A kind of in situ generation of mil-101(fe) composite catalytic material on 3d-rgo and its preparation method and application

A catalytic material and in-situ generation technology, applied in the fields of chemistry and environment, can solve problems such as no research report, inability to efficiently degrade plant straw, etc., and achieve the effect of improving catalytic performance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to solve the above problems, the present invention is achieved through the following technical solutions:

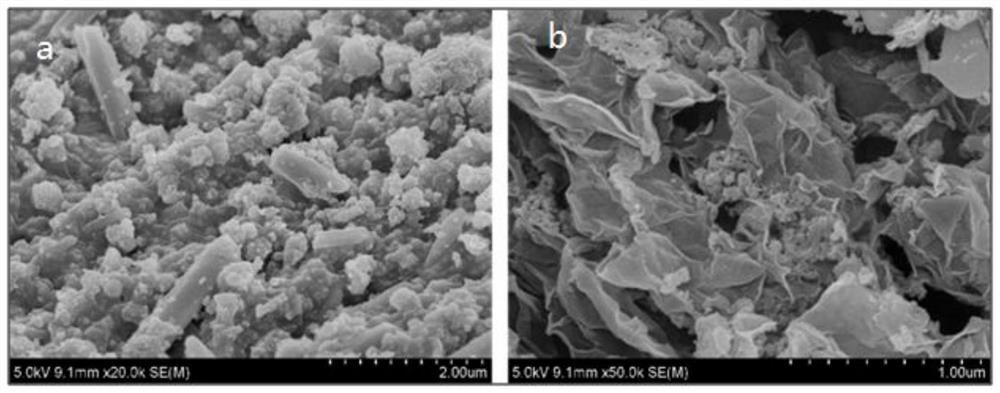

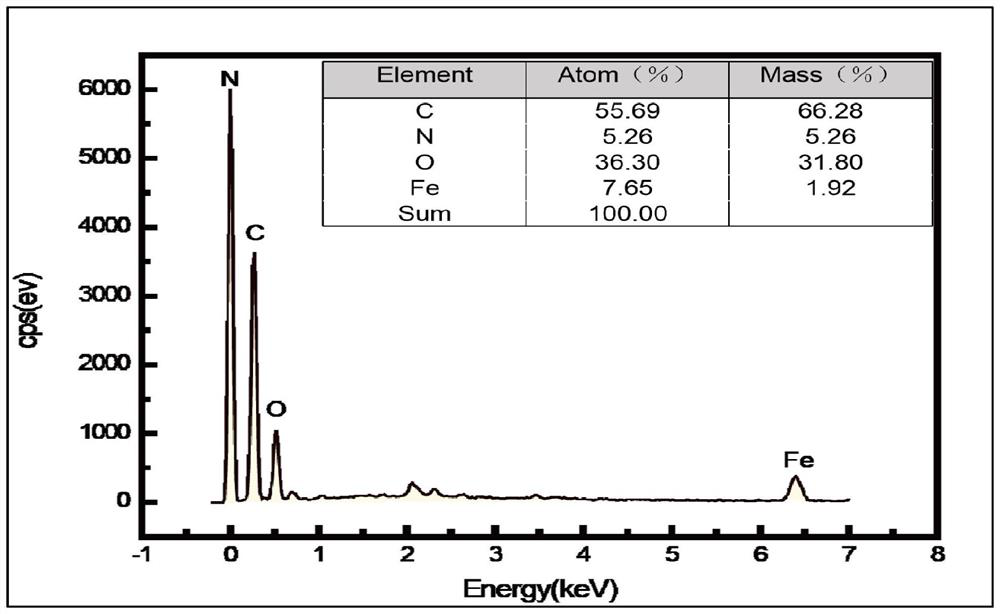

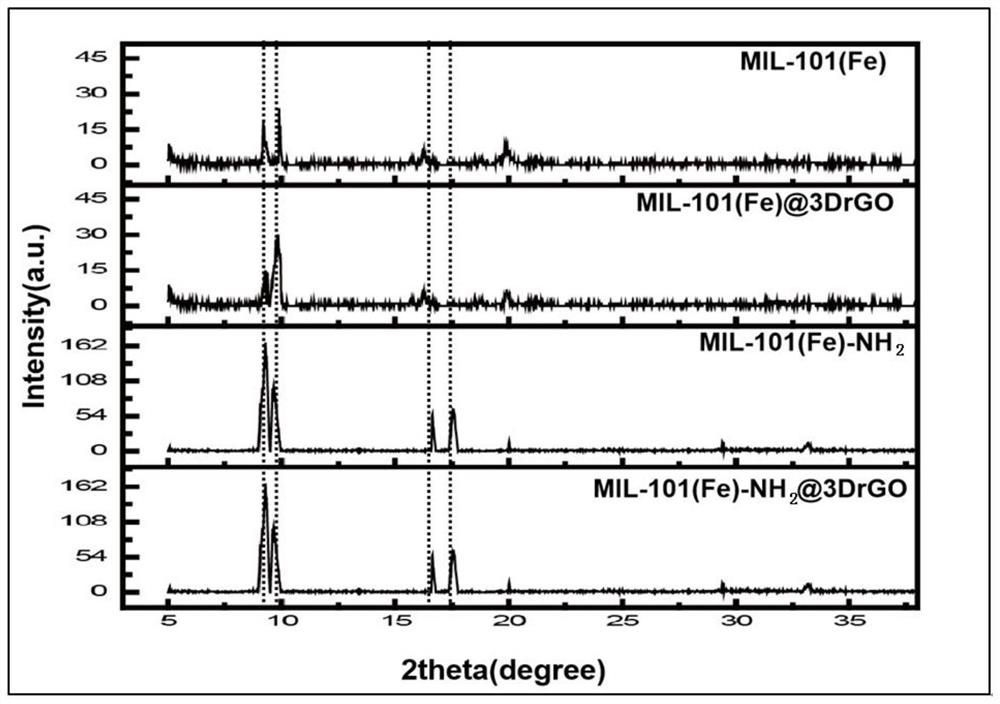

[0014] An in situ generated MIL-101(Fe) composite catalytic material on 3D-rGO, including porous three-dimensional graphene (3D-rGO), with MIL-101 ( Fe) or MIL-101(Fe)-NH 2 , MIL-101(Fe) or MIL-101(Fe)-NH 2 The mass ratio to porous three-dimensional graphene (3D-rGO) is 1:1, and the composite catalytic material has a microporous structure as a whole.

[0015] The second purpose of the present invention is to provide a preparation method for in-situ generation of MIL-101(Fe) composite catalytic material on 3D-rGO.

[0016] A kind of preparation method that in situ generates MIL-101 (Fe) composite catalytic material on 3D-rGO, comprises steps as follows:

[0017] (1) Disperse the iron salt and the organic ligand in an organic solvent, stir to completely dissolve the solid to obtain a suspension; add porous three-dimensional graphene (3D-rGO) to the suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com