Patents

Literature

55results about How to "Less alkali consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting xylan from woody fiber material

A process for extracting xylan from wooden fibre material features that under the catalysis of microwave, the alkali solution containing hydrogen peroxide in directly sued to treat raw material for performing extraction of xylane and bleaching it at same time. Its advantages are high speed, less consumption of alkali, and high extracting rate. The resultant xylan solution can be deposited in organic solvent or superfilted and dried to obtain light-color xylan product.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

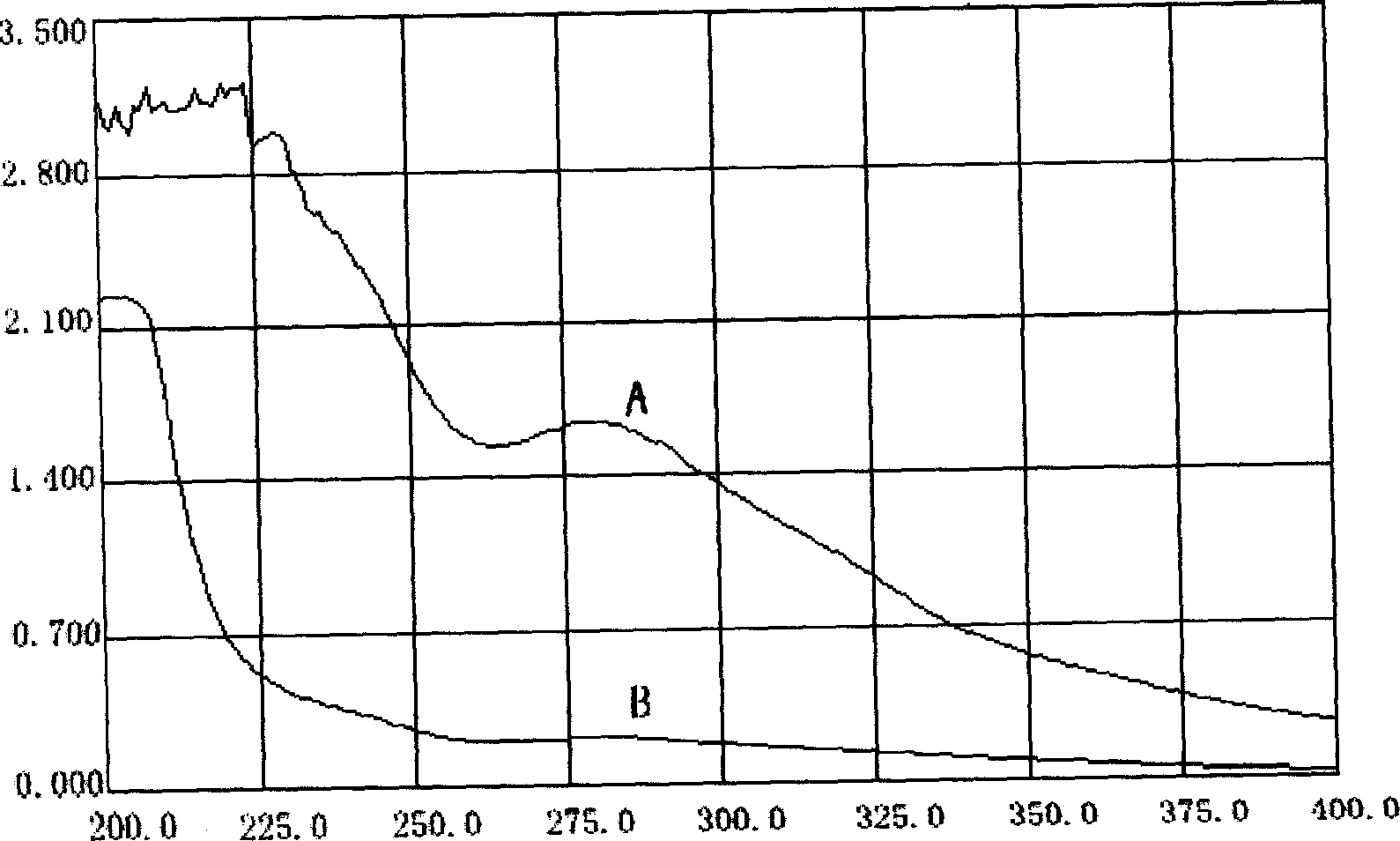

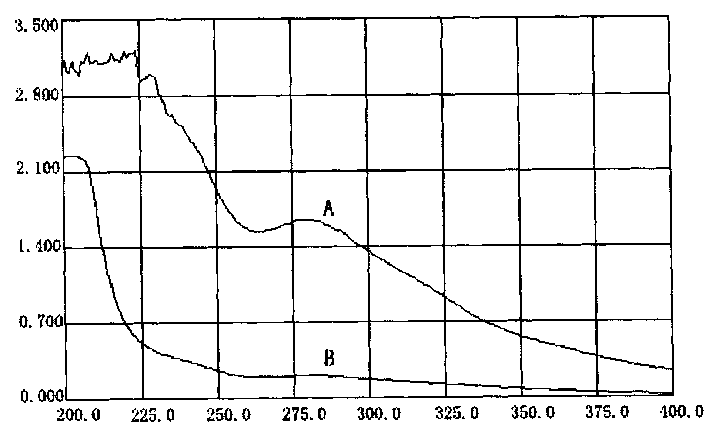

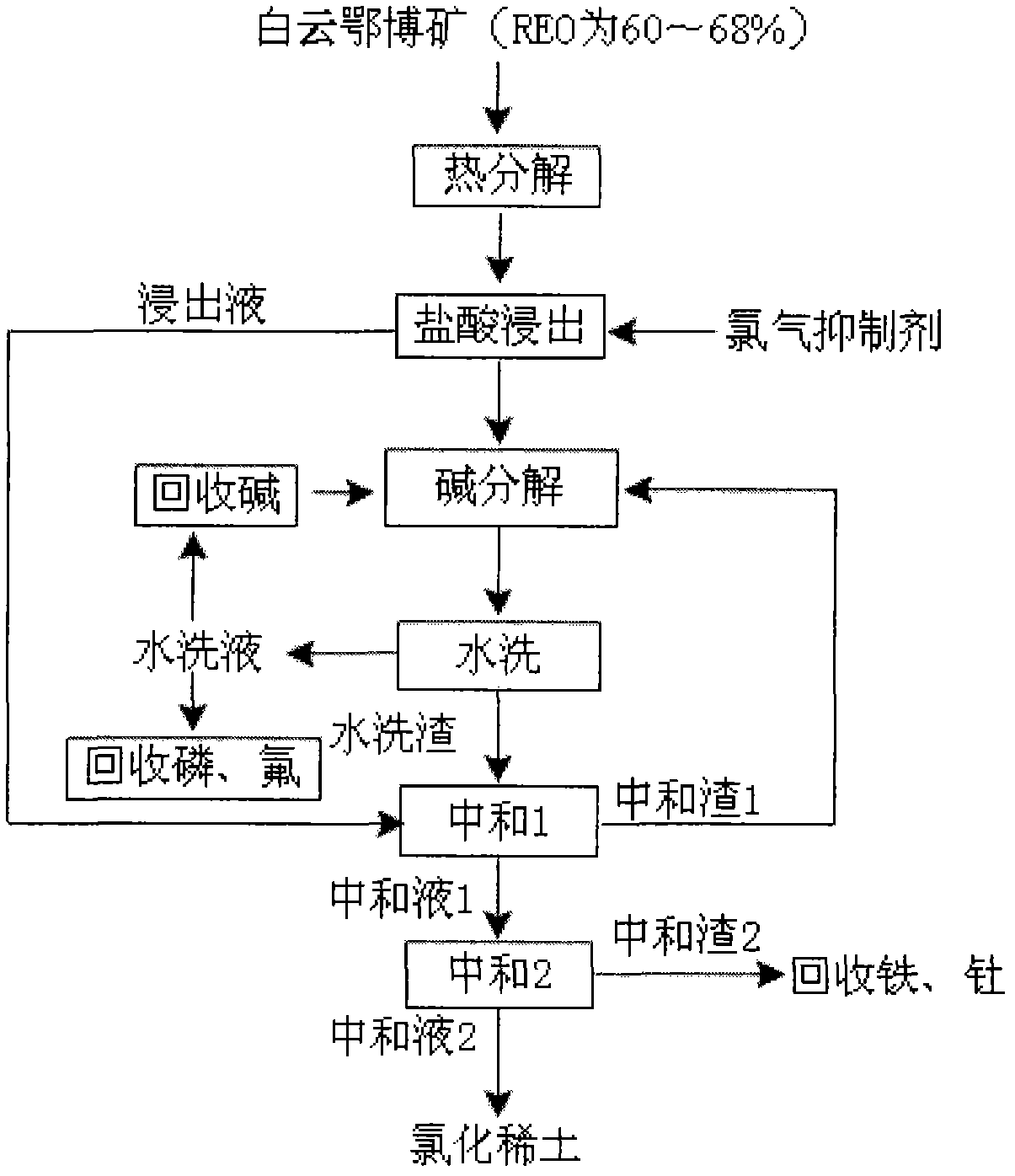

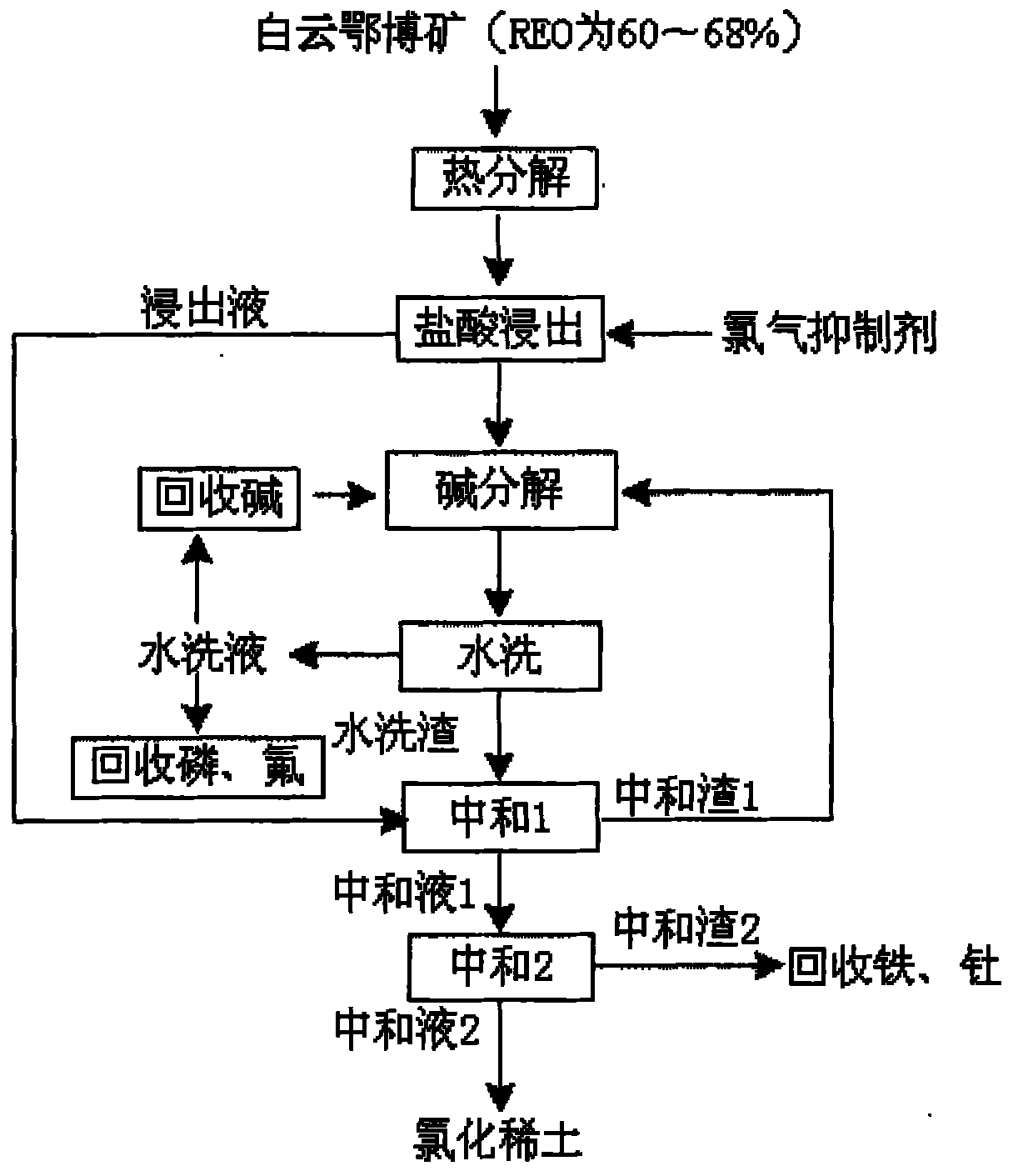

A New Method for Preparing Rare Earth Chloride from Baiyun Obo Rare Earth Concentrate

The invention relates to a new method for preparing rare earth chloride by using Baiyunebo rare earth concentrate and belongs to the field of wet-process metallurgy. The invention comprises the following steps: performing thermal decomposition, wherein a raw material used is Baiyunebo mixed rare earth concentrate with a grade of 60 to 80 percent; leaching in hydrochloric acid, namely leaching oreobtained after thermal decomposition in hydrochloric acid; performing alkaline decomposition, namely decomposing filter residue obtained after leaching in hydrochloric acid with solution of sodium hydroxide; washing, namely washing the ores obtained after alkaline decomposition with water till the pH value is 7 to 9, and recovering fluorine and phosphorus from washing solution; performing primaryneutralization, namely mixing hydrochloric acid leachate and water washing residue, and neutralizing till the pH value is 0.5 to 2.5; and performing secondary neutralization, namely neutralizing the filtrate obtained by the primary neutralization till the pH value is 4 to 5, wherein the filtrate of the secondary neutralization is solution of rare earth chloride. The method has the advantages of facilitating recovery of other elements, avoiding waste gas, waste water and waste residue, along with small alkali consumption, stable process and high rare earth recovery rate of more than or equal to 95 percent.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

