Insulating flame retardant for packaging paper as well as preparation method and application thereof

A technology for wrapping paper and flame retardant, applied in papermaking, paper, paper coatings, etc., can solve the problems of non-static, poor recycling performance and functional failure of wrapping paper, and achieve good recycling and degradation performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a preparation method of an insulating flame retardant for wrapping paper described in the above technical solution, comprising the following steps:

[0028] Mix and disperse dicyclohexenyl hypophosphite, nano silicon dioxide, carboxylated styrene-butadiene latex and silicone lubricant to obtain an insulating flame retardant for wrapping paper.

[0029] In the present invention, the mixing and dispersing is carried out under stirring conditions, the stirring speed is preferably 100-300r / min, more preferably 150-250r / min, and the time is preferably 5-60min, more preferably 20-50min , more preferably 25 to 40 minutes.

[0030] After the mixing and dispersing is completed, the present invention preferably further includes: filtering the obtained dispersed mixed liquid, and the mesh size of the mesh used for the filtering is 100 mesh. The invention removes ununiformly dispersed large-particle impurities by filtering to obtain a uniform insulat...

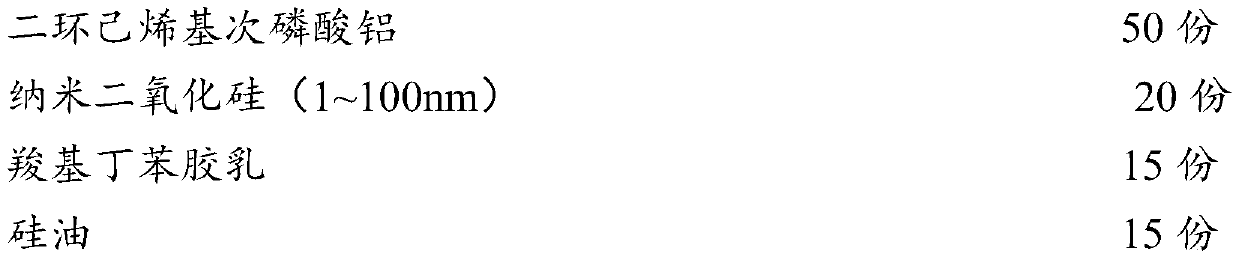

Embodiment 1

[0035] In parts by weight, the component distribution ratio of the insulating flame retardant for wrapping paper is:

[0036]

[0037] Mix and disperse the above-mentioned components in parts by weight, the dispersion speed is 300r / min, and the dispersion time is 50min to obtain a dispersion mixture, and then filter the dispersion mixture with a 100-mesh sieve to obtain an insulating material for wrapping paper. flame retardant.

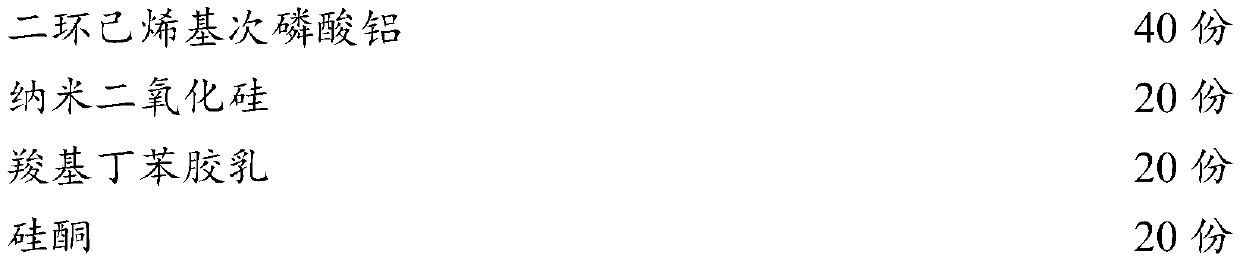

Embodiment 2

[0039] In parts by weight, the component distribution ratio of the insulating flame retardant for wrapping paper is:

[0040]

[0041] Mix and disperse the above-mentioned components in parts by weight, the dispersion speed is about 200r / min, and the dispersion time is 30min to obtain a dispersion mixture, which is filtered through a 100-mesh screen to obtain an insulation barrier for wrapping paper. Fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com