Method for producing metallurgy-grade alumina by taking pulverized fuel ash and recycled ammonium salt as raw materials

A technology for the production of metallurgy and fly ash, applied in the direction of alumina/aluminum hydroxide, solid waste removal, etc., can solve the problems of large entrainment of ammonium sulfate, increased alkali consumption, long aging time, etc. The effect of reducing the amount of entrainment, reducing the amount of evaporated water, and facilitating the dissolution and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

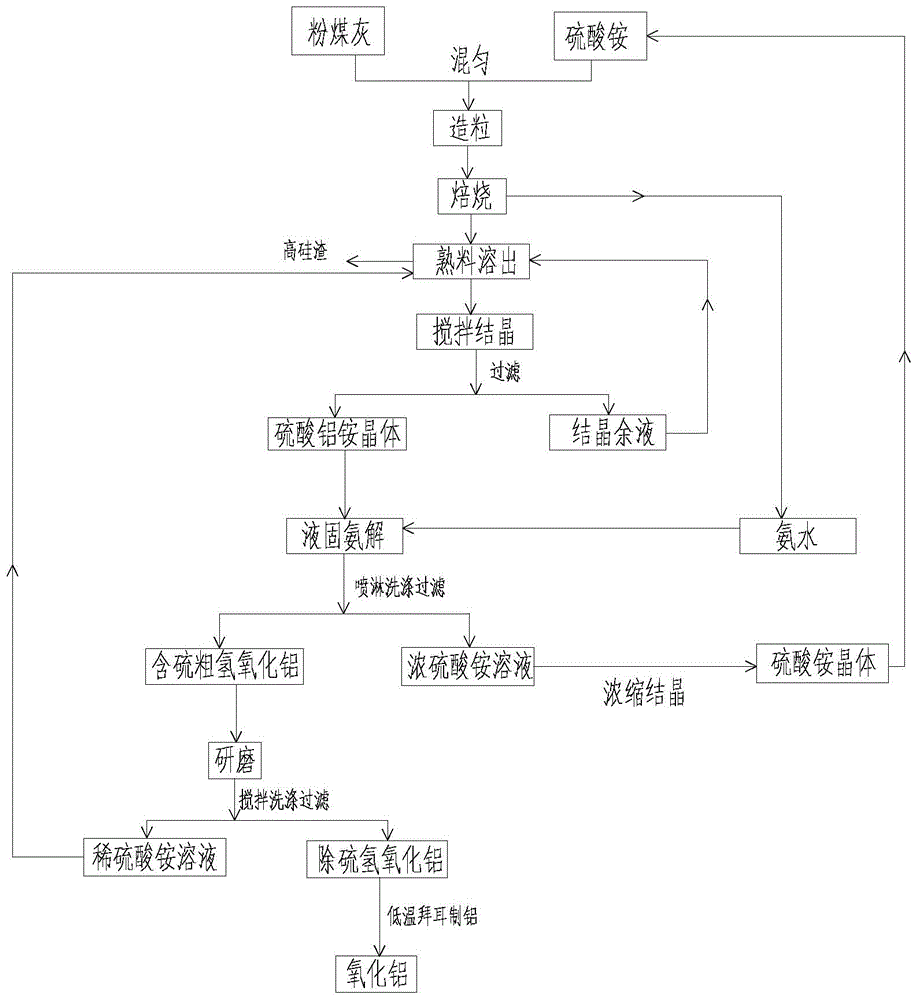

[0039] Embodiment 1: A method for producing metallurgical grade alumina using fly ash and recyclable ammonium salt as raw materials, which includes the following steps: (1) material preparation; (2) roasting; (3) dissolution; (4) crystallization; (5) Liquid-solid ammonolysis reaction; (6) Grinding and desulfurization; (7) Low-temperature Bayer aluminum production; among them,

[0040] (1) Stock preparation: the fly ash is ground and activated, ground to 150 orders, and the fly ash and ammonium sulfate after grinding are ground in a ratio of 1:3.5 of the molar ratio of aluminum oxide and ammonium sulfate contained in the fly ash. Mix evenly, and then add water to granulate to form granular materials. The mass ratio of the mixed material composed of the fly ash and the ammonium sulfate to the water is 100:3;

[0041] (2) Roasting: the granular material is roasted at 390° C. for 3 hours, and roasted clinker and ammonia gas are generated during roasting;

[0042] (3) Dissolution:...

