Patents

Literature

190results about How to "Reduce ammonia content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanobubble-containing liquid solutions

ActiveUS20160236158A1Quality improvementReduce ammonia contentNanostructure manufactureFlow mixersChemistryHigh concentration

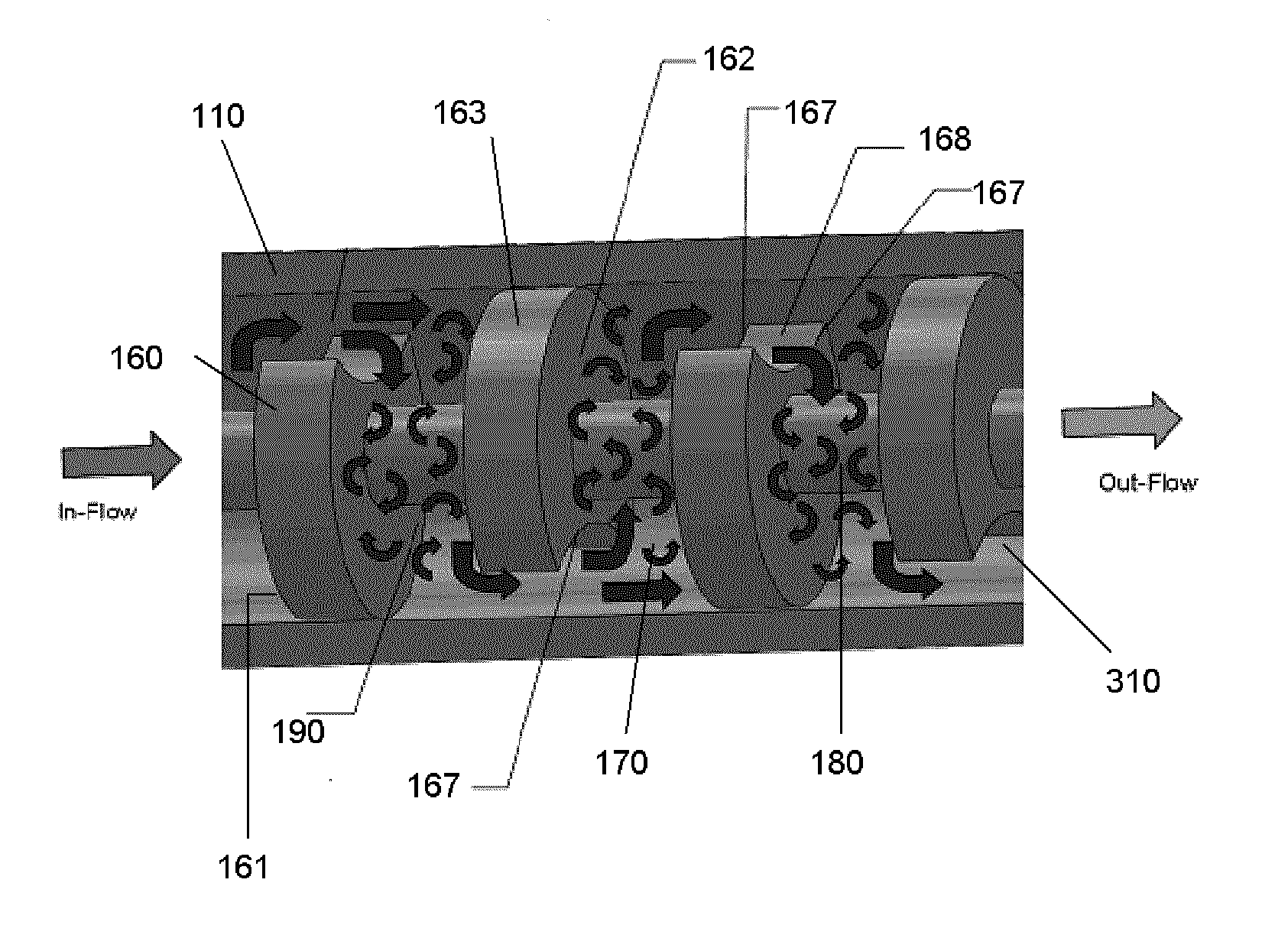

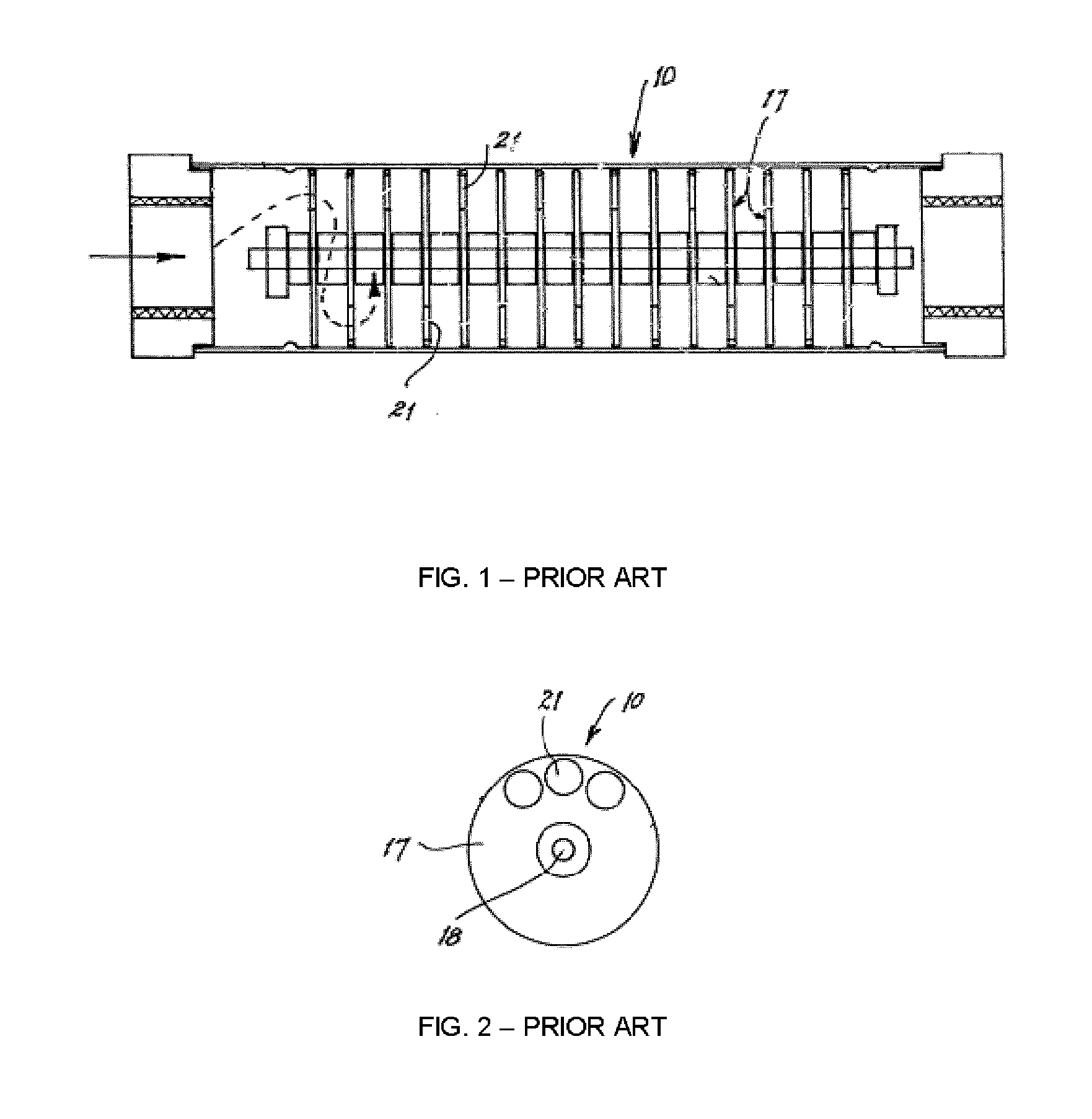

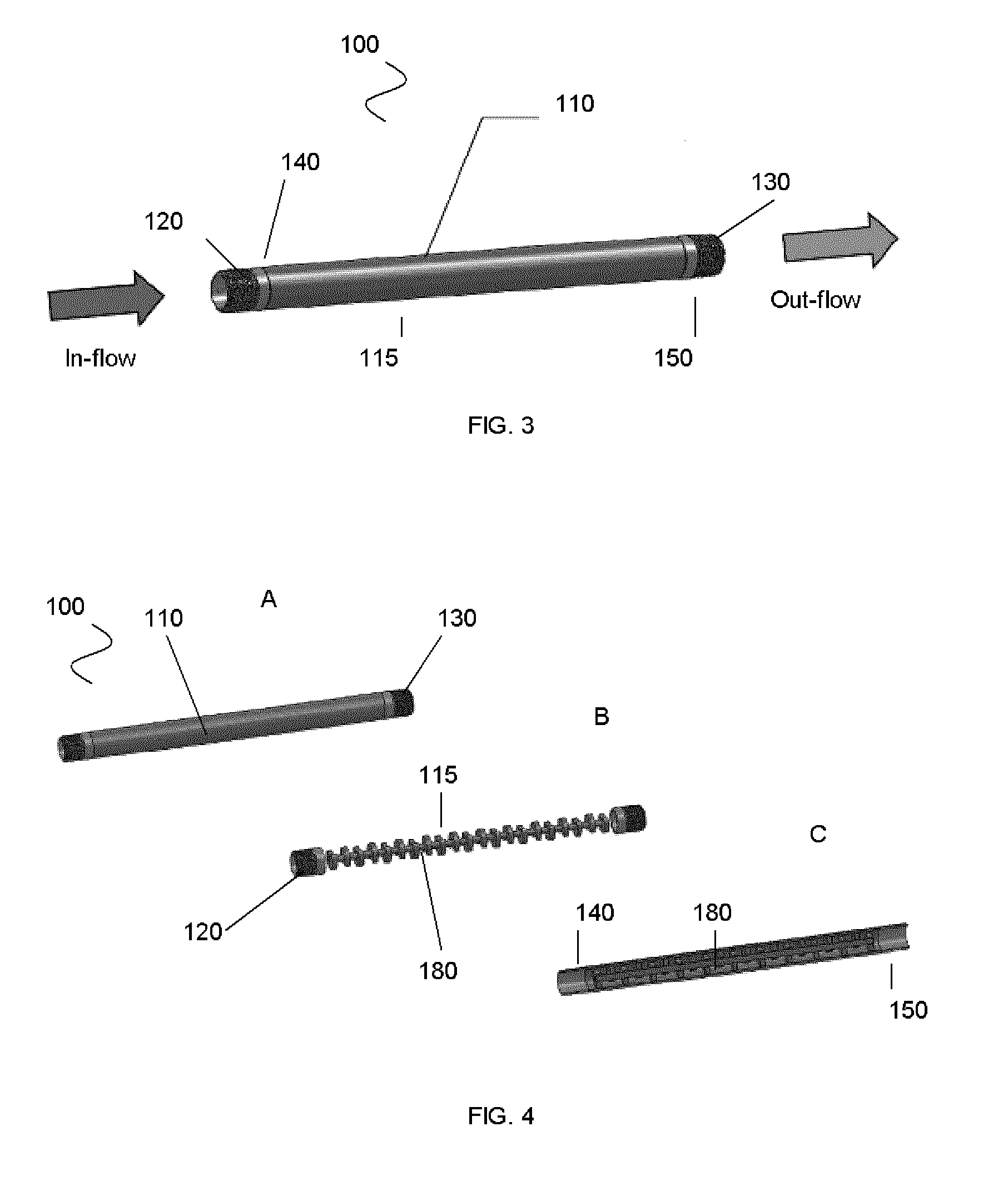

A nanobubble generator, a nanobubble-containing liquid solution comprising a substantially high concentration of nanobubbles, a system and methods of producing the nanobubble-containing liquid solution. The nanobubble generator includes an inflow portion for receiving a source liquid solution, a series of at least two sequential cavitation zones and shear planes to treat the source liquid solution and producing nano-bubble containing liquid solution, and an outflow portion for releasing the nanobubble-containing liquid solution.