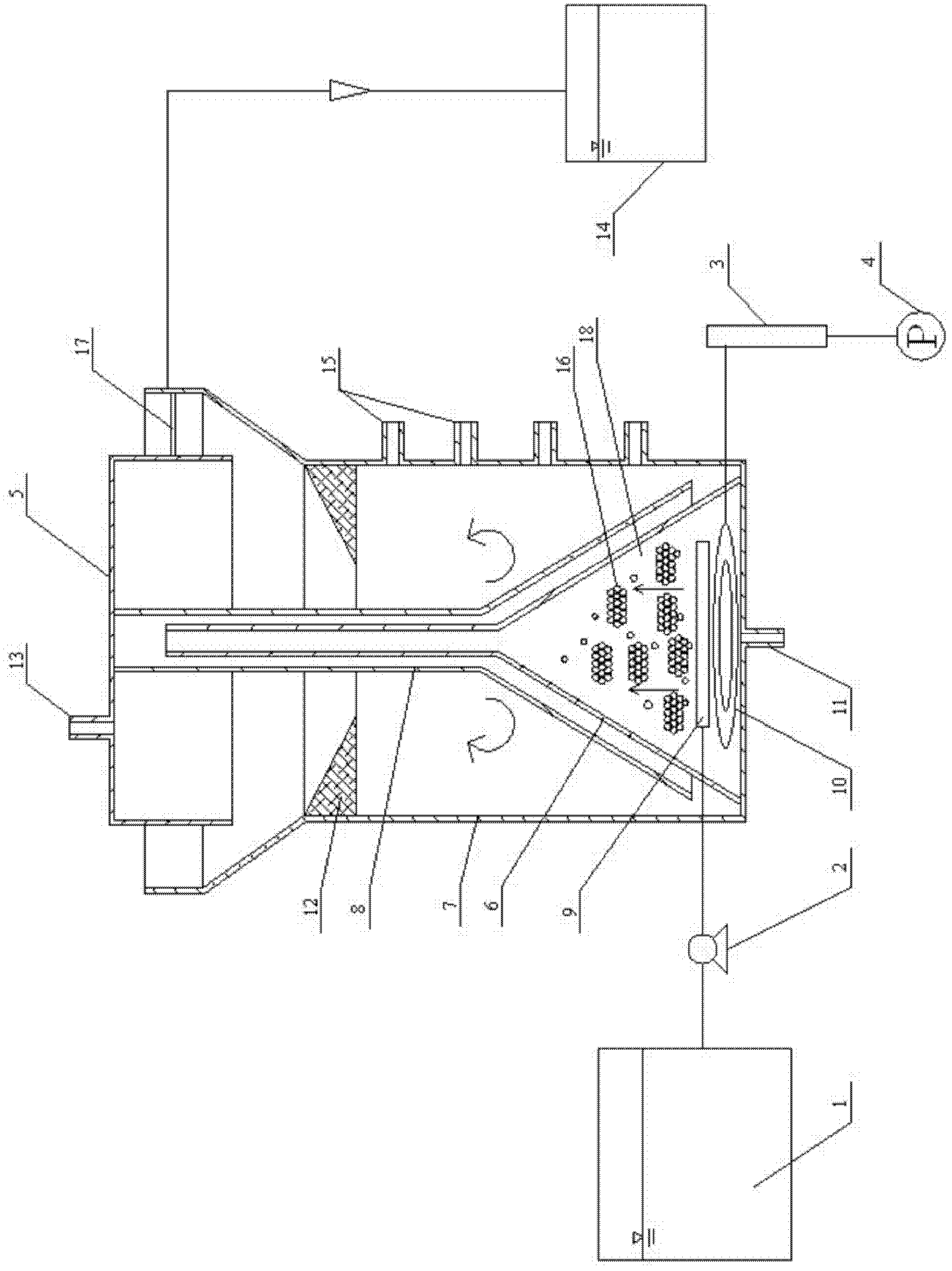

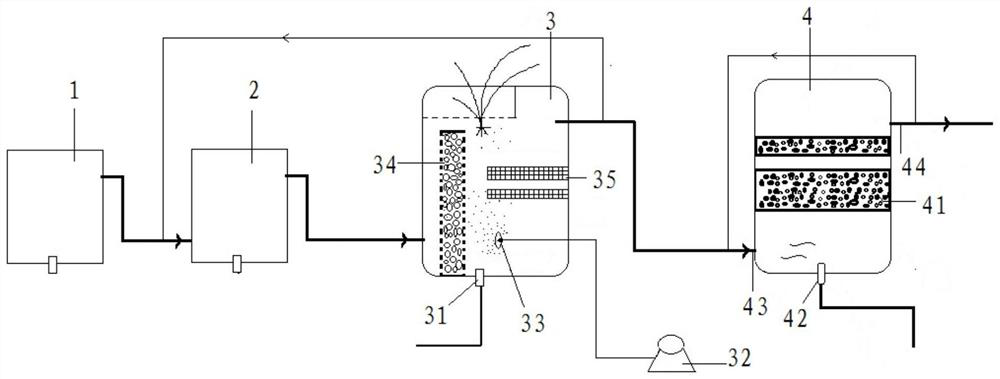

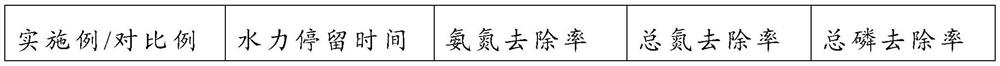

Room temperature nitrosation-anaerobic ammoxidation coupling symbiotic denitrification device for municipal sewage and sewage treatment method

InactiveCN102531172AReduce yieldReduce aerationTreatment with aerobic and anaerobic processesChemical oxygen demandNitration

The invention provides a room temperature nitrosation-anaerobic ammoxidation coupling symbiotic denitrification device for municipal sewage and a sewage treatment method and relates to a sewage treatment method, solving the technical problems that in the existing nitration-anaerobic ammoxidation process, occupied area is large and operation cost is high. The method comprises the following steps of: carrying out film formation with an intermittent film formation mode; introducing municipal sewage; completing the removal of COD (chemical oxygen demand) in the outer barrel and generating a small amount of NO2<-1>-N; and introducing mixed sludge subjected to nitrosation and anaerobic ammoxidation into the outer barrel so as to realize nitrosation-anaerobic ammoxidation coupling symbiotic denitrification. According to the invention, a continuous operation mode is adopted for the device; the device is small in occupied area, and the effective volume of a structure is reduced; and the device is simple and convenient in management, high in treatment efficiency, low in operation cost and the like, and specifically aims at domestic sewage having the characteristics of low substrate concentration and large water yield.

Owner:NORTHEAST FORESTRY UNIVERSITY

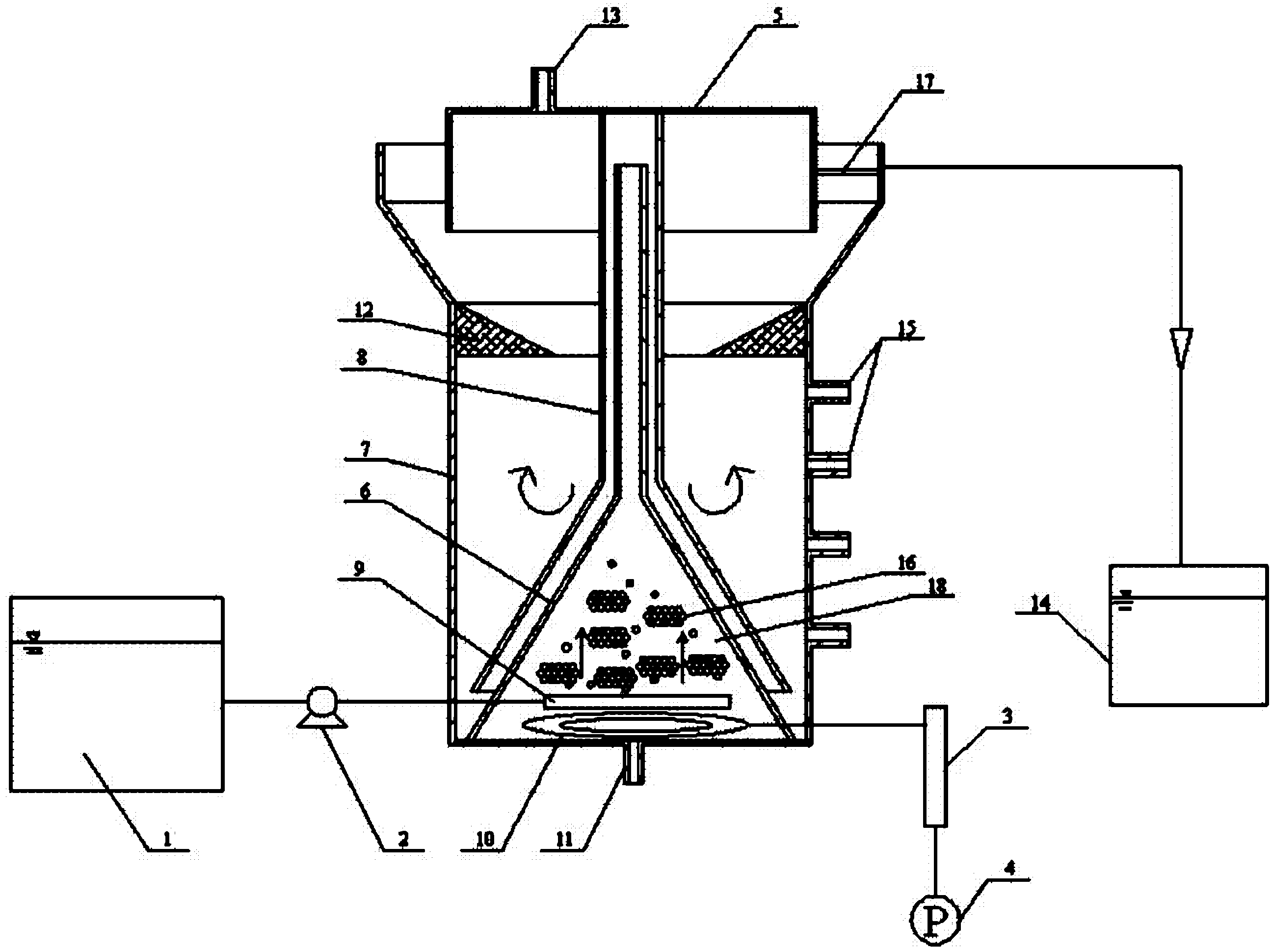

Method for preparing rare earth chloride from mixed rare earth concentrate or monazite concentrate

InactiveCN105543510AShort processAlkali decomposition temperature range is lowProcess efficiency improvementRare earthMonazite

The invention relates to a method for preparing rare earth chloride from mixed rare earth concentrate or monazite concentrate and belongs to the field of hydrometallurgy. According to the method, the rare earth chloride with the rare earth leaching rate reaching 94.87-99.26% is prepared by controlling the alkali decomposing temperature, the reaction time and the reaction pressure of the mixed rare earth concentrate or the monazite concentrate in the high-pressure alkali decomposing process. The method has the beneficial effects that the mineral decomposing rate is high under the high-pressure condition, the decomposing temperature is reduced, the reaction time is shortened, and energy conservation and environment friendliness are achieved; caustic soda can be recycled, so that cost is reduced; no three-waste pollution is generated, and various valuable elements are comprehensively recycled; and the technological process is short, and the method is suitable for industrial production.

Owner:李梅

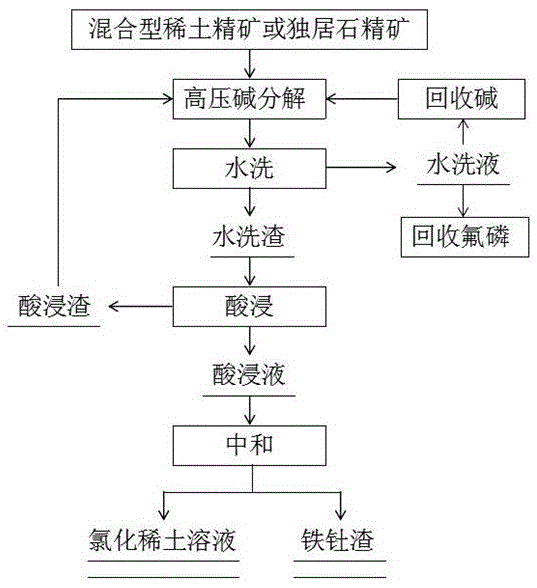

Efficient separating purifying technique for lignin, hemi-cellulose and cellulose

ActiveCN106192514AAvoid damageAvoid destructionPulp de-wateringPulping with inorganic basesPurification methodsFiltration membrane

The invention relates to an efficient separating purifying technique for lignin, hemi-cellulose and cellulose and belongs to the technical field of biomass separation and purification. The efficient separating purifying technique is adopted for solving the problem that the biomass separation and purification method in the prior art cannot fully extract lignin, hemi-cellulose and cellulose. The separating purifying technique provided by the invention comprises the following steps: adopting NaOH solution for performing alkali extraction in advance on the biomass containing lignin, hemi-cellulose and cellulose and performing spiral shoving, thereby obtaining an alkali extraction solution and the biomass after alkali extraction; separating and concentrating the alkali extraction solution through a nano-filtration membrane, and then performing acid hydrolysis and centrifugal separation, thereby obtaining lignin, xylose and a nano-filtration penetrating solution containing NaOH; performing hot alkali extraction and spiral shoving on the biomass after the alkali extraction in advance, thereby obtaining cellulose and alkali extracting solution; separating and concentrating the alkali extracting solution through the nano-filtration membrane, thereby obtaining the nano-filtration concentrated solution containing lignin and the nano-filtration penetrating solution containing NaOH. According to the technique, lignin, hemi-cellulose and cellulose in the raw materials are fully separated; the technique is environment-friendly; the alkali recovery rate is high; the energy consumption of production is low.

Owner:长春达新水处理技术有限公司

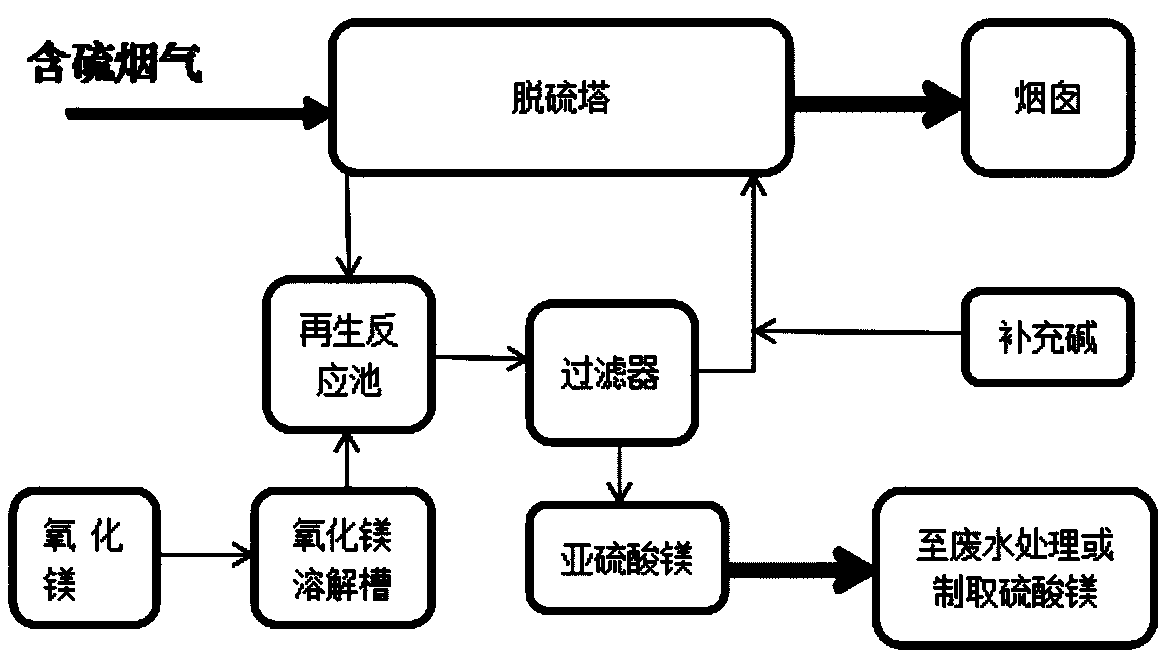

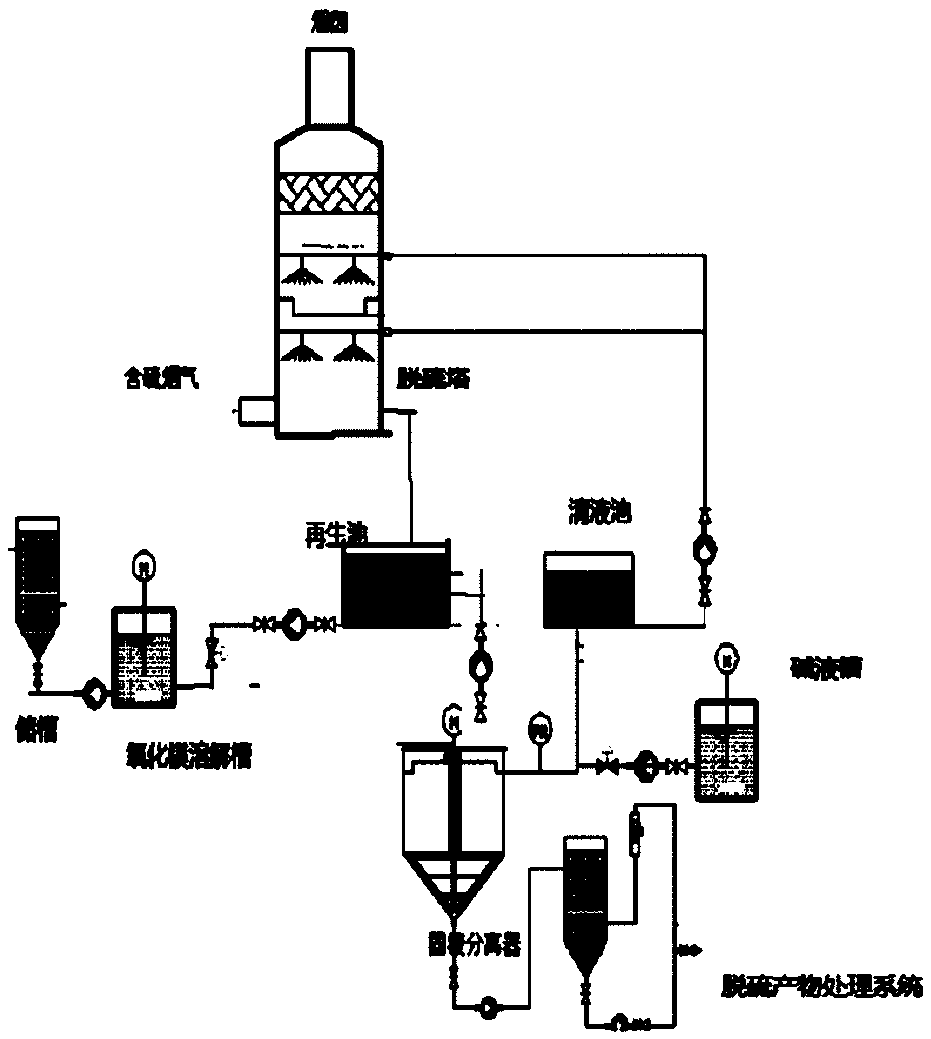

Novel dual-alkali flue gas desulfurization method and flue gas desulfurization system

InactiveCN105498503AImprove absorption efficiencyImprove desulfurization effectGas treatmentDispersed particle separationSulfite saltMagnesium sulfite

The invention provides a novel dual-alkali flue gas desulfurization method and flue gas desulfurization system, and relates to the technical field of flue gas purification. The method comprises the following steps of absorbing SO2 in flue gas to generate an absorption solution containing sodium sulfite and sodium bisulfite by taking sodium hydroxide or sodium carbonate as an absorbent, enabling the absorption solution to enter a regenerated reactor, regenerating the absorption solution in the regenerated reactor by using magnesium oxide or magnesium hydroxide, performing precipitation separation by virtue of a solid-liquid separator, enabling sodium sulfite or sodium hydroxide formed by regeneration to return to a desulfurization tower for flue gas absorption for recycling, enabling magnesium sulfite precipitates obtained by solid-liquid separation to enter a desulfurization product treatment system, and directly discharging magnesium sulfite or preparing magnesium sulfate. According to the method and the system, a sodium and magnesium dual-alkali method is adopted for flue gas desulfurization, so that a good desulfurization effect is achieved, oxidation is not required by the system, accumulation of sodium sulfate is avoided, and the system can run for a long time; moreover, the materials in the system can be regenerated and recycled, therefore alkali consumption is reduced, and the cost is reduced.

