Patents

Literature

49results about How to "Increase desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

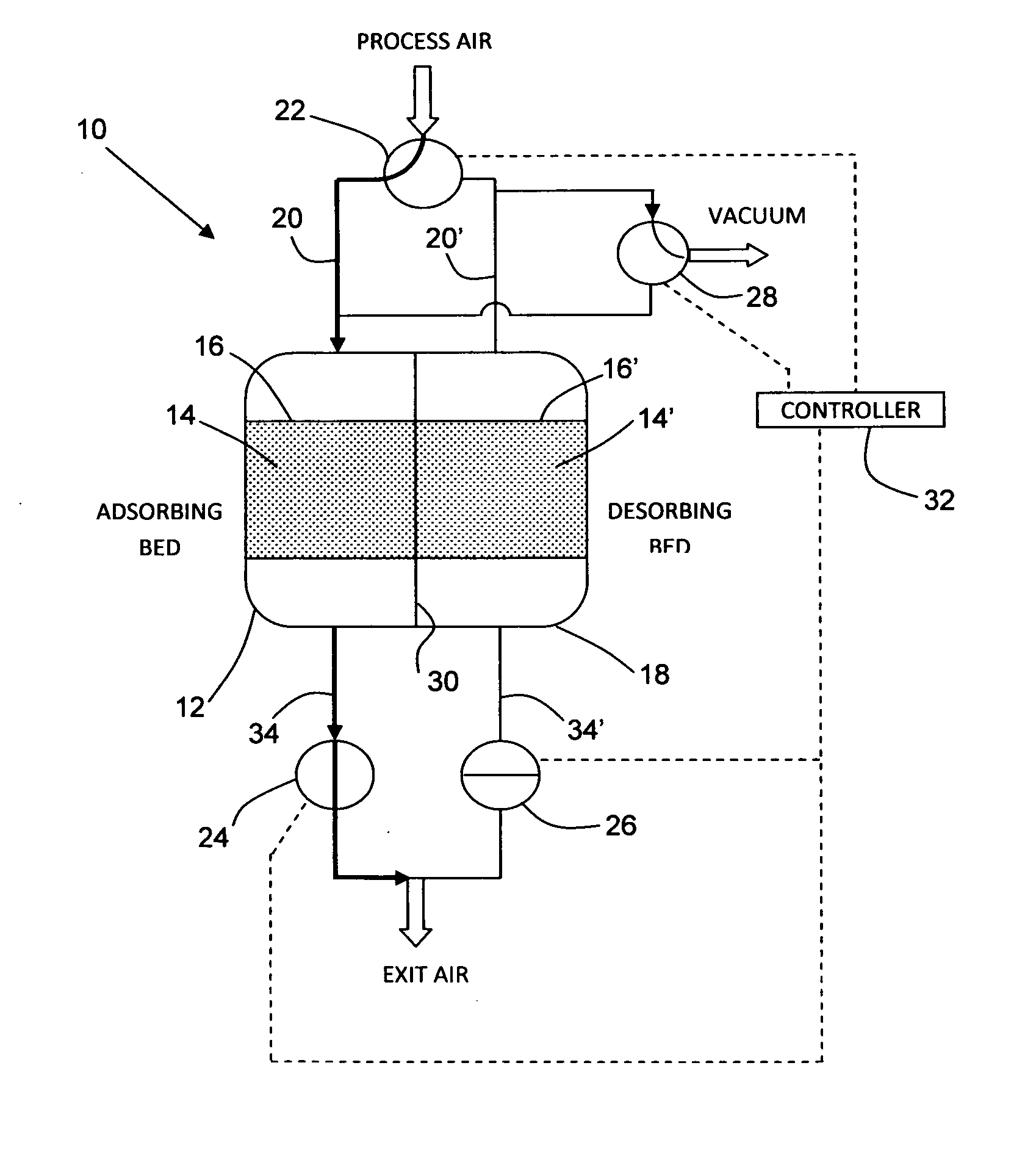

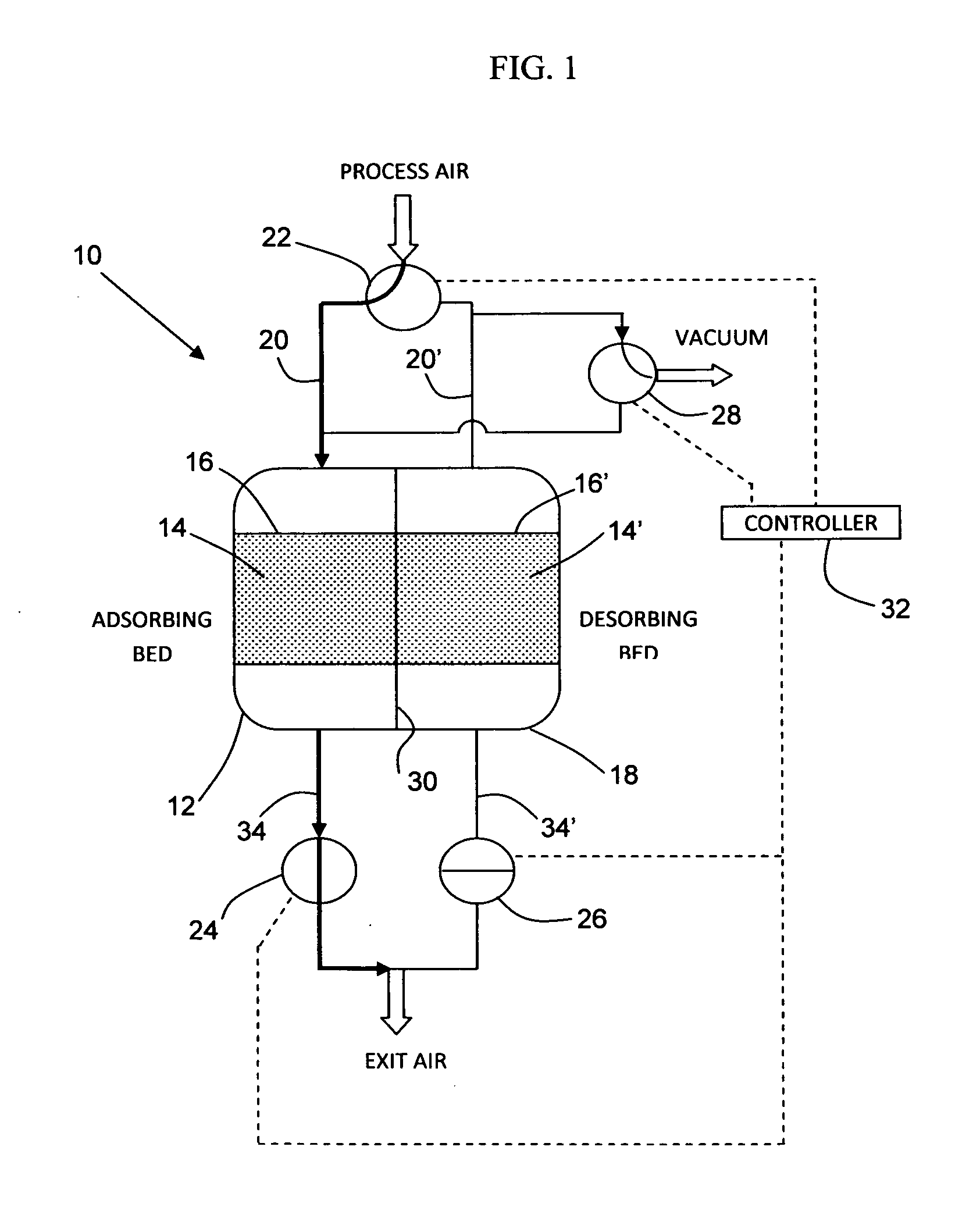

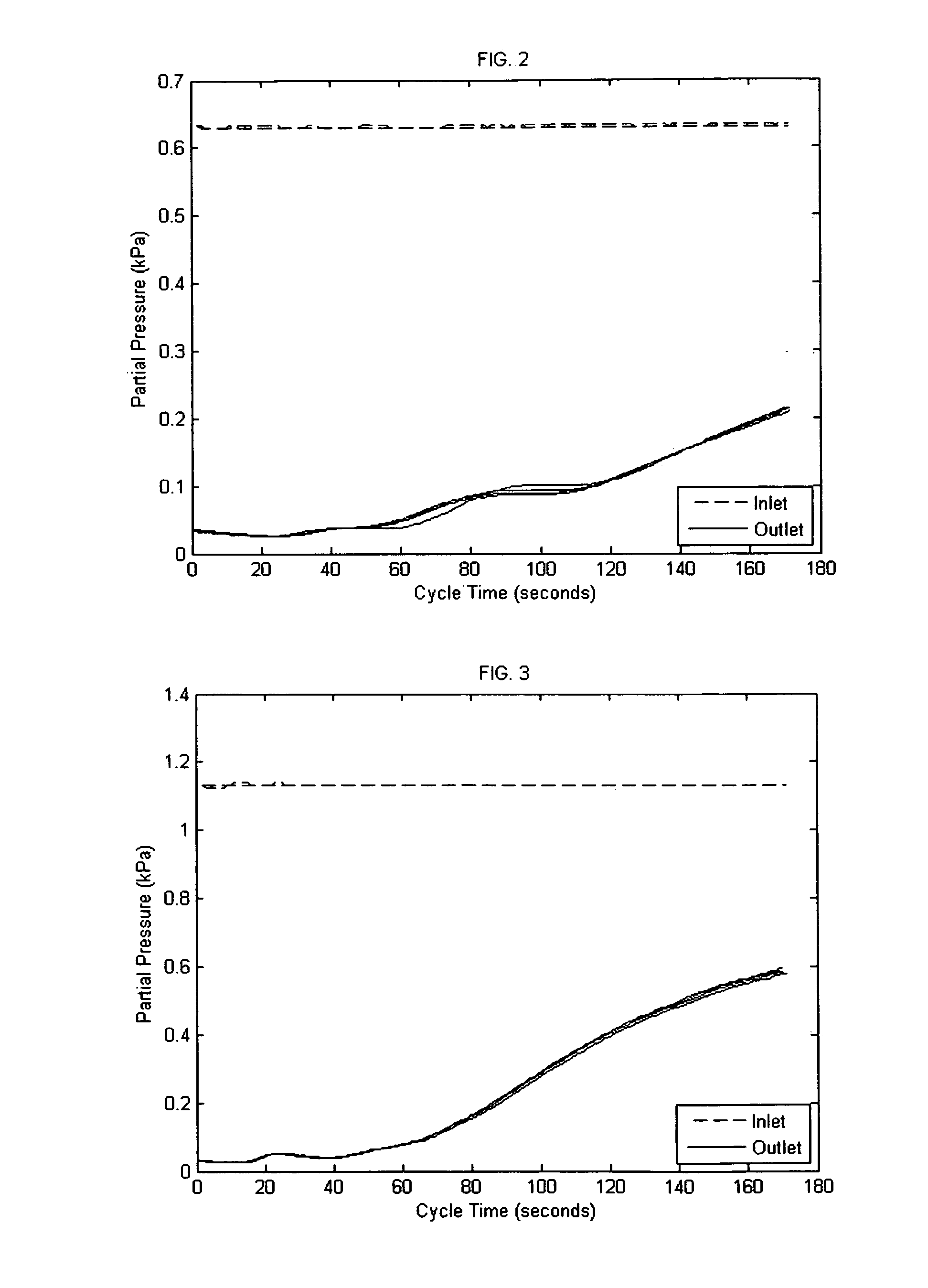

Adsorption-desorption apparatus and process

InactiveUS20120006193A1Light in massSmall volumeGas treatmentDispersed particle filtrationSorbentAdsorption desorption

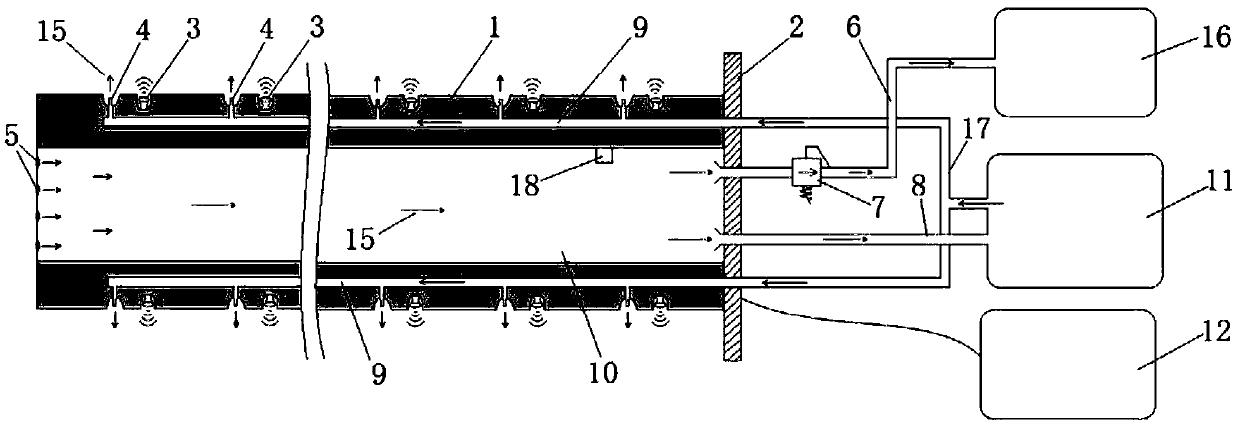

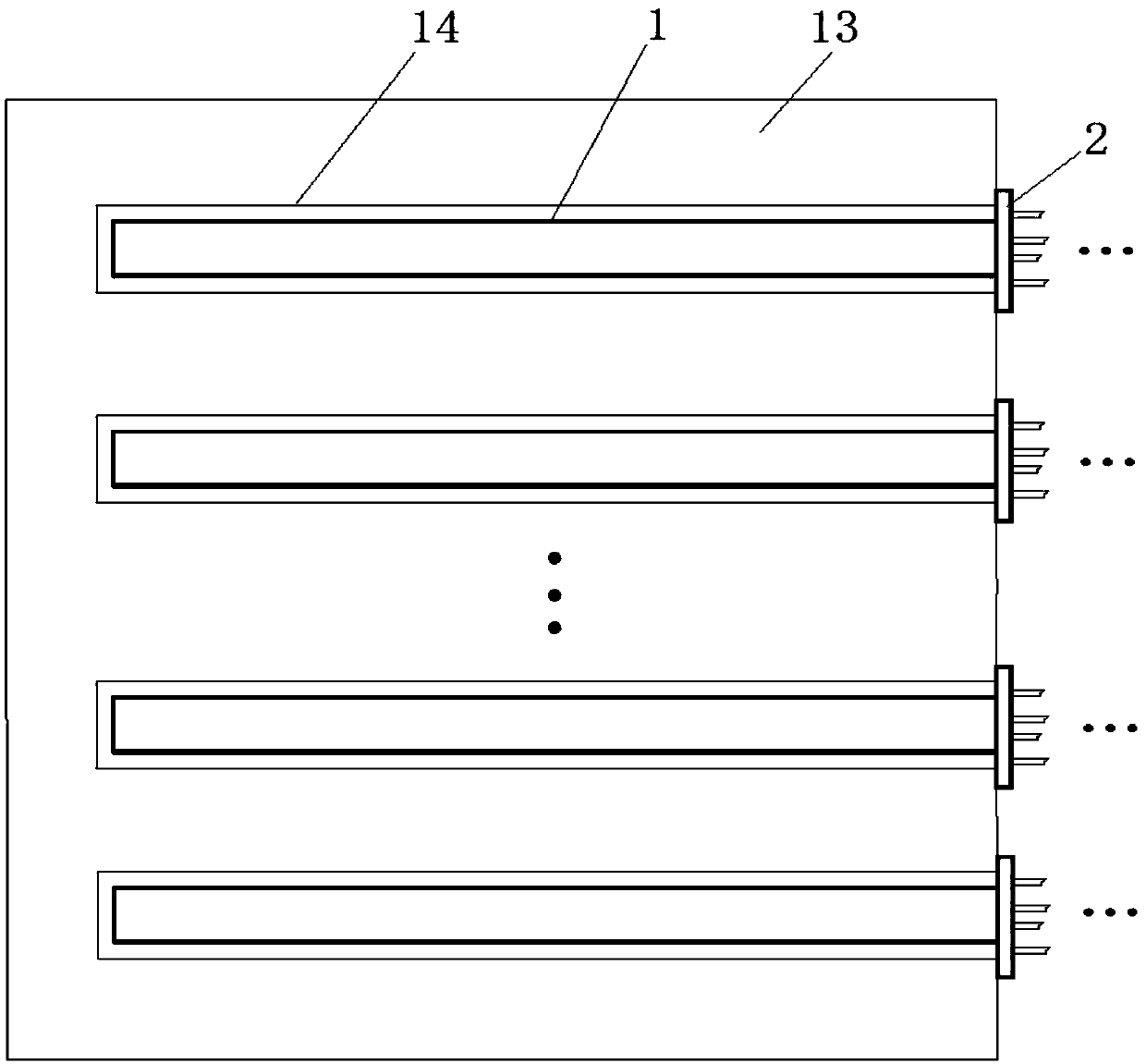

An apparatus and process for thermally-linked adsorption-desorption. The process involves (a) at least one pair of adjacent sorbent beds, referenced herein as first and second sorbent beds, each pair of adjacent beds being thermally-linked one to the other through a thermally conductive wall; wherein each sorbent bed comprises a heat conductive foam, such as a reticulated metallic foam or sponge, having a sorbent coated thereon; then (b) alternating a flowstream between the beds such that at least one bed operates in adsorption cycle to remove target compound(s) from the flowstream with generation of heat of adsorption, which is conductively transferred away from the first bed towards the second bed, while operating the second bed in desorption cycle to remove the adsorbed target compound(s).

