Patents

Literature

75results about How to "Complete desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

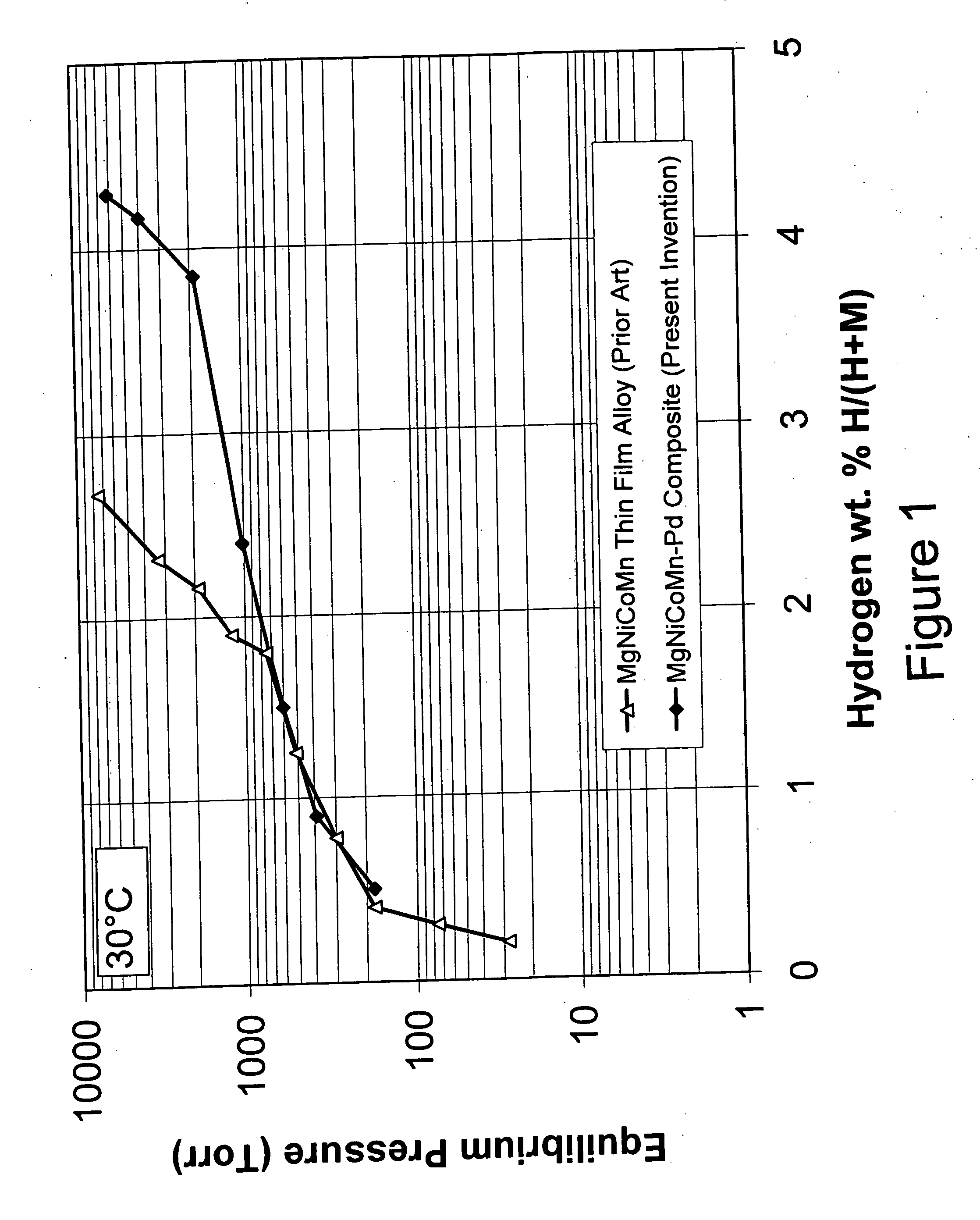

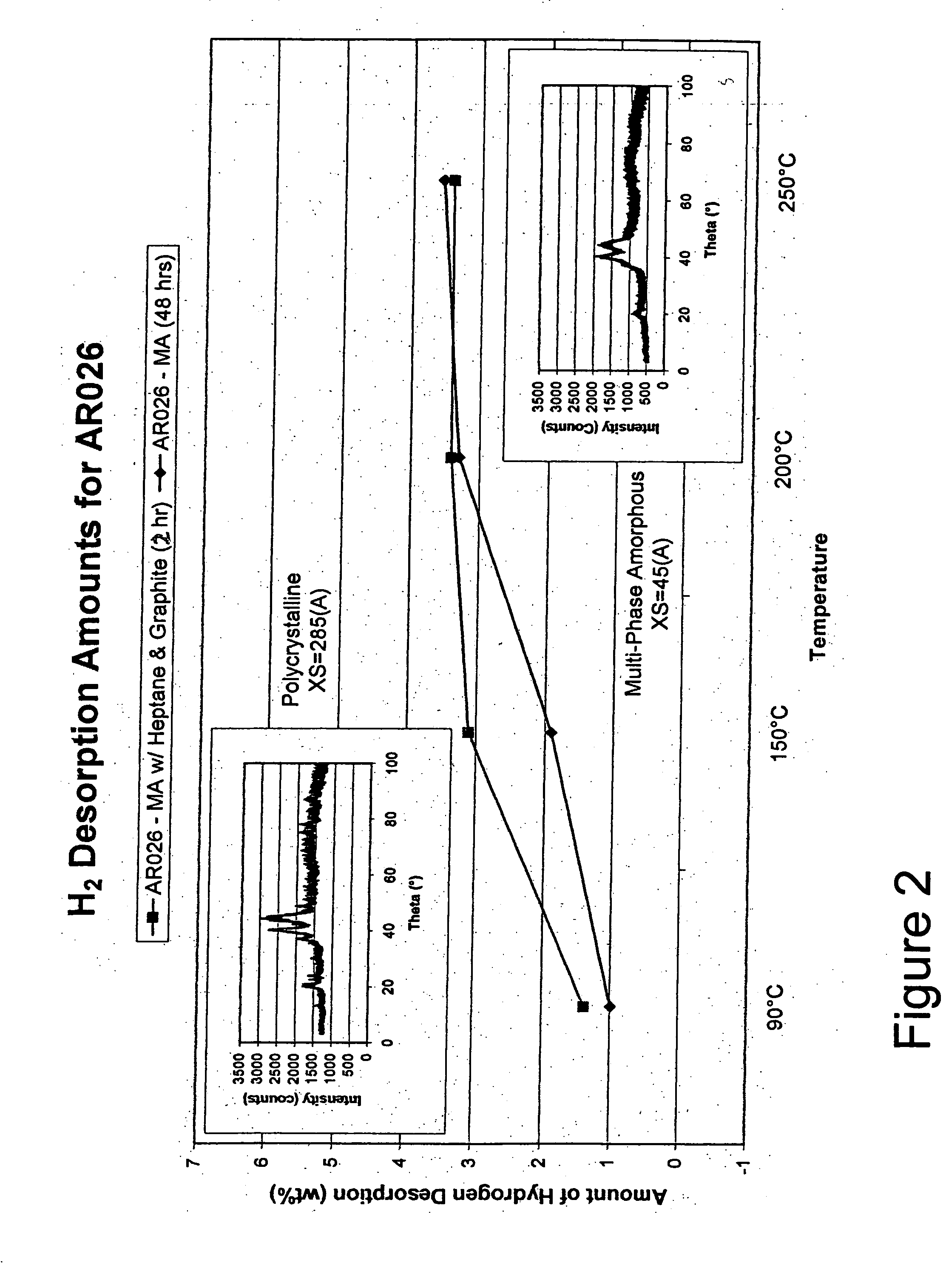

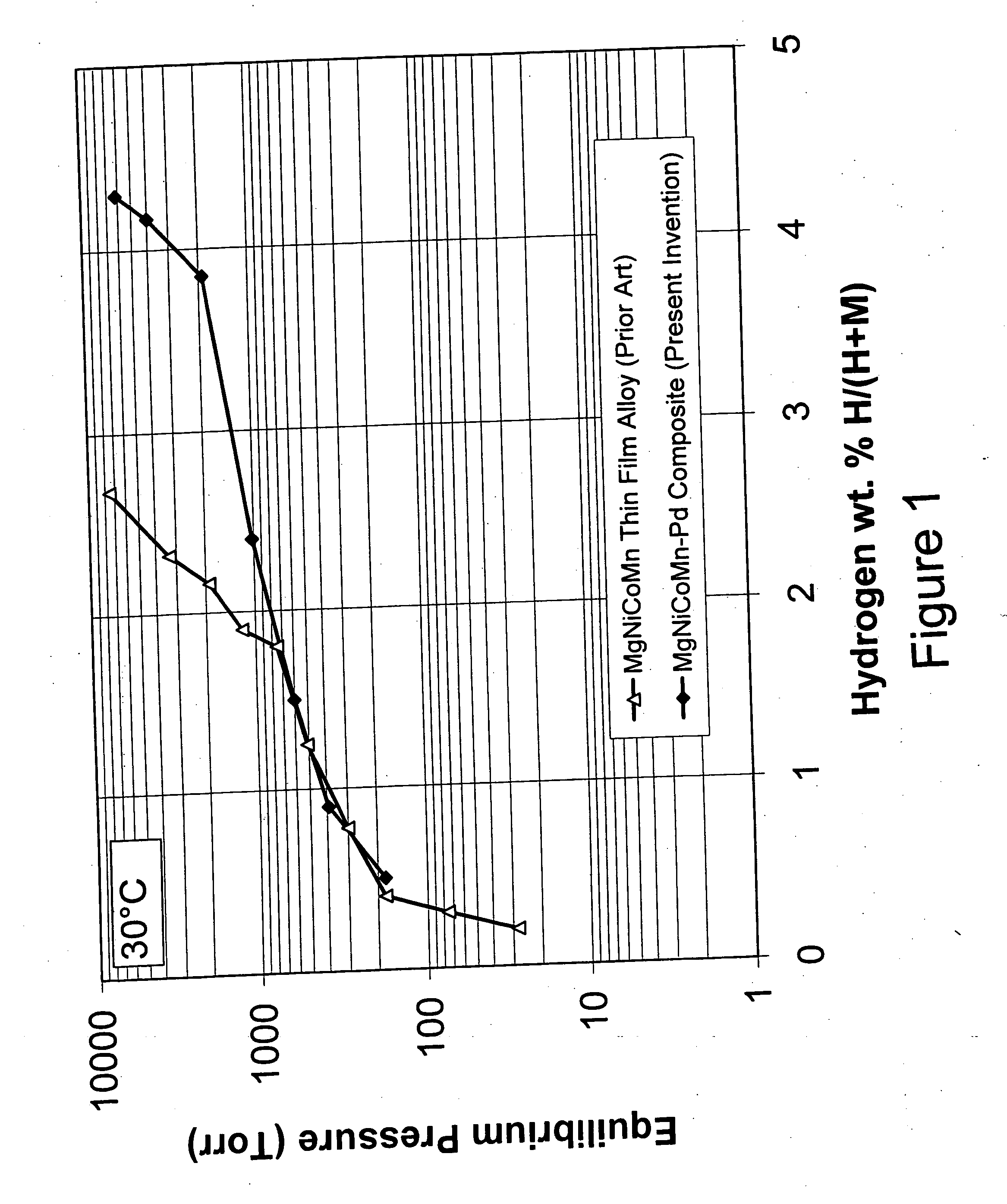

Mg-Ni hydrogen storage composite having high storage capacity and excellent room temperature kinetics

InactiveUS20050129566A1High adsorption rateIncrease storage capacityHydrogenAlkaline accumulator electrodesRoom temperaturePalladium

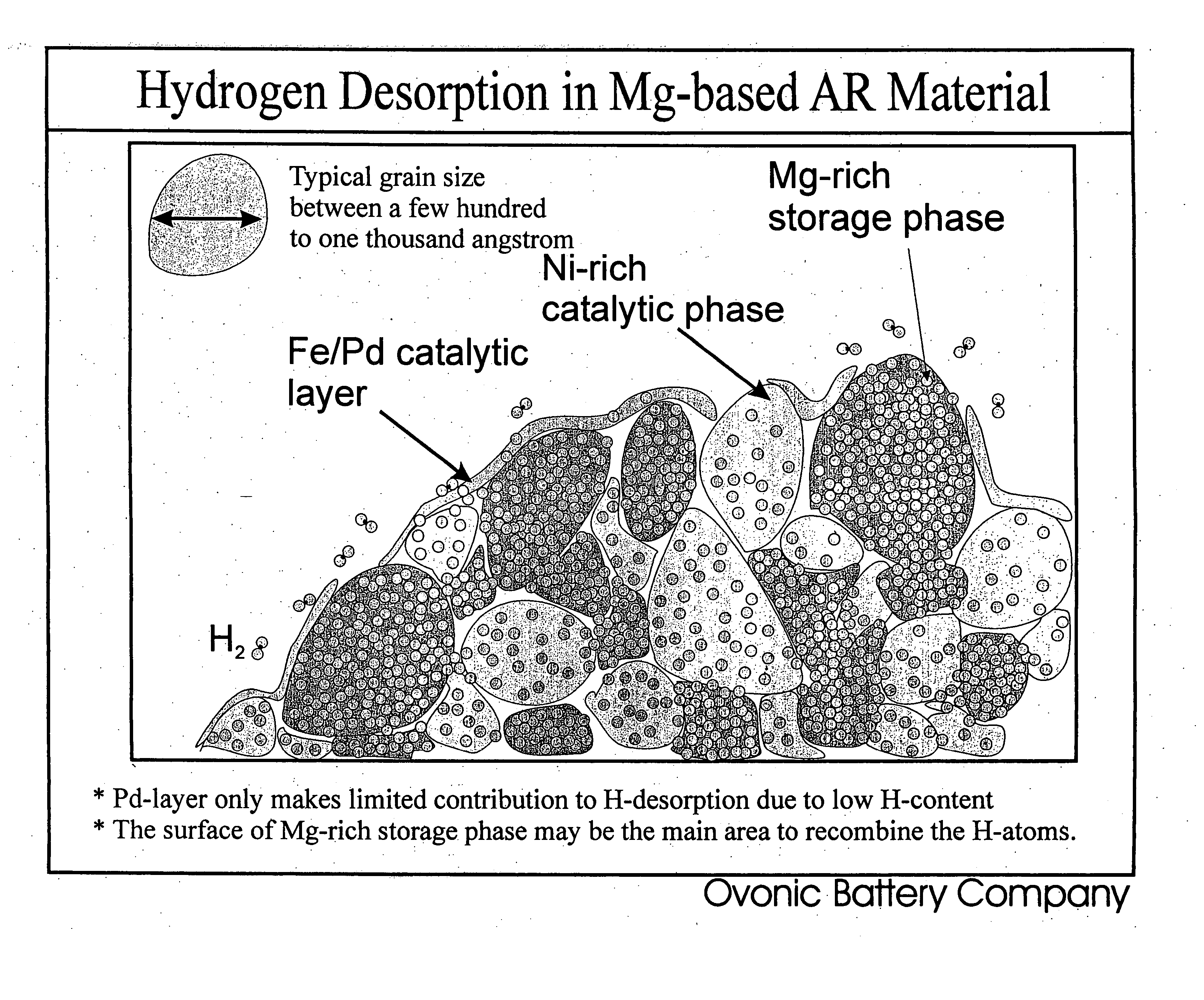

A hydrogen storage composite material having a Mg—Ni based alloy with a coating of a catalytically active metal deposited on at least a portion of a surface of said Mg—Ni based alloy. The coating is less than about 200 angstroms thick and preferably is formed from iron or palladium. The composite material is capable of adsorbing at least 3 weight percent hydrogen and desorbing at least 1 weight percent hydrogen at 30° C. The Mg—Ni based alloy has a microstructure including both a Mg-rich phase and a Ni-rich phase, micro-tubes having an inner core of Ni-rich material surrounded by a sheathing of Mg-rich material, amorphous structural regions and microcrystalline structural regions.

