Patents

Literature

175results about How to "High desorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

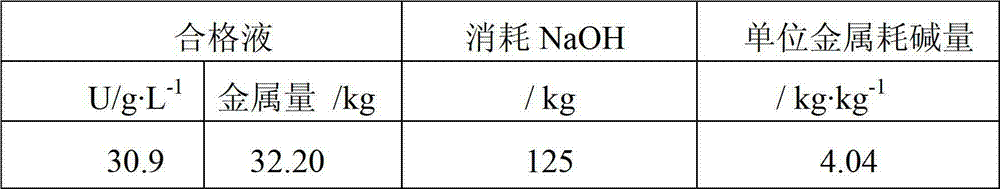

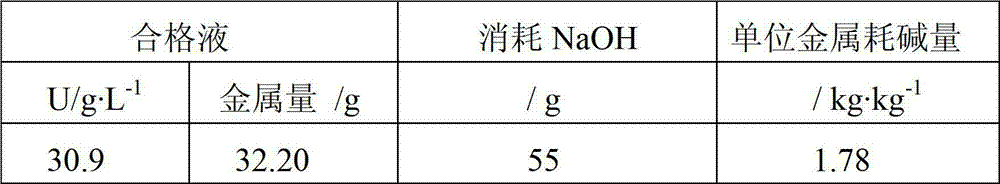

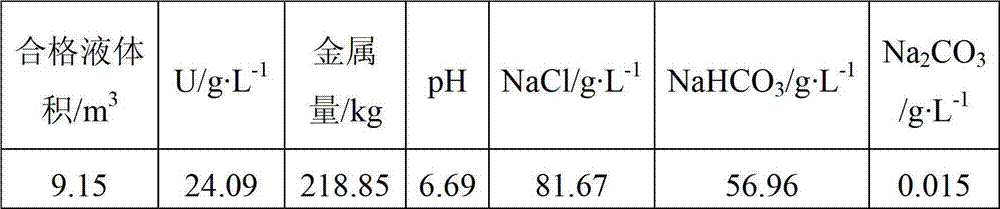

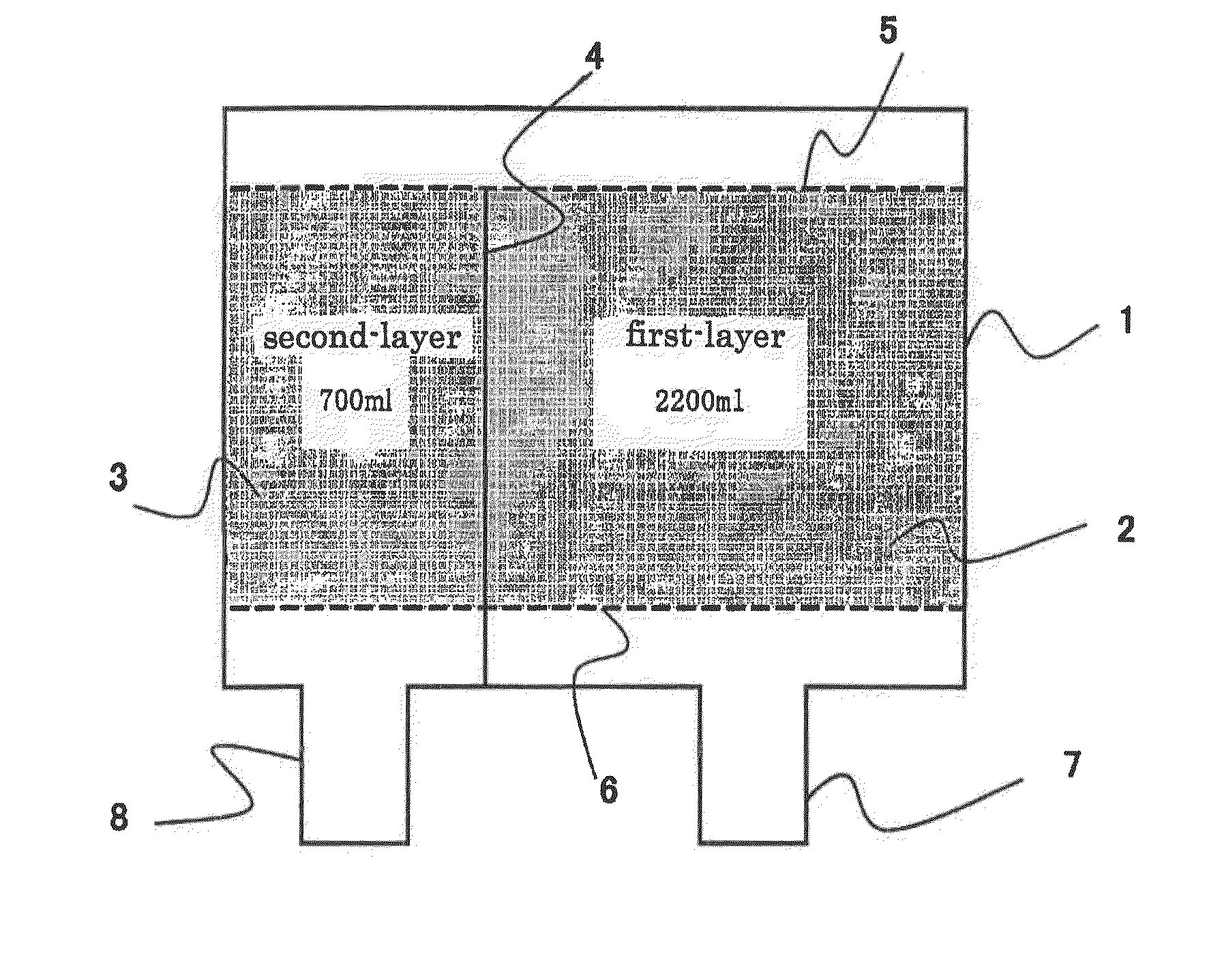

In-situ uranium leaching and mining treatment method by adding O2 into CO2

The invention provides an in-situ uranium leaching and mining treatment method by adding O2 into CO2. The invention comprises the steps of (1) adding O2 into leaching solution, then injecting an underground mine-water contained layer into a liquid injection pipeline, and preparing the leaching solution by adopting different oxygenation concentrations according to different underground leaching periods; (2) adding 100-300mg / L of CO2 into the leaching solution containing uranium; (3) conducting ion exchange adsorption on the leaching solution containing uranium, adopting macroporous styrene strong-base anion exchange resin, adsorbing to obtain saturated resin adsorption tail solution; and (4) washing saturated resin by adopting an eluting agent, and then analyzing uranyl carbonate ion solution to obtain Na2U2O7 sediment slurry and sediment mother liquor. According to the method, a high-temperature heating device is eliminated, so that the energy consumption and equipment investment are lowered greatly, the alkali consumption is lowered, control parameters are refined, the consumption of alkali is saved, and the production cost is lowered.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

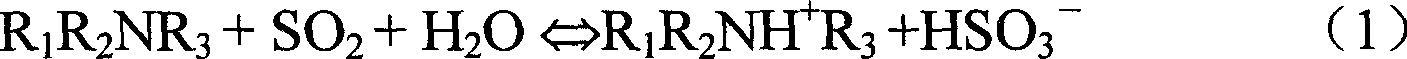

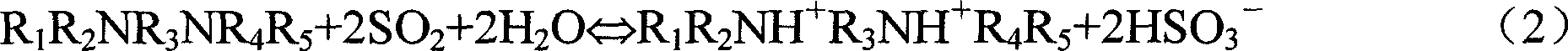

Smoke desulphurization agent and smoke desulphurization method

ActiveCN101721884AHigh desulfurization rateReduce absorptionDispersed particle separationAbsorption capacityDesorption

The invention provides a smoke desulphurization agent. The desulphurization agent is aqueous solution containing a main absorption component, an activating agent, an anti-oxidation component and acid, wherein the main absorption component is one or more of alkyl piperazine, hydroxyalkyl piperazine and hydroxyalkyl piperazine ketone; the activating agent comprises piperazine and diazabicyclo; and the anti-oxidation component is at least one of 4-tert-butyl catechol, 2,6-di-tert-butyl-p-phenylcresol, acetone oxime and N,N-bi (2-ethoxy) glycine. The smoke desulphurization agent provided by the invention can remove and reclaim sulfur dioxide in the smoke, and has higher desulphurization rate; moreover, even if the smoke desulphurization agent is strongly oxidized and then is recycled, the absorption capacity for the sulfur dioxide is still stable; and in addition, the rich liquor formed by desulphurization after adopting the desulphurization agent has better desorption performance such as high desorption rate.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

