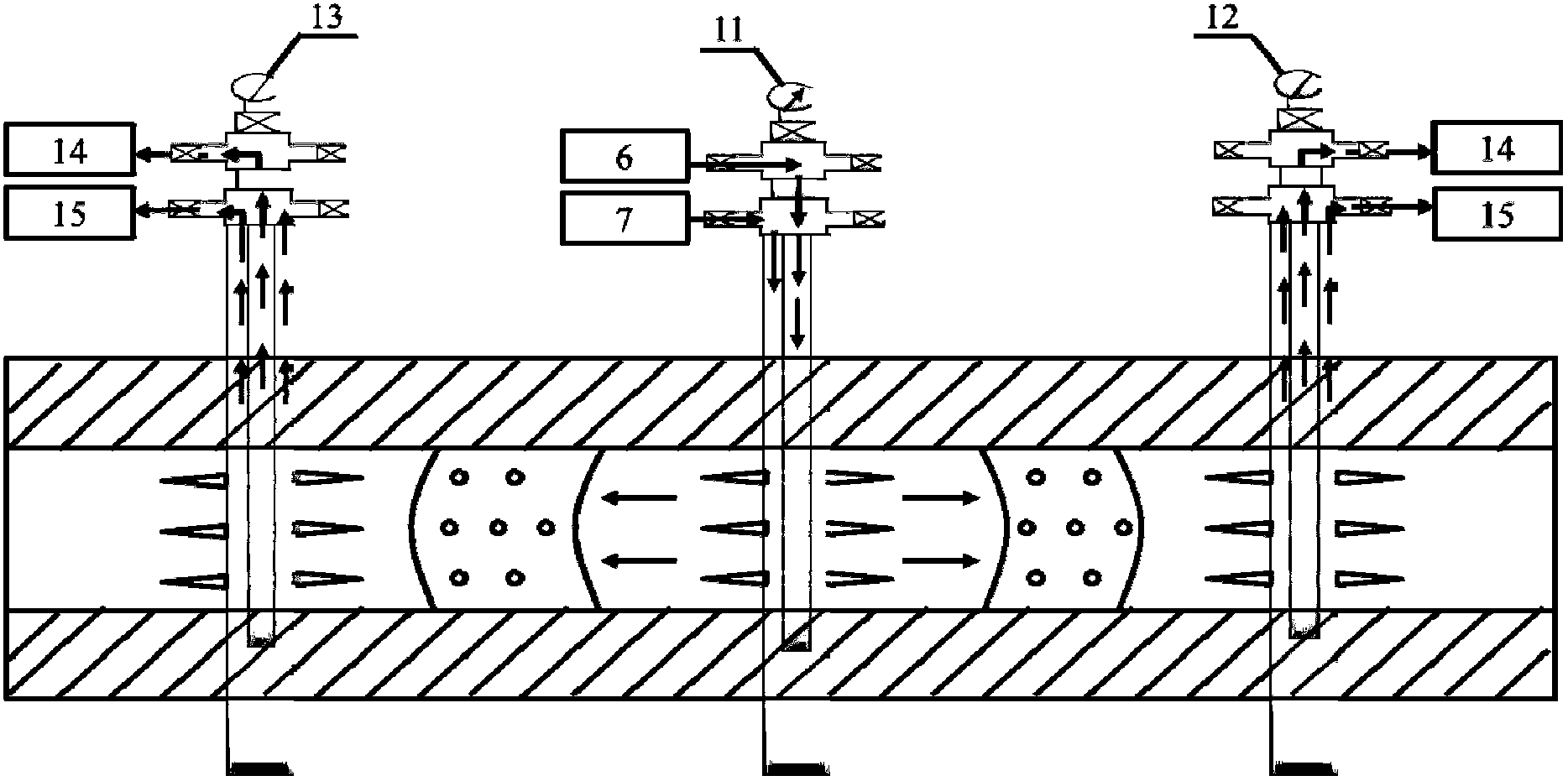

A multi-component thermal fluid enhanced recovery method for coalbed methane wells

ActiveCN103122759BImprove permeabilityEnhanced overall recoveryFluid removalRecovery methodHigh pressure

The invention discloses a coal bed gas well multiple thermal fluid strengthening mining method. Coal bed gas mined in other gas wells is compressed to be fuel, then mixed with pressed air, filled into a multiple thermal fluid generating device and combusted to generate high-temperature high-pressure mixed gas such carbon dioxide and nitrogen. Mined underground water filled with the mixture and processed is vaporized by the high-temperature high-pressure mixed gas to generate a multiple thermal fluid mainly comprising mixed gas of the high-temperature high-pressure steam, the carbon dioxide and the nitrogen. The generated multiple thermal fluid is filled into an underground coal bed along an oil pipe from a well mouth, shut-in and soak are performed and after sleeving pressure goes stable, the well is opened for production. The coal bed gas well multiple thermal fluid strengthening mining method solves the problem that a carbon dioxide source is hard to obtain.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method and device for measuring rock gas content data

ActiveCN106290058BIncrease desorption rateImprove accuracyMaterial analysisThermal desorptionPetrology

The embodiment of the invention discloses a method and device for testing gas containing data of rock. The method comprises the steps of placing the rock to be tested into a desorption device for natural desorption, and monitoring desorption rate; obtaining the function relationship between the desorption rate and desorption time through fitting, and calculating the volume of lost gas according to the function relationship; conducting natural desorption till it is monitored that gas in the rock to be tested is completely desorbed, and measuring the volume of desorbed gas obtained from natural desorption and fast desorption; adding the volume of the lost gas and the volume of the desorbed gas together to obtain total volume, and then obtaining the gas content of the rock to be tested through calculation. By the adoption of the embodiments of the invention, testing processes can be effectively simplified, and the accuracy of a test result is improved.

Owner:PETROCHINA CO LTD

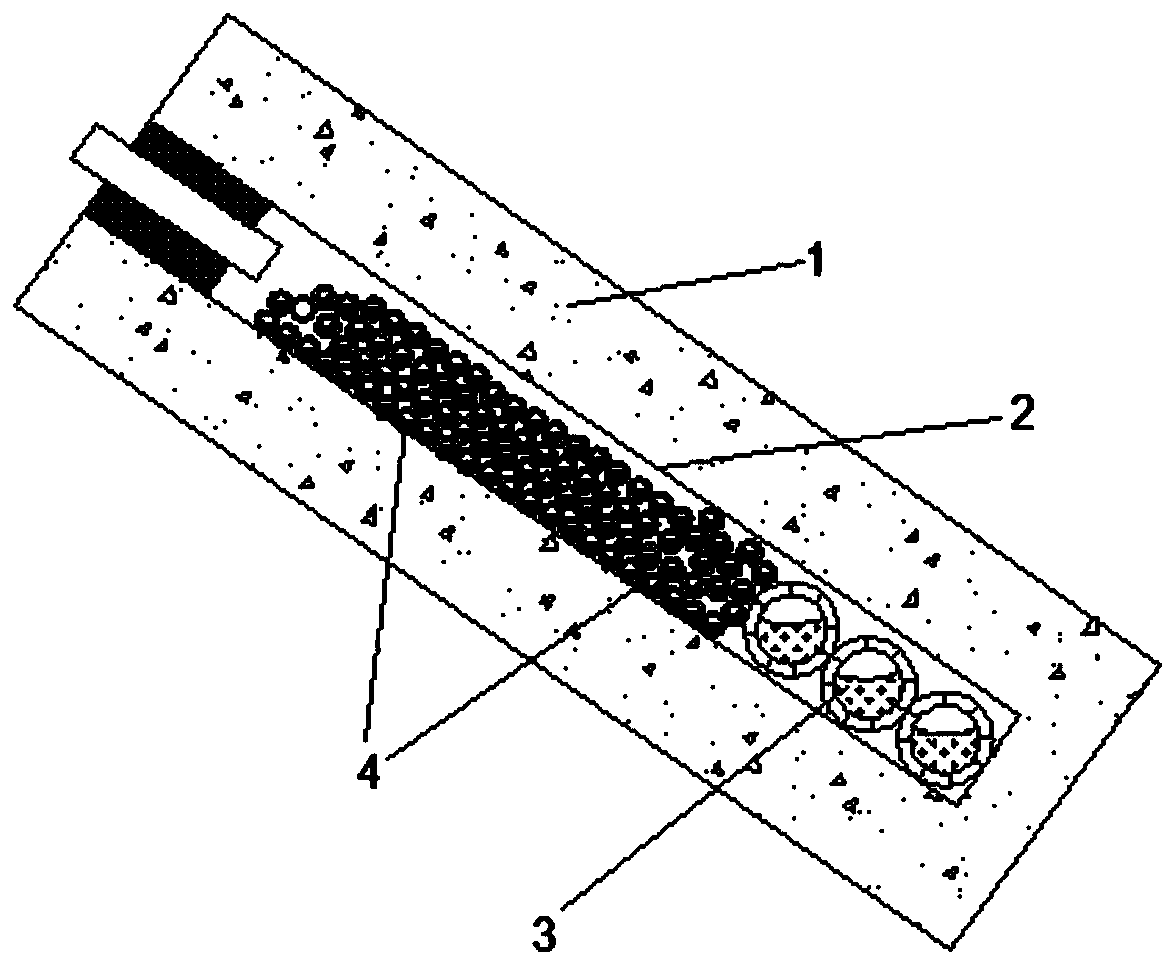

Mine gas permeability improving method and device

PendingCN113236338AImprove permeabilityReduce adsorptionFluid removalGas removalThermodynamicsFracturing fluid

