Anti-corrosion and anti-scaling integrated control system and method for thermal equipment of power plant

A thermal equipment and control system technology, applied in control/regulation system, multiple fluid ratio control, non-electric variable control, etc., can solve problems such as fast rise in boiler pressure difference, high iron content in corrosion products, frequent regeneration of mixed beds, etc. , to achieve the effect of reduced control range and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

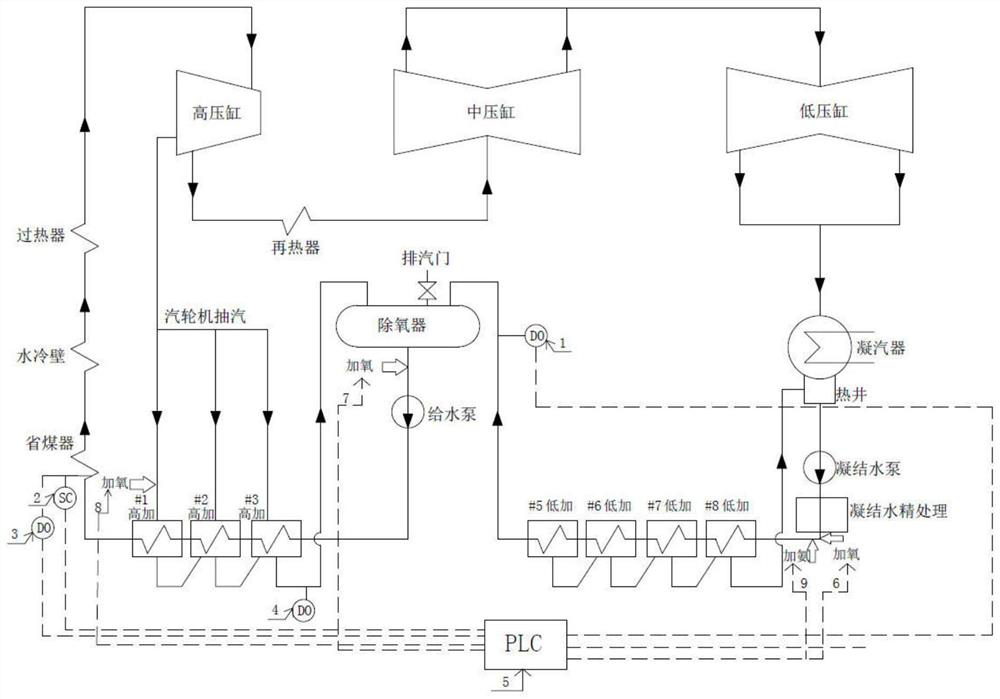

[0017] Such as figure 1 As shown, the present invention is an integrated anti-corrosion and anti-scaling control system for thermal equipment in a power plant, including an online dissolved oxygen meter 1 at the inlet of the deaerator, and an on-line meter for the inlet of the economizer on the inlet pipeline of the economizer. Conductivity table 2, online dissolved oxygen meter at the inlet of the economizer 3, high-pressure water-repellent online dissolved oxygen meter set on the high-pressure water drainage pipeline 4, condensate polishing outlet oxygen addition point on the condensate polishing outlet main pipe 6 . Deaerator downpipe feed water oxygenation point on the deaerator downpipe 7. High water and oxygen addition point on the high pressure drainage pipe 8. Condensate polishing outlet ammonia addition point on the condensate polishing outlet main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com