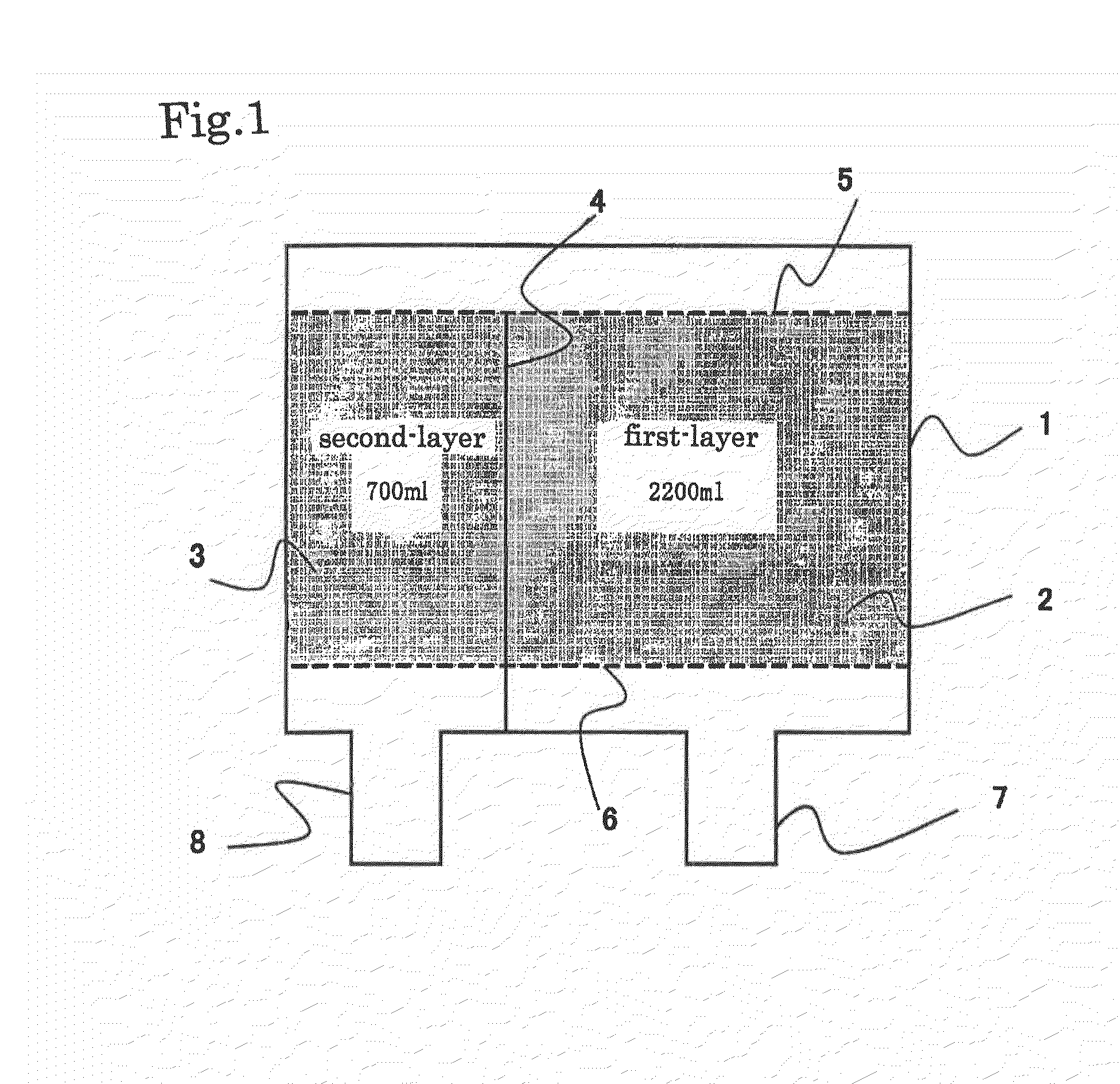

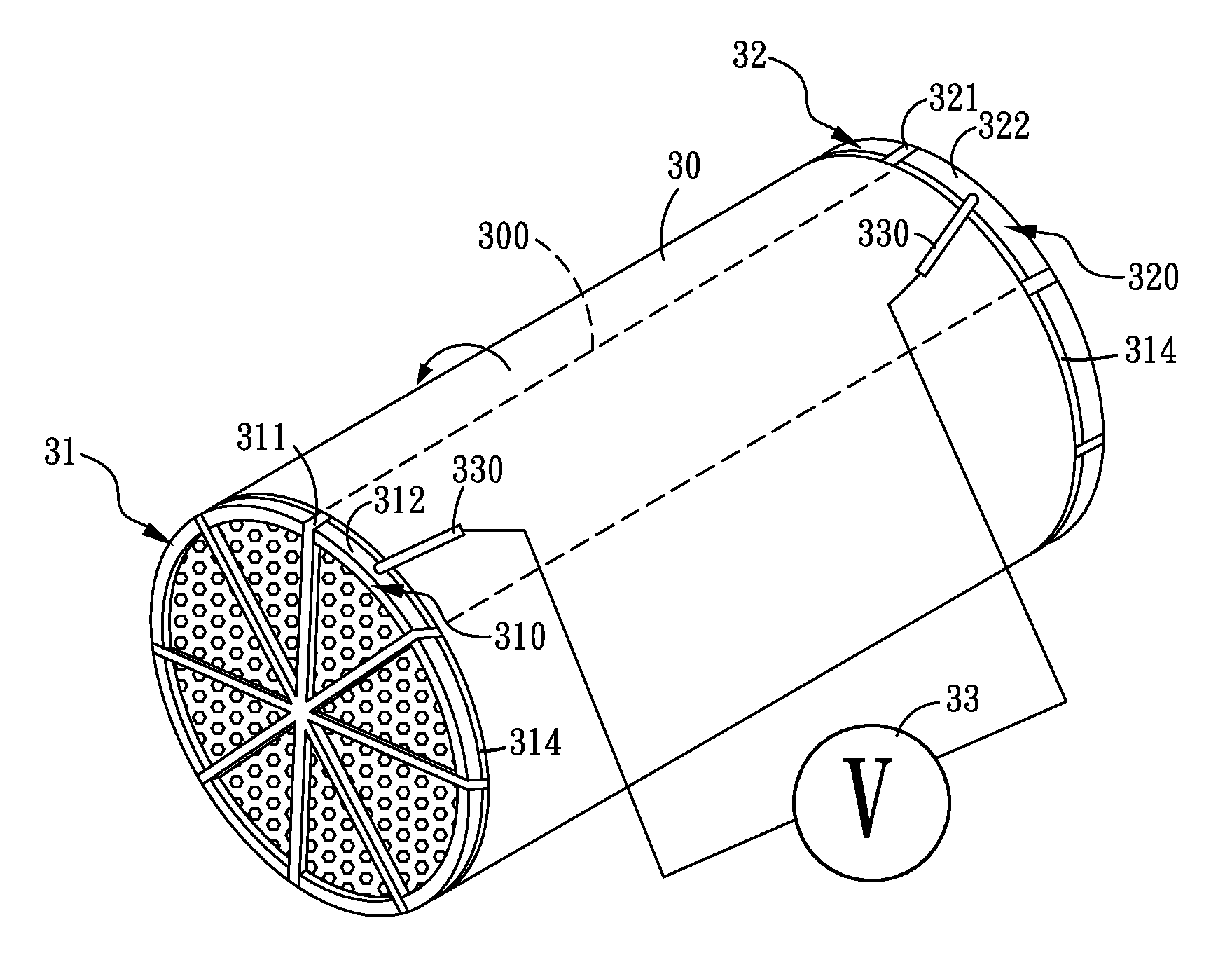

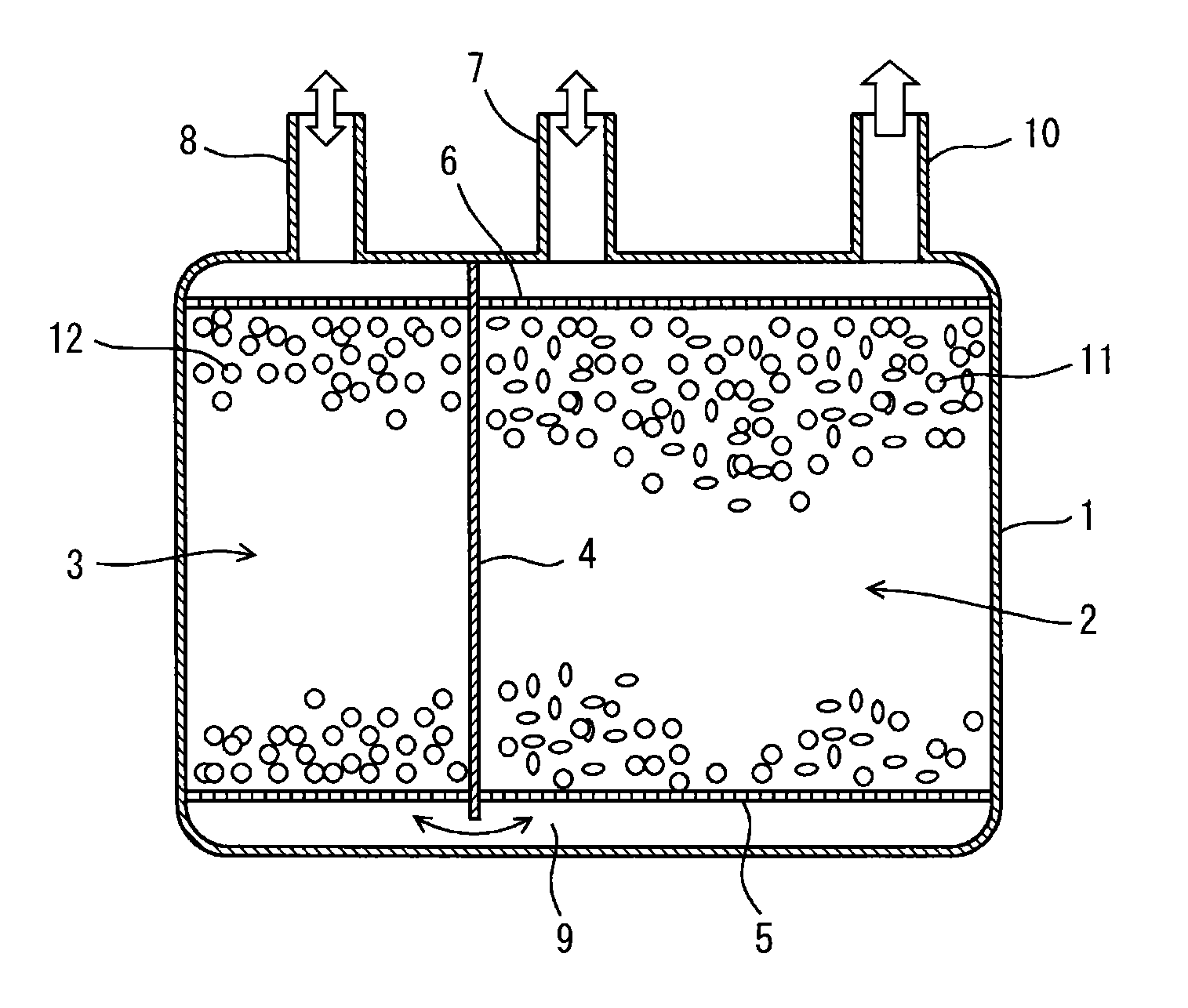

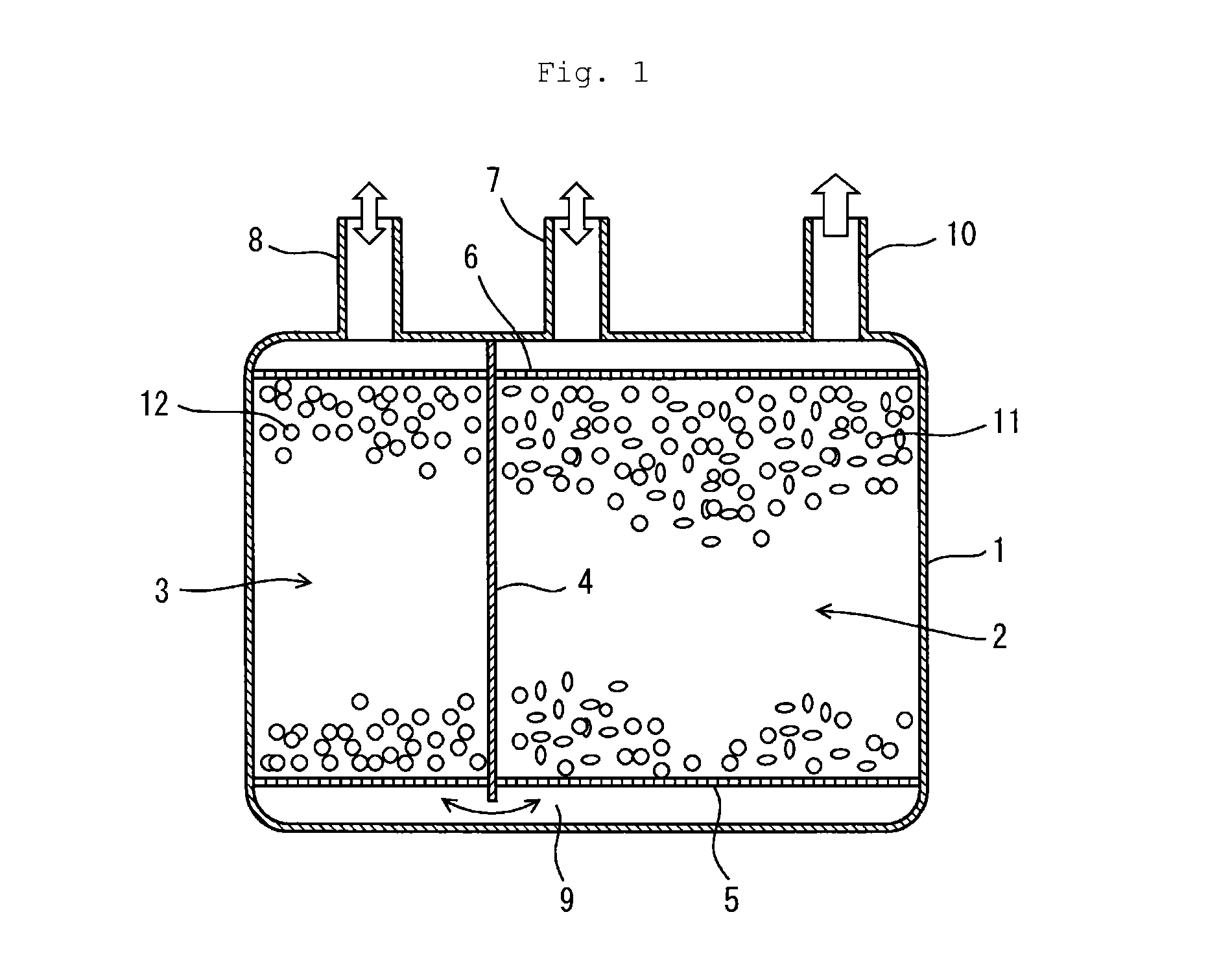

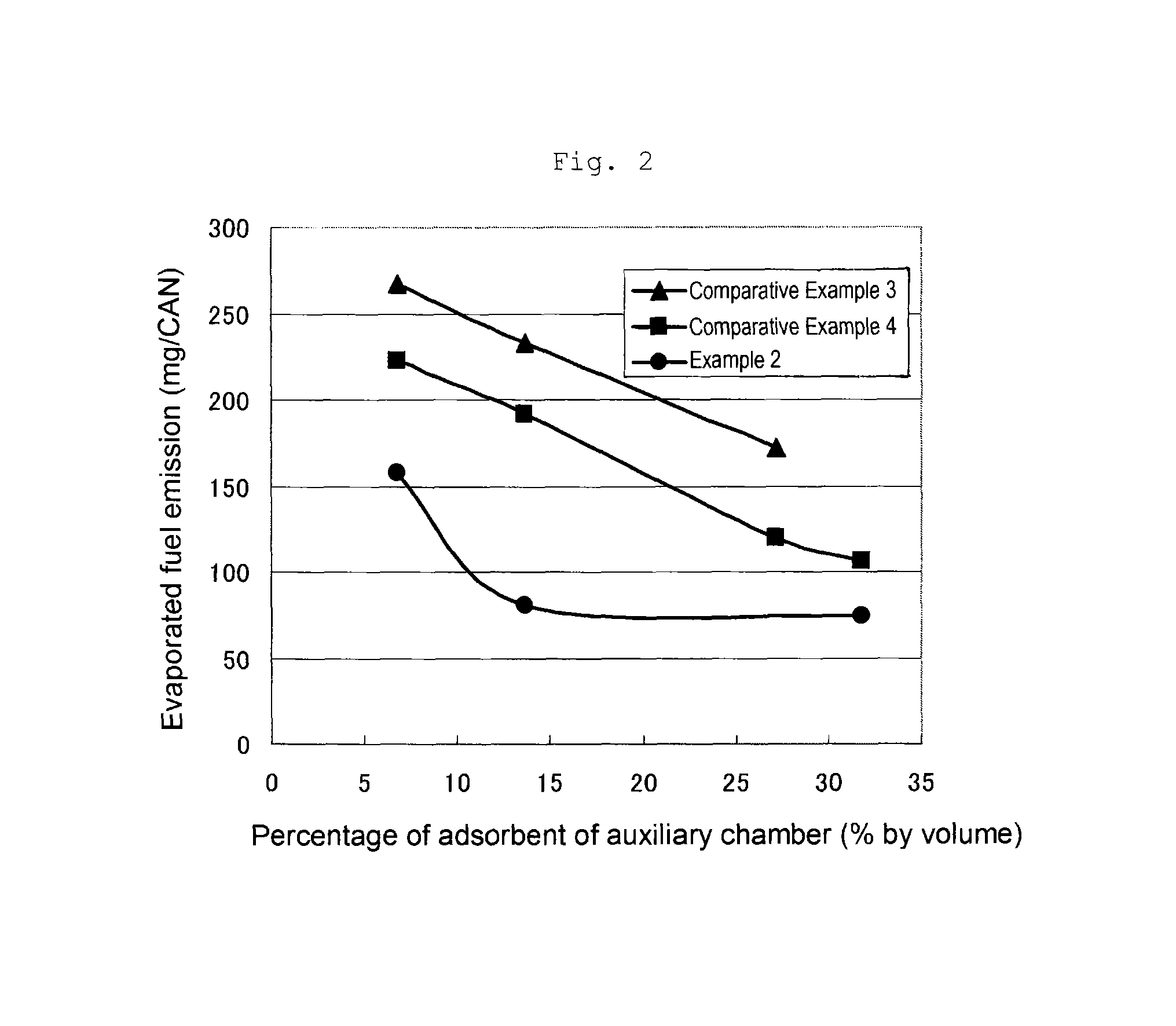

Adsorbent, process for producing the same, canister and method for using the same

ActiveUS20100212496A1High desorption rateReduce the amount requiredGas treatmentNon-fuel substance addition to fuelSorbentProduct gas

An object of the present invention is to provide an adsorbent suitable as an adsorbent for a canister which is capable of reducing an amount of evaporated fuel gas released into the atmosphere even where a motor vehicle is allowed to park for a prolonged period of time, a process for producing the adsorbent as well as a canister using the adsorbent and a method for using the canister. The above object can be accomplished by an adsorbent in which an integrated volume of pores having an average diameter of 3,000 to 100,000 nm as measured with a mercury porosimeter is 6.5 mL / dl or more and an equilibrium adsorption as measured in an n-butane volume concentration of 2,000 ppm is 0.16 g / dL or more, a process for producing the adsorbent, as well as a canister and a method for using the canister.

Owner:KURARAY CO LTD

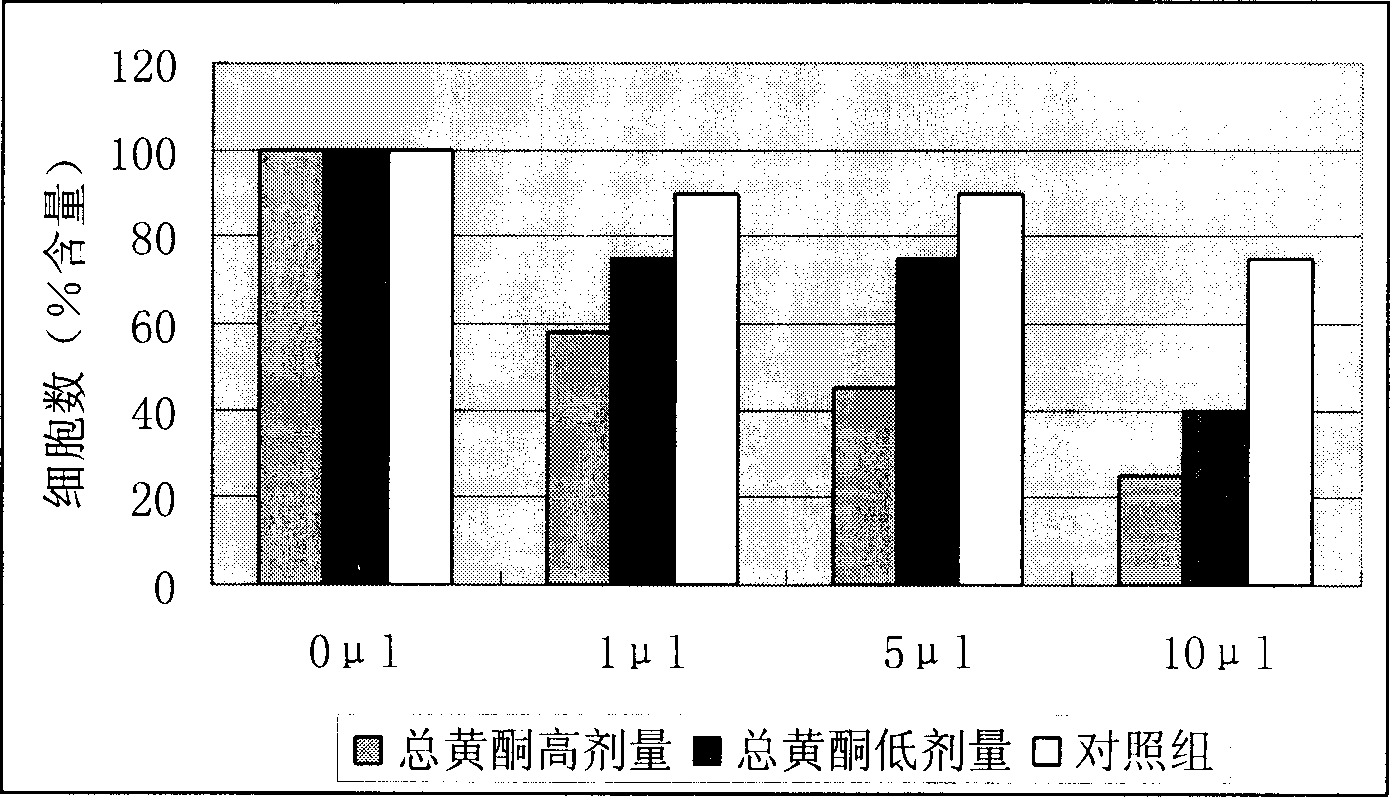

American goldenrod herb total flavone extract and its preparing method and use

InactiveCN1899341AEfficient enrichmentHigh in flavonoidsSugar derivativesSugar derivatives preparationDiseaseChlorogenic acid

The present invention relates to American goldenrod herb total flavone extract and its preparation process and use. The American goldenrod herb total flavone extract contains quercetin, quercetin-3-O-beta-D-heteroside, kaempferol-3-O-alpha-L-rhamnoside, chlorogenic acid, etc. capable of preventing and treating senile dementia, various inflammatory respiratory diseases, esophagus cancer, etc. The preparation process is simple, high extracting rate, and the extract has high pharmacological effect, stable property, low toxicity and controllable quality.

Owner:LINSAIJIAO BIOLOGICAL SCI & TECH DEV SHANGHAI

Renewable flue gas desulfuration agent and applications thereof

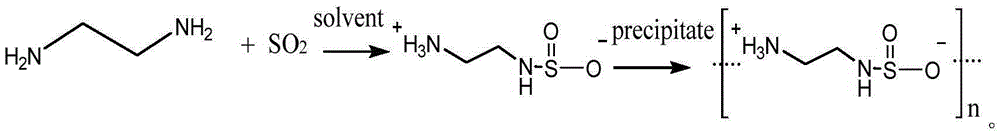

ActiveCN103801182AImprove desulfurization effectImprove the desorption effectDispersed particle separationDiamineIon

The invention discloses a renewable flue gas desulfuration agent and applications thereof, which aim at overcoming the defects that an adsorbent in the prior art is easily oxidized to generate heat stable salt, and thus the capability of the adsorbent in absorbing SO2 is lost, and the like. The desulfurization agent comprises the following compositions in percentage by weight: (A) 5-60% of diamine compounds containing ethoxyl or hydroxypropyl; (B) 2-40% of desorption auxiliaries; (C) 0.1-0.5% of an antioxidant; (D) 0.5-1% of a corrosion inhibitor; and (E) 5-90% of deionized water. The desulfurization agent can be used in the fields of coal-fired power plants, refinery enterprises, nonferrous metallurgy enterprises and the like, is low in energy consumption, capable of being recycled and free from secondary pollution, and heat stable salts are generated slowly.

