Method for regenerating and recycling oxygen-containing adsorbent in fixed bed regeneration device

A regeneration device and oxygen adsorbent technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of high cost of adsorbent, poor mechanical strength, small adsorption capacity, etc. Production cost, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

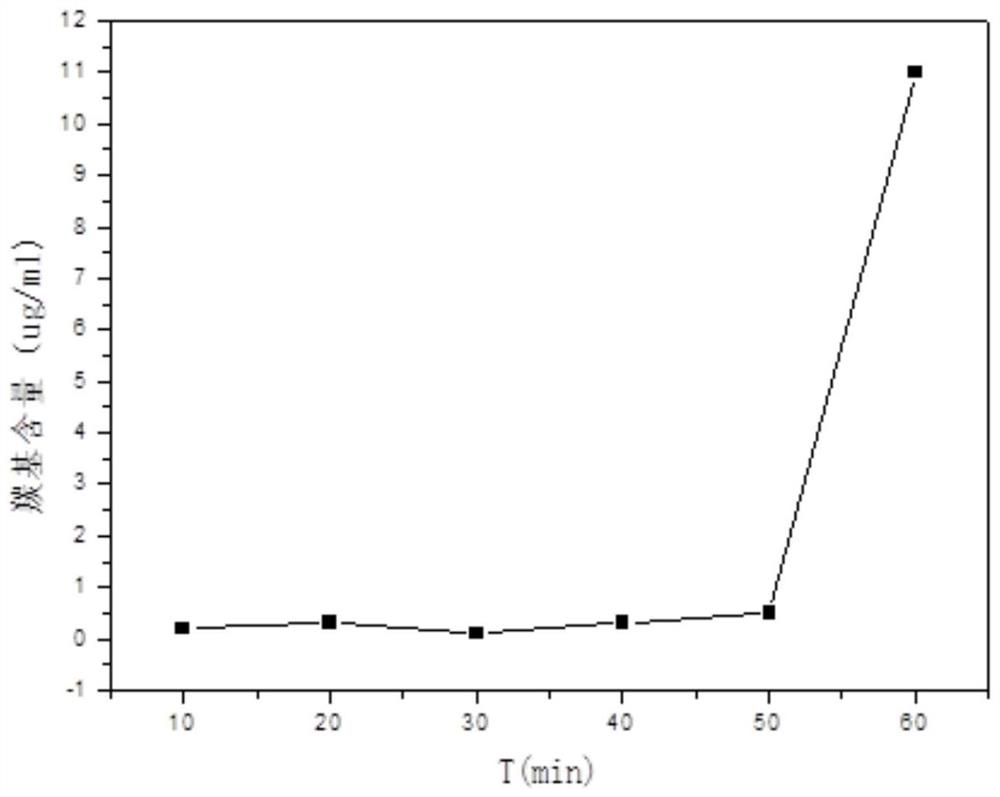

[0078] This embodiment provides a method for regeneration and recycling of an oxygen-containing adsorbent in a fixed bed regeneration device, specifically as follows:

[0079] (1) Pretreatment of adsorbent

[0080] Take the 13X molecular sieve adsorbent and lay it flat in the special firing pool of the muffle furnace. The amount of each roasting is about 30g, and the particle size of the adsorbent is 0.85-1.15m. The adsorbent was calcined at 700°C for 6 hours (the heating rate of the muffle furnace was 5°C / min), and when the temperature in the muffle furnace was naturally lowered to 150°C, it was taken out and placed in a desiccator for later use.

[0081] (2) Adsorbent filling

[0082] The filling capacity of the fixed bed adsorption tube is 45.2g, and the filling volume is 70.6mL. The upper and lower sides of the adsorbent bed are filled with quartz wool.

[0083] (3) Calibration of real feed pump

[0084] The first-class water is used as the calibration medium, and the ...