Owner:TEXACO OVONIC HYDROGEN SYST LLC +1

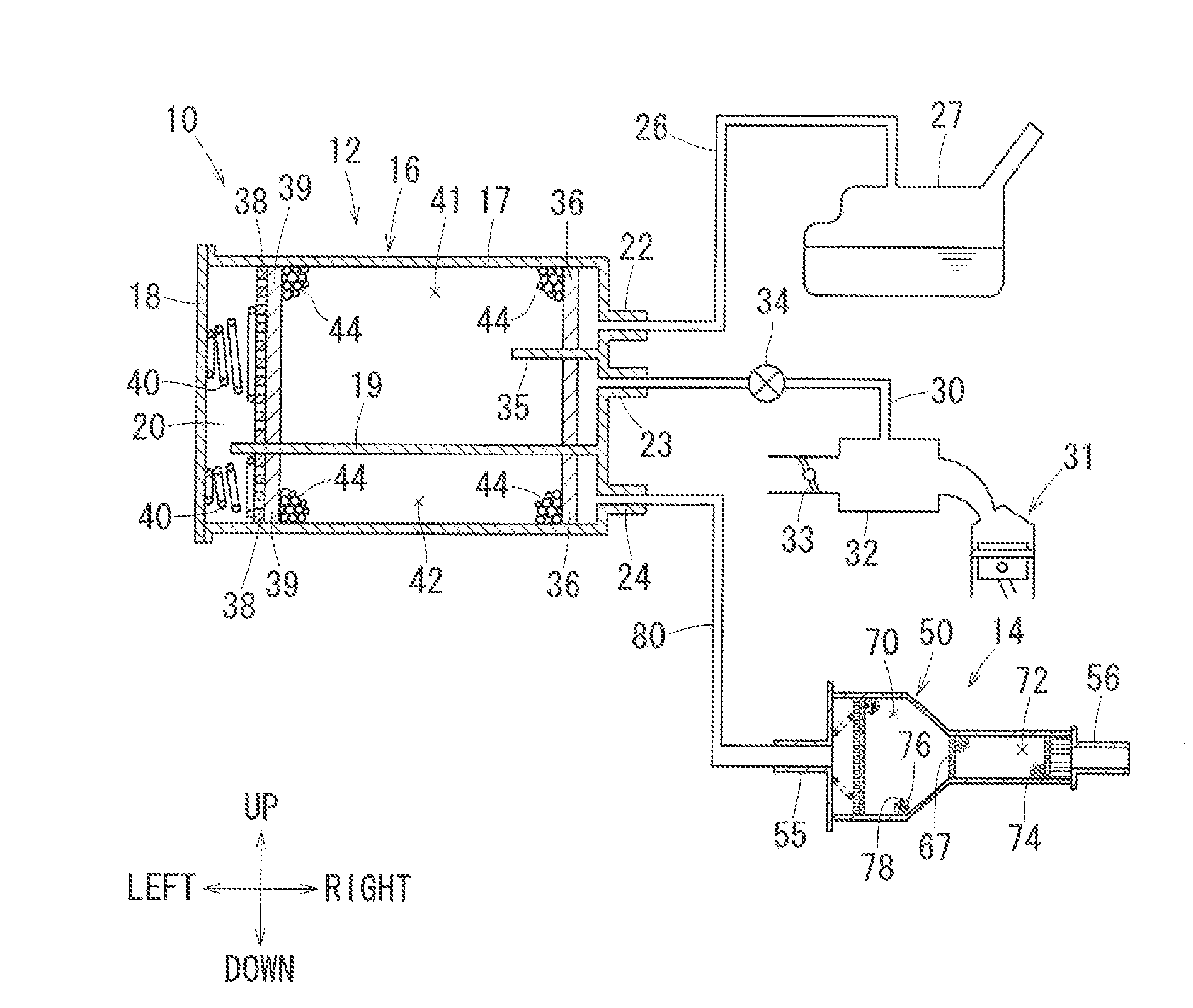

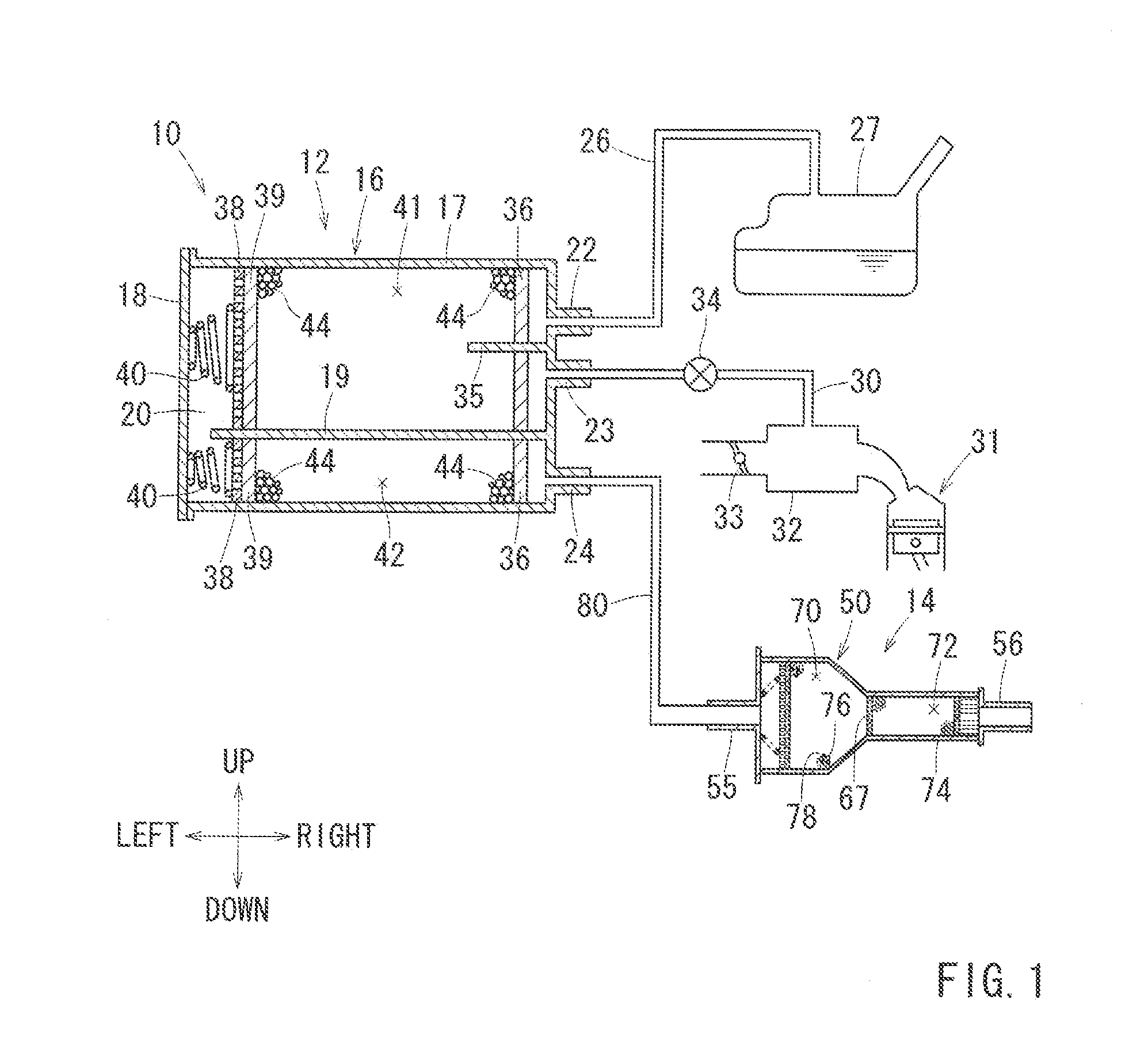

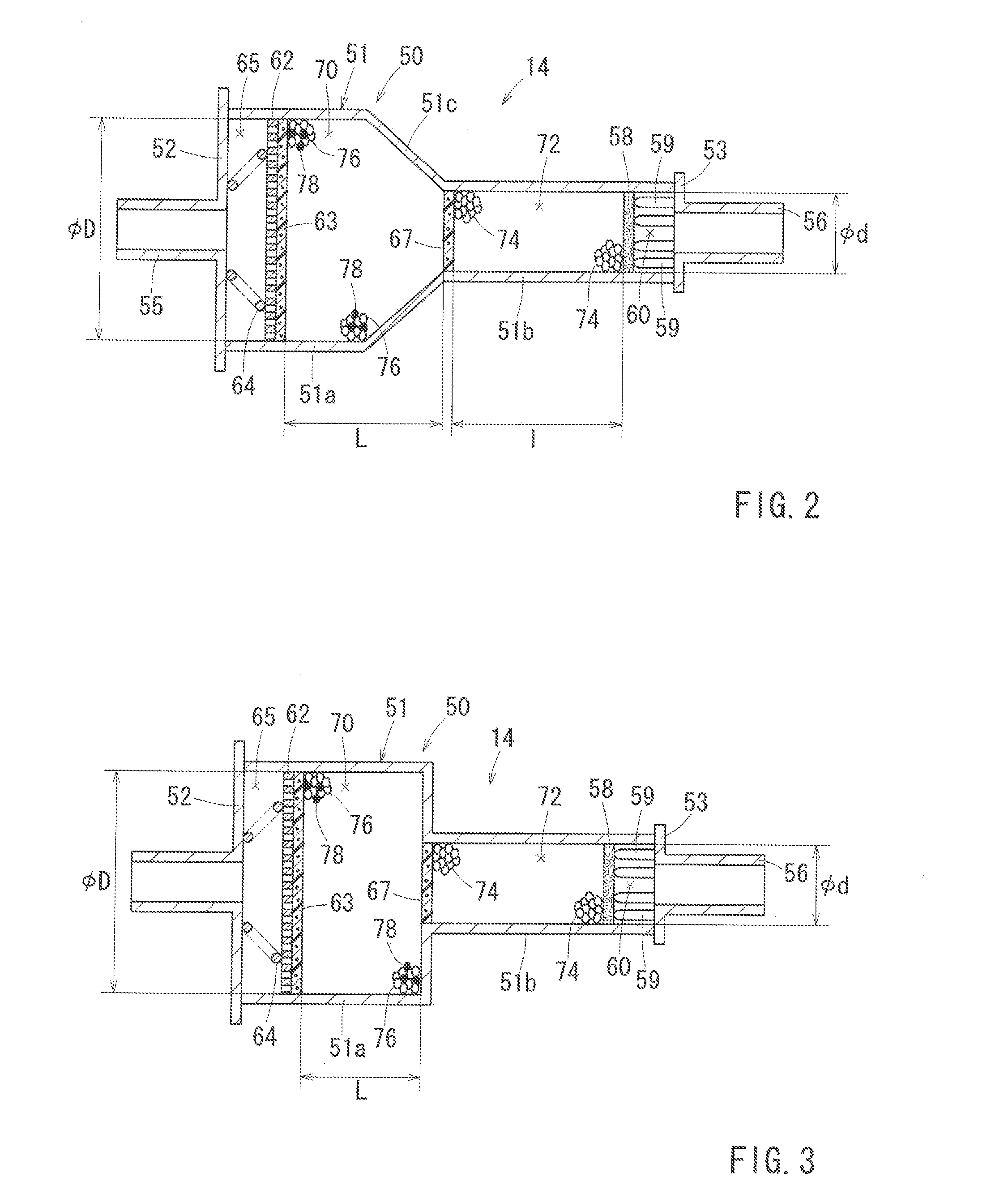

Trap canister capturing fuel vapor

InactiveUS20130186375A1Reduce the amount of fuelReduce pressure lossNon-fuel substance addition to fuelMachines/enginesNuclear engineeringFuel vapor

A trap canister is configured to capture fuel vapor contained in breakthrough gas discharged from an adsorbent canister. The trap canister has a housing defining an adsorption chamber therein, a breathable partition member disposed in the housing and dividing the adsorption chamber into a first chamber and a second chamber, an adsorbent filled in the first chamber and the second chamber, and a latent heal storage material tilled in the first chamber in a mixed manner with the adsorbent. The first chamber is configured to receive breakthrough gas, while the second chamber is configured to communicate with the atmosphere. The first chamber has a cross-sectional area larger than that of the second chamber.

Owner:AISAN IND CO LTD

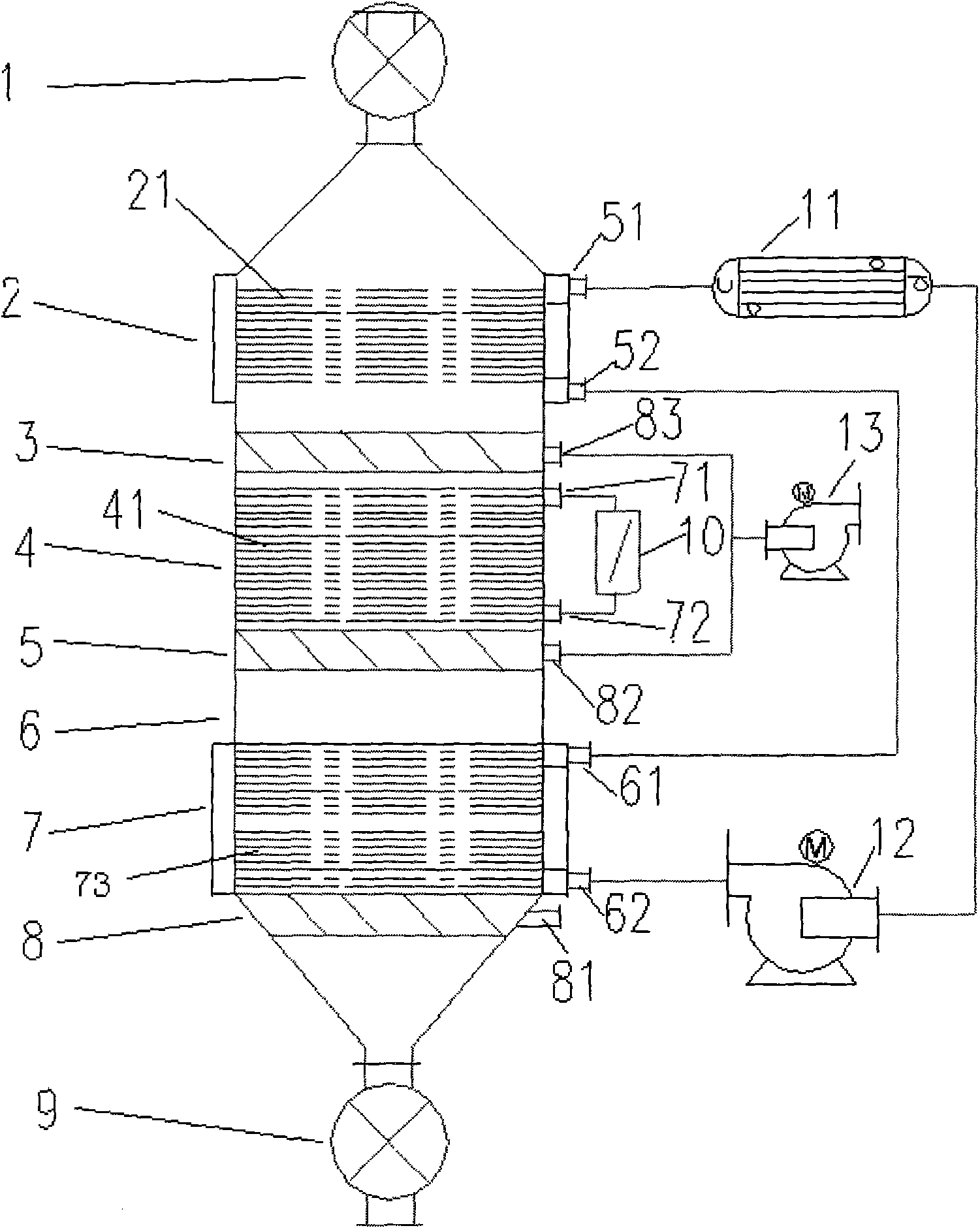

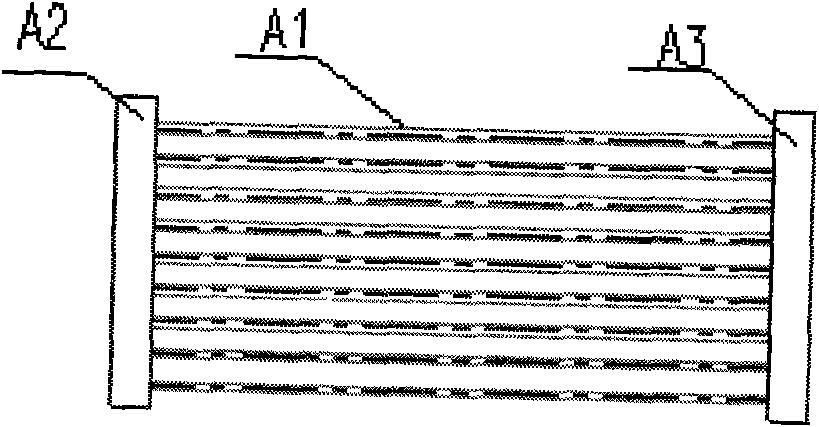

Movable desorption device of activated coke

ActiveCN101584958ASimple structureImprove space utilizationDispersed particle separationCombustible gas purificationProcess engineeringCorrosion

The invention discloses a movable desorption device of activated coke. An inlet blocking valve, a heating chamber, a reaction chamber, a cooling chamber and an outlet blocking valve are sequentially connected from top to bottom in the reactor main body; the heating chamber is provided with a heating heat exchanger therein which is connected with a thermal source device; a cooling heat exchanger is arranged in the cooling chamber; a preheating chamber is arranged between the inlet blocking valve and heating chamber and provided with a preheating heat exchanger, which forms a heat circulating system with a circulating medium heat exchanger, a circulating pump and the cooling heat exchanger; a first cloth gas guide mechanism is arranged between the preheating chamber and heating chamber; a second cloth gas guide mechanism is arranged between the heating chamber and reaction chamber; and the first and second cloth gas guide mechanisms are respectively connected with a gas recovery suction pump for recycling desorption gas. The invention has higher utility ratio of heat energy by redesigning each part in the reactor, and has more complete air suction, higher desorption efficiency and less corrosion to devices by adding the cloth gas guide mechanisms.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

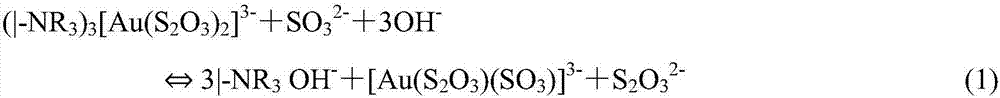

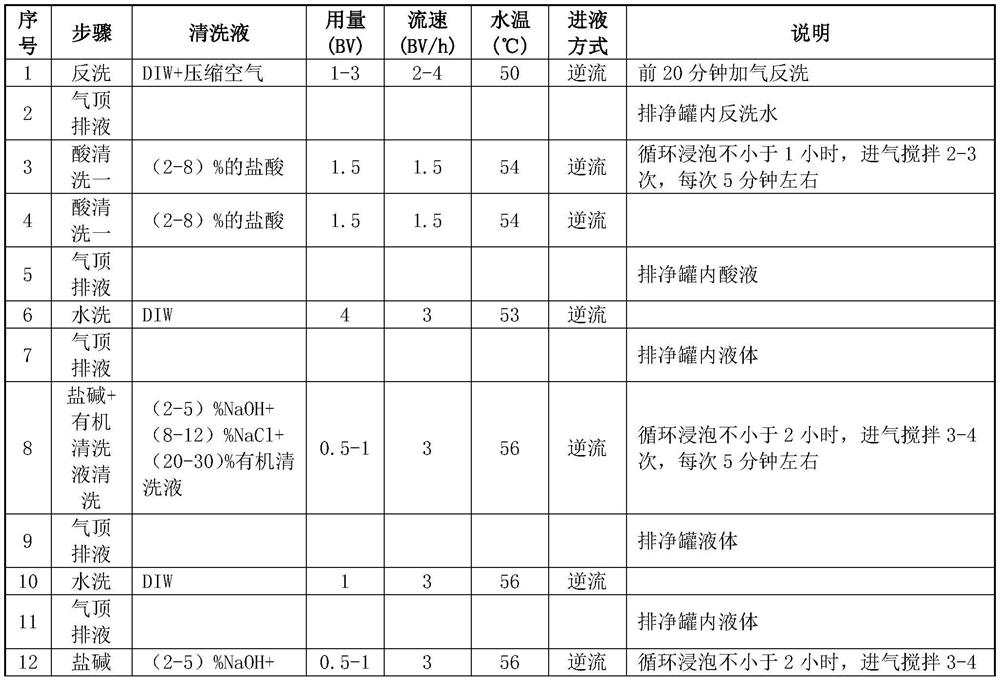

Method for synergistically desorbing gold thiosulphate coordination ions from strongly-alkaline anion exchange resin

ActiveCN107488789AStable in natureReduce desorption costProcess efficiency improvementNitrateDesorption

The invention discloses a method for synergistically desorbing gold thiosulphate coordination ions from strongly-alkaline anion exchange resin. A mixed solution of Na2SO3 and NaOH serves as a desorption agent, and dynamic desorption is conducted on the strongly-alkaline anion exchange resin loaded with the gold thiosulphate coordination ions. According to the method, the synergistic effect of two components, namely SO3<2> and OH, is utilized, and desorption is conducted on the [Au(S2O3)2]<3> coordination ions adsorbed on the strongly-alkaline anion exchange resin; and the desorption rate of gold can reach 97% or above. Compared with traditional methods that a thiocyanate solution or a polythionate solution or a nitrate solution or another type of solution composed of a single component is adopted for desorption, the desorption method has the remarkable beneficial effects that reagents are free of toxicity; performance is stable; desorption cost is low; resin desorption and regeneration are completed by the same step; and the gold in the desorption solution can be further recycled conveniently. And good industrial application prospect is achieved.