Owner:PRECISION COMBUSTION

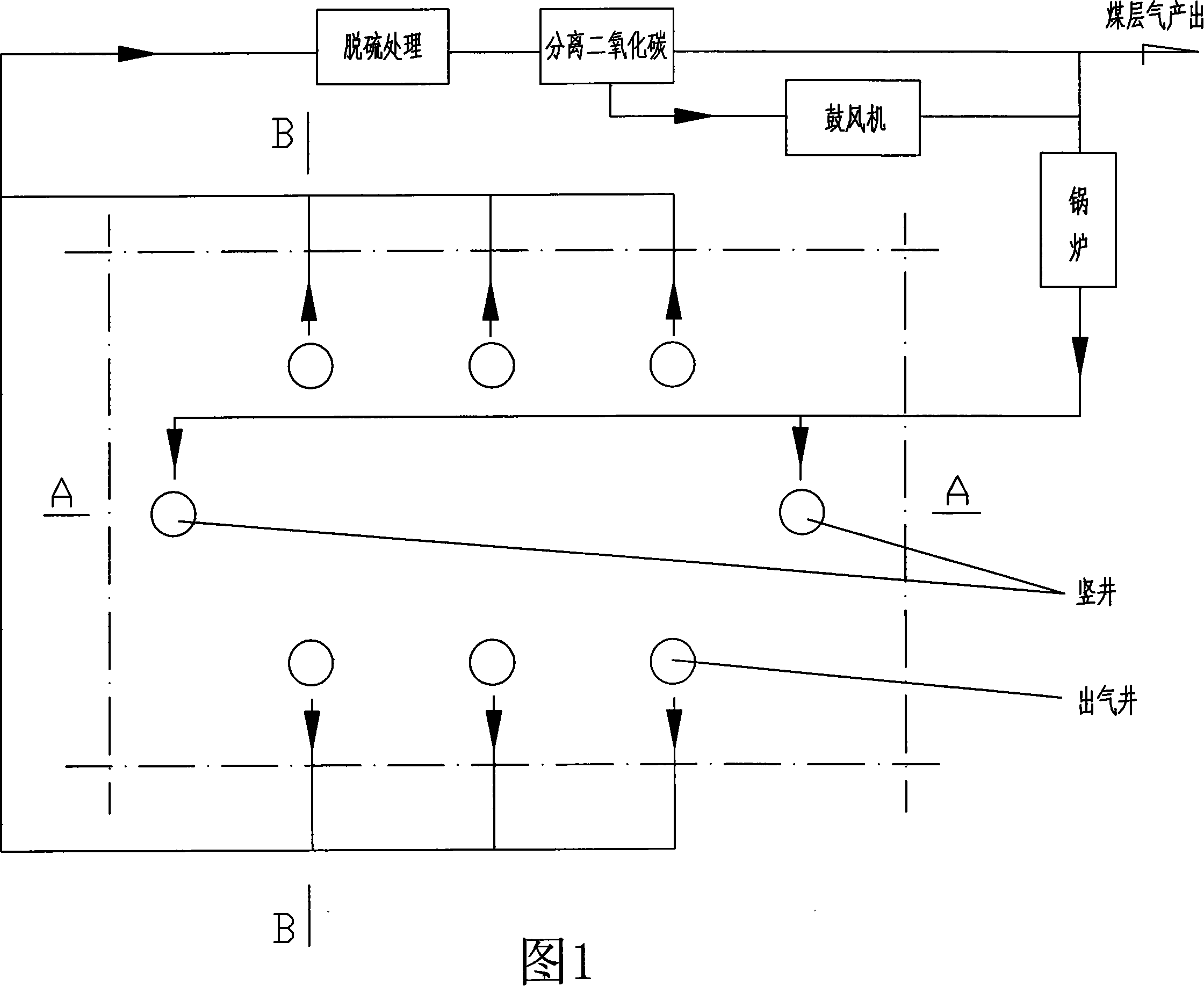

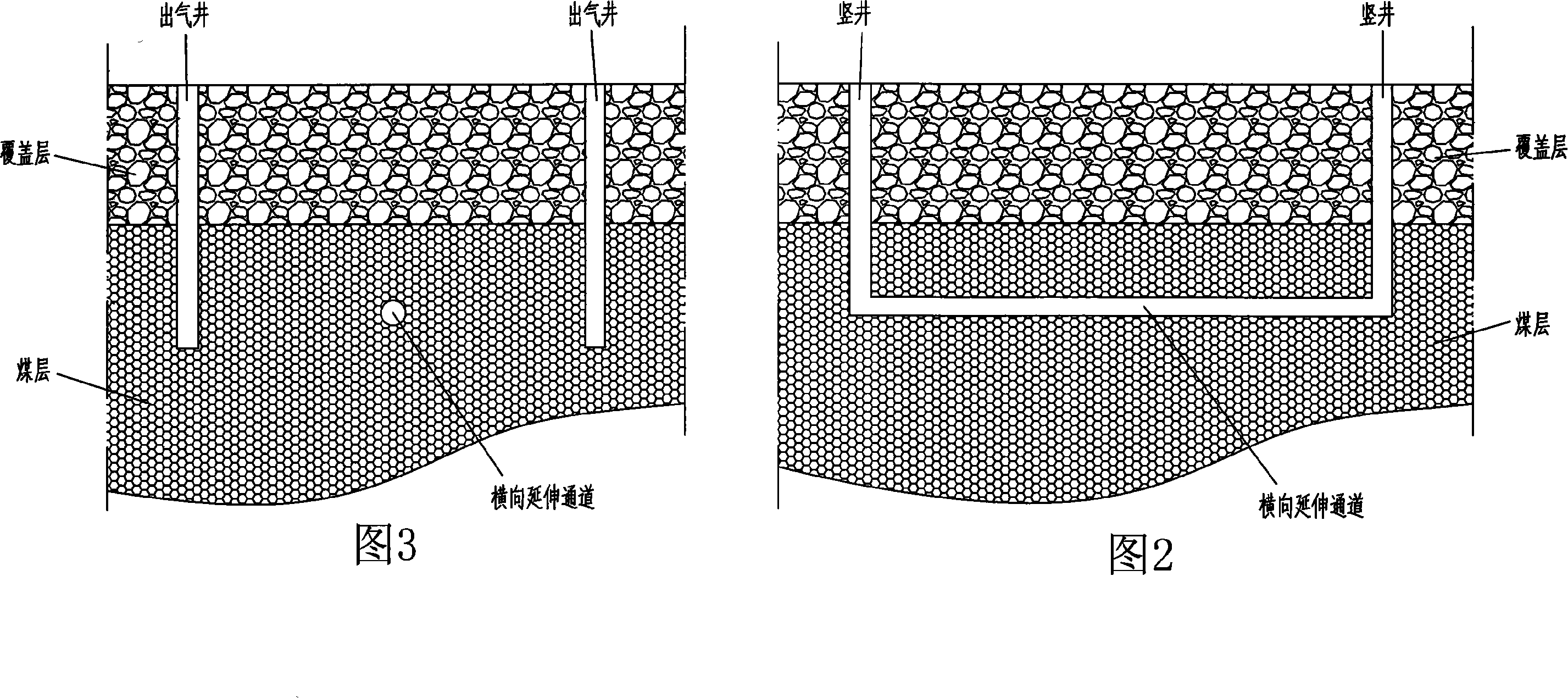

Coal bed gas mining novel technology

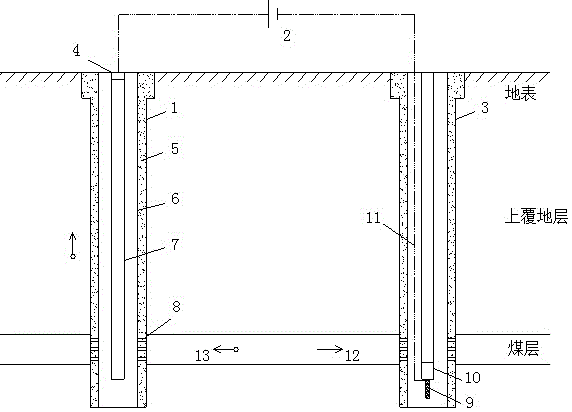

The invention discloses a new coal-bed methane exploitation technology and is divided into the following steps. (1) A gas intake mine comprising a vertical shaft and a passage extending transversely is arranged. (2) Then one side or both sides of the passage extending transversely is provided with an air outtake mine. (3) Fracturing treatment is done through high-pressure fluid with the prior art. (4) A coal bed at the bottom of the air outtake mine is burnt, meanwhile, the high-pressure air or oxygen is injected to the air intake mine. Thereby an air passage formed by cracks of coal bed is established between the air intake mine and the air outtake mine by making use of pressure difference between the air intake mine and the air outtake mine and the characteristics that water and oxygen in the coal mine tend to get close to the burning point at the air outtake mine. (5) Mixed gas discharged from the air outtake mine is collected and treated and then the coal-bed methane is obtained. Part of the obtained coal-bed methane is taken to be burnt completely and thermal smoke from burning is reinjected to the air intake mine to ensure a stable gas supply from the air outtake mine. The invention overcomes the effects caused by unfavorable factors such as low permeability, low pressure and low saturation and realizes commercial production of coal-bed methane.

Owner:ENN SCI & TECH DEV

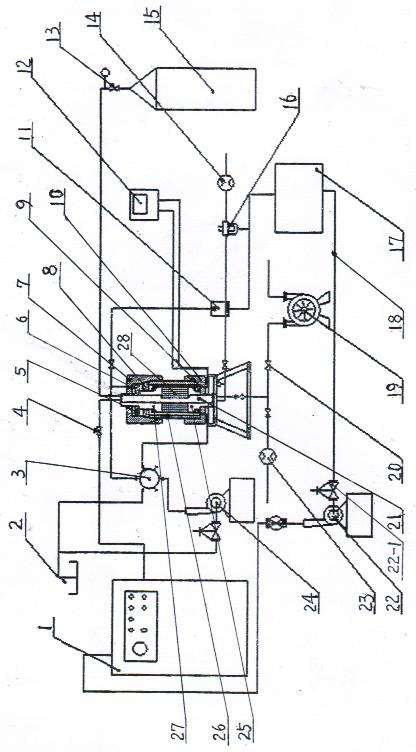

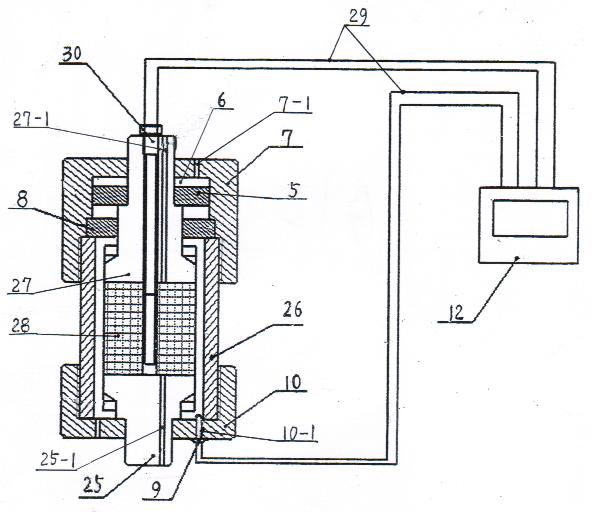

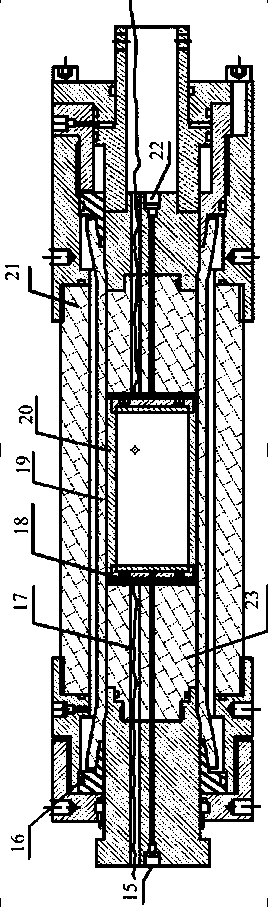

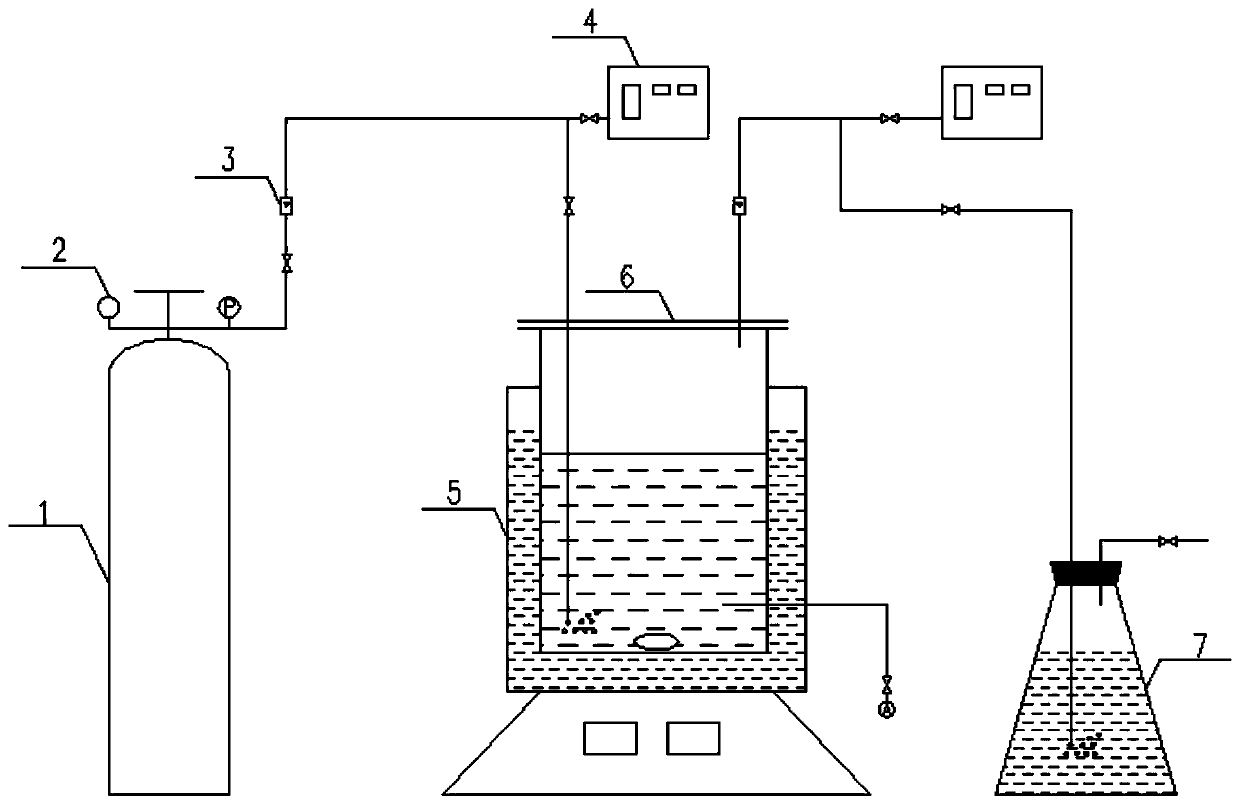

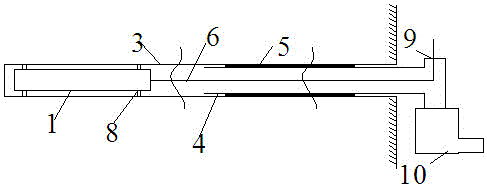

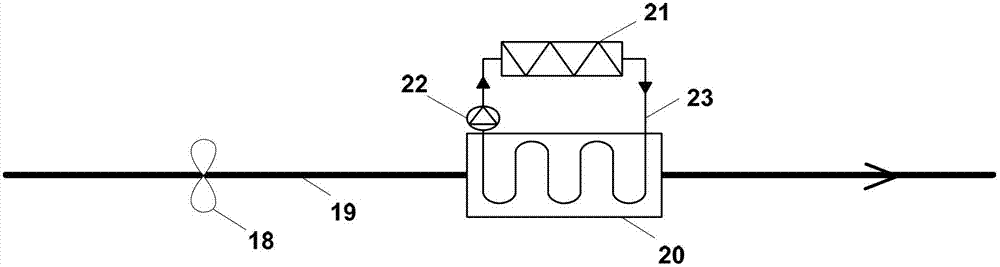

Double-purpose vapor and electric-heating three-shaft desorption and permeation test device

InactiveCN102680373AIncrease desorptionImprove permeabilityFuel testingPermeability/surface area analysisGas cylinderDesorption

The invention belongs to gas content experiment equipment in a coal bed of a coal mine, and particularly relates to a double-purpose vapor and electric-heating three-shaft desorption and permeation test device. An upper pressing cap (7) is connected with the upper end of a sleeve (26) of a three-shaft pressure chamber (6) by threads; a lower pressing cap (10) is connected with the lower end of the sleeve (26) by threads; a coal sample (28) is mounted in the middle of the sleeve (26); an upper pressing head (27) is mounted above the coal sample (28); a lower pressing head (25) is mounted below the coal sample (28); a baffle (8) is mounted on the connection part of the sleeve (26) on the upper pressing head (27) and the upper pressing cap (7); a piston (5) is mounted at a step of the upper pressing head (27); a thermocouple sensor (9) is mounted in a lower pressing cap hole (10-1); an electric heater (30) is arranged on the upper pressing head (27) and the coal sample (28); a vapor channel (21) is arranged in the upper pressing head (27), the lower pressing head (25) and the coal sample (28); and an upper pressing head hole (27-1) is connected with a methane gas bottle (15) through a pipeline (18) and a pressure adjusting valve (13), so that the gas absorption amount is reduced, and the gas desorption amount and the gas permeation amount in the coal bed can be increased.