Owner:刘安明

Method for preparing idesia polycarpa edible vegetable oil by immobilized enzyme and hot brine treatment process

InactiveCN102041167AHigh yieldLess alkali consumptionFatty-oils/fats refiningEdible oils/fatsEdible oilImmobilized enzyme

The invention discloses a method for preparing idesia polycarpa edible vegetable oil by an immobilized enzyme and hot brine treatment process, belonging to the field of food. The method comprises the following steps: raw oil degumming, acidity reduction by immobilized enzyme, alkali refining, water washing, debitterizing by hot brine, and vacuum deodorization. The invention is characterized in that the immobilized enzyme is utilized to treat degummed oil, thereby lowering the acidity and reducing the alkali consumption and the amount of the formed saponin; the hot brine is utilized to treat the alkali-refined oil and thoroughly remove the bitter principles from the oil to finally obtain the high-quality edible vegetable oil, thereby saving the removal time and the water consumption; and meanwhile, the invention has the advantages of simple technological process, mild operating conditions, low requirements for equipment, high safety and environmental protection, and has wide application prospects in the production of idesia polycarpa edible oil.

Owner:四川省毛叶山桐子科技股份有限公司 +1

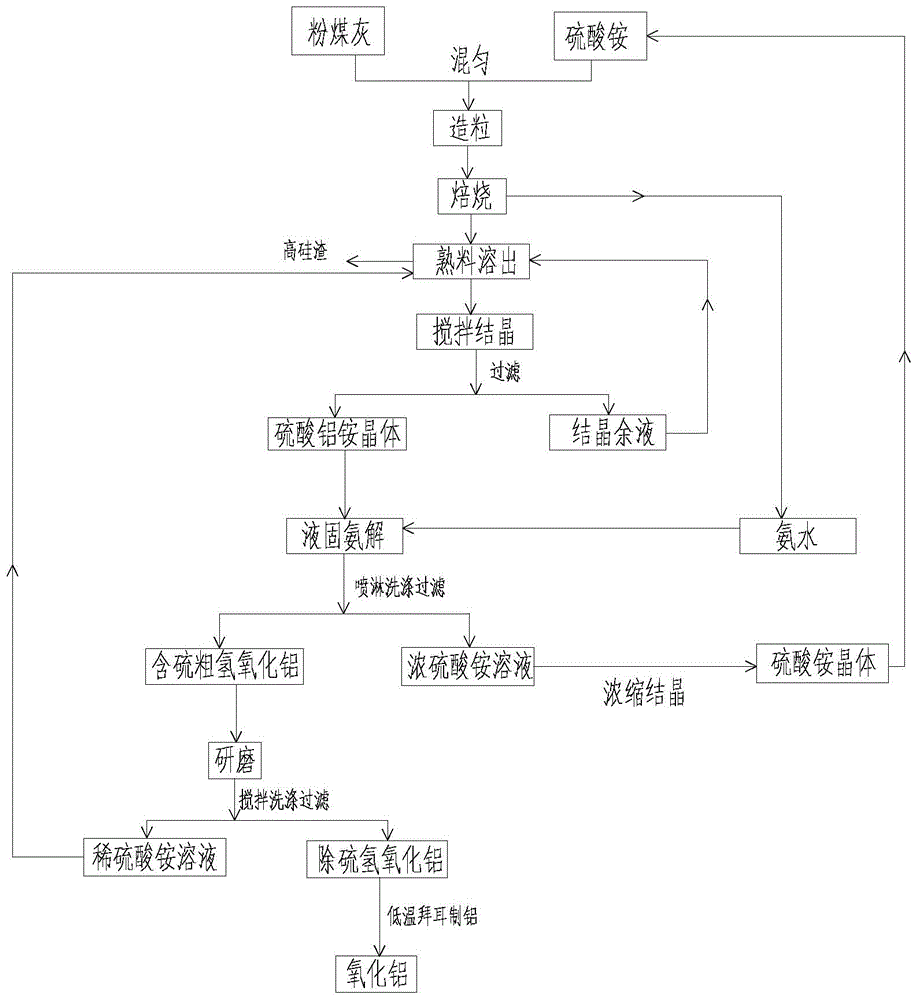

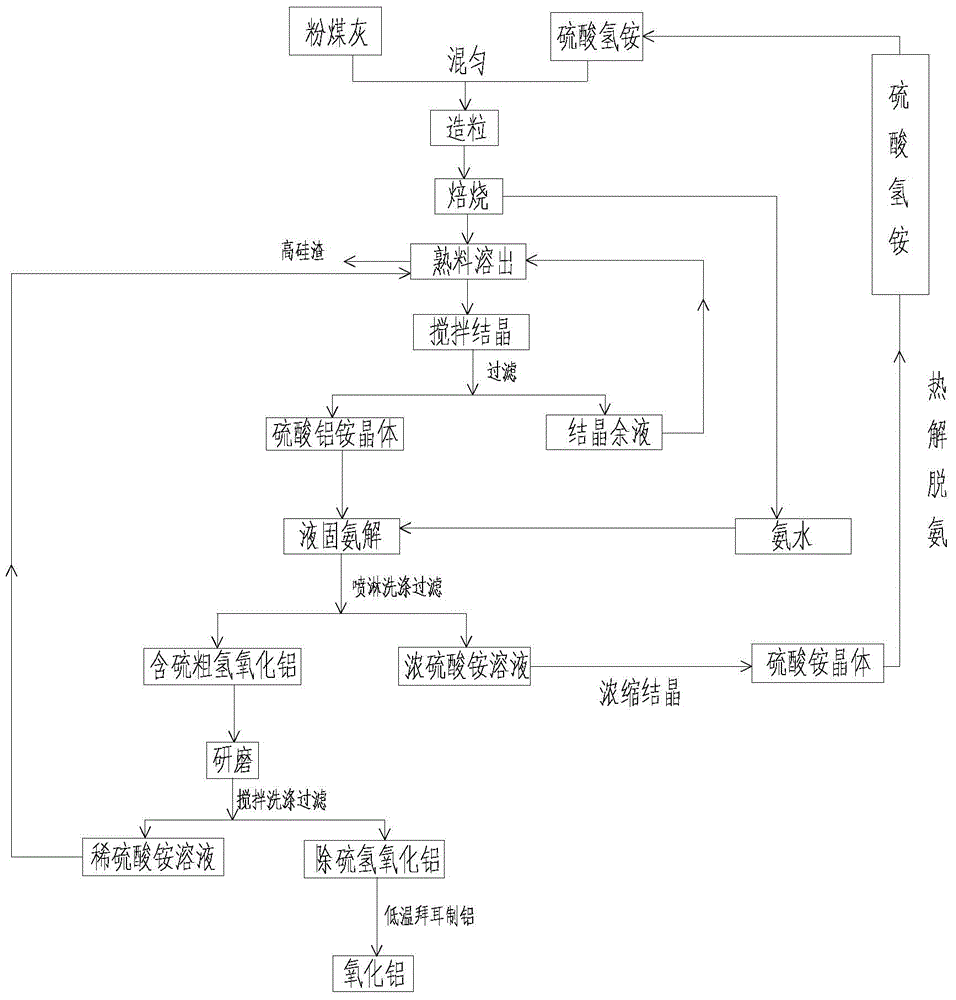

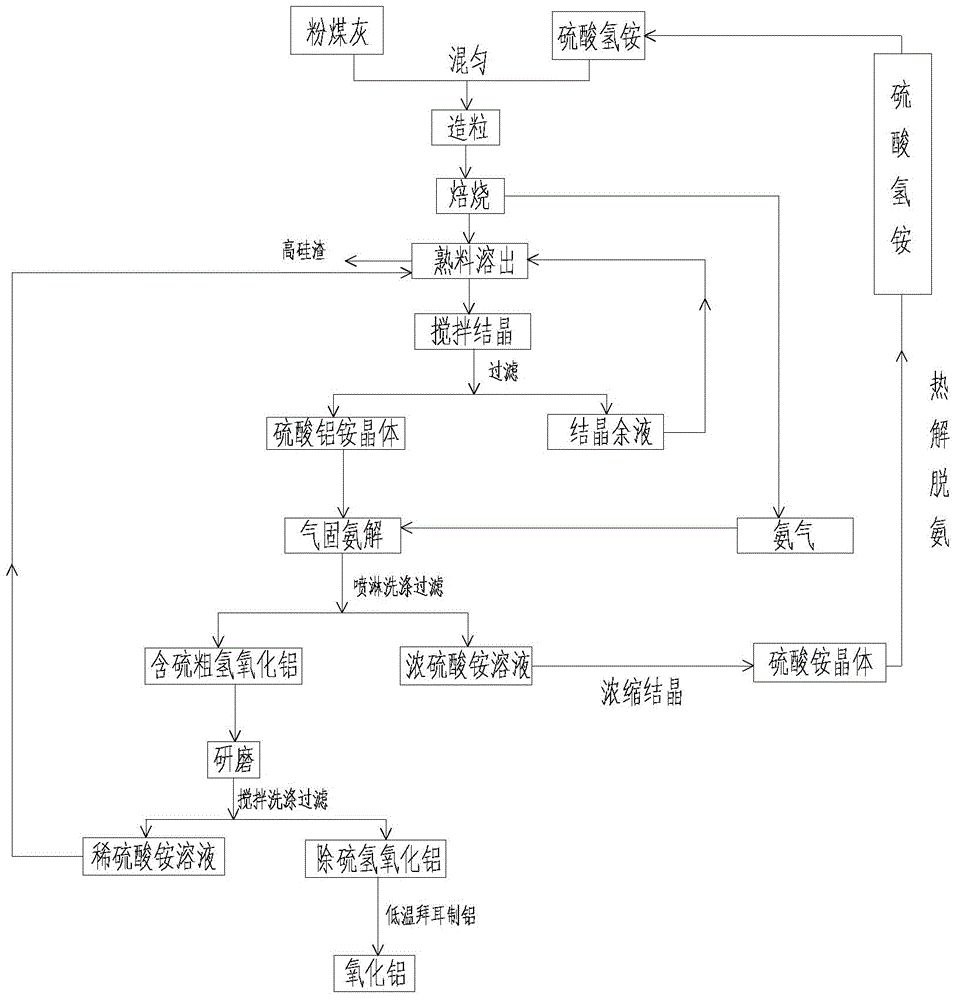

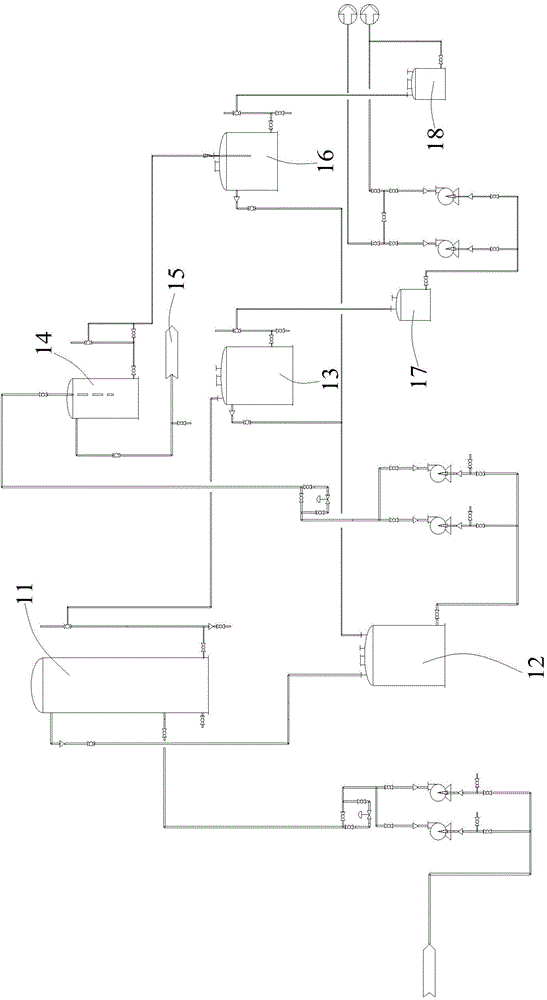

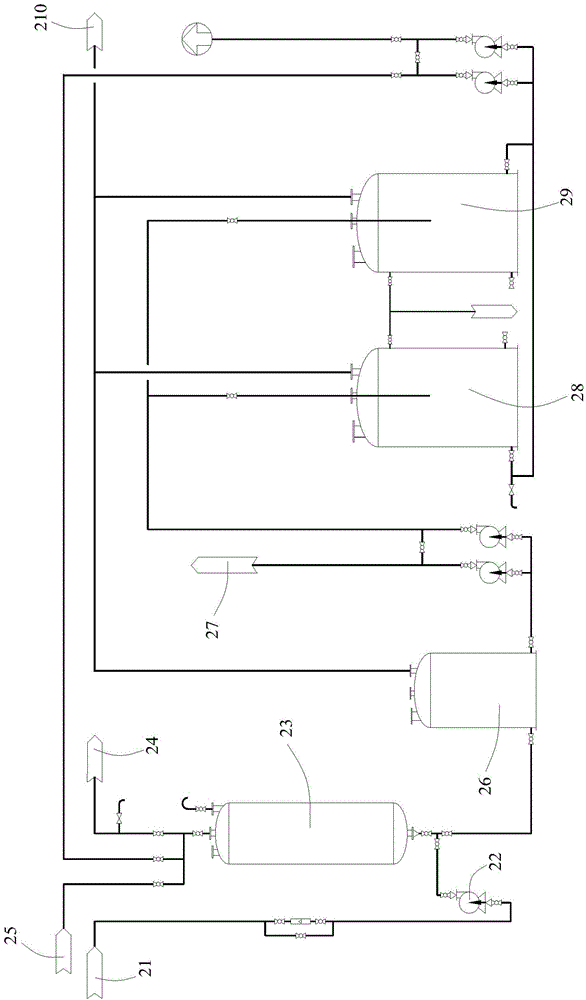

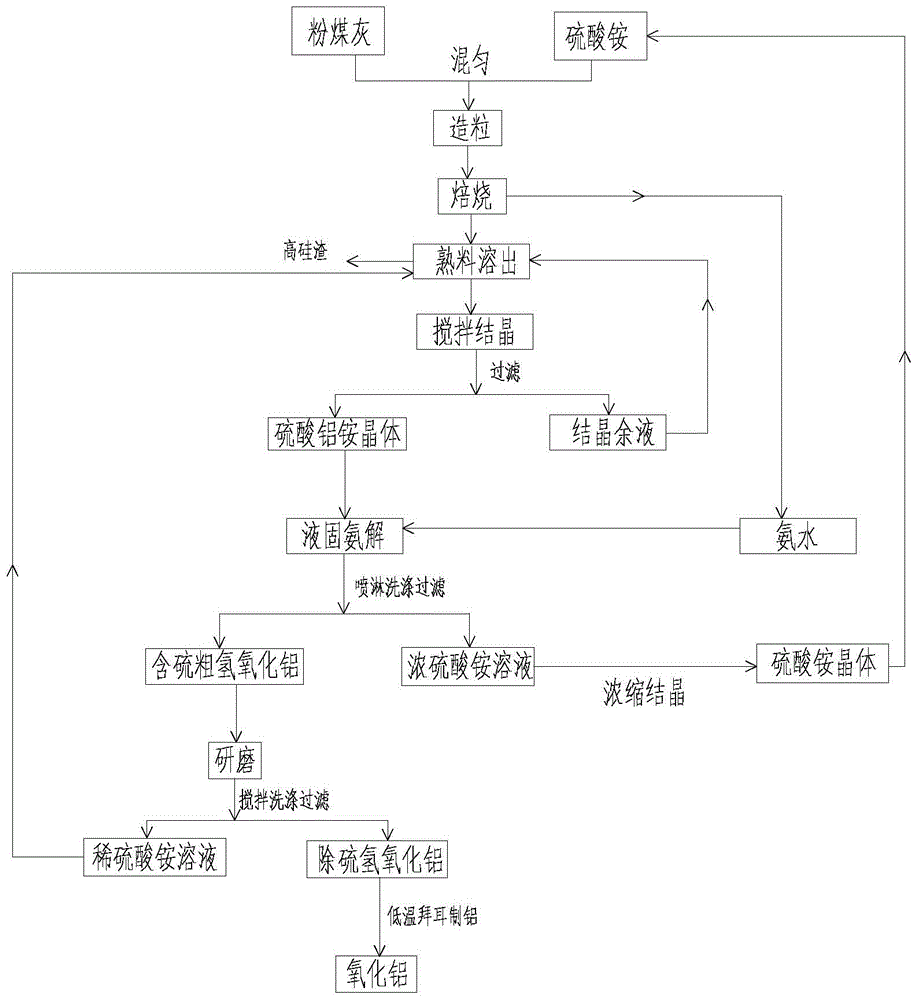

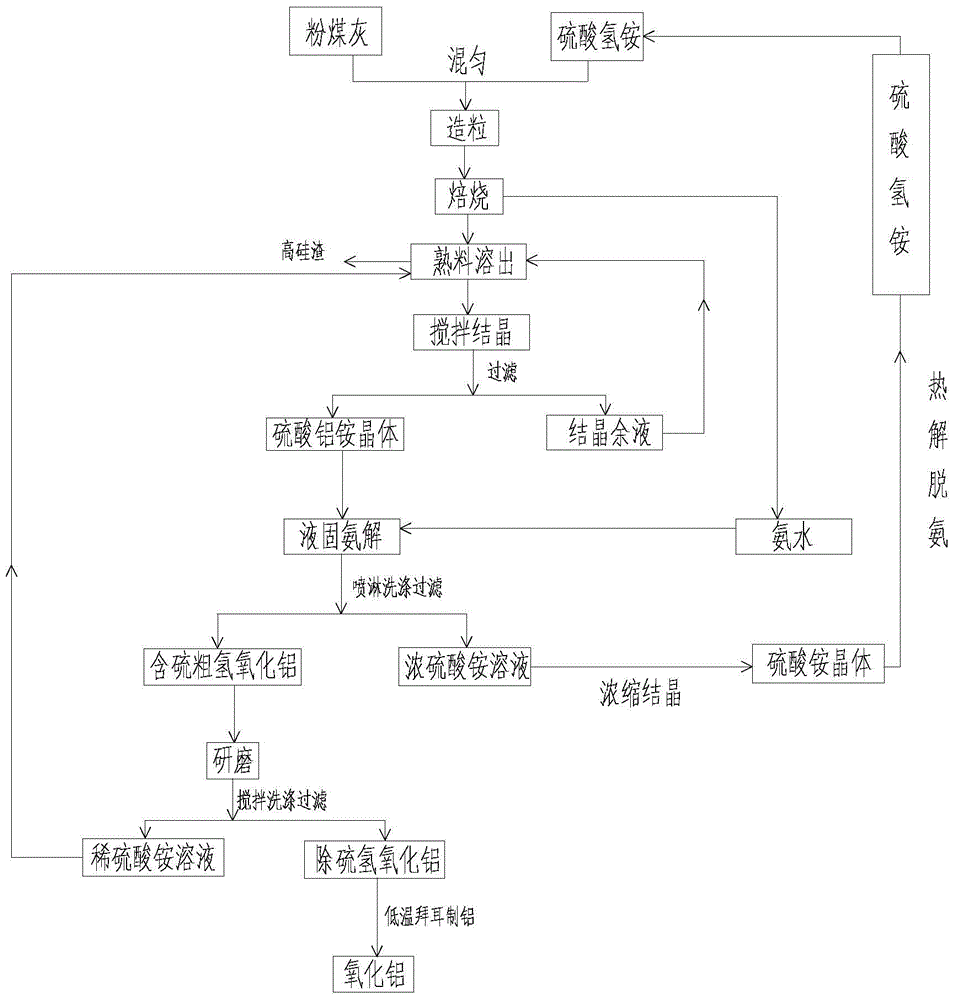

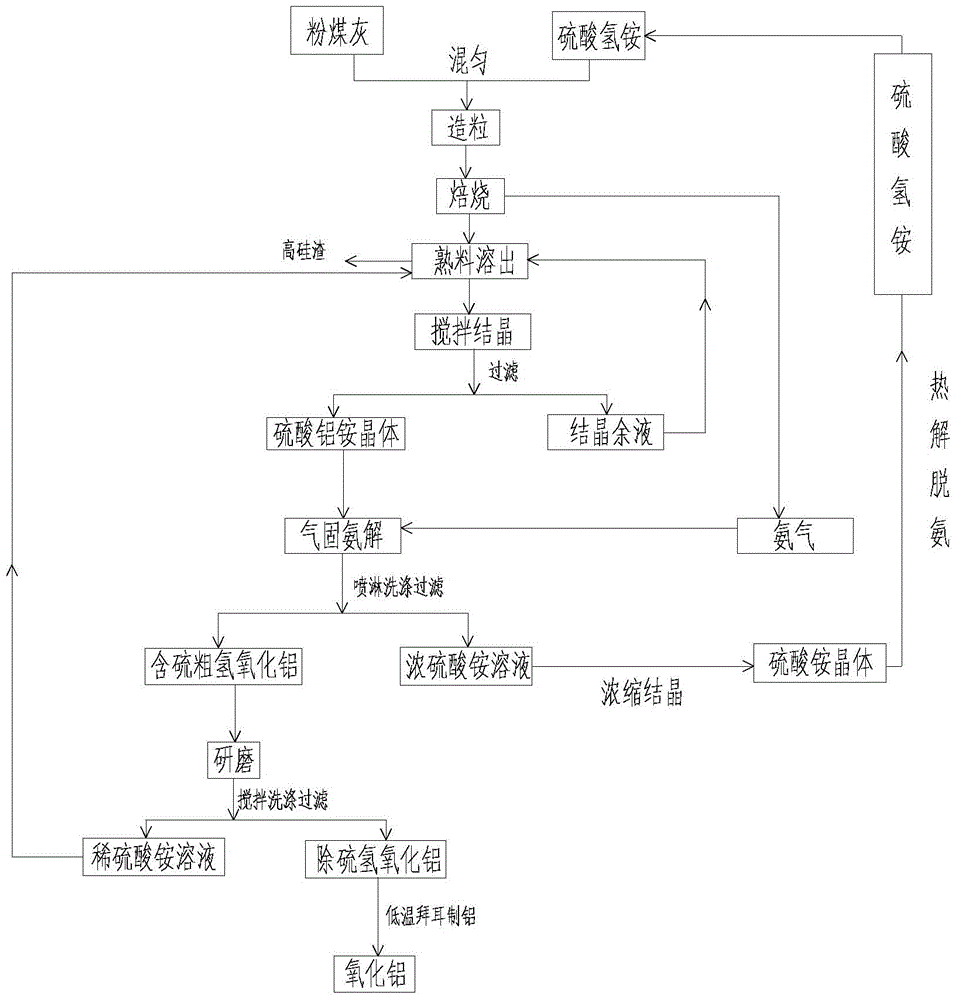

Method for producing metallurgy-grade alumina by taking pulverized fuel ash and recycled ammonium salt as raw materials

InactiveCN104628020AReduce solubilityReduce evaporationSolid waste disposalAluminium oxides/hydroxidesStrong acidsAluminium

The invention discloses a method for producing metallurgy-grade alumina by taking pulverized fuel ash and recycled ammonium salt as raw materials. The method comprises the following steps: (1) preparing materials; (2) roasting; (3) dissolving; (4) crystallizing; (5) carrying out a liquid-solid ammonolysis reaction; (6) grinding and removing sulfur; and (7) performing low-temperature Bayer aluminum production. The method disclosed by the invention has the advantages that an aluminum salt ammonolysis method suitable for strong acid and weak base is adopted, namely liquid-solid or gas-solid ammonolysis is performed, the production efficiency is improved by over 60 percent compared with that a liquid-liquid ammonolysis method, the process conditions of the ammonolysis method are optimized, optimal process parameters are determined, the obtained product, namely crude aluminum hydroxide, is easy to filter and wash, the model selection of equipment is simple, and industrial mass production can be realized.

Owner:NORTH UNITED POWER +1

Technology for removing ferric trichloride from chlorination liquid generated in chlorobenzene production

ActiveCN103819306AReduce productionNo precipitationHalogenated hydrocarbon preparationBenzenePhysical chemistry

The invention discloses a technology for removing ferric trichloride from chlorination liquid in chlorobenzene production. The technology comprises the following steps specifically: collecting chlorination liquid generated in chlorobenzene production to a chlorination liquid intermediate tank; introducing the chlorination liquid in the chlorination liquid intermediate tank into a resin adsorption tower from the bottom of the resin adsorption tower, keeping full and soaking for 10-18 hours, discharging the chlorination liquid from the top of the tower, detecting the content of ferric trichloride in the adsorbed chlorination liquid, and when the content of ferric trichloride is larger than 10 ppm, stopping adsorption; using diluted hydrochloric acid to resolve ferric trichloride complexes adsorbed by the resin, and using water to wash the resin adsorption tower till the content of ferric trichloride in the scrubbing solution is smaller than 10 ppm. In the technology, the resin adsorption tower and a continuous automatic processing method are utilized to process ferric trichloride from chlorination liquid in monochlorobenzene production; the chlorination liquid is adsorbed by the resin adsorption tower to remove ferric trichloride from the chlorination liquid for one time, and the content of ferric trichloride in the chlorination liquid during the monochlorobenzene production after the chlorination reaction is reduced from 150-1000 ppm to 0-10 ppm.