The invention relates to the technical field of unconventional natural gas extraction, in particular to a mine gas permeability improving method and device. The device comprises a pipeline, a liquid CO2 supply unit and a fracturing fluid supply unit, wherein the inner end of the pipeline is used for being placed in a coal seam, and the outer end of the pipeline is connected with the liquid CO2 supply unit and the fracturing fluid supply unit in parallel; and after the fracturing fluid supply unit injects high-temperature and high-pressure fracturing fluid into the coal seam through the pipeline, the liquid CO2 supply unit injects liquid CO2 into the coal seam through the pipeline. The mine gas permeability improving method and device provided by the invention have the advantages that the permeability of the coal seam can be effectively improved, the desorption speed of coal bed gas (gas) in the coal seam is accelerated, and the extraction efficiency of the coal bed gas (gas) can be obviously improved.

Owner:中国煤炭地质总局勘查研究总院

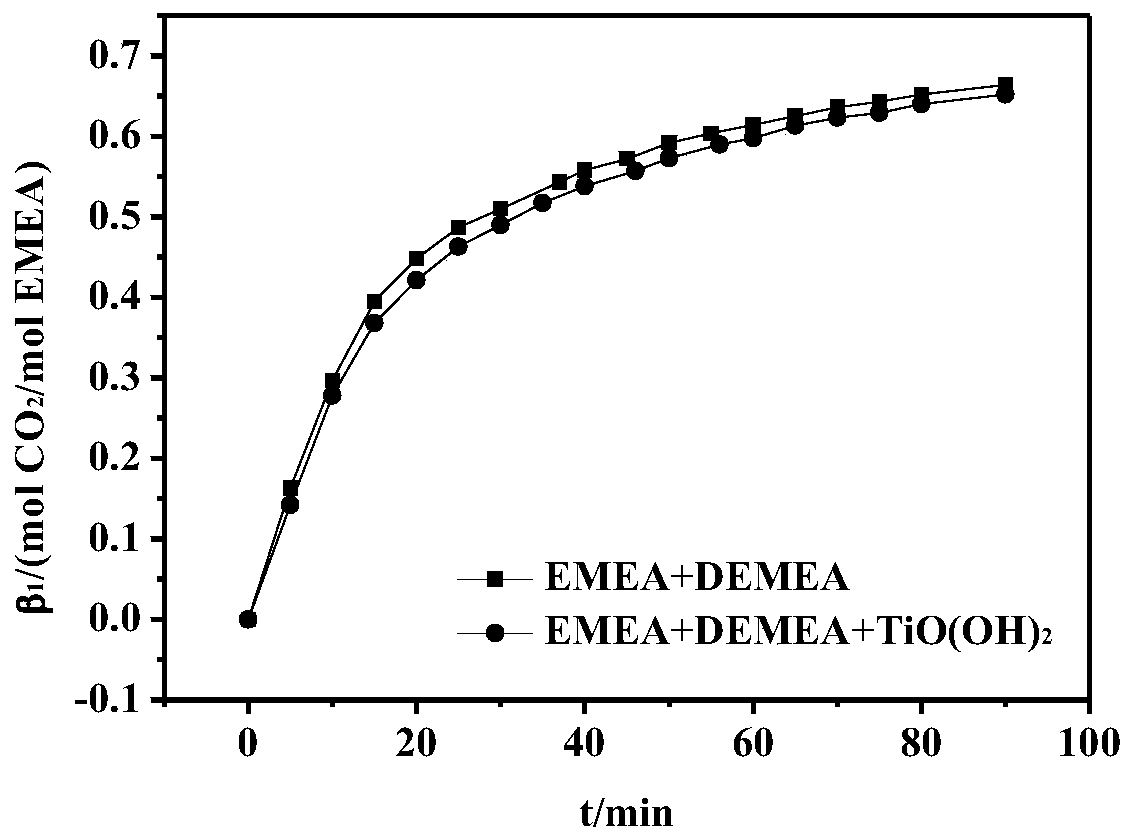

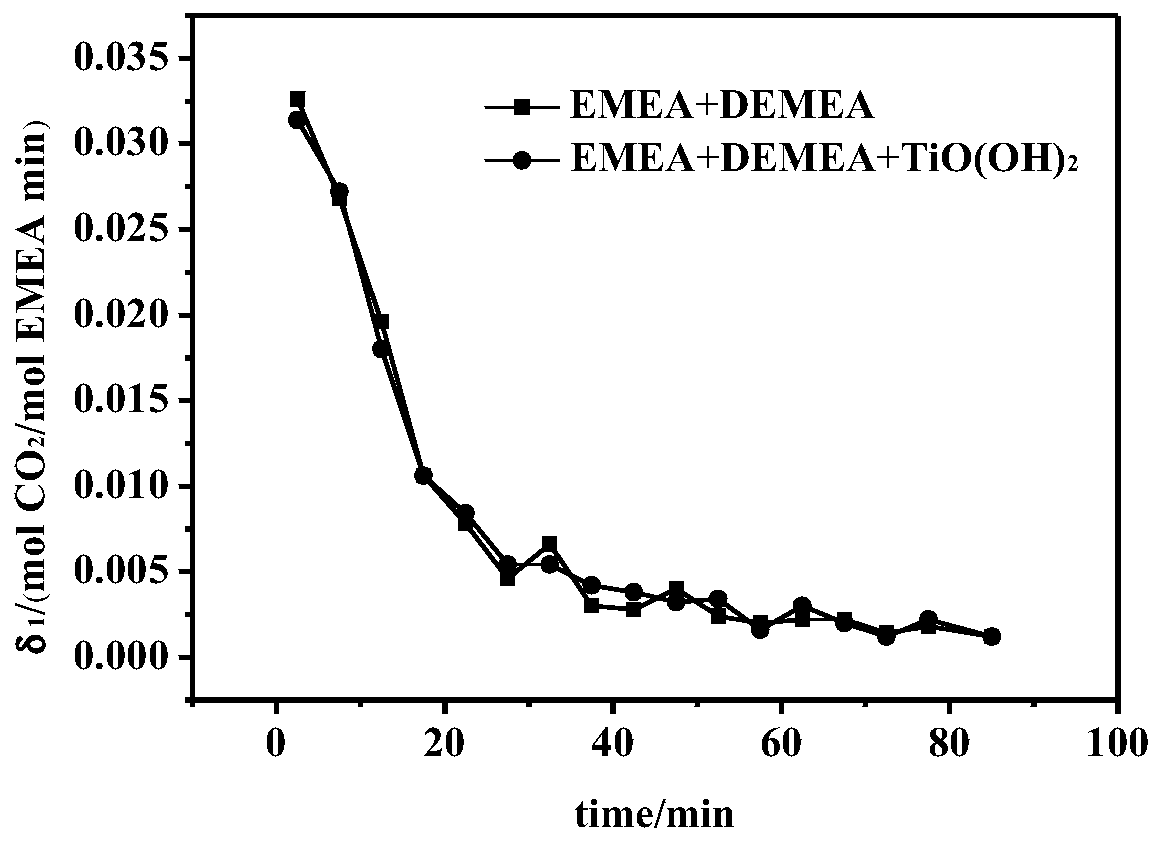

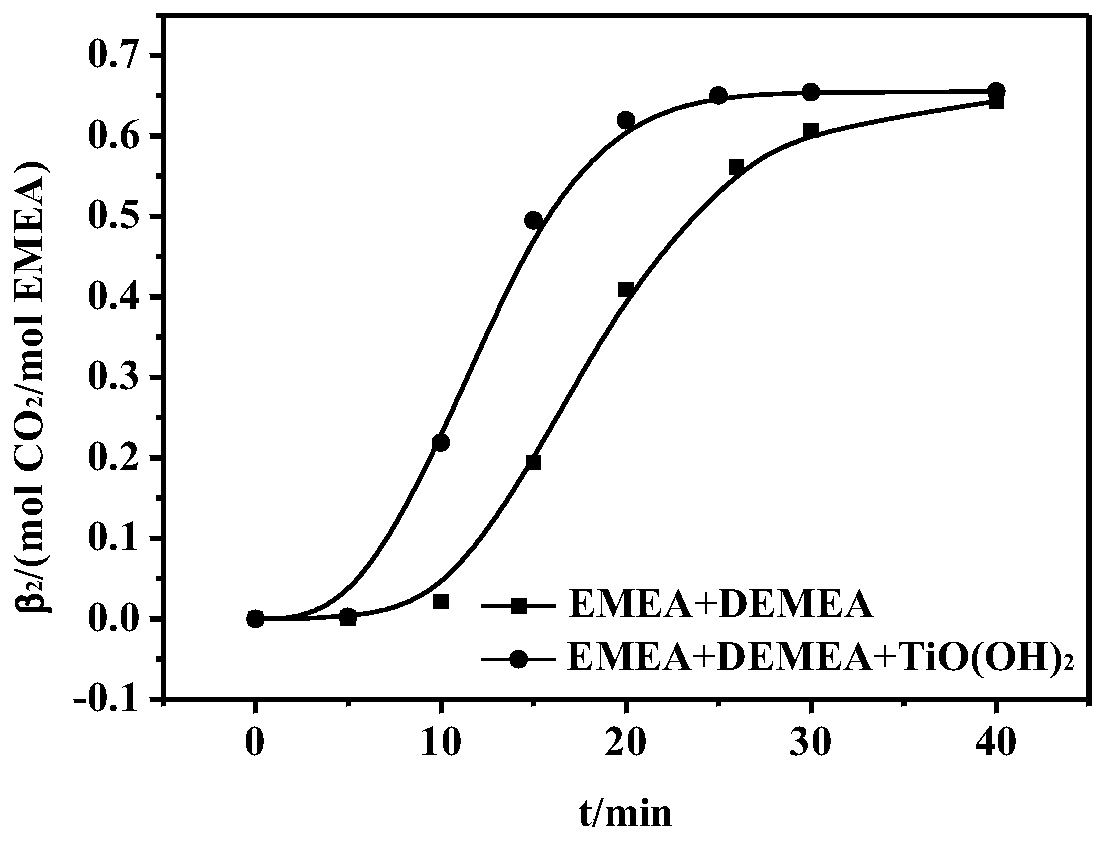

A two-phase mixture for capturing carbon dioxide

ActiveCN106984152BPromote regenerationIncrease speedGas treatmentDispersed particle separationEthylene diamineDesorption

The invention provides a novel two-phase mixture for trapping carbon dioxide, and belongs to the field of technologies for trapping carbon dioxide gas. The novel two-phase mixture comprises two phases including, by weight, 99.0-99.5 wt% of non-aqueous solution and 0.5-1.0 wt% of porous solid materials. The non-aqueous solution comprises, by weight, 30-50 wt% of solutes and 50-70 wt% of solvents, and the solutes are N-ethylethanolamine; the solvents are N, N-diethyl ethylene diamine. The solid porous materials are TiO (OH) 2. The novel two-phase mixture has the advantages that the non-aqueous solution is modified by the TiO (OH) 2, absorption effects of the non-aqueous solution cannot be improved by the TiO (OH) 2, but the desorption rate can be greatly increased by the TiO (OH) 2, the optimal desorption rate can reach 250 Nm<3> CO2 / m<3> solution, and the desorption rate can be increased as compared with the original non-aqueous solution.

