Method for extracting beta-1,3-D-glucan from cell walls of fungi

A cell wall and glucan technology, applied in the biological field, can solve the problems of low efficiency and large alkali consumption, and achieve the effects of reducing cost, low alkali consumption and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

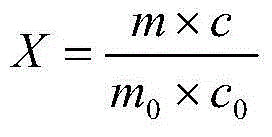

Image

Examples

preparation example 1

[0030] This preparation example is used to prepare the cell wall used in each example.

[0031] Brewer's yeast pretreatment: Use 200 mesh net cloth to screen waste beer yeast (dry matter content of 16% by weight, provided by Tianjin Snow Beer Co., Ltd.) to remove impurities, centrifuge at 2000×g for 10 minutes, and use cold saline for precipitation Wash twice to get clean beer yeast cells.

[0032] Preparation of the cell wall of brewer's yeast: pretreated clean brewer's yeast cells and distilled water to prepare a 50% by weight cell suspension, use a high-pressure homogeneous crusher under 1700bar conditions to break twice; 8341 × g centrifugation for 20 minutes, precipitation Washed with cold deionized water for 3 times and centrifuged to remove the supernatant to obtain the cell wall of beer yeast (water content of 82% by weight).

[0033] Take a large cup mushroom (purchased from China Forestry Microbial Culture Collection and Management Center, CFCC87186), prepare the cell wall...

Embodiment 1

[0035] Add 12g of brewer’s yeast cell wall to 48mL of 0.9g / 100mL NaOH solution to form a cell wall suspension, treat it at 108°C for 5min, cool to 45°C, centrifuge at 9690×g for 20min, wash with water to pH 6.5, 105 Dry at ℃ for 2h. The content of β-1,3-D-glucan in the obtained β-1,3-D-glucan product was 77.11%, and the extraction rate was 77.38%.

Embodiment 2

[0041] Add 12g of the cell wall of brewer’s yeast to 48mL of 0.8g / 100mL NaOH solution to form a cell wall suspension, treat it at 105°C for 5min, cool to 45°C, centrifuge at 9690×g for 20min, and wash with water to pH 7,80 Dry at ℃ for 4h. The content of β-1,3-D-glucan in the obtained β-1,3-D-glucan product is 76.95%, and the extraction rate is 78.31%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com