A multi-stage thermal desorption remediation system for organic polluted soil

A technology of organic pollution and remediation system, applied in the field of soil remediation, can solve the problem of no exhaust waste heat reuse, etc., achieve broad application prospects and practical value, easy to use, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

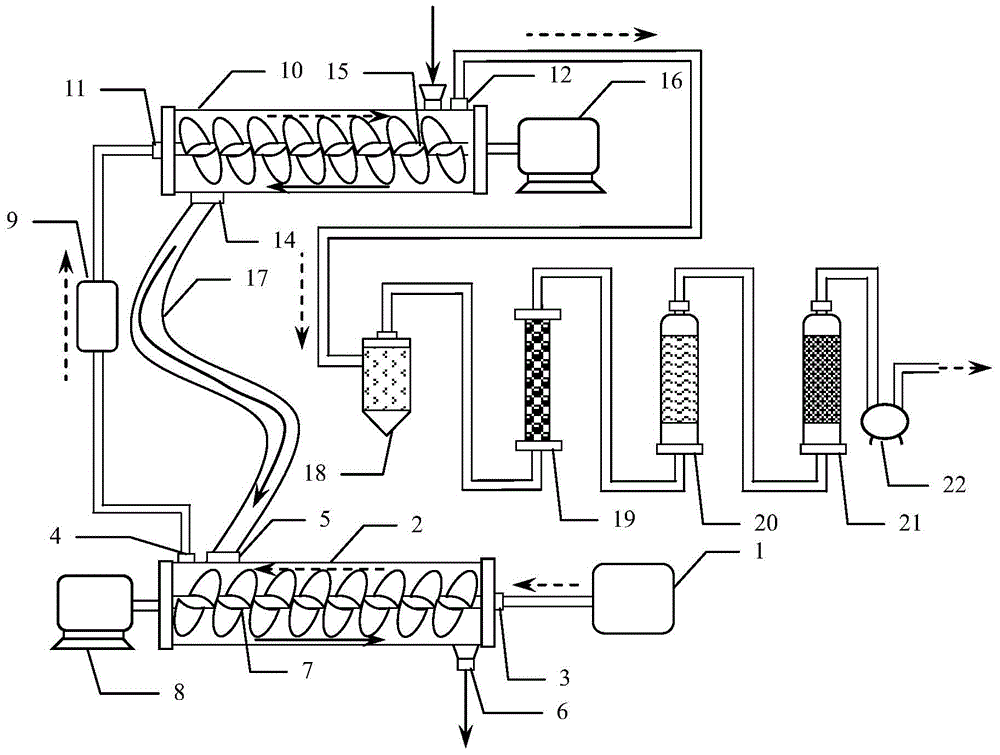

[0016] The present invention is described in further detail below in conjunction with accompanying drawing, see accompanying drawing.

[0017] A multi-stage thermal desorption restoration system for organic polluted soil, which is composed of a first-stage thermal desorption device, a second-stage thermal desorption device, a tail gas treatment device, a secondary combustion chamber 9 and a drop conveyor belt 17 .

[0018] The first-stage thermal desorption device is composed of a combustion chamber 1, a first-stage thermal desorption chamber 2, a first stirrer 7 and a first motor 8. The first-stage thermal desorption chamber 2 is a horizontal cylindrical hollow cylinder, and two Each end is provided with a sealing cover, and a first agitator 7 with a rotating shaft parallel to the center line is provided on the center line of the first-stage thermal desorption chamber 2, and one end of the rotating shaft of the first agitator 7 moves through the first-stage thermal desorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com