Technology for removing ferric trichloride from chlorination liquid generated in chlorobenzene production

A technology of ferric chloride and chlorinated liquid, which is applied in the fields of organic chemistry, chemical instruments and methods, halogenated hydrocarbon preparation, etc., can solve the problems of increasing alkali consumption in alkali washing, long process pipelines, and large floor space. Achieve the effect of reducing waste water production, extending operating time and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

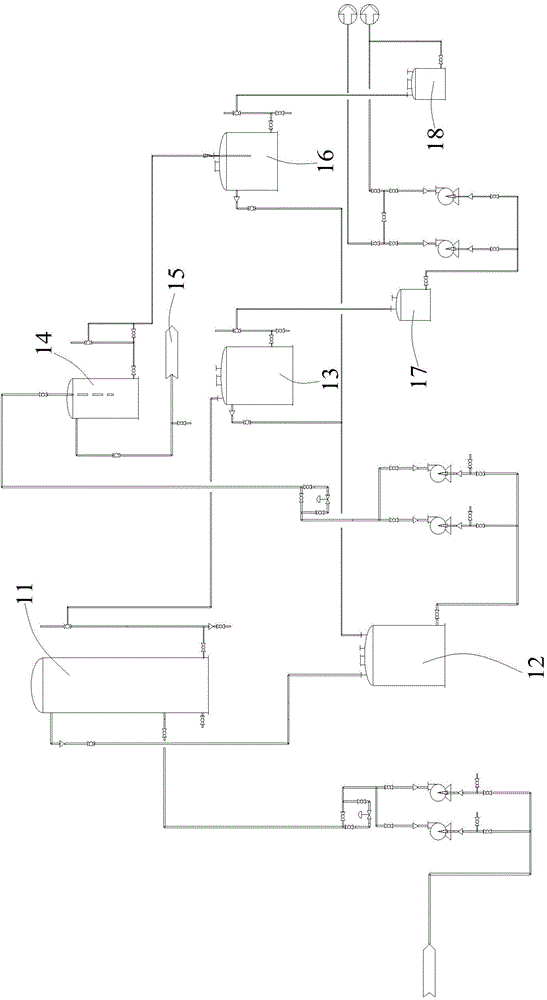

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

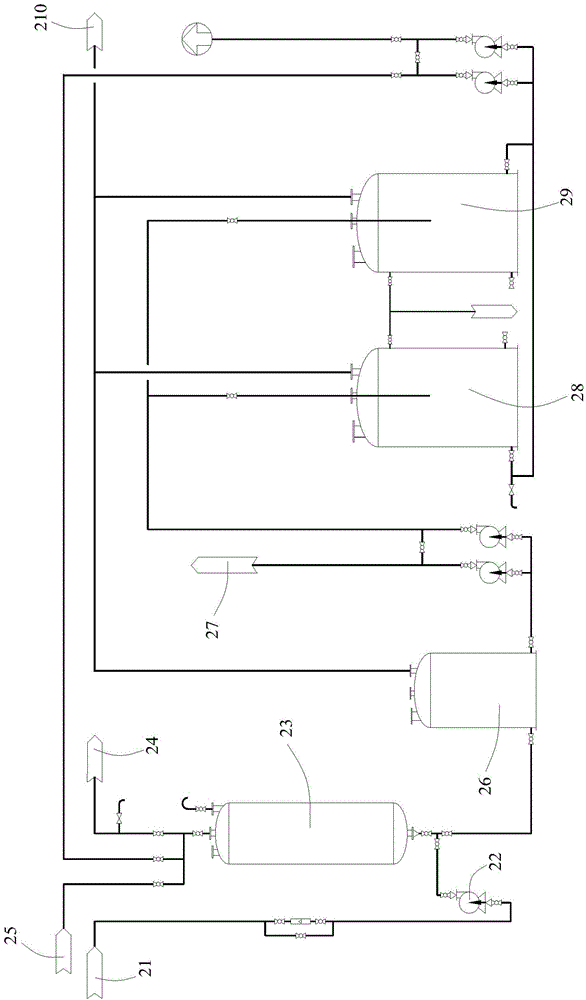

[0022] Such as figure 2 Shown:

[0023] (1) Collecting the chlorinated solution: collect the chlorinated solution produced in the production of chlorinated benzene into the intermediate tank 21 of the chlorinated solution, and the content of ferric chloride was detected to be 220 ppm;

[0024] (2) Enter the chlorinated solution: check the liquid level of the chlorinated solution intermediate tank 21, check whether the chlorinated solution intermediate pump 22 entering the resin adsorption tower 23 is normal, after confirming that it is normal, start the chlorinated solution intermediate pump 22, and chlorinate the chlorinated solution. The chlorinated liquid in the liquid intermediate tank 21 enters the resin adsorption tower 23 from the bottom of the resin adsorption tower 23. When the liquid level exceeds the height of the resin layer in the tower by 100-200 mm, stop the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com