Nitrogen purification method

A purification method and nitrogen technology, applied in the direction of nitrogen purification/separation, etc., can solve the problems of reducing the water content of nitrogen, insufficient cooling, drying and dehydration, and inability to obtain high-purity nitrogen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

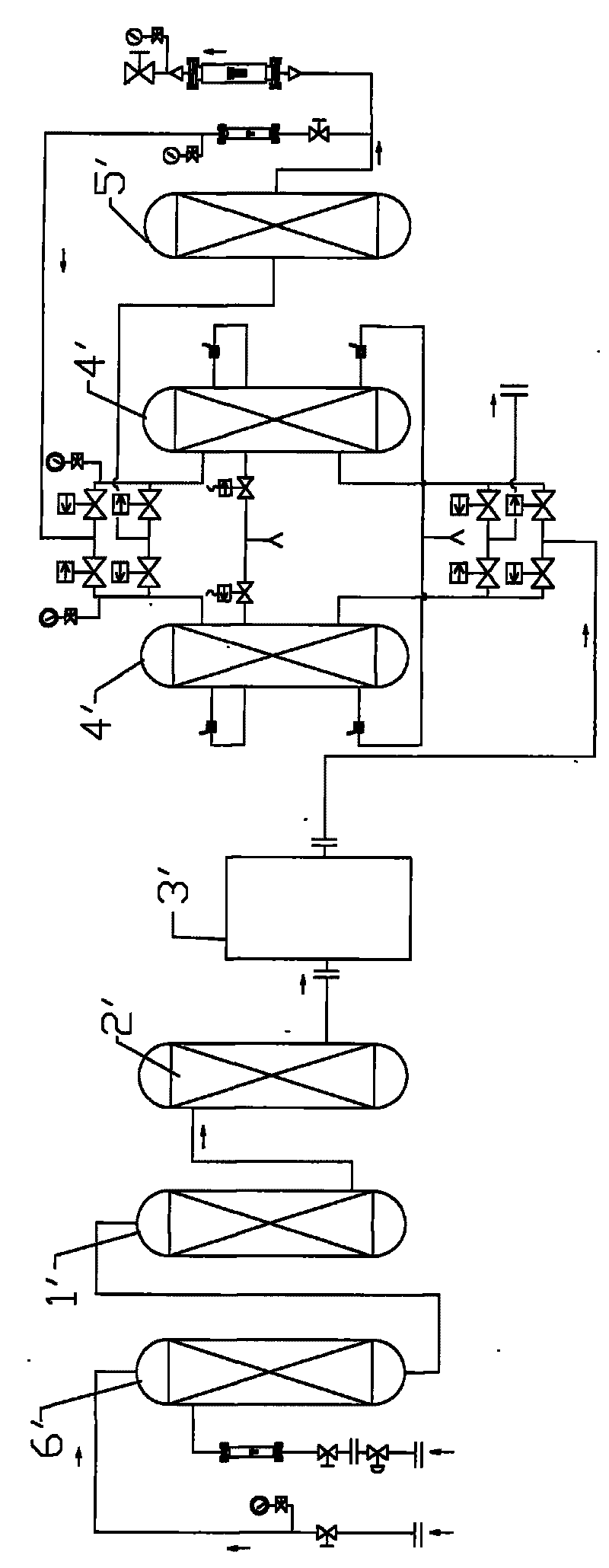

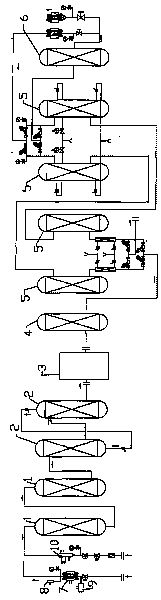

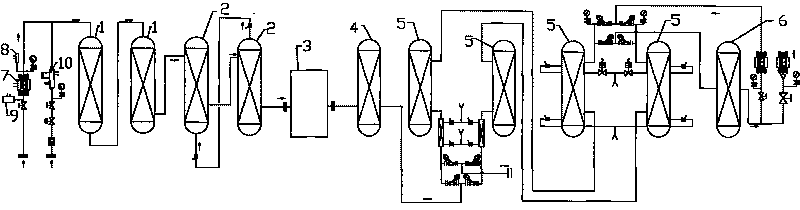

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] A method for purifying nitrogen, the method comprising the following steps: (1) Nitrogen and hydrogen mixed with oxygen impurities are input into a deaerator 1 through a pipeline, and there are multiple deaerators, and the multiple deaerators 1 are sequentially connected in series (2) Nitrogen is input into cooler 2 after multi-stage oxygen removal, and there are multiple coolers, and multiple coolers 2 are sequentially connected in series; (3) Nitrogen is input into cold dryer after multi-stage water removal In 3, nitrogen is freeze-dehydrated; (4) then nitrogen enters the steam-water separator 4 for further dehydration; (5) then nitrogen enters the drier 5, and there are multiple driers, which are divided into two groups, and the two groups of drier 5 alternate Circular work, each group has a plurality of dryers, and the plurality of dryers 5 are connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com