Owner:EBED HLDG

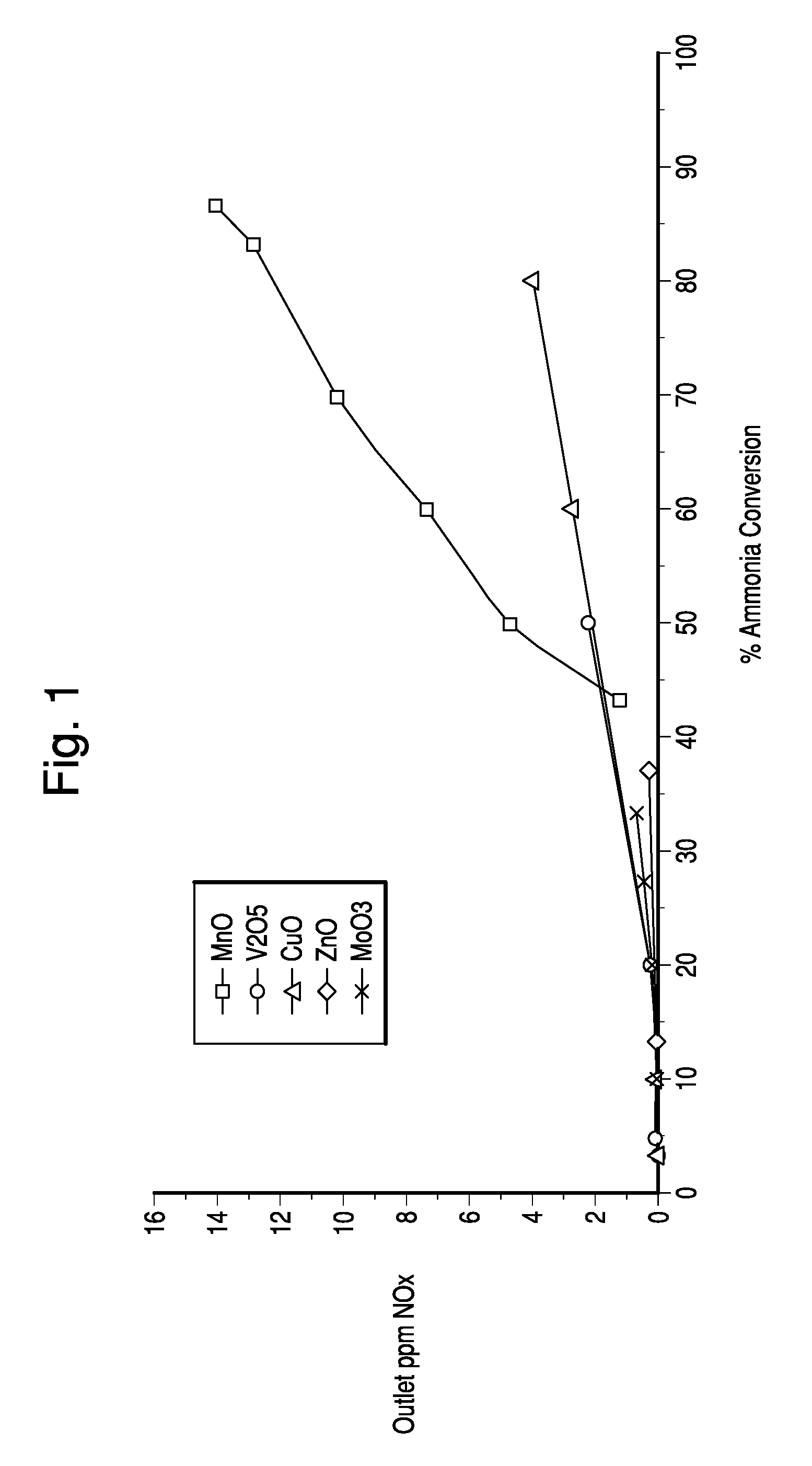

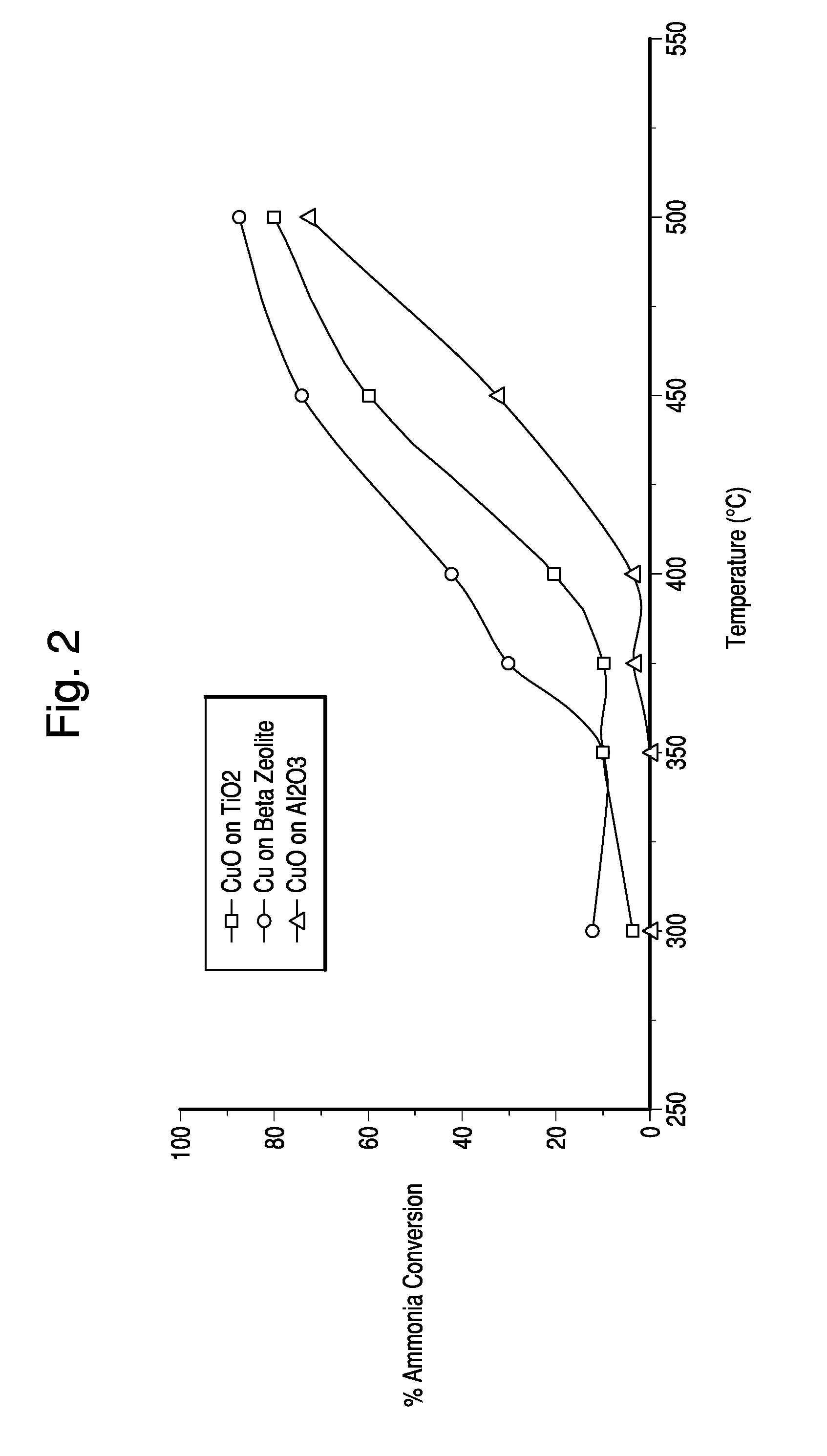

Ammonia Oxidation Catalyst for Power Utilities

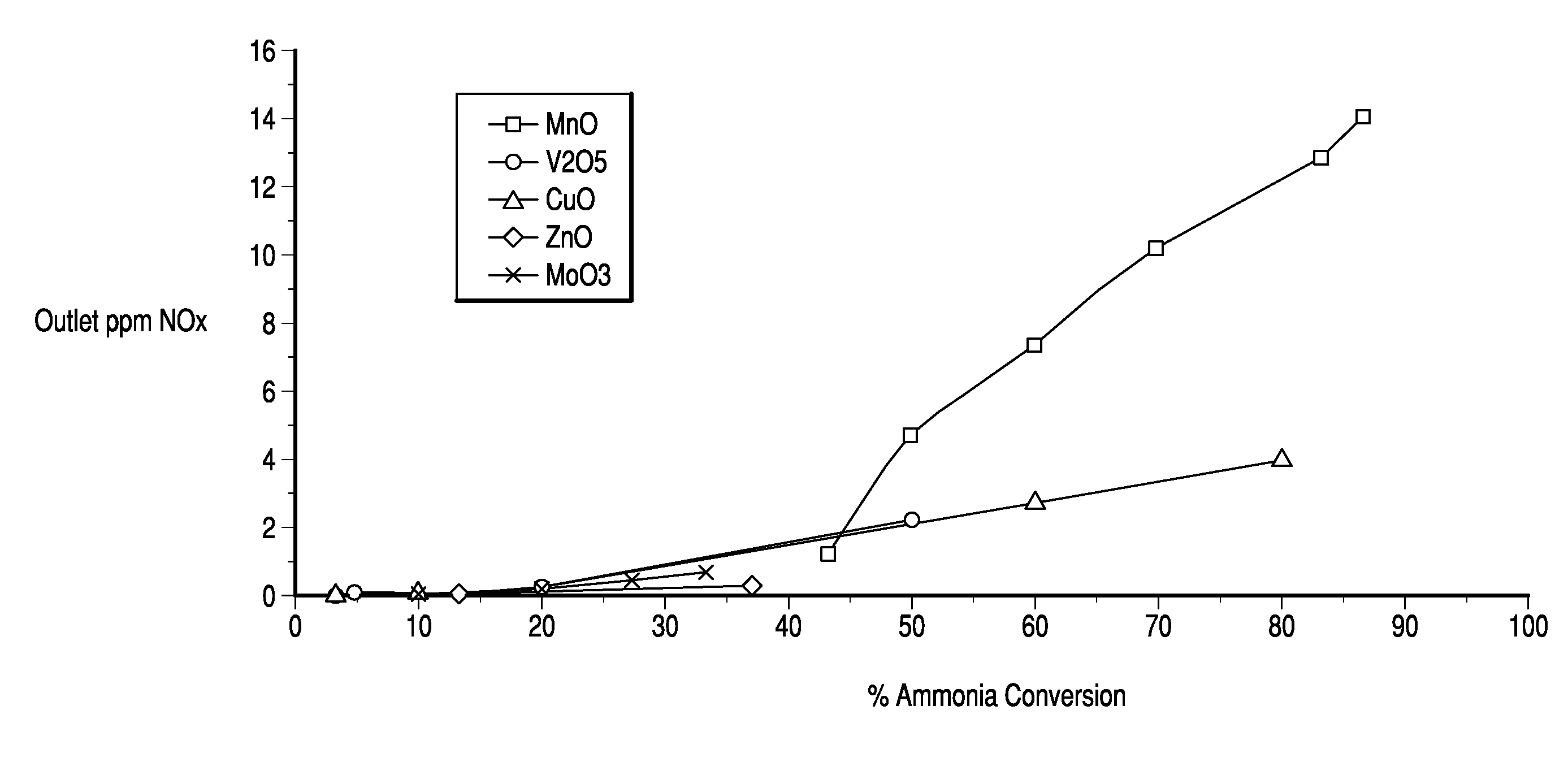

The present invention is directed to a method for removal by oxidation of the excess ammonia (NH3) gas (“ammonia slip”) resulting from flue gases that have been subjected to selective catalytic reduction (SCR) for reduction of nitrogen oxides (NOx) with ammonia. More specifically, the inventive method uses an ammonia oxidation catalyst consisting of a zeolite, one or more precious metals, and a base metal compound, to catalyze the oxidation of both ammonia and carbon monoxide (CO), while minimizing the formation of nitrogen oxides (NOx). The present invention is useful in treating flue and exhaust gases.