Owner:CENT SOUTH UNIV

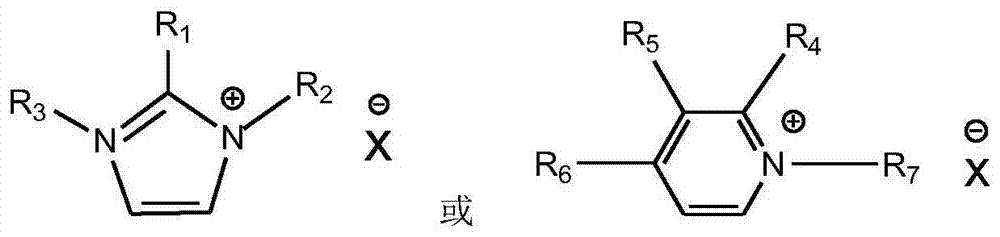

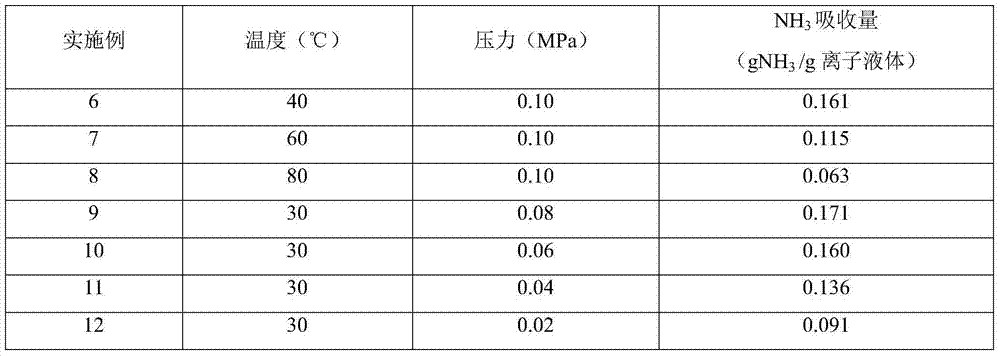

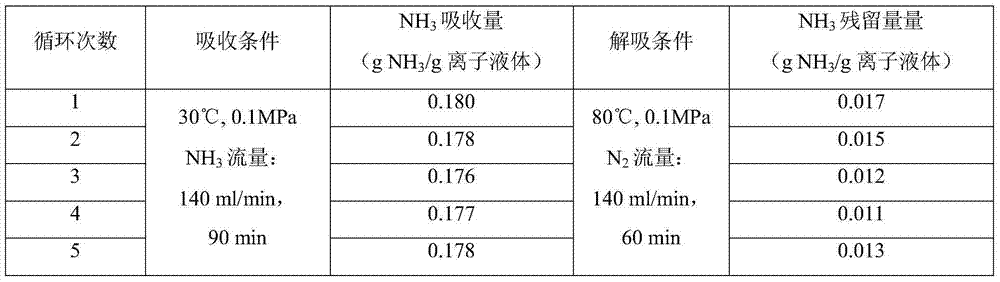

Novel efficient and reversible ion type ammonia gas absorbent

ActiveCN104740975APromote absorptionImprove stabilityDispersed particle separationDesorptionDivalent metal

The invention relates to a novel efficient and reversible ion type ammonia gas absorbent and belongs to the technical field of gas separation and purification. The absorbent is Lewis acid ion liquid prepared from pyridine or imidazole and derivative cations thereof and anions containing divalent metal cobalt ions. The absorbent can realize efficient absorption of ammonia gas through the chemical complexing effect between the divalent metal cobalt ions in the anions and ammonia gas molecules and the hydrogen bond effect between the cations and the ammonia gas molecules; and the absorbent has the advantages of good stability, easiness for desorption, capability of being circularly used for a plurality of times and the like, and the novel absorbent is provided for separation and recycling, and purification on the ammonia gas in industrial ammonia-containing tail gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

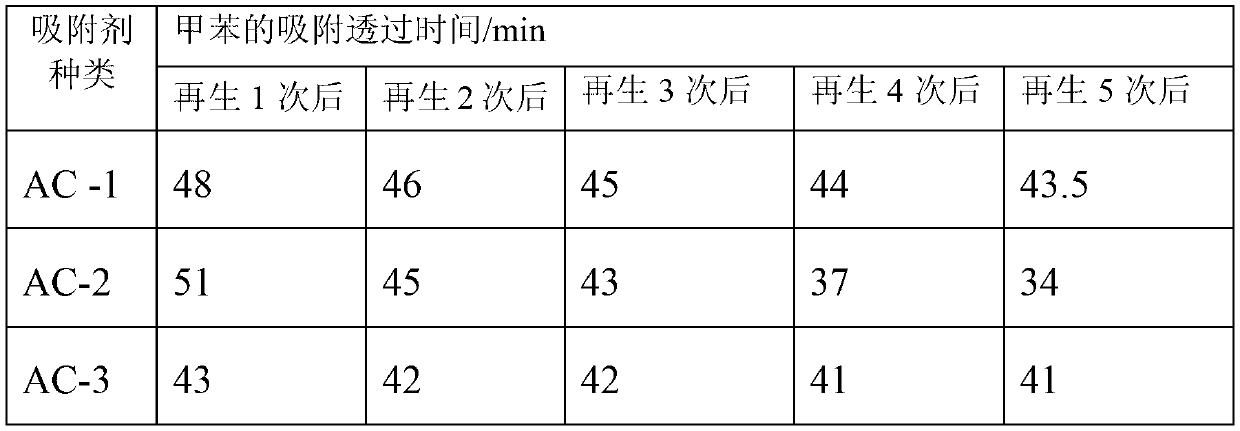

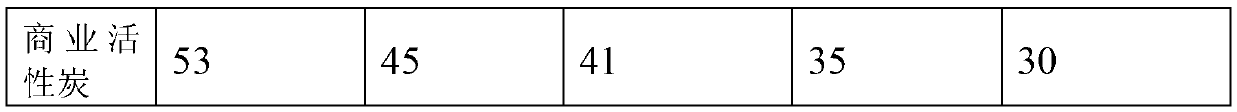

Method for preparing high thermal conductivity active carbon taking waste cotton cloth as raw material

The invention discloses a method for preparing high thermal conductivity active carbon taking waste cotton cloth as a raw material. The method comprises the following steps: placing waste cotton pieces into a zinc chloride solution to soak, distilling under reduced pressure, then drying, adding 5-40 wt% of expanded graphite, mixing fully, firing and activating in the presence of nitrogen at 300-500 DEG C for 0.5-2 h, stopping heating, cooling to room temperature in the presence of nitrogen, washing with deionized water to neutral, and drying. In the present invention, waste cotton cloth is used as the raw material for the production of activated carbon, thereby achieving to control pollution with waste and expand production raw material sources of activated carbon. The activated carbon prepared by the invention is high in thermal conductivity, can be efficiently recycled, can keep good adsorption properties after multiple regenerations, and helps to expand industrial application field and scope of activated carbon.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC +1

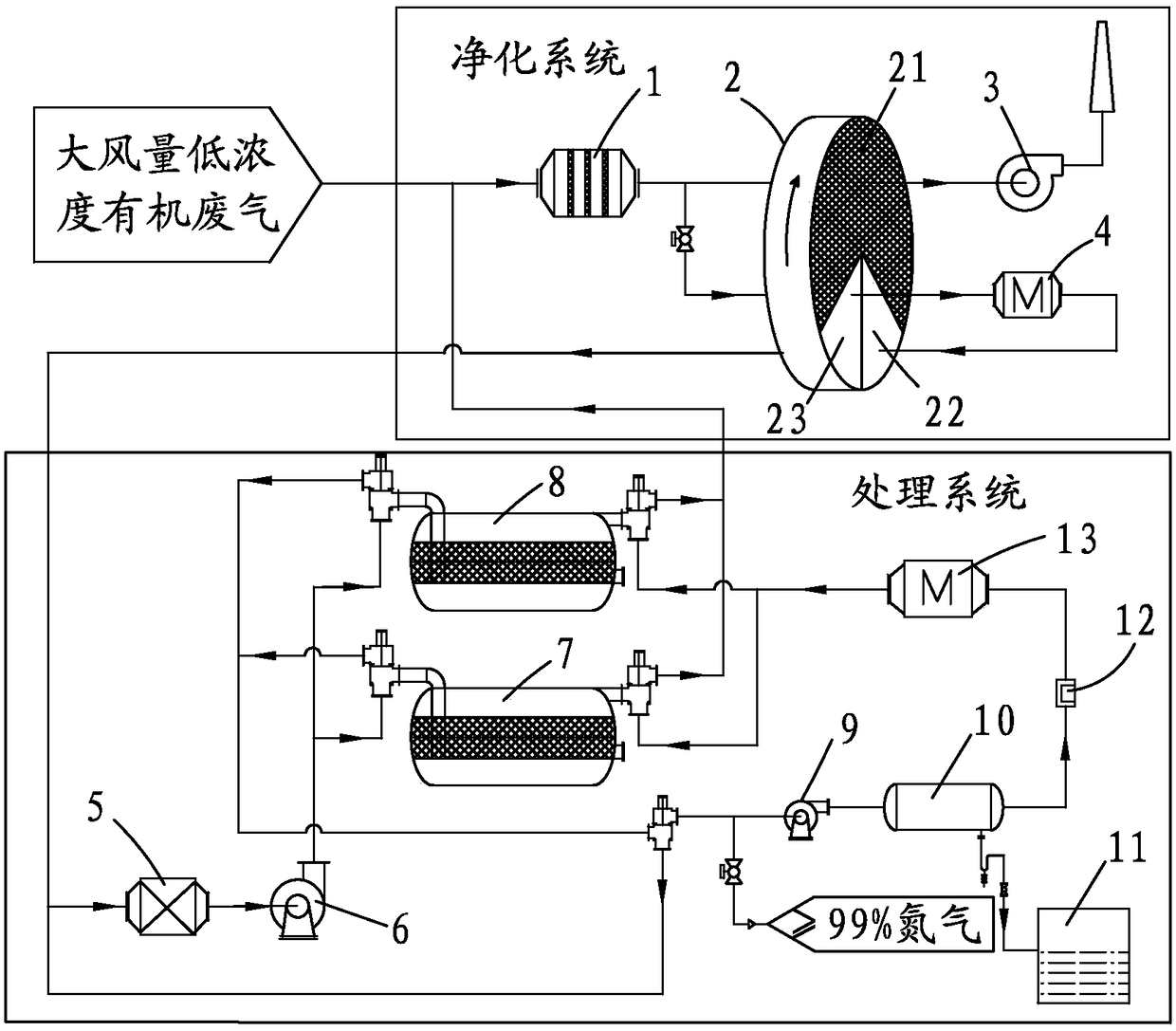

Device and method for treating organic waste gas with large airflow and low concentration

PendingCN108079740AReduce configurationAchieve reuseGas treatmentDispersed particle filtrationHigh concentrationAir volume

The invention belongs to the field of organic waste gas treatment and particularly relates to a device and a method for treating organic waste gas with large airflow and low concentration. The devicecomprises a purification system and a treatment system, wherein the purification system comprises a filter, a molecular sieve rotating wheel and an exhaust fan which are connected sequentially througha pipe, and further comprises a heat exchanger; the treatment system comprises a surface air cooler, an adsorption fan I, activated carbon adsorption beds, an adsorption fan II, a condensing unit, anonline oxygen content analysis device and a heater which are connected sequentially through a pipe; the condensing unit comprises a condenser and a recovered liquid storage tank. By means of characteristics of molecular sieve rotating wheel equipment, the waste gas with large airflow and low concentration is concentrated and changed into waste gas with small airflow and medium-high concentration;the treatment system adopts the activated carbon adsorption-nitrogen adsorption recovery technology for recovery and treatment, and the organic solvent is recovered while the organic waste gas is treated. Tail gas is discharged up to standard, recovery efficiency is high, investment cost is low, small area is occupied, and resource recycling is realized.

Owner:GARDEN ENVIRONMENTAL PROTECTION

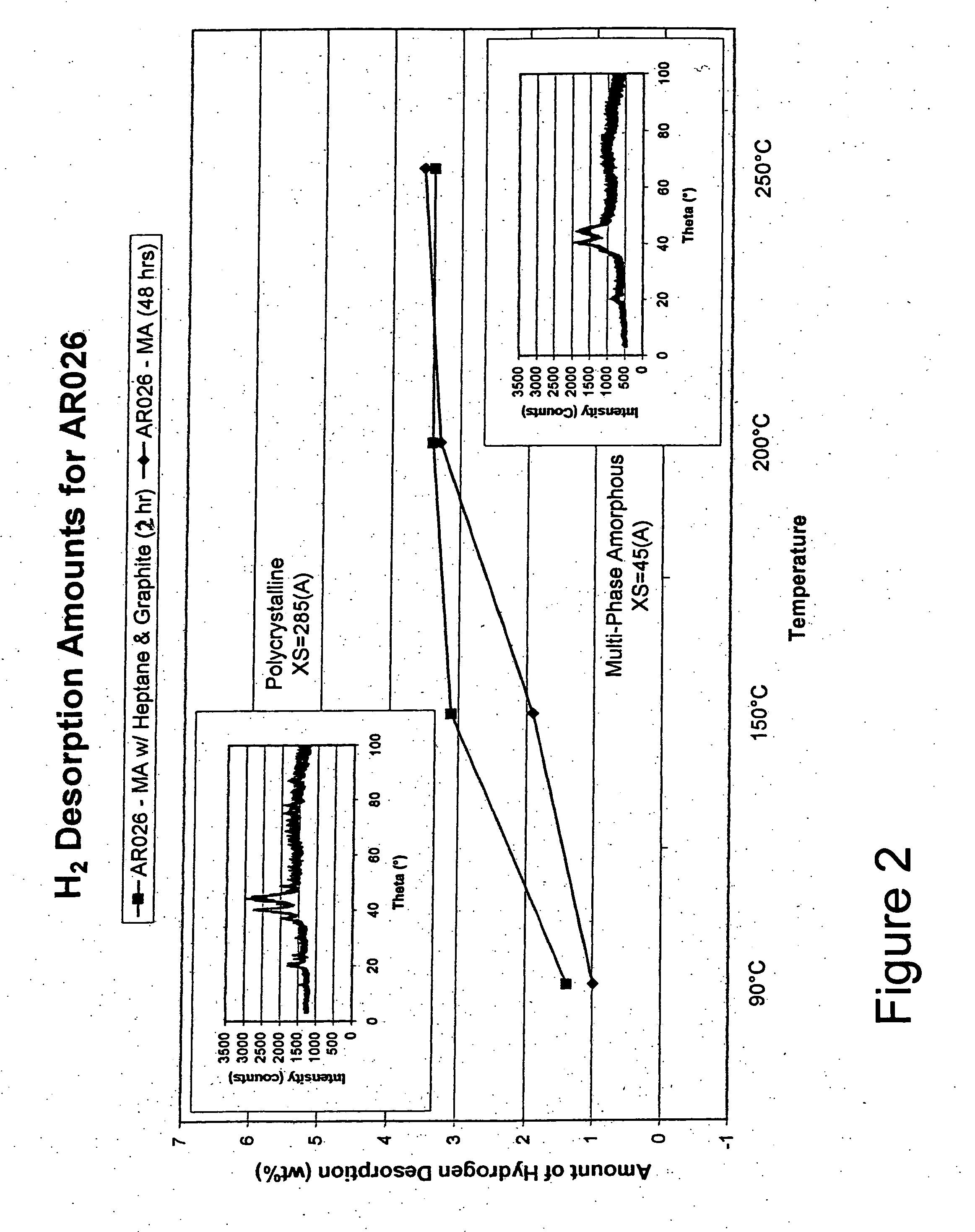

Mg-Ni hydrogen storage composite having high storage capacity and excellent room temperature kinetics

InactiveUS20060266441A1High adsorption rateIncrease storage capacityHydrogenAlkaline accumulator electrodesPorosityRoom temperature

A hydrogen storage alloy having an atomically engineered microstructure that both physically and chemically absorbs hydrogen. The atomically engineered microstructure has a predominant volume of a first microstructure which provides for chemically absorbed hydrogen and a volume of a second microstructure which provides for physically absorbed hydrogen. The volume of the second microstructure may be at least 5 volume % of atomically engineered microstructure. The atomically engineered microstructure may include porous micro-tubes in which the porosity of the micro-tubes physically absorbs hydrogen. The micro-tubes may be at least 5 volume % of the atomically engineered microstructure. The micro-tubes may provide proton conduction channels within the bulk of the hydrogen storage alloy and the proton conduction channels may be at least 5 volume % of the atomically engineered microstructure.

Owner:FETCENKO MICHAEL A +4

Technology for removing ferric trichloride from chlorination liquid generated in chlorobenzene production

ActiveCN103819306AReduce productionNo precipitationHalogenated hydrocarbon preparationBenzenePhysical chemistry

The invention discloses a technology for removing ferric trichloride from chlorination liquid in chlorobenzene production. The technology comprises the following steps specifically: collecting chlorination liquid generated in chlorobenzene production to a chlorination liquid intermediate tank; introducing the chlorination liquid in the chlorination liquid intermediate tank into a resin adsorption tower from the bottom of the resin adsorption tower, keeping full and soaking for 10-18 hours, discharging the chlorination liquid from the top of the tower, detecting the content of ferric trichloride in the adsorbed chlorination liquid, and when the content of ferric trichloride is larger than 10 ppm, stopping adsorption; using diluted hydrochloric acid to resolve ferric trichloride complexes adsorbed by the resin, and using water to wash the resin adsorption tower till the content of ferric trichloride in the scrubbing solution is smaller than 10 ppm. In the technology, the resin adsorption tower and a continuous automatic processing method are utilized to process ferric trichloride from chlorination liquid in monochlorobenzene production; the chlorination liquid is adsorbed by the resin adsorption tower to remove ferric trichloride from the chlorination liquid for one time, and the content of ferric trichloride in the chlorination liquid during the monochlorobenzene production after the chlorination reaction is reduced from 150-1000 ppm to 0-10 ppm.