Embodiment 2

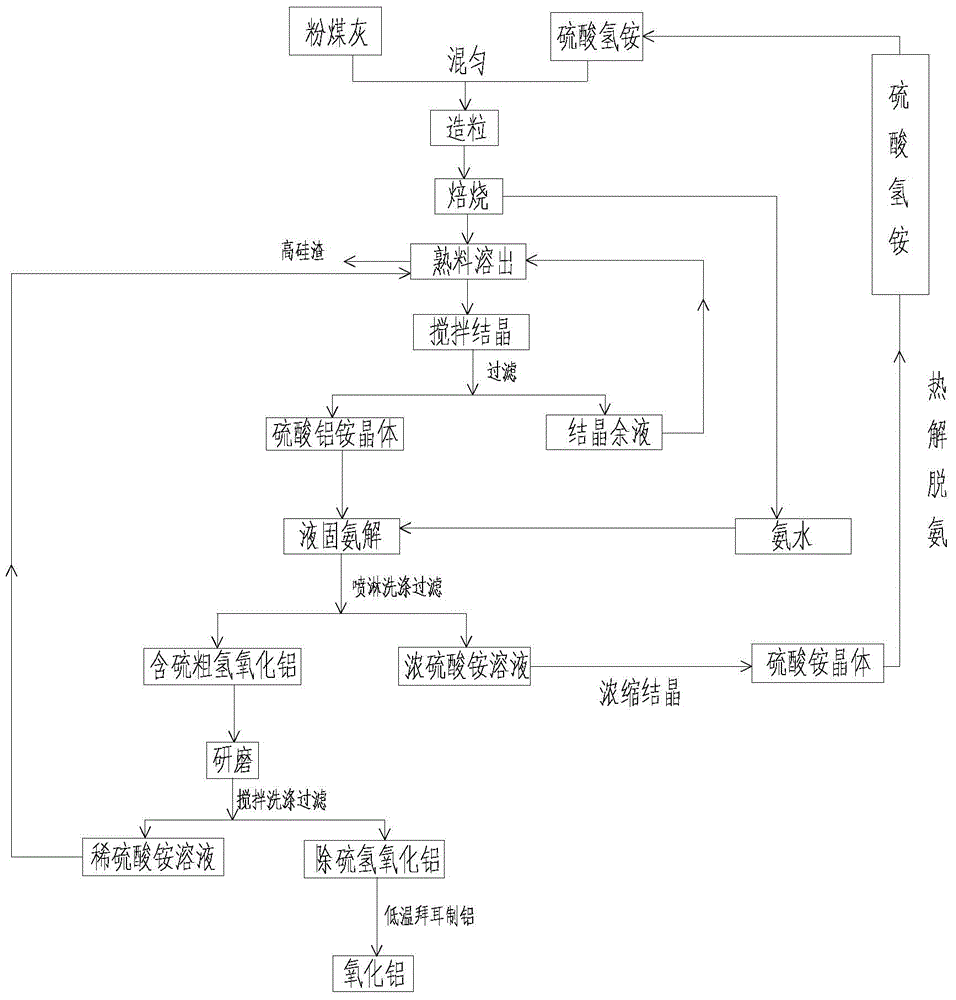

[0047] Embodiment 2: A method for producing metallurgical grade alumina using fly ash and recyclable ammonium salt as raw materials, which comprises the following steps: (1) material preparation; (2) roasting; (3) dissolution; (4) crystallization; (5) Liquid-solid ammonolysis reaction; (6) Grinding and desulfurization; (7) Low-temperature Bayer aluminum production; among them,

[0048] (1) Material preparation: Grinding and activating the fly ash, grinding it to 400 meshes, and grinding the fine fly ash and ammonium bisulfate according to the molar ratio of aluminum oxide and ammonium bisulfate contained in the fly ash to 1:7. Mix evenly, and then add water to granulate to form granular materials. The mass ratio of the mixed material composed of the fly ash and the ammonium bisulfate to the water is 100:8;

[0049] (2) Roasting: the granular material is calcined at 450° C. for 2 hours to generate calcined clinker and ammonia gas.

