Heavy metal adsorbent and preparation method thereof

An adsorbent and heavy metal technology, which is applied in the field of heavy metal adsorbent and its preparation, can solve the problems of low efficiency of absorbing heavy metals in red jade soil, and achieve the effects of high reuse times, easy recovery of heavy metals, and high adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

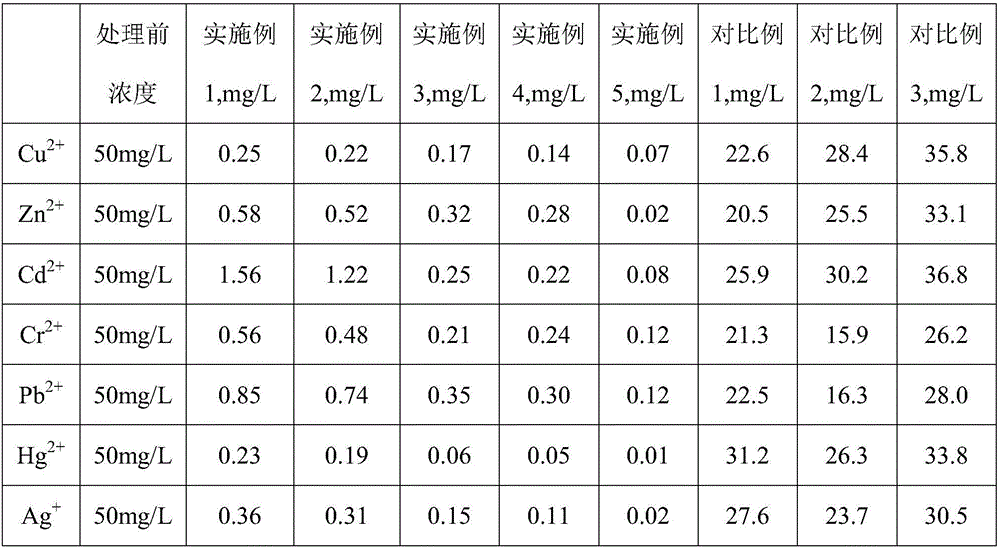

[0017] In the embodiment of the present invention, a heavy metal adsorbent is composed of the following raw materials in parts by weight: 27 parts of red jadeite, 13 parts of tert-butyl chloroacetate, 2 parts of isopropanol, and 5 parts of salicylic alcohol.

[0018] Mix tert-butyl chloroacetate with 4.8 times the mass of deionized water to prepare tert-butyl chloroacetate solution. Mix and grind red jade soil and isopropanol, pass through a 120-mesh sieve, then add tert-butyl chloroacetate solution, raise the temperature to 72°C and ultrasonically treat at this temperature for 32min, the ultrasonic power is 1000W, then add salicyl alcohol dropwise, dropwise After completion, heat up to 112°C and seal and stir at this temperature for 53 minutes, then microwave for 20 minutes with a microwave power of 800W, stir at 99°C until dry, and then calcinate in a muffle furnace at 430°C for 4 hours. get the adsorbent.

[0019] Through repeated experiments, it is obtained that the adsor...

Embodiment 2

[0021] In the embodiment of the present invention, a heavy metal adsorbent is composed of the following raw materials in parts by weight: 35 parts of red jadeite, 21 parts of tert-butyl chloroacetate, 6 parts of isopropanol, and 12 parts of salicylic alcohol.

[0022] Mix tert-butyl chloroacetate with 4.8 times the mass of deionized water to prepare tert-butyl chloroacetate solution. Mix and grind red jade soil and isopropanol, pass through a 120-mesh sieve, then add tert-butyl chloroacetate solution, raise the temperature to 72°C and ultrasonically treat at this temperature for 32min, the ultrasonic power is 1000W, then add salicyl alcohol dropwise, dropwise After completion, heat up to 112°C and seal and stir at this temperature for 53 minutes, then microwave for 20 minutes with a microwave power of 800W, then stir until dry at a temperature of 101°C, and then calcinate in a muffle furnace at 430°C for 4 hours. get the adsorbent.

[0023] Through repeated experiments, it is...

Embodiment 3

[0025] In the embodiment of the present invention, a heavy metal adsorbent is composed of the following raw materials in parts by weight: 29 parts of red jade earth, 15 parts of tert-butyl chloroacetate, 3 parts of isopropanol, and 7 parts of salicylic alcohol.

[0026] Mix tert-butyl chloroacetate with 4.8 times the mass of deionized water to prepare tert-butyl chloroacetate solution. Mix and grind red jade soil and isopropanol, pass through a 120-mesh sieve, then add tert-butyl chloroacetate solution, raise the temperature to 72°C and ultrasonically treat at this temperature for 32min, the ultrasonic power is 1000W, then add salicyl alcohol dropwise, dropwise After completion, heat up to 112°C and seal and stir at this temperature for 53 minutes, then microwave for 20 minutes with a microwave power of 800W, then stir at 100°C until dry, and then calcinate in a muffle furnace at 430°C for 4 hours. get the adsorbent.

[0027] Through repeated experiments, it is obtained that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com