Owner:CHINA PETROCHEMICAL CORP +1

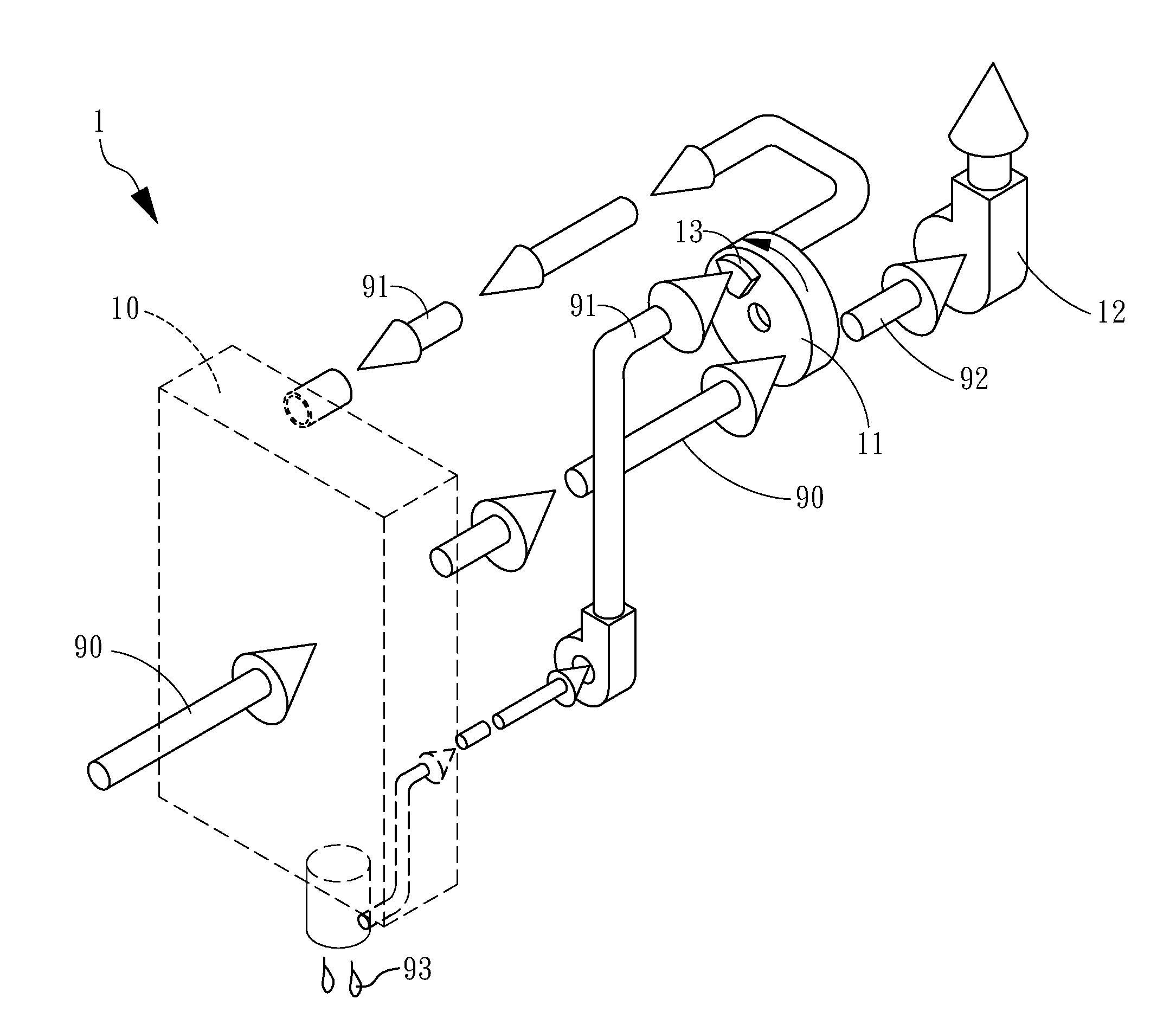

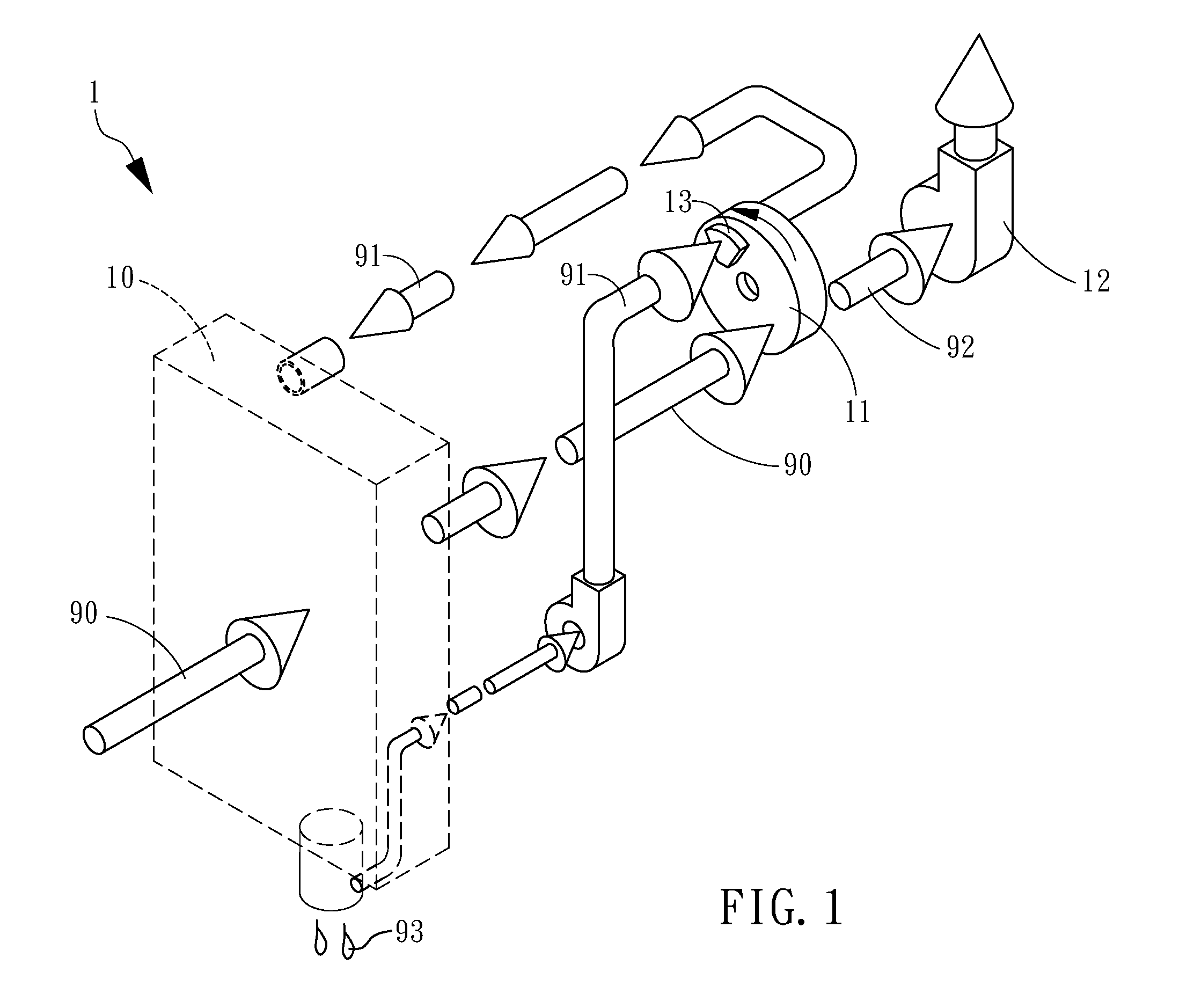

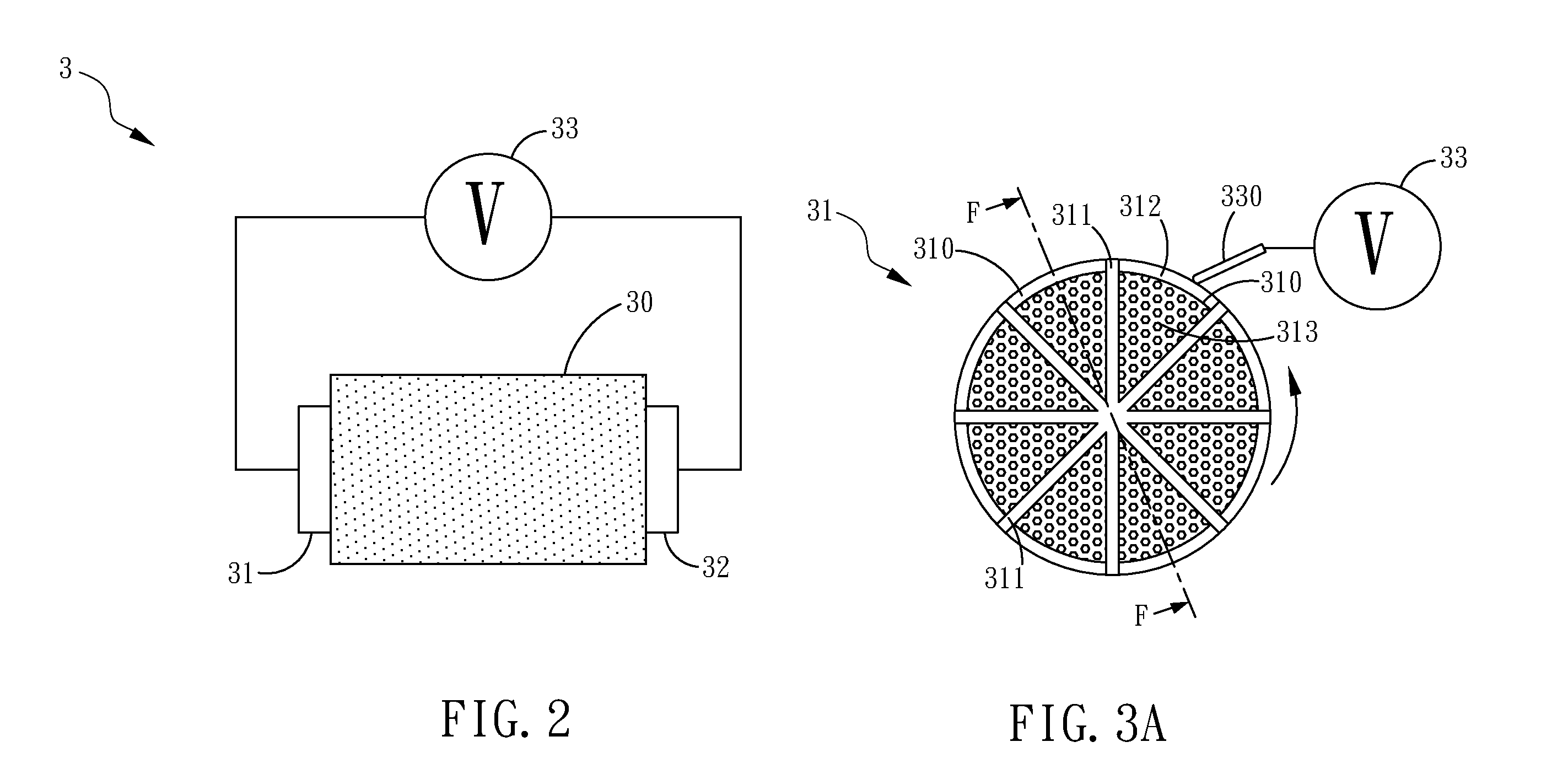

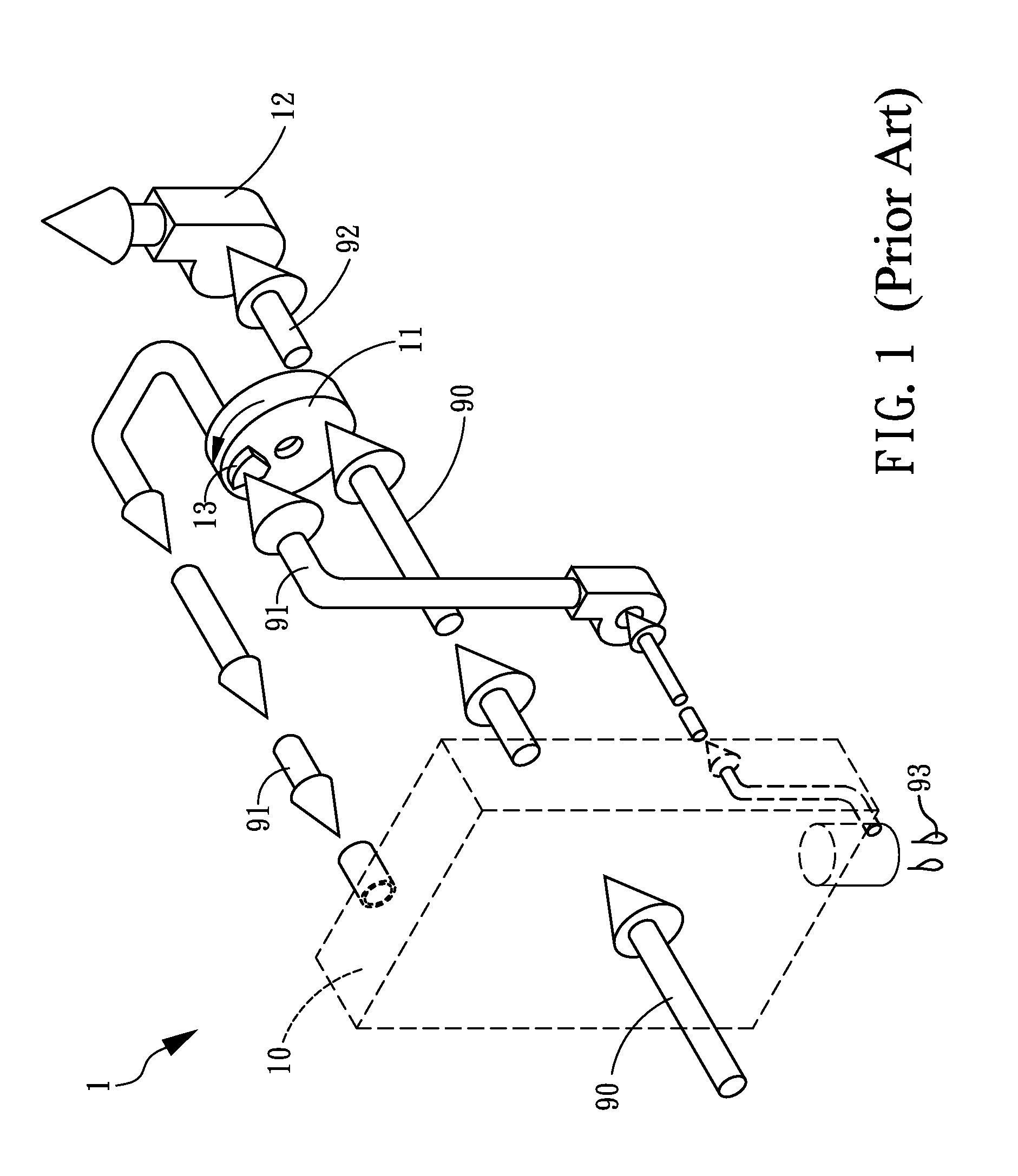

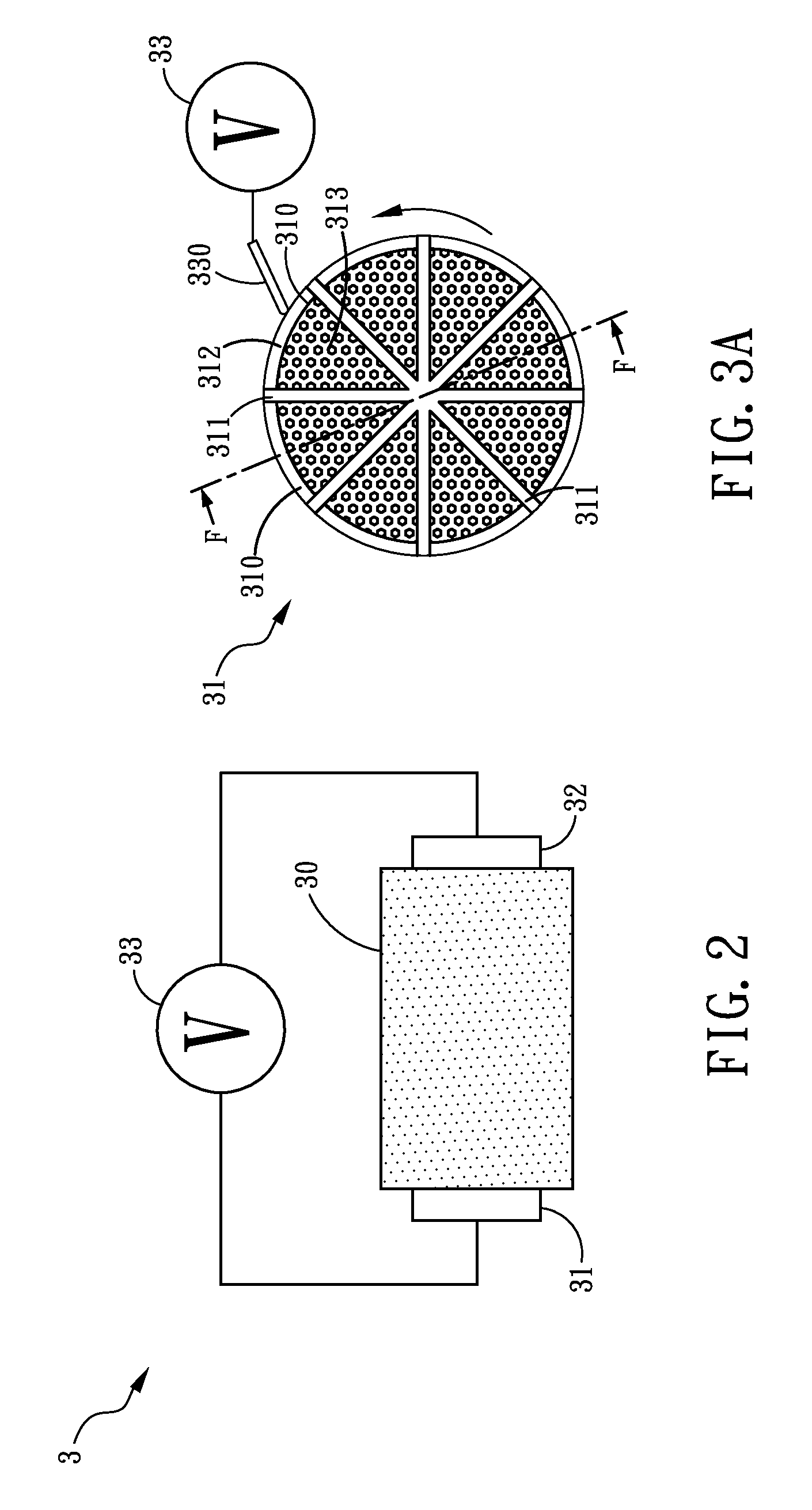

Low power consuming desorption apparatus and dehumidifier using the same

InactiveUS20100175557A1Reduce power consumptionHigh desorption rateGas treatmentIsotope separationDesorptionAbsorbent material

The present invention provides a low power consumption desorption apparatus, which utilizes a pair of electrodes coupled to an absorbing material to provide an electric current flowing through the absorbing material so as to desorb the substances absorbed within the absorbing material. By means of the desorption apparatus of the present invention, the absorbing material is able to enhance the desorbing efficiency and reducing power consumption during desorption. The present invention further provides a dehumidifier using the low power consumption desorption apparatus for providing a continuous dry air flow to desorb and regenerate the moisture from the absorbing material so that the dehumidifier is capable of removing moisture in the air repeatedly to reduce the humidity.

Owner:IND TECH RES INST

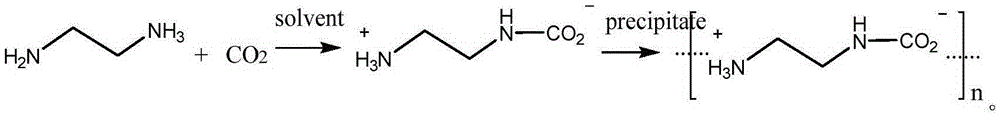

Mixed organic solution for trapping CO2 and SO2 acid gas through phase transformation

ActiveCN105289209AEasy to separateReduce desorption energy consumptionDispersed particle separationAlcoholOrganic solvent

The invention relates to a mixed organic solution for trapping CO2 and SO2 acid gas through phase transformation, and belongs to the technical field of environmental protection and gas purification. The mixed organic solution is prepared from, by mass, 5-35 parts of organic amine absorbing agents and 65-95 parts of organic solvent; one of chain amines, diamines, steric hindered amines, alcohol amines and amides or mixtures of more than two of chain amines, diamines, steric hindered amines, alcohol amines and amides which are mixed in any proportion is / are adopted as the organic amine absorbing agents; one of alcohols, ethers, ketones and esters or mixtures of more than two of alcohols, ethers, ketones and esters which are mixed in any proportion is / are adopted as the organic solvent. The mixed organic solution aims at solving the problem that regeneration energy consumption is high in decarbonizing and desulfurizing of an organic amine regeneration method.

Owner:KUNMING UNIV OF SCI & TECH

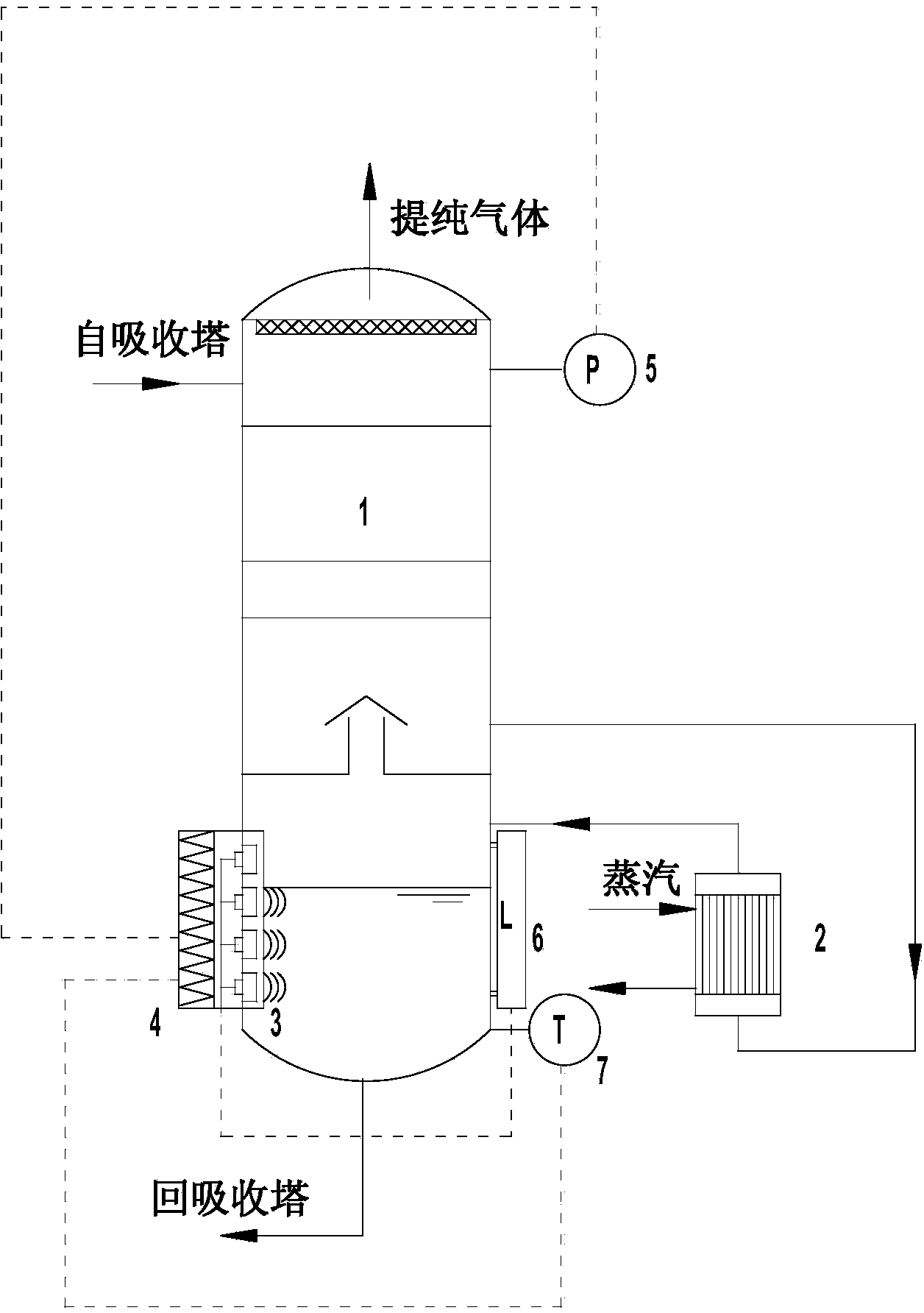

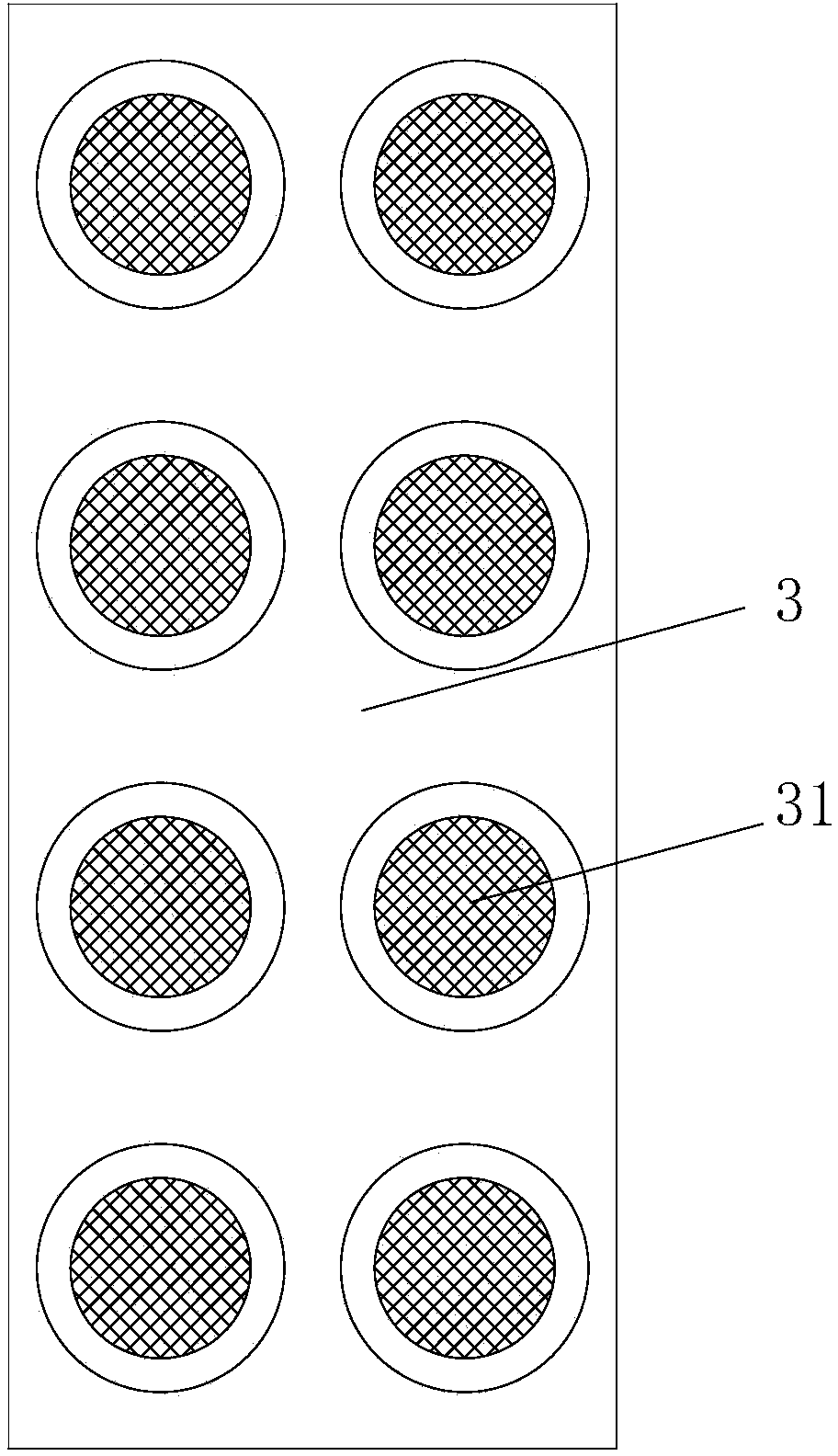

Strengthening and regenerating system and method for carbon dioxide capturing solution

A strengthening and regenerating system for a carbon dioxide capturing solution comprises a regeneration tower, a reboiler, a supersonic generator panel, a supersonic controller, a pressure sensor, a liquid position sensor, and a temperature sensor; rich liquor from an absorption tower enters the regeneration tower from the top part of the regeneration tower, then flows to the bottom part of the regeneration tower, enters the reboiler, absorbs the thermal energy there, and then is returned to the regeneration tower; when the solution submerges the supersonic generator panel, according to the liquid position information obtained by the liquid position sensor, a vibrator in the supersonic generator panel under the liquid position is started to work, then the carbon dioxide in the liquid phase is promoted to evaporate from the liquid phase through a supersonic cavitation effect, then the carbon dioxide rises to the top part of the regeneration tower and forms a pressure; and according to the pressure value measured by the pressure sensor and the temperature value measured by the temperature sensor, the supersonic controller adjusts the output frequency and power of the vibrator in the supersonic generator panel. The system can accelerate the evaporation speed of the carbon dioxide in the solution, reduces the desorption temperature, reduces the external steam consumption, improves the absorption rate of carbon dioxide and the regeneration degree of the solution, and reduces the energy consumption of each unit of carbon dioxide.

Owner:HUANENG CLEAN ENERGY RES INST

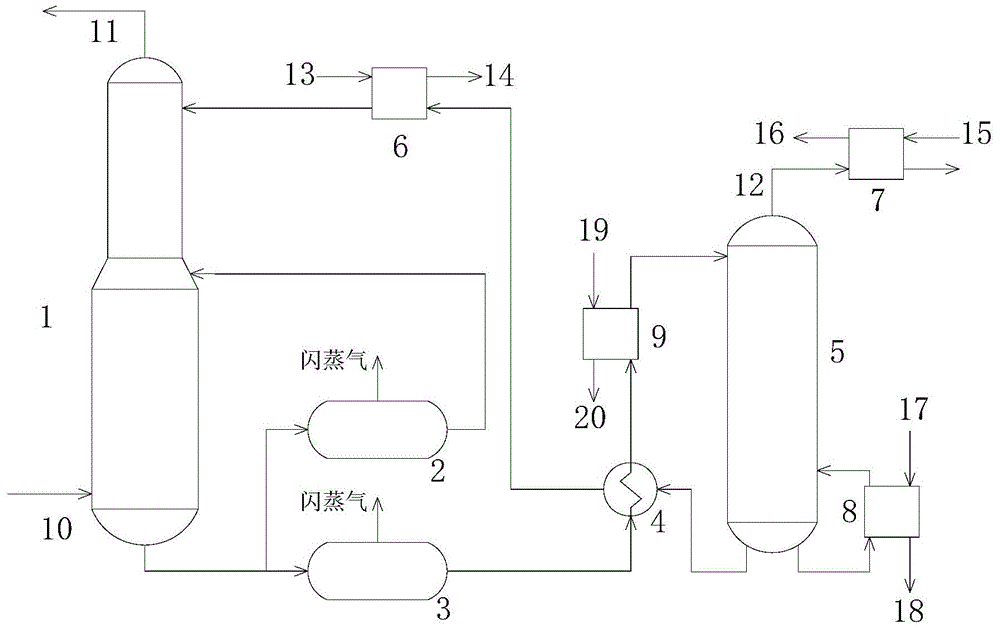

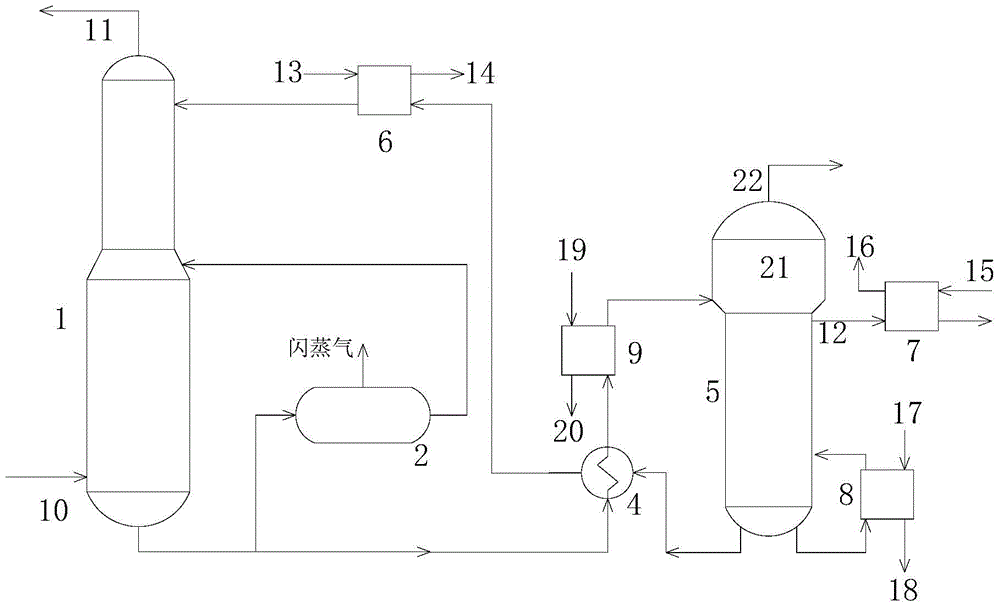

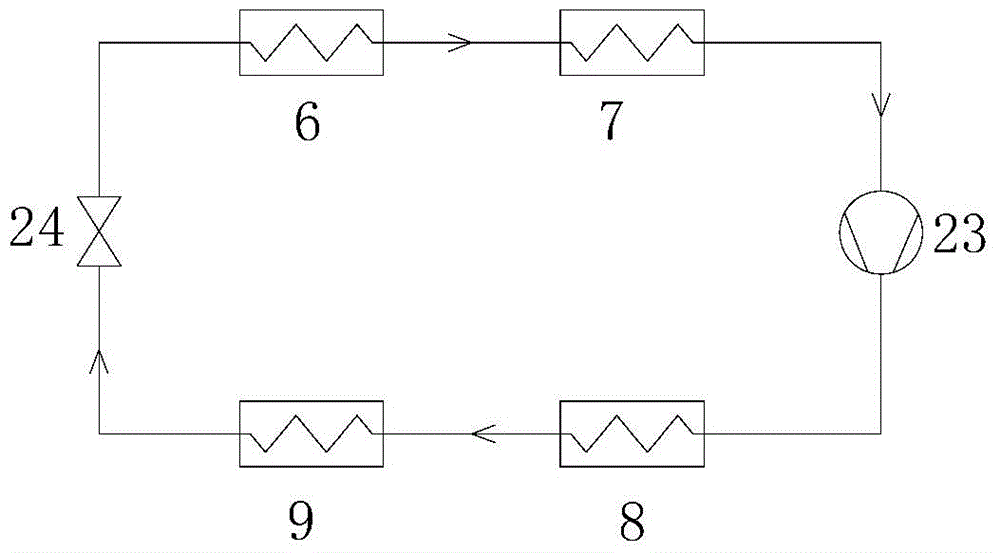

Method and device for reducing regeneration energy consumption of decarburization absorption liquid