Owner:LIAONING TECHNICAL UNIVERSITY

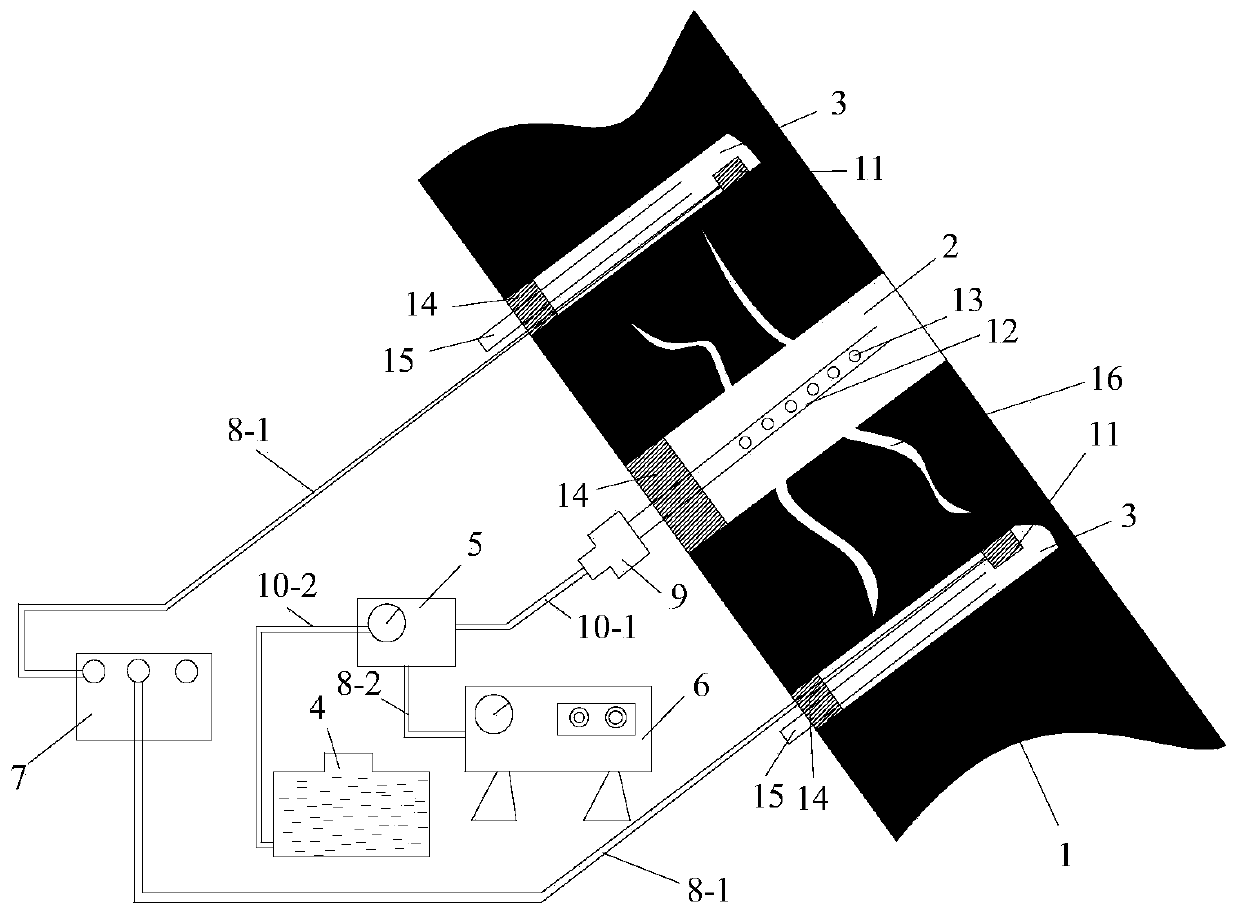

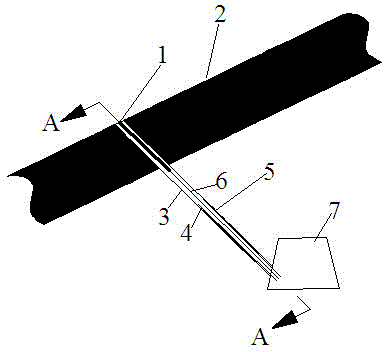

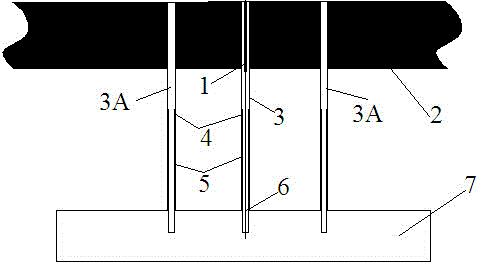

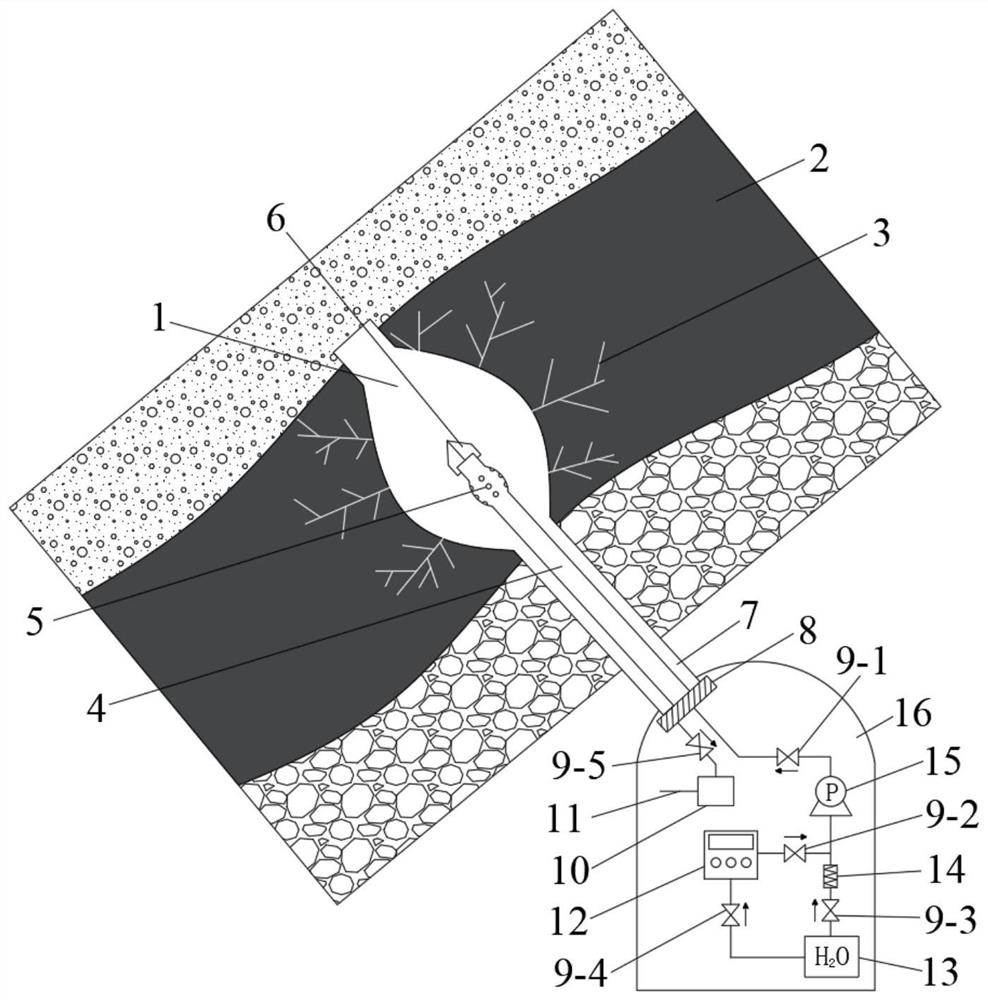

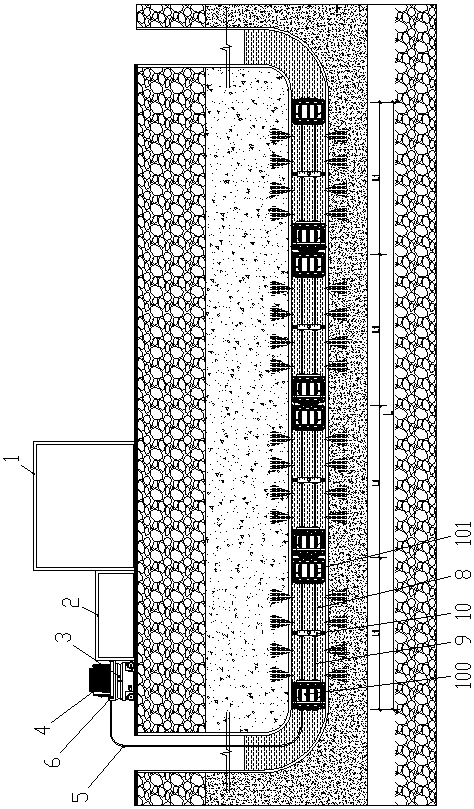

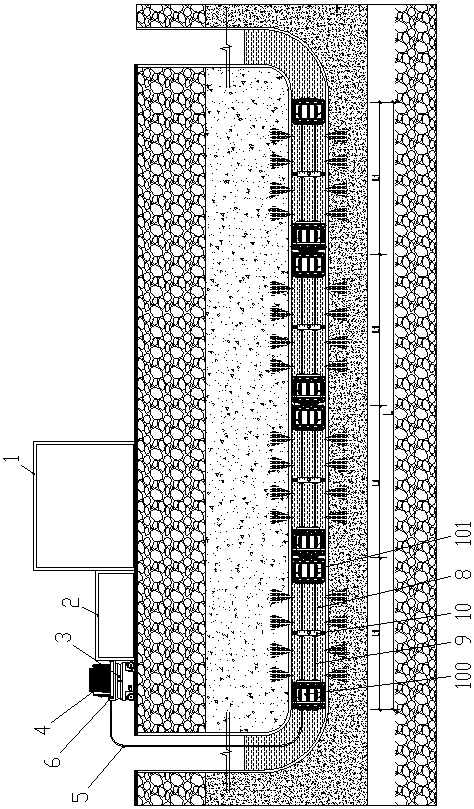

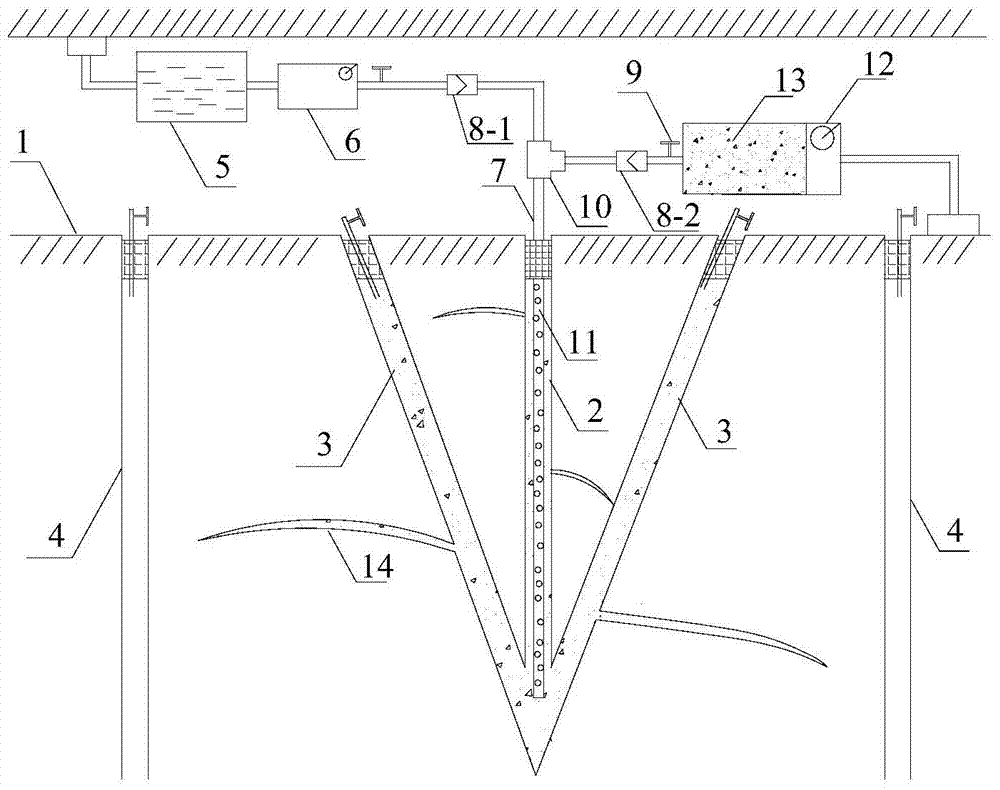

Method for strengthening regional gas extraction through hydro-thermal coupling fracturing

InactiveCN105114116ASolve hydrothermal coupled fracturingRealize hydrothermal coupled fracturingFluid removalGas removalIsoetes triquetraHydraulic fracturing

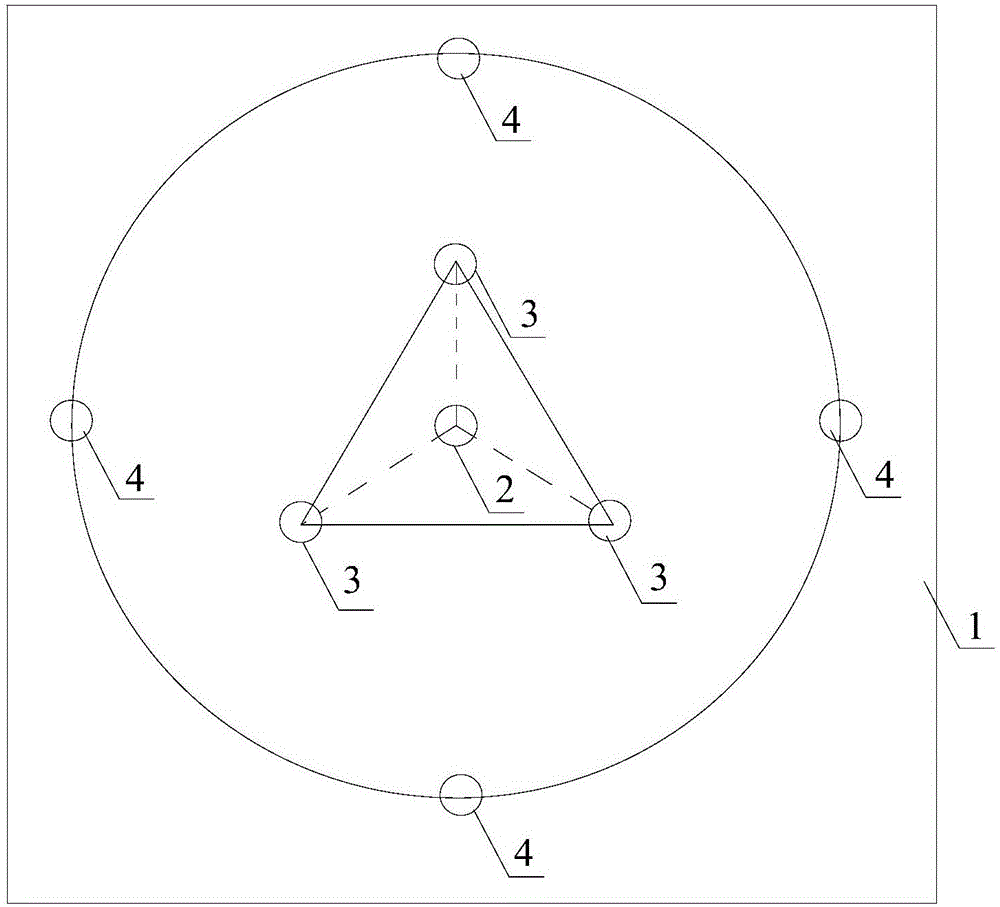

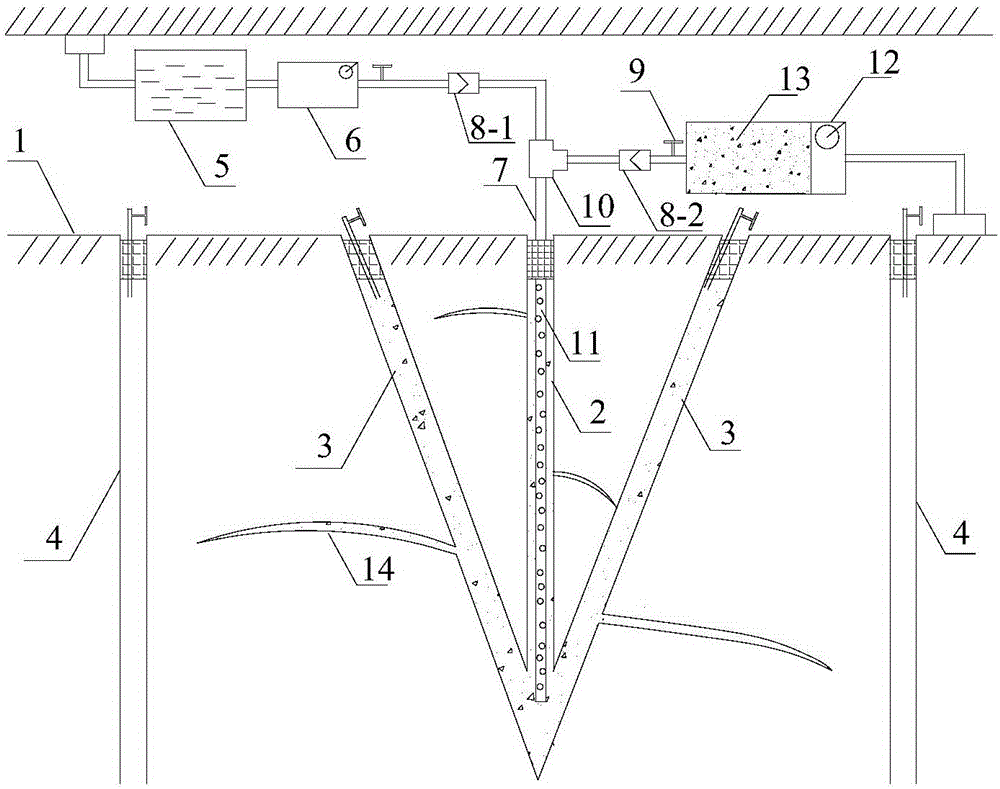

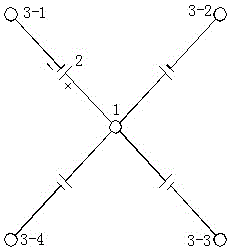

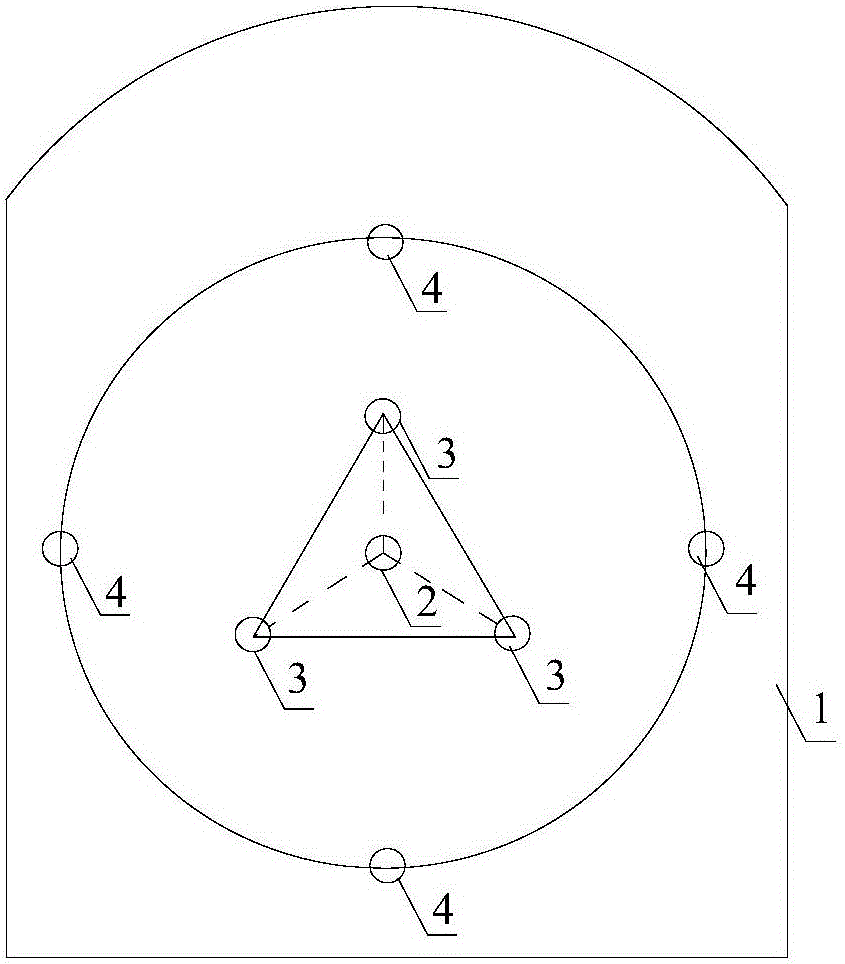

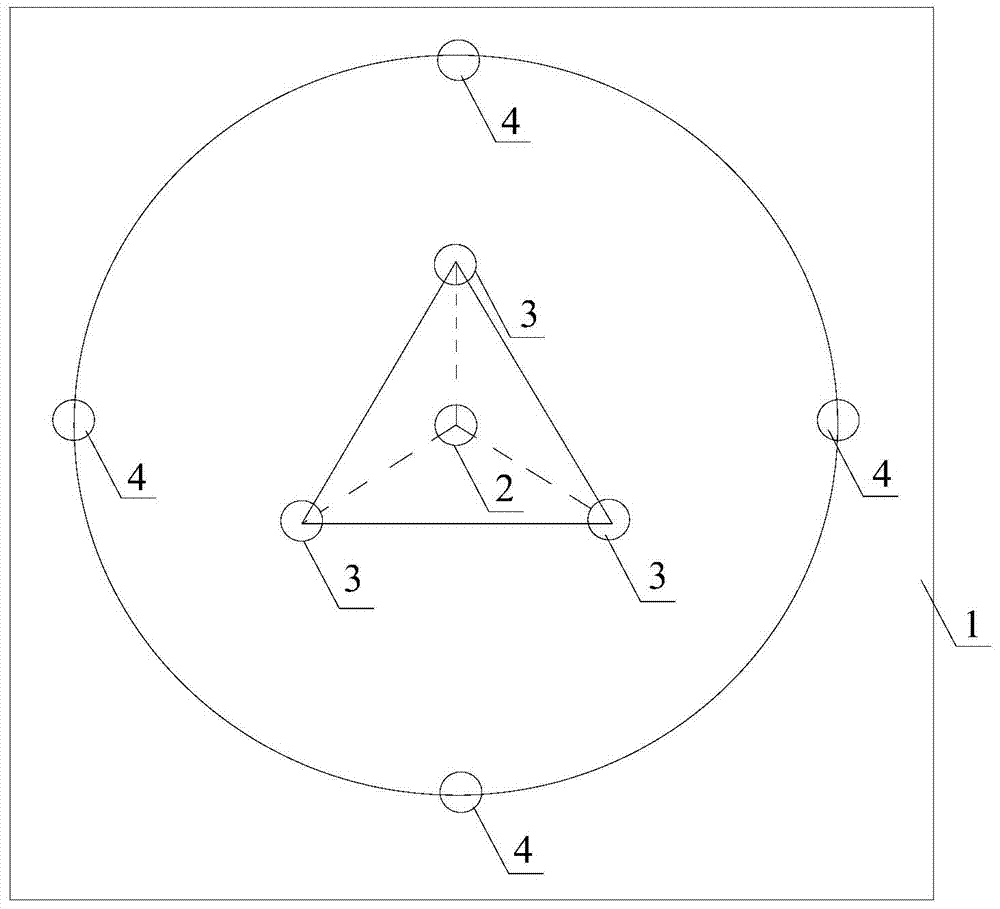

The invention discloses a method for strengthening regional gas extraction through hydro-thermal coupling fracturing. The method comprises steps as follows: firstly, a main fracturing hole, branch fracturing holes and lead holes are sequentially formed in a coal seam roadway through construction, the main fracturing hole is formed in the central position of an equilateral triangle, the opening positions of the branch fracturing holes are distributed at three vertexes of the equilateral triangle separately, the borehole bottom locations of the branch fracturing holes are converged in a center line of the equilateral triangle, the lead holes are located in a circle with the main fracturing hole serving as a center of the circle, and the radius of the circle is 5-15 m; fracturing equipment comprises water injection equipment and a powder injection device, and the water injection comprises an intelligent water tank and a fracturing pump. Quicklime powder in the powder injection device is injected into the main fracturing hole and the branch fracturing holes through underground air pressure; the water injection equipment performs hydraulic fracturing on the main fracturing hole, the quicklime powder is carried by high-pressure water to enter cracks, meanwhile, the quicklime powder and water have a thermal reaction to generate a large amount of heat, and hydro-thermal coupling fracturing is realized; with the implementation of the method for strengthening the regional gas extraction through the hydro-thermal coupling fracturing, the regions influenced by fracturing are increased, the concentration of extracted gas is increased, the effect is remarkable, and demands of work such as regional gas treatment in a coal mine site and the like are met.

