Preparation method and application of heterogeneous catalyst for desorbing CO2 in solution

A heterogeneous catalyst, CO2 technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as large demand for low-pressure steam flow, low absorption and desorption rates, and changes in the size of regeneration towers. The effect of reducing desorption energy consumption, increasing desorption rate, and reducing desorption energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] SO 4 2- / ZrO 2 -HZSM-5 catalyst preparation scheme: using ion exchange method, using Zr(SO 4 )2 4H 2 Ion exchange between O and HZSM-5 to synthesize SO catalysts with different zirconia contents 4 2- / ZrO 2 -HZSM-5.

[0038] 20g of Zr(SO 4 ) 2 4H 2 O was dissolved in 400mL deionized water, and after stirring evenly, 14g, 28, and 56g of HZSM-5 were added to the above solution respectively, and the resulting solution was stirred at 80-90°C for 24-48h, cooled to room temperature, and the obtained precipitate The material was centrifugally washed with deionized water for 5 times, then dried at 110-130°C for 12-24h, and finally calcined at 500-600°C for 4-6 hours at a heating rate of 5°C / min to obtain SO 4 2- / ZrO 2 -HZSM-5 white powder. Produced SO 4 2- / ZrO 2 -HZSM-5 heterogeneous catalyst material, in which ZrO is theoretically calculated 2 The mass is 7g, and the theoretically calculated ZrO 2 SO with three different zirconia contents at a mass ratio of...

Embodiment 2

[0040] Simulate the actual decarburization process and build a SO 4 2- / ZrO 2 -HZSM-5 heterogeneous catalytic desorption carbon capture process absorbs CO in liquid 2 Process plan, process flow such as Figure 8 As shown, the technological process is as follows:

[0041] The stainless steel screen plate is used as the substrate, and the heterogeneous catalyst SO is loaded on its surface 4 2- / ZrO 2 -HZSM-5, to obtain a plate-type catalyst, after treatment, the plate-type catalyst unit is assembled into a catalyst module 4, and a plurality of catalyst modules 4 are arranged at intervals along the height direction of the tower, using this structure CO 2 The absorption tower performs the decarburization process.

[0042] A plurality of catalyst modules 4 will be arranged at intervals along the tower height direction, and a plurality of non-interfering agitators 5 will be arranged below each layer of catalyst modules 4 to obtain CO 2 Desorption tower structure.

[0043] C...