InactiveCN103977683AIncrease temperatureImprove acid gas analysis efficiencyProductsCarbon compoundsSupersonic wavesDecarburization

The invention relates to a method and a device for reducing regeneration energy consumption of decarburization absorption liquid. A heating regeneration process is carried out to a rich solution which absorbs carbon dioxide and is discharged from a bottom of an absorption column. Heat is recovered, by a heat pump, from gas discharged from a top of a regeneration column and / or a heat-exchanged and temperature-reduced barren solution discharged from the bottom of the regeneration column, wherein the heat is supplied to be provided for heating liquid in the bottom of the regeneration column and a heat-exchanged rich solution. With the heat pump, temperature of the rich solution is increased and the energy consumption of heating is significantly reduced, and furthermore, desorption efficiency of acid gas in the regeneration column is increased. After the majority of the rich solution is subjected to a flash evaporation process by reducing the pressure to a normal pressure, the flash-evaporated solution is free of heating regeneration and is directly flowed back to the regeneration column for absorbing high-concentration CO2, so that regeneration amount of the rich solution is greatly reduced with an absorption effect being ensured, thereby regeneration energy consumption is reduced and decarburization operation cost is saved. Supersonic wave is used for desorbing CO2 in a flashed solution so that desorption efficiency of CO2 can be further improved.

Owner:TIANJIN UNIV

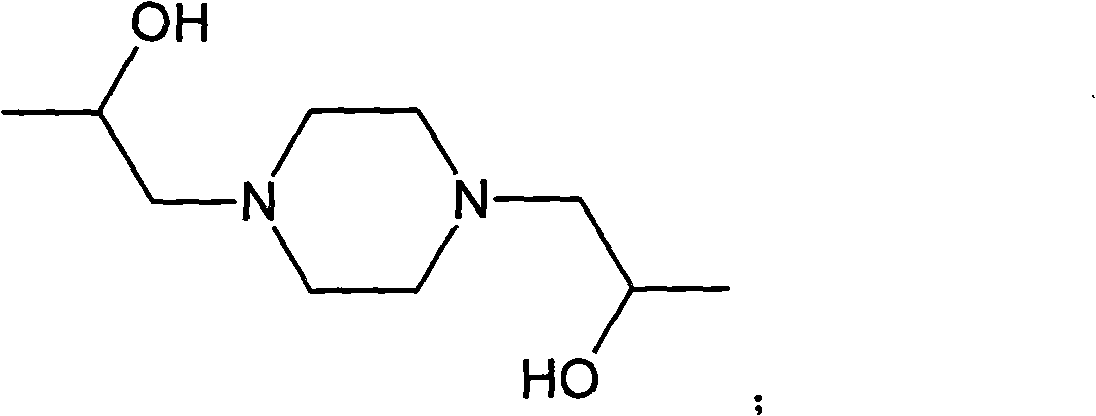

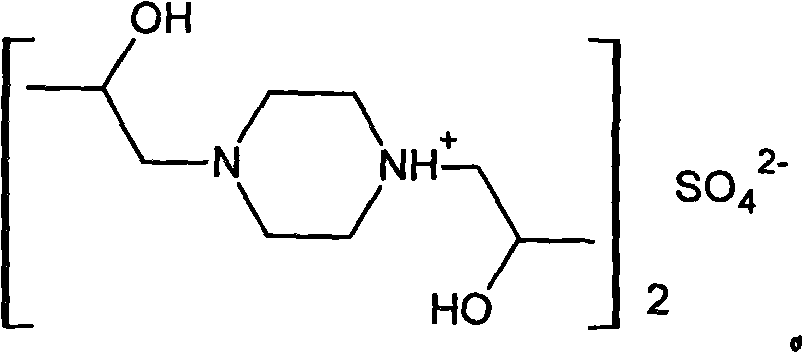

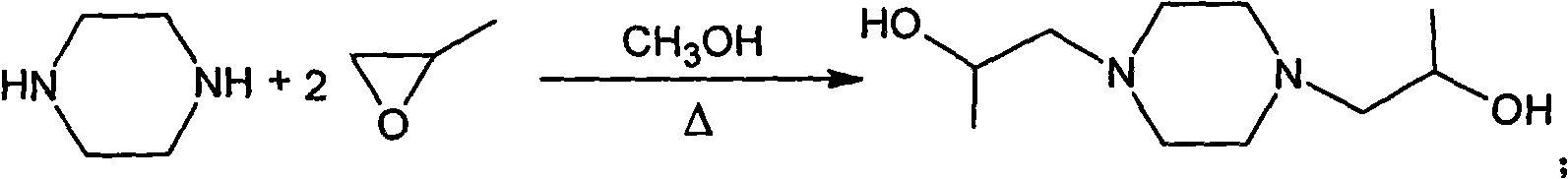

Renewable flue gas desulfurization agent and preparation method thereof

ActiveCN101584961AHigh desorption rateLow desorption temperatureDispersed particle separationSulfateConjugate acid

The invention relates to a renewable flue gas desulfurization agent and the preparation method thereof. The flue gas desulfurization agent is the aqueous solution of 1,4-bis(2-hydroxypropyl) piperazinyl sulfate containing 30% of 1,4-bis(2-hydroxypropyl) piperazinyl by mass. The flue gas desulfurization can be prepared from the of 1,4-bis(2-hydroxypropyl) piperazinyl and other raw materials, by mixing according to a certain proportioning at normal temperature. Because the pKa1 of the conjugate acid of the 1,4-bis(2-hydroxypropyl) piperazinyl is 3.8, and the pKa2 of that is 8.2, the obtained flue gas desulfurization agent achieves the advantages of large absorbing capacity, high de-absorbing ratio, low de-absorbing temperature and suitable temperature difference in the absorbing and de-absorbing process; can reduce the energy consumption in absorbing and de-absorbing process obviously, and is very suitable for the application in process of removing SO2 in discharged flue gas in coal fired power plant and so on.

Owner:HEFEI UNIV OF TECH

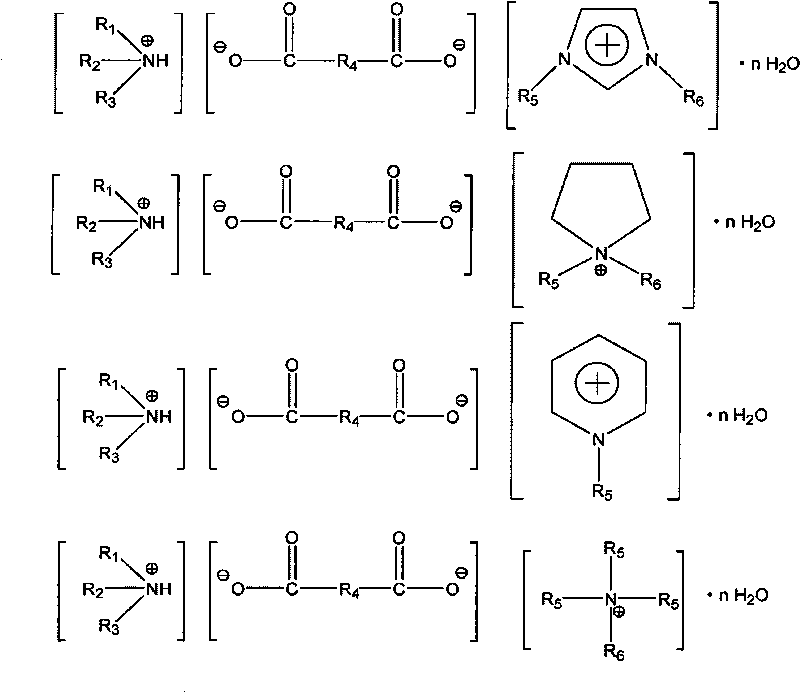

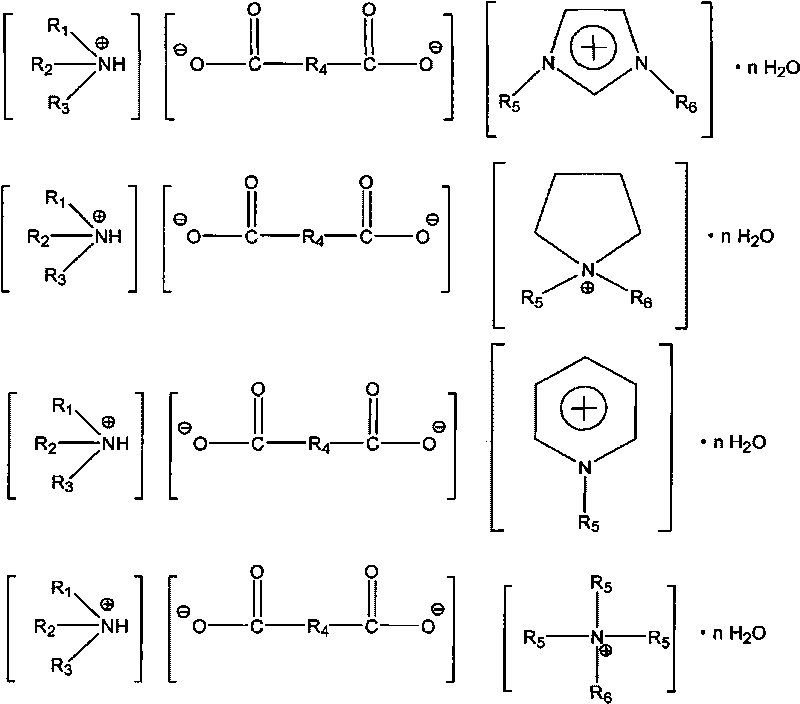

Hybrid ionic liquid hydrate, preparation process and application thereof

InactiveCN101693692ALow viscosityMass transfer rate is fastOrganic chemistryOther chemical processesProtonationWastewater

Hybrid ionic liquid hydrate consists of two types of positive ions containing nitrogen and binary or polybasic carboxylate negative ions which are different in structure and property. One type of positive ions includes protonated alkylamine positive ions, and another type of positive ions inlcudes N,N-dialkyl imidazole positive ions or N, N-dialkyl pyrrole positive ions or N-alkyl pyridines positive ions or N, N, N, N-tetraalkyl ammonium positive ions. Positive ions at one end of binary acid or polybasic acid of the hybrid ionic liquid hydrate have faintly acid while positive ions at the other end are neutral, and binary or polybasic carboxylic acid negative ions have alkalescence, thereby enabling the hybrid ionic liquid hydrate to have ultra-strong pH buffer capacity and to be capable of reversibly absorbing or adsorbing SO2 gas in an environment-friendly high-efficient circulating form. The hybrid ionic liquid hydrate which is utilized as SO2 absorbent is simple in requirements to equipment for absorbing SO2, moderate in operation condition of absorbing and desorbing SO2 and high in desulfuration efficiency without problems of waste liquid and waste water discharge and the like. Further, the invention discloses a process for preparing the hybrid ionic liquid hydrate.

Owner:NANJING UNIV

Low power consuming desorption apparatus and dehumidifier using the same

InactiveUS8187368B2Reduce power consumptionHigh desorption rateGas treatmentIsotope separationDesorptionAbsorbent material

The present invention provides a low power consumption desorption apparatus, which utilizes a pair of electrodes coupled to an absorbing material to provide an electric current flowing through the absorbing material so as to desorb the substances absorbed within the absorbing material. By means of the desorption apparatus of the present invention, the absorbing material is able to enhance the desorbing efficiency and reducing power consumption during desorption. The present invention further provides a dehumidifier using the low power consumption desorption apparatus for providing a continuous dry air flow to desorb and regenerate the moisture from the absorbing material so that the dehumidifier is capable of removing moisture in the air repeatedly to reduce the humidity.

Owner:IND TECH RES INST

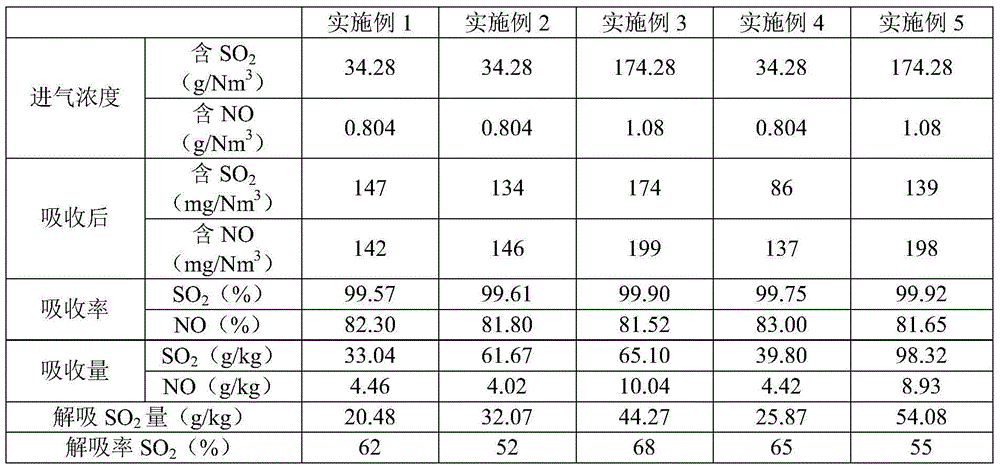

Flue gas absorbent of desulfurization and denitrification, and desulfurization and denitrification method thereof

InactiveCN104437059AHigh desulfurization and denitrification rateHigh desorption rateDispersed particle separationAir quality improvementDesorptionAntioxidant

The invention provides a flue gas absorbent of desulfurization and denitrification and a desulfurization and denitrification method thereof. The flue gas absorbent of desulfurization and denitrification is prepared from the following components in percentage by weight: 2%-40% of an absorbing component, 0.02%-10% of an active component, 1%-20% of a reducing component, 0.001%-0.1% of an antioxidant and the balance of water, wherein the pH value of the absorbent of desulfurization and denitrification is 3.5-7; the absorbing component is one or more of piperazine and derivatives thereof; the active component is diazabicyclo; and the reducing component is urea. According to the flue gas absorbent of desulfurization and denitrification, provided by the invention, NOx in the flue gas can be effectively reduced into nitrogen, and SO2 is desorbed and regenerated after being absorbed, so as to obtain pure SO2. The flue gas absorbent of desulfurization and denitrification is high in desulfurization and denitrification rate, rapid to desorb, high in desorption rate, and relatively low in desorption energy consumption, and has high practicability.

