Method for treating copper slag

A copper slag and pretreatment technology, applied in the field of metal smelting, can solve the problems of less than 1% iron utilization rate, less than 12% copper utilization rate, difficult magnetic separation process, etc., to avoid metal loss and large water consumption, Solve the effects of occupying land and polluting the environment and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

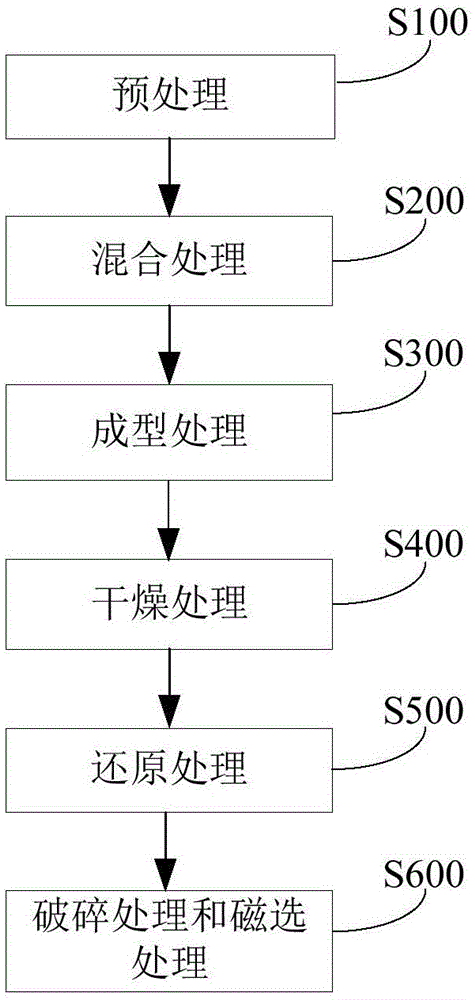

Image

Examples

Embodiment 1

[0058] Copper slag composition: 43.75wt% TFe, 0.45wt% Cu, 1.23wt% Zn and 0.27wt% Pb;

[0059] Processing steps: first dry, crush and sieve copper slag, anthracite and limestone respectively to obtain copper slag particles, anthracite particles and limestone particles, and obtain copper slag particles, anthracite particles and limestone particles in a mass ratio of 100:18 : 11 carry out mixed treatment, obtain mixed material, then adopt pair of roller type high-pressure ball briquetting machine to carry out molding process to mixed material, obtain copper slag pellet, then copper slag pellet is carried out drying treatment, then will pass through drying by distributing device The copper slag pellets are distributed into the regenerative rotary hearth furnace and reduced for 55 minutes at 1550 degrees Celsius to obtain a solid reduction product containing iron-copper alloy particles and flue gas containing lead and zinc elements (the recovered ZnO is 71%, and the zinc recovery T...

Embodiment 2

[0061] Copper slag composition: 37.84wt% TFe, 1.37wt% Cu, 0.6wt% Zn and 0.21wt% Pb;

[0062] Processing steps: first dry, crush and screen copper slag, bituminous coal and sodium carbonate respectively to obtain copper slag particles, bituminous coal particles and sodium carbonate particles, and obtain copper slag particles, bituminous coal particles and sodium carbonate particles according to the mass ratio of Mix at 100:22:15 to obtain the mixed material, and then use the double-roller high-pressure briquetting machine to shape the mixed material to obtain copper slag pellets, then dry the copper slag pellets, and then pass the material distribution device Put the dried copper slag pellets into the regenerative rotary hearth furnace and reduce them for 30 minutes at 1450 degrees centigrade to obtain a solid reduction product containing iron-copper alloy grains and flue gas containing lead-zinc elements (the recovered ZnO is 66% , the zinc recovery rate is 95.5%, the lead rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com