Owner:DALIAN UNIV OF TECH

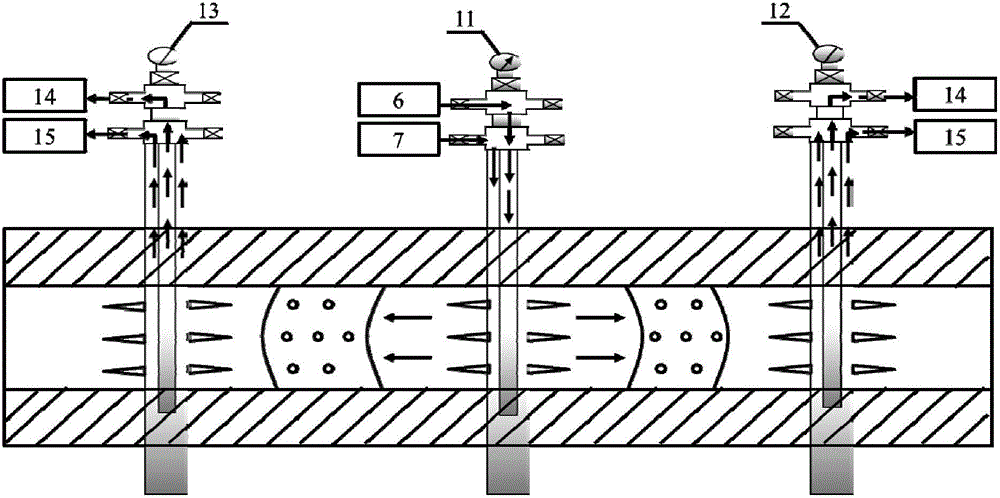

A multi-component thermal fluid foam displacement coalbed methane mining method

ActiveCN103061730BImprove permeabilityHard to getOther gas emission reduction technologiesFluid removalHigh pressure waterHigh pressure

The invention discloses a method for coal bed methane mining by multi-element thermal fluid foam displacement. Multi-element thermal fluid is injected into a coal bed of an injection-production well group through an injection well, and foaming agent is injected at intervals. A multi-element thermal fluid foam slug is formed in the coal bed to displace the coal bed methane in order to improve the recovery efficiency of the coal bed methane. The method specifically includes that extracted coal bed methane is compressed and mixed with compressed air, and then the mixture is injected into a multi-element thermal fluid generation device for ignition, extracted processed ground water is mixed to produce the multi-element thermal fluid mainly with high-temperature and high-pressure water vapor and mixed gas of carbon dioxide and nitrogen, the produced multi-element thermal fluid is injected into the underground coal bed through the injection well, a foaming system composed of preferred alkyl ether sulfonate and corrosion inhibitor is injected from an oil jacket annulus at intervals, the multi-element thermal fluid foam slug is formed under the ground to displace the coal bed methane, and water is drained and gas is recovered from a production well. The method has the advantages that fuel is easy to obtain, principles are clear and distinct, and the like, and can provide guidance for implementation of well stimulation of the coal bed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