Owner:JIANGHAN UNIVERSITY

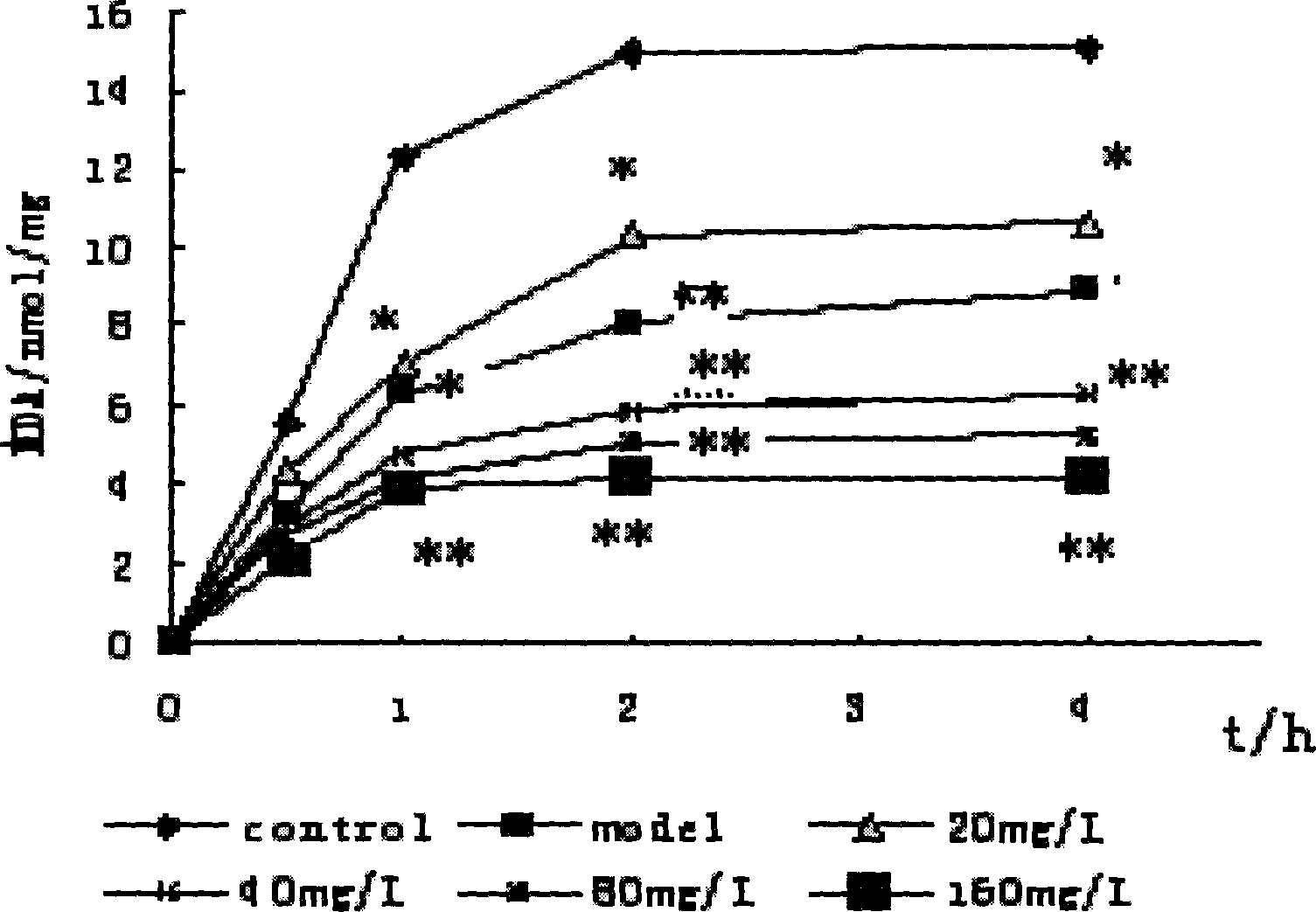

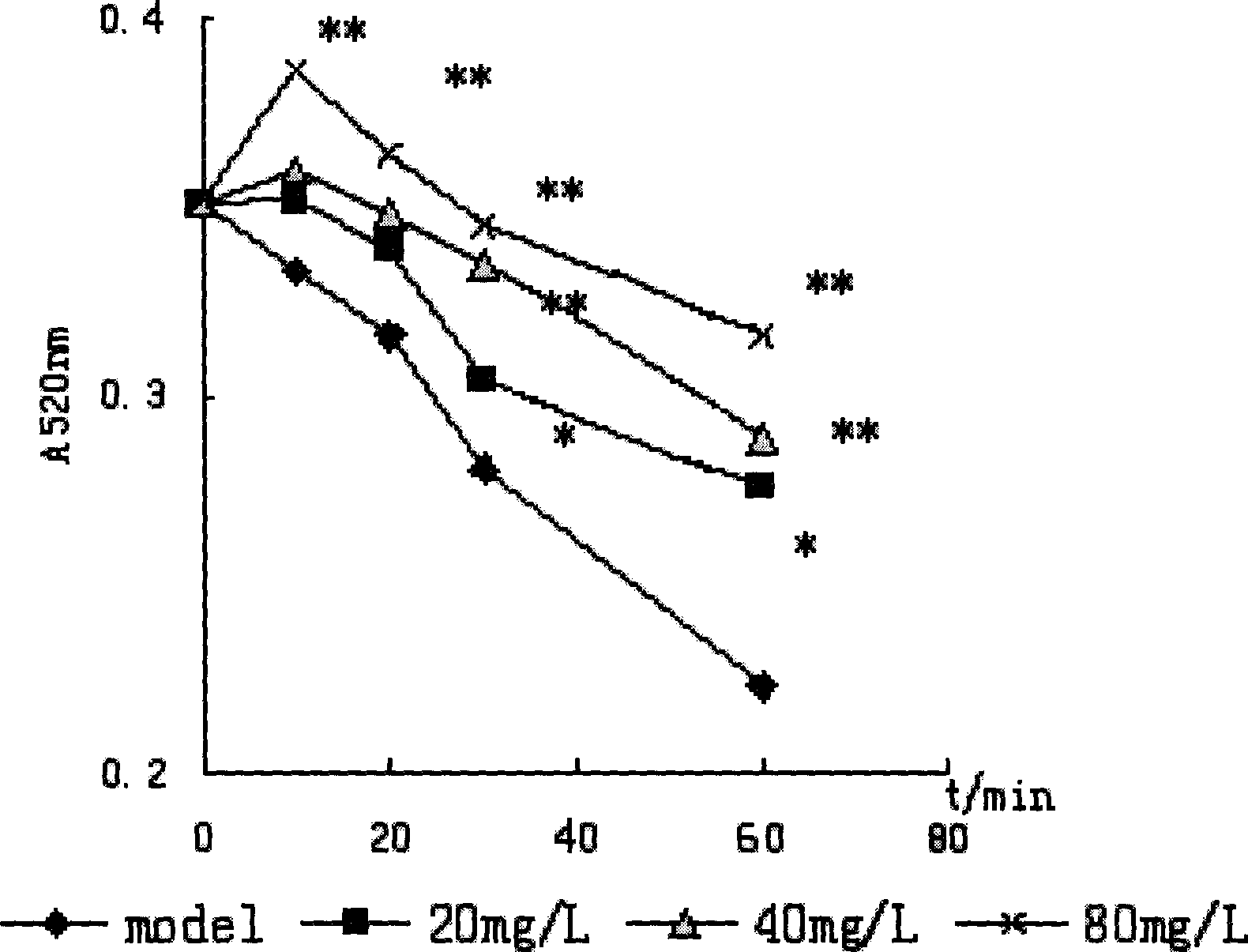

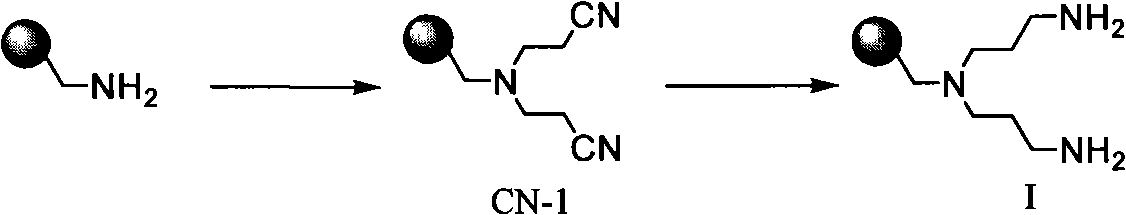

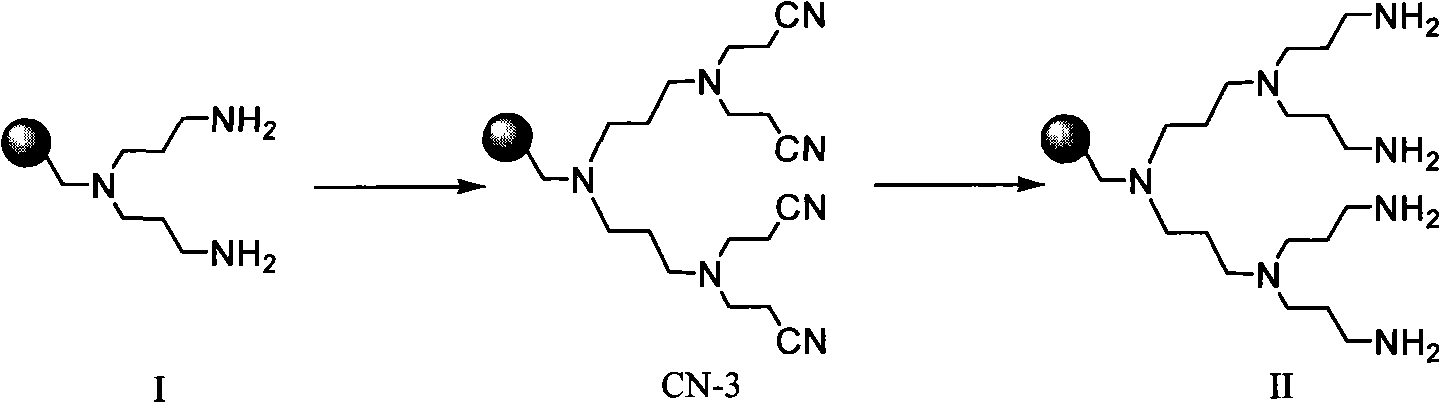

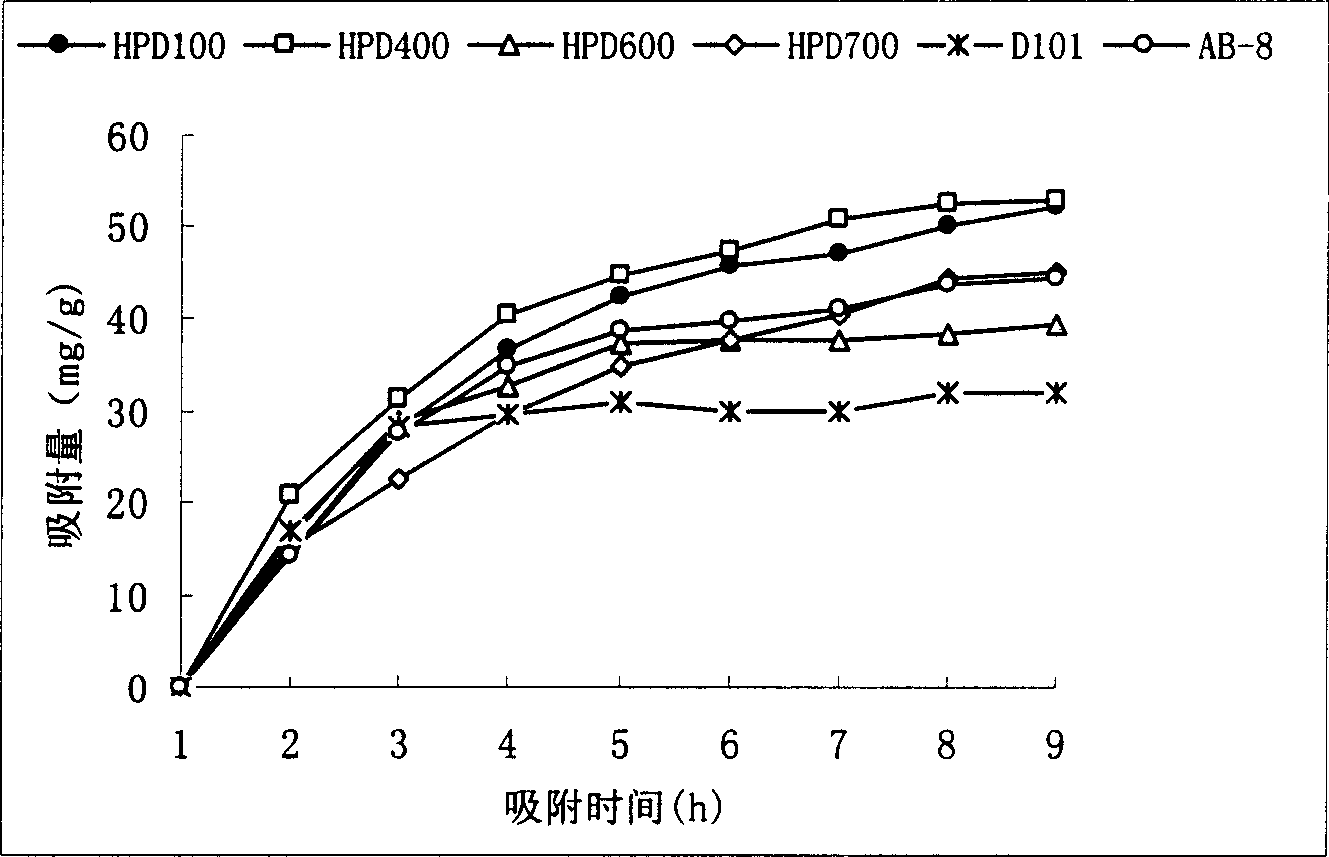

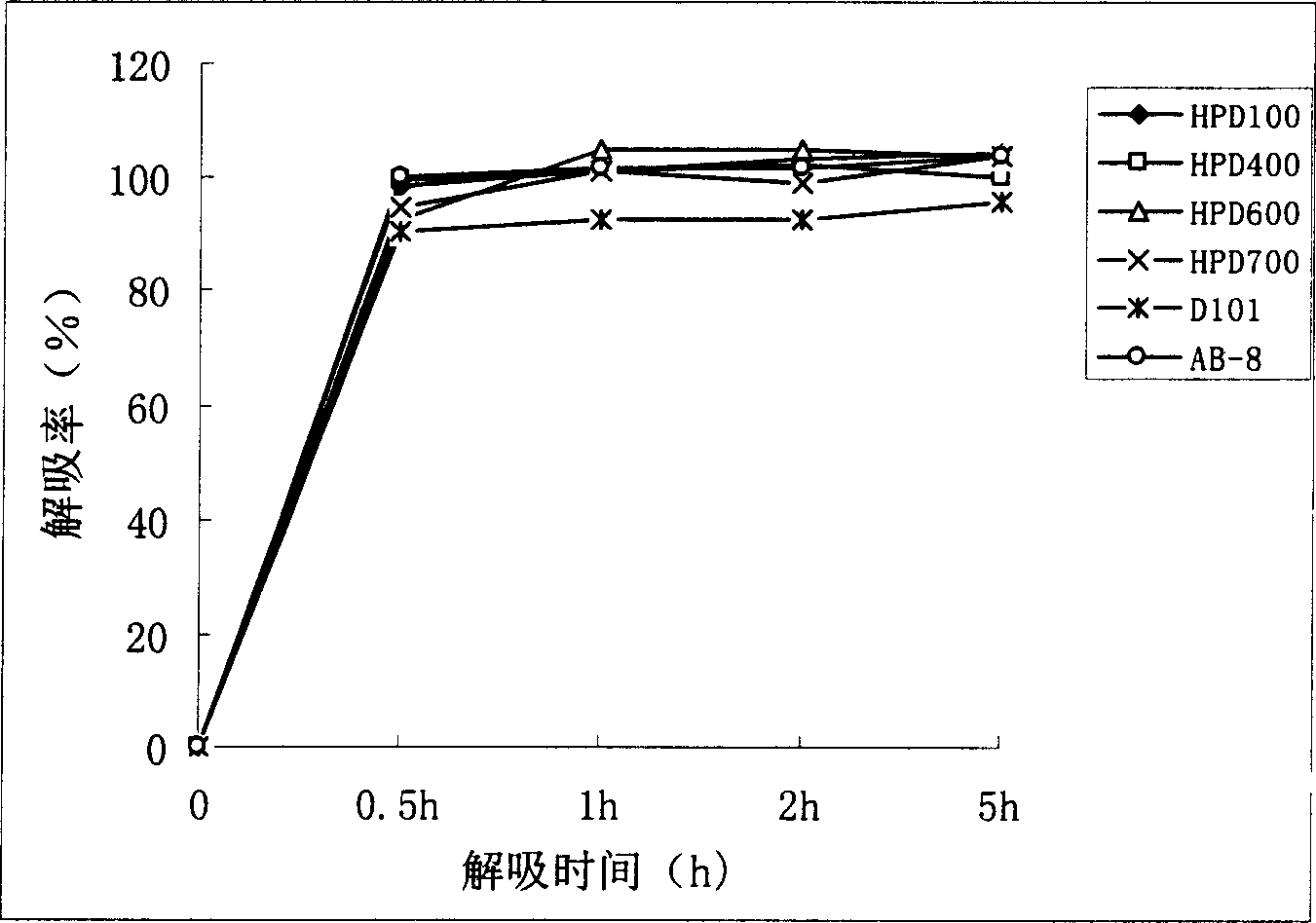

Method for adsorbing and recycling phenol in wastewater by polyamine macroporous resin

ActiveCN101898937AImprove adsorption capacityLarge adsorption capacityOrganic chemistryOrganic compound preparationSorbentDesorption

The invention discloses a method for adsorbing, removing and recycling phenol in water by polyamine macroporous resin and relates to a method for processing phenol-contained wastewater. The polyamine macroporous resin is used as an adsorbent for processing phenol-contained water, phenol in water is adsorbed by the resin, and the phenol adsorbed on the resin is recycled by eluting. The method is carried out according to the following steps of: (1) adjusting the phenol-contained water to be weak acid and leading the phenol-contained water to pass through an adsorbing column filled with the polyamine macroporous resin; (2) after the polyamine macroporous resin in a device to be processed absorbs the wastewater to reach saturated, emptying residual liquid in an adsorbing device and eluting the resin in the adsorbing column by using the mixing liquid of water and methanol; (3) adjusting the polyamine macroporous resin subjected to elution processing to neutrality, which can be repeatedly used for processing the phenol-contained wastewater; and (4) concentrating an eluant for recycling sodium phenate which can be reused after adding acid for neutralization and purifying, By adopting thepolyamine macroporous resin as the adsorbent, the invention has the advantages of high adsorbing capability, convenient desorption and high desorbing rate.

Owner:溧阳常大技术转移中心有限公司

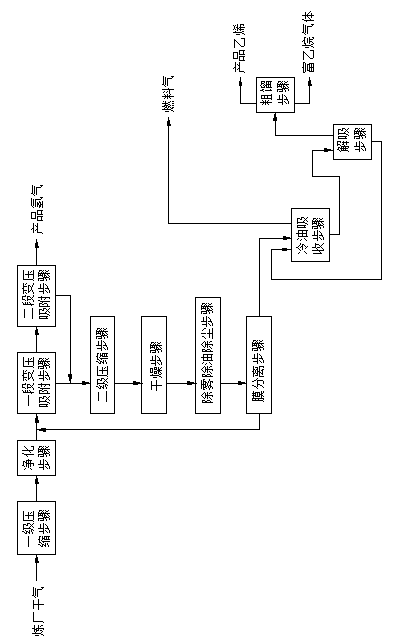

Method for recovering high yield and high purity hydrogen and ethylene from refinery dry gas

ActiveCN104045502AHigh yieldExtended service lifeHydrogen separationDistillation purification/separationProcess engineeringRefinery

The invention discloses a method for recovering high yield and high purity hydrogen and ethylene from refinery dry gas. The method comprises the following steps: a first stage pressure swing adsorption, a second stage pressure swing adsorption, membrane separation, cold oil absorption and coarse distillation. The invention has the advantages that the method combines adsorption separation method, membrane separation method and cold oil absorption method to process refinery dry gas, so as to obtain high purity hydrogen, ethylene and C2 and above gas rich in ethane, ensure high yield, and achieve clear separation of hydrogen, ethylene and gas rich in ethane.

Owner:SICHUAN TECHAIRS

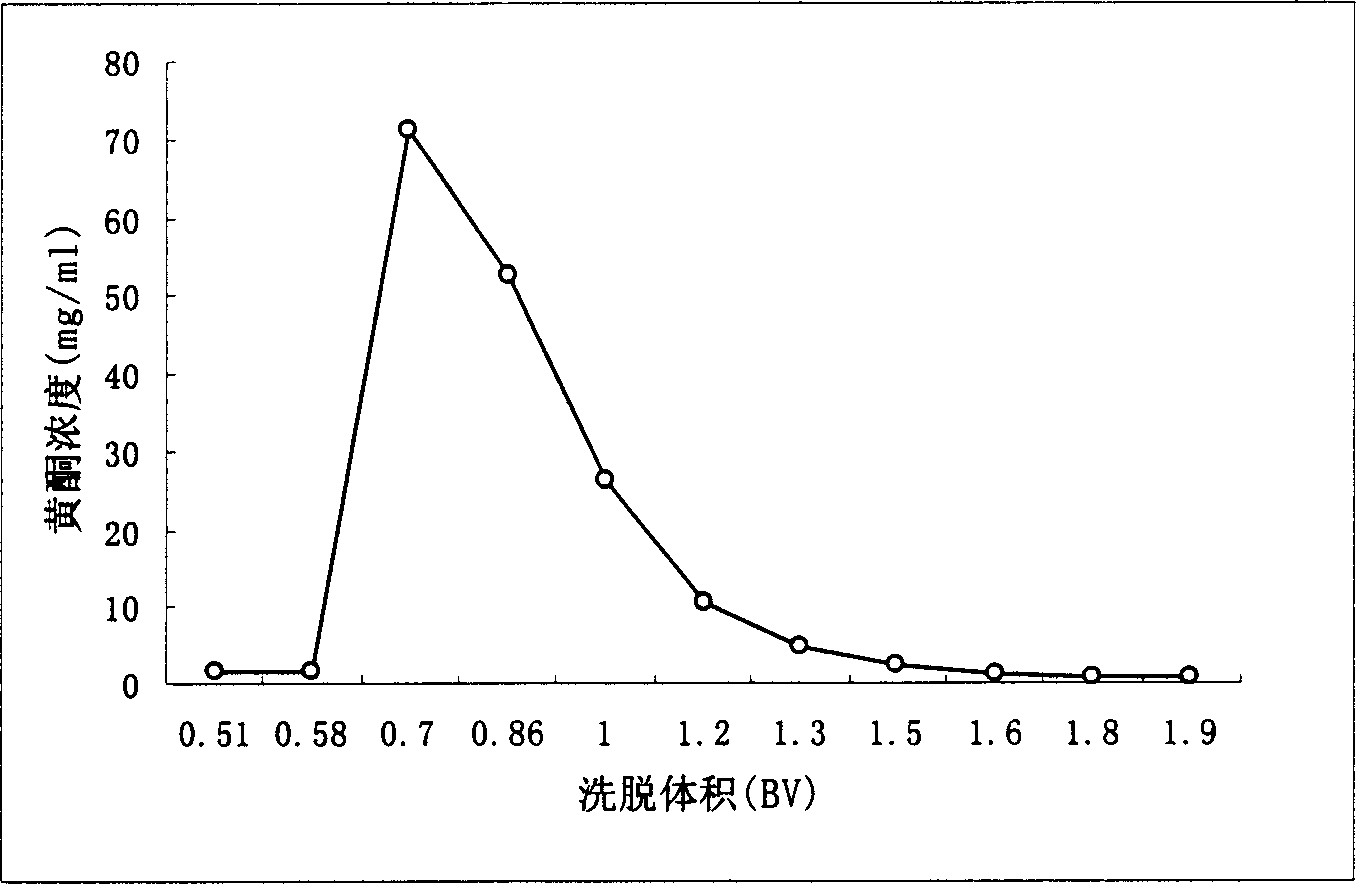

Method for extracting rose flavone from rose residue solution

ActiveCN103588742AEfficient separationOptimize process flowOrganic chemistryNatural dyesAlcoholFiltration

The invention relates to a method for extracting rose flavone from a rose residue solution. The method comprises the following steps: (1), filtering the rose residue solution, concentrating, adding ethyl alcohol to adjust the pH value of the solution, refrigerating and standing in the absence of light; (2), performing suction filtration on the solution in the step (1), and concentrating, so as to obtain rose flavone pigment coarse powder; (3), performing separation and purification on the rose flavone pigment coarse powder obtained in the step (2), so as to obtain eluant; (4), concentrating and drying the eluant, so as to obtain dry flavone. According to the invention, the flavone extraction ratio reaches above 8% to the maximum extent, and is greatly improved compared with the flavone extraction ratio being not higher than 5% in the prior art; the obtained flavone is bright red in color, and can be widely applied to the fields of medicine and food.

Owner:银谷芳香科技有限公司

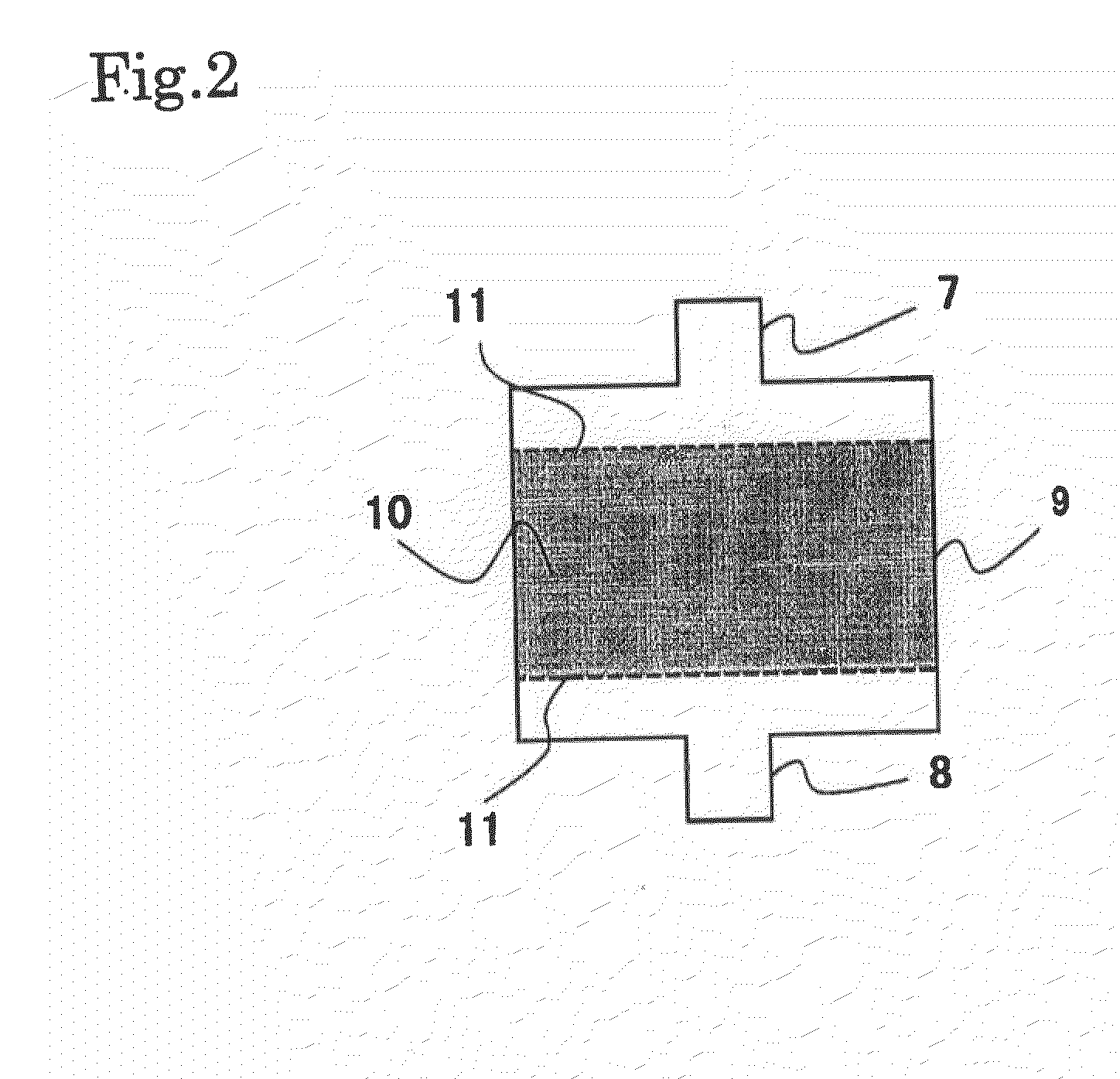

Method for reducing evaporated fuel emission, canister and adsorbent therefor

ActiveUS8864877B2Emission reductionImprove adsorption capacityNon-fuel substance addition to fuelIsotope separationActivated carbonChemistry

To provide an adsorbent which achieves a low-emission performance while maintaining the adsorption performance for adsorbing an evaporated fuel component, a canister comprising the adsorbent, and a method for reducing evaporated fuel emission. A second adsorbent (e.g., a granule) filled in a second compartment disposed in a downstream side with respect to a first compartment comprises an activated carbon as an adsorption site and a solid diluent as a non-adsorption site. The adsorbent has a difference in n-butane adsorption volume of not less than 35 g / L between a n-butane vapor concentration of 5% by volume and a n-butane vapor concentration of 50% by volume measured at 25° C., a butane working capacity measured in accordance with ASTM D5228 of not less than 8 g / dL, and a butane desorption rate of not less than 45% when a purge air amount measured in accordance with ASTM D5228 is 30 bed volumes of the adsorbent volume.