Owner:ANHUI BAYI CHEM IND

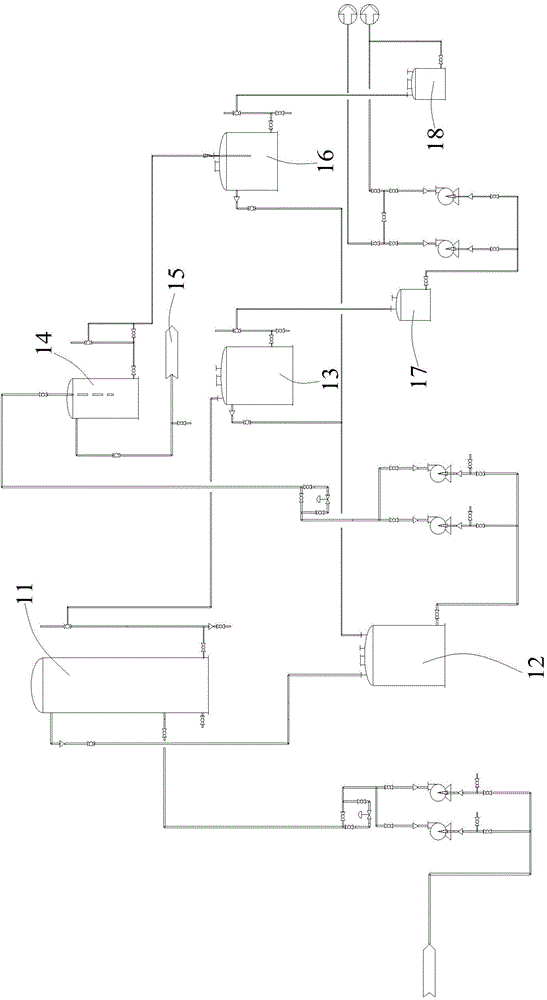

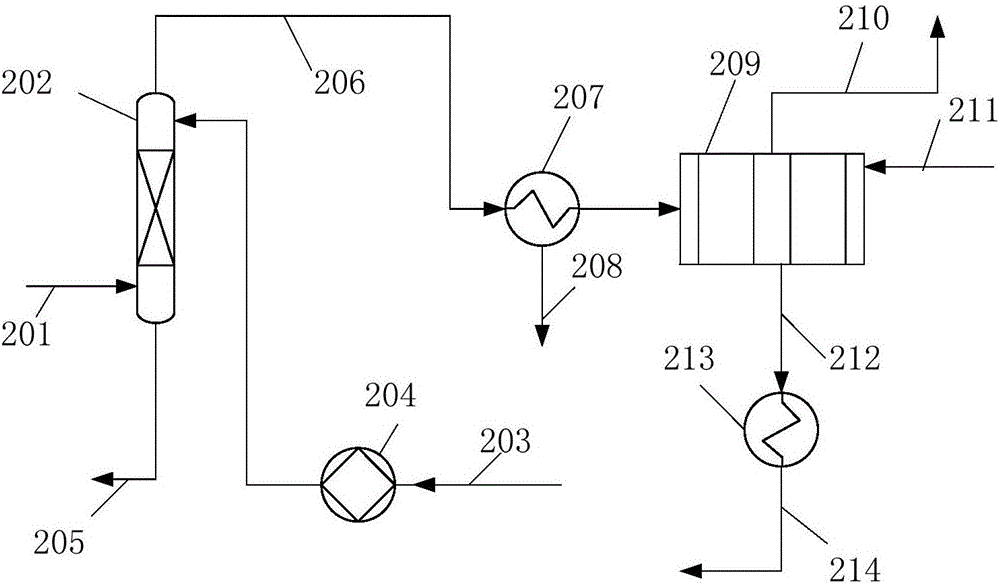

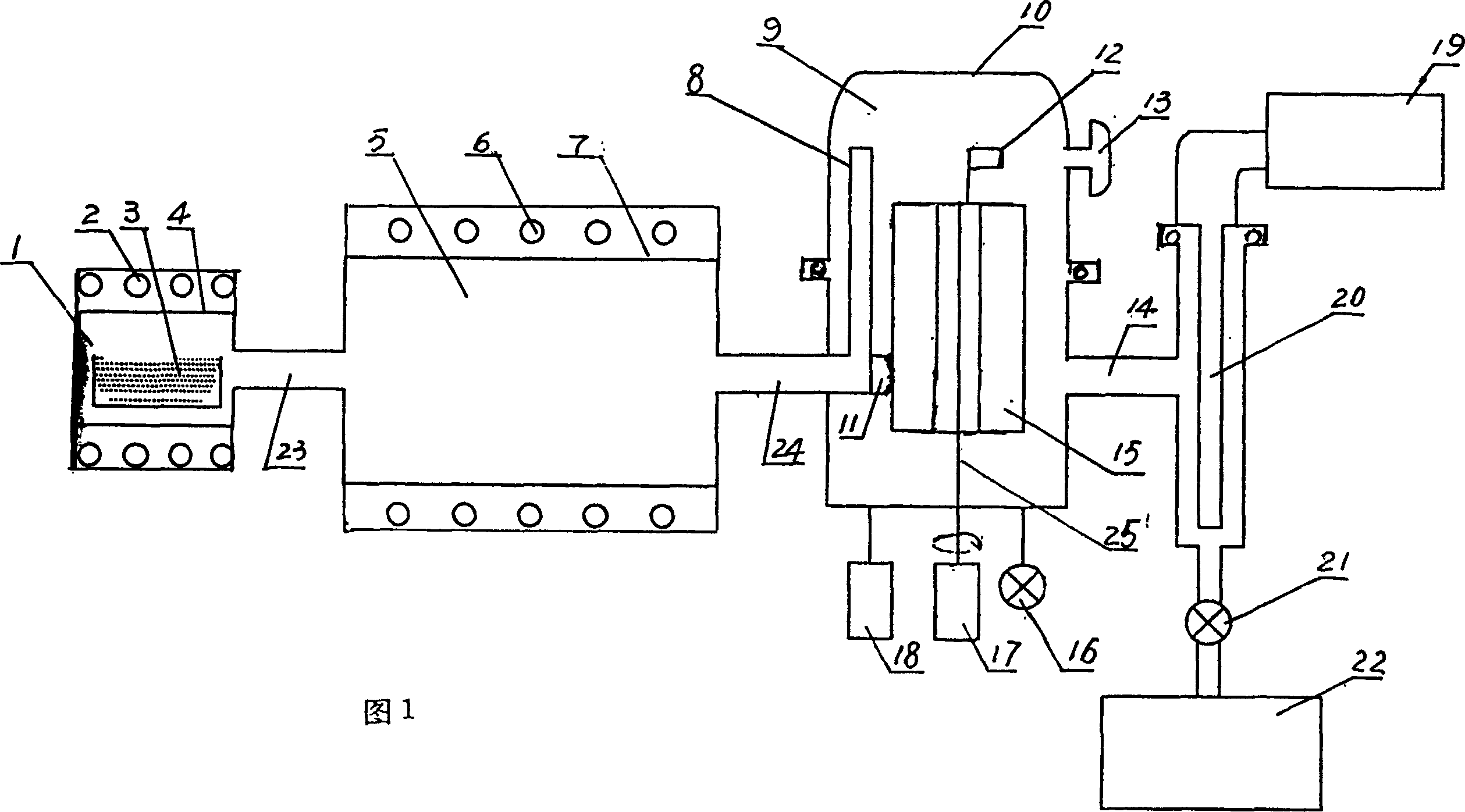

A multi-stage thermal desorption remediation system for organic polluted soil

ActiveCN104607455BImprove utilization efficiencyShorten repair timeContaminated soil reclamationCombustion chamberRetention time

The invention relates to a multi-stage thermal desorption remediation system for organic polluted soil, and belongs to the technical field of soil remediation. The system consists of a first-stage thermal desorption device, a second-stage thermal desorption device, a tail gas treatment device, a secondary combustion chamber and a falling type conveying belt. Soil is preheated and desorbed primarily by high-temperature tail gas generated by thermal desorption; a two-stage or multi-stage polluted soil treatment method is adopted, and the residual heat of the tail gas is utilized fully, so that the comprehensive utilization ratio of heat energy of the system is improved obviously; soil enters a thermal desorption cabin with relatively high temperature under the gravity effect by virtue of the S-shaped falling type conveying belt, so that the energy consumption of a conveying and transmitting device and the conveying process is prevented; meanwhile, the soil conveying path and the conveying time are prolonged, the retention time is prolonged, and thus soil pollutants are desorbed relatively fully. The thermal desorption soil remediation system is reasonable in structure, is simple to operate, is convenient to use, has no secondary pollution, recycles residual heat of tail gas, and has wide application prospect and high practical value.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

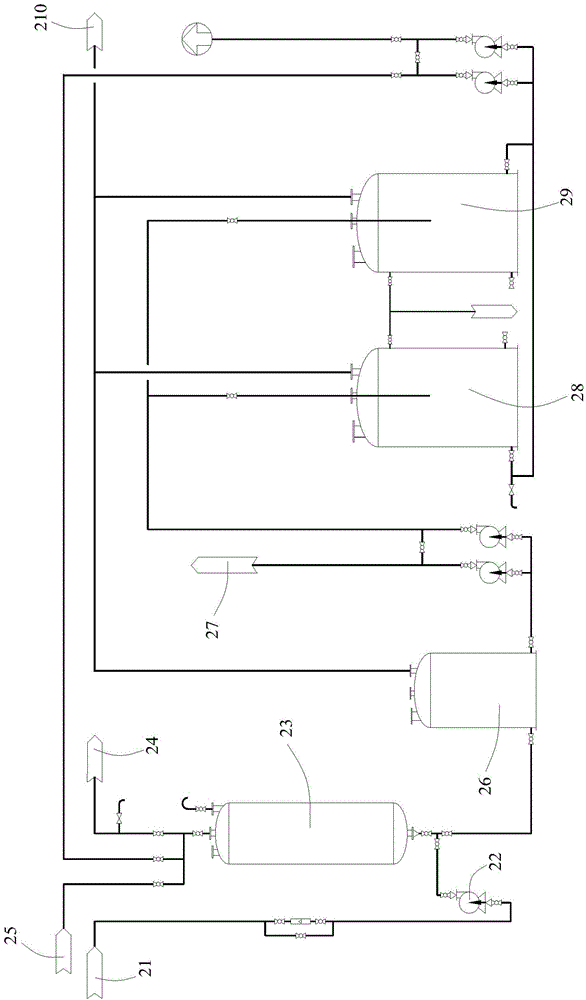

Novel efficient absorption type oil and gas recovery system for gas station

InactiveCN105084289ASolve the problem of oil and gas emissionsSimple structureLiquid transferring devicesHigh concentrationDesorption

The invention provides a novel efficient absorption type oil and gas recovery device for a gas station. The device mainly comprises an oil and gas collection section, an oil and gas deep absorption section and a vacuum desorption section, and has the advantages that (1) the oil and gas collection section can be used for collecting oil and gas which are produced during oil collection of an underground oil tank and automobile refueling; (2) two absorption columns are adopted by the recovery device, so that the work continuity can be ensured after switching; the absorption columns are filled with a home-made adsorbent special for oil and gas recovery of the gas station, so that tail gas of the system can reach the standard to be discharged, and the oil and gas recovery rate is greater than 99%; and (3) a spray and absorption link of the traditional recovery technology is abandoned for high-concentration oil and gas which are produced by desorption of a desorption section vacuum pump, and the high-concentration oil and gas directly return the underground oil tank and are recycled by a specially-made absorption head, so that the recovery cost is low and the effect is obvious.

Owner:CHANGZHOU UNIV

Ionic liquid adsorbent used for adsorbing CO2 and formulation system

InactiveCN102489117ALow viscosityPromote absorptionDispersed particle separationBy absorptionTetrafluoroborateSorbent

The invention relates to ionic liquid adsorbent used for adsorbing CO2 and a formulation system. The ionic liquid adsorbent is formed by formulating the following components as per parts by weight: 2 to 5 parts of 1-(1-aminopropyl)-3-methylimidazolium bromide and 1 part of 1-(1-aminopropyl)-3-butyllimidazolium tetrafluoroborate. The ionic liquid adsorbent used for adsorbing CO2 has low viscosity and large absorptive amount, is suitable for serving as adsorbent, adsorbs thoroughly, and can be used circularly.

Owner:DAQING VOCATIONAL COLLEGE

Method for separation of hydrogen chloride from mixed gas containing hydrogen chloride, method for separation and recovery of hydrogen chloride and application

ActiveCN109603437ARealize separation and recoveryFast desorptionGas treatmentDispersed particle separationGas phaseDiethylene glycol

The invention relates to a method for separation of hydrogen chloride from mixed gas containing hydrogen chloride, a method for separation and recovery of hydrogen chloride and application. The methodfor separation of hydrogen chloride adopts diethylene glycol as the absorbent to absorb hydrogen chloride in the mixed gas containing hydrogen chloride to obtain hydrogen chloride gas absorbed diethylene glycol and the residual gas phase. Through a lot of experiments, diethylene glycol is screened out as the absorption solvent of hydrogen chloride in the mixed gas, can selectively absorb and separate hydrogen chloride from the mixed gas at room temperature, and the solvent that absorbs hydrogen chloride of certain concentration can quickly desorb hydrogen chloride at certain temperature, andcan be recycled, thus efficiently and economically realizing separation and recovery of hydrogen chloride in the mixed gas.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

Method for efficiently extracting V/W/Ti from waste denitration catalyst

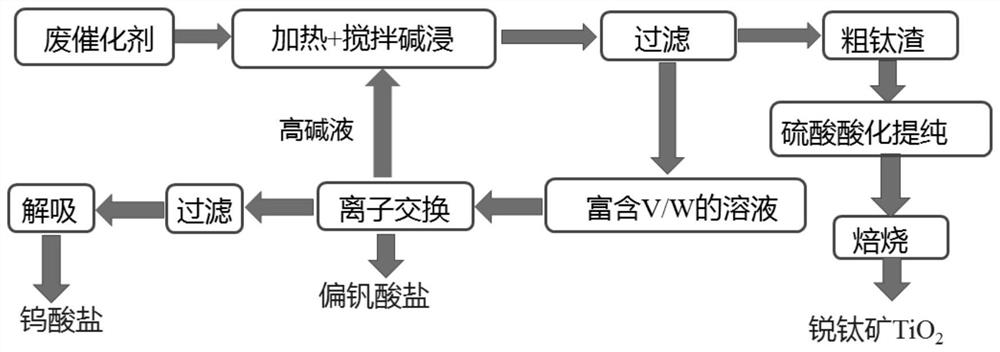

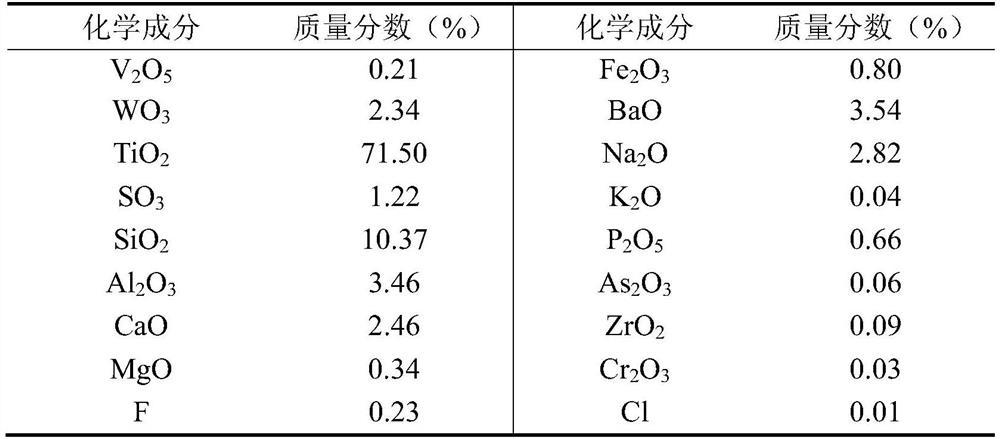

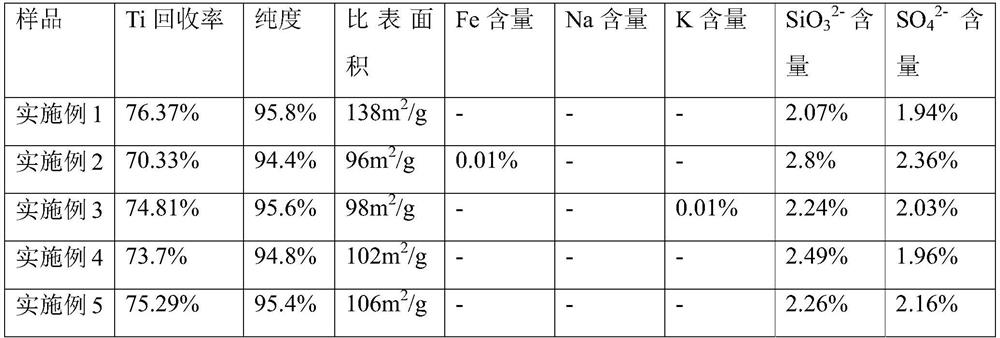

ActiveCN112981113AHigh viscosityLow priceTitanium dioxideProcess efficiency improvementFiberSocial benefits

The invention discloses a method for efficiently extracting V / W / Ti from a waste denitration catalyst. The method comprises the following steps of carrying out soot blowing, water washing, grinding and sieving on the waste denitration catalyst, heating, stirring, carrying out alkaline leaching, and filtering to obtain filtrate rich in V and W and coarse titanium slag; introducing the filtrate into a glass tube filled with anion exchange fibers to realize efficient separation of VO3 <-> and WO4 < 2-> in the filtrate, and then adding ammonium chloride into the filtrate to precipitate vanadium; washing the ion exchange fiber adsorbing WO4 < 2-> with a desorption solution, and evaporating and crystallizing the obtained solution to obtain ammonium paratungstate; and finally, adding the coarse titanium slag into an acid solution, adding a filter aid, stirring, filtering, washing and drying to obtain acidified titanium slag, and roasting to obtain purified TiO2. According to the technical route provided by the invention, the recovery rates of V, W and Ti are correspondingly 100%, 100% and 76.37% at most, the efficient recycling of the waste denitration catalyst is realized, and the method has great economic and social benefits.