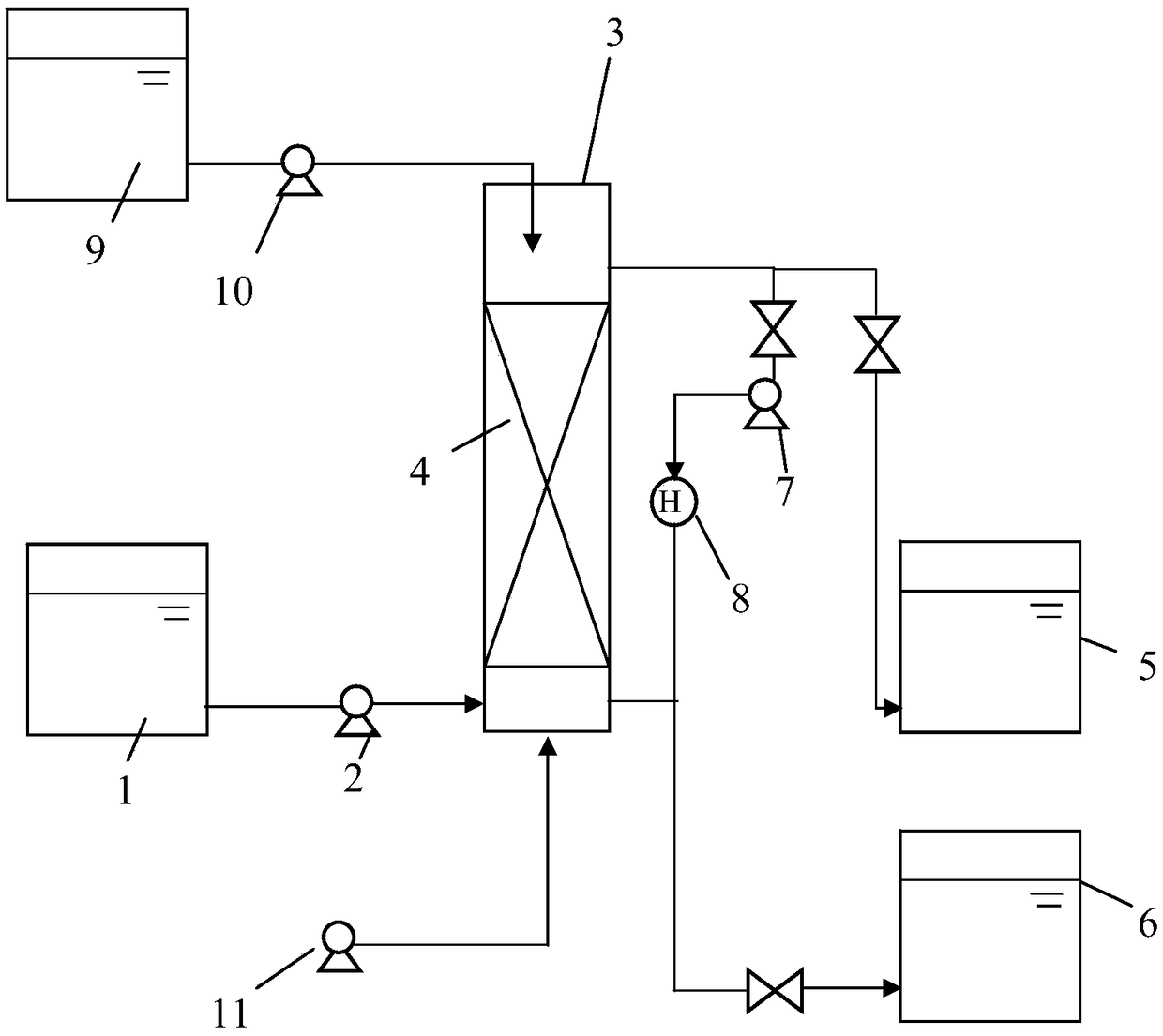

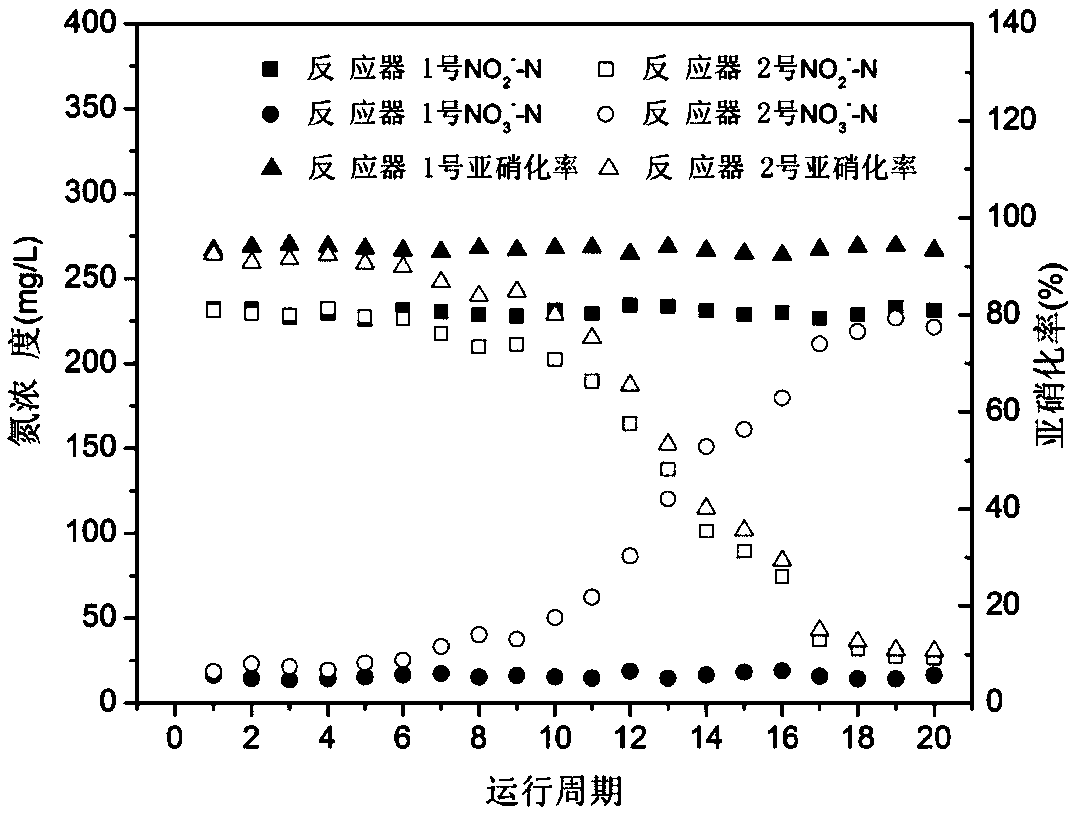

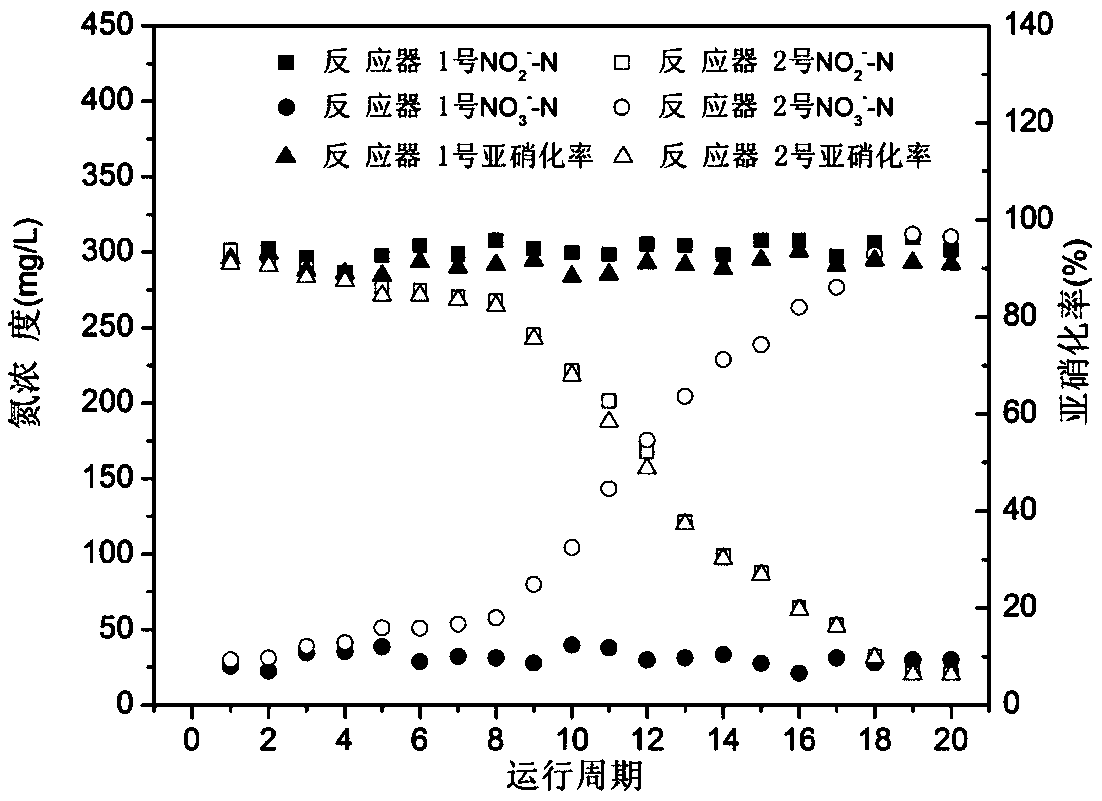

Method for achieving stable nitrosation of low-concentration ammonia-nitrogen wastewater

InactiveCN109231697AStable nitrosationStable biochemical desorptionSpecific water treatment objectivesWater contaminantsHigh concentrationDesorption

The invention belongs to the technical field of treatment of low-concentration ammonia-nitrogen wastewater and discloses a method for achieving stable nitrosation of low-concentration ammonia-nitrogenwastewater. The method comprises the following steps: (1) introducing low-concentration ammonia-nitrogen wastewater into a fixed-bed reactor filled with an ammonia-nitrogen adsorbent for adsorbing, then inoculating the wastewater with nitration sludge for carrying out biofilm formation culturing after finishing adsorbing; (2) discharging wastewater, introducing the low-concentration ammonia-nitrogen wastewater for adsorbing, stopping supplying water when the ammonia-nitrogen concentration in the discharged water is close to a discharge limit value and finishing adsorbing; (3) adding alkali into the fixed-bed reactor after finishing adsorbing, aerating, increasing the temperature, carrying out biochemical desorption under an internal circulation condition and discharging regenerated liquid; (4) introducing the low-concentration ammonia-nitrogen wastewater into the fixed-bed reactor again for adsorbing; (5) finishing adsorbing and carrying out biochemical desorption according to step (3); and (6) circulating steps (4) and (5). The method is capable of achieving stable nitrosation of the low-concentration ammonia-nitrogen wastewater; meanwhile, the regenerated liquid contains high-concentration nitrite nitrogen, so that the subsequent denitrification treatment cost can be reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