[0050] (3) Dissolution: The roasted clinker ...

Embodiment 3

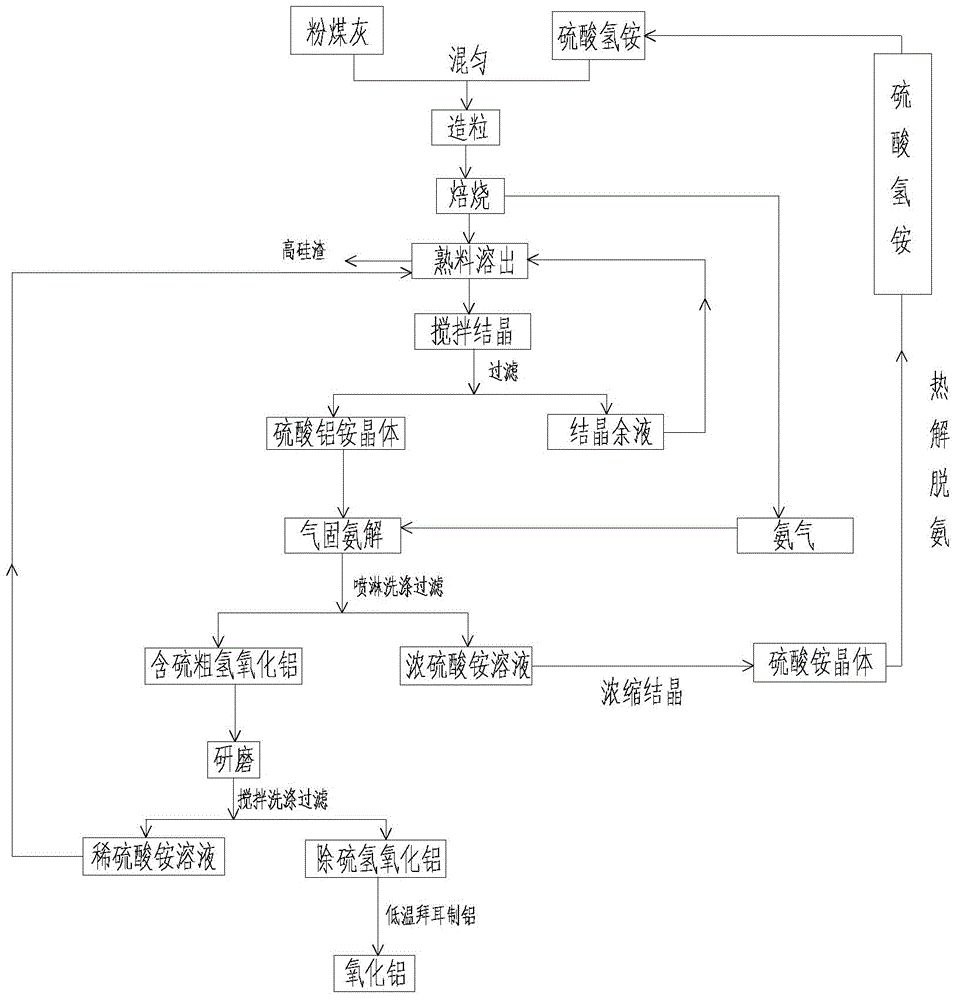

[0055] Embodiment 3: A method for producing metallurgical grade alumina using fly ash and recyclable ammonium salt as raw materials, which includes the following steps: (1) material preparation; (2) roasting; (3) dissolution; (4) crystallization; (5) Liquid-solid ammonolysis reaction; (6) Grinding and desulfurization; (7) Low-temperature Bayer aluminum production; among them,

[0056] (1) Material preparation: Grinding and activating the fly ash, grinding it to 300 mesh, and grinding the fine fly ash and ammonium bisulfate according to the ratio of 1:4.5 molar ratio of aluminum oxide and ammonium bisulfate contained in the fly ash Mix evenly, and then add water to granulate to form granular materials. The mass ratio of the mixed material composed of the fly ash and the ammonium bisulfate to the water is 100:5;

[0057] (2) Roasting: the granular material is calcined at 400° C. for 1.7 hours, and calcined clinker and ammonia gas are produced.

[0058](3) stripping: described r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com