Novel dual-alkali flue gas desulfurization method and flue gas desulfurization system

A technology of desulfurization system and double-alkali method, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of long running time and failure of double-alkali method, achieve long running time, improve absorption efficiency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

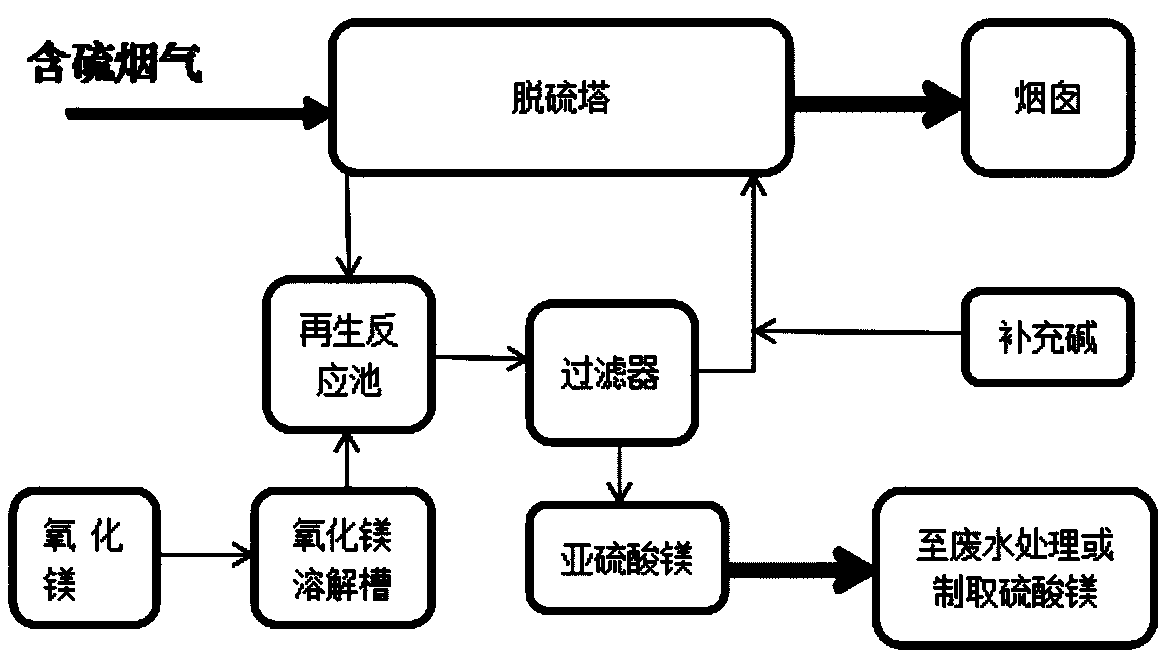

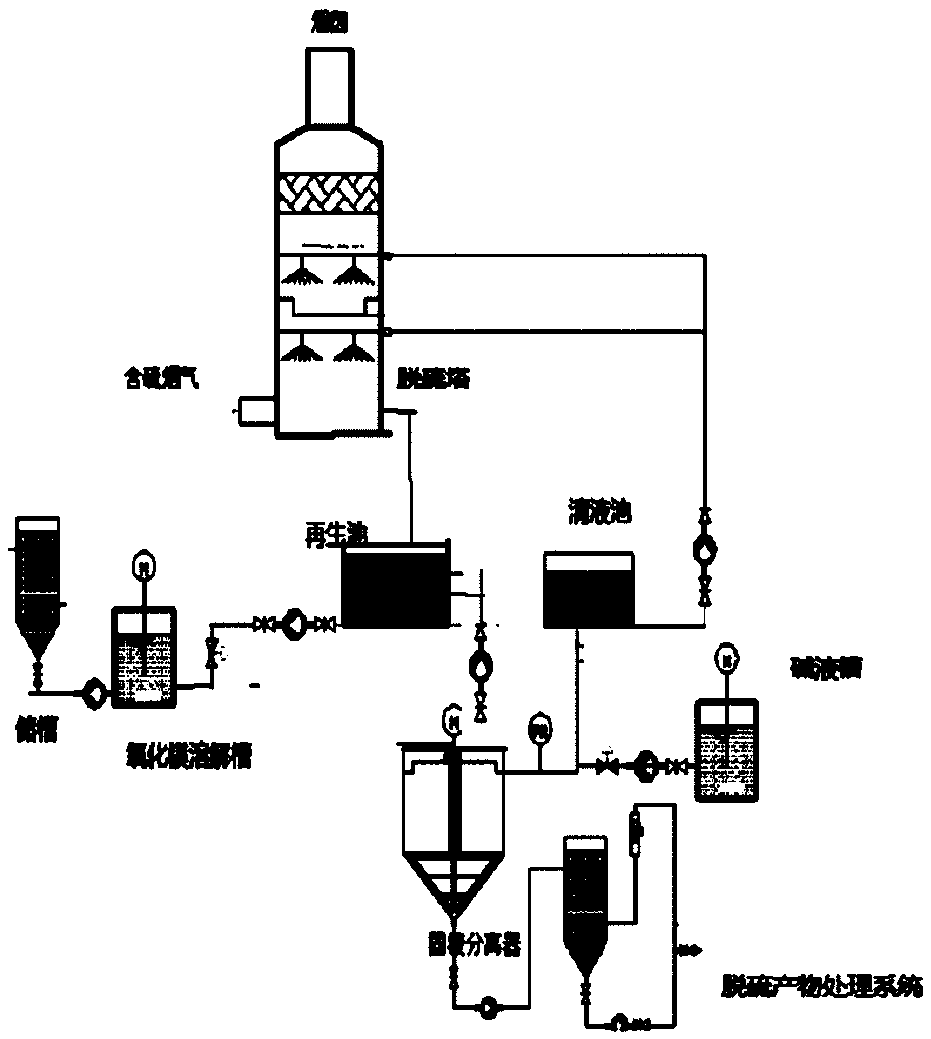

[0029] see figure 1 and figure 2 , a new double-alkali flue gas desulfurization system, including a desulfurization tower, a chimney, a regeneration tank, a magnesium oxide dissolution tank, an alkali solution tank, a solid-liquid separator, a clear liquid tank and a desulfurization product treatment system, and the flue gas outlet of the desulfurization tower It is connected with the chimney, the liquid outlet of the desulfurization tower is connected with the liquid inlet of the regeneration tank through a pipeline, the liquid outlet of the magnesium oxide dissolving tank is connected with the liquid inlet of the regeneration tank through a pipeline, and the outlet of the regeneration tank is connected with the pipeline. The liquid port is connected to the liquid inlet of the solid-liquid separator through a pipeline, the liquid outlet of the solid-liquid separator is connected to the inlet of the clear liquid tank through a pipeline, and the clear liquid outlet of the cle...

Embodiment 2

[0037] see figure 1 and figure 2 , a new dual-alkali flue gas desulfurization system, including a single-tower desulfurization tower, a chimney, a regeneration tank, a magnesium oxide dissolution tank, an alkali solution tank, a solid-liquid separator, a clear liquid tank and a desulfurization product treatment