Owner:SHANDONG UNIV OF SCI & TECH

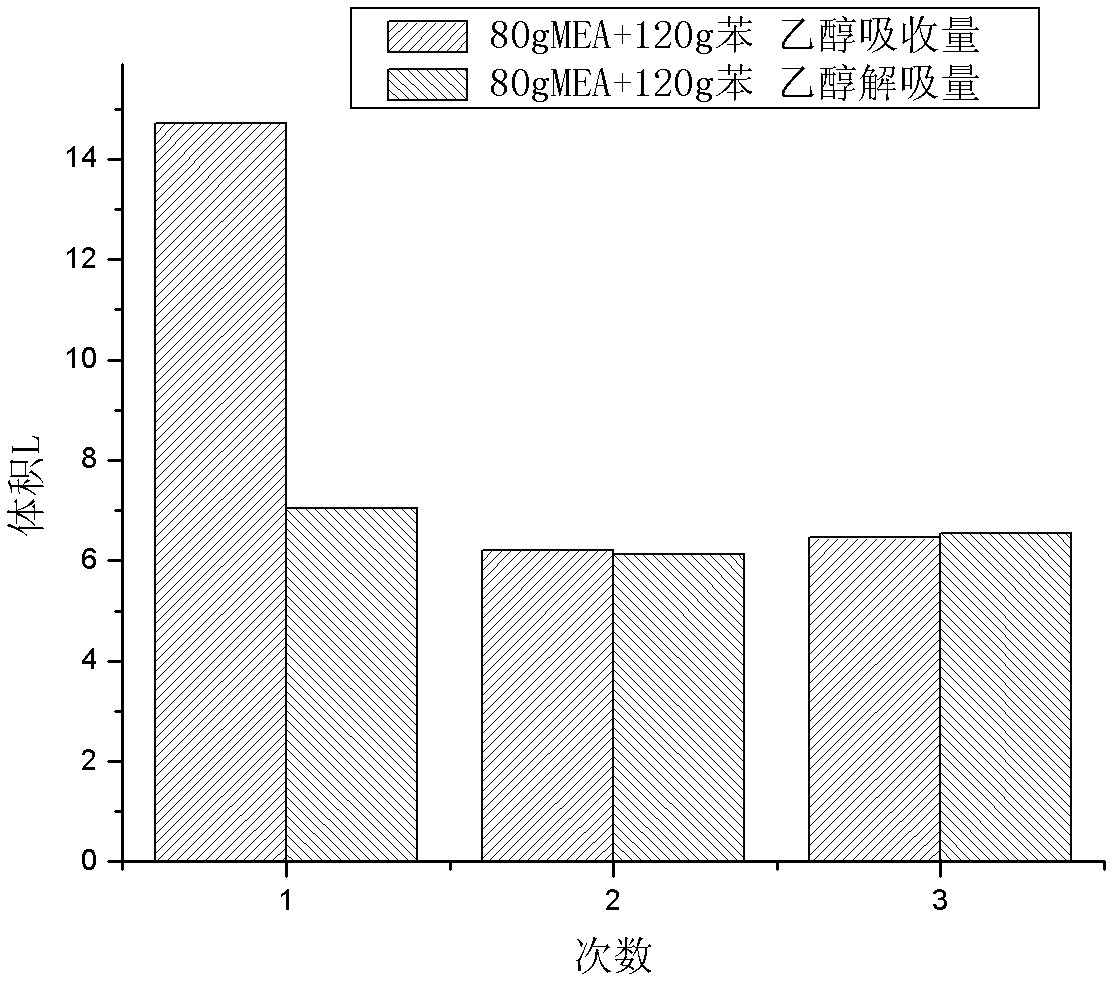

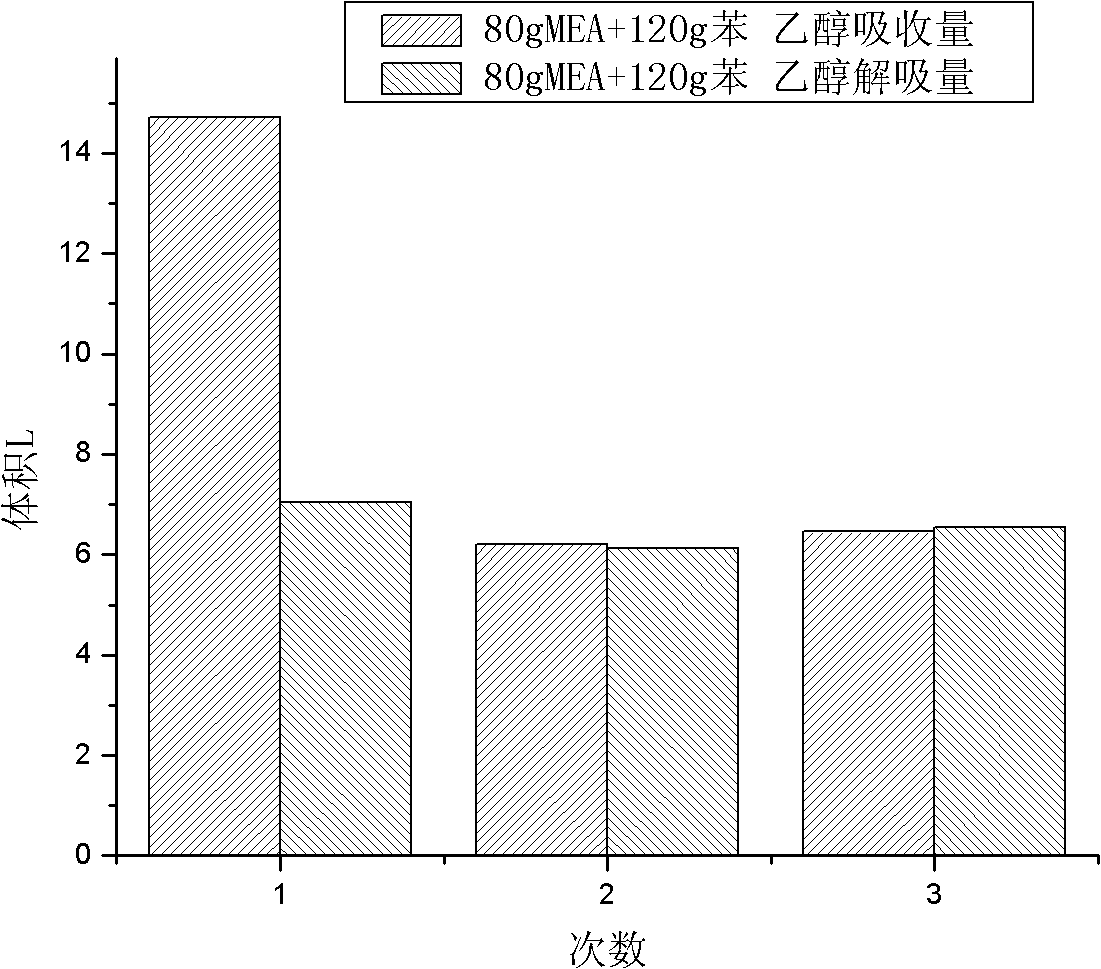

A method for capturing carbon dioxide in mixed gas with composite decarburization solution

InactiveCN102284227APromote absorptionIncrease desorptionCarbon compoundsDispersed particle separationAbsorption capacityChemical reaction

The invention relates to a composite decarburization solution for capturing carbon dioxide in mixed gas, belonging to the technical field of carbon dioxide gas capture. It relates to a composite decarburization solution, which is composed of solvent benzyl alcohol, phenyl alcohol, N-methylpyrrolidone or a mixture thereof, main absorption component MEA, auxiliary absorption components EDA, DETA and TETA, active components PZ and 2, 3-butanedione, the corrosion inhibitor is sodium chromate, and the antioxidant is sodium metavanadate and copper carbonate. Since the composite decarburization liquid uses a mixed solvent, it not only improves the absorption capacity, purification degree and desorption rate of carbon dioxide, expands the reaction temperature range, but also reduces the volume of the desorption tower, greatly reduces regeneration energy consumption, and reduces equipment investment and operating costs. The invention is mainly used for capturing carbon dioxide in various chemical reaction tail gas, ore decomposition gas, combustion flue gas, natural gas, city gas and biogas, and has broad application prospects.

Owner:DALIAN UNIV OF TECH

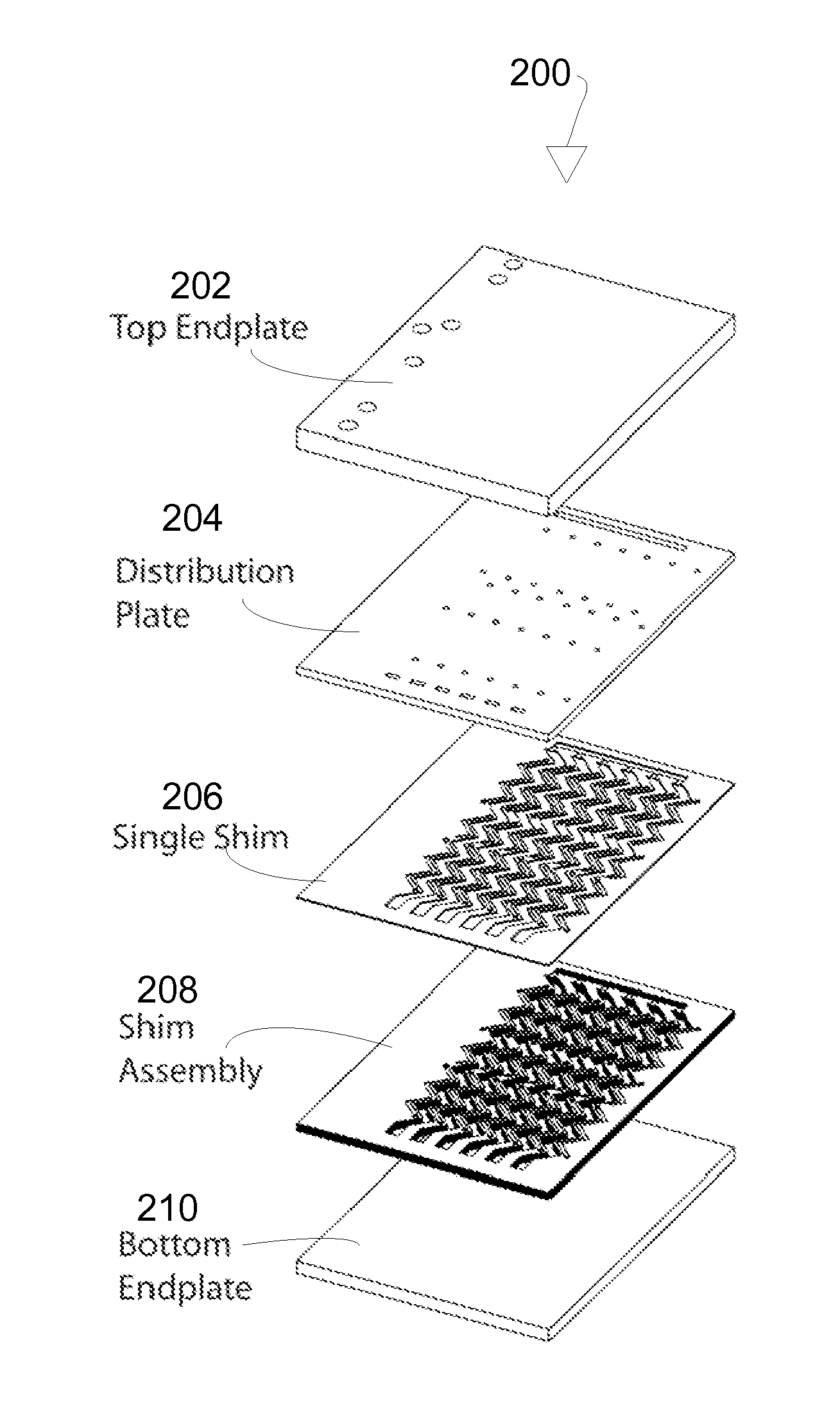

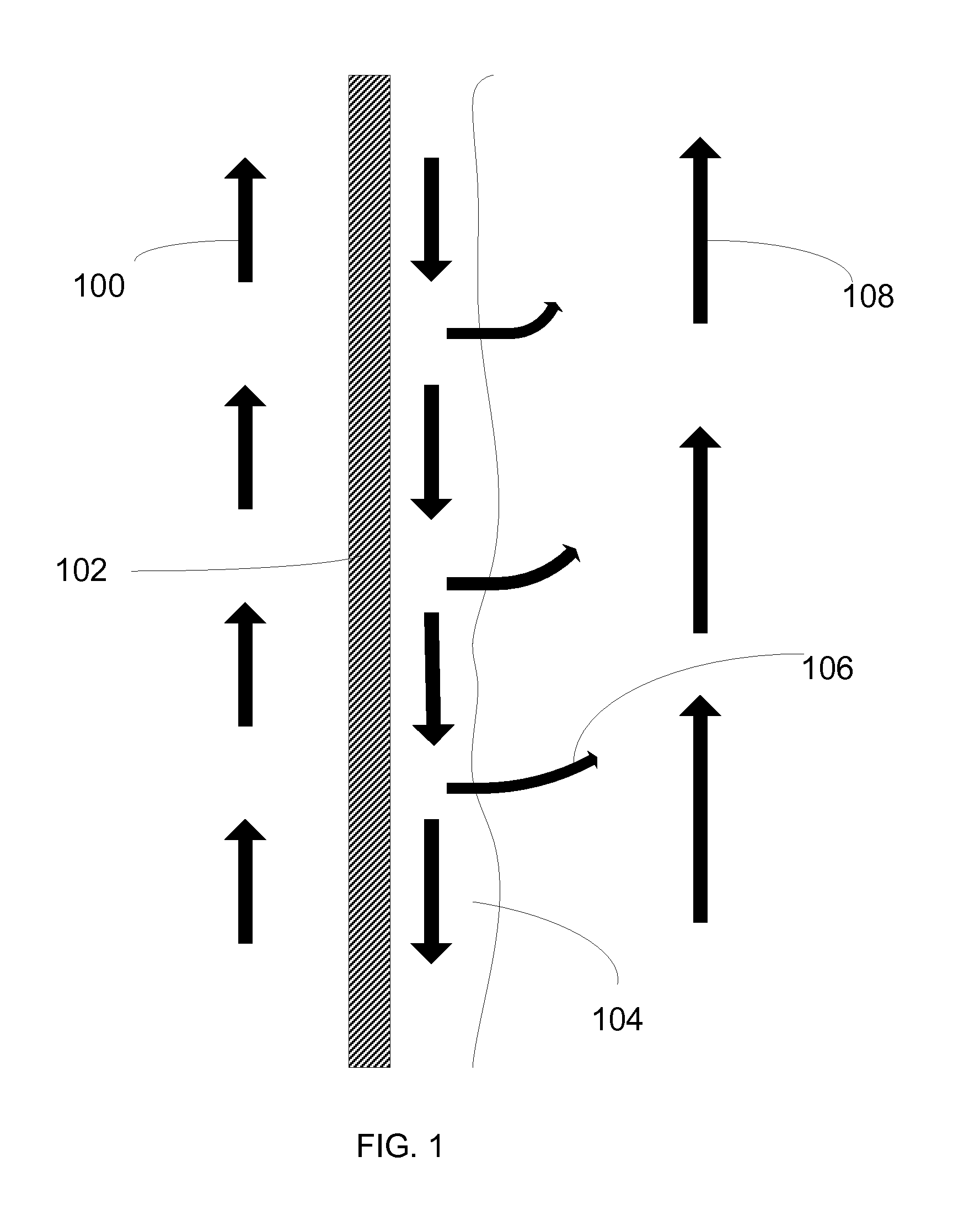

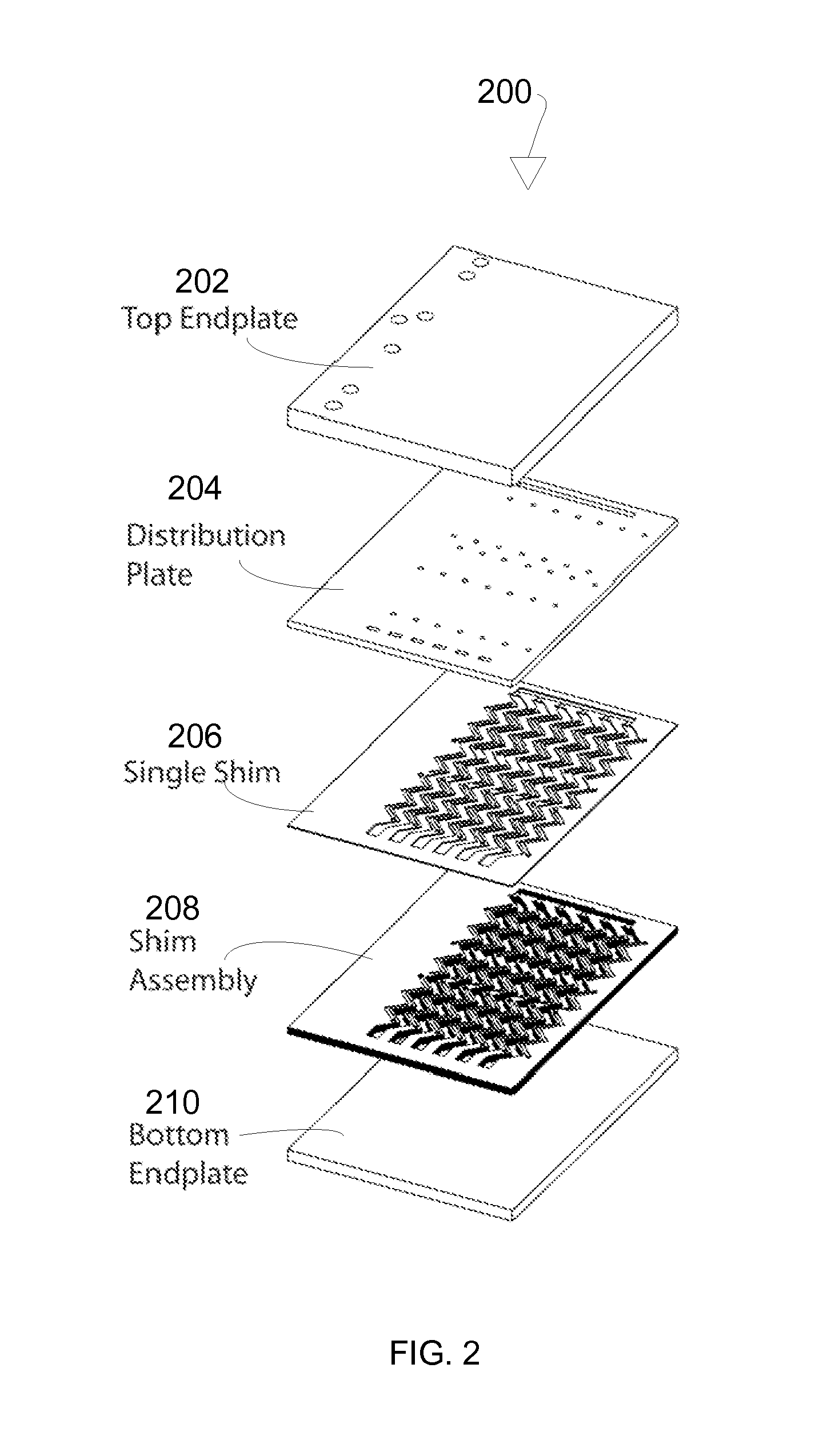

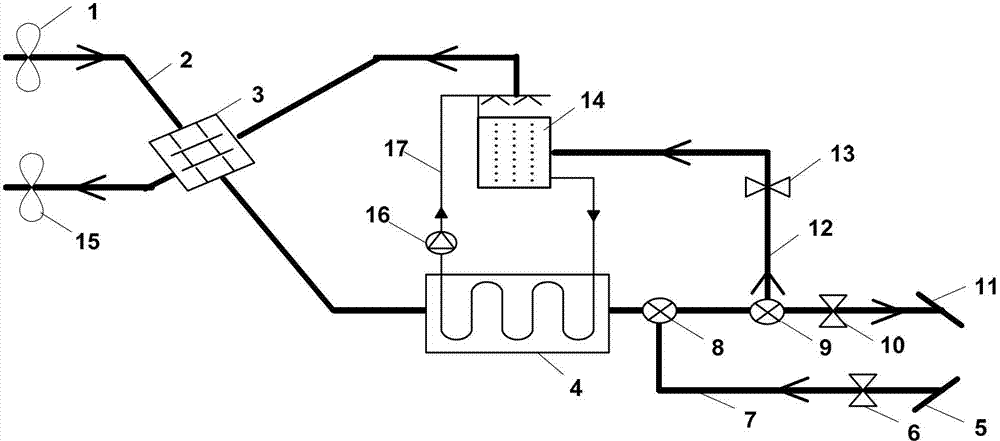

Vapor-liquid heat and/or mass exchange device

ActiveUS20130133346A1Increase desorptionImprove distributionHeat pumpsBoiler absorbersVapor liquidWorking fluid

The invention is directed toward a vapor-liquid heat and / or mass exchange device that can be used in an integrated heat and / or mass transfer system. To achieve high heat and mass transfer rates, optimal temperature profiles, size reduction and performance increases, appropriately sized flow passages with microscale features, and countercurrent flow configurations between working fluid solution, vapor stream, and / or the coupling fluid in one or more functional sections of the desorber are implemented. In one exemplary embodiment of the present invention, a desorber section utilizes a heating fluid flowing in a generally upward direction and a concentrated solution flowing in a generally downward direction with gravity countercurrent to the rising desorbed vapor stream. To further increase the efficiency of the system, various types of column configurations can be used. Additionally, the surfaces of the microchannels can be altered to better transfer heat.