Embodiment 3

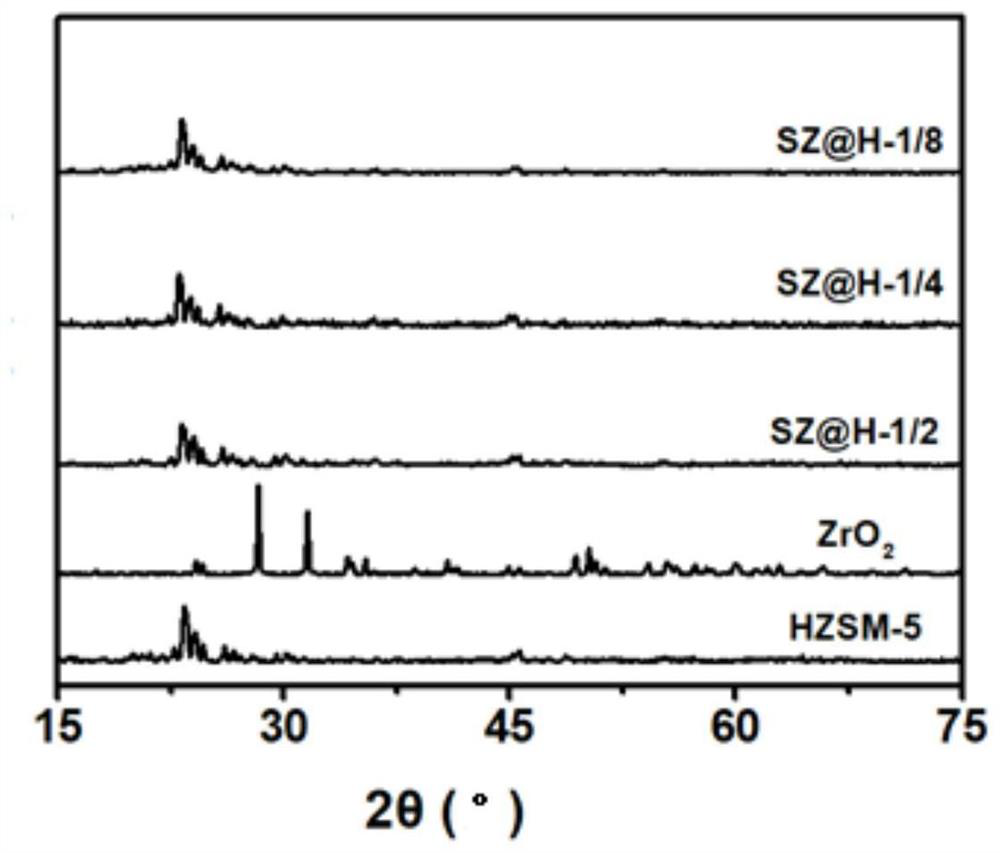

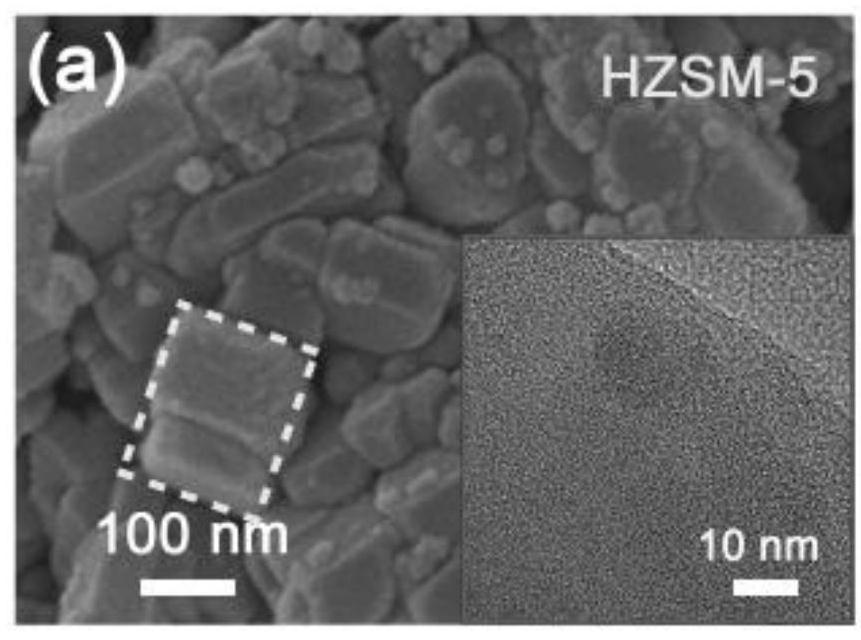

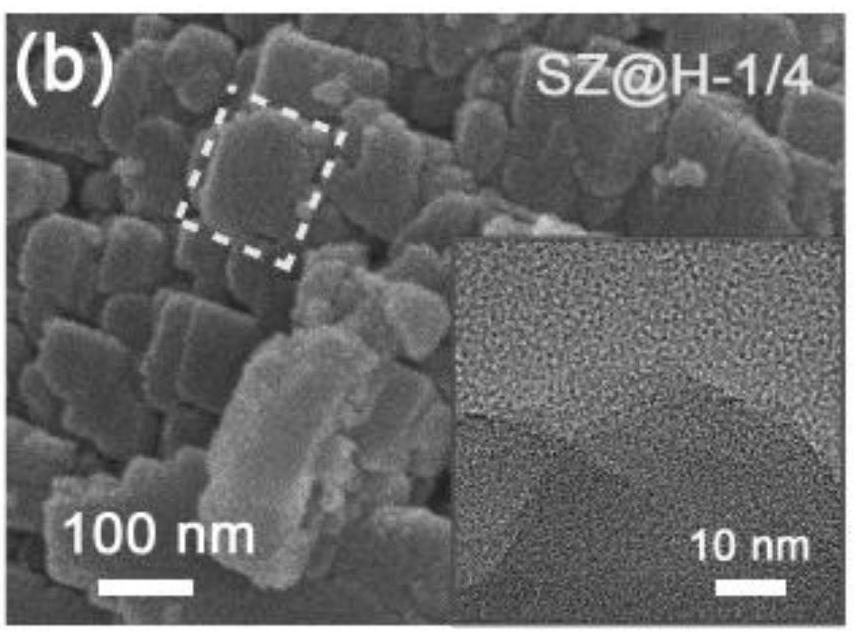

[0045] The theoretically calculated ZrO prepared by embodiment 1 2 SO with three different zirconia contents at a mass ratio of 1 / 2, 1 / 4, and 1 / 8 to HZSM-5 4 2- / ZrO 2 -HZSM-5, named SZ@H-1 / 2, SZ@H-1 / 4 and SZ@H-1 / 8 respectively. Characterize it and study its structural information. ICP data (Table 1) XRD ( figure 1 ), SEM and TEM ( Figure 2a with Figure 2b ), and NH 3 -TPD and Py-IR spectra ( Figure 3a with Figure 3b ) is as follows, it can be determined that ZrO in the prepared catalyst 2 The content is 0.24-3.08wt.%, SO 4 2- / ZrO 2 Evenly dispersed on the surface of the catalyst to form uniformly dispersed active sites, in which ZrO 2 When the content is 3.08wt.%, it has the strongest acidity and the strongest active site.

[0046] Table 1 is the ICP and XRF results of three catalysts, when ZrO 2 When the mass ratio of HZSM-5 and HZSM-5 is 1 / 4, the prepared catalyst ZrO 2 and sulfate content are the most, so 1 / 4 is the best preparation ratio, and the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com