Owner:KURARAY CO LTD

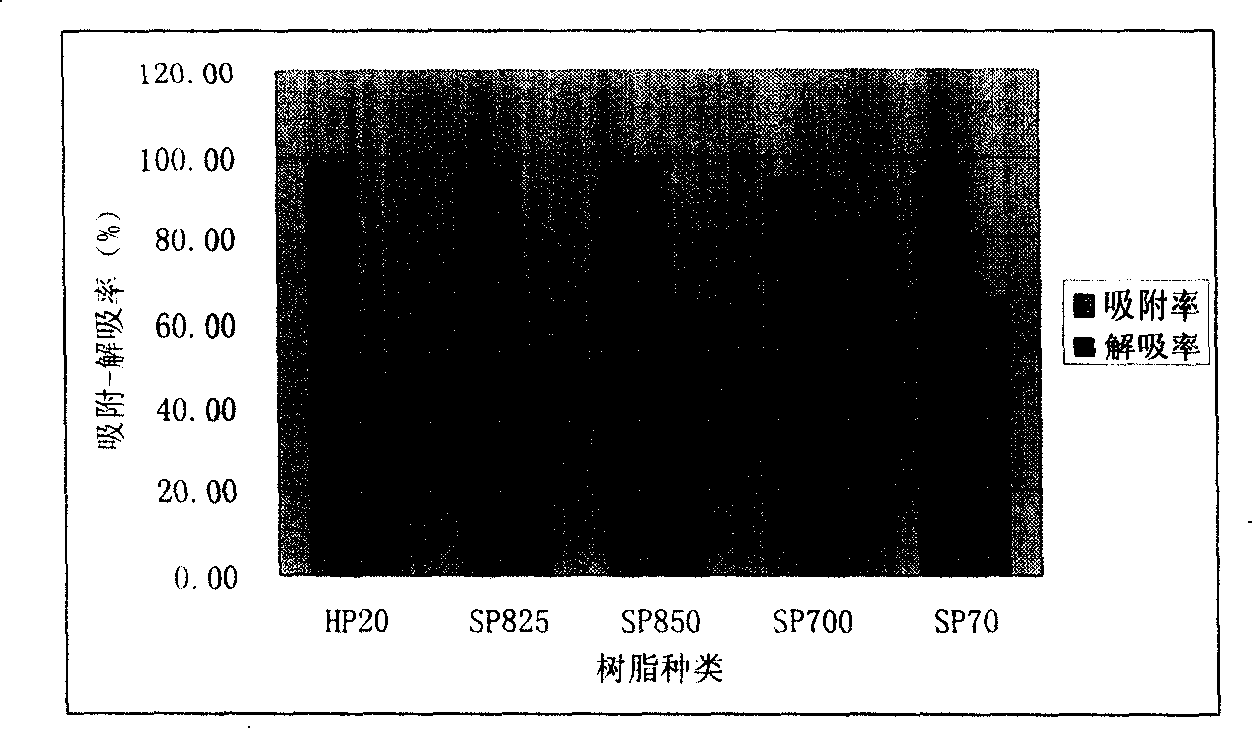

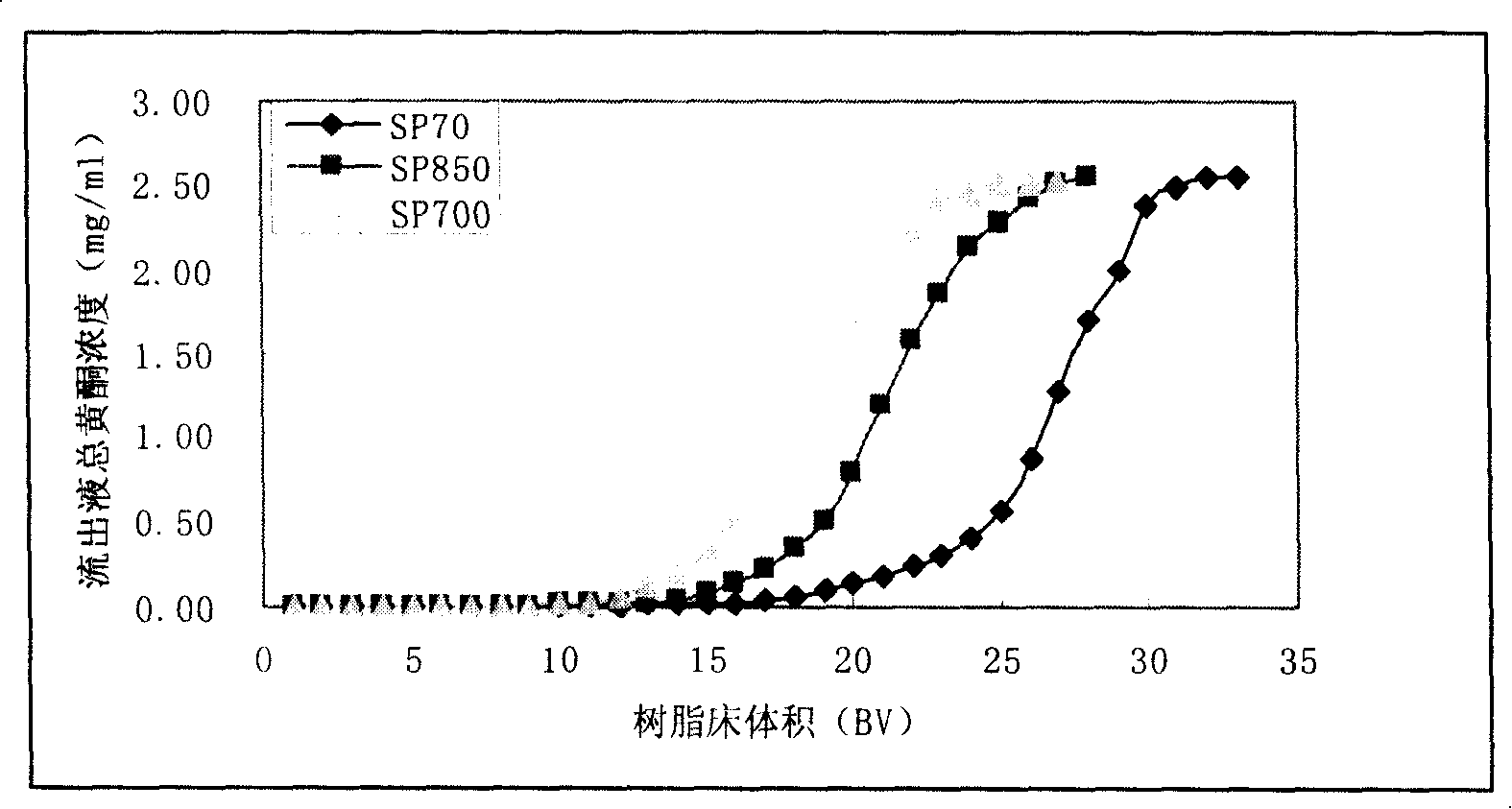

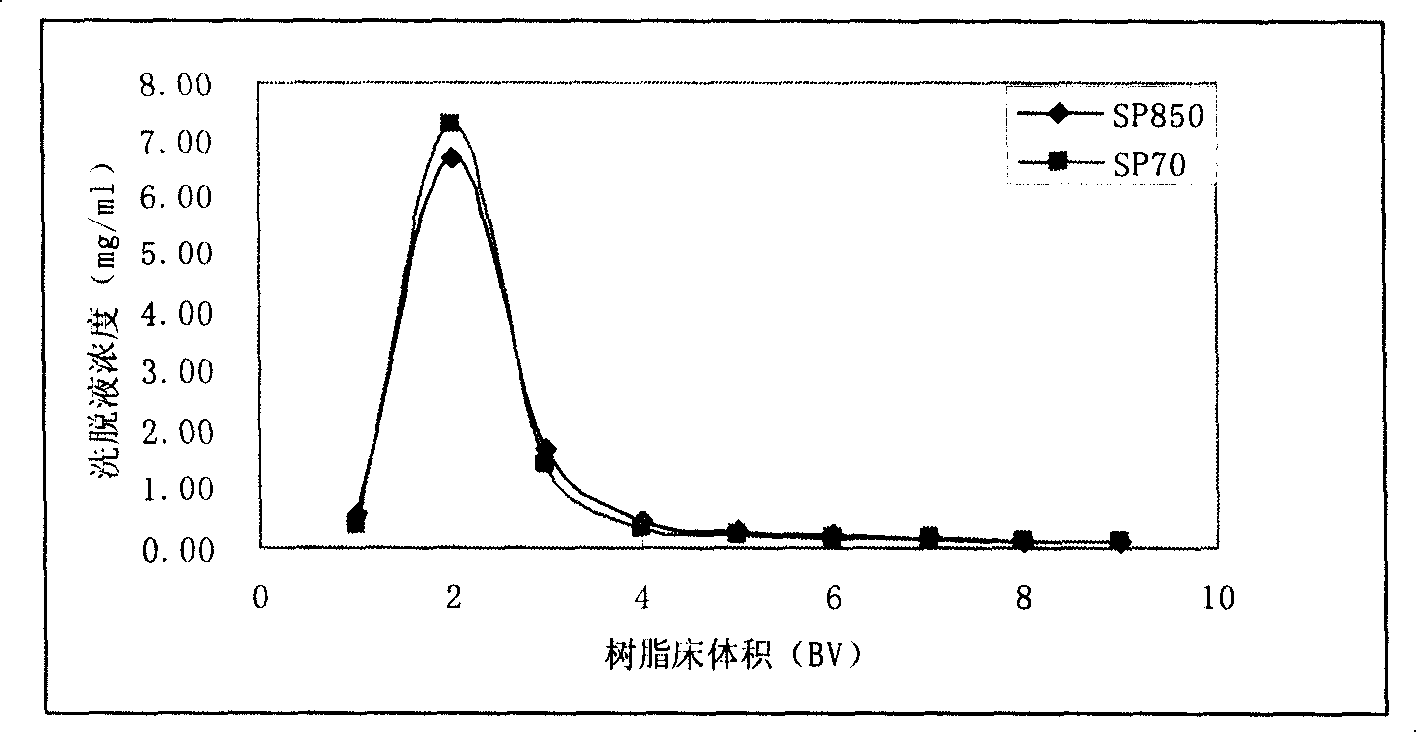

Chrysanthemum total flavone resin purification method

InactiveCN1460678ASimple and fast operationEasy to operateOrganic chemistryPurification methodsSolvent

The present invention adopts macroporous resin adsorption to make chrysanthemum extract undergo the processes of resin column treatment, elution, collecting elute, concentrating and drying so as to obtain the purified chrysanthemum total flavone. The transferrin rate of its total flavone can be up to above 95%, and its purified total flavone content can be up to above 65%, its reproducibility is good, and said resin can be repeatedly used.

Owner:浙江现代中药与天然药物研究院有限公司 +1

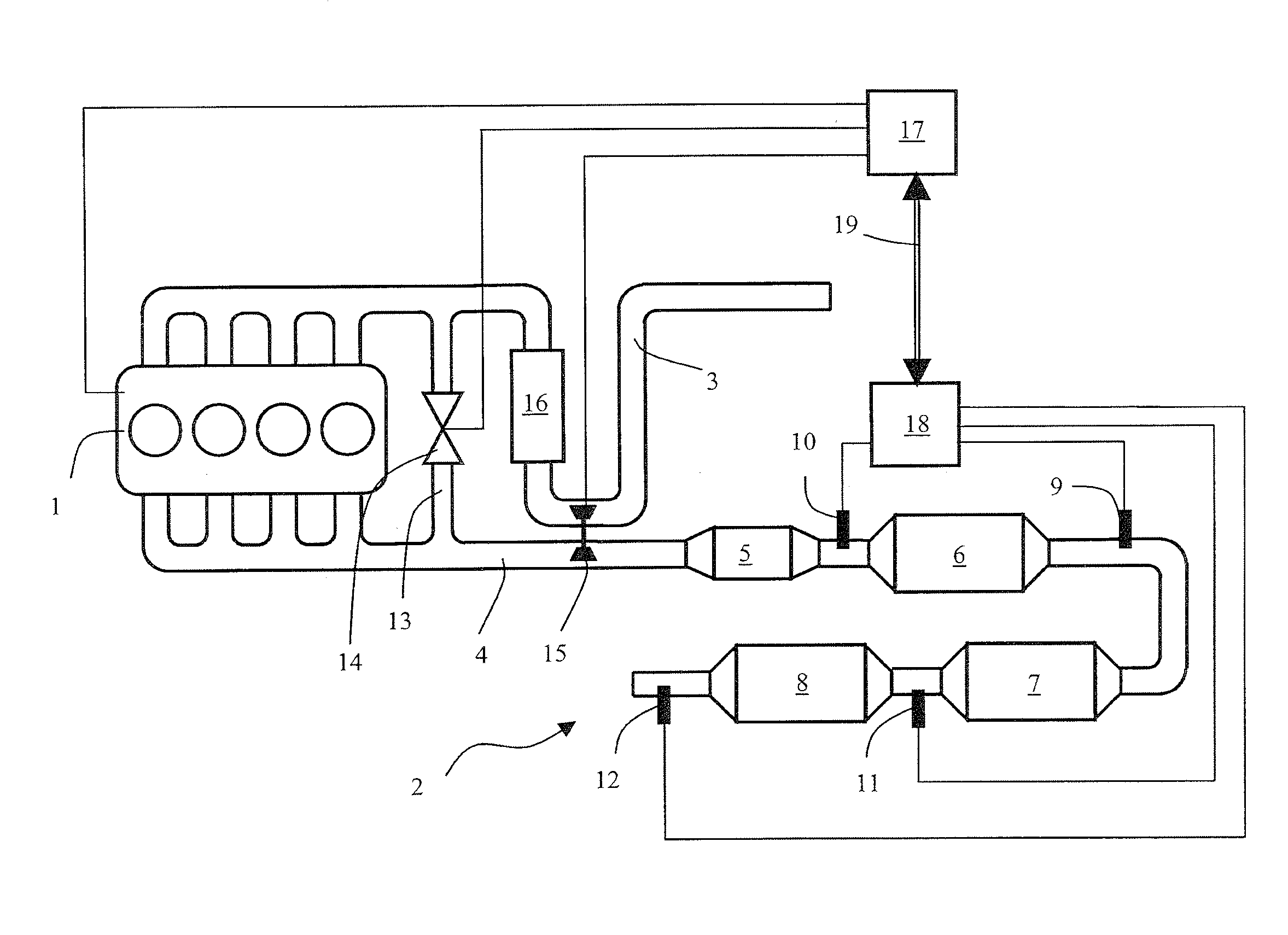

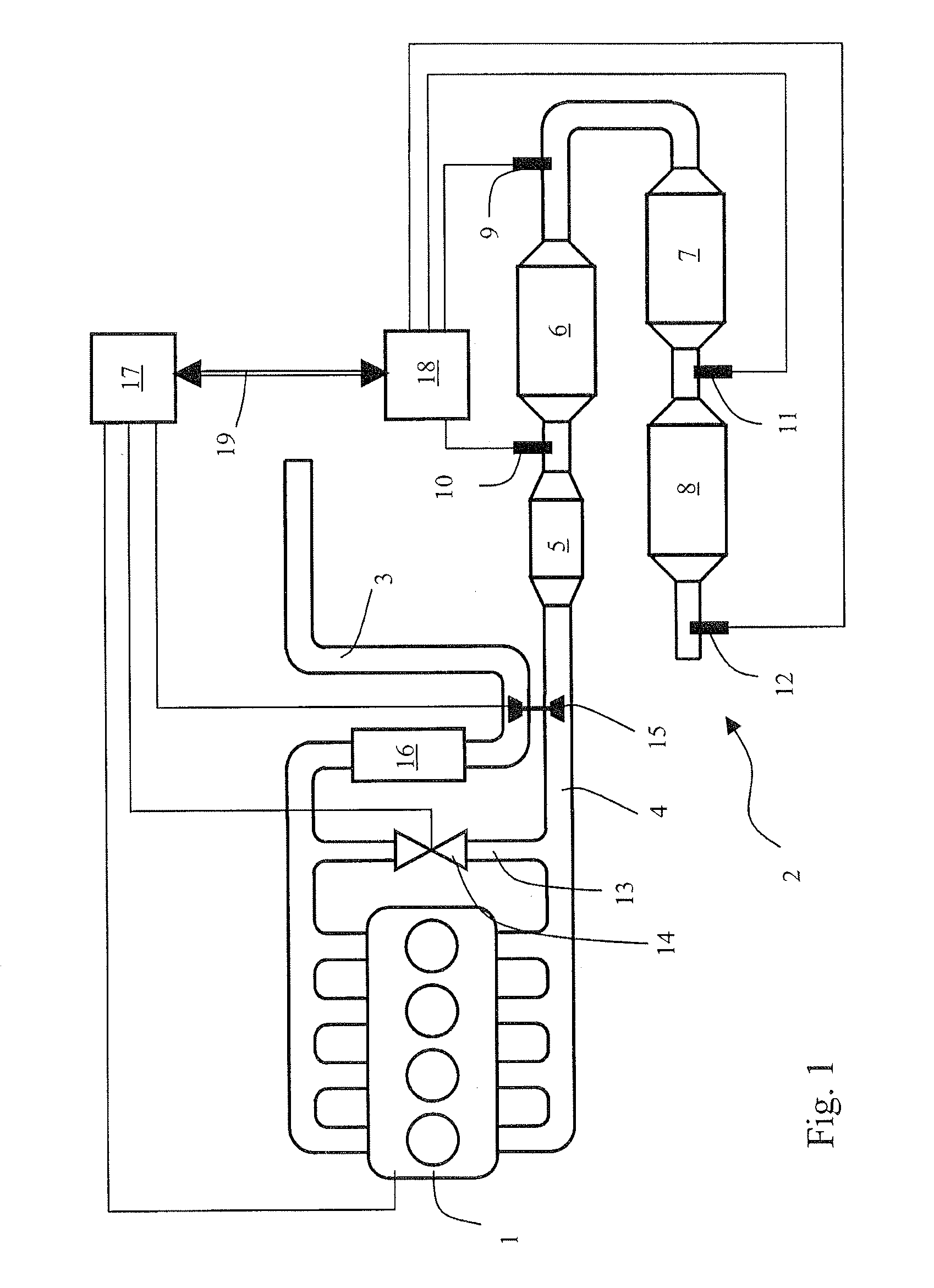

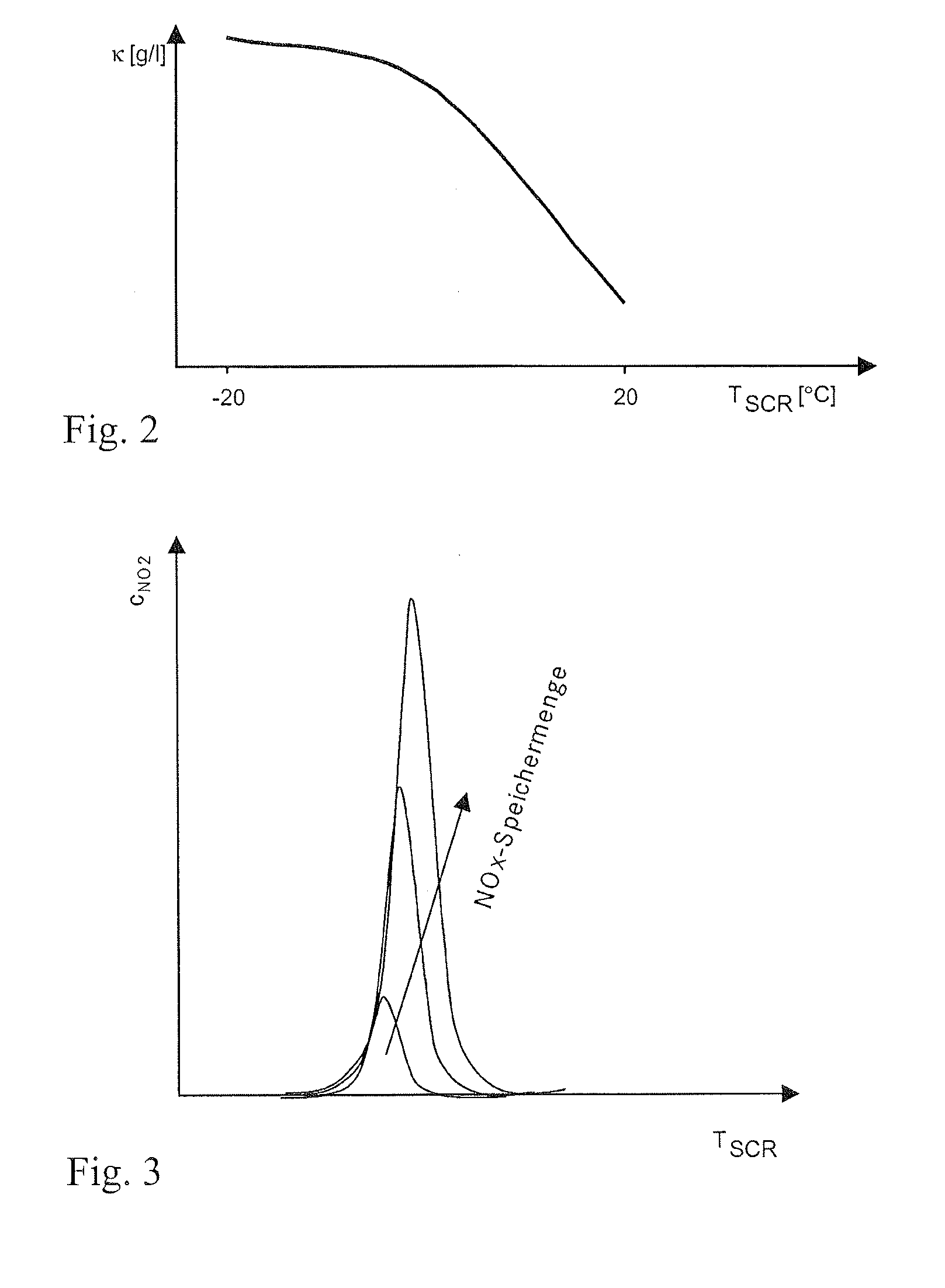

Method for the Operation of an Internal Combustion Engine Comprising an Emission Control System that Includes an SCR Catalyst

InactiveUS20120004825A1Quickly increasing desorptionHigh desorption rateAnalogue computers for vehiclesElectrical controlNitrogen oxidesControl system

A method for operating an internal combustion engine comprising an exhaust gas cleaning system that includes a SCR catalyst. In conjunction with a cold start and / or a warm-up of the internal combustion engine, the internal combustion engine is operated using a cold start engine operation method having predefineable values for predefineable operating parameters of the internal combustion engine. An amount of nitrogen oxides stored in the SCR catalyst is estimated, and the cold start engine operation method is activated when the estimation indicates that the nitrogen oxide storage amount exceeds a predefineable nitrogen oxide storage amount limit value.

