Method for preparing high thermal conductivity active carbon taking waste cotton cloth as raw material

A high thermal conductivity, activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of poor thermal conductivity, low energy utilization, and low thermal conductivity of activated carbon, and achieve economical preparation and regeneration technology, The preparation process is easy to realize and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

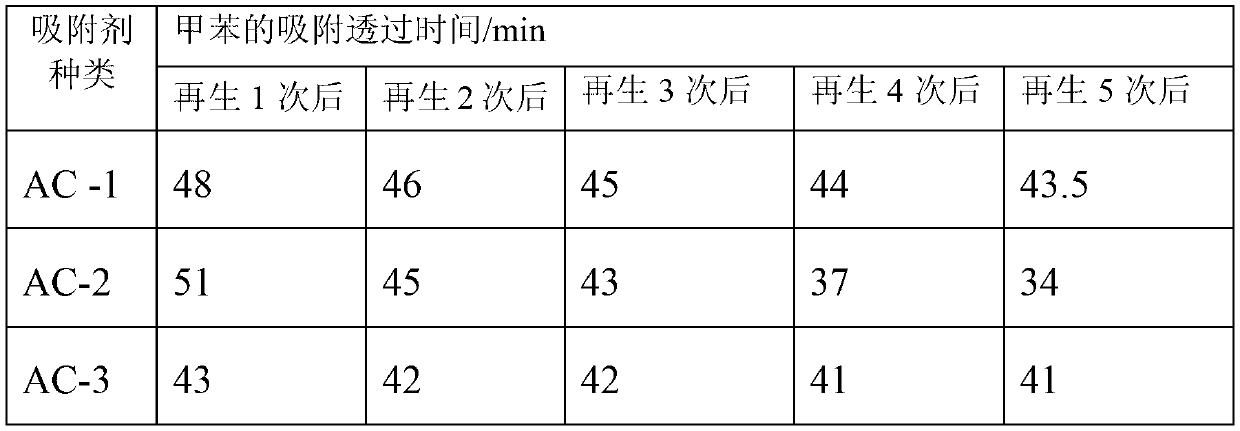

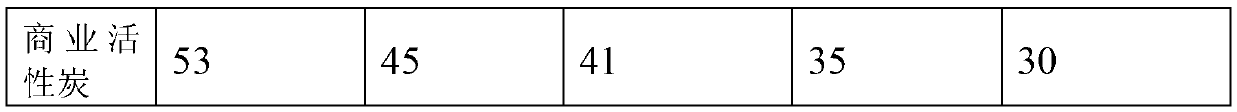

Embodiment 1

[0024] Put 5g of waste cotton cloth fragments with a diameter less than 5mm into 50mL of zinc chloride solution with a concentration of 0.3g / ml and soak for 24 hours, then carry out vacuum distillation in a rotary evaporator to obtain a carbon source material containing an activator, which is placed in After drying in an oven at 110°C for 24 hours, add expanded graphite with a mass percentage of 20%, mix thoroughly to form a solid mixture, and finally send the resulting solid mixture into an atmosphere tube furnace and burn it under a nitrogen atmosphere at 400°C After activating for 0.5h, stop heating and cool to room temperature in a nitrogen atmosphere, rinse with deionized water until neutral, and dry in an oven at 110°C to constant weight to obtain activated carbon with high thermal conductivity, marked as AC-1.

Embodiment 2

[0026] 5g of waste cotton cloth fragments with a diameter less than 5mm are put into 50mL of zinc chloride solution with a concentration of 0.3g / ml and soaked for 36 hours, and then carry out vacuum distillation in a rotary evaporator. The resulting solid is the carbon source material containing the activator. Dry in an oven at 100°C for 26 hours, add expanded graphite with a mass percentage of 5%, and mix well to form a solid mixture, and finally send the resulting solid mixture into an atmosphere tube furnace under a nitrogen atmosphere at 300°C Ignite and activate for 2 hours, stop heating and cool to room temperature in a nitrogen atmosphere, rinse with deionized water until neutral, and dry in an oven at 120°C to constant weight to obtain high thermal conductivity activated carbon, marked as AC-2.

Embodiment 3

[0028] 5g of waste cotton cloth fragments with a diameter less than 5mm were put into 50mL concentration and soaked in a zinc chloride solution of 0.3g / ml for 48 hours, and then carried out vacuum distillation in a rotary evaporator to obtain a solid that contained an activator. Dry in an oven at 120°C for 22 hours, add expanded graphite with a mass percentage of 40%, and mix well to form a solid mixture, and finally send the obtained solid mixture into an atmosphere tube furnace under a nitrogen atmosphere at 500°C Ignite and activate for 1 hour, stop heating and cool to room temperature in a nitrogen atmosphere, rinse with deionized water until neutral, and dry in an oven at 100°C to constant weight to obtain high thermal conductivity activated carbon, marked as AC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com