Owner:ANHUI BAYI CHEM IND

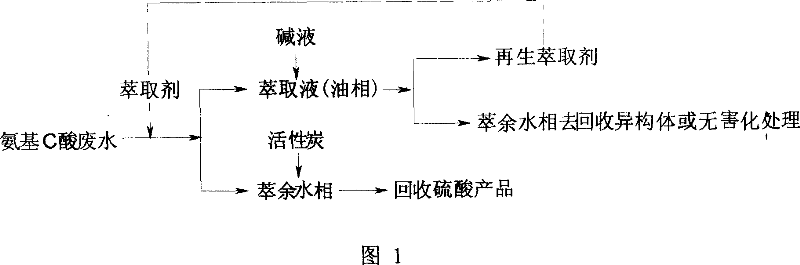

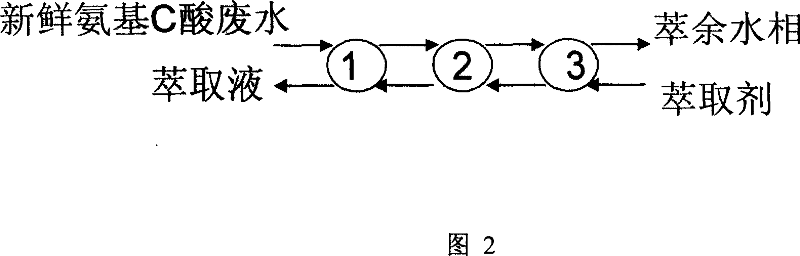

Recovering handling method for amino C acid wastewater

InactiveCN101041476ASimple processConditions are easy to controlWater contaminantsSulfur-trioxide/sulfuric-acidChemistrySulfuric acid

The invention discloses a recovery processing method of amino C acid acid-wastewater, which comprises the following steps: adding finite proportion extractant into waste water; shocking sharply; mixing fully; stewing; layering; sharing oil phase and water phase; extracting most of organic matter into oil phase; removing oil phase; adding into finite quantity queous alkali; proceeding strip; getting regenerate extractant; cycling using in craft; separating out organic matter from waste water; forming strip water phase; getting the reclaiming sulphuric acid; making total clearance of acid waste water CODCr reach above 93% and reclaiming sulfuric acid density at 560g.L-1; setting reclaiming rate of sulfuric>92%.

Owner:NANJING NORMAL UNIVERSITY

Process for preparing solid potassium ferrate

InactiveCN1749166ALow costEasy to operateIron compoundsSodium/potassium compoundsHypochloriteNitrate

The preparation process of solid potassium ferrate includes the following steps: introducing chlorine into purified waste alkali solution to prepare hypochlorite solution; adding ferric nitrate into the solution to prepare potassium ferrate solution; adding solid potassium hydroxide, dissolving and filtering to obtain coarse potassium ferrate product; washing coarse potassium ferrate product with potassium hydroxide solution; filtering to obtain re-crystallized potassium ferrate product; washing with organic solvent and vacuum drying to obtain stable solid potassium ferrate product; collecting all the filtrate and treating for reuse. The present invention has the circulated utilization of waste alkali solution, low cost and less environmental pollution.

Owner:SHENZHEN POLYTECHNIC

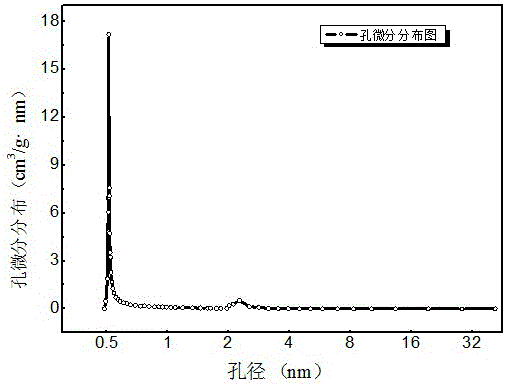

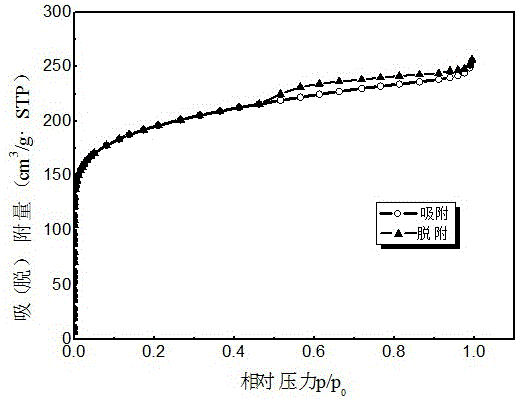

Uniform ultra-microporous activated carbon for gas separation and preparation method of uniform ultra-microporous activated carbon

InactiveCN106517189AReduce dosageReduce corrosionHydrogen separation by selective and reversible uptakeCarbon compoundsActivation methodMass ratio

The invention relates to uniform ultra-microporous activated carbon for gas separation and a preparation method of the uniform ultra-microporous activated carbon. According to the technical scheme of the preparation method, mixing semi-coke with KOH in a mass ratio being 1: (0.01-0.2), adding water and an activating aid to impregnate the mixture for 1-36 h; increasing the temperature to 800-950 DEG C in a programmed manner under N2 protection, controlling thermal decomposition, and introducing water for activation of part of steam for 0.5h-1.5h; finally, washing the mixture with acid and water until the mixture is neutral to obtain the uniform ultra-microporous activated carbon. The pore size is distributed centrally between 0.45 and 0.55 nm, the pores belong to ultra-micropores and have microporosity of 70% or more, and the adsorption capacity of hydrogen is 77cm<3> / g or higher. The semi-coke is taken as a raw material, low in price and low in energy consumption and needs not to be carbonized; an activation method integrates KOH impregnation pretreatment and activation of part of steam, little KOH is consumed, and the activation method has the characteristics of being low in cost and pollution, helpful for reducing corrosion of equipment and the like. The activated carbon prepared with the method has the characteristics of uniform pore size distribution, extremely rich ultra-microporous structure and the like, and can be used in gas separation fields such as pressure swing adsorption hydrogen making or hydrogen storage and the like.