Owner:GEORGIA TECH RES CORP

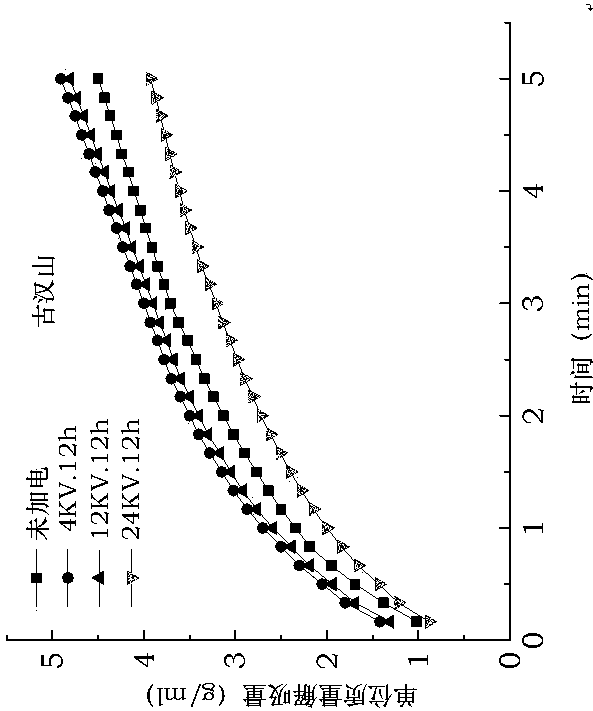

Method for improving coal bed gas recovery efficiency by electrochemistry

ActiveCN106437638AEnhanced overall recoveryImprove drainage and gas production capacityFluid removalElectrolytic agentCalcite

A method for improving coal bed gas recovery efficiency by electrochemistry is characterized in that a vertical well is drilled, a well net is formed, an anode electrode is placed at a wellhead of a liquid injection well, a cathode electrode is fixed at the bottom of a gas recovery well, fracturing liquid with electrolyte is used for fracturing a coal bed, the electric osmosis direction of an electrochemically modified area points to the bottom of the gas recovery well from the wellhead of the liquid injection well after a direct-current power supply is turned on, water is drained to the gas recovery well, and coal bed gas is displaced. The electrophoretic direction points to the wellhead of the liquid injection well from the bottom of the gas recovery well, solid particles such as pulverized coal and rock powder in coal reservoir pore fractures migrate towards the wellhead of the liquid injection well, and a methane migration channel is dredged. Filling minerals such as calcite and pyrite in the coal reservoir pore fractures are corroded by electrolysis, the number of the fractures is increased, and permeability of the coal bed is improved. The temperature of a coal reservoir and the electrolyte is increased by electric heating action, and desorption-diffusion characteristics of methane are improved. Under the combined action of electric drive, electric plug removal, electric permeability increase, electric heating and the like, the desorption and seepage capacity of the coal reservoir is effectively enhanced, gas production is improved by 3-10 times, and the recovery efficiency is improved to 60-90%.

Owner:TAIYUAN UNIV OF TECH

Method for coal uncovering in cross cut by hydrothermal coupling based coal fracturing

InactiveCN105003294APromote fissure developmentImprove good performanceFluid removalGas removalIsoetes triquetraCoupling

The invention discloses a method for coal uncovering in a cross cut by hydrothermal coupling based coal fracturing. The method includes: sequentially constructing a main fracturing hole, branched fracturing holes and guide holes in a rock stratum roadway section, wherein the main fracturing hole is formed in the center of an equilateral triangle, hole starting positions of the branched fracturing holes are arranged at three vertexes of the equilateral triangle while hole finishing positions of the same meet at a central line of the equilateral triangle, the guide holes are positioned on a circle taking the main fracturing hole as a circle center and with radius of 5-15m, and herein fracturing equipment comprises water injection equipment composed of an intelligent water tank and a fracturing pump and a powder injector; injecting quicklime powder in the powder injector into the main fracturing hole and the branched fracturing holes through underground air pressure; hydraulically fracturing the main fracturing hole through the water injection equipment, wherein the quicklime powder carried by high-pressure water enters fractures and thermally reacts with water to generate a lot of heat to realize coal uncovering in the cross cut through hydrothermal coupling based coal fracturing. By the method, ground stress and gas pressure of pre-uncovering coal seams are lowered, safety effect is remarkable, and cost is low.

Owner:SHANDONG UNIV OF SCI & TECH

Method using high-viscosity absorbent to separate CO2 based on dissolution assisting effect

ActiveCN105709566ALess quantityThe solubilizing effect is weakenedGas treatmentDispersed particle separationOrganic solventDesorption

The invention relates to a method using a high-viscosity absorbent to separate CO2 based on a dissolution assisting effect and belongs to the technical field of gas separation and the field of environment protection. The method is characterized in that due to the dissolution assisting effect of amine, a novel absorbent can be obtained by mixing an organic solvent which does not dissolve in water with the high-viscosity amine absorbent; the novel absorbent reacts with to-be-separated CO2, the novel absorbent forms liquid-liquid phases or liquid-solid phases due to the fact that the amine is reduced during the reaction and the dissolution assisting effect is weakened, and the two phases are respectively a CO2-loaded rich phase and a CO2-loaded poor phase; desorption is performed only on the CO2-loaded rich phase to obtain CO2; the absorbent after the desorption is mixed with the CO2-loaded poor phase to perform circulation absorption. The method has the advantages that the viscosity of the absorbent is lowered during the absorption, the concentration of the absorbent is increased during the desorption, the treatment quantity of a desorption unit is reduced, water evaporation amount and temperature rising energy consumption are lowered, and the high-viscosity absorbent can be used to separate the CO2 with low energy consumption.

Owner:BEIJING UNIV OF CHEM TECH

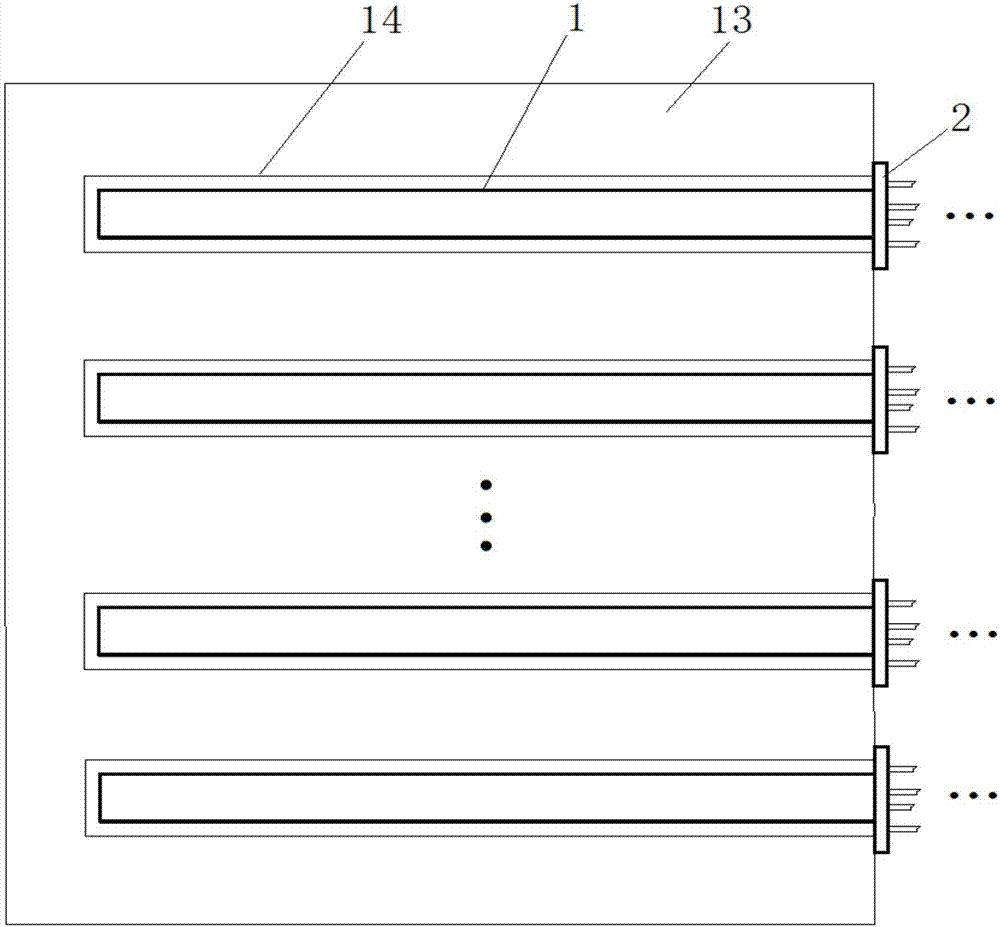

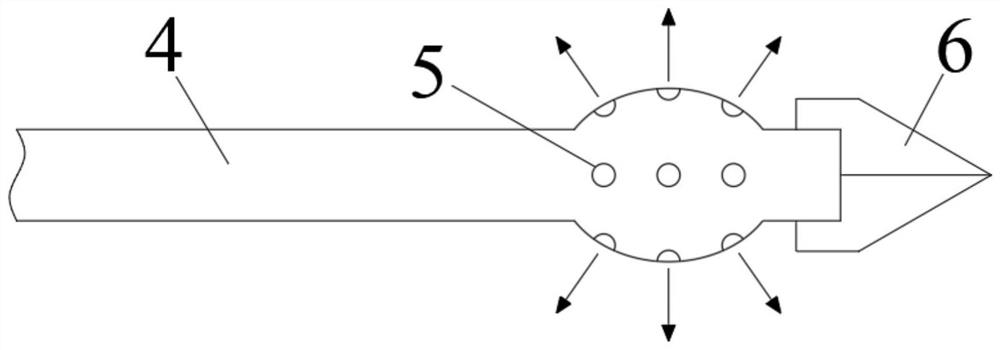

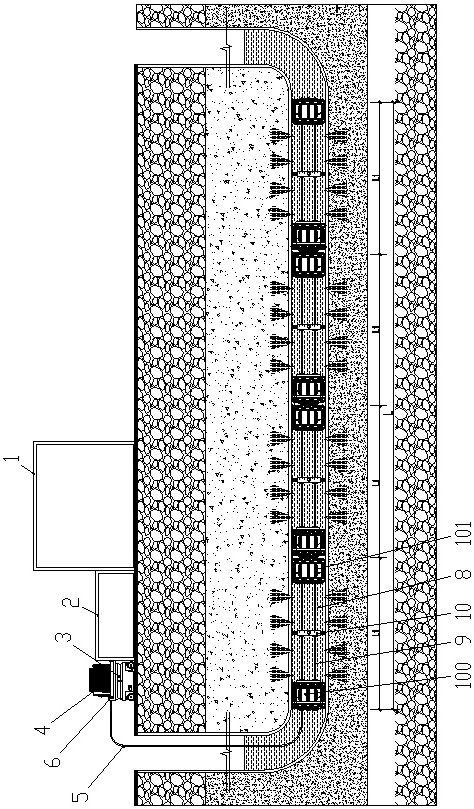

Device and method for desorption of gas in coal seam by utilizing ultrasonic principle

The invention discloses a device and method for desorption of gas in a coal seam by utilizing an ultrasonic principle. The device comprises a plurality of gas desorption columns disposed in each coal bed gas producing well. The side surfaces of column bodies of the gas desorption columns are provided with a plurality of gas nozzles and a plurality of ultrasonic wave emission heads connected with a ultrasonic generator; a gas inlet channel and a gas outlet channel are formed in each column body; a pressure sensor is disposed in each gas inlet channel; the gas inlet channel is connected with a gas feeding end of a gas compressor; a gas discharging end of the gas compressor is connected with the gas outlet channel; the gas outlet channel is connected with each gas nozzle; and the gas inlet channel is further connected with a gas output system via a gas discharging pipe equipped with a pressure limiting valve. Desorption of the gas in the coal seam can be obtained by ultrasonic waves; high-pressure injection airflows produced by the gas can be sprayed to the coal seam, so gas extraction can be assisted.

Owner:XIAN UNIV OF SCI & TECH

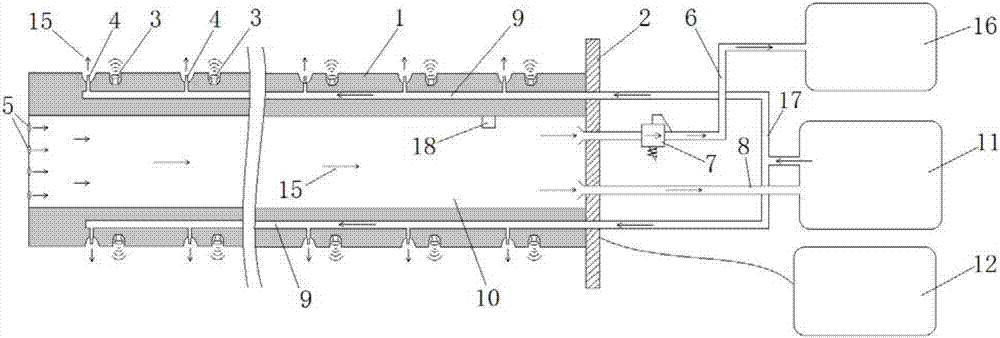

Recovery device and method of shale gas

PendingCN110185421AGood physical propertiesEnhanced overall recoverySurveyFluid removalDesorptionMicro fracture

The embodiment of the invention discloses a recovery device and method of shale gas, and relates to the technical field of energy extraction. The recovery device comprises a controller, a hole detection mechanism, an inherent frequency detection mechanism and a vibration generating mechanism; the inherent frequency detection mechanism detects the inherent frequency of a destination layer where perforation holes are located and sends the inherent frequency to the controller; through artificial intelligence control, the vibration frequency of the vibration generating mechanism is adjusted to enable the destination layer to resonate, under a resonant state, methane molecules adsorbed on the surface of a shale matrix are induced to be desorbed, thus the desorbed gas amount is increased, and meanwhile micro fractures continue being generated along the shale bedding surface and continuously extend towards the far end; the permeability of shale of the part is effectively improved, and then the recovery rate of unconventional natural gas is increased; and the condition for generating pressure expansion can further be caused in the shale, thus the tail ends of micropores in the shale continue being fractured and expanded internally to form shale gaps and cracks, and the diffusion and desorption processes of the shale gas are accelerated so as to increase the recovery rate of a shale gaswell.

Owner:龚雨诗

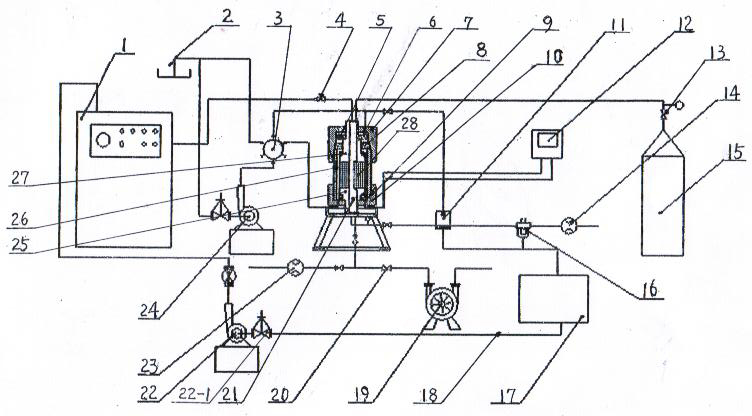

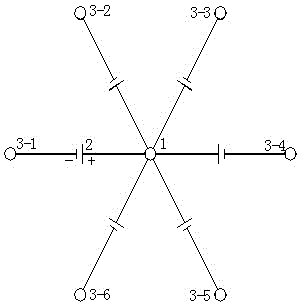

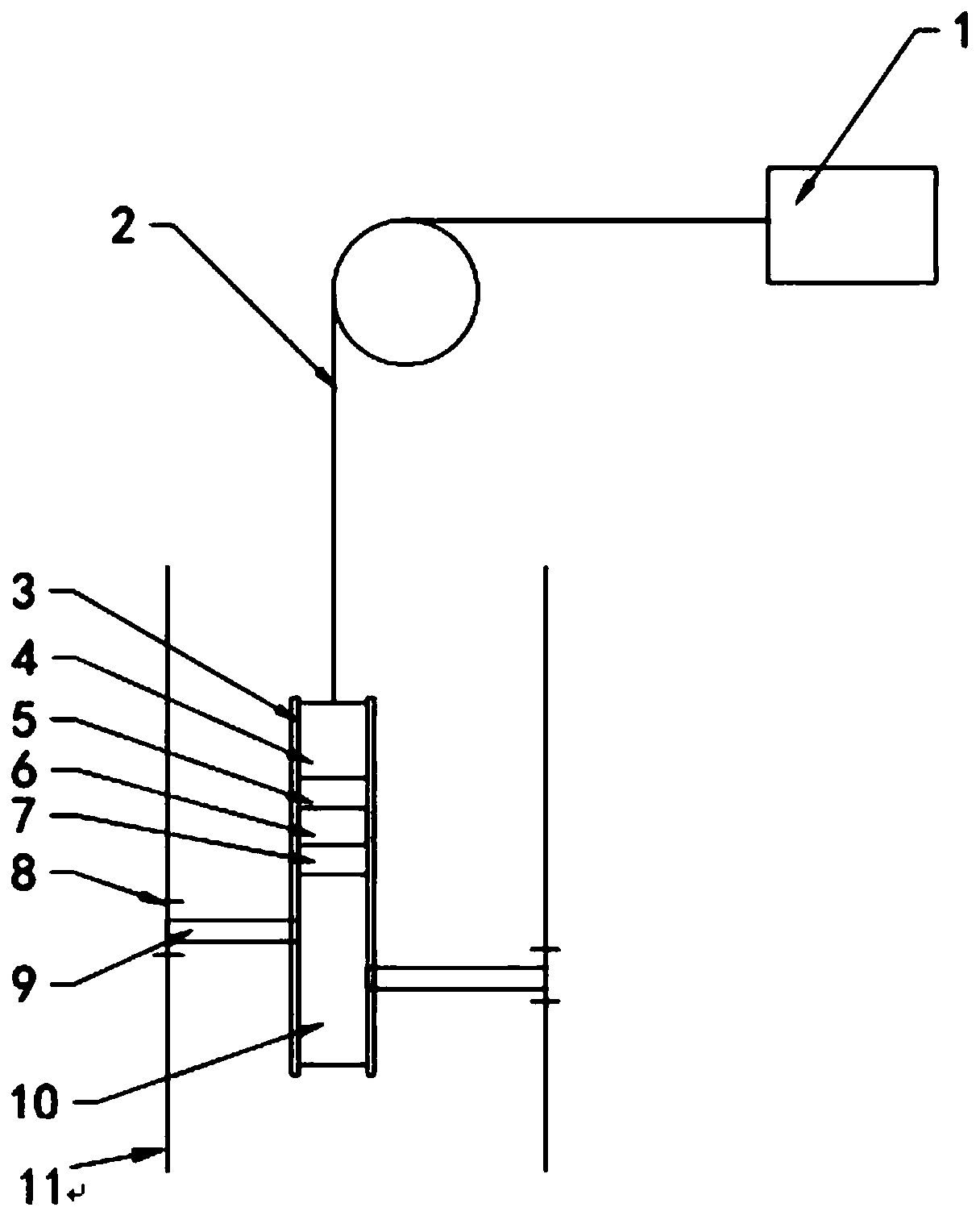

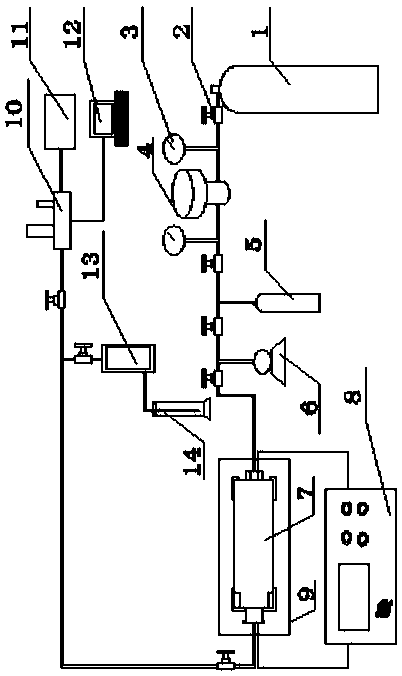

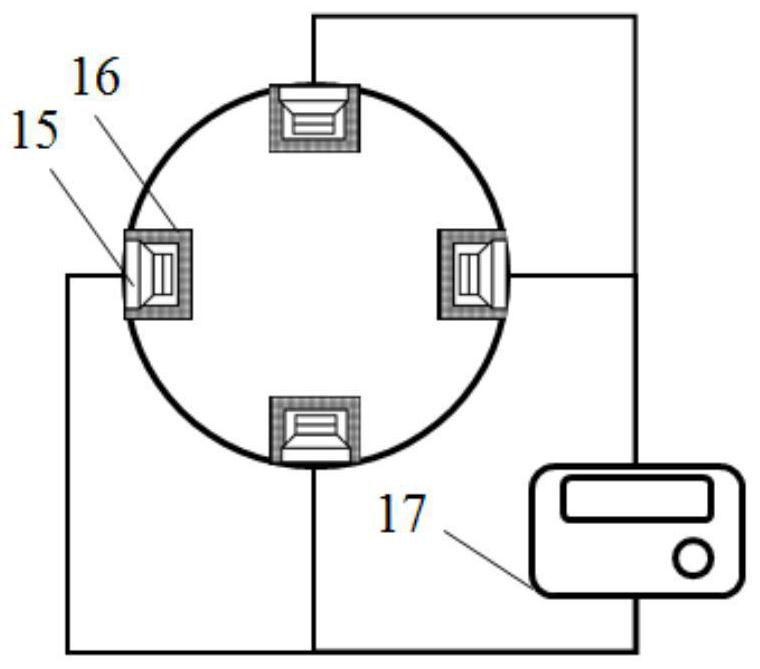

System and method for judging competitive field intensity of gas adsorption and desorption

PendingCN108593492AIncrease desorption rateIncrease desorptionMaterial analysisWater bathsDesorption

The invention relates to a system and a method for judging competitive field intensity of gas adsorption and desorption. The system comprises a methane tank, a valve, a pressure gauge, a pressure regulating valve, a reference cylinder, a vacuum pump, a clamp device, a high-voltage power source, a constant-temperature water bath box, a flow rate sensor, a gas collecting box, a computer and a gas water drain device, wherein the clamp device comprises a cylinder body, and a coal sample cylinder is arranged in the cylinder body; a left electrode plate and a right electrode plate are arranged at both ends of the coal sample cylinder, and are respectively connected with an anode and a cathode of the high-voltage power source; the methane tank is connected with a gas inlet of the clamp device; agas outlet of the clamp device is connected with a gas exhaust pipeline, and the tail end of the gas exhaust pipeline is connected with the gas collecting box; the gas water drain device comprises a first metering cylinder and a second metering cylinder; the first metering cylinder is connected with the gas outlet of the clamp device, and the first metering cylinder is connected with the second metering cylinder. The system and the method have the advantage that the gas adsorption and desorption are measured by externally adding different electric fields, so as to obtain the gas adsorption anddesorption rule, find the competitive field intensity of gas extraction rate, and provide powerful experiment support for the recovery of coal beds.

