Degumming method of China hemp fibers

A technology of hemp fiber and degumming method, which is applied in the field of textile processing, can solve the problems of large environmental pollution, low degumming rate, and large alkali consumption, and achieve the effects of small alkali consumption, light color, and low COD value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

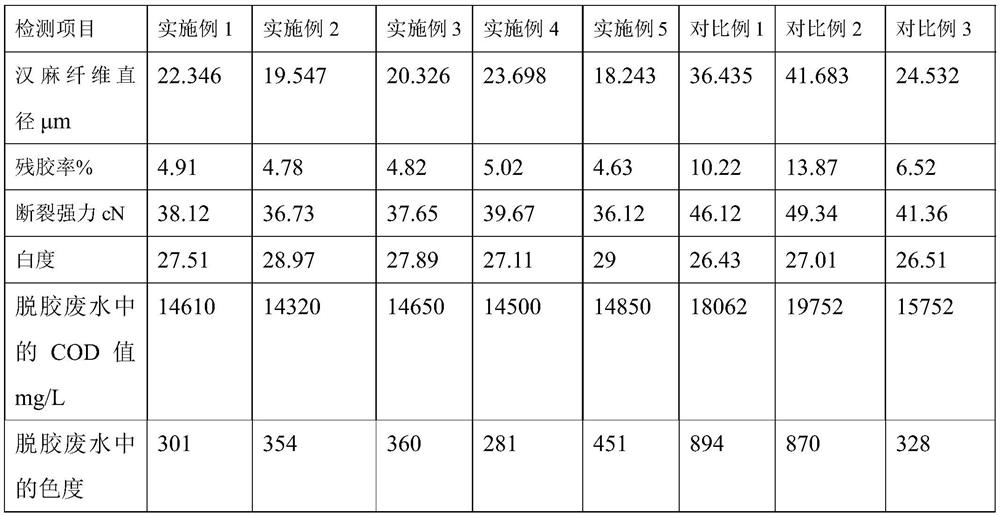

Examples

Embodiment 1

[0021] A kind of degumming method of hemp fiber, comprises the steps:

[0022] 1) Pre-alkali treatment of hemp

[0023] The conditions are: the weight ratio of hemp to the treatment solution is 1:10, the concentration of sodium hydroxide is 4g / L, the temperature is 70°C, the treatment time is 6min, and the pH value is neutral after washing with water;

[0024] 2), under weakly acidic conditions, add anhydrous ferric sulfite as a hydrogen peroxide catalyst and use electricity to assist in further degumming of hemp fibers;

[0025] The conditions are: the weight ratio of hemp to the treatment solution is 1:20, the pH value is 4.0, the concentration of anhydrous ferrous sulfate is 9g / L, the concentration of hydrogen peroxide is 8g / L, the treatment temperature is 50°C, and the treatment time is 40min. Voltage 5V, wash with water until the pH value is neutral;

[0026] 3) Deep degumming of hemp fibers by alkali-oxygen one-bath method

[0027] The conditions are: the weight ratio...

Embodiment 2

[0029] A kind of degumming method of hemp fiber, comprises the steps:

[0030] 1) Pre-alkali treatment of hemp

[0031] The conditions are: the weight ratio of hemp to the treatment solution is 1:20, the concentration of sodium hydroxide is 4g / L, the temperature is 60°C, the treatment time is 10min, and the pH value is neutral after washing with water;

[0032] 2), under weakly acidic conditions, add anhydrous ferric sulfite as a hydrogen peroxide catalyst and use electricity to assist in further degumming of hemp fibers;

[0033] The conditions are: the weight ratio of hemp to the treatment solution is 1:20, the pH value is 5.0, the concentration of anhydrous ferrous sulfate is 8g / L, the concentration of hydrogen peroxide is 9g / L, the treatment temperature is 60°C, and the treatment time is 30min. Voltage 10V, wash with water until the pH value is neutral;

[0034] 3) Deep degumming of hemp fibers by alkali-oxygen one-bath method

[0035] The conditions are: the weight rat...

Embodiment 3

[0037] A kind of degumming method of hemp fiber, comprises the steps:

[0038] 1) Pre-alkali treatment of hemp

[0039] The conditions are: the weight ratio of hemp to the treatment solution is 1:30, the concentration of sodium hydroxide is 3g / L, the temperature is 70°C, the treatment time is 15min, and the pH value is neutral after washing with water;

[0040] 2) Under weakly acidic conditions, add anhydrous ferric sulfite as a hydrogen peroxide catalyst and use electricity to assist in further degumming of hemp fibers

[0041] The conditions are: the weight ratio of hemp to the treatment solution is 1:20, the pH value is 6.0, the concentration of anhydrous ferrous sulfate is 10g / L, the concentration of hydrogen peroxide is 8g / L, the treatment temperature is 50°C, and the treatment time is 50min. Voltage 20V, wash with water until the pH value is neutral;

[0042] 3) Deep degumming of hemp fibers by alkali-oxygen one-bath method

[0043] The conditions are: the weight rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com