Owner:WUHAN UNIV OF SCI & TECH

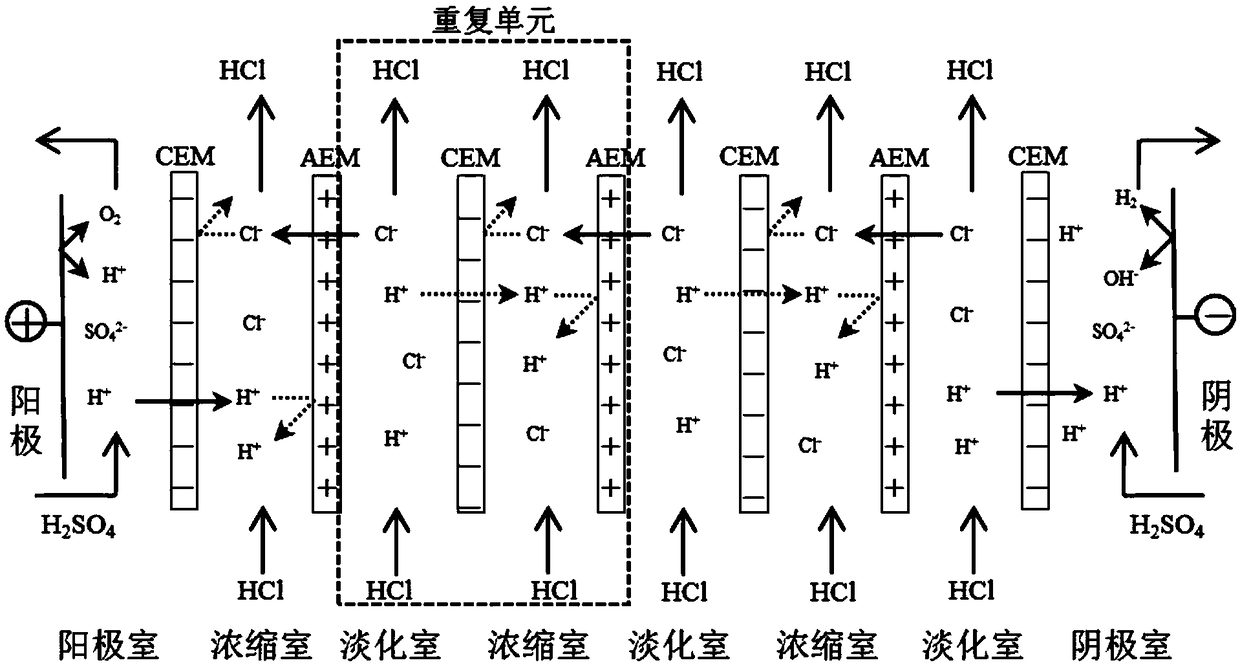

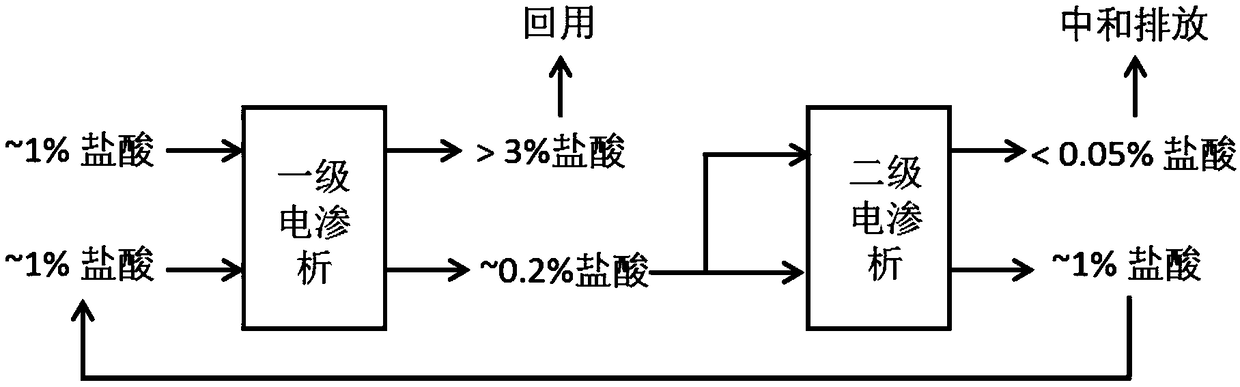

Method for concentrating wastewater containing hydrochloric acid by two-stage electrodialysis

InactiveCN108793516ALess alkali consumptionReduce salt concentrationWater contaminantsMultistage water/sewage treatmentElectrodialysisLiquid waste

The invention discloses a method for concentrating wastewater containing hydrochloric acid by two-stage electrodialysis. The method includes that first a waste liquid containing about 1% hydrochloricacid is concentrated by first-stage electrodialysis, the concentration of the hydrochloric acid in the concentrated liquid can reach 3% or more, and the hydrochloric acid can be directly reused; the concentration of the hydrochloric acid in a desalinated solution can be reduced to less than 0.2%; then the desalinated solution of the first-stage electrodialysis can be further desalinated and concentrated by second-stage electrodialysis to reduce the concentration of the hydrochloric acid to less than 0.05%, meanwhile the concentration of the hydrochloric acid in the concentrated solution can reach more than 1%, and the concentrated liquid is returned to the first-stage electrodialysis as a concentration chamber initial solution for recycling. The method is simple in operation, economical and environmentally friendly. The low concentration hydrochloric acid in the waste liquid can be directly concentrated and reused, and the concentration of the hydrochloric acid in the desalinated solution is very low, and the desalinated solution can be discharged by simply adding a small amount of alkali for neutralization, so that treatment of the wastewater containing the low-concentration hydrochloric acid can be achieved.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

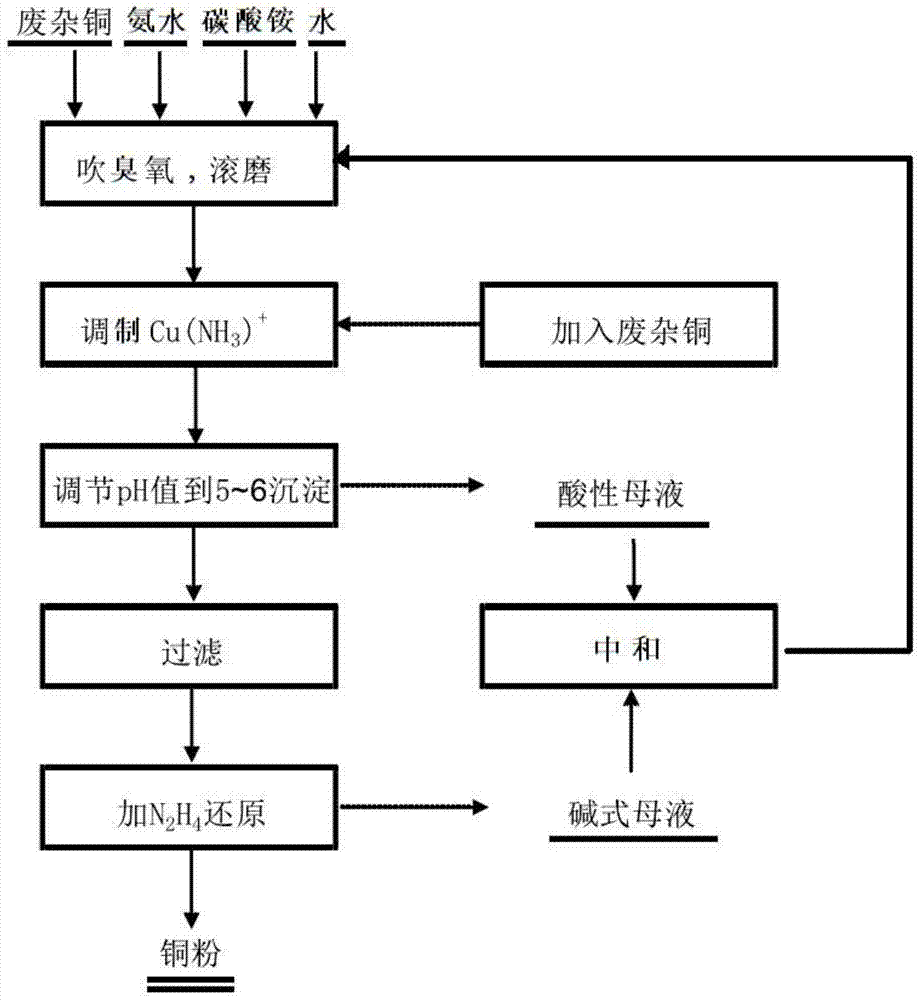

Process for circulation strengthening extraction of high purity copper powder by using copper scrap

InactiveCN104775033AImprove efficiencyIncrease dissolved oxygenProcess efficiency improvementPhysical chemistryDouble salt

The present invention relates to a process for circulation strengthening extraction of high purity copper powder by using copper scrap. According to the present invention, with the process, metal copper is dissolved with an ammonia copper leaching liquid to form the cuprous ions and the ammonia, the cuprous ions and the ammonia can be rapidly oxidized into a divalent copper ammonia solution so as to promote the dissolving reaction process of the metal copper, the finally-obtained leaching solution stays in the cuprous ammonia state, the pH value of the solution is appropriately adjusted to make the copper and the ammonia form various double salt solids so as to be precipitated and filter and separate the ammonia copper mother liquor, the double salt solids form the complex and react with hydrazine hydrate so as to completely convert into the high purity copper powder, and the ammonia copper mother liquor is slightly added with partial alkali so as to be recovered and then returns to the leaching process so as to continuously perform the new round of the copper leaching operation. With the new process method of the present invention, the ammonia leaching efficiency on the copper scrap can be substantially promoted, the copper powder preparation yield can be significantly increased, the alkali consumption required by blending of the precipitation mother liquor into the alkaline state is significantly reduced, and the zero emission and the closed internal circulation are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Reduction smelting slag and application of reduction smelting slag to reduction smelting of coarse antimony oxide

The invention relates to reduction smelting slag and application of the reduction smelting slag to reduction smelting of coarse antimony oxide, and belongs to the field of nonferrous metallurgy. The designed reduction smelting slag comprises, by mass, 20-40 parts of SiO2, 20-40 parts of FeO, 5-20 parts of CaO and 5-25 parts of Na2O. During reduction smelting of the coarse antimony oxide, the set reduction smelting slag is supplemented, the temperature ranging from 900 DEG C to 1,200 DEG C is kept for 30-120 min, coarse antimony, glass slag, smoke and flue gas can be generated, the coarse antimony and the slag are independently discharged after settling separation, the smoke is subjected to powder returning treatment, and the flue gas is exhausted after being purified. The design technology has the beneficial effects that the smelting temperature is low, the antimony content of the slag is small, the antimony direct recovery rate is high, and the powder returning amount is small; and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

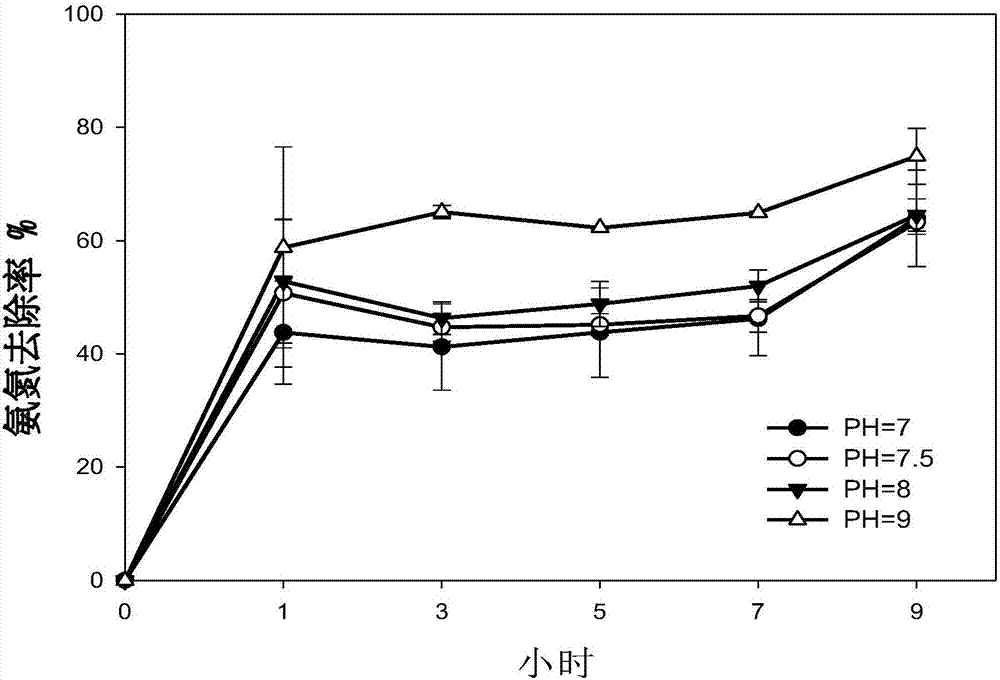

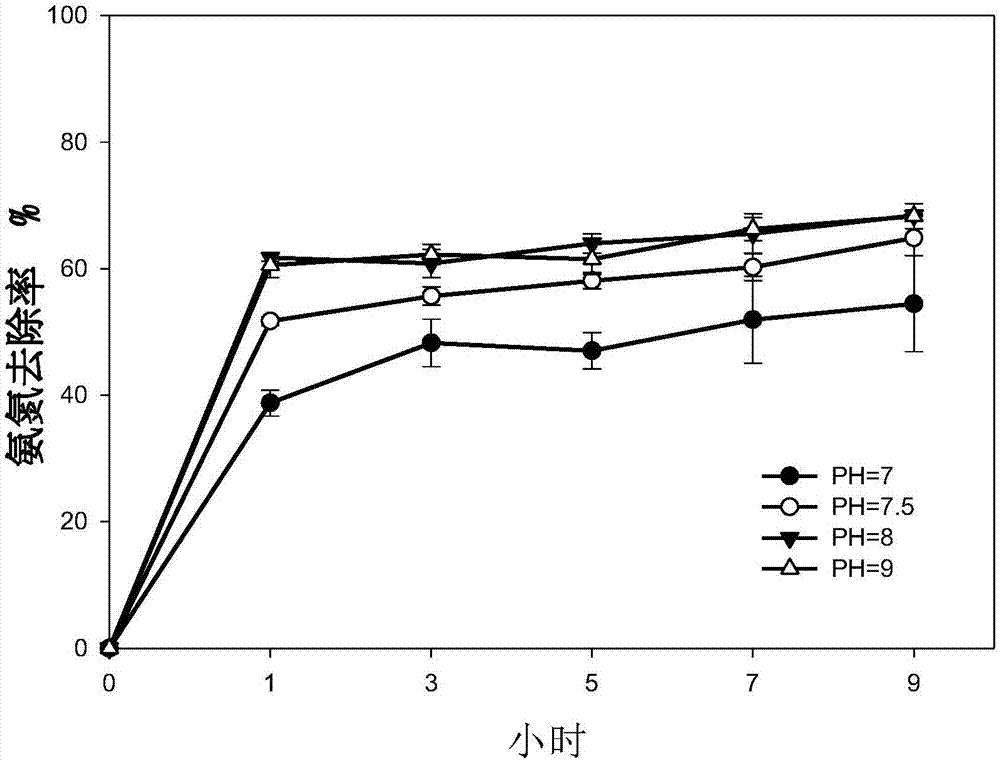

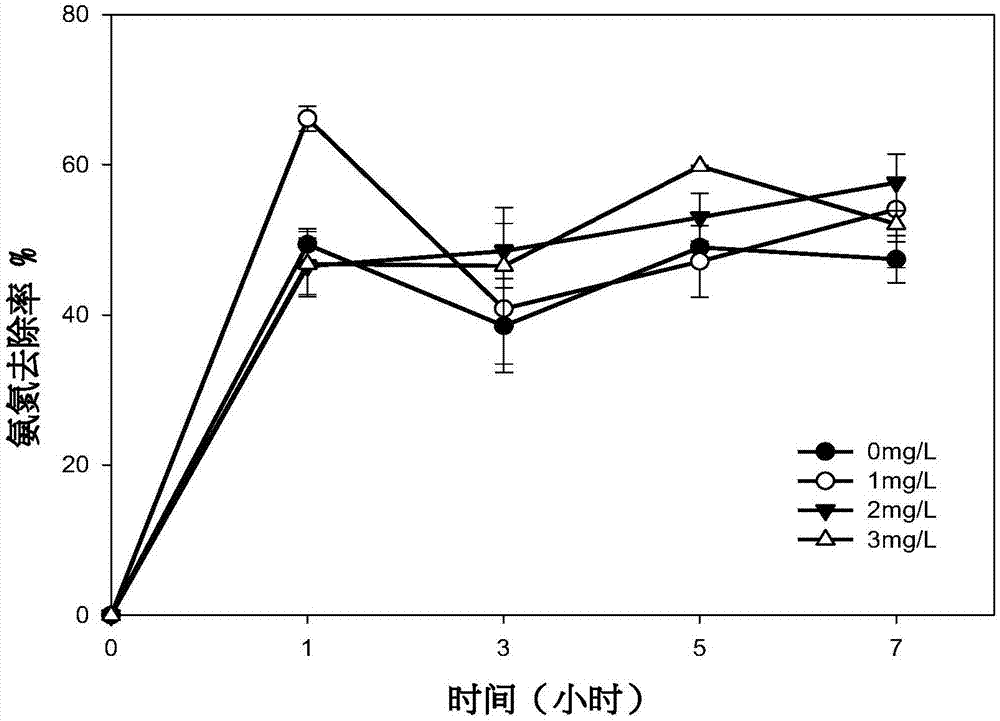

Method for eliminating ammonia inhibition in anaerobic fermentation process of livestock and poultry excrement

InactiveCN106865936AReduce consumptionRapid responseWaste water treatment from animal husbandryBiological sludge treatmentFecesVolatile fatty acids

The invention provides a method for eliminating ammonia inhibition in an anaerobic fermentation process of livestock and poultry excrement. According to the method, a struvite crystallization and sedimentation technology is used for detecting the concentration of NH<4+> in an ammonia inhibition system under the conditions that the pH value is 7-9, and the mass concentration ratio of volatile fatty acid to total inorganic carbon is less than 0.4; magnesium salt and phosphorus salt are added into a livestock and poultry excrement fermentation reaction system according to a molar ratio of the NH<4+> to Mg<2+> to PO4<3-> being equal to 1: 1: 1; the concentration of ammonia nitrogen is reduced to about a concentration value of the fermentation process without ammonia inhibition. The method for eliminating the ammonia inhibition in the anaerobic fermentation process of the livestock and poultry excrement is established by studying the influence factors of an ammonium magnesium phosphate reaction in the inner environment of an anaerobic fermentation tank and the self-limiting factors of the reaction. The method is simple in technology; furthermore, struvite precipitation produced in the reaction is slow release fertilizer, and not only can eliminate the ammonia nitrogen inhibition, but also can recover nutrients such as nitrogen and phosphorus, so that the operating cost is lowered.