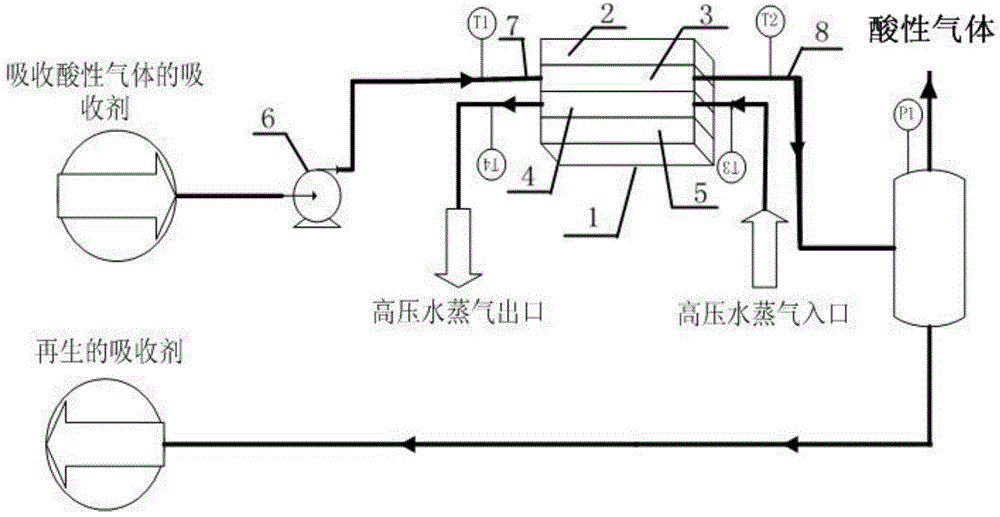

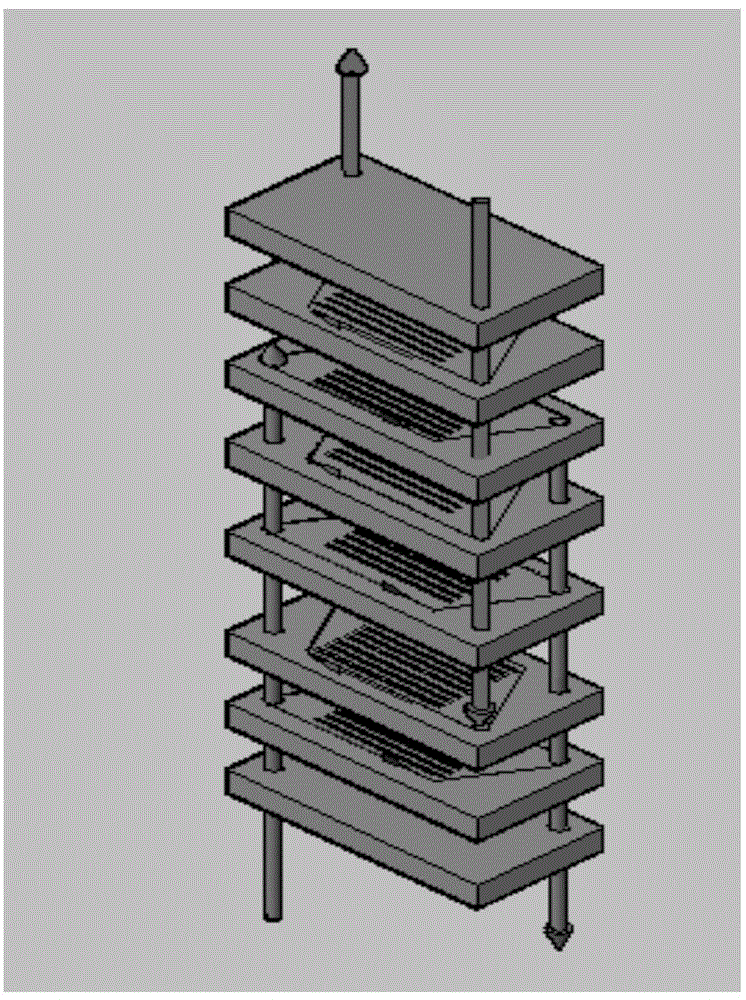

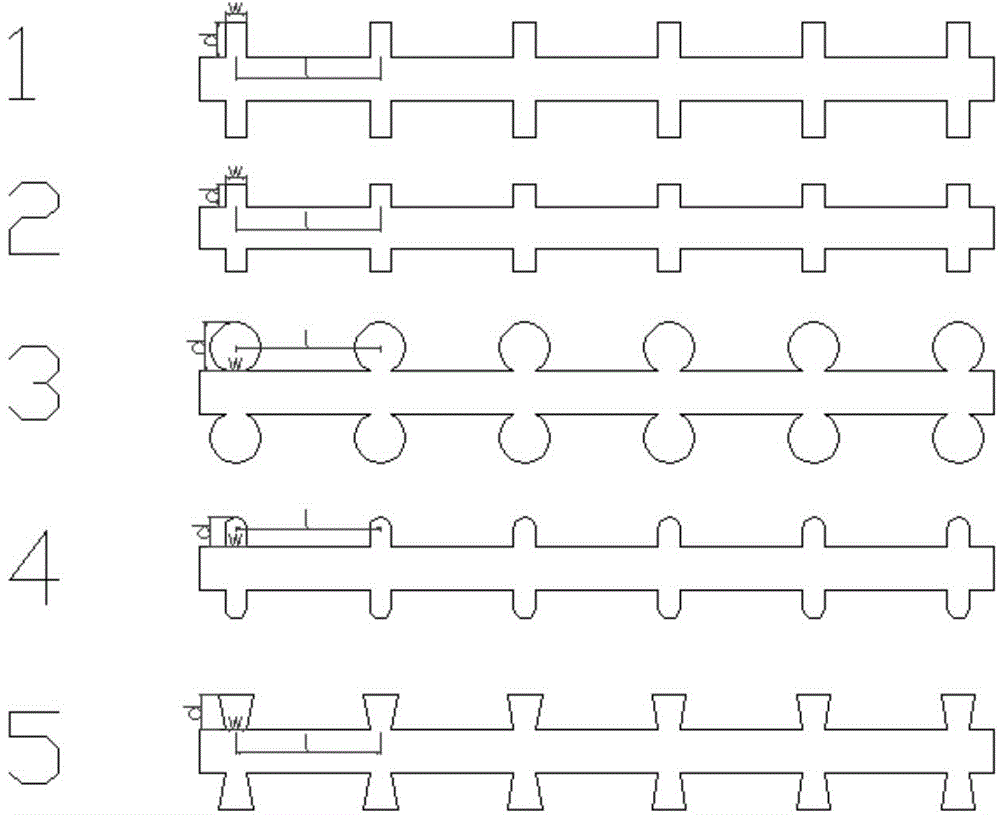

Reinforced desorption method of acidic gas

InactiveCN105749701AReduced compression energy consumptionAvoid thermal decompositionDispersed particle separationChemical/physical/physico-chemical processesMaterial consumptionProduct gas

The invention provides a reinforced desorption method of an acidic gas. The method is characterized in that inner groove-shaped micro-channels are introduced to a micro-channel reactor, and desorption process reinforcement of a carbon dioxide absorption liquid is carried out under 0.1-1MPa at 90-160DEG C for 0.01-100s. The micro-reactor comprises a plate heat exchange unit and a plate desorption unit, and the plate desorption unit is formed by the parallel inner groove-shaped micro-channels. The method can realize carbon dioxide desorption in an extremely short time, prevent absorbent overheating and reduce the volume of evaporated water, and has a small size in order to greatly reduce the energy and material consumption in the desorption process of the carbon dioxide absorption liquid and the occupied area. The energy consumption, the material consumption and the occupied area of the reinforced desorption method are respectively 20% or above lower than those of traditional tower desorption systems.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