Owner:DAIMLER AG

Method for extracting chrysanthemum total flavone

ActiveCN101167775AEasy to operateLarge adsorption capacityAntimycoticsMetabolism disorderDesorptionSolvent

The invention discloses a method for extracting total flavonoids from chrysanthemums. The method is to extract the chrysanthemums with ethanol, and then use a macroporous resin adsorption method to put the extract on a column, elute, collect the eluate, concentrate and dry to obtain the total flavonoids of chrysanthemums. The flavonoid approach. The method for extracting total flavonoids from chrysanthemums involved in the present invention is a method with simple and quick operation. The selected macroporous resin has the characteristics of large adsorption capacity and high desorption rate. The method of the invention uses ethanol as a solvent, which is cheap and nontoxic. The content of the total flavonoids extracted from the chrysanthemum by the method of the invention can reach more than 55%, and the reproducibility is good, and the resin can be used repeatedly.

Owner:北京荃方生物科技有限公司

Method for synergistically desorbing gold thiosulphate coordination ions from strongly-alkaline anion exchange resin

ActiveCN107488789AStable in natureReduce desorption costProcess efficiency improvementNitrateDesorption

The invention discloses a method for synergistically desorbing gold thiosulphate coordination ions from strongly-alkaline anion exchange resin. A mixed solution of Na2SO3 and NaOH serves as a desorption agent, and dynamic desorption is conducted on the strongly-alkaline anion exchange resin loaded with the gold thiosulphate coordination ions. According to the method, the synergistic effect of two components, namely SO3<2> and OH, is utilized, and desorption is conducted on the [Au(S2O3)2]<3> coordination ions adsorbed on the strongly-alkaline anion exchange resin; and the desorption rate of gold can reach 97% or above. Compared with traditional methods that a thiocyanate solution or a polythionate solution or a nitrate solution or another type of solution composed of a single component is adopted for desorption, the desorption method has the remarkable beneficial effects that reagents are free of toxicity; performance is stable; desorption cost is low; resin desorption and regeneration are completed by the same step; and the gold in the desorption solution can be further recycled conveniently. And good industrial application prospect is achieved.

Owner:CENT SOUTH UNIV

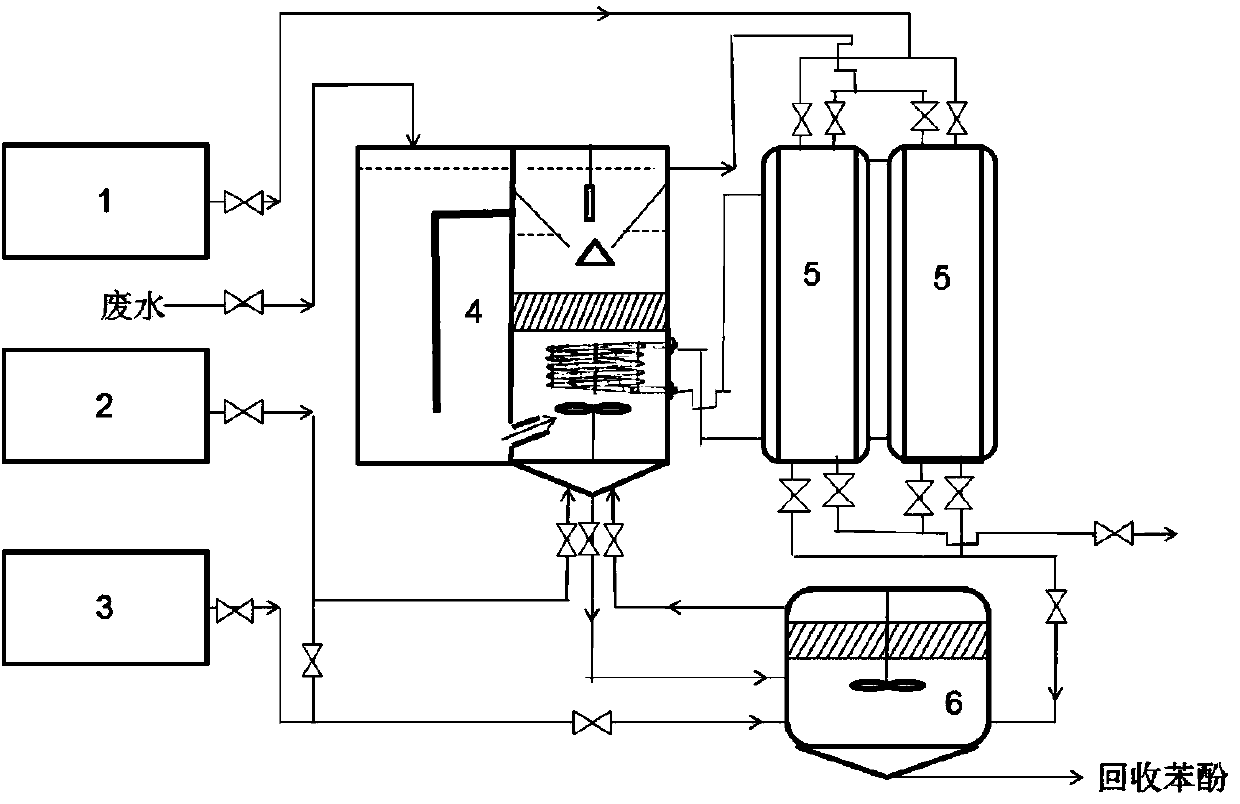

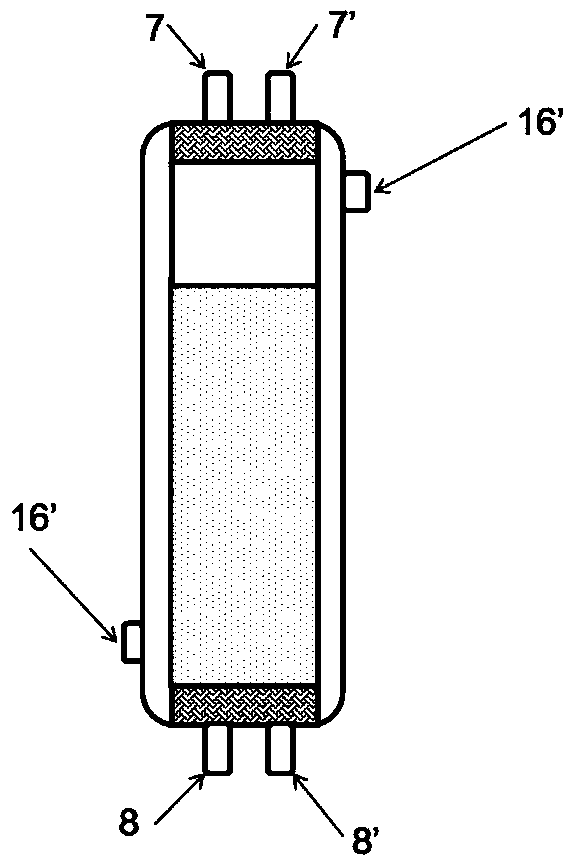

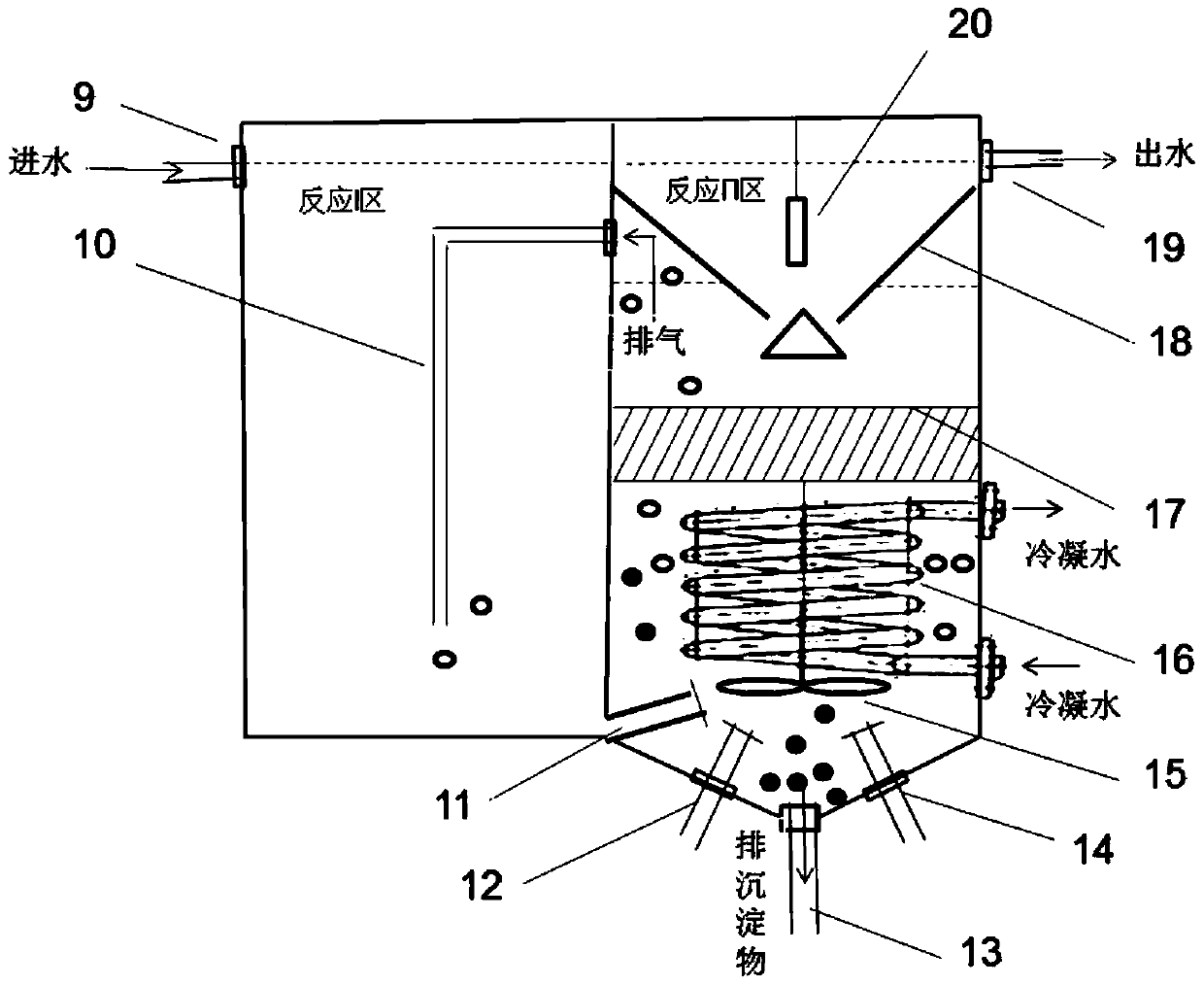

Condensation mother liquid waste water pretreatment and resource system and method in compound neutralization reactor in disperse blue 56 production process

ActiveCN103588329AReduce dosageAvoid harmOrganic chemistryOrganic compound preparationLiquid wasteNitrite ion

The invention discloses condensation mother liquid waste water pretreatment and a resource system and a method in a compound neutralization reactor in a disperse blue 56 production process, which belongs to the waste water treatment field. The method comprises the following steps: highly basic condensation mother liquid waste water in the disperse blue 56 production process and a mixed acid solution (sulfuric acid and sulfamic acid) in the compound neutralization reactor are neutralized, three purposes of reducing the pH value of waste water, precipitating phenol and removing nitrite can be simultaneously realized; the neutralized waste water passes through a fixed bed adsorption column filled with adsorption resin, so that residual phenol in the waste water can absorb on the resin column. Resin after adsorption saturation is carried out with desorption and regeneration by using a NaOH solution and then the resin is repeatedly usable, and the desorption liquid passes through the processes of acidity adjusting and vacuum distillation of phenol to realize recycling of phenol. According to the condensation mother liquid waste water which is pretreated in the disperse blue 56 production process, CODCr value is decreased from about 55000mg / L to less than 500mg / L, the phenols substance concentration is decreased from about 19000mg / L to less than 20mg / L, the nitrite ion is decreased from 87000mg / L to less than 20mg / L; thereby the treatment and resource utilization of waste water can be effectively realized.

Owner:江苏吉易达环保科技有限公司

Absorbent for circularly absorbing sulfur dioxide gas in tail gas of natural gas and application of absorbent

ActiveCN107019996ALarge absorption capacityReduce desorption energy consumptionDispersed particle separationAbsorption capacityDesorption

The invention discloses an absorbent for circularly absorbing sulfur dioxide gas in tail gas of natural gas and an application of the absorbent. The absorbent comprises the following components in percentage by mass: 30-60wt% of cyclic tertiary amine compounds, 5-10wt% of a desulfurization fortifier, 10-30wt% of a latent solvent, 0.5-3wt% of an activating agent, 1-2wt% of an antioxidant, 0.5-2wt% of a corrosion inhibitor and the balance of water. The application refers to applying the absorbent to removal of the sulfur dioxide gas in the tail gas of the natural gas at an absorption temperature of 20-70 DEG C. According to the invention, by utilizing the structure characteristics of the cyclic tertiary amine compounds which are high in sulfur dioxide absorption capacity and low in desorption energy consumption, and adding corresponding auxiliary agents at the same time, the absorption of absorption liquid to sulfur dioxide has high efficiency and specificity; and the absorbent can selectively remove SO2 from the tail gas of the natural gas, so as to greatly reduce the gas purification cost, and facilitate follow-up utilization of recycled acid gas.

Owner:CHINA PETROLEUM ENG CORP LTD +2

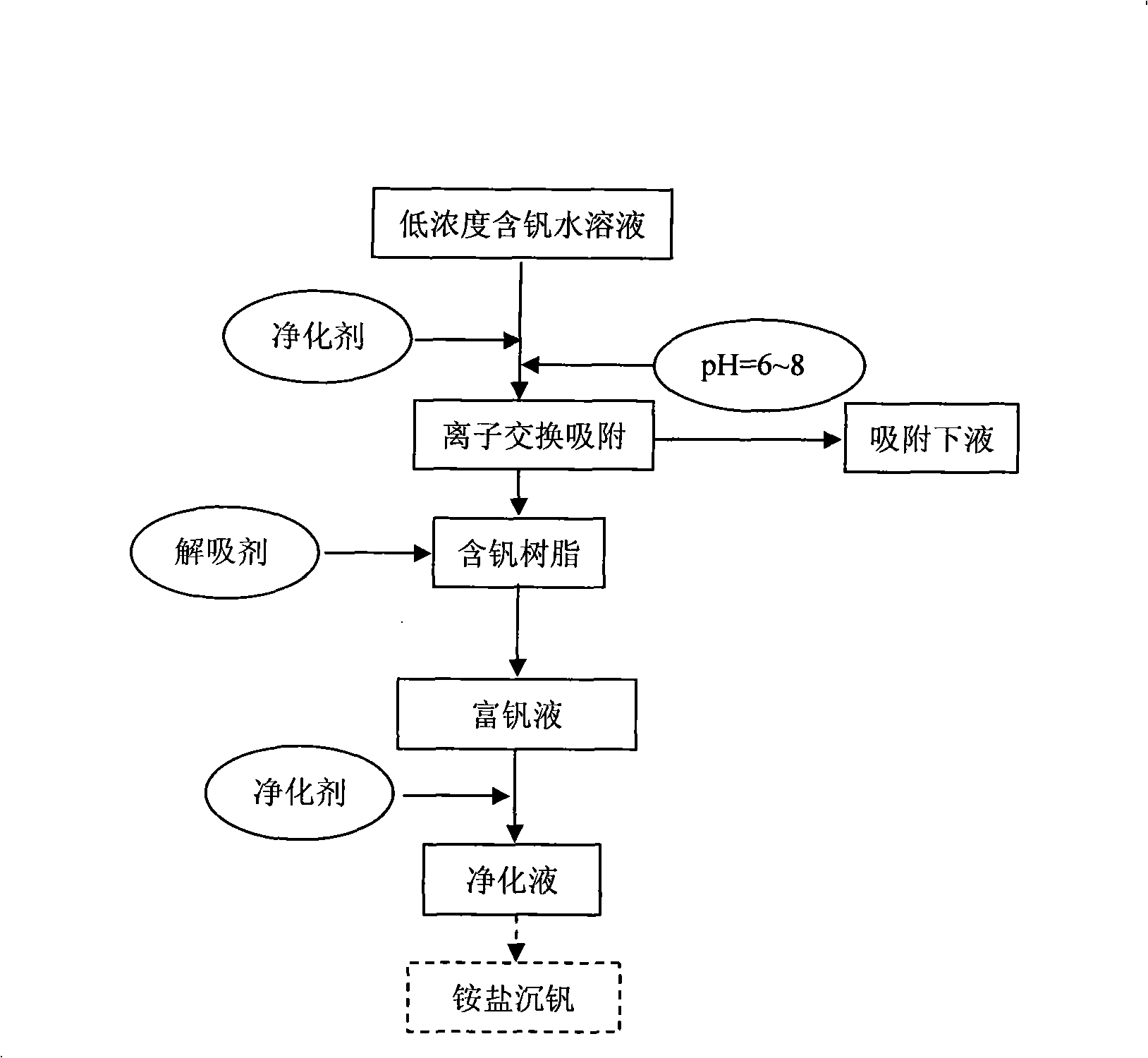

Method for purifying and enriching low-concentration vanadium-containing water solution

InactiveCN101260467ASimple purification processReduce dosageProcess efficiency improvementDesorptionIon exchange

The invention relates to a method for purifying and enriching a low concentration water solution with vanadium content. The technical proposal is as follows: a purifying agent with the concentration ranging from 0.6 to 10g / L is added into the low concentration water solution containing vanadium with the concentration of V2O5 of ranging from 2000 to 5000mg / L, the mixture is mixed evenly with a pH value ranging from 6 to 8; the low concentration water solution containing vanadium performs the ion exchange adsorption through the strongly basic anion ion exchange resin at a speed of 2.0 to 10mLh<-1>mL<-1> wet resin to the adsorption and saturation of the strongly basic anion ion exchange resin to obtain the resin containing vanadium and the adsorption under liquid; and then the mixing solution of 3 to 5wt percent of sodium hydroxide and 8 to 13wt percent of sodium chloride is prepared to be as a strippant, the use level of the strippant is three to five times of the volume of the resin containing vanadium, the strippant performs the desorption through the resin containing vanadium at a speed of 0.8 to 1.6 mLh<-1>mL<-1> wet resin to obtain the vanadium enriching fluid; finally, the purifying agent with the concentration ranging from 0.1 to 2.5g / L is added into the vanadium enriching fluid, the purified fluid is obtained after the solid-fluid separation. The method has the characteristics that the purifying time is shortened, the purifying agent consumption is reduced, the vanadium loss is reduced, the purifying effect is good and the technique is simple.