Owner:CHINA AGRI UNIV

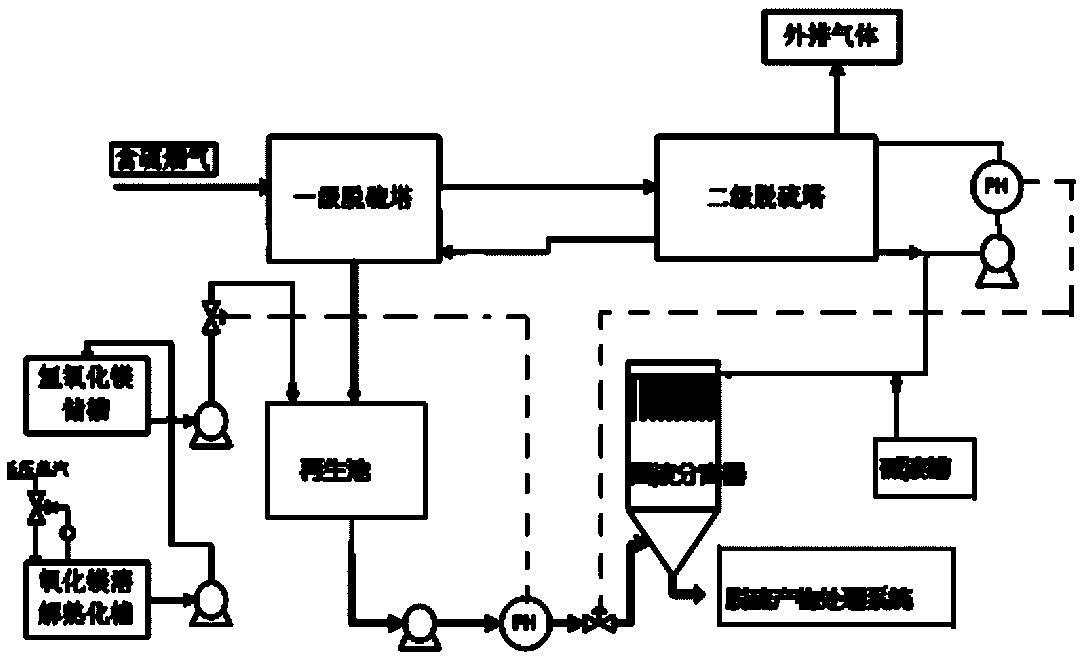

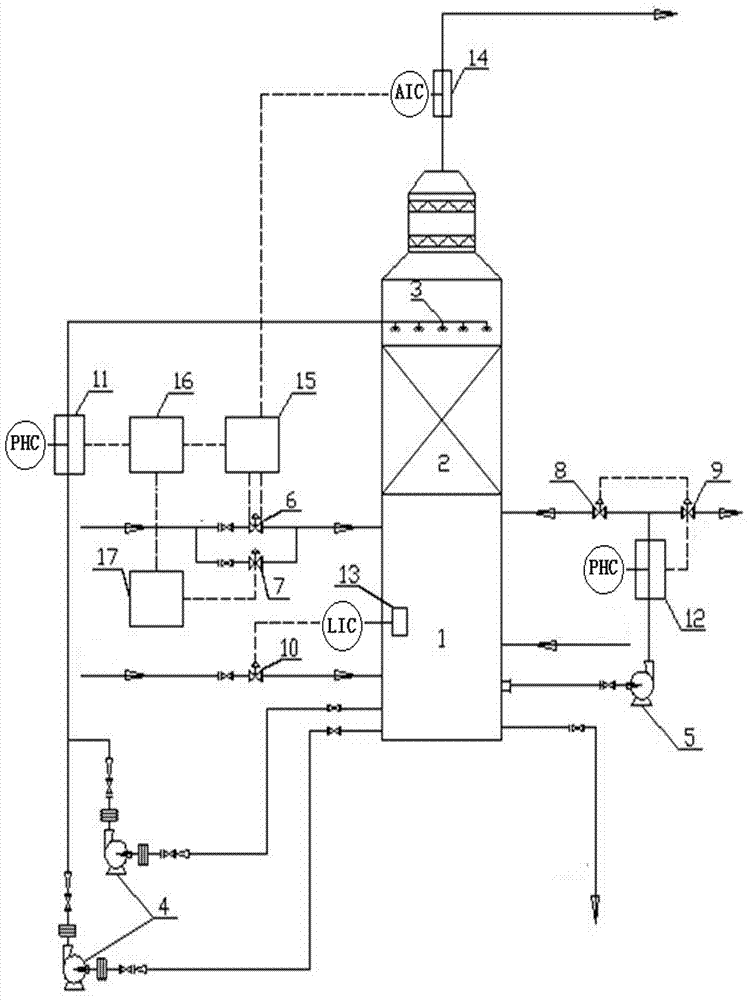

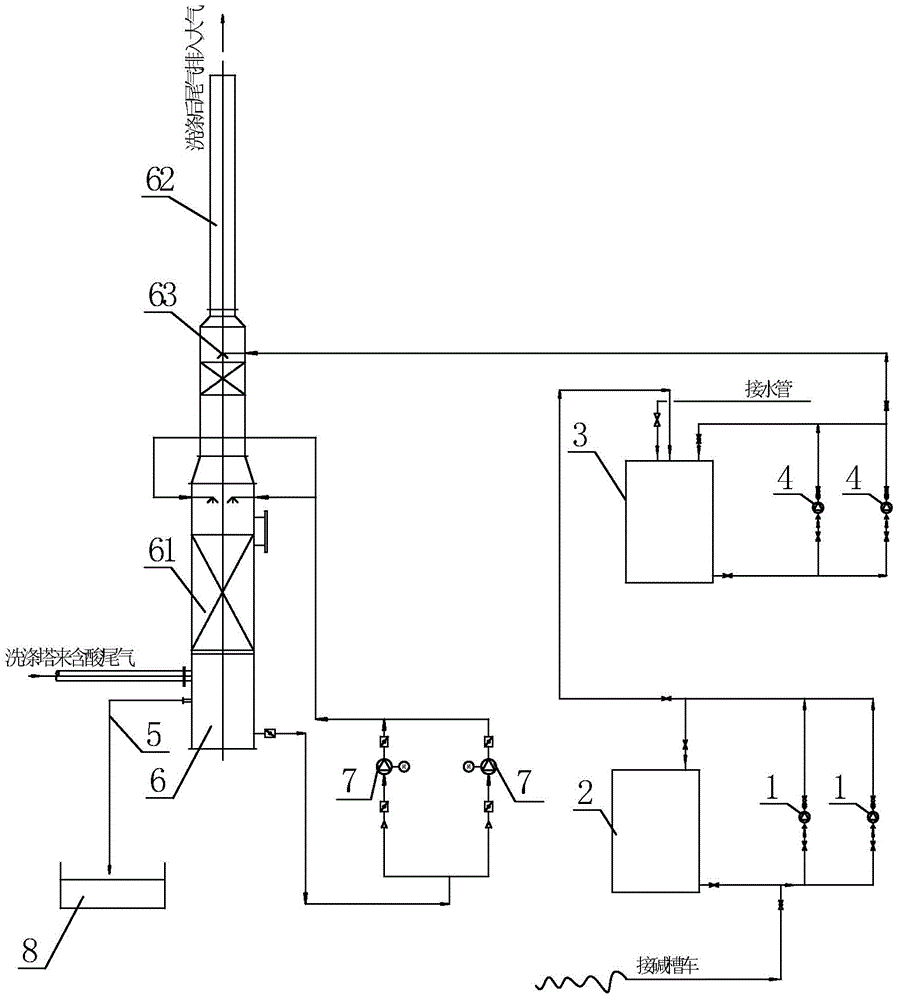

Device and method for carrying out low-concentration SO2 flue gas desulfurization by utilizing fuzzy alkali-feeding method

InactiveCN107224862ALess alkali consumptionGuarantee that emissions meet the standards all the timeDispersed particle separationExhaust gasProcess engineering

The invention discloses a device and a method for carrying out low-concentration SO2 flue gas desulfurization by utilizing a fuzzy alkali-feeding method. The device comprises a desulfurization tower, a main alkali-feeding valve, a fuzzy alkali-feeding valve, a reflowing valve, a liquid discharging valve, a water feeding valve, a primary circulating system pH (Potential of Hydrogen) detector, a secondary circulating system pH detector, a liquid level detector, a flue gas outlet SO2 concentration analyzer, a DCS (Distributed Control System) switching system, a signal isolator and an intelligent fuzzy controller. The point is that alkali-feeding desulfurization is carried out through logic control by utilizing the intelligent fuzzy controller; different alkali-feeding manners can be realized by alkali-feeding controlling through the DCS switching system according to different working conditions; the alkali-feeding controlling is more accurate, and the desulfurization effect is remarkable; meanwhile, consumed alkali in a tail gas control process is saved; a technological process is simple, and the operation is reliable; when normal production is performed, whole-time standard reaching of tail gas exhausting can be effectively ensured. Meanwhile, the labor intensity of maintenance personnel is reduced, and operating personnel conveniently control the device; a condition that tail gas emission exceeds standards, caused by the fact that the operating personnel are careless and the control is not in time, is eliminated.

Owner:JINCHUAN GROUP LIMITED

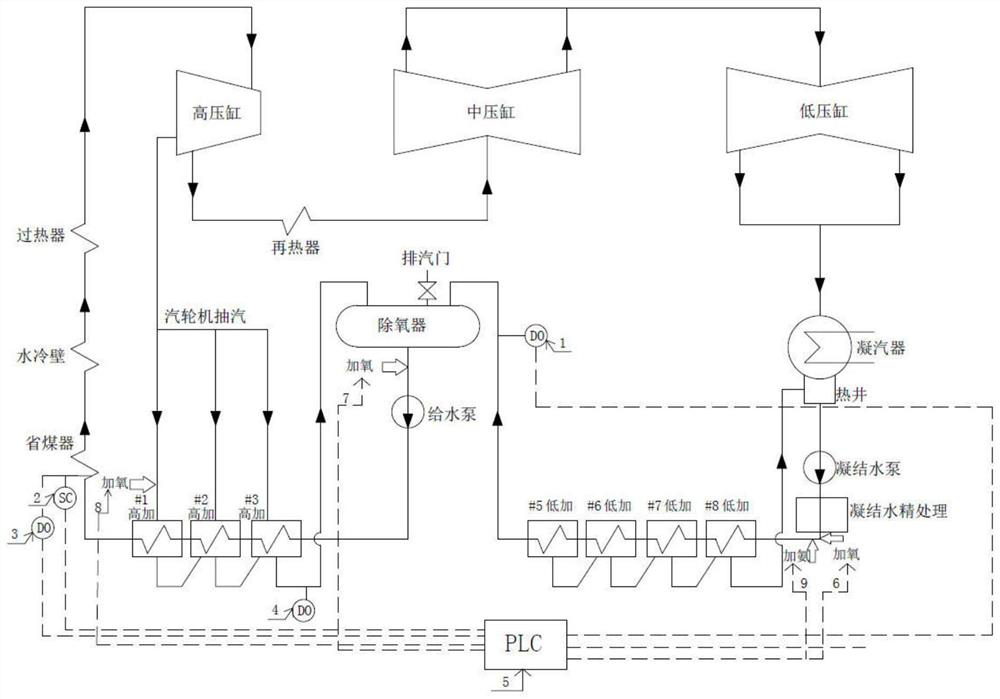

Anti-corrosion and anti-scaling integrated control system and method for thermal equipment of power plant

ActiveCN112323073ADissolved Oxygen Control Range ReducedAvoid the risk of concentrated spallingControlling ratio of multiple fluid flowsSolid state diffusion coatingDeaeratorMechanical engineering

The invention discloses an anti-corrosion and anti-scaling integrated control system and method for thermal equipment of a power plant. According to the system, an economizer inlet pipeline is provided with an online conductivity meter, and a deaerator inlet, an economizer inlet and a high-pressure heater drainage pipeline are each provided with an online dissolved oxygen meter. When the measuredvalue of the economizer inlet on-line dissolved oxygen meter is lower than the lower limit of a set value or higher than the upper limit of the set value, a PLC increases or decreases the ammonia adding amount on the condensed water fine treatment outlet main pipe, and when the measured value of the economizer inlet on-line conductivity meter is lower than the lower limit of the set value or higher than the upper limit of the set value, the PLC increases or decreases the oxygen adding amount of feed water on a descending pipe of the deaerator, so that the dissolved oxygen and the direct conductivity at the economizer inlet are made to be within the optimal control range. And when the high-pressure heater hydrophobic dissolved oxygen is lower than the lower limit value or higher than the upper limit value, the PLC increases or decreases the oxygen adding amount on the high-pressure heater hydrophobic pipeline, so that the high-pressure heater hydrophobic oxygen content is made to be within the control range. And integrated control over corrosion prevention and scale prevention of the thermal equipment is achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

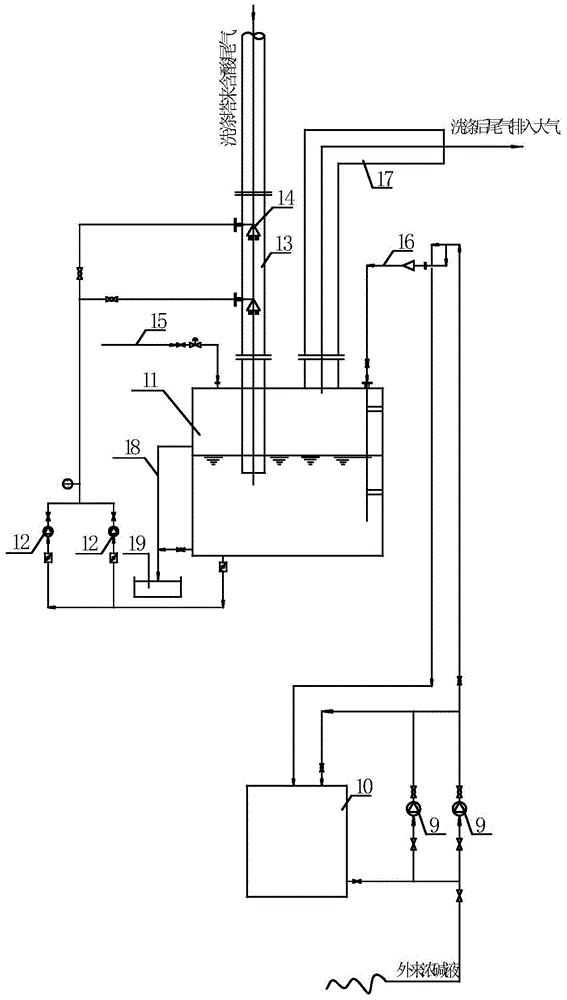

Acid-regeneration acid tail gas purification system by using spray roasting method and tail gas purification process

ActiveCN103977685AEasy to operateSmall fluctuationDispersed particle separationProcess engineeringCirculating pump

The invention relates to an acid-regeneration acid tail gas purification system by using a spray roasting method and a tail gas purification process. A tail gas purification system adopting an alkaline tower comprises the alkali wash tower, an alkali preparation tank and an alkali storage tank, wherein the alkali wash tower, the alkali preparation tank and the alkali storage tank are communicated through pipelines; an alkali wash tower circulating pump is arranged on a self-circulation pipeline of the alkali wash tower; an alkali discharge pump I is arranged on a pipeline between the alkali storage tank and the alkali preparation tank, and an alkali liquor spray pump is arranged on a pipeline between the alkali preparation tank and the alkali wash tower. A tail gas purification system adopting an alkali wash circulating tank comprises the alkali wash circulating tank and a concentrated alkali tank, wherein the alkali wash circulating tank and the concentrated alkali tank are communicated with each other through a pipeline; an alkali wash tank circulating pump is arranged on a self-circulation pipeline of the alkali wash circulating tank, and an alkali discharge pump II is arranged on a pipeline between the alkali wash circulating tank and the concentrated alkali tank. Compared with the prior art, the acid-regeneration acid tail gas purification system has the benefits that (1) the acid tail gas is purified in an alkali wash manner through the wash tower, a pH valve approaches 7, and the treated acid tail gas achieves the emission standard of the nation; (2) the system is stable in operation, small in fluctuation and low in alkali consumption; and (3) the system is small in investment and fast in effect and has popularization and utilization values.