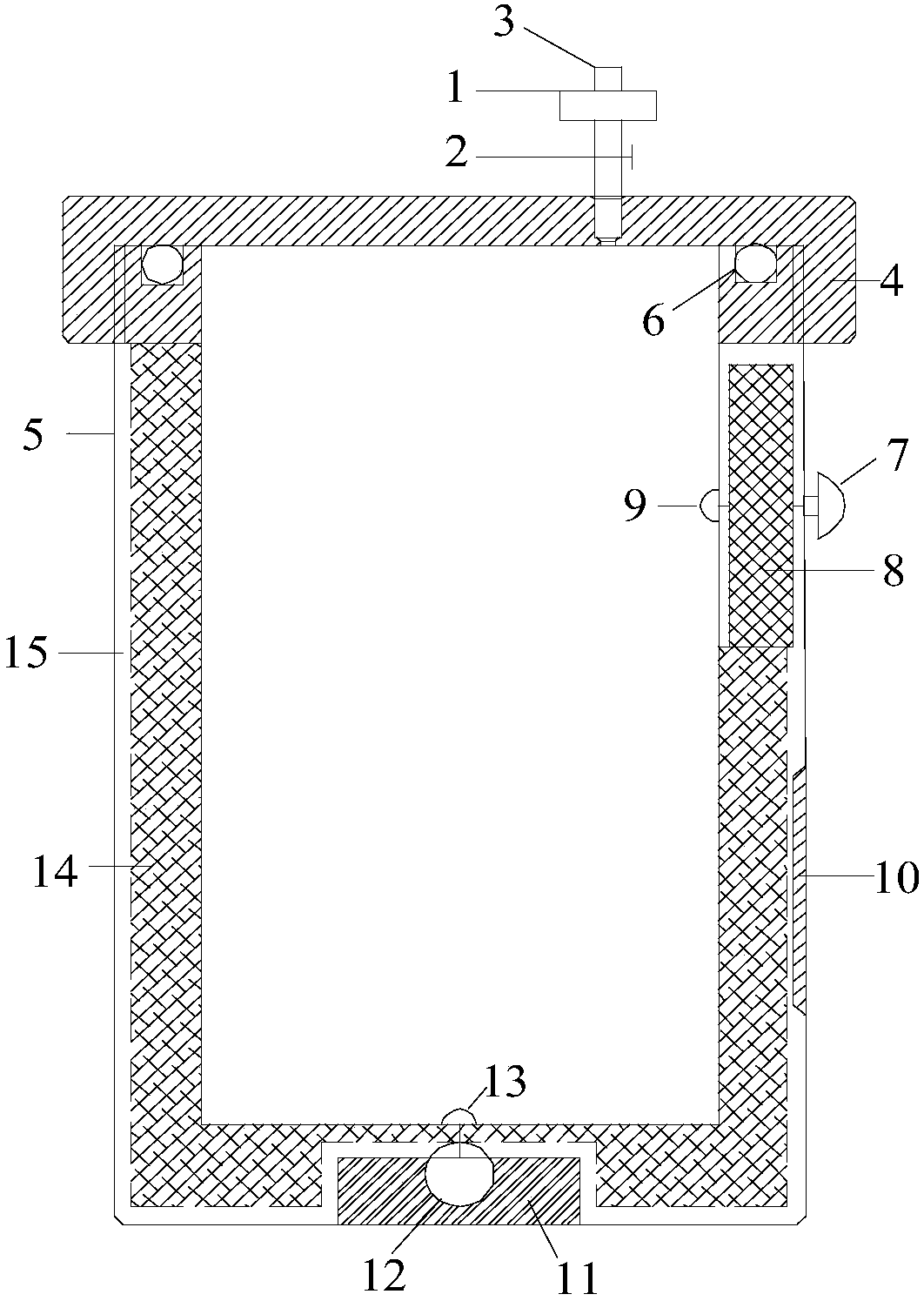

Intelligent constant temperature and ultrasonic wave promoting desorption integrated coal sample tank and using method thereof

InactiveCN108442972AIncrease desorption rateComplete desorptionMining devicesGas removalCoalEngineering

The invention discloses an intelligent constant temperature and ultrasonic wave promoting desorption integrated coal sample tank and a using method thereof. The coal sample tank comprises a tank bodyand a tank cover, the tank cover is provided with an exhaust pipe, and the exhaust pipe is provided with a gas flow meter and an air exhaust valve. A temperature regulating inner container is arrangedon the inner wall of the tank body, and a thermal insulating layer is further arranged between the temperature regulating inner container and the inner wall of the tank body. A temperature sensor isinstalled in the tank body, and an intelligent temperature control device is installed on the side wall of the tank body. The temperature regulating inner container and the temperature sensor are bothelectrically connected with the intelligent temperature control device. According to the intelligent constant temperature and ultrasonic wave promoting desorption integrated coal sample tank and theusing method thereof, intelligent dynamic regulation and ultrasonic wave desorption promotion of the temperature inside the tank body can be performed for arbitrary downhole temperature, and adsorption gas in a coal sample is evenly oscillated, so that the gas desorption rate in the coal sample is accelerated, the desorption is more complete, and the determination of gas content in underground coal samples is more accurate.

Owner:SOUTHWEST PETROLEUM UNIV

Vacuum thermal regeneration method of saturated activated carbon for adsorbing VOCs (volatile organic compounds)

PendingCN113559831AImproved pore size distributionIncrease the number of poresGas treatmentDispersed particle separationActivated carbonEnvironmental engineering

The invention discloses a vacuum thermal regeneration method of saturated activated carbon for adsorbing VOCs (Volatile Organic Compounds), which comprises the following processes: in a vacuum environment of 10Pa-100Pa, heating the activated carbon for adsorbing the VOCs to 280-350 DEG C, preserving heat for 20-40 minutes, and then breaking vacuum when the activated carbon is cooled to 100 DEG C or below along with a furnace, so as to realize regeneration of the activated carbon for adsorbing the VOCs. Compared with a traditional thermal desorption method and an existing vacuum regeneration method, the method has the advantages that the desorption efficiency is higher, the desorption speed is higher, meanwhile, the pore size distribution of the activated carbon is improved, the number of micropores is increased, and the activated carbon can be recovered to 95% or above of the adsorption performance of new activated carbon after being regenerated for 10 times.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Coalbed methane well automatic heating and re-injection water stimulation technology

The invention relates to an automatic reinjection water heating production increasing process of a coal-bed gas well. The process comprises the following steps: A, performing precipitation and filtration treatment on produced liquid once or for more times to remove more than 95 percent of solid particles; B, heating the treated clear liquid through solar energy to increase the water temperature to 60-90 DEG C; C, injecting hot water into a shaft through a hot water reinjection pipeline, extending the hot water reinjection pipeline to the space below a coal bed through an oil sleeve annulus and increasing the temperature of the original shaft liquid to over 20 percent; D, circularly performing the steps. The process has the advantages that the heat energy is injected into the shaft liquid in a hot water injection mode and the brownian motion of coal dust in the shaft liquid is increased so as to increase the divergence of the coal dust in the water, favorably reduce the concentration of the coal dust and discharge the coal dust, besides a part of heat energy is transferred to a coal-bed gas storage layer of an immediate vicinity of a wellbore, so that the free energy of the coal-bed gas can be increased to increase the desorption rate of the coal-bed gas, and meanwhile the gas is expanded on heating, so that a seepage passage can be expanded, the permeability of a reservoir stratum is improved and the production increase of the coal-bed gas is realized.