Owner:BASF CATALYSTS LLC

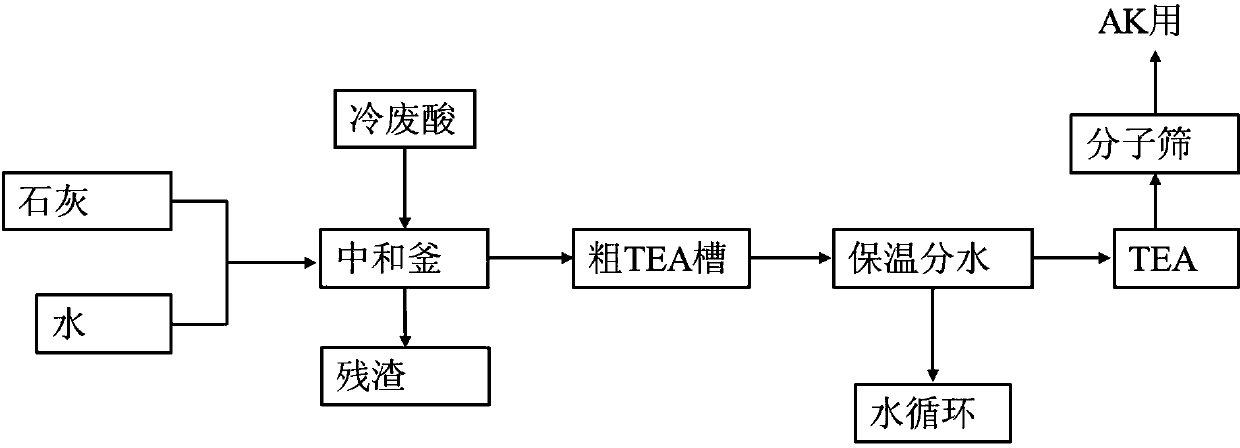

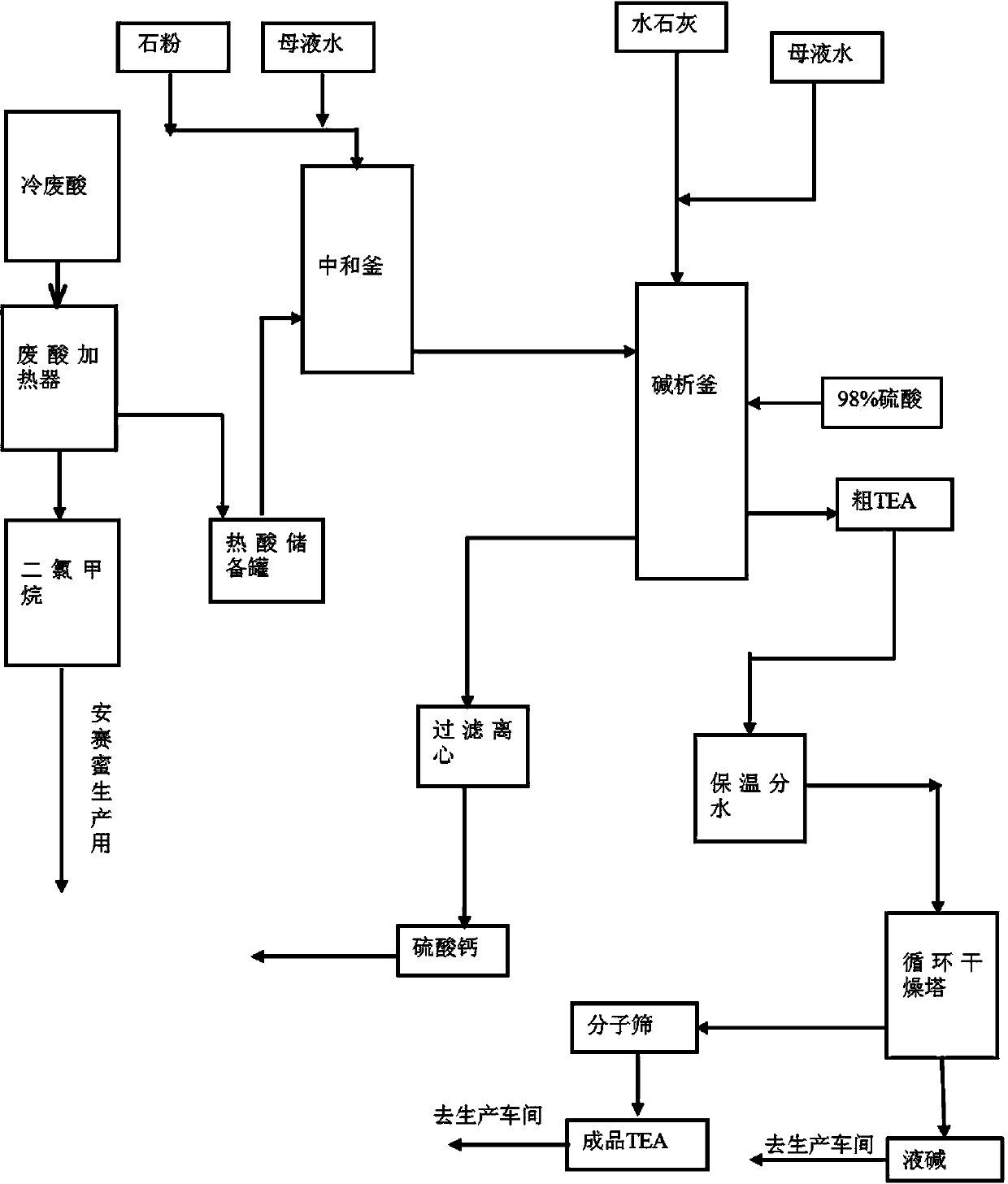

Recovery method of catalyst triethylamine in acesulfame potassium production

ActiveCN104193625ANo lossEfficient use ofAmino compound purification/separationCalcium/strontium/barium sulfatesPtru catalystMethylene Dichloride

The invention belongs to the technical field of acesulfame potassium production and relates to a recovery method of catalyst triethylamine in the acesulfame potassium production. A one-step one-kettle reaction is changed into a two-kettle three-step reaction, and the purpose of recovering triethylamine is achieved by the following steps: (1) preheating, and recovering methylene dichloride; (2) carrying out neutralization reaction; (3) reacting in an alkali separation kettle and dropwise adding sulfuric acid; (4) carrying out heat preservation and water distribution. Compared with a traditional method, the recovery method has the advantages that the recovery rate is greatly improved, the labor intensity of workers is reduced at the same time, and produced wastes also reach the environmental treatment standards.