Owner:SOUTH CHINA UNIV OF TECH

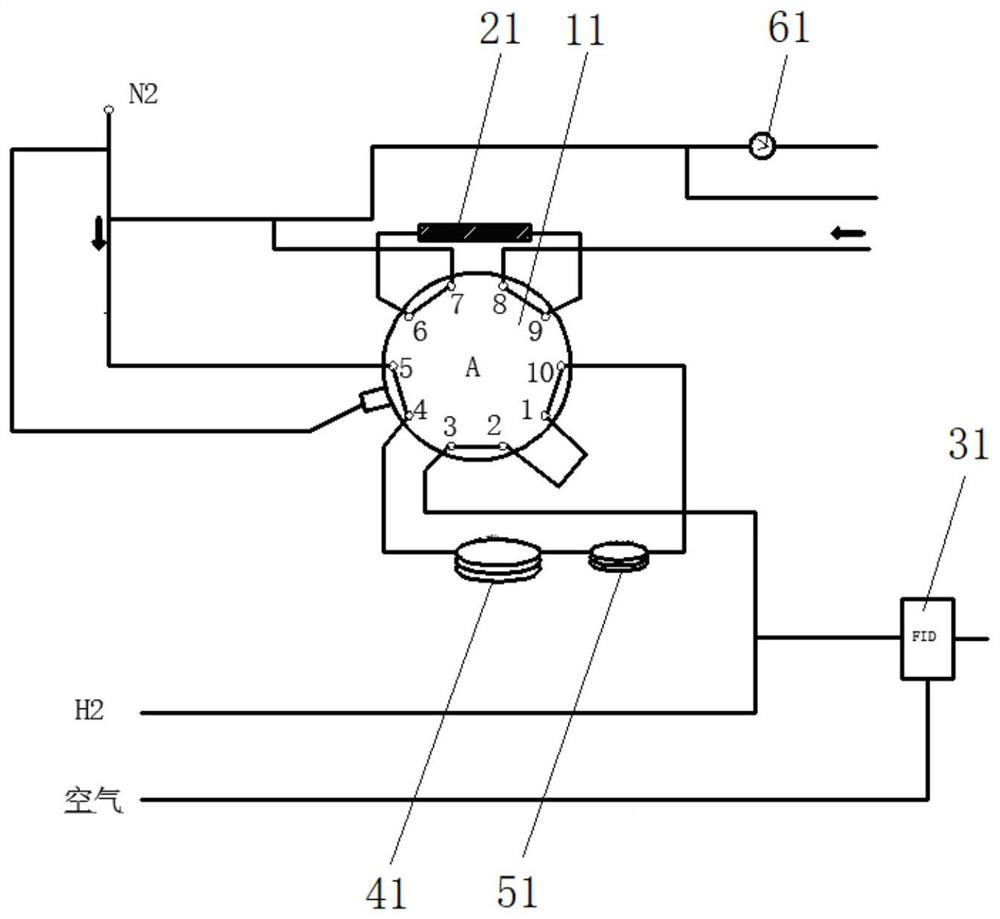

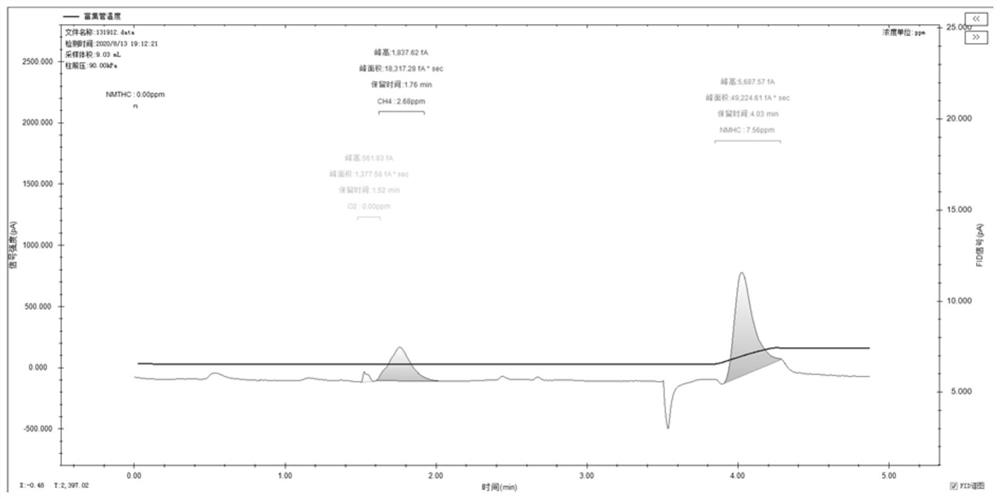

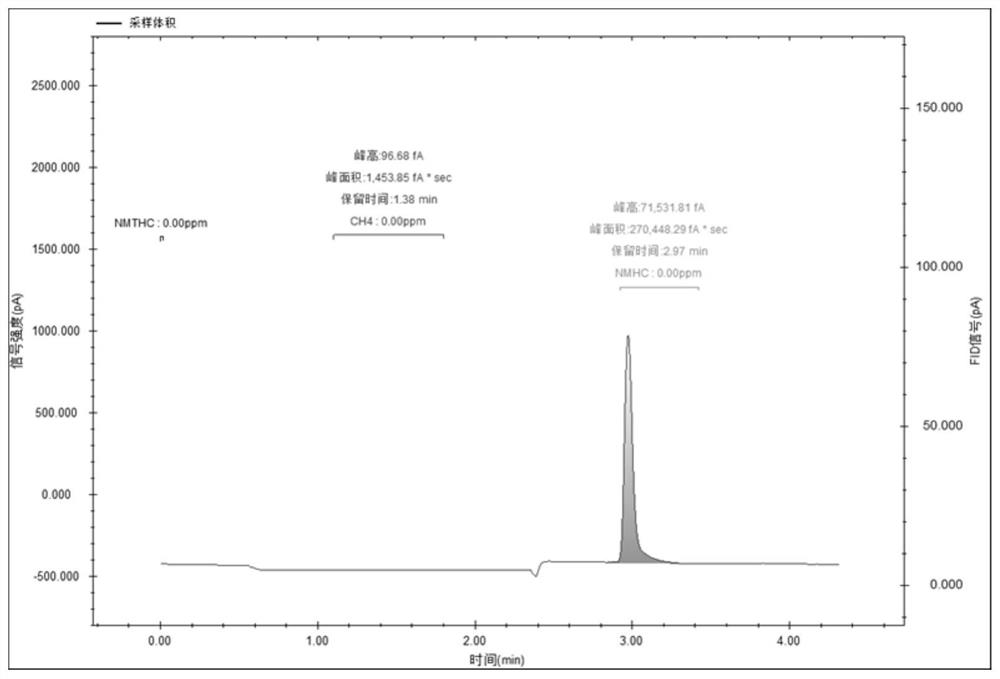

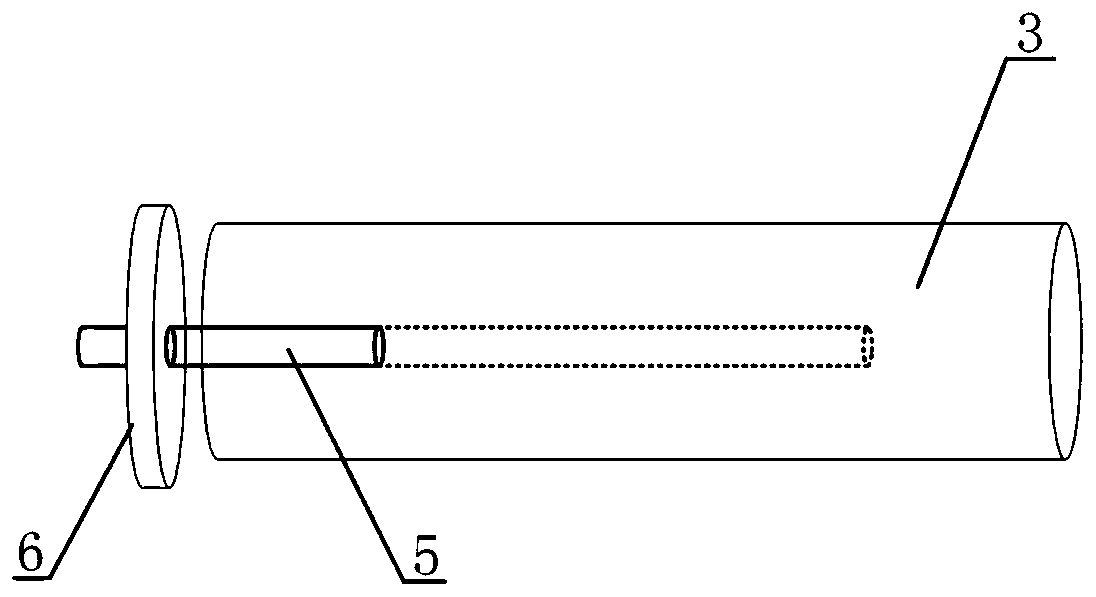

Non-methane total hydrocarbon detection system and method based on single valve

InactiveCN113155988ASimple structureSimple flow pathComponent separationTemperature controlPhysical chemistry

The invention provides a non-methane total hydrocarbon detection system and method based on a single valve. The non-methane total hydrocarbon detection system based on a single valve comprises a sample loop, a chromatographic column and a detector. The ports of only one multi-way valve are respectively communicated with the two ends of the sample loop, the two ends of the chromatographic column, sample gas, carrier gas and the detector. The carrier gas is selectively communicated with one end of the sample loop and one end of the chromatographic column, and the other end of the sample loop is selectively communicated with the sample gas and the other end of the chromatographic column. An adsorption tube is connected with the chromatographic column in series. During sample introduction, gas in the sample loop sequentially passes through the adsorption tube and the chromatographic column, and the adsorption tube adsorbs non-methane hydrocarbon. A temperature control unit is used for heating and refrigerating the adsorption tube. The system has the advantages of simple structure and the like.

Owner:HANGZHOU PUYU TECH DEV CO LTD

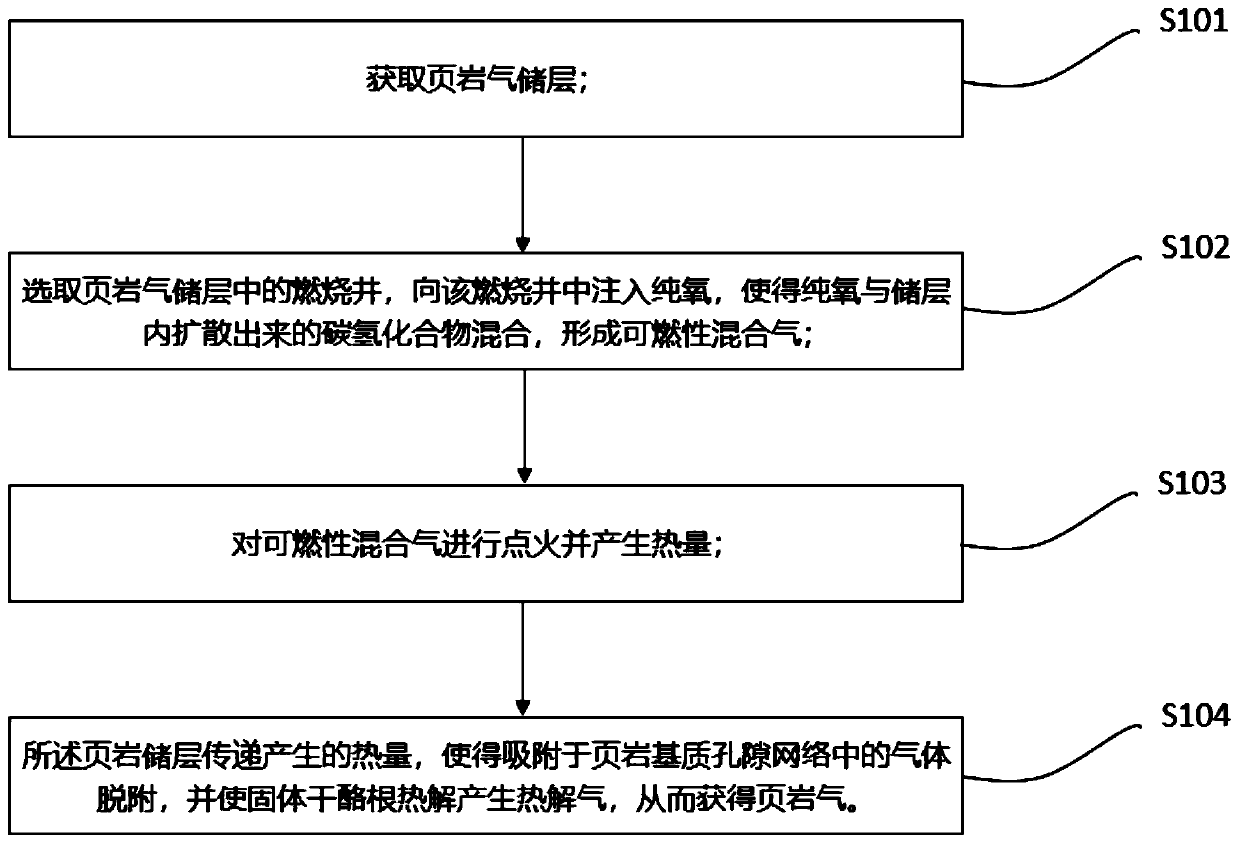

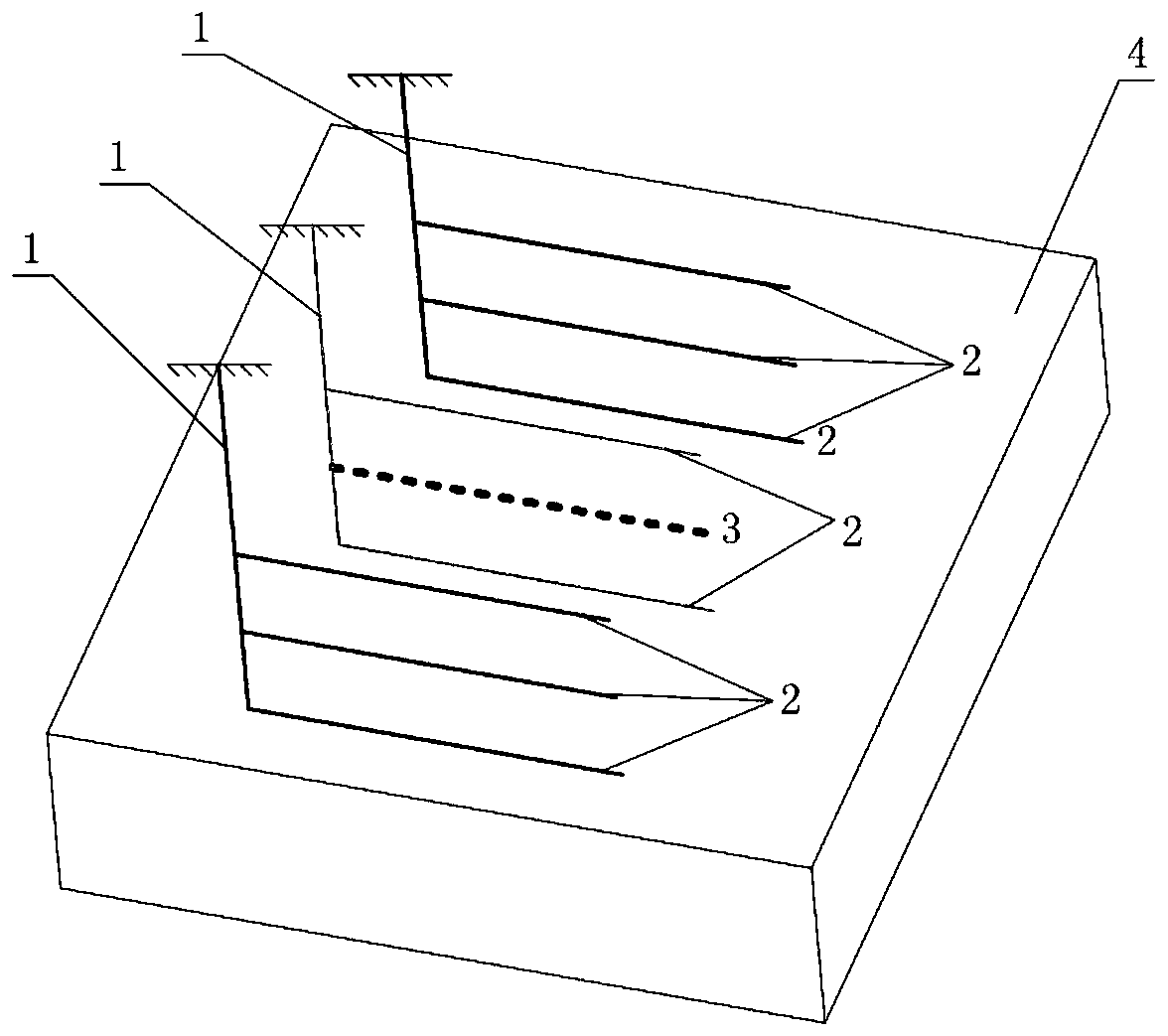

Shale gas exploitation method and system

InactiveCN110017125ASimple structureImprove mining efficiencyOther gas emission reduction technologiesFluid removalOil shale gasKerogen pyrolysis

The invention discloses a shale gas exploitation method and system. The method comprises the following steps: pure oxygen is introduced into a shale gas reservoir, free-state shale gas preferentiallydiffused in a horizontal well and the reservoir is subjected to controllable combustion, thermal generated by combustion is transferred to a shale gas storage layer, the free energy of shale gas is improved, the intermolecular interaction force is reduced, methane and other gases adsorbed in a shale matrix pore network are desorbed, solid kerogen is pyrolyzed to generate pyrolysis gas, and thus shale gas is obtained. The system comprises a gas injection module, a gas collection module and a gas flow regulation module. The system is simple in structure and convenient to implement, the combustion degree can be controlled through the oxygen supply amount, no additional fuel is needed for heating, the economical efficiency is good, and combustion products are mainly water and carbon dioxide, so that environmental pollution is small.

Owner:SUZHOU UNIV

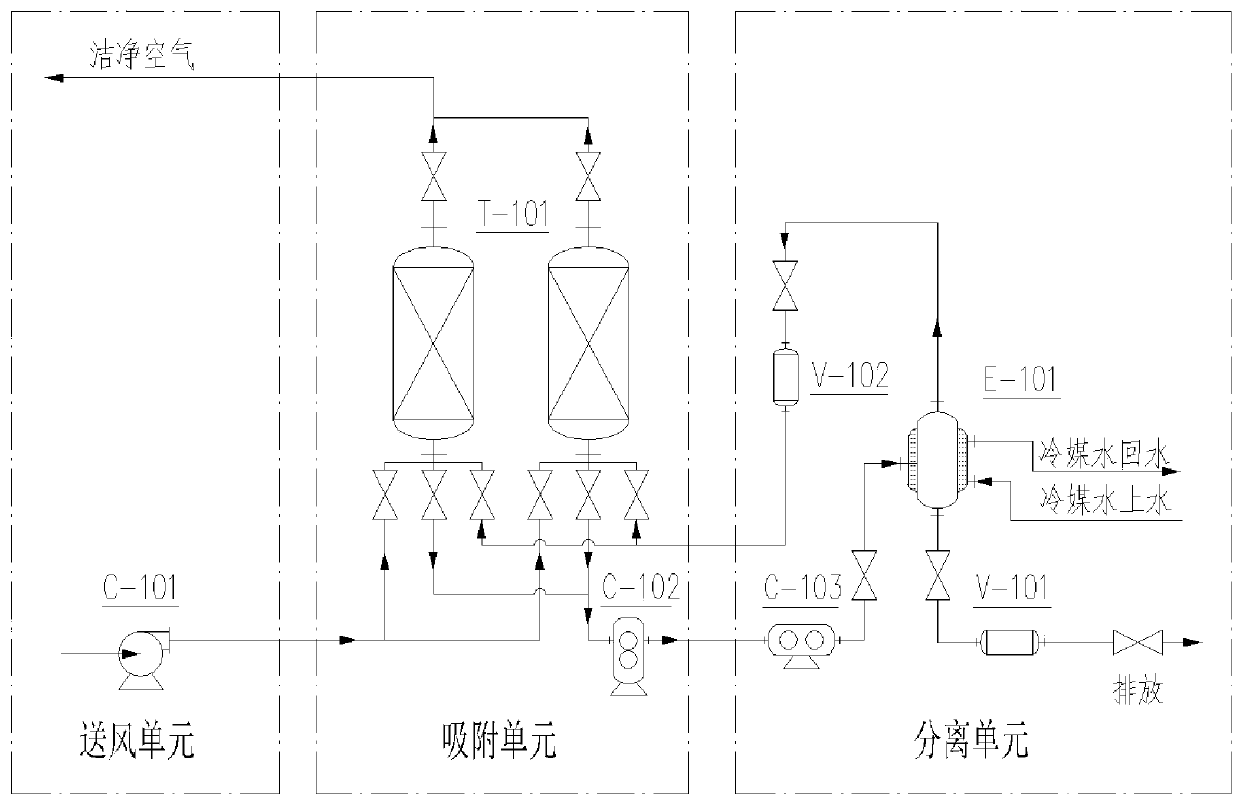

System and method for purifying carbon dioxide

PendingCN110813017AExtended service lifeAdsorption completeGas treatmentDispersed particle separationMicrowaveSeparation technology

The invention provides a system for purifying carbon dioxide. The system comprises an air supply unit, a microwave adsorption and desorption unit and a separation unit which are connected in sequence;the microwave adsorption and desorption unit combines an adsorption tower with a microwave heating device, and a waveguide tube extending into the adsorption tower is arranged on the microwave heating device, so that the regeneration efficiency of the adsorbent is greatly improved, the device size is small, and the service life of an adsorbent is long; according to the method for purifying the carbon dioxide by utilizing the device, an adsorption technology, a microwave heating regeneration technology and a condensation separation technology are combined, so that the desorption regeneration efficiency of the adsorbent is improved, the cycle operation time is shortened, the energy consumption is reduced, carbon dioxide with the volume concentration of 85% or more can be obtained, and the system and method have a relatively high practical application value.