Embodiment 2

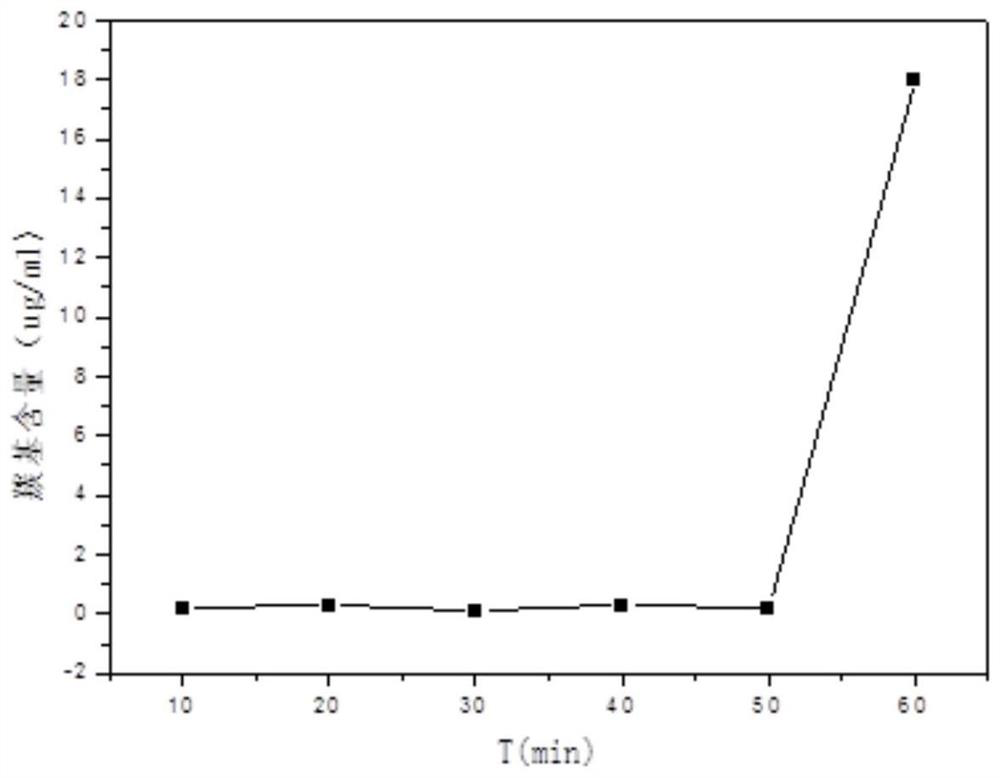

[0094] This embodiment provides a method for regeneration and recycling of an oxygen-containing adsorbent in a fixed bed regeneration device, specifically as follows:

[0095] (1) Pretreatment of adsorbent

[0096] Take the 13X molecular sieve adsorbent and lay it flat in the special firing pool of the muffle furnace. The amount of each roasting is about 30g, and the particle size of the adsorbent is 0.85-1.15m. The adsorbent was calcined at 700°C for 6 hours (the heating rate of the muffle furnace was 5°C / min), and when the temperature in the muffle furnace was naturally lowered to 150°C, it was taken out and placed in a desiccator for later use.

[0097] (2) Adsorbent filling

[0098] The filling capacity of the fixed bed adsorption tube is 44.7g, and the filling volume is 69.8mL. The upper and lower sides of the adsorbent bed are filled with quartz wool.

[0099] (3) Calibration of real feed pump

[0100] The first-class water is used as the calibration medium, and the ...

Embodiment 3

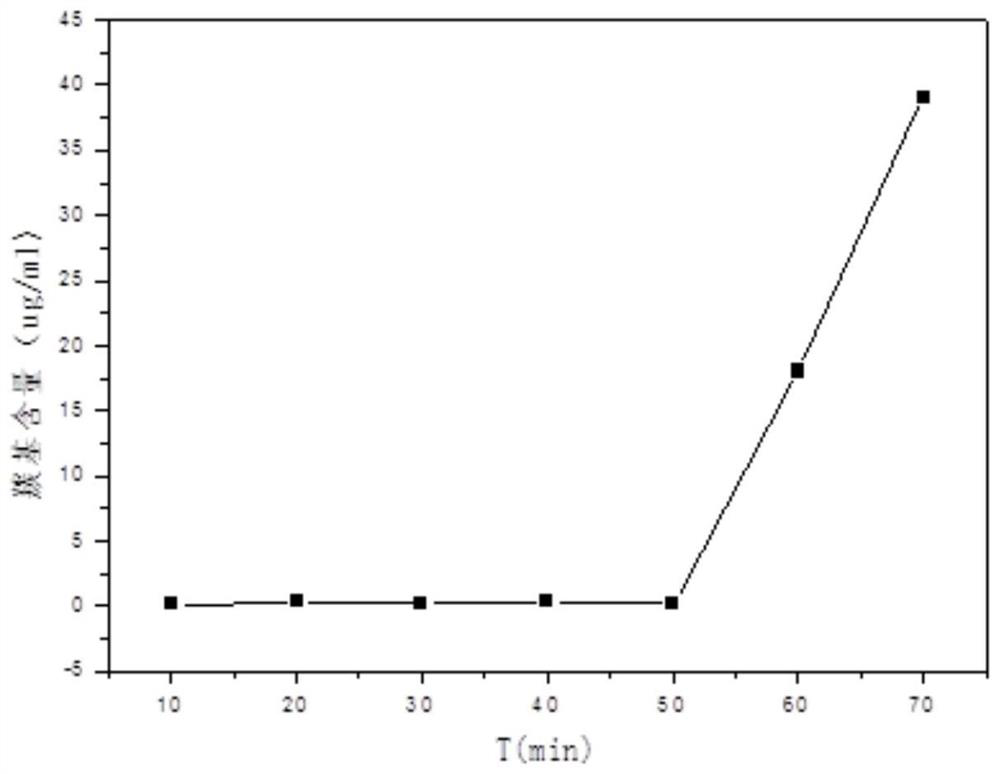

[0110] This embodiment provides a method for regeneration and recycling of an oxygen-containing adsorbent in a fixed bed regeneration device, specifically as follows:

[0111] (1) Pretreatment of adsorbent

[0112]Take the 13X molecular sieve adsorbent and lay it flat in the special firing pool of the muffle furnace. The amount of each roasting is about 28g, and the particle size of the adsorbent is 0.85-1.15m. The adsorbent was calcined at 680°C for 6.5 hours (the heating rate of the muffle furnace was 4.5°C / min), and when the temperature in the muffle furnace was naturally lowered to 148°C, it was taken out and placed in a desiccator for later use.

[0113] (2) Adsorbent filling

[0114] The filling capacity of the fixed bed adsorption tube is 45g, and the filling volume is 70mL. The upper and lower sides of the adsorbent bed are filled with quartz wool.

[0115] (3) Calibration of real feed pump

[0116] The first-class water is used as the calibration medium, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com