Owner:HENAN POLYTECHNIC UNIV

Reinforced gas extraction method based on phase change pulse wave

ActiveCN110836123ADrainage implementationSolving technical deficiencies in extractionFluid removalGas removalLiquid carbonPulse wave

The invention discloses a reinforced gas extraction method based on a phase change pulse wave. The method comprises the following steps of: firstly, constructing phase change cracking holes on the roadway side of a vertical coal seam, respectively constructing pulse induction holes at 10m positions of the two ends of the phase change cracking holes, arranging phase change cracking pipes in the phase change cracking holes, arranging a gas extraction pipe and a pulse sensor in the pulse induction holes, connecting the pulse sensor with a monitoring station, connecting the phase change cracking pipes with a liquid carbon dioxide storage station through a pressure reducer, connecting the pressure reducer with a pulse frequency modulator through a cable, changing a liquid carbon dioxide phase into gaseous carbon dioxide by controlling the pressure reducer, entering the gaseous carbon dioxide into the phase change cracking holes to crack the coal seam to generate a crack, controlling the pulse wave frequency modulator, so that the gaseous carbon dioxide generates a pulse effect and the gaseous carbon dioxide generates pulse wave crack on the coal seam, and realizing the reinforced gas extraction based on the phase change pulse wave. Through the reinforced gas extraction method based on the phase change pulse wave, the gas desorption amount is large, the gas extraction effect is obvious, the success rate is high, the cost is low, and the needs of gas control and other work in a coal mine field area are met.

Owner:SHANDONG UNIV OF SCI & TECH

Humidity/heat-exchange device e.g. plate heat exchanger, hygroscopic drum, adsorption damp-clearing dump or the like device

InactiveCN101107494ARapid regeneration abilityImprove adsorption capacityMaterial nanotechnologyGas treatmentEngineeringSorption

The invention relates to a humidity- and / or heat-exchange device, for example a plate heat exchanger a sorption rotor, an adsorption dehumidifying rotor or the similar, provided with humidity- and / or heat-exchange surfaces which make it possible to introduce humidity and / or heat into a fluid flow and / or to remove them therefrom and / or to exchange said humidity and / or heat between fluid flows. The inventive device is also provided with a coating, which makes it possible to cover said humidity and heat exchange surfaces and consists of a zeolithe material and a bonding agent. In order to improve the performance of the humidity- and / or heat-exchange device, the zeolithe material is embodied in the form of a synthetic nano-zeolithe consisting of particles whose size is < 1000 nm.

Owner:KLINGENBURG +1

Compound amine absorbent for absorbing sulfur dioxide and preparation method thereof

InactiveCN110124449ALow viscosityStrong selectivityGas treatmentDispersed particle separationAbsorption capacityDefoaming Agents

The invention provides a composite amine absorbent for absorbing sulfur dioxide and a preparation method thereof, belonging to the field of gas purification and recovery, and the composite amine absorbent comprises the following components in percentage by mass: 30-50% of piperazine and derivatives thereof, 0.5-10% of an activator, 1-5% of a pH corrosion inhibiting solution, 0.1-0.5% of a defoaming agent and the balance of water. The preparation method comprises the following steps of: adding the piperazine and derivatives thereof, the activator, the pH corrosion inhibitor and the defoaming agent into the water according to a certain proportion, dissolving and stirring uniformly. The composite amine for absorbing the sulfur dioxide gas adopts the piperazine as an absorbent main body, and has the characteristics of low viscosity and strong sulfur dioxide absorption selectivity; the saturated absorption capacity can reach 2.6 mol / mol of amine, and the composite amine absorbent has a highdesorption capacity of 1.53 mol / mol. Compared with that of absorption solutions commonly used in industry, the desorption capacity of the composite amine absorbent after multiple absorption can stillreach more than 98%. In addition, the composite amine absorbent is added with a pH slow release liquid to reduce the corrosivity of the amine absorbent to equipment.

Owner:西安悟能环境工程有限公司

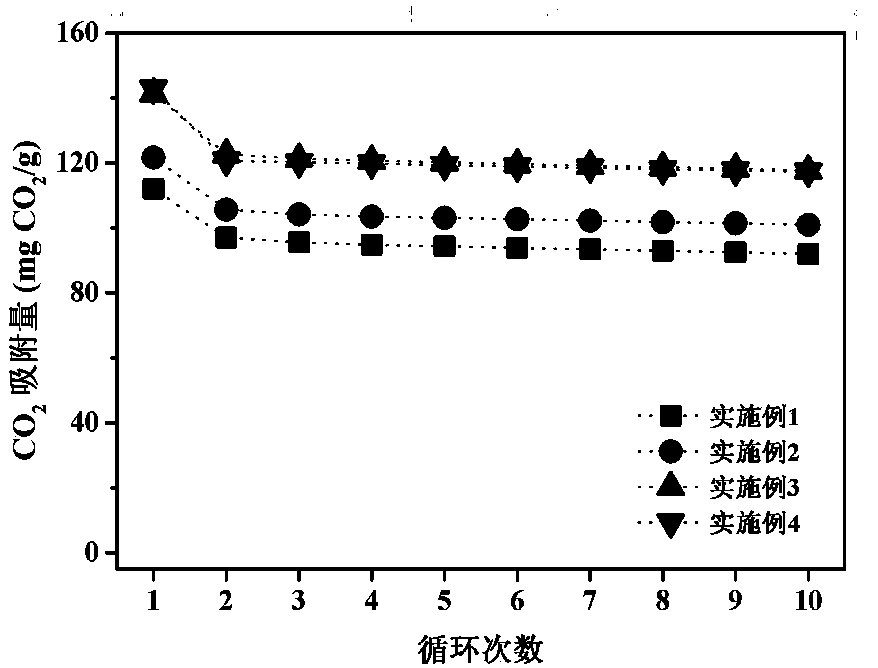

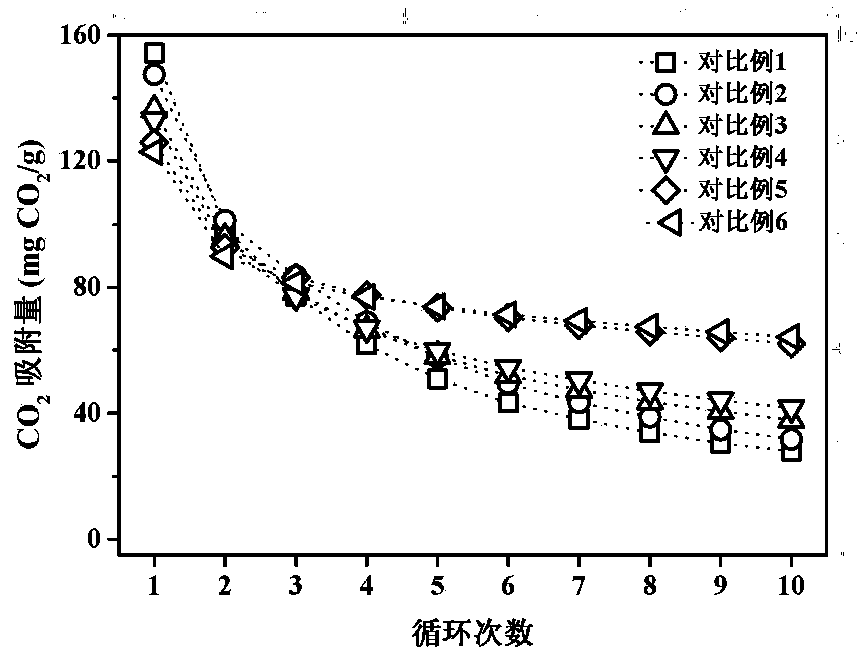

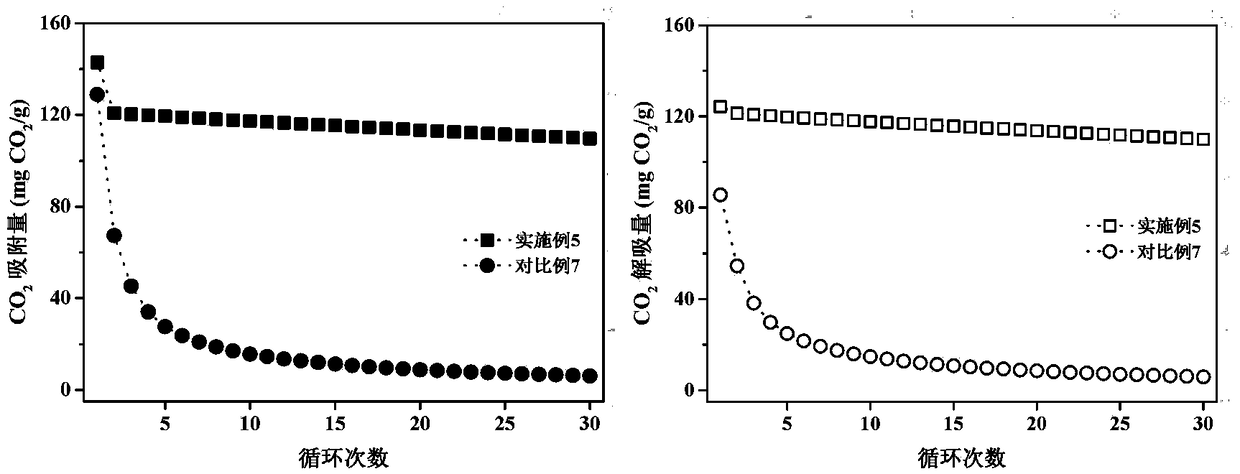

Preparation method of solid adsorption material for biogas decarburizing purification

ActiveCN108404883AImprove cycle stabilityMitigation of inactivation problemsOther chemical processesGaseous fuelsSolventIon

Disclosed is a preparation method of a solid adsorption material for biogas decarburizing purification. The preparation method includes pretreating NKA-9, to be specific, filling a resin column with NKA-9, washing NKA-9 with deionized water until generating out-flowing water without any white turbidity; soaking NKA-9 with HNO3 solution, washing NKA-9 with deionized water until generating out-flowing water with neutral pH value; drying cleaned NKA-9 in an oven until its weight is constant; loading organic amine to NKA-9; weighing BPEI, dissolving BPEI completely with stirring at the room temperature by taking absolute methanol as a solvent; weighing pretreated NKA-9 and pouring the same into BPEI dissolved solution, further adding absolute methanol to wash NKA-9 on the wall of a container;stirring systematically until the solvent volatilizes completely; subjecting residues to vacuum drying in a vacuum drying box to obtain the solid adsorption material. The solid adsorption material hashigh adsorption capacity and high stability in adsorption-desorption circulation.

Owner:TSINGHUA UNIV

Infrared method for improving coal bed gas extraction rate

InactiveCN104481471AImprove extraction speedIncrease kinetic energyFluid removalGas removalDesorptionControl line

The invention discloses an infrared method for improving a coal bed gas extraction rate. The infrared method for improving the coal bed gas extraction rate comprises the following steps of (1) measuring coal bed physicochemical properties and primarily designing a plurality of groups of infrared parameter schemes; (2) digging a bottom extraction channel or a top extraction channel along a coal bed, punching a transformation hole from the bottom extraction channel or the top extraction channel to the coal bed and arranging extraction drilling holes in the lateral side of the transformation hole; (3) placing an infrared radiation pipe at a coal bed section of the transformation hole, sealing the transformation hole and the extraction drilling holes, directly connecting the extraction drilling holes to a gas extraction pipeline and connecting an infrared control line of the infrared radiation pipe to an infrared controller; (4) opening the infrared controller and continuously irradiating the coal bed through infrared light waves; (5) selecting an optimal parameter scheme with the extraction amount, the extraction concentration and the extraction rate being served as judgment criterions and adjusting an infrared parameter of an integral extraction area construction unit to be an optimal parameter scheme. The infrared method for improving the coal bed gas extraction rate can increase the coal bed gas desorption volume.

Owner:HENAN POLYTECHNIC UNIV

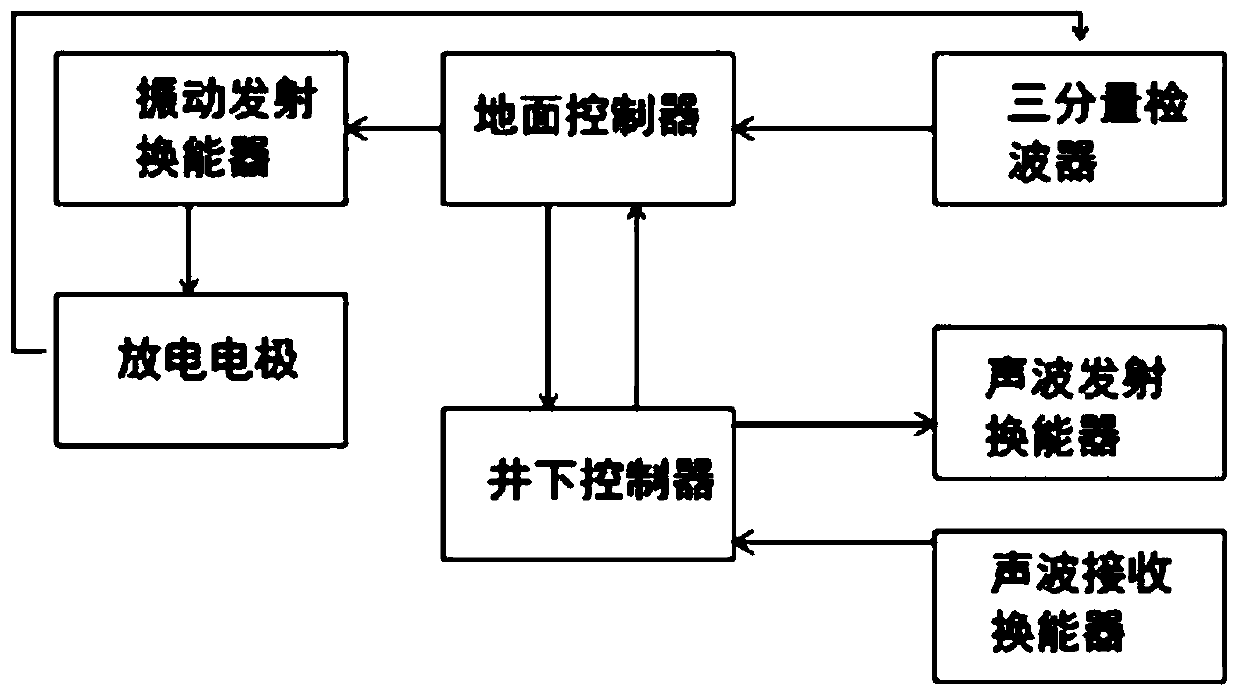

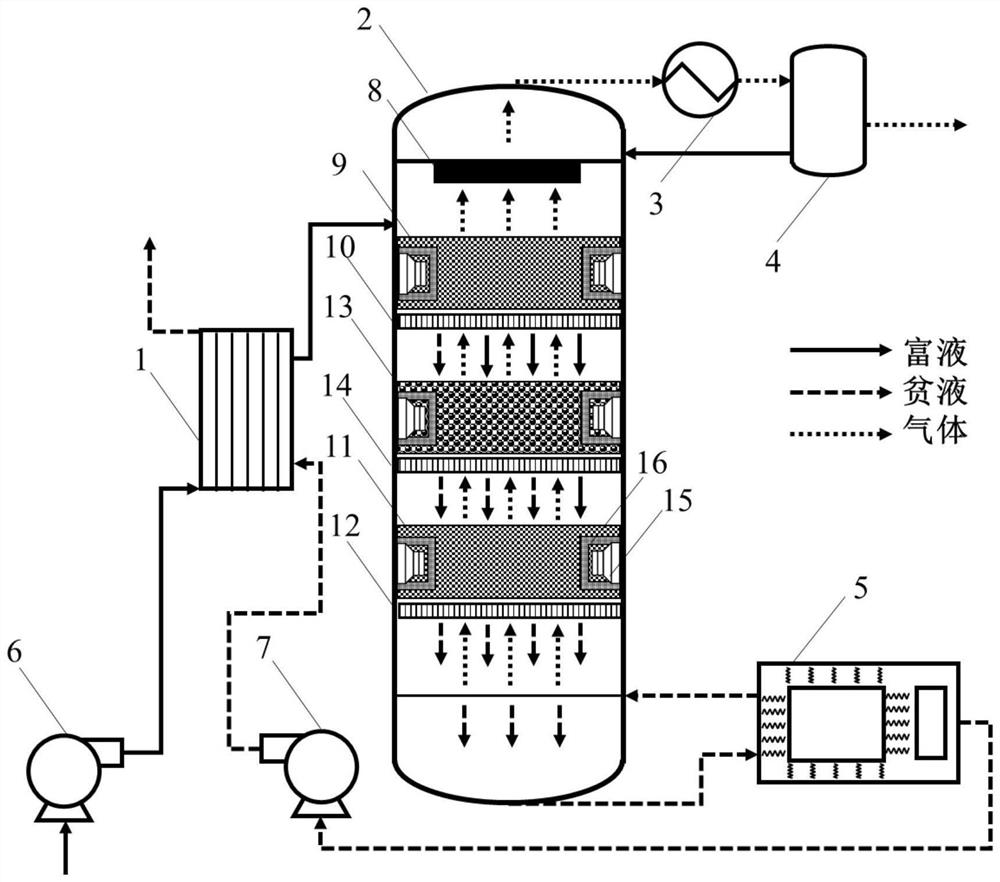

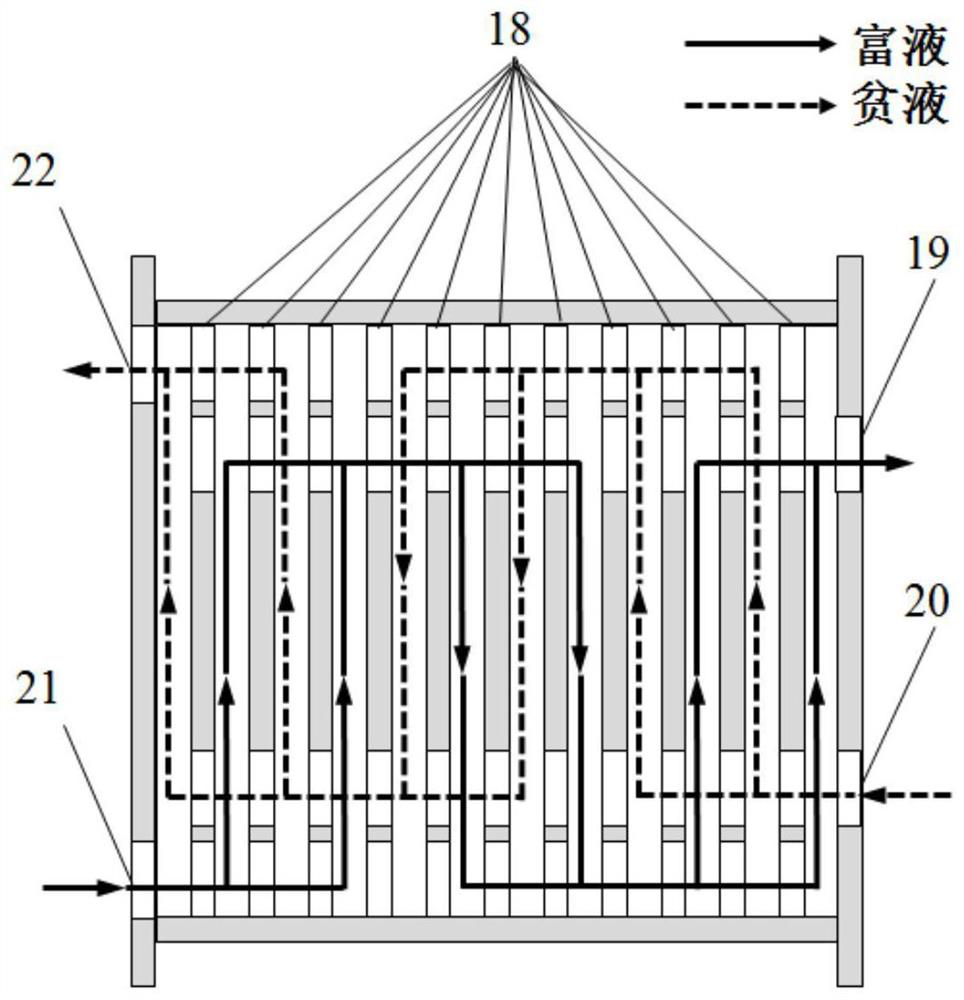

Low-energy-consumption desorption system and method for carbon dioxide through cooperation of catalyst and external field reinforcement