Owner:上海穗杉实业股份有限公司

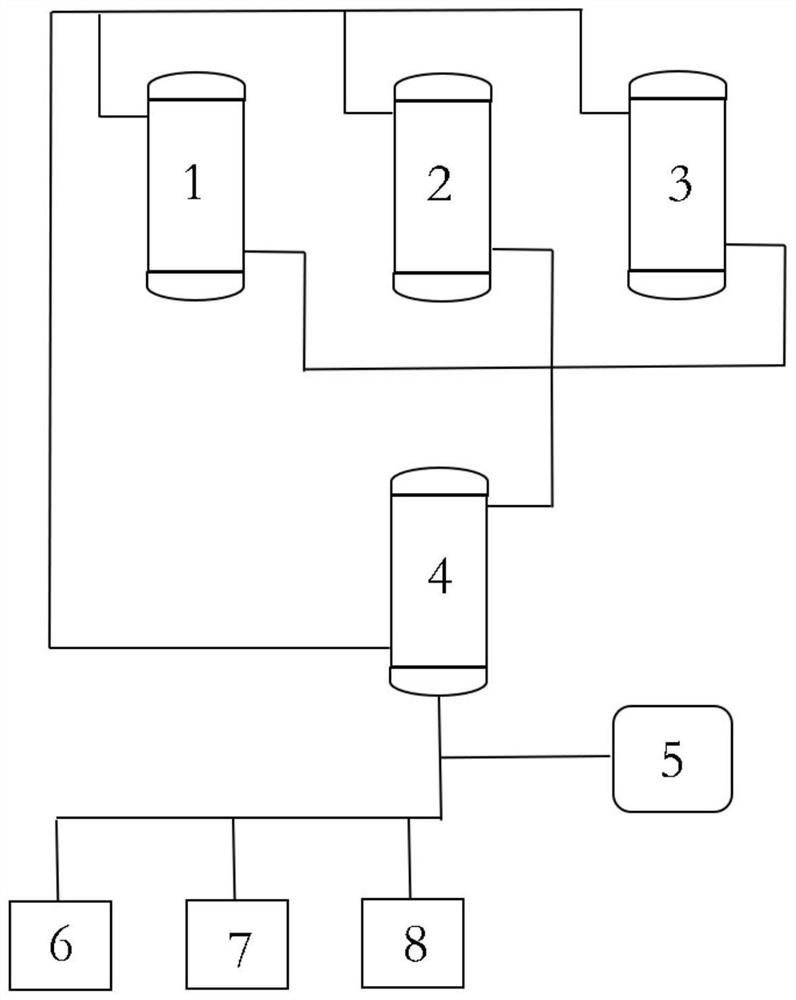

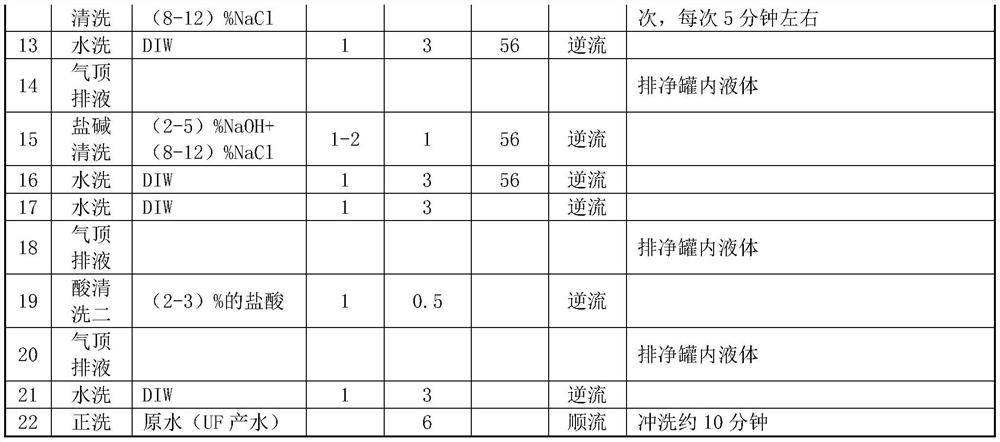

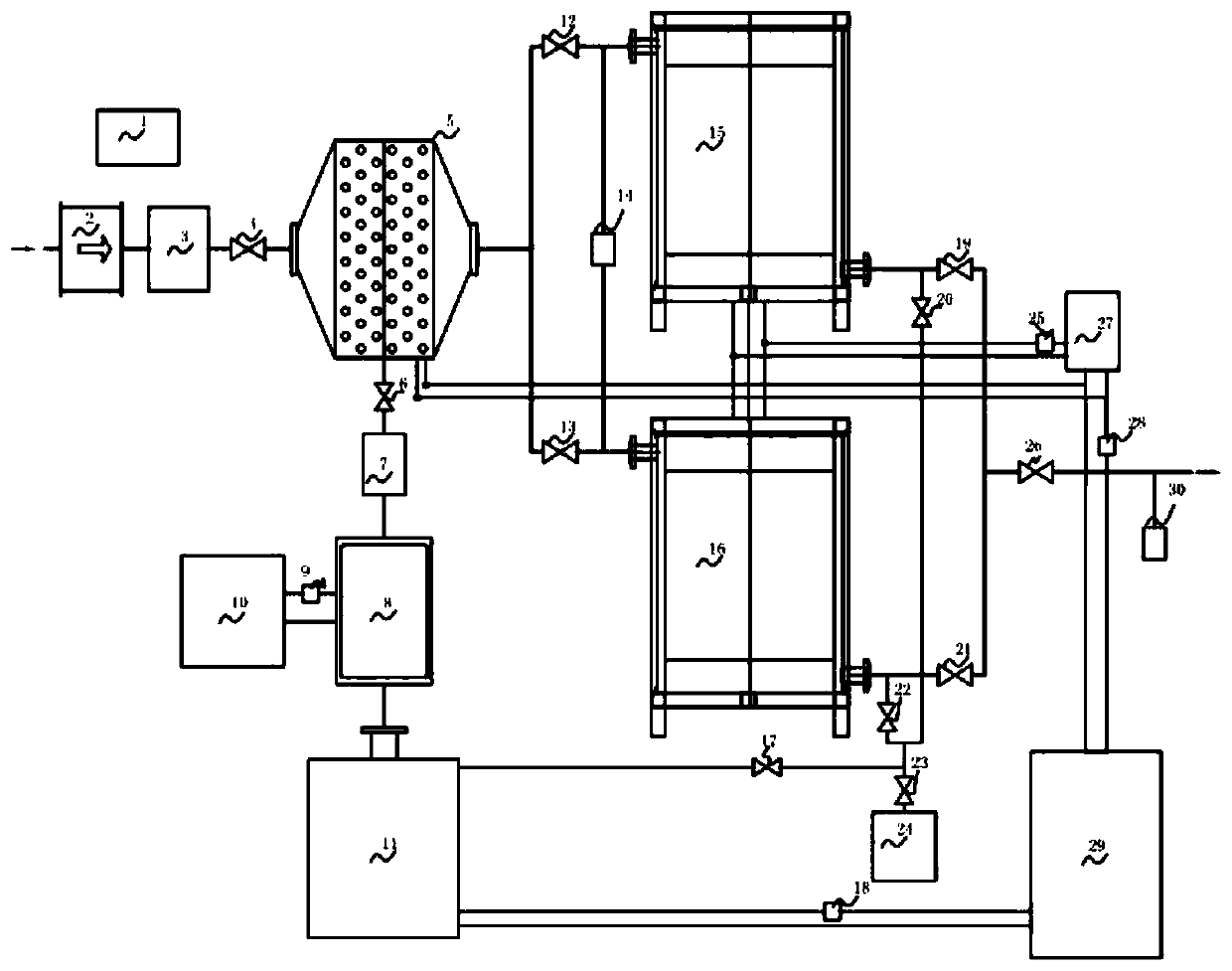

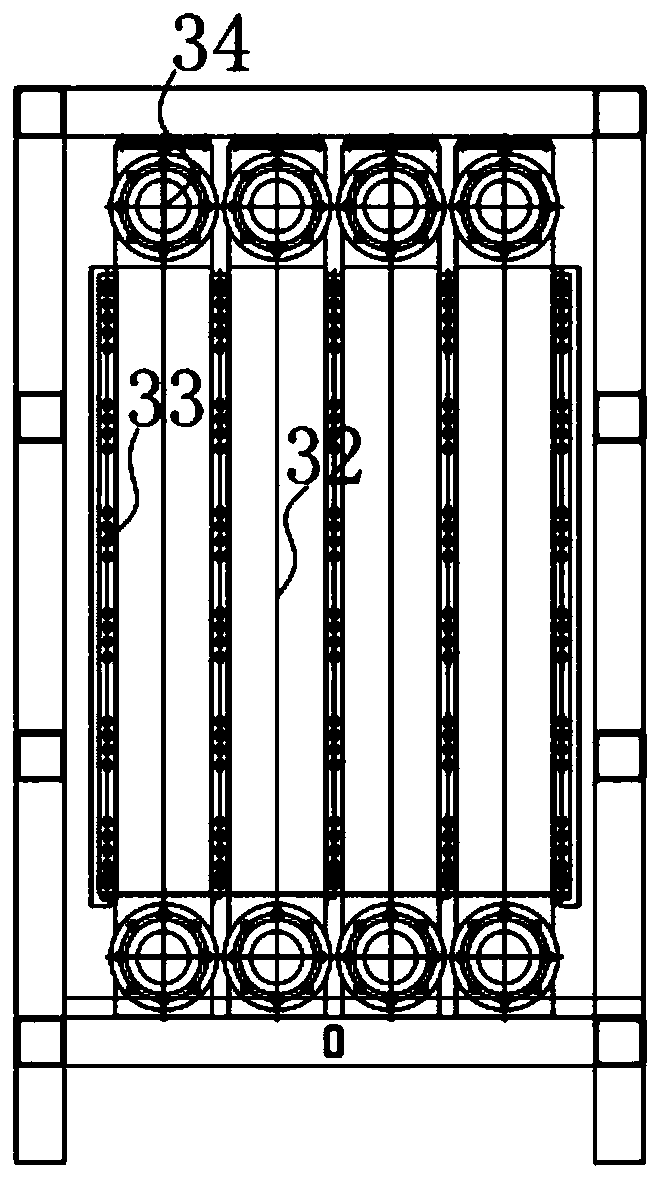

Industrial wastewater treatment method

ActiveCN114538653AImprove the desorption effectEasy to transportSpecific water treatment objectivesScale removal and water softeningIndustrial waste waterEnvironmental engineering

The invention discloses an industrial wastewater treatment method. The industrial wastewater treatment method comprises the following steps: S1, pretreatment; s2, feeding water into an adsorption tank I, and adsorbing organic matters through resin; s3, stopping feeding water after the first adsorption tank reaches the working exchange capacity, feeding water into the second adsorption tank and adsorbing, and feeding the resin in the first adsorption tank into a desorption tank through a resin transfer pipe to desorb the resin in the desorption tank; s4, after the resin in the desorption tank is desorbed, transferring the resin to an adsorption tank I through a resin transfer pipe; s5, stopping feeding water after the second adsorption tank reaches the working exchange capacity, feeding water into the first adsorption tank and adsorbing, and feeding the resin in the second adsorption tank into a desorption tank through a resin transfer pipe to desorb the resin in the desorption tank; s6, after the resin in the desorption tank is desorbed, the resin is transferred to an adsorption tank II through a resin transfer pipe; and S7, repeating the steps S2-S6. According to the technical scheme, the process of adsorption and desorption in a resin tank in the prior art is improved into the process of in-vivo adsorption and in-vitro desorption, and the desorption effect of polluted resin is remarkably improved.

Owner:北京欧美环境工程有限公司

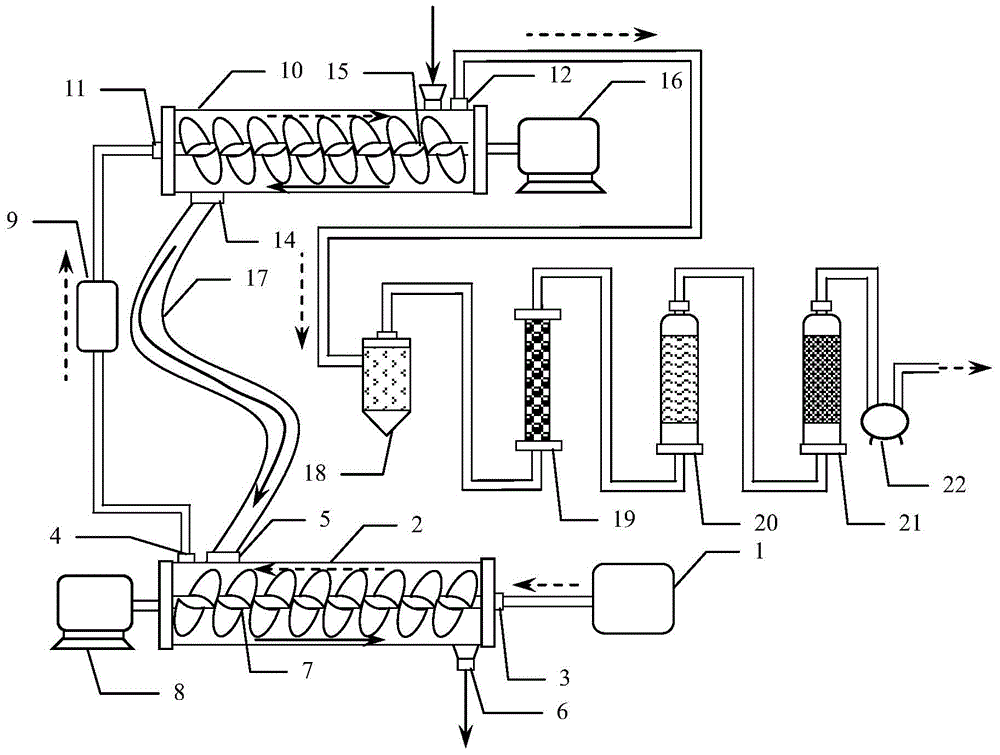

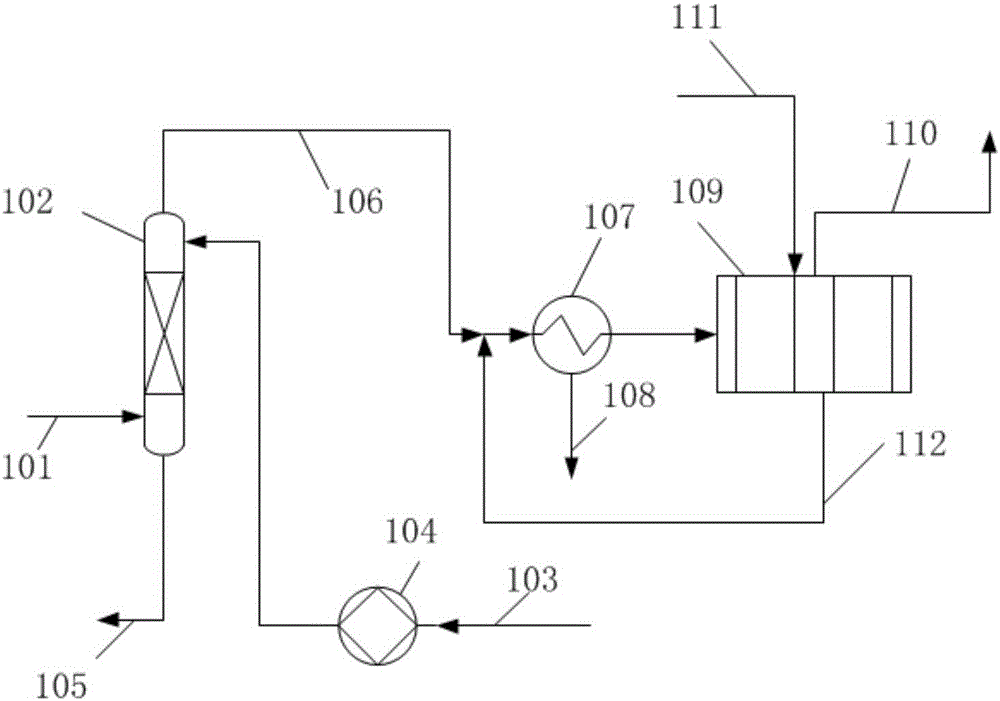

Organic waste gas recycling device and method

ActiveCN110124443AControl and achieve a suitable low temperature adsorption temperatureImprove adsorption efficiencyGas treatmentDispersed particle separationDesorptionLiquid storage tank

The invention discloses an organic waste gas recycling device. The device comprises an adsorption fan, a dust removal filter, a first heat exchanger, an adsorption / desorption device, a nitrogen production unit and a low-temperature liquid storage tank, which are sequentially connected, the first heat exchanger is also connected with an oilless air compressor; the oilless air compressor is connected with a second heat exchanger; the low-temperature liquid storage tank and the first refrigerating unit are respectively connected with the second heat exchanger; a plurality of adsorption / desorptioncavities are formed in the adsorption / desorption device; electric heating plates are arranged on the two sides of each adsorption / desorption cavity. The organic waste gas recycling method comprises the steps of dehydration before adsorption, low-temperature adsorption, thermal-storage desorption under protective gas, recovery through pressurized condensation, and active cooling adsorption tower treatment. According to the device and the method, the cost and the energy consumption of the waste gas recycling device are reduced, and meanwhile, the waste gas recycling efficiency is improved.

Owner:浩辰弘明(北京)科技有限公司

Method for treating high-concentration ammonia and nitrogen in coking gas

InactiveCN102776034AComplete desorptionAvoid secondary pollutionCombustible gas purificationHigh concentrationLutetium

The invention relates to a method for treating high-concentration ammonia and nitrogen in coking gas and belongs to the field of wastewater treatment. Coking gas containing ammonia and nitrogen is desulfurized and absorbed by orthophosphate before being introduced into an ammonia still, and N2 is generated and emitted to air under the catalytic action of organic denitrifying agent and heavy metal oxide. The catalyst mainly comprises, by mass percent, 20%-25% of bismuth oxide, 15%-20% of lutetium oxide, 10-15% of yttrium oxide, beta-Fe3O4 and the like. The organic denitrifying agent comprises, by mass percent, 40%-60% of polypropylene cyanide, 40%-60% of ethylene cyanide, and 10%-20% of CH3(SiOH)3. The method for treating ammonia and nitrogen waste gas has the advantages that resource consumption is low, recycling rate of absorbent is high, secondary pollution is avoided and the like. After the waste gas with the ammonia-nitrogen concentration of 3000-4000mg / L from a coking gas plant is treated by the method, the ammonia-nitrogen concentration decreases to lower than 12mg / L, and removal rate reaches more than 99.96%.