Owner:ANHUI JINGHE IND

Two-stage hydrocracking method for high-nitrogen raw material

InactiveCN103102957AEffectively play an active roleReduce ammonia contentTreatment with hydrotreatment processesPtru catalystProcess engineering

The invention relates to a two-stage hydrocracking method for a high-nitrogen raw material. According to the method, high-nitrogen heavy distillate oil is used as a raw material, and two-stage process flow is employed; under hydrorefining conditions, the raw material heavy distillate oil and hydrogen are mixed and enter into a first-stage reaction zone which uses a hydrorefining catalyst, and an effluent of the first-stage reaction zone enters into a separation system; a separated liquid phase of the effluent of the first-stage reaction zone enters into a second-stage reaction zone with hydrogen, the hydrorefining catalyst and a hydrocracking catalyst are successively utilized along a flow direction of reaction materials in the second-stage reaction zone, and an effluent of the second-stage reaction zone enters into the separation system so as to obtain a hydrocracking reaction product. Compared with conventional two-stage hydrocracking technology, the method provided by the invention has the following advantages: process flow is more flexible, and more inferior raw materials can be processed. Compared with conventional one-stage tandem hydrocracking technology, the method can substantially improve processing capability of an apparatus. Moreover, the method can be carried out at mild conditions, which is favorable for increasing a running period of a hydrogenation apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Making method of biological fermentation bed for pig farming

InactiveCN102783424AHarmlessThe purpose of harmlessness is a pollution-freeAnimal feeding stuffAnimal housingMicroorganismAnimal science

The invention relates to livestock feeding technology, in particular to a making method of a biological fermentation bed for pig farming. Using the biological fermentation bed to farm pigs strictly sticks to the scientific process flow. Raw materials (such as sawdust and rice hull) and strain are mixed from top to bottom for three times and are picked for fermentation for about a week. Core temperature of padding reaches 60DEG C-85 DEG C and is kept for 3-5 days. Even pathogenic microbes included in the raw materials can be killed. As strongest pathogenic microbes survive tens of hours at most at 60 DEG C, healthy pigs entering the fermentation bed can grow more healthily.

Owner:张庆云

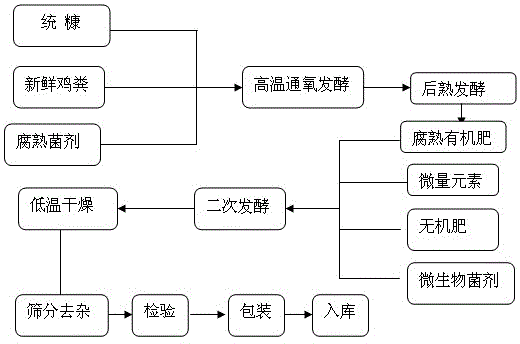

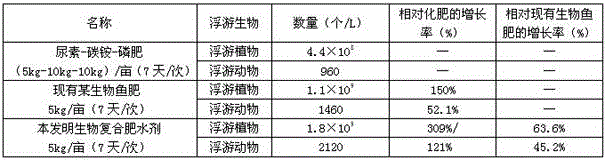

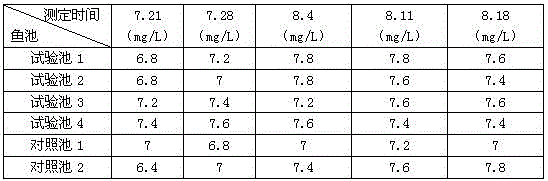

Biological composite fertilizer aqua and production method thereof

The invention relates to the technical field of biological fish guano and discloses a biological composite fertilizer aqua and a production method thereof. The biological composite fertilizer aqua comprises chicken manure / cow dung, unite bran, a decomposition microbial inoculum, inorganic fertilizer, domestic fungus slag, calcium superphosphate, trace elements, soybean meal / rapeseed meal, bacillus subtilis, actinomyces and photosynthetic bacteria as raw materials. The production method comprises the following steps of carrying out mixing fermentation on chicken manure / cow dung, unite bran and a decomposition microbial inoculum to obtain thoroughly decomposed organic fertilizer, fully mixing the thoroughly decomposed organic fertilizer and other raw materials, and carrying out secondary fermentation, drying and split charging. The biological composite fertilizer aqua is efficient, superior and eco-friendly fish guano which is obtained by combination of a plurality of beneficial microbial florae, organic fertilizer and inorganic fertilizer and is added with a plurality of medium trace elements. The production method of the biological composite fertilizer aqua is simple, has simple and easily-controllable processes and has a low cost. The biological composite fertilizer aqua has good quality, can fast improve water fertility and purify water, realizes combination of fertilizer and feed, has high comprehensive income, improves fish immunity and improves product quality.

Owner:HUBEI INFLAMMATION AGRI BIOTECH

Manifold microbe mixed culture fermentation agent and method for producing high energy protein biology feedstuff

InactiveCN101390566AEnsure safetyConducive to preservationFood processingAnimal feeding stuffBiotechnologyPropanoic acid

The invention relates to the biological fermentation technology, in particular to a compound microbial starter, and a method which uses the compound microbial starter to produce high-energy protein biological feed. The compound microbial starter selects cellulomonas sp dinitrogen, cellulomonas flavigena, condensate bacillus, lactobacillus acidophilus, bacillus subtilis, lactobacillus starch, compound enzyme bacteria, propionic acid bacteria, candida yeast, saccharomyces diastaticus, saccharomyces cerevisiae, as well as aroma-producing yeast as the bacteria sources, and makes use of the modern biotechnology to prepare various microbial agents; the microbial agents are then treated with anaerobic fermentation with the discarded sweet corn cobs, corn stalks, pea skins, abandoned vegetables and other discarded crops, so as to obtain the high-energy protein biological feed required in livestock and poultry breeding industry. The invention solves the problem of low utilization rate of crop resources; and the high-energy protein biological feed can improve the palatability of feed, increase the enzyme content of the feed, provide an effective way for developing the animal husbandry and solving the food conflicts between people and livestock, as well as reduce the pollution to the environment caused by the traditional crop waste burning.

