System and method for judging competitive field intensity of gas adsorption and desorption

An adsorption, desorption and gas technology, applied in the direction of analysis of materials and instruments, can solve the problems of low average coal seam gas drainage rate, poor desorption and seepage, and no coal seam gas drainage method has been found, so as to ensure safety and increase the amount of gas desorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

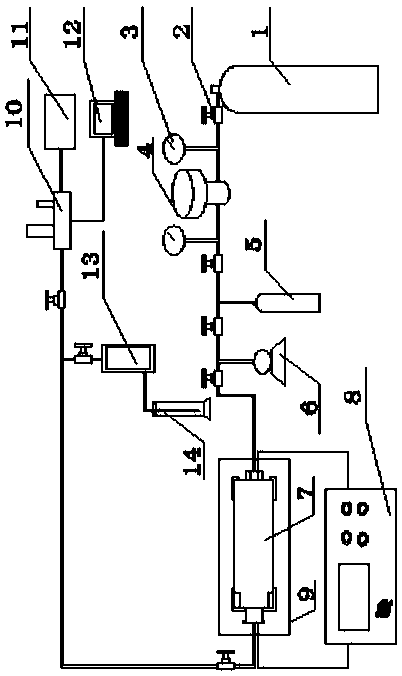

[0062] A system for identifying the dominant field strength of gas adsorption and desorption, such as figure 1 and figure 2 As shown, it includes methane tank 1, valve 2, pressure gauge 3, pressure regulating valve 4, reference cylinder 5, vacuum pump 6, holder 7, high voltage power supply 8, constant temperature water bath 9, flow sensor 10, gas collection box 11, The computer 12, the gas drainage device, and the holder 7 are arranged in the constant temperature water bath box 9, so as to ensure that the coal sample in the holder 7 maintains a constant temperature and ensure the stability and reliability of the measurement process.

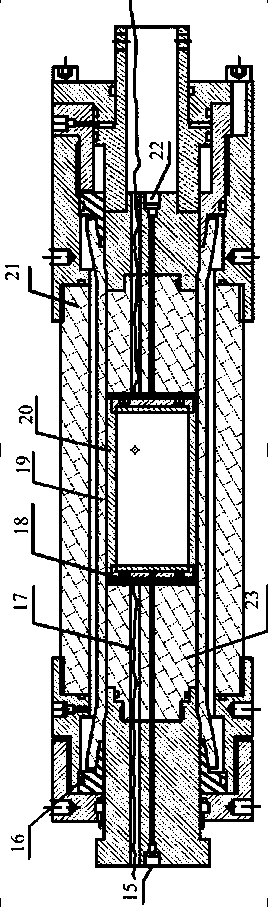

[0063] The holder 7 includes a cylinder body 21, a coal sample cylinder 20 is arranged inside the cylinder body 21, and a gas inlet 15 and a gas outlet 22 are communicated with the coal sample cylinder 20; meanwhile, left electrodes are respectively arranged at both ends of the coal sample cylinder 20. plate 18 and the right electrode plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com