Method and device for purifying coke oven gas

A technology for coke oven gas and tar, which is applied in the refining field of chemical products, can solve the problems of intractable waste water treatment costs, etc., and achieve the effects of small investment in equipment, reduction of air pollution, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

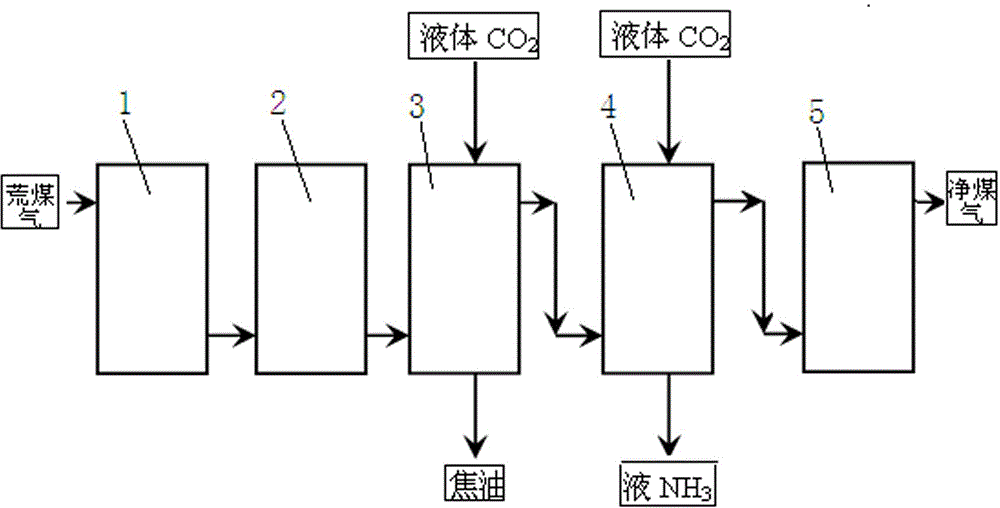

[0015] The coke oven gas purification device of the present invention is as figure 1 As shown, it includes primary cooler 1, dehydration tower 2, tar recovery tower 3, liquid ammonia recovery tower 4 and methanol washing tower 5. The inlet of the primary cooler is connected to the coke oven gas pipeline, the primary cooler, the dehydration tower, the tar recovery tower, the liquid ammonia recovery tower and the methanol scrubber are connected in sequence, and the methanol scrubber is connected to the clean gas tank. The tar recovery tower and the liquid ammonia recovery tower are respectively connected to the liquid carbon dioxide pipeline, the tower bottom outlet of the tar recovery tower is connected to the tar recovery equipment, and the tower bottom outlet of the liquid ammonia recovery tower is connected to the liquid ammonia recovery equipment. The dehydration tower 2 is a 12-layer vibrating sieve plate tower, the methanol washing tower is a spray tower, and the device i...

Embodiment 2

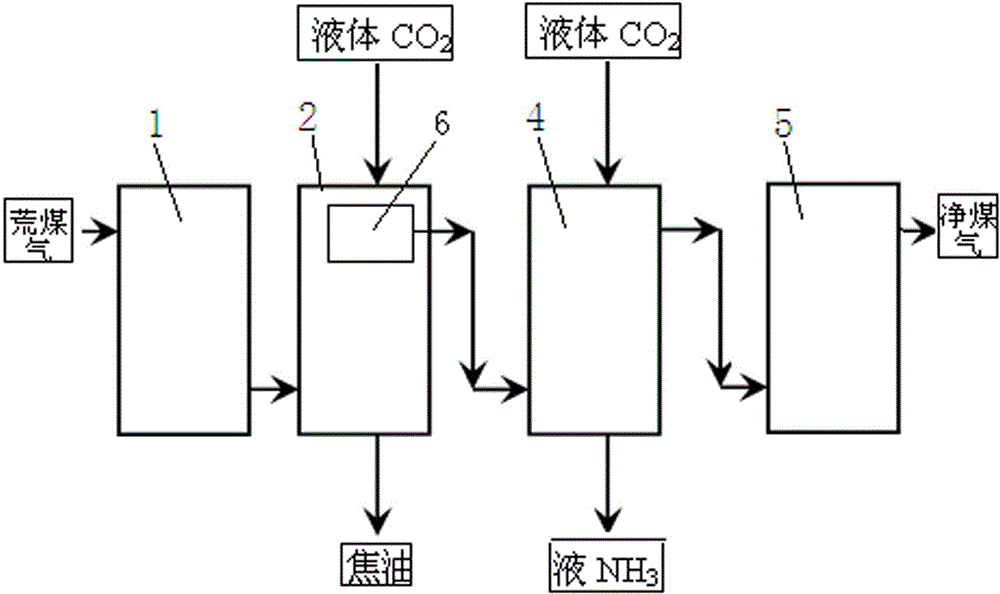

[0018] The coke oven gas purification device of the present invention is as figure 2 As shown, it includes primary cooler 1, dehydration tower 2, liquid ammonia recovery tower 4 and methanol washing tower 5. The primary cooler, dehydration tower, liquid ammonia recovery tower and methanol scrubber are connected in sequence, and the methanol scrubber is connected with the clean gas tank. The tar recovery tower and the liquid ammonia recovery tower are respectively connected to the liquid carbon dioxide pipeline, the tower bottom outlet of the tar recovery tower is connected to the tar recovery equipment, and the tower bottom outlet of the liquid ammonia recovery tower is connected to the liquid ammonia recovery equipment. The dehydration tower 2 is a 12-layer vibrating sieve plate tower, the methanol washing tower is a spray tower, and the device is equipped with methanol regeneration equipment and calcium oxide regeneration equipment. The top of the dehydration tower 2 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com