Owner:CNOOC ENERGY TECH & SERVICES

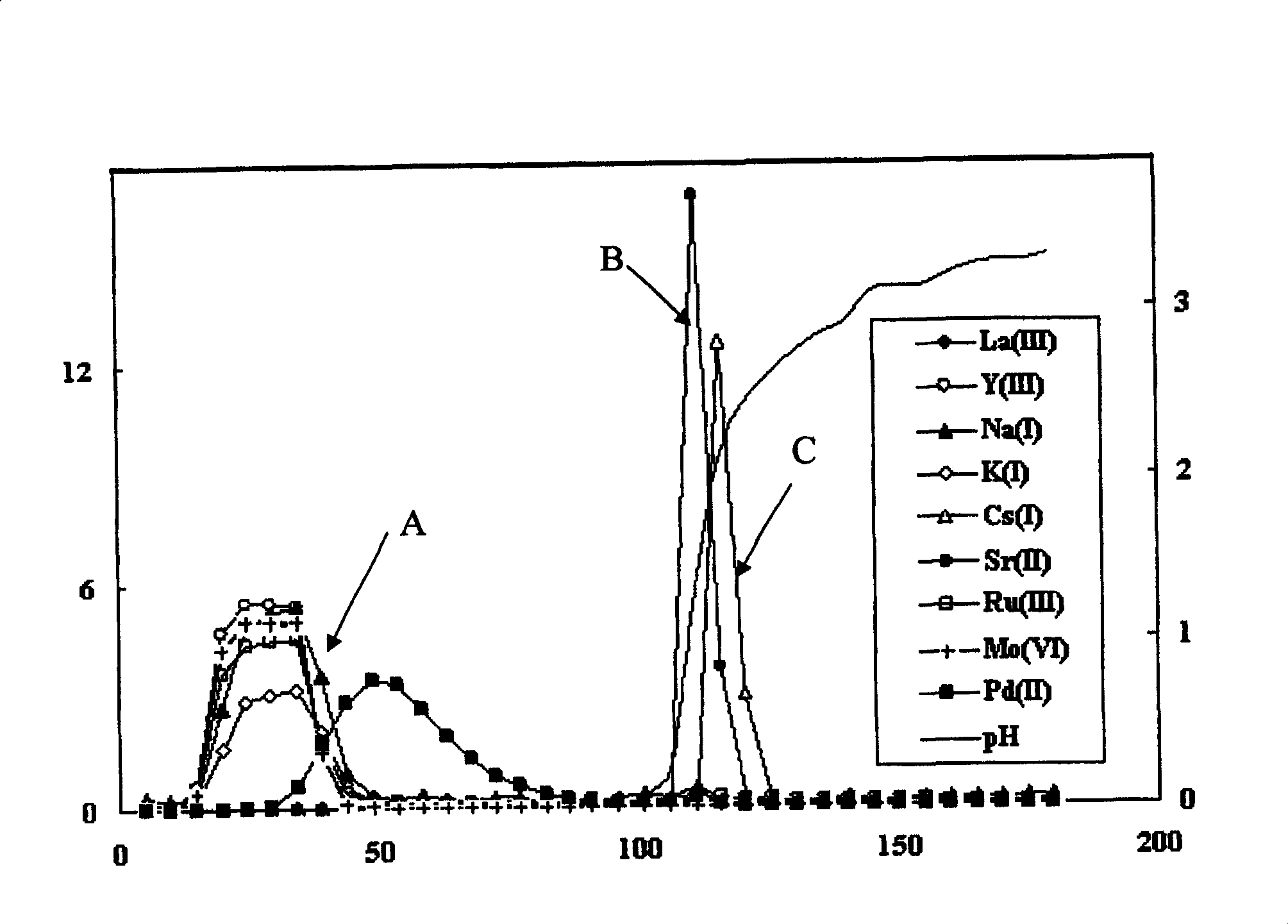

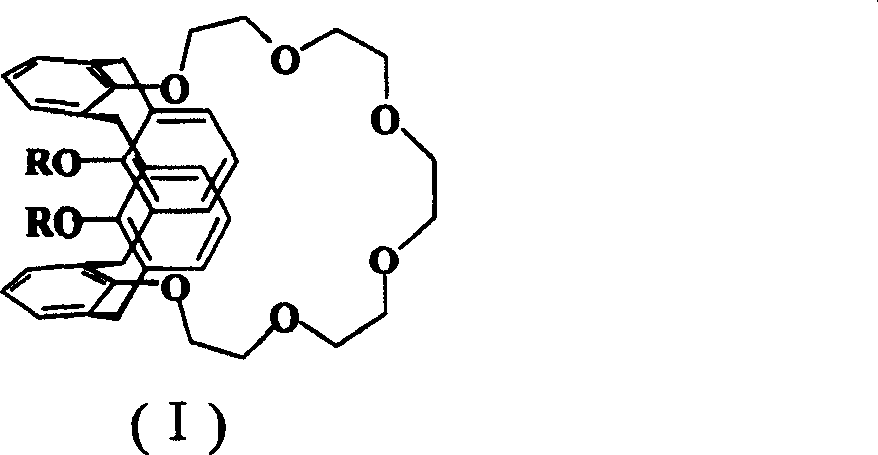

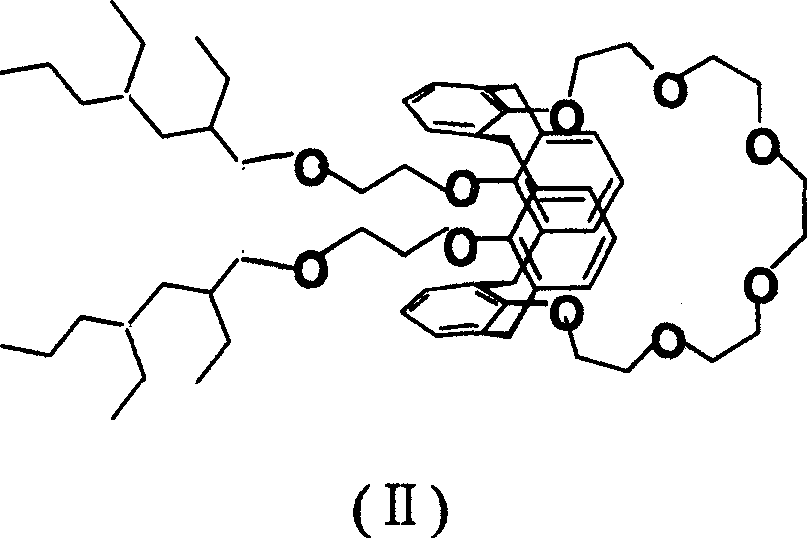

Adsorbent capable of separating heating element cesium and strontium at the same time and preparation method and application thereof

InactiveCN100460057CFacilitated DiffusionSafe handlingOther chemical processesRadioactive decontaminationSorbentEther

The invention relates to the absorbent manufacturing for separating Cs and Sr, made of crown ether and aromatic ether loaded on the big hole SiO2 coated with polymer, molecule ratio of the composition being 0. 3-2. 0, mass of the SiO2 being 2-40 times of the total mass of the aromatic ether that has general structural formula I and crown ether 4, and the Sio2 being phenylethene and divinylbenzene polymer. It does not need special dilution or solution treatment, getting over the deficiency of solution extracting, preserving the high volume of extraction.

Owner:ZHEJIANG UNIV

Non-consumptive type device and method for removing multisource trace harmful gases

ActiveCN106178827AReduced supply needsAchieve broad-spectrum comprehensive eliminationGas treatmentDispersed particle separationAviationFiber

The invention belongs to the technical field of life support and environmental control in spaceflight and aviation and particularly relates to a non-consumptive type device and method for removing multisource trace harmful gases. The non-consumptive type device comprises an air feeding unit and an adsorbing and desorbing unit, and also comprises necessary parts, namely a control valve, a connecting pipeline and a control system, wherein the adsorbing and desorbing unit is an integrated separator, and comprises a lower adsorber and an upper adsorber; the lower adsorber adopts a large-aperture hydrophobic type hollow fiber molecular sieve as an adsorbent for adsorbing toxic and harmful gases in raw gas; the upper adsorber adopts a small-aperture hydrophobic type hollow fiber molecular sieve as an adsorbent for adsorbing a little amount of toxic and harmful gas molecules with smaller particle diameter and water; a desorbing device is arranged between the upper adsorber and the lower adsorber and is used for heating and regenerating the used adsorbent. Multiple integrated separators can be arranged in parallel or in series for operation. The non-consumptive type device has the advantages that broad-spectrum comprehensive removal of multisource trace harmful gases in a cabin can be effectively realized, and the weight, the power consumption and consumable supplementing need of the system are reduced.

Owner:上海穗杉实业股份有限公司

Gas-liquid separator for oil field

ActiveCN105909229BIncrease desorption rateFacilitate desorptionFluid removalEnergy based chemical/physical/physico-chemical processesVapor–liquid separatorDesorption

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Coal bed gas mining technology

ActiveCN101113666BIncrease temperatureImprove single well productionFluid removalEngineeringHigh pressure

The invention discloses a coal-bed methane exploitation technology and is divided into the following steps. (1) A gas intake mine comprising a vertical shaft and a passage extending transversely is arranged. (2) Then one side or both sides of the passage extending transversely is provided with an air outtake mine. (3) Fracturing treatment is done through high-pressure fluid with the prior art. (4) A coal bed at the bottom of the air outtake mine is burnt, meanwhile, the high-pressure air or oxygen is injected to the air intake mine. Thereby an air passage formed by cracks of coal bed is established between the air intake mine and the air outtake mine by making use of pressure difference between the air intake mine and the air outtake mine and the characteristics that water and oxygen in the coal mine tend to get close to the burning point at the air outtake mine. (5) Mixed gas discharged from the air outtake mine is collected and treated and then the coal-bed methane is obtained. Part of the obtained coal-bed methane is taken to be burnt completely and thermal smoke from burning is reinjected to the air intake mine to ensure a stable gas supply from the air outtake mine. The invention overcomes the effects caused by unfavorable factors such as low permeability, low pressure and low saturation and realizes commercial production of coal-bed methane.