Owner:CHANGZHOU UNIV

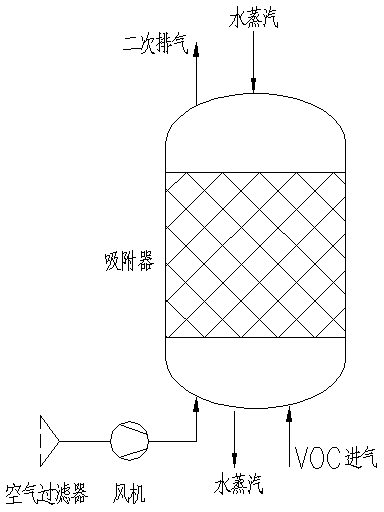

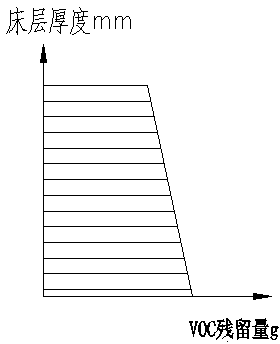

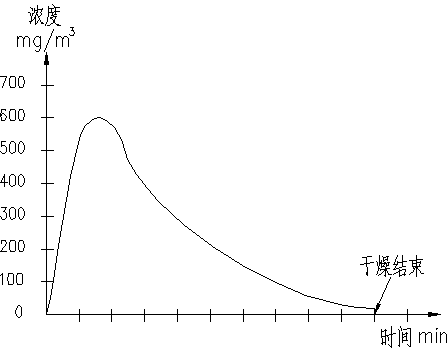

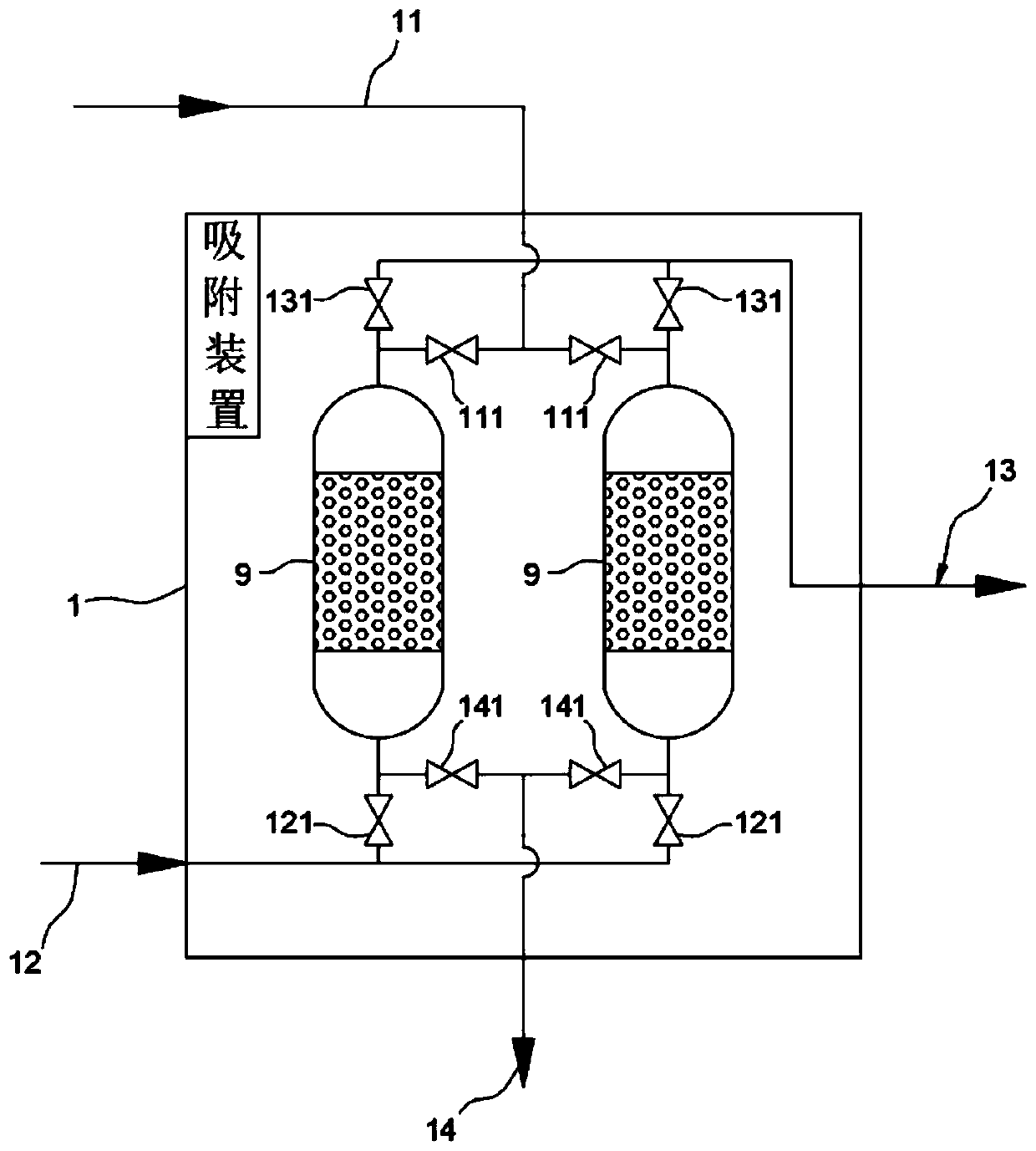

Device for recycling waste gas containing volatile organic compounds

ActiveCN103977670AResidue reductionComplete desorptionDispersed particle separationVolatile organic compoundChemical compound

The invention discloses a device for recycling waste gas containing volatile organic compounds. The device comprises one or more adsorbing devices, a circulating fan, a recycling condenser and / or a dehumidification condenser, a water vapor source and a control system, wherein a waste gas outlet is further connected with an air outlet of the recycling condenser or the dehumidification condenser through an air inlet valve C and the circulating fan; a water vapor outlet is connected with an air inlet of the dehumidification condenser through an air outlet valve C, and a liquid outlet of the dehumidification condenser is connected with a separation device. The device has the beneficial effects that by carrying out cooling and drying by virtue of an external-circulation cooling and drying manners, a phenomenon that secondary emission exceeds the standard is basically avoided in cooling and drying processes, the emission reaches the national emission standards, and secondary pollution is low or even avoided; the adsorption efficiency is high, and the recovery rate of volatile organic compounds (VOC) is high. The device can be applied to the production of novel equipment as well as the remolding of used equipment and is very convenient to use.

Owner:李玉彪

Absorption and adsorption treatment method of high-concentration benzene gas

ActiveCN106669215AEmission complianceTo achieve the purpose of purificationGas treatmentDispersed particle separationActivated carbonFiber

The invention relates to an absorption and adsorption treatment method of high-concentration benzene gas. The method comprises the steps of (a) carrying out absorption treatment on the high-concentration benzene gas by using efficient absorption equipment, forming absorption liquid and absorbed gas and recycling the absorption liquid; (b) carrying out condensation treatment on the absorbed gas through a condenser, wherein the condensation temperature is -40 DEG C to 5 DEG C, and forming condensate and a condensed gas after condensation treatment and recycling the condensate; and (c) adsorbing and purifying the condensed gas through activated carbon fiber adsorber, forming a purified gas for discharging, carrying out desorption treatment to form desorbed gas and forming recyclable desorbed gas condensate after condensation. The absorption and adsorption treatment method aims at solving the technical problem of how to reduce the concentration of benzene in the benzene gas to 4mg / Nm<3> or below, and meanwhile, the absorption liquid and the condensate can be separated or can be directly used for other processes. The method provided by the invention is applied to treatment of a benzene material lift truck, tail gas generated by a benzene storage tank and other high-concentration benzene gases.

Owner:BEIJING CREDITCONGRUITY ENERGY TECH CO LTD

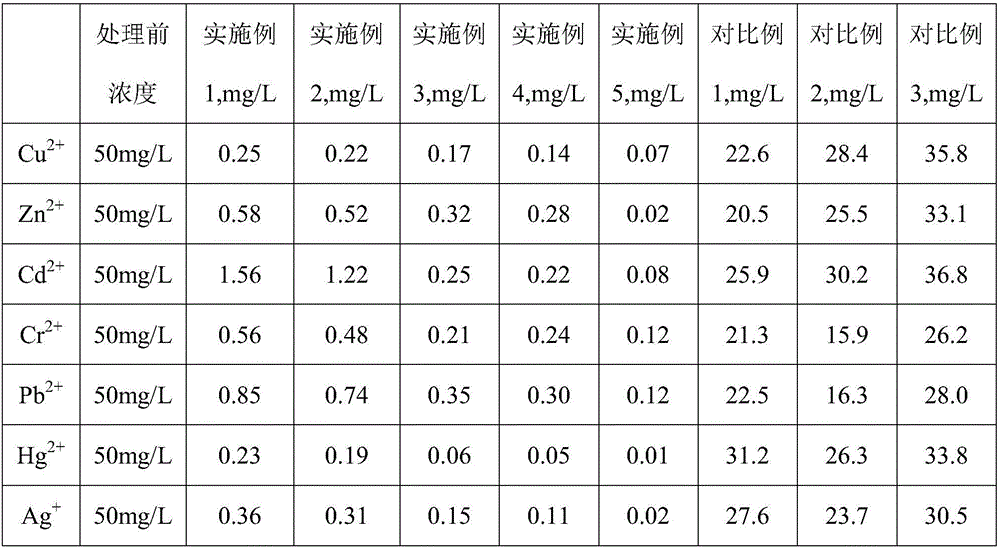

Heavy metal adsorbent and preparation method thereof

InactiveCN106669609AImprove adsorption efficiencyHigh adsorption capacityOther chemical processesWater/sewage treatment by sorptionHeavy metalsSorbent

The invention discloses a heavy metal adsorbent and a preparation method thereof. The adsorbent comprises the following raw materials, by weight part, 27-35 parts of akamada, 13-21 parts of tert-butyl chloroacetate, 2-6 parts of isopropanol and 5-12 parts of saligenol. The preparation method comprises: mixing and grinding akamada and isopropanol, adding a tert-butyl chloroacetate solution, performing ultrasonic treatment, adding saligenol drop by drop, and performing sealed heating and stirring, performing microwave treatment, performing stirring till the obtained product is dried, and performing high temperature calcination to obtain the heavy metal adsorbent. The prepared adsorbent has super-high heavy metal adsorption efficiency and can be repeatedly used for more than 100 times. The heavy metal adsorbent is large in adsorption capacity and high in adsorption speed. The preparation method is simple, heavy metal can be recycled through treatment of the used adsorbent with acid, and the used adsorbent can be recycled through high temperature calcination at 450 DEG C, wherein the adsorbent can be frequently used. Desorption can be completely carried out, so that the recycle cost of heave metal is low. The adsorbent for treating heavy metal wastewater is low in treatment cost and simple in process, causes no secondary pollution, and is suitable for industrial production.

Owner:HENAN BALING ELECTRONICS TECH CO LTD

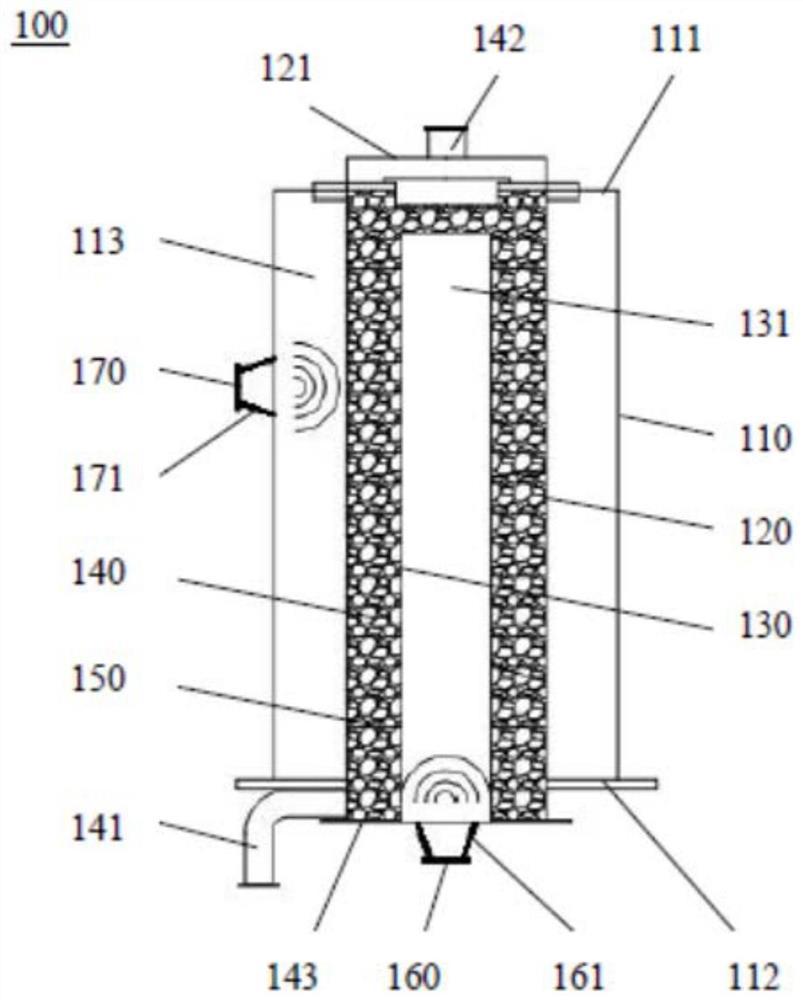

Polluted gas adsorption and desorption equipment and method

PendingCN113209772AThorough adsorptionThorough adsorption and desorptionGas treatmentDispersed particle separationMicrowaveSorbent

The invention relates to the technical field of pollution gas treatment, and discloses pollution gas adsorption and desorption equipment and method. The pollution gas adsorption and desorption equipment disclosed by the invention not only can adsorb pollution gas in waste gas, but also can realize uniform and rapid heating of the adsorbent by arranging an annular adsorption channel and respectively transmitting microwaves to an adsorbent in the adsorption channel from the inner side and the outer side of the adsorption channel by adopting different microwave generators; and desorption methods such as vacuum and purging can be coupled to realize thorough desorption of the adsorbent in a short time, so that the regeneration efficiency of the adsorbent and the capability of repeatedly adsorbing pollution gas are remarkably improved, and the service life of the adsorbent is effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Activated carbon fiber desorption method

InactiveCN108176388AComplete desorptionSolve drying problemsOther chemical processesCombustible gas purificationFiberActivated carbon

The invention discloses an activated carbon fiber desorption method. The method comprises the steps as follows: (1) activated carbon fiber adsorbing organic matter is placed in a vacuum environment; (2) the activated carbon fiber is energized until the temperature of the activated carbon fiber reaches or exceeds the boiling point of the adsorbed organic matter, and the organic matter is evaporatedfrom the activated carbon fiber; (3) the organic matter escaped from the activated carbon fiber in the vacuum environment is extracted from the vacuum environment. According to the activated carbon fiber desorption method, the activated carbon fiber is subjected to conductive desorption in the vacuum environment by use of the conductivity of the activated carbon fiber, so that the temperature ofthe activated carbon fiber reaches or exceeds the boiling point of the adsorbed organic matter, the organic matter in the activated carbon fiber can be desorbed thoroughly, the desorption cost is reduced, the desorption effect is good, and the adsorption function of the activated carbon fiber can be completely recovered after desorption, and the drying problem after wet desorption is solved.