ActiveCN114699883ALower activation energyIncrease speedGas treatmentDispersed particle separationThermodynamicsPtru catalyst

The invention relates to a low-energy-consumption desorption system and a low-energy-consumption desorption method for carbon dioxide through cooperation of a catalyst and an external field. Rich liquor absorbing CO2 is conveyed through a rich liquor conveying pump, and the rich liquor and barren liquor conveyed through a barren liquor conveying pump after desorption are subjected to heat exchange in a barren liquor and rich liquor heat exchanger to be heated; the heated rich solution enters a desorption tower, the regenerated barren solution is vaporized by a microwave reboiler and then provides desorption energy for the rich solution in the desorption tower, the barren solution vaporized by the microwave reboiler is in reverse contact with the rich solution, and the contact area sequentially comprises a filler area with an ultrasonic strengthening area and a catalytic area with the ultrasonic strengthening area from top to bottom; the desorbed gas mixture is cooled by a gas-liquid cooler, and liquid obtained after gas-liquid separation by a gas-liquid separator is continuously injected into the desorption tower for circulation; and the energy consumption is reduced by more than 40%. The low-energy-consumption desorption of the carbon dioxide is realized under the action of the catalyst cooperating with the external fields such as the ultrasonic field / microwave electromagnetic field.

Owner:ZHEJIANG UNIV +1

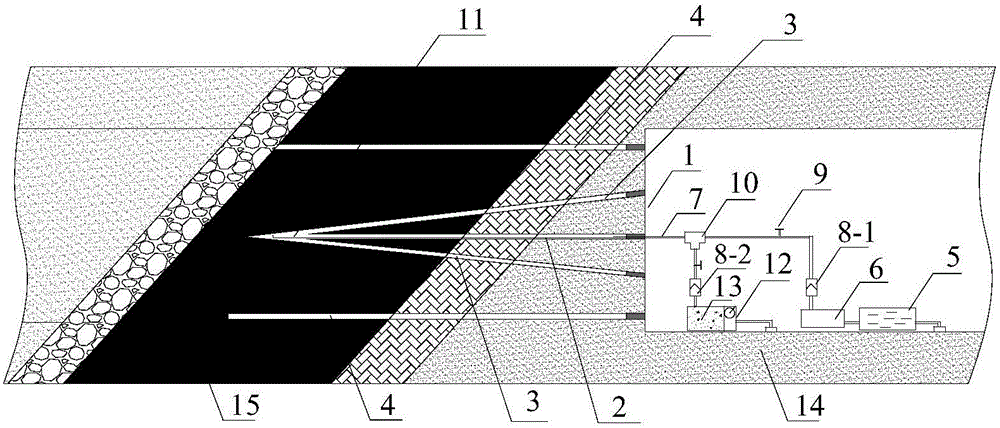

Method for strengthening gas extraction through cooperation of hydraulic punching and cave forming and steam injection

ActiveCN114183114AIncrease temperatureReduce adsorptionLiquid/gas jet drillingFluid removalThermodynamicsPunching

The invention discloses a method for strengthening gas extraction through cooperation of hydraulic punching and cave building and steam injection, which comprises the following steps: firstly, drilling a layer-crossing drill hole in a coal seam, injecting high-pressure water into the drill hole for hydraulic punching, so as to form a punching hole in the drill hole, and forming a plurality of cracks around the punching hole; then discharging residues and waste water in the punching hole through a gas-slag separator, and extracting gas; after gas extraction is conducted for a certain time, high-temperature and high-pressure steam is injected into the punching hole, the high-temperature and high-pressure steam exchanges heat with the coal seam after entering the punching hole, the steam enters cracks of the coal seam to further apply pressure, and the cracks of the coal seam are further expanded and developed to achieve secondary fracturing after being subjected to the effects of high temperature and high pressure; and finally, under the multiple actions of high-temperature hydraulic punching, secondary fracturing of high-temperature and high-pressure steam and reduction of coal seam adsorbability, yield increase of gas extraction is achieved. According to the method, the coal seam gas extraction effect can be effectively improved and lasts for a long time, and meanwhile the workload of drilling construction is reduced.

Owner:CHINA UNIV OF MINING & TECH +1

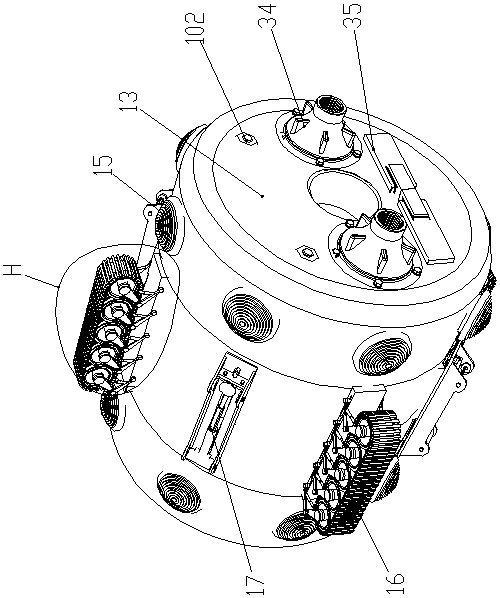

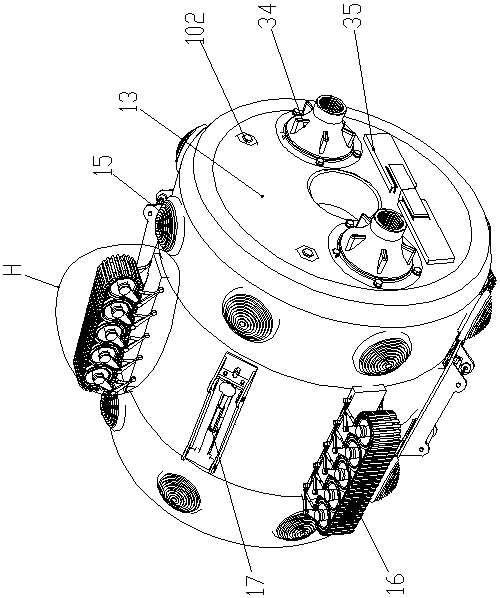

Coal seam heating and pulverized coal removing method

ActiveCN111119822AImprove mobilityAvoid breakingCleaning apparatusInsulationThermodynamicsProcess engineering

The invention discloses a coal seam heating and pulverized coal removing method. The method comprises the following steps that firstly, the length of a coal seam to be subjected to thermal recovery isL, a ground control center, a generator and a ground wire winding vehicle are arranged on the ground above the coal seam, an intelligent cable winch is arranged on the ground wire winding vehicle, ahigh-temperature-resistant tensile cable is wound around the intelligent cable winch, and a first tension sensor is arranged at the wire outlet end of the intelligent cable winch; and n hollow pipeline robot groups are assembled, one end of the high-temperature-resistant tensile cable is connected with the generator, and the other end of the high-temperature-resistant tensile cable is connected with the rearmost hollow pipeline robot group. In conclusion, the method is high in automation degree, convenient to operate and good in pulverized coal removing effect, and the coalbed methane mining efficiency is improved.

Owner:SHANXI SHANDI GEOPHYSICAL SURVEY TECH CO LTD

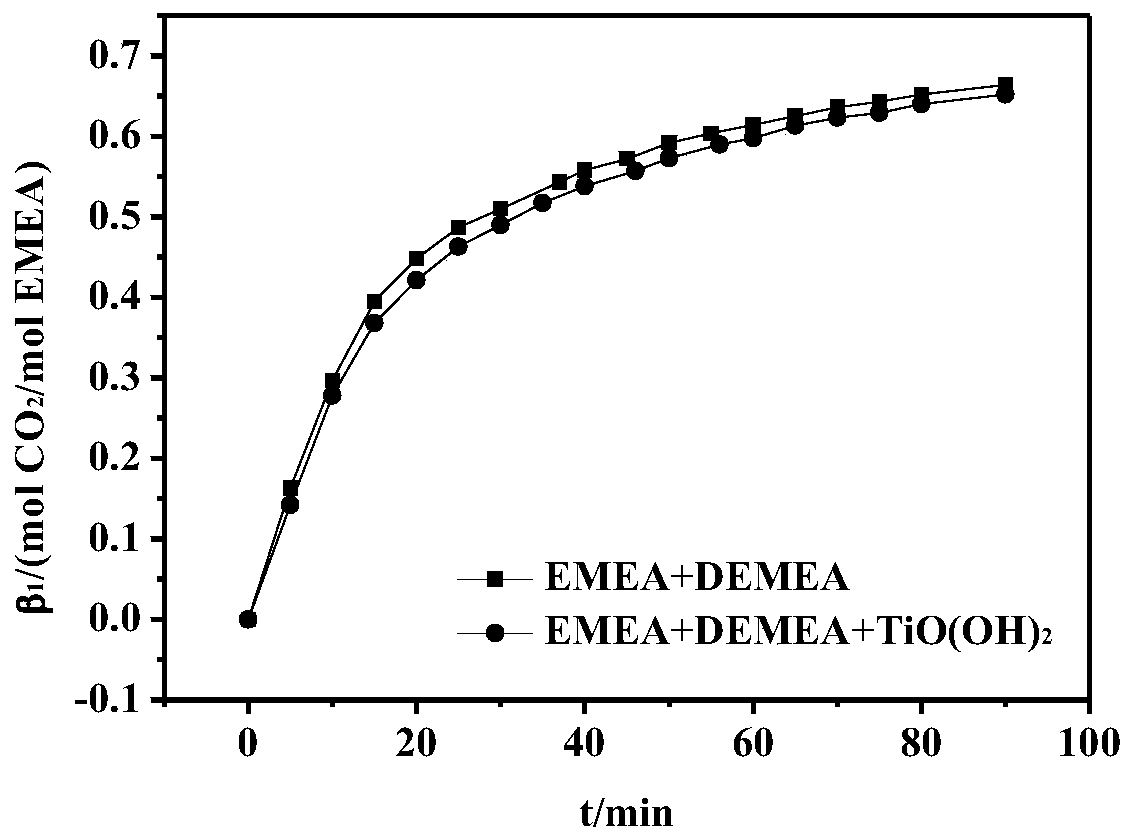

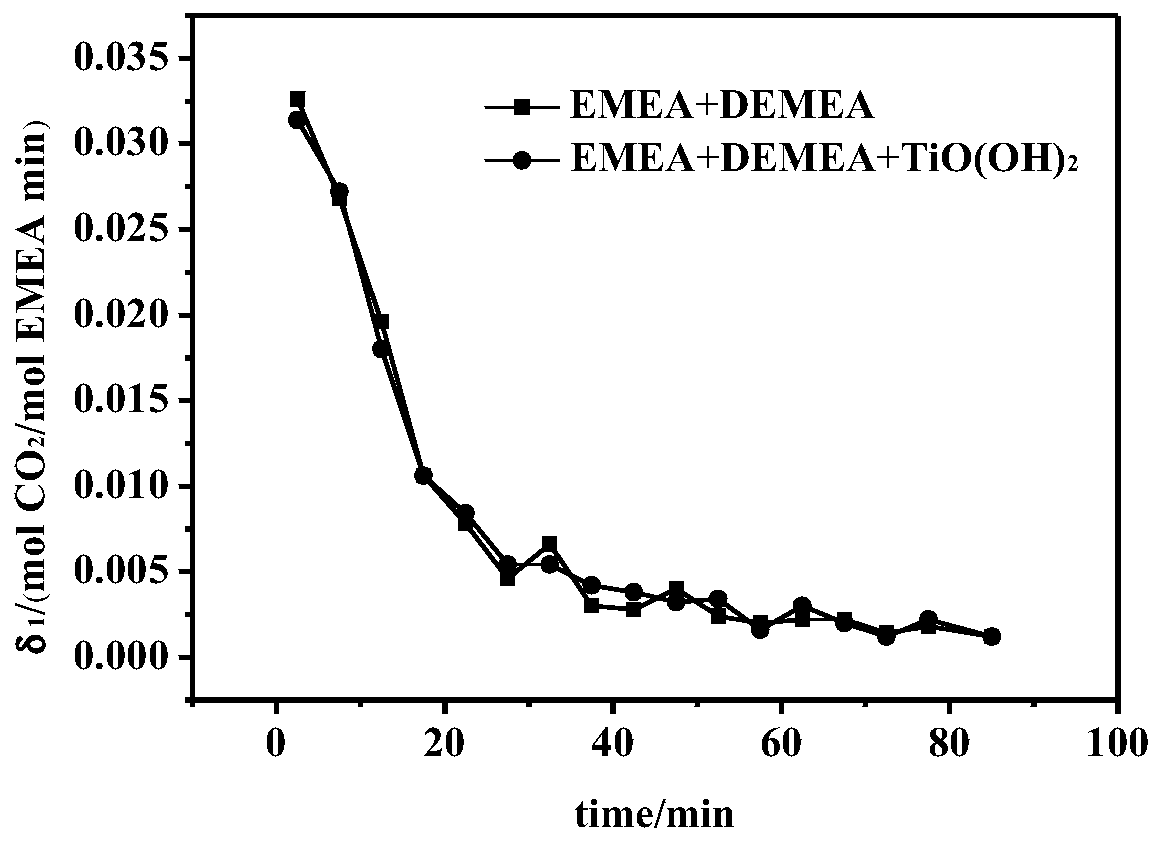

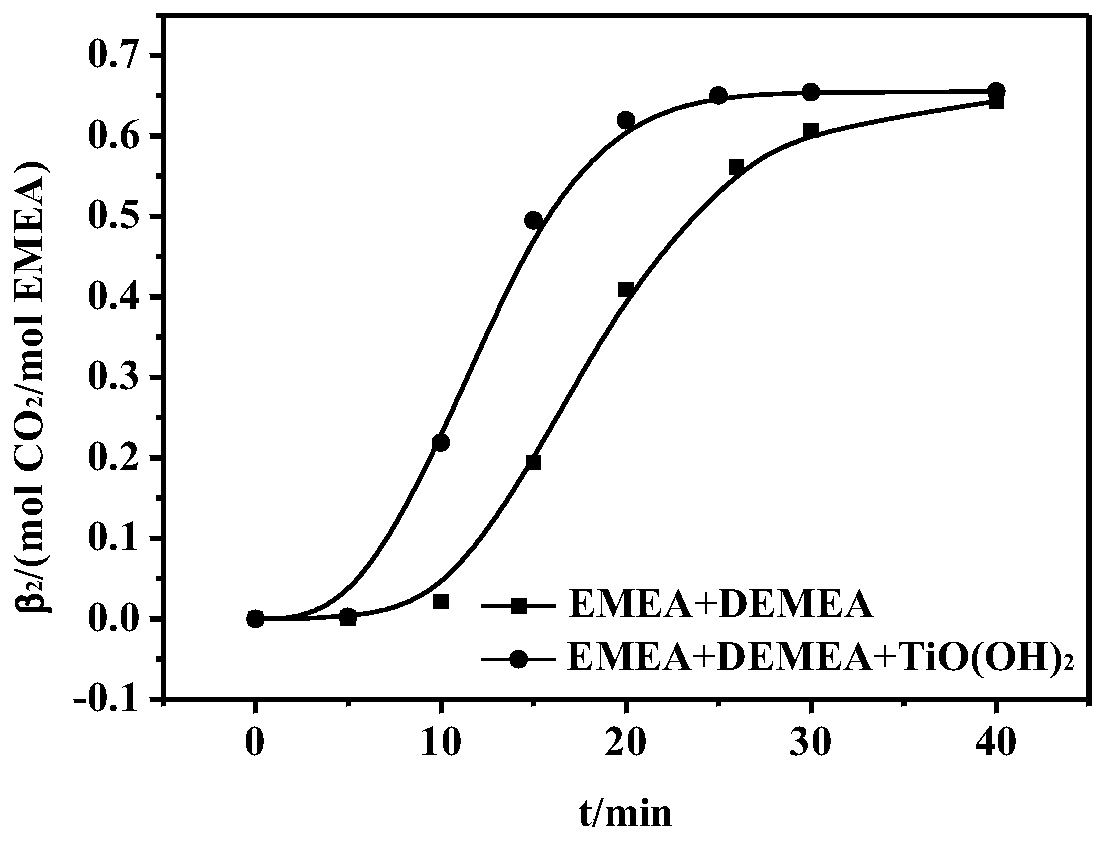

A two-phase mixture for capturing carbon dioxide

ActiveCN106984152BPromote regenerationIncrease speedGas treatmentDispersed particle separationEthylene diamineDesorption

The invention provides a novel two-phase mixture for trapping carbon dioxide, and belongs to the field of technologies for trapping carbon dioxide gas. The novel two-phase mixture comprises two phases including, by weight, 99.0-99.5 wt% of non-aqueous solution and 0.5-1.0 wt% of porous solid materials. The non-aqueous solution comprises, by weight, 30-50 wt% of solutes and 50-70 wt% of solvents, and the solutes are N-ethylethanolamine; the solvents are N, N-diethyl ethylene diamine. The solid porous materials are TiO (OH) 2. The novel two-phase mixture has the advantages that the non-aqueous solution is modified by the TiO (OH) 2, absorption effects of the non-aqueous solution cannot be improved by the TiO (OH) 2, but the desorption rate can be greatly increased by the TiO (OH) 2, the optimal desorption rate can reach 250 Nm<3> CO2 / m<3> solution, and the desorption rate can be increased as compared with the original non-aqueous solution.

