Device and method for treating organic waste gas with large airflow and low concentration

A technology of organic waste gas and treatment equipment, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of large floor area, high investment cost, and low purification efficiency, and achieve small floor area and low investment cost. Low, high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

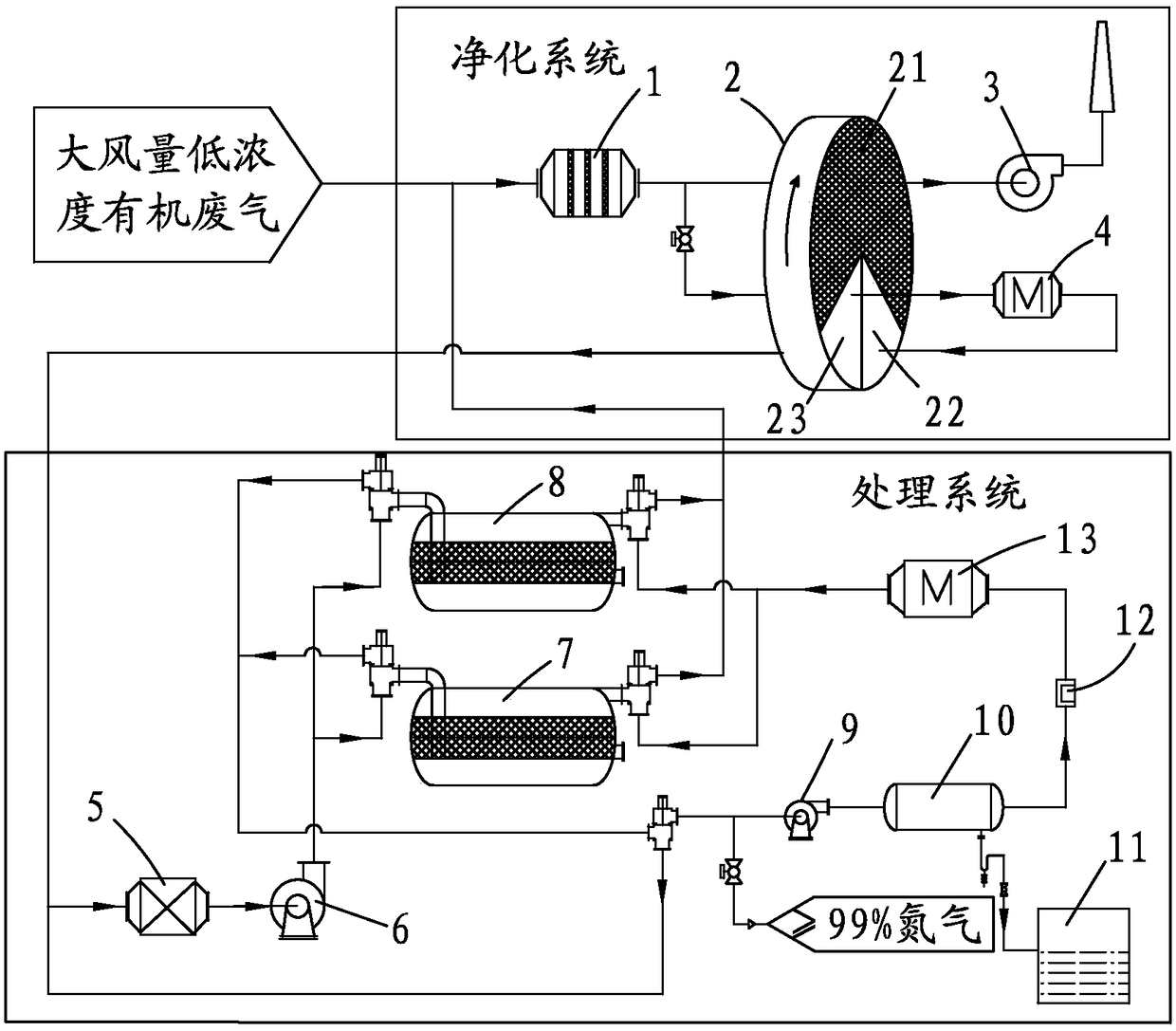

[0032] Such as figure 1 Shown, device of the present invention is made up of purification system and treatment system two parts:

[0033] (1) The purification system includes a high-efficiency filter 1 (for filtering the impurity particles contained in the front-end exhaust gas to protect the service life and purification efficiency of the rear-end molecular sieve runner), a molecular sieve runner 2, Exhaust fan 3; the molecular sieve runner 2 condenses organic waste gas with large air volume and low concentration into high concentration organic waste gas with small air volume. The runner system is divided into three zones, adsorption zone 21, desorption zone 22 and cooling zone 23. The function of the adsorption zone 21 is mainly to adsorb and purify organic waste gas; the function of the desorption zone 22 is mainly to regenerate the molecular sieve after adsorption saturation at high temperature; the function of the cooling zone 23 is mainly to cool down the regenerated hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com