system, and a single-tower desulfurization tower The flue gas outlet is connected to the chimney, the liquid outlet of the single-tower desulfurization tower is connected to the liquid inlet of the regeneration tank through pipelines, the liquid outlet of the magnesium oxide dissolution tank is connected to the liquid inlet of the regeneration tank through pipelines, The liquid outlet of the regeneration tank is connected with the liquid inlet of the solid-liquid separator through a pipeline, the liquid outlet of the solid-liquid separator is connected with the inlet of the clear liquid tank through a pipeline, and the clear liquid outlet of the clear liquid tank is c...

Embodiment 3

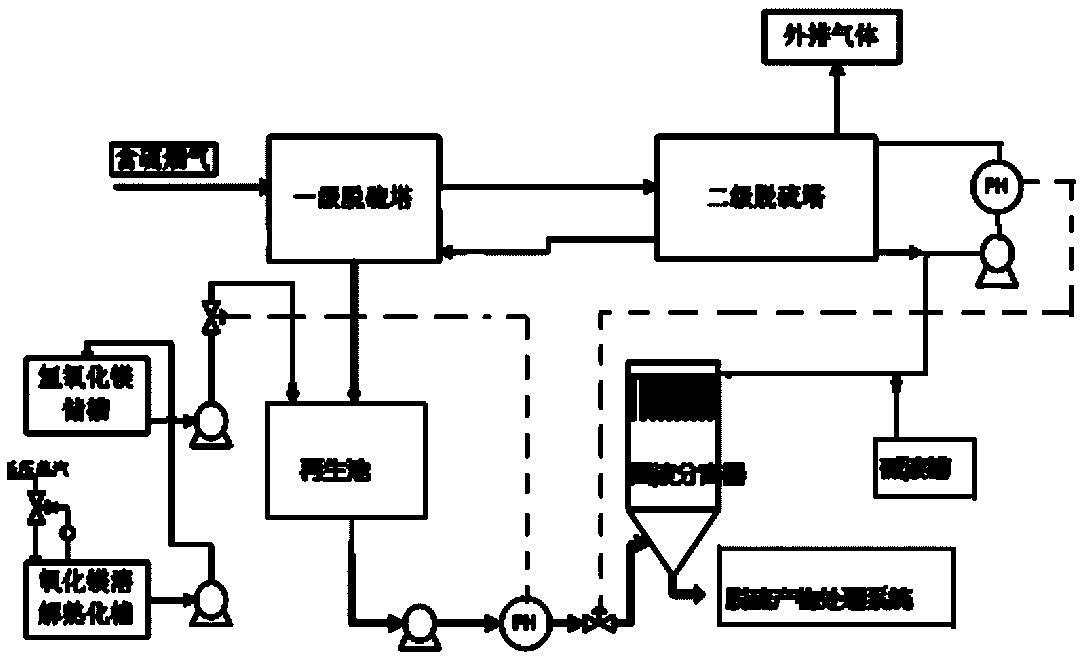

[0045] In this example, the new sodium-magnesium double-alkali flue gas desulfurization system is used for desulfurization. The desulfurization tower is a double-tower desulfurization tower. emissions, such as image 3 shown.

[0046] Including primary desulfurization tower, secondary desulfurization tower, chimney, regeneration tank, magnesium oxide dissolving tank, lye tank, solid-liquid separator and desulfurization product treatment system, the inlet of the secondary desulfurization tower is connected with the outlet of the primary desulfurization tower through pipelines , the outlet of the secondary absorption tower is connected to the discharge chimney, the liquid outlet of the primary desulfurization tower is connected to the liquid inlet of the regeneration tank through pipelines, the liquid outlet of the magnesium oxide dissolution tank is connected to the liquid inlet of the regeneration tank through pipelines The liquid outlet of the regeneration tank is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com