Owner:DALIAN UNIV OF TECH

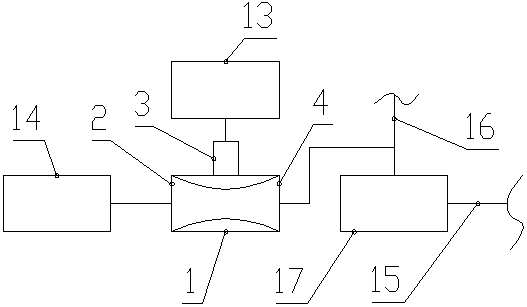

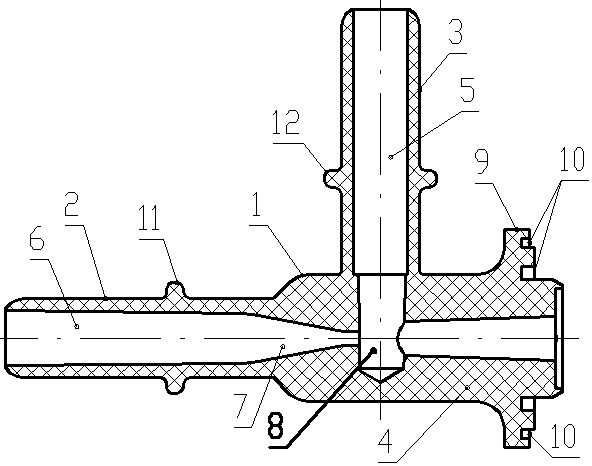

Carbon tank desorption mechanism for motor vehicle

InactiveCN108533423AImprove sealingReduce defective rateNon-fuel substance addition to fuelMachines/enginesDesorptionAir filter

The invention discloses a carbon tank desorption mechanism for a motor vehicle. The carbon tank desorption mechanism comprises a carbon tank, an air filter and an engine supercharger mounted in the motor vehicle, and a Venturi tube, wherein the air filter is connected with an air inlet pipe and an air outlet pipe; the engine supercharger is provided with an air inlet end and an air outlet end; theVenturi tube comprises a shell; the shell comprises an air inlet pipe segment, a desorption pipe segment and an exhaust pipe segment; the air inlet pipe segment of the Venturi tube is connected withthe air outlet end of the engine supercharger; the exhaust pipe segment of the Venturi tube is connected with the air outlet pipe of the air filter; the desorption pipe segment of the Venturi tube isconnected with the carbon tank. The carbon tank desorption mechanism has lower negative influence on an engine, and has a better desorption effect. The Venturi tube is made by one-time injection molding, so that the sealing performance is much more greatly enhanced than before, the defective rate is greatly reduced, and the overall cost of the product is lowered.

Owner:PINGYUAN FILTER

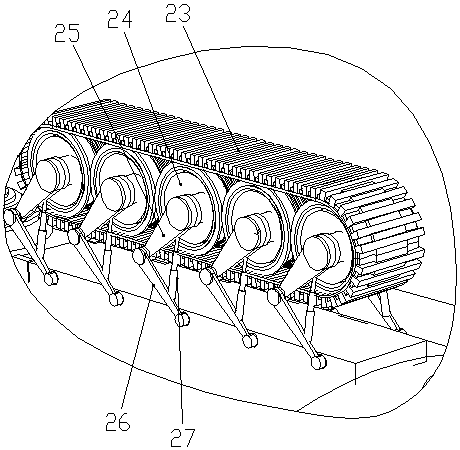

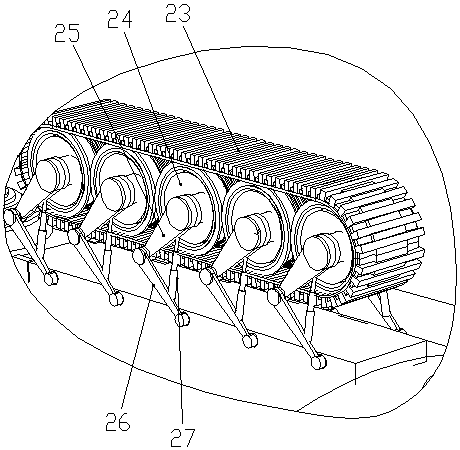

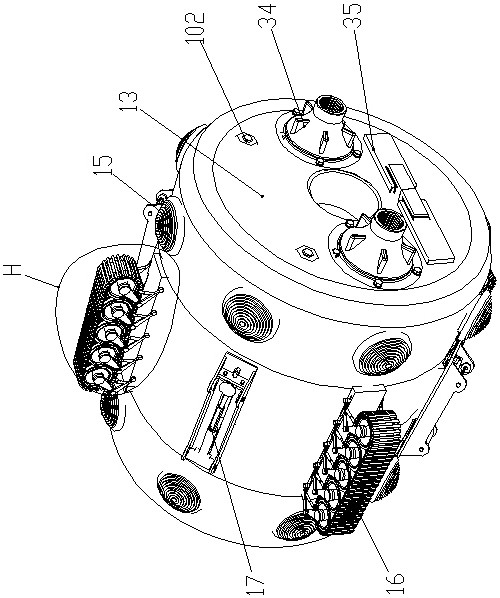

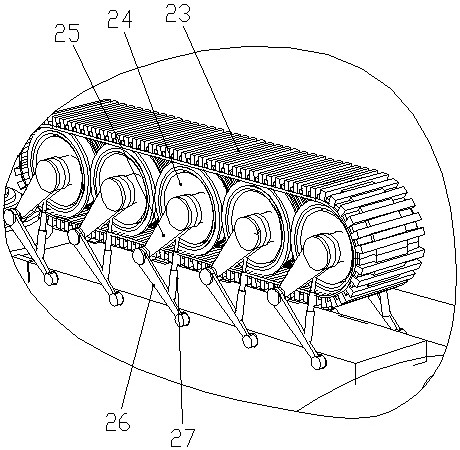

Pipeline robot used for coal seam heating and pulverized coal removing

ActiveCN111119823AImprove mobilityAvoid breakingCleaning apparatusInsulationThermodynamicsProcess engineering

The invention provides a pipeline robot used for coal seam heating and pulverized coal removing. The pipeline robot used for coal seam heating and pulverized coal removing comprises a ground wire winding vehicle, a generator, a ground control center and a plurality of groups of hollow pipeline robot sets, an intelligent cable winch is arranged on the ground wire winding vehicle, and a high-temperature-resistant tensile cable is wound on the intelligent cable winch; a plurality of groups of pipeline robots are connected through resistance wires. According to the pipeline robot used for coal seam heating and pulverized coal removing, the multiple groups of pipeline robots are connected through resistance wires, each group of pipeline robots form a relatively sealed space through forms of high-temperature-resistant air bags, electric valve sealing and the like, a high-temperature water-gas mixture generated by heating fracturing water flow by utilizing the resistance wires is pressed intoa coal seam, gas desorption is increased, the permeability of the coal seam is improved, reinforced extraction of the coal-bed methane is realized; and moreover, the multiple groups of pipeline robots have the function of removing pulverized coal, so that the gas production efficiency and the gas production rate of a coal-bed gas well are improved.

Owner:TAIYUAN UNIV OF TECH

Self-cooling type solid desiccant cooling dehumidification air-conditioning system

ActiveCN102721133BReduce the temperatureDecrease the equilibrium adsorption temperatureSpace heating and ventilation safety systemsLighting and heating apparatusThermal energyDesorption

The invention discloses a self-cooling type solid desiccant cooling dehumidification air-conditioning system. The air-conditioning system comprises a cooling dehumidification system and a heating regeneration system which are connected with each other. Dehumidifying heat exchangers formed by enabling solid dehumidifying materials to be attached to surfaces of finned tube type heat exchangers independently performing sensible heat exchange traditionally are adopted in the cooling dehumidification system and the heating regeneration system. Dehumidifying turning wheels are replaced by the dehumidifying heat exchangers. In the dehumidification process, chilled water generated by regenerating evaporating cooling is led into the dehumidifying heat exchangers, so that a self-cooling type low temperature inner heat source is formed, and cooling is carried out in the desiccant dehumidification process; in the regenerating process, hot water generated through low-grade heat energy serves as a heating inner heat source to be led into the desiccant desorption process; and by switching the dehumidification process and the regenerating process, thermodynamic cycle for continuous refrigeration is achieved. Compared with a dehumidifying turning wheel system, the self-cooling type solid desiccant cooling dehumidification air-conditioning system not only has the advantages of being small in size and low in cost, but also can achieve the self-cooling type cooling dehumidification process, and the efficiency of the whole system is greatly improved.

Owner:SHANGHAI JIAOTONG UNIV

A Method for Separating CO2 Using High Viscosity Absorbent Based on Solubilizing Effect

ActiveCN105709566BLess quantityThe solubilizing effect is weakenedGas treatmentDispersed particle separationOrganic solventDesorption

The invention relates to a method using a high-viscosity absorbent to separate CO2 based on a dissolution assisting effect and belongs to the technical field of gas separation and the field of environment protection. The method is characterized in that due to the dissolution assisting effect of amine, a novel absorbent can be obtained by mixing an organic solvent which does not dissolve in water with the high-viscosity amine absorbent; the novel absorbent reacts with to-be-separated CO2, the novel absorbent forms liquid-liquid phases or liquid-solid phases due to the fact that the amine is reduced during the reaction and the dissolution assisting effect is weakened, and the two phases are respectively a CO2-loaded rich phase and a CO2-loaded poor phase; desorption is performed only on the CO2-loaded rich phase to obtain CO2; the absorbent after the desorption is mixed with the CO2-loaded poor phase to perform circulation absorption. The method has the advantages that the viscosity of the absorbent is lowered during the absorption, the concentration of the absorbent is increased during the desorption, the treatment quantity of a desorption unit is reduced, water evaporation amount and temperature rising energy consumption are lowered, and the high-viscosity absorbent can be used to separate the CO2 with low energy consumption.

Owner:BEIJING UNIV OF CHEM TECH

Compound decarburization solution for recovering carbon dioxide in gas mixture

ActiveCN100493673CPromote absorptionIncrease desorptionProductsCarbon compoundsChemical industryAbsorption capacity

The invention belongs to the gas separation technology area, it relates to a decarbonization solution which recycles or removes the carbon dioxide gas from the mixed gas which contains carbon dioxide, said invention specially relates to an ethoxyl ethylenediamine decarbonization solution. Its characteristic lies in: the invention has designed a new compound decarbonization solution which is composed of the main absorption component, the aid absorption component, the activation component, the corrosion inhibitor, the oxidation inhibitor and the water. Among, the main absorption component is AEE, the aid absorption component is AMP, MDEA and TEA, the activation component is MEA, DEA and PZ, the corrosion inhibitor is vitriol sour sodium, the oxidation inhibitor is the sodium sulfite and the cupric acetate. The effect and the profit of the invention are that it can be used in recycling many kinds of chemical industry reaction exhaust, the carbon dioxide of the combustion flue gas and the mixed gas, may also used in removing the carbon dioxide of town gas, the natural gas and so on, the merit of the decarbonization fluid is that the absorption capacity is big, purification is high, desorption rate is big, regeneration energy consumption is low.

Owner:DALIAN UNIV OF TECH

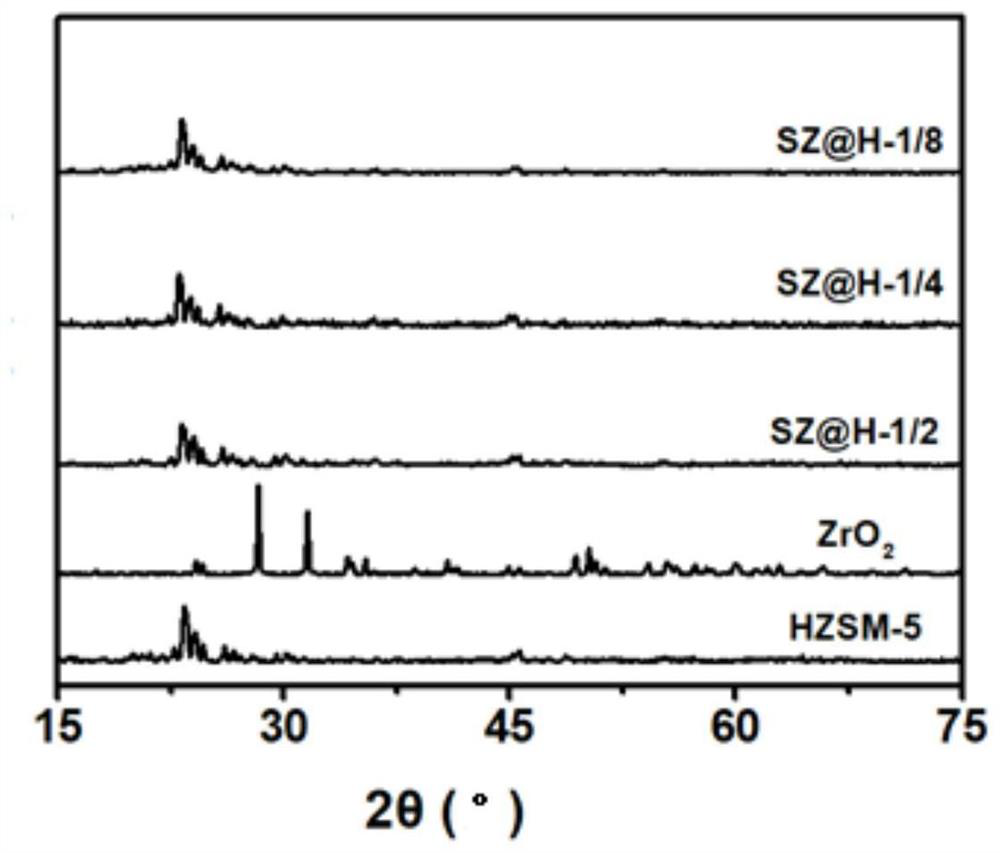

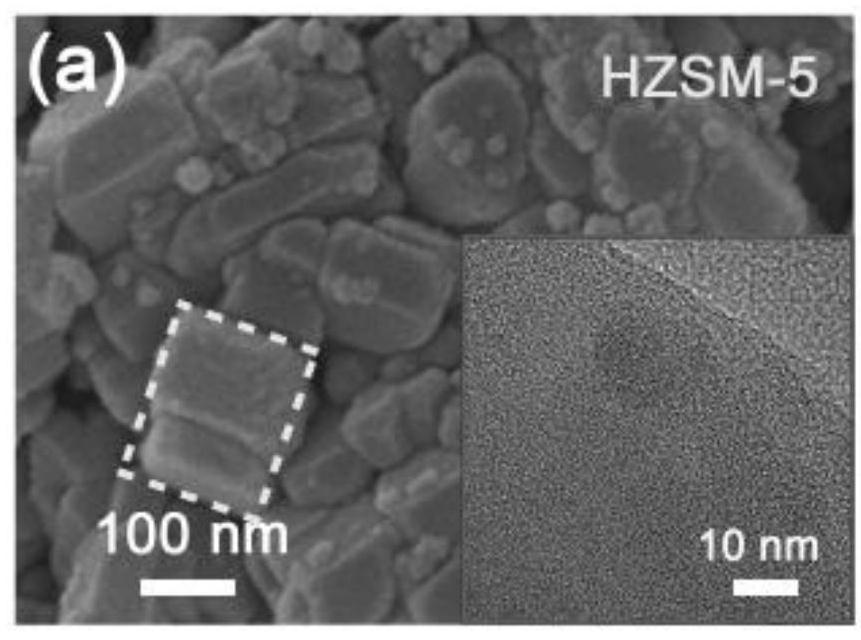

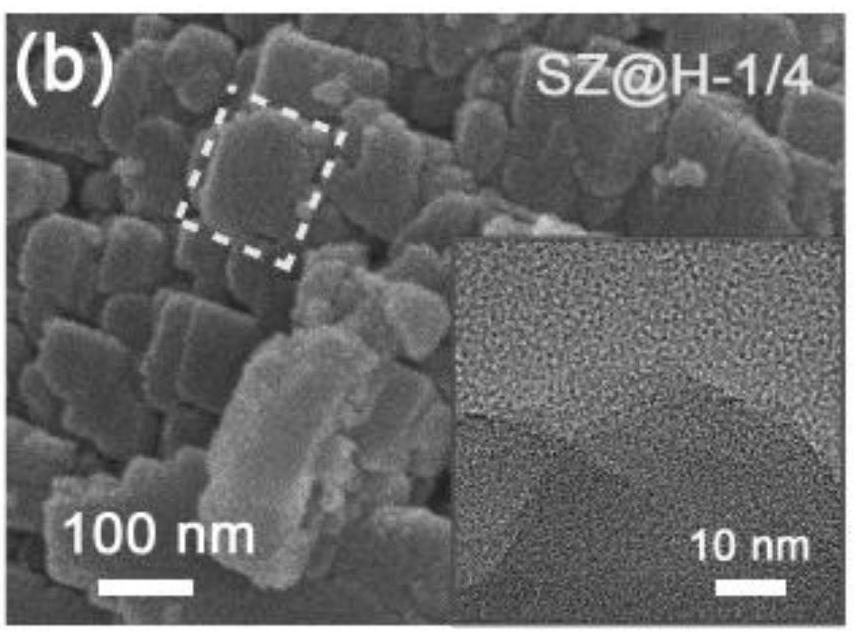

Preparation method and application of heterogeneous catalyst for desorbing CO2 in solution

InactiveCN111715274AGood recycling performanceSimple preparation processMolecular sieve catalystsDispersed particle separationPtru catalystCo2 absorption

The invention discloses a preparation method and application of a heterogeneous catalyst for desorbing CO2 in a solution, and belongs to the technical field of industrial boiler and power plant CO2 capture. The heterogeneous catalyst is prepared by loading SO4 < 2-> / metal oxide on an HZSM-5 carrier, and the method comprises the following specific steps: adding sulfate of a metal oxide into water,then adding an HZSM-5 carrier, heating and stirring, cooling and filtering to obtain a precipitate; and washing, drying and roasting the precipitate to obtain the SO4 < 2-> / metal oxide-HZSM-5 heterogeneous catalyst. The heterogeneous catalyst provided by the invention has the advantages that the absorption liquid can be promoted to desorb CO2, and the CO2 absorption performance of absorption liquid is improved; compared with the process of capturing the CO2 in the flue gas without adding a catalyst, the desorption rate is improved by 35-45%, the absorption efficiency is improved by 30-40%, thestability and the recycling performance are good, and the CO2 desorption energy consumption can be greatly reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Device and method for desorbing gas in coal seam by using ultrasonic principle

The invention discloses a device and method for desorption of gas in a coal seam by utilizing an ultrasonic principle. The device comprises a plurality of gas desorption columns disposed in each coal bed gas producing well. The side surfaces of column bodies of the gas desorption columns are provided with a plurality of gas nozzles and a plurality of ultrasonic wave emission heads connected with a ultrasonic generator; a gas inlet channel and a gas outlet channel are formed in each column body; a pressure sensor is disposed in each gas inlet channel; the gas inlet channel is connected with a gas feeding end of a gas compressor; a gas discharging end of the gas compressor is connected with the gas outlet channel; the gas outlet channel is connected with each gas nozzle; and the gas inlet channel is further connected with a gas output system via a gas discharging pipe equipped with a pressure limiting valve. Desorption of the gas in the coal seam can be obtained by ultrasonic waves; high-pressure injection airflows produced by the gas can be sprayed to the coal seam, so gas extraction can be assisted.

Owner:XIAN UNIV OF SCI & TECH

Coal Seam Heating and Coal Powder Removal Method

The coal seam heating and coal dust removal method comprises the following steps: step 1, the length of the coal seam to be thermally mined is L, and the ground control center, the generator and the ground coiler are placed on the ground above the coal seam, wherein the ground coiler is An intelligent cable winch is installed, and a high-temperature-resistant and tensile cable is wound on the intelligent cable winch. The machine phase is connected, and the other end of the high-temperature-resistant tensile cable is connected with the hollow pipeline robot group at the rear; in summary, the present invention has a high degree of automation, is easy to operate, has a good coal dust removal effect, and improves the mining efficiency of coalbed methane .

Owner:SHANXI SHANDI GEOPHYSICAL SURVEY TECH CO LTD

A Method for Strengthening Regional Gas Drainage with Hydrothermal Coupled Fracturing

InactiveCN105114116BSolve hydrothermal coupled fracturingRealize hydrothermal coupled fracturingFluid removalGas removalIsoetes triquetraHydraulic fracturing

The invention discloses a gas drainage method in a hydrothermal coupling fracturing strengthening area. Firstly, the main fracturing hole, branch fracturing holes and guide holes are sequentially constructed on the side of the coal seam, and the main fracturing holes are arranged in the center of an equilateral triangle. position, the opening positions of the branch fracturing holes are respectively arranged at the three vertices of the equilateral triangle, the positions of the final holes meet at the center line of the equilateral triangle, and the leading holes are located at the center of the main fracturing hole, On a circle with a radius of 5-15m; the fracturing equipment includes water injection equipment and a powder injector composed of intelligent water tanks and fracturing pumps. The quicklime powder in the powder injector is injected into the main fracturing hole and the branch fracturing hole through the downhole wind pressure; the main fracturing hole is hydraulically fractured through the water injection equipment, and the quicklime powder enters the fracture under the pressure of high-pressure water. The thermal reaction between powder and water generates a large amount of heat, realizing hydrothermal coupling fracturing; through the implementation of hydrothermal coupling fracturing to strengthen the regional gas drainage method, the area affected by fracturing increases, and the concentration of gas drainage increases. The effect is remarkable, which meets the The needs of coal mine site area gas control and other work.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com