Method for synergistically desorbing gold thiosulphate coordination ions from strongly-alkaline anion exchange resin

A technology of gold thiosulfuric acid and exchange resin, which is applied in the field of hydrometallurgy, can solve the problems of increased gold recovery cost, adverse effects of gold recovery, and long desorption process, and achieves the effects of economical desorbent, thorough desorption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

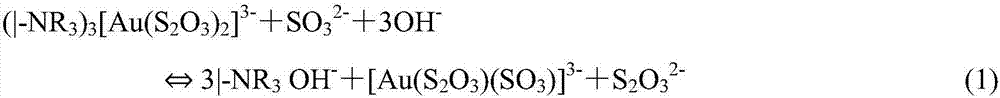

Method used

Image

Examples

Embodiment 1

[0024] Firstly, the simulated thiosulfate leaching solution was used to prepare the gold-loaded resin by the method of stirring and adsorption. Among them, the gold concentration in the simulated thiosulfate leach solution is 20mg / L, the sodium thiosulfate concentration is 0.3mol / L, the copper concentration is 0.03mol / L, the ammonia water concentration is 1mol / L, the volume of the simulated leach solution is 2L, and the adsorption resin Tulsion A-21S strong basic resin was used, the amount of resin was 10mL, the stirring speed was 150r / min, and the adsorption time was 1h. After the adsorption is finished, a resin with a gold loading of 5 kg / t is obtained. Then, the obtained gold-loaded resin was packed into a column. Wherein, the inner diameter of the exchange column is 4 mm, the height of the resin bed is 80 cm, and the volume of the resin bed is 10 mL.

[0025] Using Na 2 SO 3 The mixed solution with NaOH is used as a desorbent to dynamically desorb the above-mentioned g...

Embodiment 2

[0027] The gold-loaded resin used is the same as in Example 1, using Na 2 SO 3 The mixed solution with NaOH is used as a desorbent to dynamically desorb the above-mentioned gold-loaded resin. In desorbent: Na 2 SO 3 The concentration is 0.4mol / L, and the NaOH concentration is 0.3mol / L. The desorbent flow rate was 3 resin bed volumes / hour and the dosage was 18 resin bed volumes. Under these conditions, the concentration of gold in the obtained desorption solution was 190.2mg / L, and the desorption rate of gold was 97.8%.

Embodiment 3

[0029] The gold-loaded resin used is the same as in Example 1, using Na 2 SO 3 The mixed solution with NaOH is used as a desorbent to dynamically desorb the above-mentioned gold-loaded resin. In desorbent: Na 2 SO 3 The concentration is 0.5mol / L, and the NaOH concentration is 0.4mol / L. The desorbent flow rate was 3 resin bed volumes / hour and the dosage was 16 resin bed volumes. Under these conditions, the concentration of gold in the obtained desorption solution was 214.8mg / L, and the desorption rate of gold was 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com