Method for adsorbing and recycling phenol in wastewater by polyamine macroporous resin

A macroporous resin and polyamino technology, which is applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of long treatment cycle, high treatment cost, large floor area, etc., and achieve desorption Convenience, high desorption rate and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

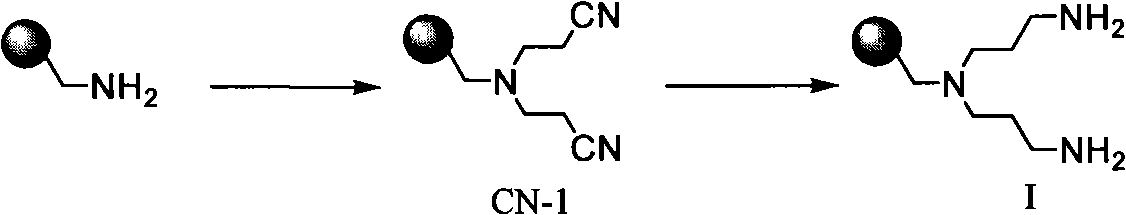

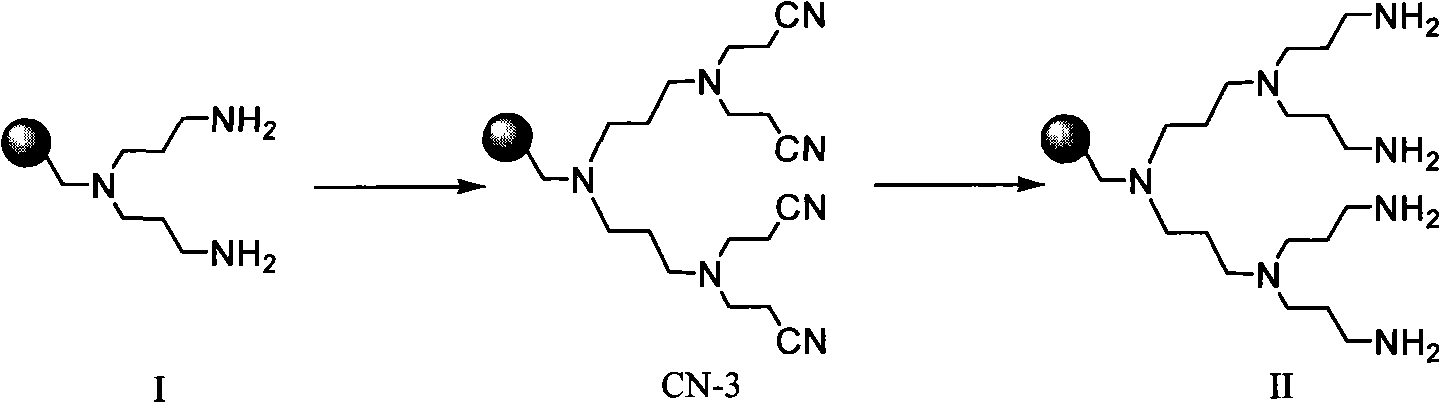

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 20g of material I resin and fill it into a glass column with an inner diameter of 14mm to prepare adsorption column I;

[0029] 2. Adjust the aqueous solution with a phenol content of 3.0 mg / mL to pH=6.4, make it flow through the adsorption column I, and control the flow rate so that the phenol content of the effluent is controlled below 0.5 ppm until the adsorption column I is saturated. A total of 1.68 L of effluent was collected, and the adsorption capacity of material I was 252 mg / g;

[0030] Three, empty the remaining liquid in the adsorption column I, use the methanol-water mixture containing 0.4% sodium hydroxide (the volume ratio of water and methanol is 1: 1) to elute the resin in the adsorption column, collect eluent 186mL After acidification with 1N hydrochloric acid, the total amount of phenol was determined to be 4740 mg, and the elution rate was 94%.

Embodiment 2

[0032] 1. The adsorption column I used in Example 1 is washed with deionized water to neutrality, and is referred to as the adsorption column I 再 use again;

[0033] 2. Adjust the aqueous solution with a phenol content of 3.0 mg / mL to pH=6.4, and make it flow through the adsorption column I 再 , control the flow rate so that the phenol content of the effluent is controlled below 0.5ppm, to the adsorption column I 再 saturation. A total of 1.66L of effluent was collected, and the adsorption capacity of material I used again was 249mg / g;

[0034] 3. Vent the adsorption column I 再 For the liquid remaining in the medium, use methanol-water mixed solution containing 0.4% sodium hydroxide (the volume ratio of water and methanol is 1: 1) to adsorb the adsorption column I 再 The middle resin was eluted, and 195 mL of the eluate was collected, and after acidification with 1N hydrochloric acid, the total amount of phenol was determined to be 4730 mg, and the elution rate of material I ...

Embodiment 3

[0036] 1. Weigh 20g of material II resin and fill it into a glass column with an inner diameter of 14mm to prepare adsorption column II;

[0037] 2. Adjust the aqueous solution with a phenol content of 3.0 mg / mL to pH = 6.4, make it flow through the adsorption column II, control the flow rate so that the phenol content of the effluent is controlled below 0.5 ppm, until the adsorption column II is saturated. A total of 1.88 L of effluent was collected, and the adsorption capacity of material II was 281 mg / g;

[0038] 3. Empty the remaining liquid in the adsorption column II, elute the resin in the adsorption column II with methanol-water mixture containing 0.4% sodium hydroxide (the volume ratio of water and methanol is 1:1), and collect the eluate 193mL was acidified with 1N hydrochloric acid, and the total amount of phenol was determined to be 5240mg, and the elution rate was 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com