Owner:TANGSHAN SENA BIOLOGY TECH SERVICING

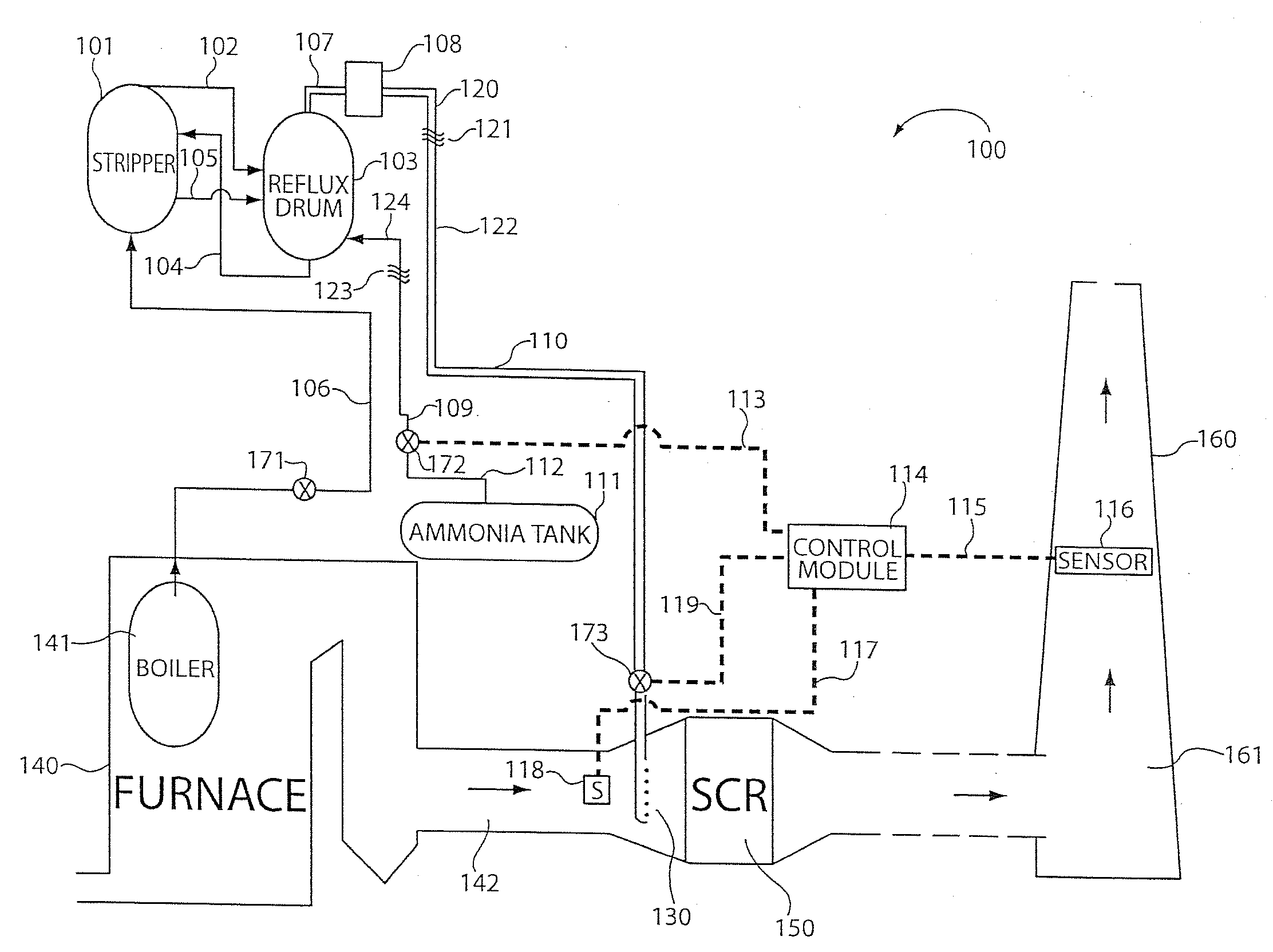