Owner:ENN SCI & TECH DEV

A method for drilling protection in soft coal seams and improving gas extraction efficiency

ActiveCN111287709BSmooth extractionFacilitate desorptionFluid removalGas removalThermodynamicsProcess engineering

The invention discloses a method for protecting drilling holes in soft coal seams and improving the efficiency of gas drainage. The method of filling large-scale plastic balls with holes and small plastic balls with holes in sequence is used. It can protect and support the gas drainage borehole, reduce the possibility of its collapse and deformation; keep the formed gas drainage channel smooth; as the concentration of gas drainage decreases, inject water into the borehole, water and quicklime A neutralization reaction occurs, and the gas desorption is accelerated after the coal body is heated, thereby improving the efficiency of gas extraction. By injecting water multiple times, the heat released by the reaction of calcium oxide and water can be effectively utilized, and the efficiency of gas extraction can be gradually improved. The invention integrates drilling protection and gas desorption rate improvement, high gas drainage efficiency and good effect, and it can ensure smooth gas drainage channel without special installation equipment, so the whole implementation process is convenient and simple to operate, convenient Field use, with a wide range of practicability.

Owner:XUZHOU UNIV OF TECH

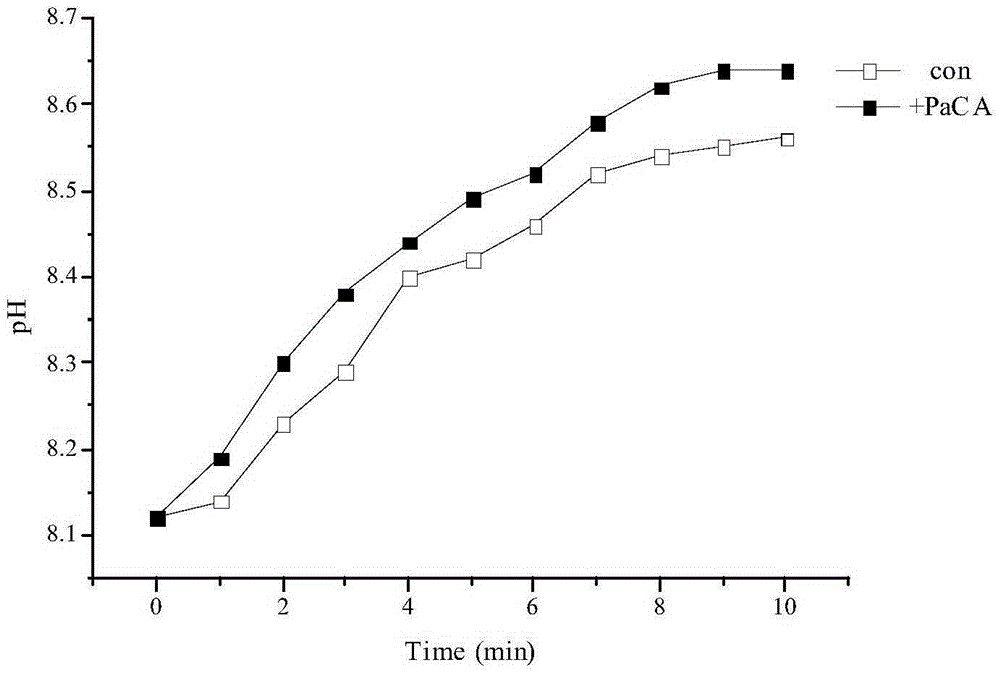

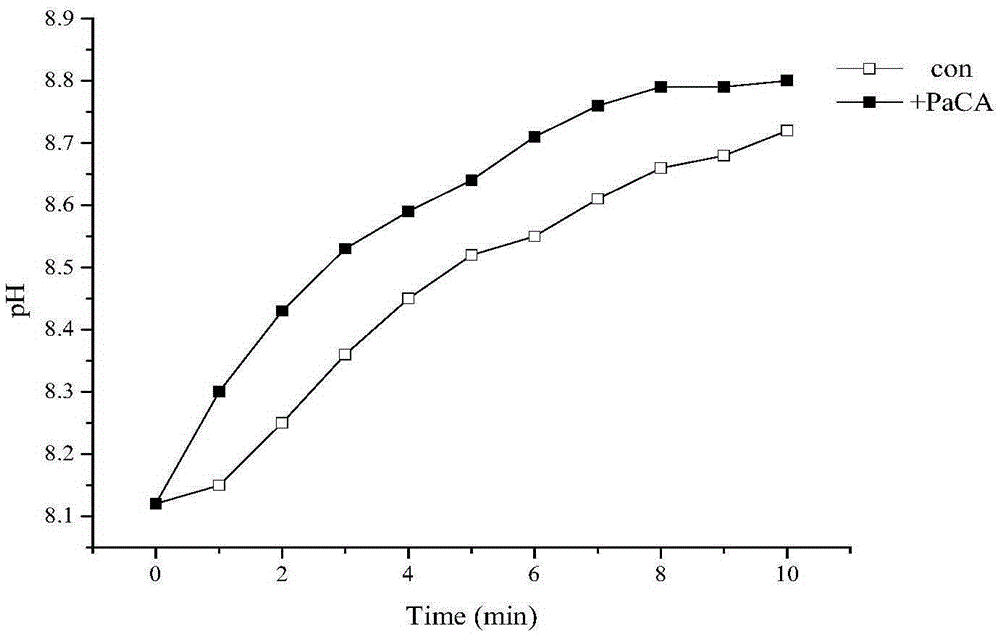

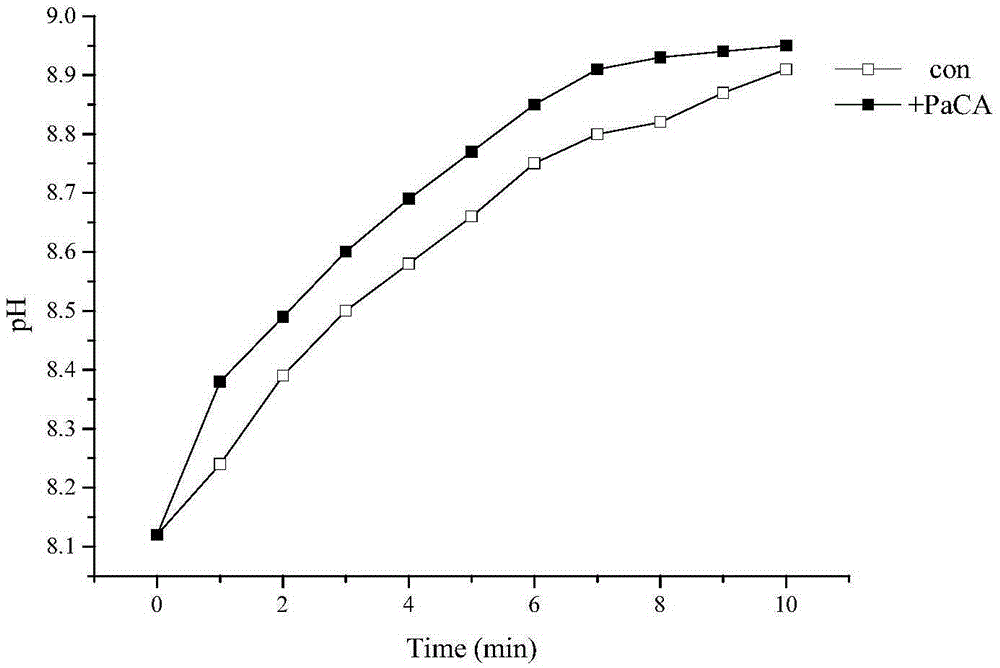

Application of a thermostable carbonic anhydrase in catalyzing the desorption of CO2 from organic amine solution

ActiveCN104437002BHigh catalytic efficiencyIncrease desorption rateDispersed particle separationBiological synthesisReduction treatmentDesorption

The invention belongs to the field of CO2 emission reduction treatment and provides application of thermal stability carbonic anhydrase in catalysis of organic amine solution and desorption of CO2. The thermal stability carbonic anhydrase is an amino acid sequence shown as SEQ ID NO:2. The carbonic anhydrase (PaCA) expressed by gene modification in a lab is adopted for catalyzing CO2 enriched organic amine solution desorption at different temperatures, and the carbonic anhydrase can effectively promote the desorption rate of CO2 at different low desorption temperatures. Compared with a mode with high needed chemical desorption temperature, the application has the advantages that the enzyme catalysis efficiency is high, the desorption temperature can be reduced, the energy consumption is reduced, and the energy is saved.

Owner:LIVINGZONE SHANGHAI BIO CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com