Process for producing wet method phosphoric acid by medium low grade phosphorus mine

A wet-process phosphoric acid, low-grade technology, used in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of reduced quality of phosphogypsum, difficulty in comprehensive utilization, and low decomposition rate of phosphate rock, reducing waste of resources, Mitigate gradual exhaustion and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Using this process technology, 80,000 tons / year P 2 o 5 The continuous test of industrial production of phosphoric acid has achieved good results as expected.

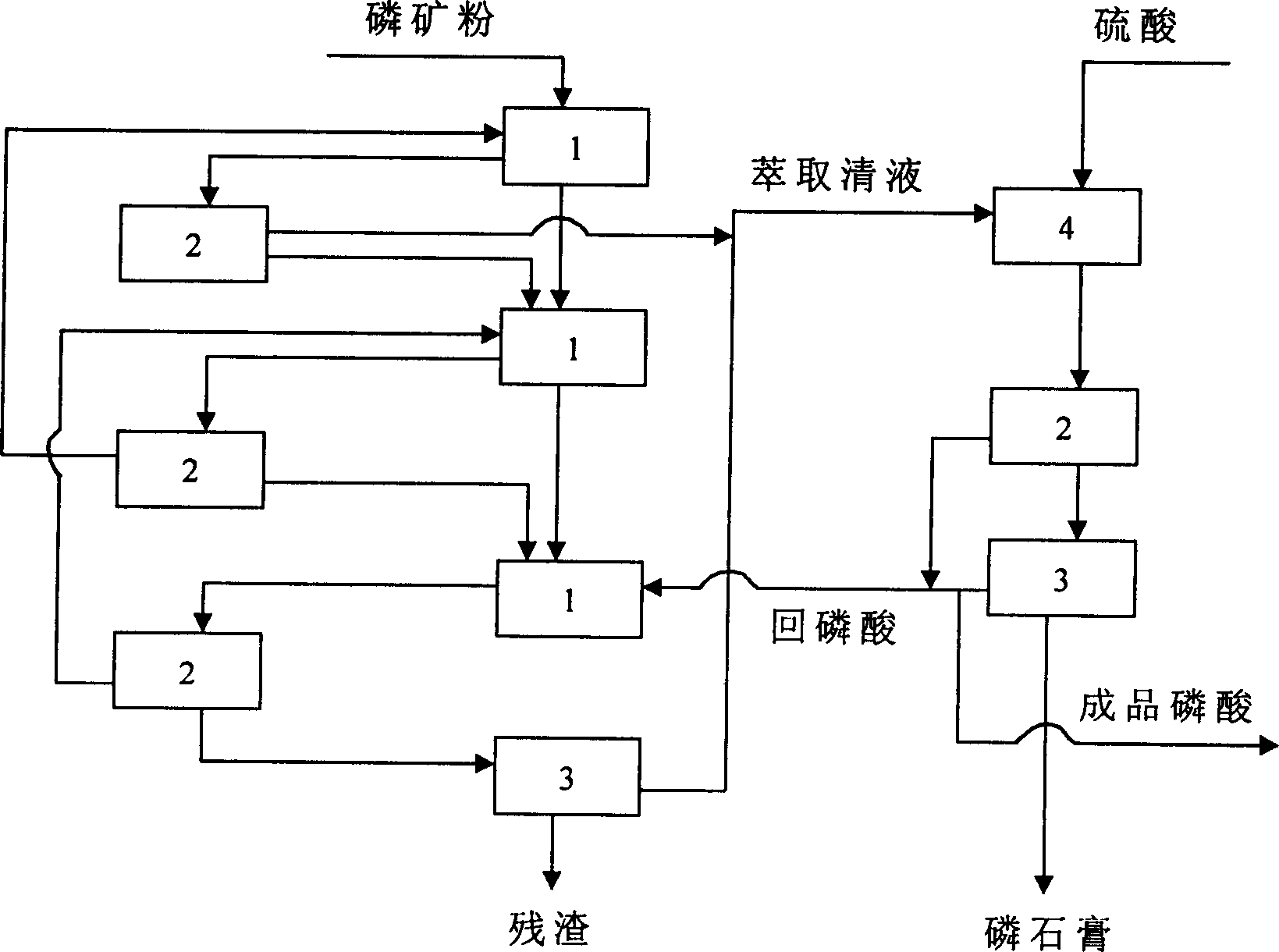

[0041] The specific process flow is: adding middle and low-grade phosphate rock into the multi-stage (3-stage) countercurrent extraction tank 1 arranged in steps, adding an excess concentration of 21.5% P 2 o 5 (WT) Phosphoric acid countercurrently decomposes phosphate rock, the liquid-solid ratio in the extraction slurry is 16.2, the reaction temperature is 75°C, and the total reaction time is 3h to generate calcium dihydrogen phosphate solution, which is combined with centrifugal sedimentation and vacuum filtration (centrifugal settler 2 adopt hydrocyclone, vacuum filter 3 adopt rotary table type vacuum filter, the same below) to carry out liquid-solid separation to remove residue to obtain extract clear liquid; in the reaction tank 4 with return slurry function, extract clear liquid and sulfuric acid to rea...

Embodiment 2

[0058] A small-scale continuous test of 1000 tons / year industrial production of phosphoric acid was carried out using this process technology with medium and low-grade phosphate rock in Yichang, Hubei (composition see Table 2) as raw material, and the expected good results were obtained.

[0059] The specific process flow is: adding middle and low-grade phosphate rock into the multi-stage (3-stage) countercurrent extraction tank 1 arranged in steps, adding an excess concentration of 22%P 2 o 5 (WT) Phosphoric acid countercurrently decomposes phosphate rock, controls the liquid-solid ratio in the extraction slurry = 16.3, the reaction temperature is 76 ° C, and the total reaction time is 3.2 hours to generate calcium dihydrogen phosphate solution. Solid separation removes the residue to obtain the extract clear liquid; in the square multi-grid reaction tank 4 with the slurry return function, the extract clear liquid is reacted with sulfuric acid, and the sulfuric acid consumpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com