Owner:鞍山创鑫环保科技股份有限公司

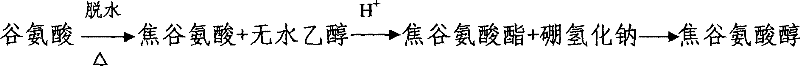

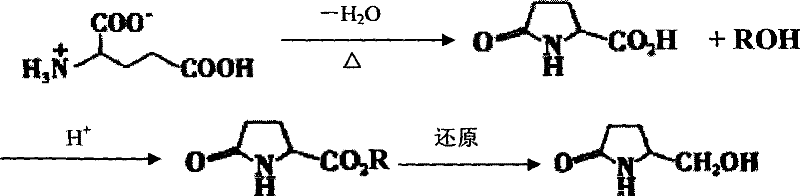

Chemical synthesis method of pyroglutamic acid alcohol and intermediates thereof

The invention provides a chemosynthesis method of pyroglutamic acid alcohol and intermediates thereof, i.e., pyroglutamic acid and pyroglutamic acid ester, wherein, glutamic acid is used as raw material which is dehydrated and cyclized in a heating environment to generate pyroglutamic acid which is then reacted with absolute alcohol under the effect of catalyst to generate pyroglutamic acid ester; finally, pyroglutamic acid ester is dissolved in organic solvent to be reduced by reducing agent to generate pyroglutamic acid alcohol. The chemosynthesizing method has the advantages that the raw material is easy to get, the process route is short, catalyst and acid consumption are little, the operation environment is good, the yield coefficient is high, the cost is low, the purity is high and the method is easy for industrialization.

Owner:SICHUAN TONGSHENG AMINO ACID CO LTD

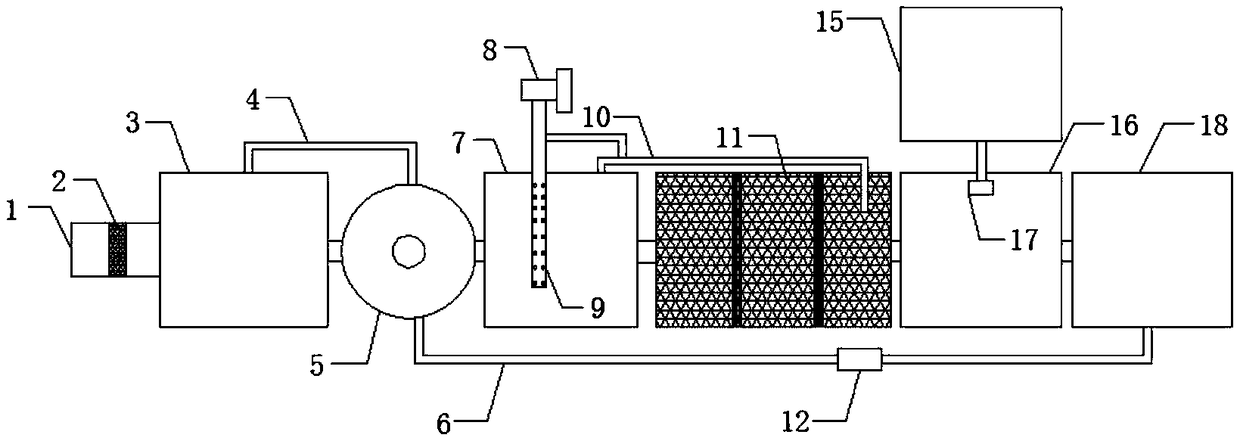

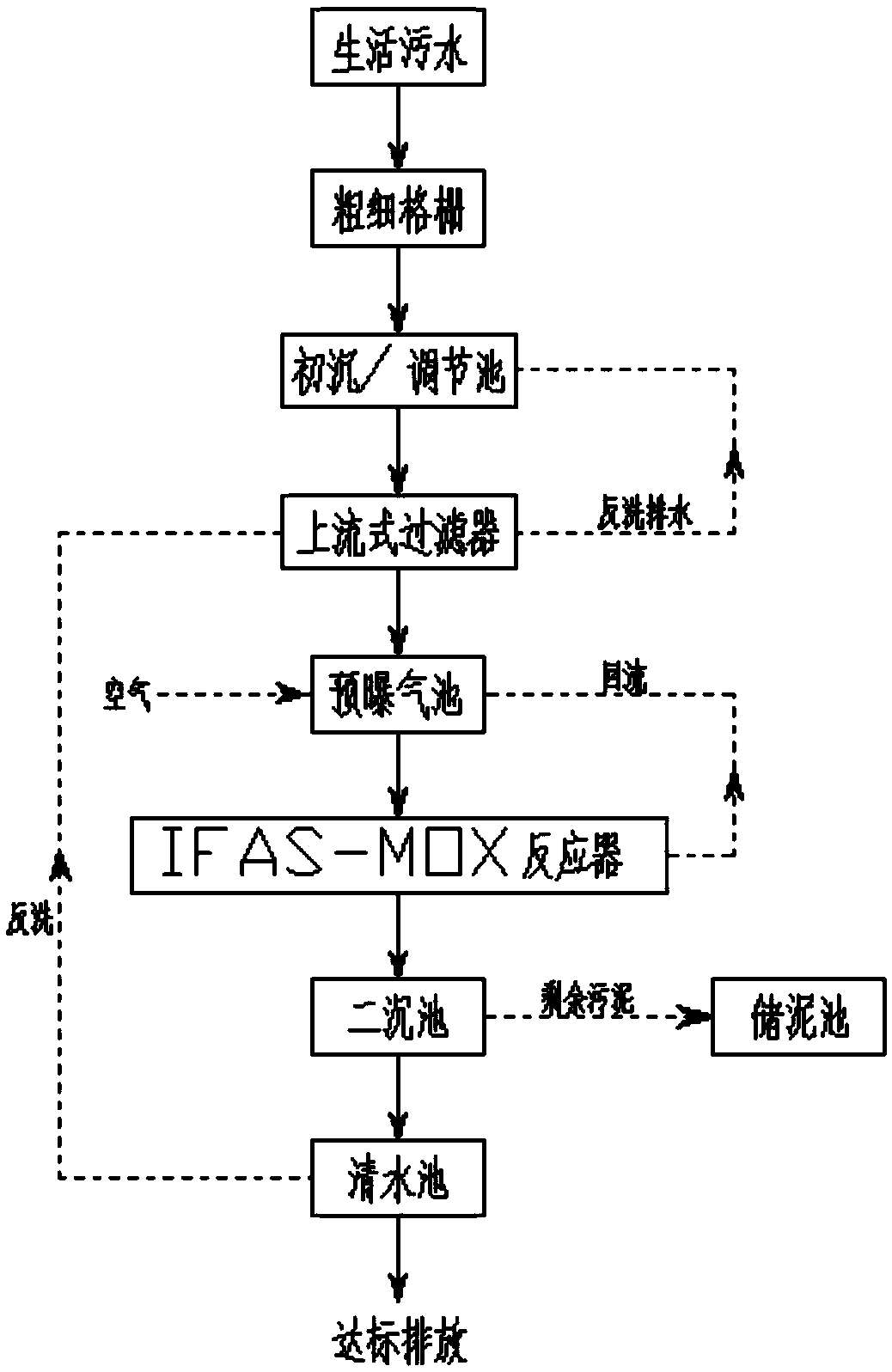

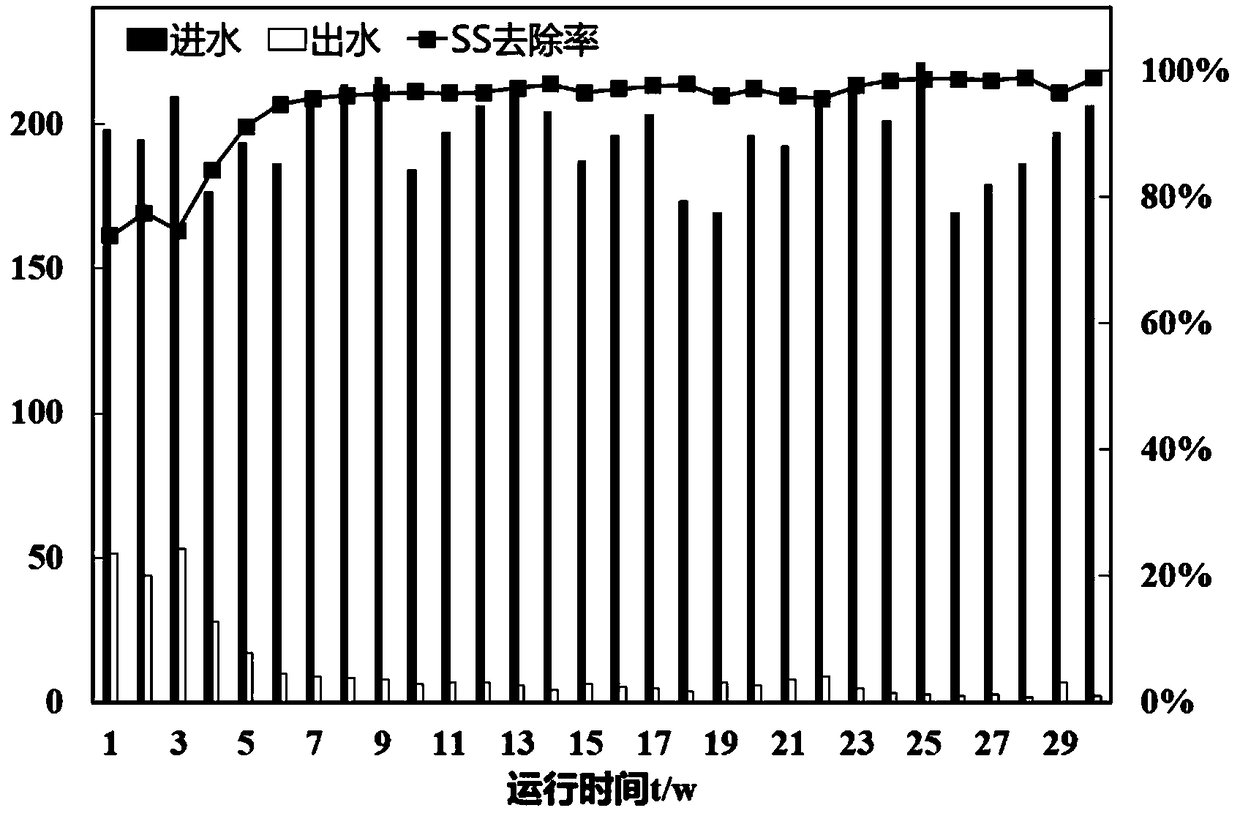

Sewage treatment process and sewage treatment system thereof

PendingCN109502892AAvoid easy cloggingFast filtrationTreatment using aerobic processesSpecific water treatment objectivesActivated sludgePopulation density

The invention discloses a sewage treatment process and a sewage treatment system thereof. The sewage treatment system comprises a primary sedimentation / adjustment tank, an up-flow type filter, a preaeration tank, an IFAS-MOX reactor, a secondary sedimentation tank and a clean water basin, wherein a sewage inlet trough is arranged on one side of the primary sedimentation / adjustment tank; a thick-thin grid is arranged in the sewage inlet trough; a micropore aerator pipe is arranged in the preaeration tank; and one end of the micropore aerator pipe communicates with a fan located on the outer side of the preaeration tank. According to the sewage treatment process and the sewage treatment system thereof provided by the invention, by utilizing the advantages of difficulty in blocking, fast filter speed and easiness in cleaning of the up-flow type filter, sewage is pretreated; by utilizing the advantages of a biofilm technology and an activated sludge technology in the IFAS-MOX reactor, without increasing the sludge concentration, the microbial population density is improved, and the sludge sedimentation performance is improved; through the dissolved oxygen gradient change, the commensalism of nitrosobacteria and anaerobic ammonium oxidation bacteria is realized, and a sewage nitrogen and phosphorus removal effect is improved. A carbon source in sewage is effectively utilized, the oxygen utilization ratio is high, the energy consumption is low, and a nitrogen and phosphorus removal effect is good.

Owner:福瑞莱环保科技(深圳)股份有限公司

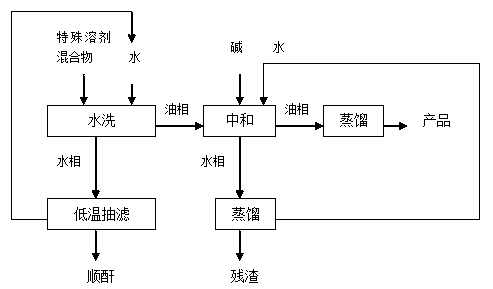

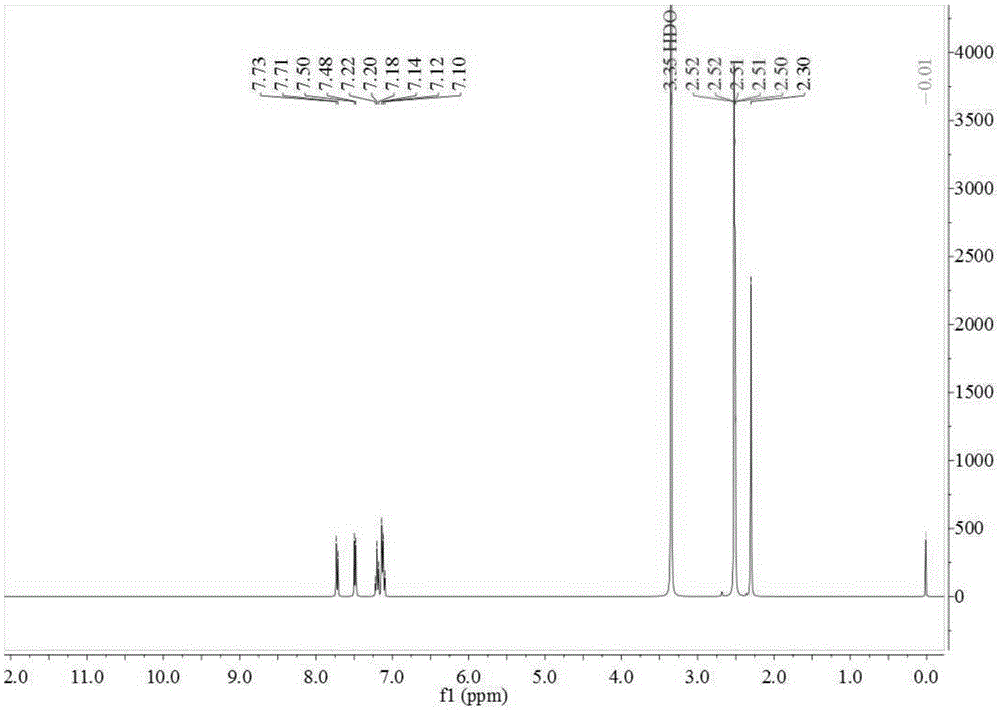

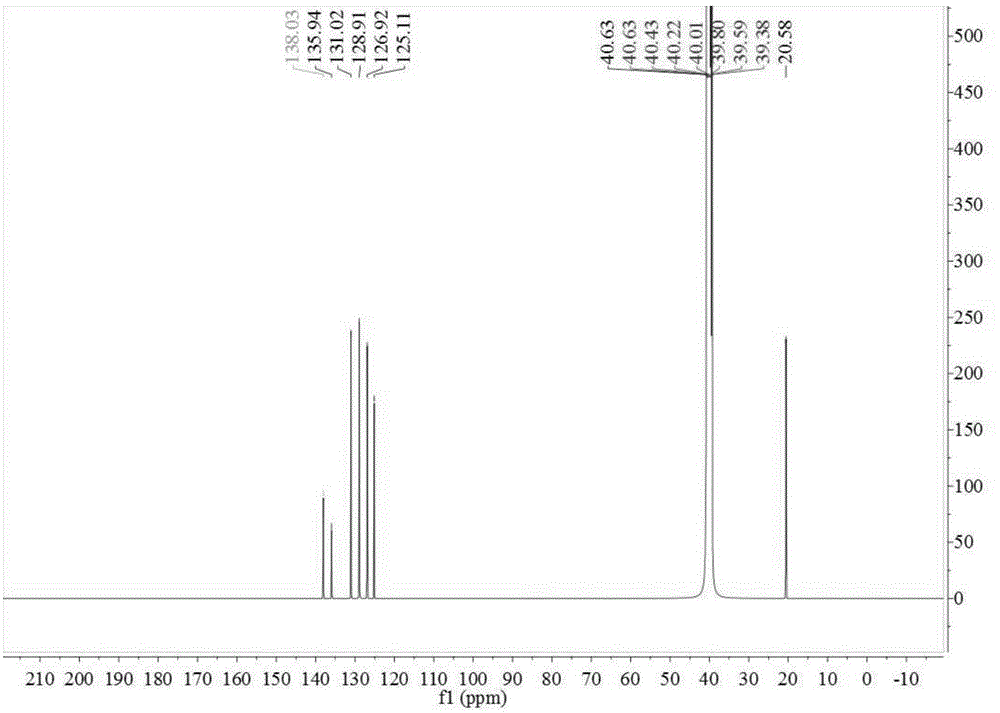

High-concentration N-phenylmaleimide reaction liquid post-treatment process

The invention relates to a high-concentration N-phenylmaleimide reaction liquid post-treatment process, which is uniquely characterized in that the reaction liquid is sequentially subjected to water washing and neutralization, and the obtained liquid is subjected to solvent removing in a rotary evaporator to obtain the product without re-crystallization. The process comprising: adding water and a solvent mixture to a N-phenylmaleimide reaction liquid according to a certain ratio in a mixing manner, stirring, cooling, separating to obtain a water layer and an oil layer, carrying out water washing on the water layer, cooling the washed water layer, and carrying out vacuum suction filtration to obtain a maleic anhydride (short for maleic anhydride) by-product solid and water, wherein the maleic anhydride is used as the reaction raw material so as to be continuously used for the N-phenylmaleimide reaction step, and the water is continuously used for the water washing step; carrying out water washing on the oil layer, separating the oil layer to obtain a water layer and an oil layer, and distilling the neutralization water layer to obtain water and trace residue, wherein the water is continuously used, and the residue is treated; and adding the neutralization oil layer to the rotary evaporator, and evaporating the solvent to obtain the N-phenylmaleimide finished product with the purity of more than or equal to 99.25%. According to the present invention, the yield of the whole post-treatment process can exceed 97.5%, no wastewater is generated, and the process is environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