Owner:张家港绿色三星净化科技有限公司

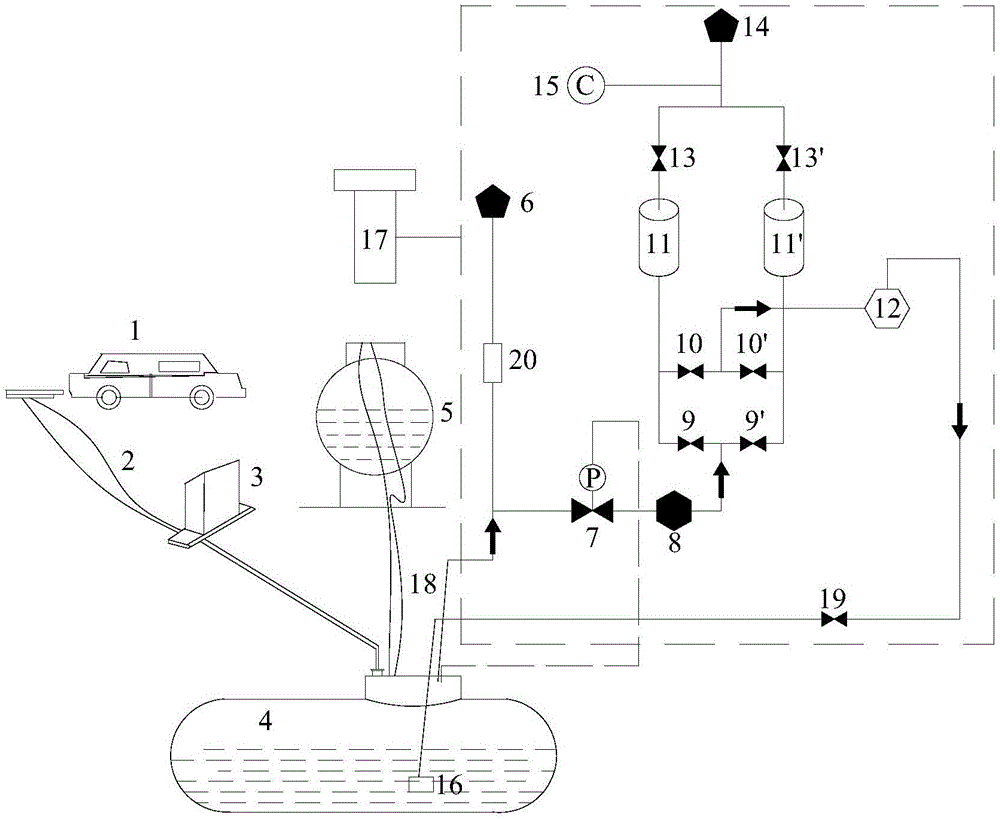

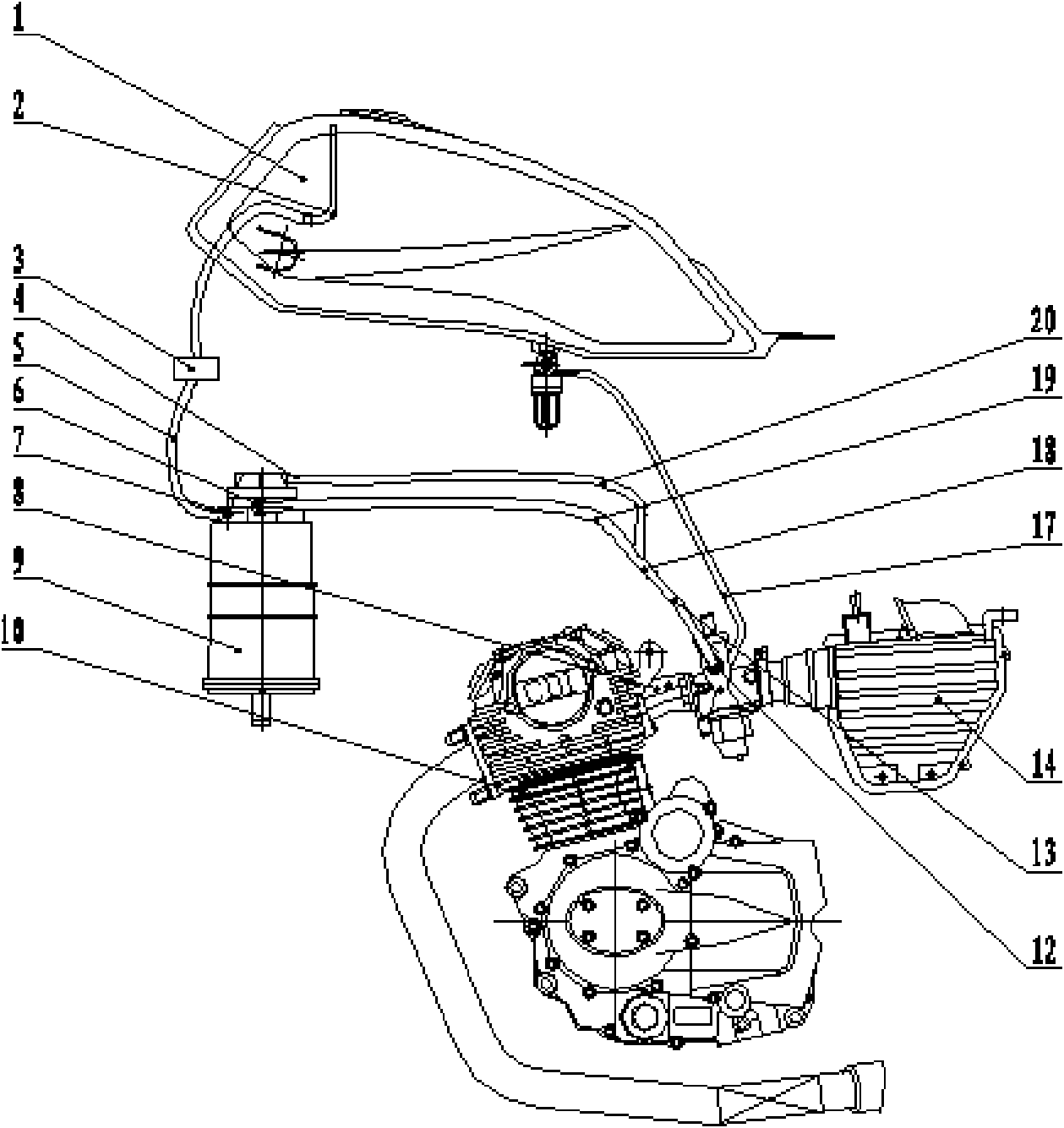

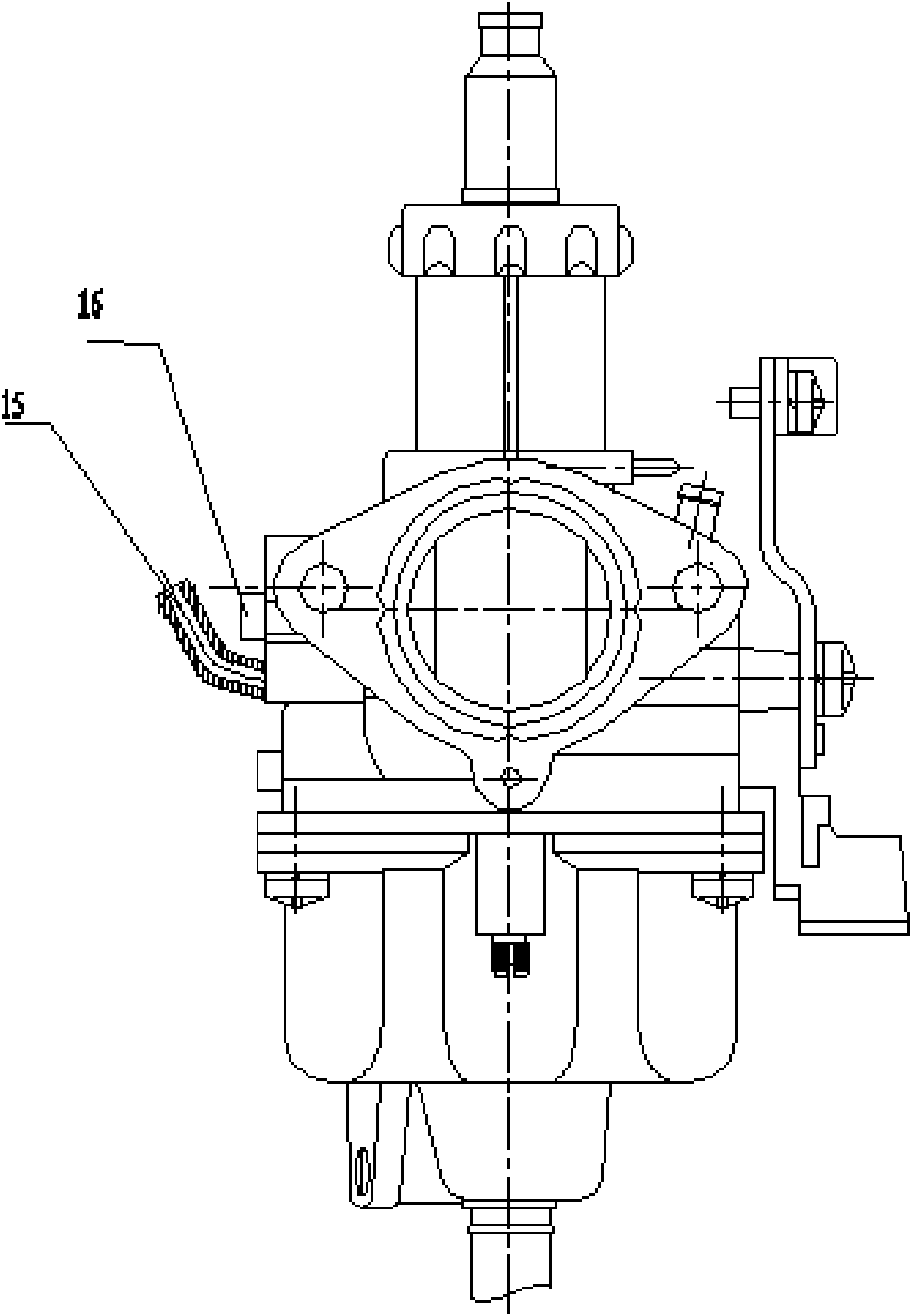

Motorcycle fuel evaporative pollutant control system

InactiveCN101539078AComplete desorptionSatisfy the desorption pressure requirementNon-fuel substance addition to fuelMachines/enginesDesorptionControl system

The invention relates to a motorcycle fuel evaporative pollutant control system comprising a carbon canister and a gasoline cut-off valve, an air inlet absorption port of the carbon canister is connected with an oil tank vent pipe by a fourth pipeline, the gasoline cut-off valve is arranged on a first pipeline, a pressure control valve of the carbon canister and an air outlet desorption port of the carbon canister are communicated with an air path of a carburetor, the pressure control valve and the desorption port of the carbon canister are respectively communicated with a three-way pipe by a second pipeline and the first pipeline, and the three-way pipe is communicated with the air path of the carburetor after being communicated with a third pipeline. The adoption of the technical proposal can not only reduce the emission of fuel evaporative pollutants, but also reduce the impacts of the fuel evaporative pollutants on the working condition emission, thereby leading the exhaust emission of motorcycles to achieve the requirement of being more environment-friendly.

Owner:CHONGQING LONCIN MOTOR

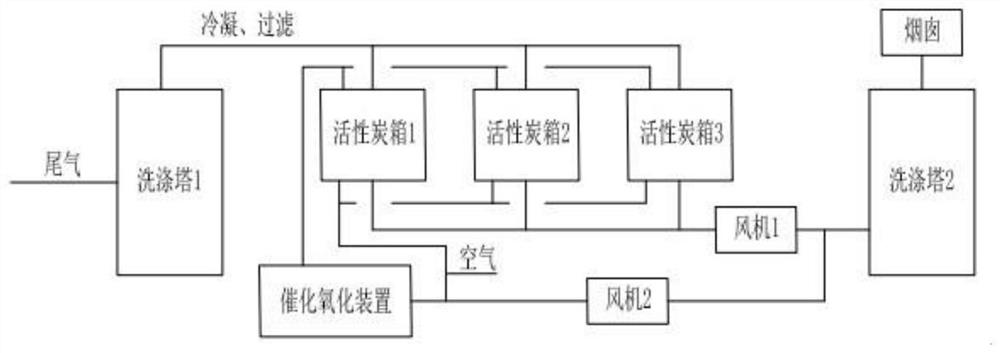

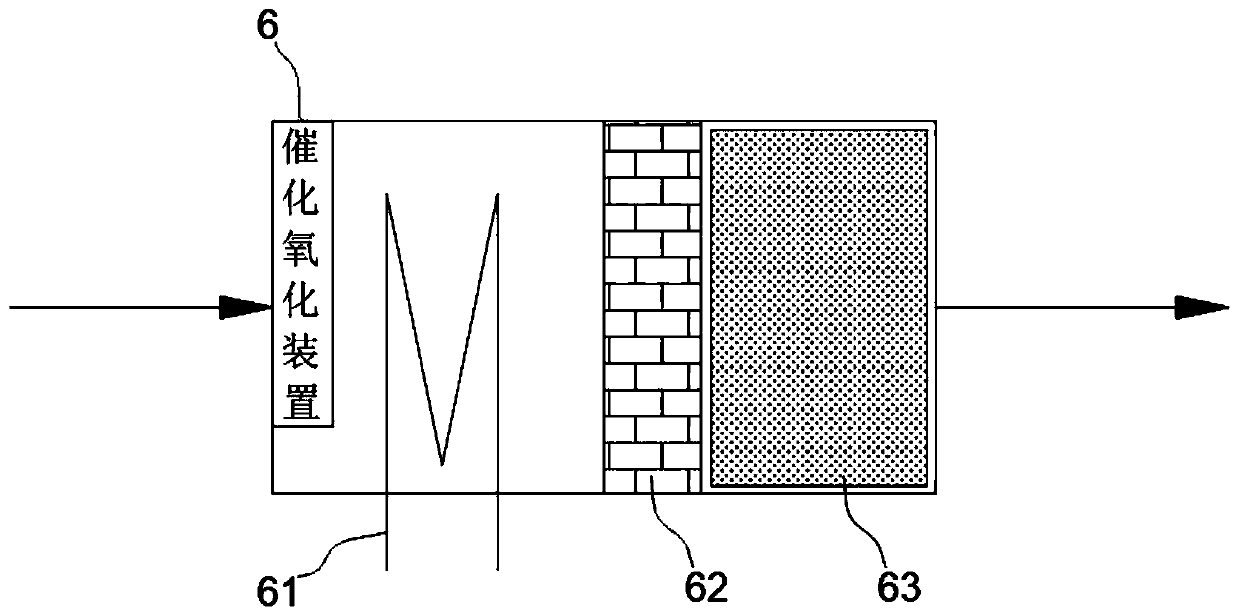

Process for adsorbing, desorbing and catalytically oxidizing VOCs by using activated carbon in pharmaceutical industry

InactiveCN113318582AReduce volumeComplete desorptionGas treatmentDispersed particle separationActivated carbonPtru catalyst

The invention discloses a process for adsorbing, desorbing and catalytically oxidizing VOCs by using activated carbon in the pharmaceutical industry. An alkaline washing tower group, an activated carbon group, a catalytic oxidation device and a fan are included; the activated carbon group comprises a first activated carbon box, a second activated carbon box and a third activated carbon box, the upper part of the activated carbon group is connected with the inlet pipeline, the lower part is connected with the gas outlet pipeline, and the activated carbon group is connected with the catalytic oxidation device through a branch pipeline to form an annular loop; a catalyst is arranged in the catalytic oxidation device, porous thin-wall honeycomb ceramic is used as a carrier of the catalyst, and a layer of nano activated aluminum oxide and a layer of Pt metal modified nanoscale material H2Pt(OH)6 are sequentially loaded on the surface of the catalyst; the volume of the catalytic oxidation reactor can be reduced, and the manufacturing cost is reduced; the energy of the high-temperature gas subjected to catalytic oxidation is utilized twice, so that the operation cost of the device is reduced; and the halogenated compound is completely converted through catalytic oxidation, so that the activated carbon is completely desorbed, and the safety of the device is guaranteed.

Owner:江苏威扬环境科技有限公司

Poly-p-xylene surface coating equipment of ancient books and literatures and its coating technology

InactiveCN1280023CGuaranteed uniformityEnsure consistencyLiquid surface applicatorsChemical vapor deposition coatingGas phaseMetallurgy

Owner:邵力为 +2

Method for treating high-concentration ammonia nitrogen in chemical waste gas

InactiveCN102772997AComplete desorptionAvoid secondary pollutionNitrogen preparationDispersed particle separationBenzoic acidHigh concentration

The invention discloses a method for treating high-concentration ammonia nitrogen in chemical waste gas. The method includes the steps: firstly, placing the chemical waste gas in an absorption tower and absorbing the chemical waste gas by orthophosphoric acid to generate diammonium hydrogen phosphate and ammonium dihydrogen phosphate mixed solution; secondly, continuously circulating the solution by a lift pump and repeatedly absorbing ammonia until diammonium hydrogen phosphate is completely generated; thirdly, introducing the generated diammonium hydrogen phosphate into an ammonia still containing Pd-Zn-Hg-Cr As-V / titanium dioxide catalysts through a pipeline and adding an organic denitrifying agent comprising polyvinyl acetate, trifluoromethyl benzoic acid and methylbenzyl alcohol; and fourthly, introducing steam into the ammonia still and decomposing the diammonium hydrogen phosphate into ammonium dihydrogen phosphate and nitrogen under the action of the organic denitrifying agent and the catalysts. Phosphoric acid is used as an absorbent for absorbing ammonia in waste gas without adjusting pH (potential of hydrogen) value, and secondary pollution is avoided as decomposition of the diammonium hydrogen phosphate is promoted by adding the organic denitrifying agent and the diammonium hydrogen phosphate is completely converted into nitrogen to be exhausted under the catalytic action of the catalysts. Besides, the generated ammonium dihydrogen phosphate can also be used as an absorbent for reabsorbing the ammonia, so that the absorbent can be recycled.

Owner:CHANGZHOU UNIV

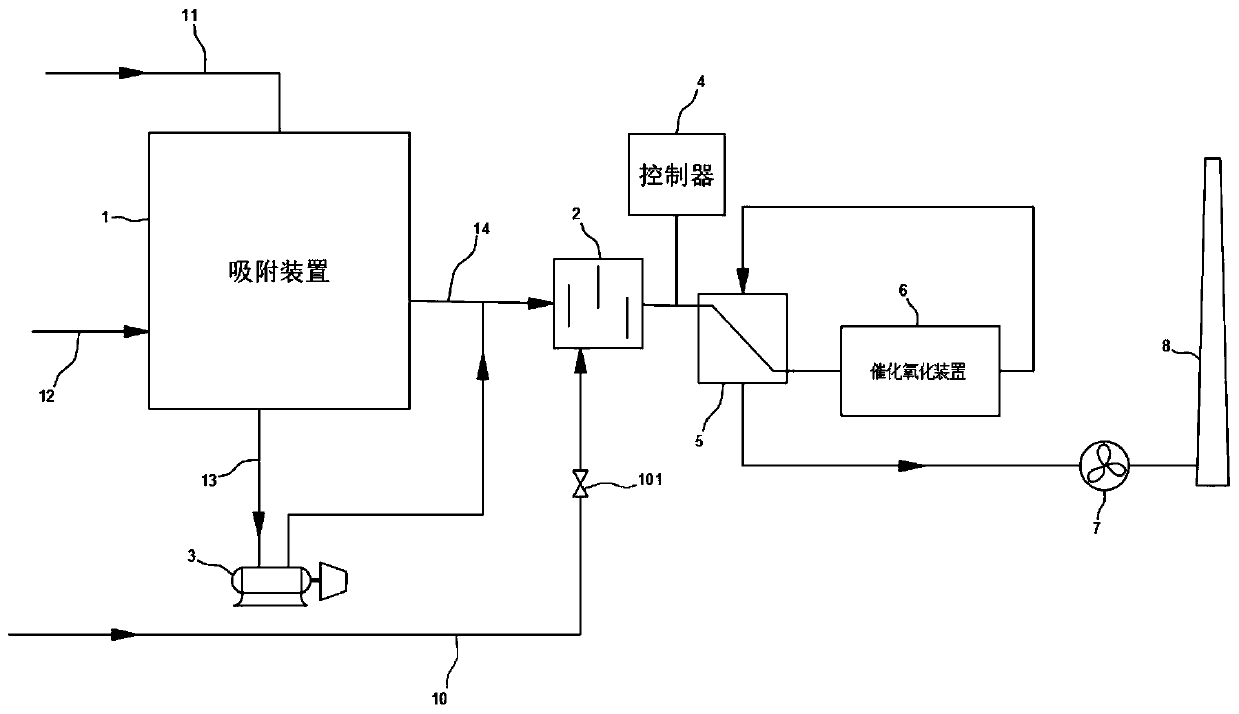

Efficient oil gas purification system

PendingCN111135710AReduce concentrationMeet the requirements of emission standardsGas treatmentDispersed particle separationCatalytic oxidationVacuum pump

The invention relates to the technical field of oil gas purification equipment, specifically to an efficient oil gas purification system. The system comprises an adsorption device, a stabilizer, a vacuum pump, a controller, a heat exchanger and a catalytic oxidation device, wherein the adsorption device is provided with a first air inlet pipe, a second air inlet pipe, a first air outlet pipe and asecond air outlet pipe; the adsorption device is communicated with an air inlet of the stabilizer through the first air outlet pipe; the second air outlet pipe is communicated with an air inlet of the vacuum pump; an air outlet of the vacuum pump is communicated with an air inlet of the stabilizer through a pipeline; the controller is installed on an air outlet of the stabilizer; an air outlet ofthe stabilizer is communicated with an air inlet of the heat exchanger through a pipeline; an air outlet of the heat exchanger is communicated with a low-temperature air inlet of the catalytic oxidation device through a pipeline; and a low-temperature air outlet of the catalytic oxidation device is communicated with an air inlet of the heat exchanger through a pipeline. The efficient oil gas purification system is high in purification efficiency, low in operation cost and simple in process.

Owner:江苏乐尔环境科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com