Owner:WUHAN UNIV OF SCI & TECH

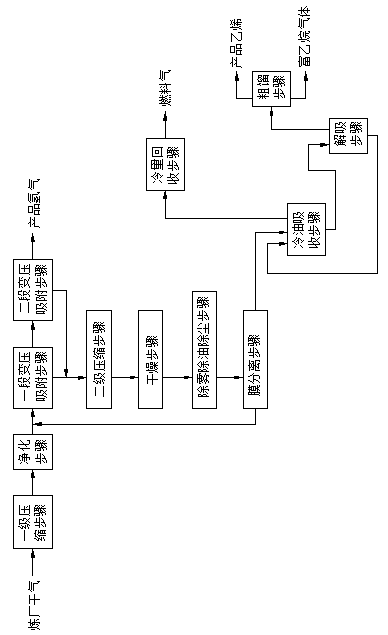

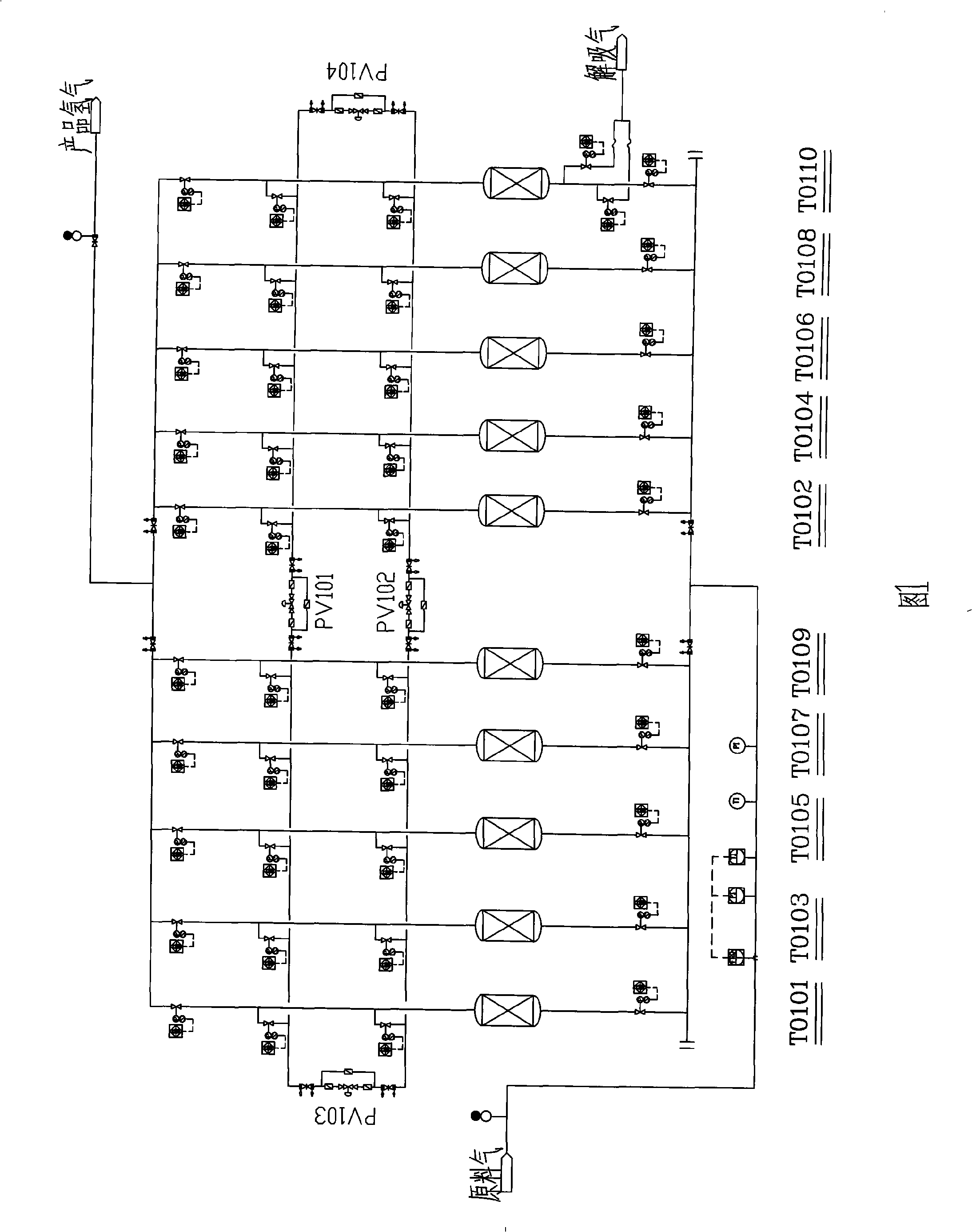

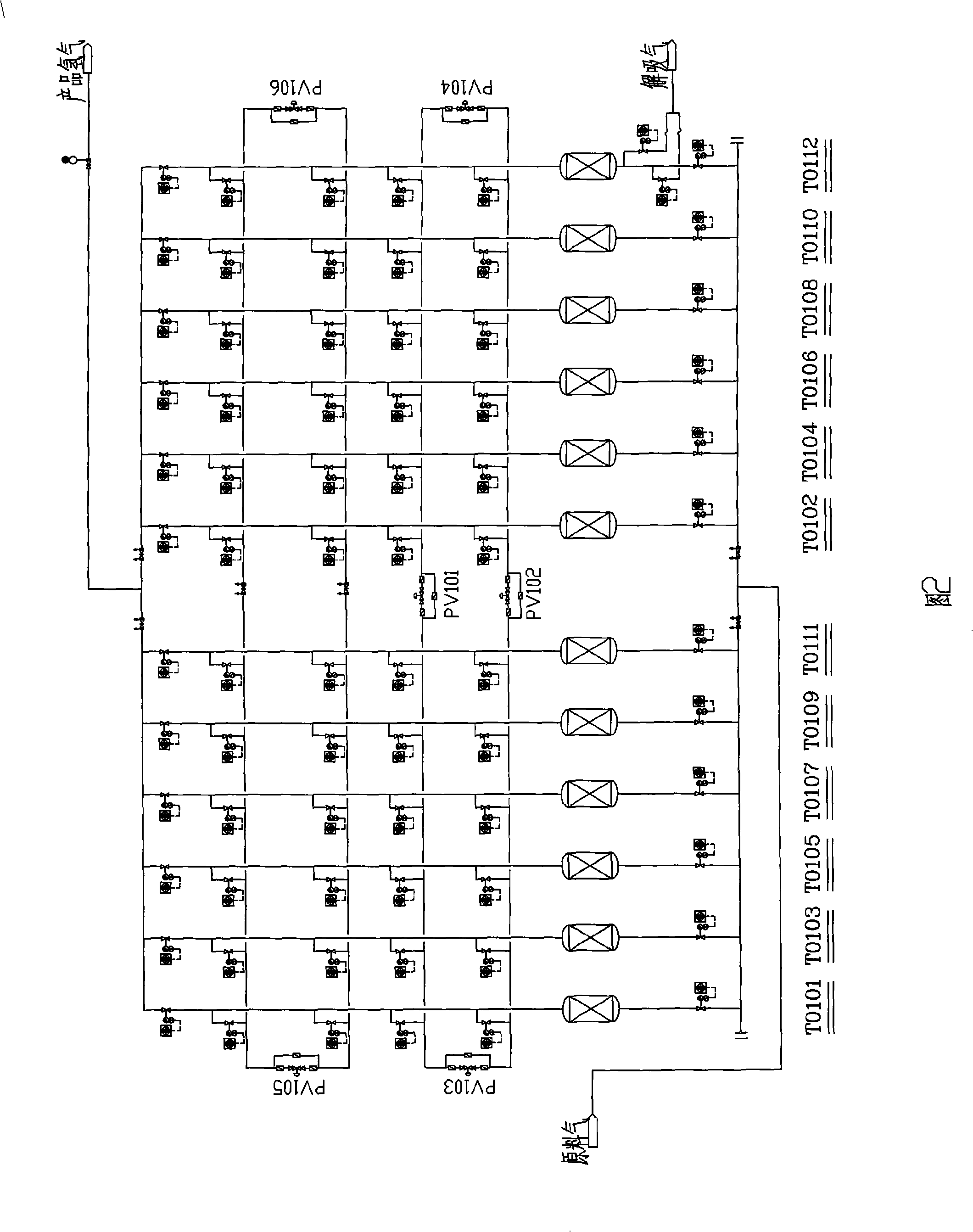

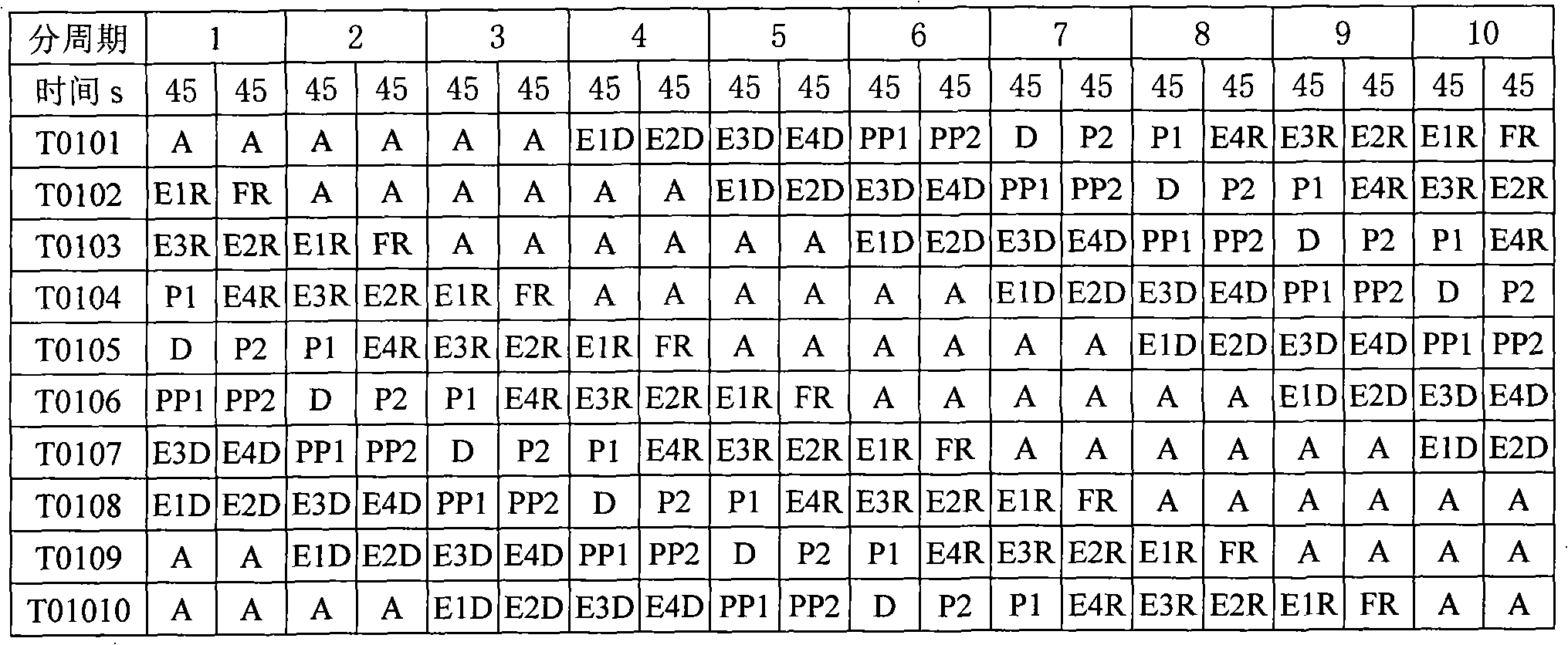

Multiple placing in turn interleaving flushing pressure variable adsorption technique

The invention discloses a pressure swing adsorption (PSA) process for multiple placing sequentially and washing alternatively. At least four regulating valves alternately distributed are arranged on each outlet line on the top of an adsorption tower; two or more sequencing valves as a sequential outlet valves and washing outlet valves are arranged on each adsorption tower at the top of the adsorption tower and the sequential placing and the process of washing can be regulated so as to realize the sequential placing procedures of three times or more sequences and the alternative washing procedures of the corresponding times reversed sequences.. The pressure swing adsorption (PSA) process of the invention increases regeneration time, improves the desorption efficiency of impurity components, reduces the consumption of washing gas and increases the rate of products gas collecting; the cycle per minute time of the adsorption is reduced, which can reduce the investment of the equipment and occupation areas. while the performance difference arisen by adopting different control valves in the sequential placing and washing procedures in different adsorption towers is avoided, thus leading the sequential placing and washing procedures of each adsorption tower are completely identical and avoiding reducing the regeneration effect of the whole equipment due to the performance difference of the control valves, thereby avoiding reducing the whole operation performance of the equipment.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

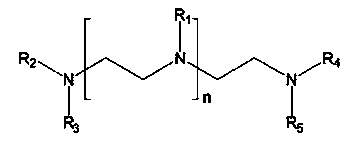

Reproducible polytertiaryamine sulfur dioxide absorbent and preparation method thereof

ActiveCN103349886AStrong absorption capacityHigh desorption rateDispersed particle separationQuinoneDry basis

The invention relates to a reproducible polytertiaryamine sulfur dioxide absorbent and a preparation method thereof. The absorbent comprises the following components: (1) polytertiaryamine having a mass concentration in the range from 1% to 80%, which is taken as the major component of the absorbent, wherein the polytertiaryamine exists in a solution in the form of unionized polytertiaryamine, partially ionized quaternary ammonium salt and completely ionized quaternary ammonium salt due to addition of an acid difficult to volatilize; (2) a phenol or quinone material having a mass concentration in the range from 0.01% to 1%, which is used as an antioxidant of the absorbent; (3) 1-50wt% of acid difficult to volatilize, which is used as the cosolvent and stabilizer for the polytertiaryamine; (4) 0.1-10wt% of monoalcohol amine, which is used as an activator of the absorbent; (5) 10-90wt% of water. The absorbent absorbs sulfur dioxide in mixed gases at a low temperature and releases the absorbed sulfur dioxide gas at a high temperature to generate a sulfur dioxide by-product having a dry basis concentration greater than 99%; the absorbent can be recovered and reused.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Method for adsorbing and separating squalene from vegetable oil deodorized distillate

InactiveCN105949025AImprove adsorption capacityEfficient purificationDistillation purification/separationHydrocarbonsPreferential adsorptionOrganic solvent

The invention discloses a method for adsorbing and separating squalene from vegetable oil deodorized distillate. According to the method for adsorbing and separating the squalene from the vegetable oil deodorized distillate provided by the invention, D101 type macroporous resin is used as an adsorbent. According to the method, an adsorbing material is directly thrown into a solution containing the squalene, and an efficient adsorption process can be completed at normal temperature. According to the method, organic solvents such as n-hexane are used for desorption, the desorption efficiency is extremely high, and the squalene can be efficiently purified. The adopted adsorbing materials do not dissolve in acid, alkali and the organic solvents, are excellent in mechanic strength, can be used repeatedly, is simple in regeneration technology, and low in reclamation cost. The adopted adsorbing materials statically and dynamically adsorb the squalene in the vegetable oil deodorized distillate at normal temperature, are excellent in preferential adsorption and desorption effects, and basically has no change in adsorbing capacity when being reused after desorption activation.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Advanced treatment process of biochemical tail water of percolate of city consumption residue

InactiveCN101289235AHigh desorption rateHigh fuel valueWater/sewage treatment by sorptionHigh concentrationEmission standard

The invention discloses an advanced treatment method for biochemical tail water of leachate of municipal household waste. Tail water mainly comes from biochemical effluent from a treatment device of the leachate of the municipal household waste or effluent of simply chemical-physical treated biochemical effluent. The steps of the method are as follows: at normal temperature and under the condition of 0.5 BV / h to10BV / h of flow, pretreated tail water is absorbed by a device filled with adsorbent resins with complex functions or macroporous resin to yield water, so as to be discharged by reaching the mark; the resin is desorbed and regenerated by sodium hydroxide solution, the flow of desorbing agent is 0.5BV / h to 3.0BV / h, desorbing liquid with high concentration is burnt or disposed by other safe disposal methods, and desorbing liquid with low concentration can be used for preparing the next batch of desorbing agent for circular application. The method of the invention can reduce the COD of the tail water to below 100mg / L from about 150mg / L to 500mg / L and can reduce the ion concentration of ammonia nitrogen, total nitrogen and heavy metal to be below first-grade state emission standard. The method of the invention has the advantages of simple technique and large treatment amount, which can make up the shortcomings of the existing treatment technology of leachate of municipal household waste.

Owner:NANJING UNIV

Industrial quick flue gas desulfurizing agent and preparation method thereof

InactiveCN103691263AHigh desorption rateWell-developed pore structureDispersed particle separationPolyethylene oxideAlkali metal oxide

The invention discloses an industrial quick flue gas desulfurizing agent. The industrial quick flue gas desulfurizing agent is prepared from the following raw materials in parts by weight: 100 to 110 parts of bamboo charcoal, 30 to 35 percent of calcium oxide, 10 to 12 parts of ferric oxide, 20 to 23 parts of copper oxide, 10 to 12 parts of silicon dioxide, 20 to 24 parts of alum, 2 to 3 parts of vanadium pentoxide, 10 to 12 parts of hibiscus syriacus, 70 to 80 parts of diatomite, 20 to 24 parts of honeysuckle, 12 to 15 parts of fructus forsythiae, 30 to 35 parts of wild chrysanthemum flower, 3 to 4 parts of lignin, 10 to 12 parts of simethicone, 1 to 2 parts of rosin-polyethylene oxide ester, 4 to 5 parts of assistant agent and a suitable amount of water. The desulfurizing agent disclosed by the invention has a developed pore structure and a large specific surface area, has excellent effects of adsorbing, decoloring, and resisting bacteria, and is favorable for environmental friendliness; desulfurization can be performed quickly by using a plurality of alkali metal oxides. The industrial quick flue gas desulfurizing agent is applicable to desulfurization of boiler gas flue, does not generate secondary pollution, can be desorbed by using ammonia gas, has an obvious effect and high desorption efficiency, and is easy and convenient to use and low in cost.

Owner:WUHU ZHONGLU IND

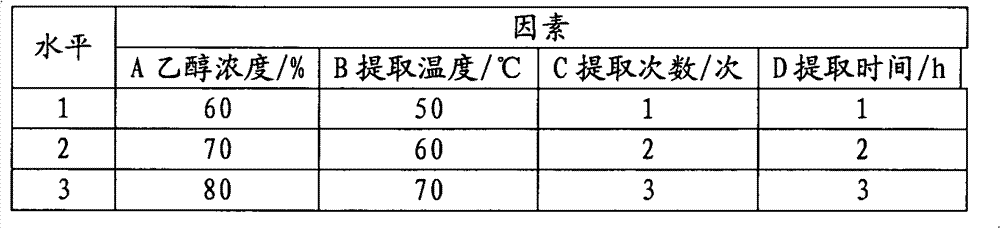

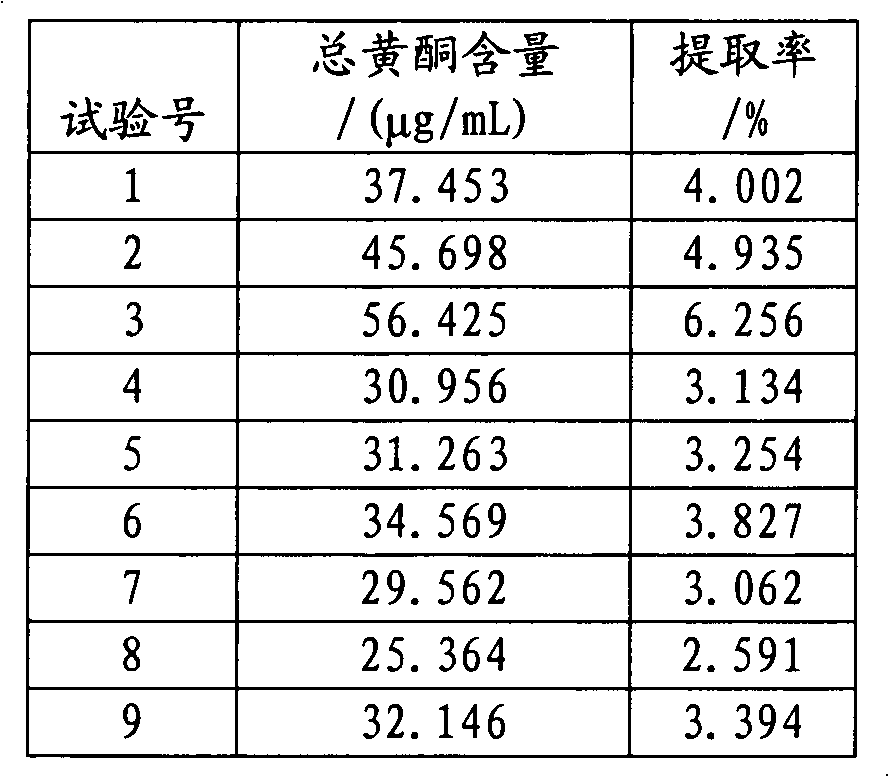

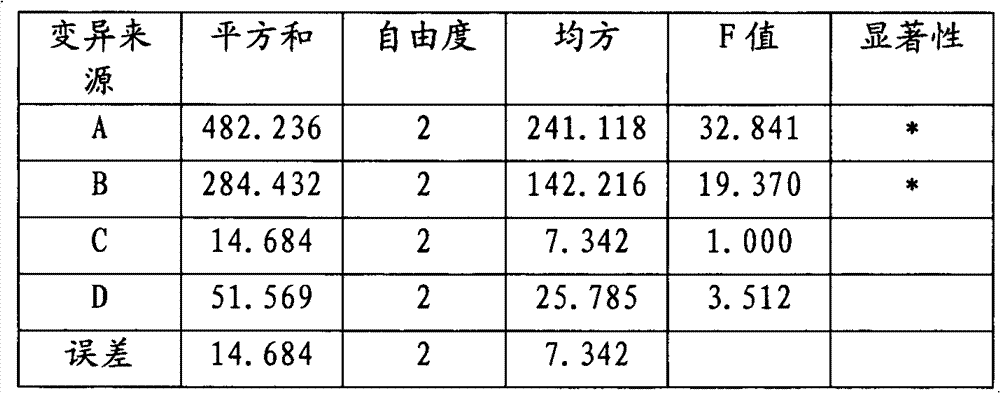

Wild chrysanthemum extraction process and measuring method for total flavonoids in wild chrysanthemums

InactiveCN102961427ABest extraction processLow costAntibacterial agentsMetabolism disorderDesorptionFiltration

The invention relates to the technical field of extraction of Chinese traditional medicines and particularly relates to a wild chrysanthemum extraction process and a measuring method for total flavonoids in wild chrysanthemums. The wild chrysanthemum extraction process sequentially comprises the following steps of: ethanol extraction, first concentration and filtration, resin adsorption, second concentration, spray drying and the like to obtain a wild chrysanthemum extract. The wild chrysanthemum extraction process and the measuring method for the total flavonoids in the wild chrysanthemums, provided by the invention, have the advantages that the ethanol heating reflux extraction is carried out on the wild chrysanthemums by using an orthogonal experiment method, the wild chrysanthemum extract is not reacted with chrysanthemum components, the total flavonoid component of the wild chrysanthemums can be dissolved to the maximum extent, and therefore, the optimal extraction process is obtained. The extraction ratio of the total flavonoids in the wild chrysanthemums is up to 6.23%, and the content of the total flavonoids is up to 9.5%. The wild chrysanthemums are low in raw material cost and suitable for large-scale industrial production, and therefore, the extraction development for the flavonoids in the chrysanthemums has higher practical significance. Macroporous resin has the characteristics of high adsorbing capacity and high desorption ratio is adopted.

Owner:安徽老炊食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com