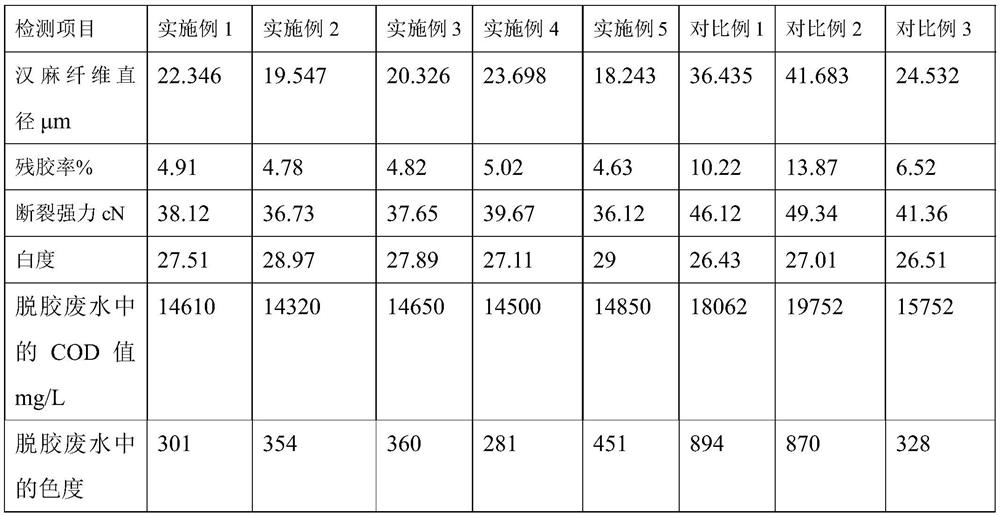

Degumming method of China hemp fibers

ActiveCN113026119AProtects Cellulose ContentQuality improvementFibre treatment to obtain bast fibreCellulosePtru catalyst

The invention relates to a degumming method of China hemp fibers. The degumming method comprises the following steps that (1), pre-alkali treatment is carried out on China hemp, and the China hemp is washed with water; (2), anhydrous ferrous sulfate is added and used as a hydrogen peroxide catalyst under a weak acid condition, and the China hemp fibers are further degummed and washed with electricity assistance; and (3), deep degumming and bleaching treatment is carried out on the China hemp fibers by using an alkali-oxygen one-bath method, washing with water and drying are carried out. Compared with a traditional process, the degumming method of the China hemp fibers is more suitable for degumming under a weakly acidic condition, cellulose components in the China hemp are better protected, the quality of the hemp fibers is improved, and the degumming period is shortened at the same time. An electrically-assisted Fenton system is applied to degumming the China hemp fibers, so that compared with the traditional process, the alkali consumption is small, COD value in degumming wastewater is low, the color is shallow, pollution to the environment is small, and environmental protection and sewage treatment are more facilitated.

Owner:QIQIHAR UNIVERSITY

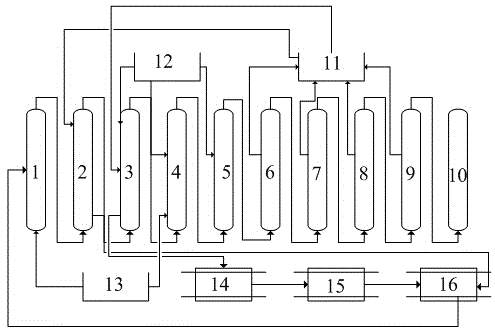

Industrialized preparation method of 2-carboxyl-3-naphthalene formic acid

InactiveCN104892406AIncrease profitProcess conditions Environmental protection and energy savingOrganic compound preparationCarboxylic compound separation/purificationHydration reactionFiltration

The invention discloses an industrialized preparation method of 2-carboxyl-3-naphthalene formic acid. The 2-carboxyl-3-naphthalene formic acid is prepared by feeding raw materials into a first reaction tower, a carboxylation reaction tower, a second reaction tower, a neutralization reaction tower, an acidification reaction tower, a filter pressing reaction tower, a refined filtration reaction tower, a hydration reaction tower, a reaction tower and a finished product storage tower in turn. The 2-carboxyl-3-naphthalene formic acid is high in product purity up to over 98.89%, high in smelting point up to 220 DEG C, low in crystallization rate less than 3% and is yellowish-brown.

Owner:张晨

DSD acid preparation method

ActiveCN106146357AIncrease profitReduce formationSulfonic acid preparationChemical synthesisWhitening Agents

The invention relates to the field of chemical synthesis, in particular to a DSD acid preparation method. The DSD acid preparation method includes the steps that methylbenzene is subjected to sulfonation, purification and separation to obtain OTS, wherein the byproduct is PTS; OTS is subjected to mixed acid nitration to obtain PNTS; PNTS is subjected to chlorine oxidative condensation to obtain DNS; DNS is subjected to catalyzed hydrogeneration reduction to obtain the high-quality target product, namely DSD acid which can be directly used for synthesizing a fluorescent whitening agent. The synthesis method greatly reduces dangerousness of the process, greatly reduces generation of harmful byproducts and waste, particularly, does not generate a lot of carcinogenic intermediate, namely ortho-nitrotoluene, completely solves the nitration safety problem of the old technology, and has the advantages of being simple in step, high in yield and the like.

Owner:上海合丽亚日化技术有限公司

Method for extracting beta-1,3-D-glucan from cell walls of fungi

The present invention discloses a method for extracting beta-1,3-D-glucan from the cell walls of fungi. The method comprises that cell walls and an alkali metal hydroxide are mixed in the presence of a solvent and an alkali treatment is performed, wherein the precipitate obtained from the alkali treatment is a beta-1,3-D-glucan crude product, the alkali metal hydroxide use amount is 65-900 g relative to per kg of the cell walls, and the alkali treatment temperature is 105-115 DEG C. With the technical scheme of the present invention, the beta-1,3-D-glucan extraction rate and the purity of the beta-1,3-D-glucan are high; the alkali consumption is low, such that the environmental pollution is less; and the time consumption is short, the extraction efficiency is high, and the unit energy consumption is less, such that the cost can be substantially reduced.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

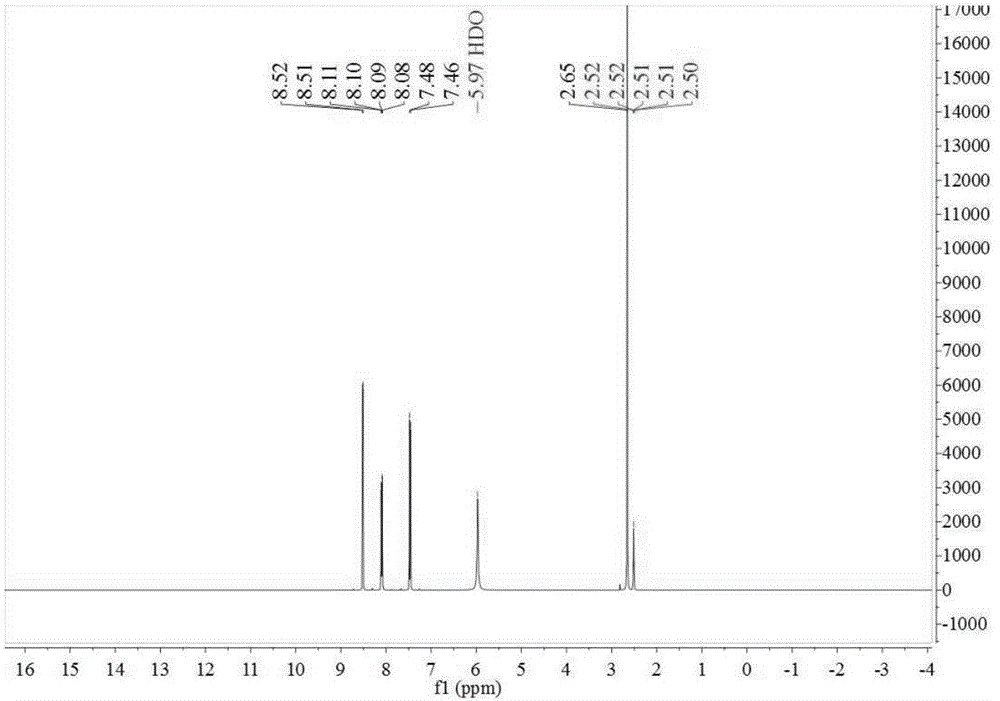

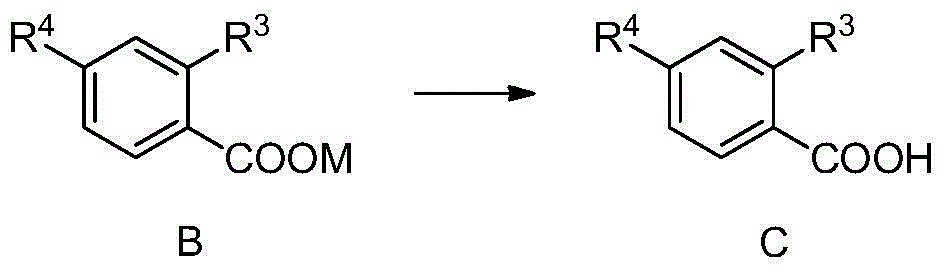

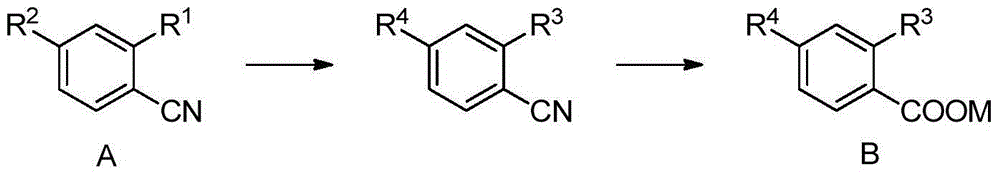

Preparation method of methoxybenzoic acid

ActiveCN104151157AReduce pollutionRaw materials are cheap and easy to getPreparation from carboxylic acid saltsCarboxylic acid nitrile preparationMethoxybenzoatesPotassium hydroxide

The invention discloses a preparation method of alkali metal methoxybenzoate shown in a formula B. The preparation method comprises the following steps: 1, under the protection of inert gas, performing nucleophilic substitution reaction on a compound A and sodium methylate in methanol, wherein the reaction temperature is 80-150 DEG C and the reaction pressure is 0.18-1.4 MPa; 2, directly mixing a solution obtained in the step 1 with alkali metal hydroxide and water, removing methanol, and performing hydrolysis reaction to obtain a compound B, wherein the reaction temperature is 90-190 DEG C, and alkali metal hydroxide is sodium hydroxide and / or potassium hydroxide; performing acidification reaction on the prepared compound B and acid to prepare methoxybenzoic acid shown in a formula C. According to the method, the raw materials are easily available, a low-price safe reagent is used, and a one-pot process is adopted; the method is low in alkali consumption, little in environmental pollution, easy to perform, high in yield and suitable for industrialized production.

Owner:联化科技(上海)有限公司 +2

A method for producing metallurgical grade alumina from fly ash and recyclable ammonium salt

InactiveCN104628020BEasy to filter washEasy to crystallize outSolid waste disposalAluminium oxides/hydroxidesSulfurStrong acids

The invention discloses a method for producing metallurgy-grade alumina by taking pulverized fuel ash and recycled ammonium salt as raw materials. The method comprises the following steps: (1) preparing materials; (2) roasting; (3) dissolving; (4) crystallizing; (5) carrying out a liquid-solid ammonolysis reaction; (6) grinding and removing sulfur; and (7) performing low-temperature Bayer aluminum production. The method disclosed by the invention has the advantages that an aluminum salt ammonolysis method suitable for strong acid and weak base is adopted, namely liquid-solid or gas-solid ammonolysis is performed, the production efficiency is improved by over 60 percent compared with that a liquid-liquid ammonolysis method, the process conditions of the ammonolysis method are optimized, optimal process parameters are determined, the obtained product, namely crude aluminum hydroxide, is easy to filter and wash, the model selection of equipment is simple, and industrial mass production can be realized.

Owner:NORTH UNITED POWER CO LTD +1

A system and method for efficiently purifying domestic sewage

ActiveCN109650661BRealize simultaneous denitrification and dephosphorizationReduce processWater contaminantsMultistage water/sewage treatmentNitrite ionMicroorganism

The invention provides a system and method for efficiently purifying domestic sewage. The system includes a primary sedimentation tank (1), an acidification tank (2), an aeration tank (3) and an anaerobic tank (4) connected in sequence. The pool (1) is used for sedimentation treatment of domestic sewage, and the domestic sewage after sedimentation treatment is transferred to the acidification pool (2); the acidification pool (2) is used for the degradation of organic matter by microorganisms; Oxygen-containing gas and nitrous bacteria are added to convert ammonia nitrogen into nitrite ion form through nitrification, and phosphorus-accumulating bacteria in domestic sewage are used to remove phosphorus; the anaerobic tank (4) is used to receive the aeration tank (3) The treated domestic sewage supernatant is denitrified by denitrification. The present invention mainly uses the combination of chemical precipitation and microbial phosphorus removal to remove phosphorus, and uses NH 4 + —NO 2 ‑ —N 2 For the denitrification route, the effective management of denitrification and phosphorus removal of domestic sewage has been realized to ensure that domestic sewage will not affect human health during human activities.

Owner:江苏长三角智慧水务研究院有限公司

Method for preparing magnesium-based flame retardant from magnesium-containing wastewater

PendingCN112645370AReduce salt concentrationLess alkali consumptionHydrotalciteEngineeringProcess engineering

The invention discloses a method for preparing a magnesium-based flame retardant from magnesium-containing wastewater, which comprises the following steps: (1) adding an aluminum-containing compound into Grignard magnesium-containing wastewater, sufficiently stirring to react for 0.5-3 hour, lowering the acidity of the wastewater solution to enable the pH value to reach 3-4, and filtering insoluble substances for the next batch of reaction; (2) supplementing and adding soluble aluminum salt according to a certain proportion to enable the amount of substance of aluminum ions to be 1 / 4-1 / 2 of the amount of substance of magnesium ions, and stirring and dissolving to obtain a mixed solution A of magnesium-aluminum metal salt; (3) preparing an alkaline mixed solution B from sodium hydroxide and sodium carbonate according to a certain ratio; and (4) quickly mixing and co-precipitating the two solutions A and B to obtain magnesium-aluminum composite hydroxide slurry, crystallizing for 3-36 hours at the temperature of 60-100 DEG C, centrifugally filtering, washing and drying to obtain the magnesium-based flame retardant. According to the method, magnesium resources in the Grignard magnesium-containing wastewater are fully utilized, and the obtained magnesium-based flame retardant has wide application, has the advantages of environmental friendliness, comprehensive utilization of resources and the like, and has a good industrial prospect.

Owner:浙江胡涂硅科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com