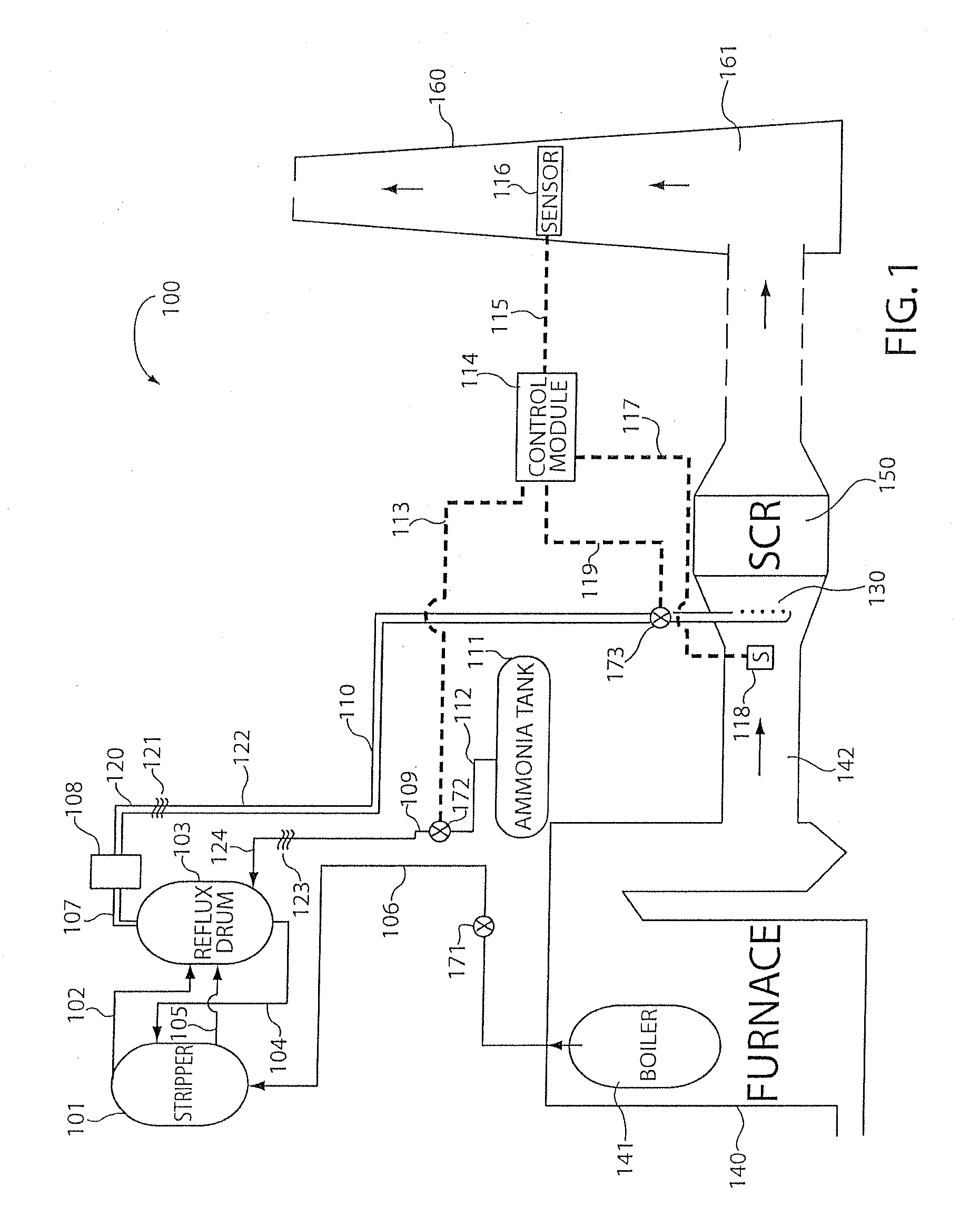

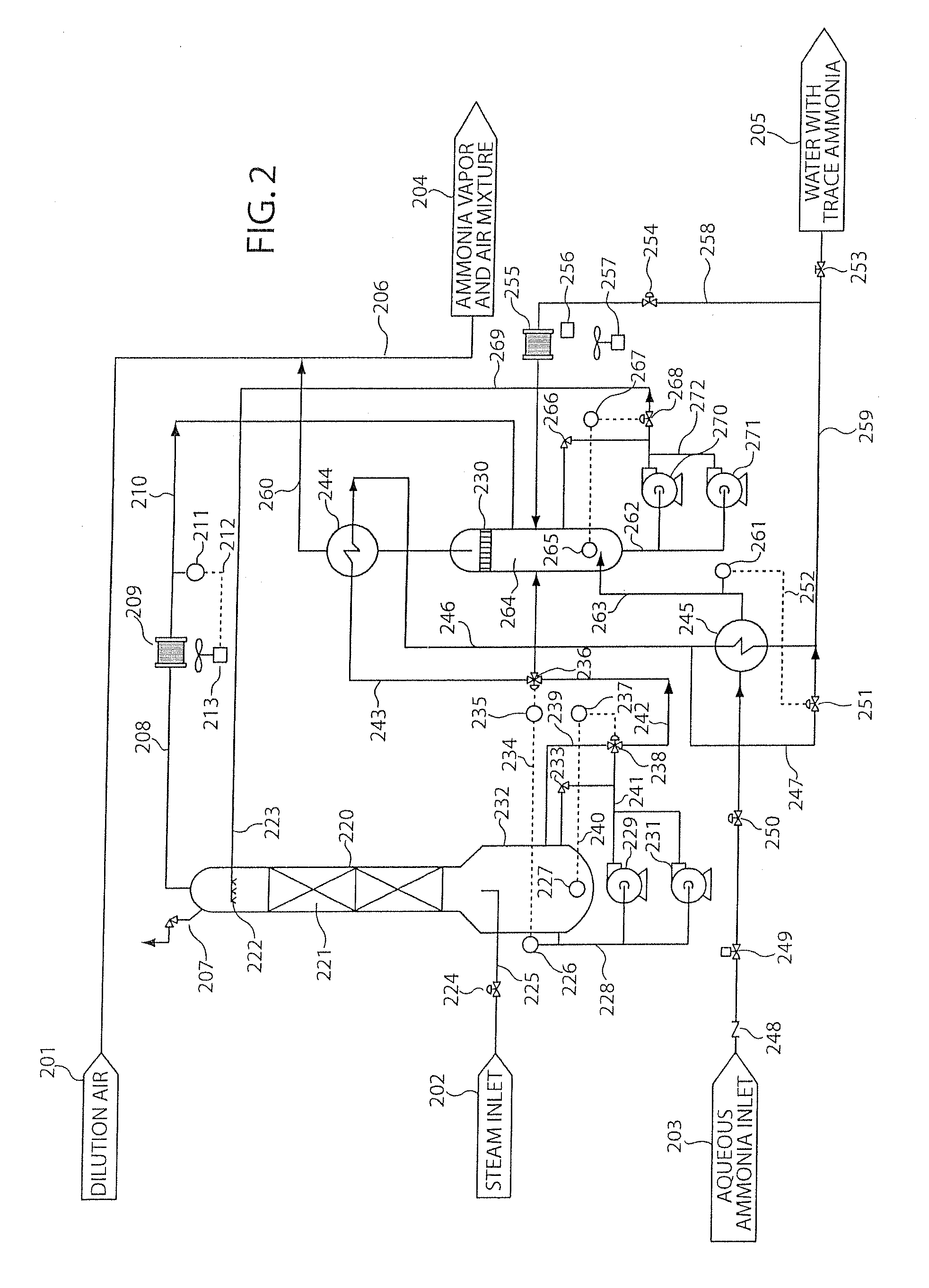

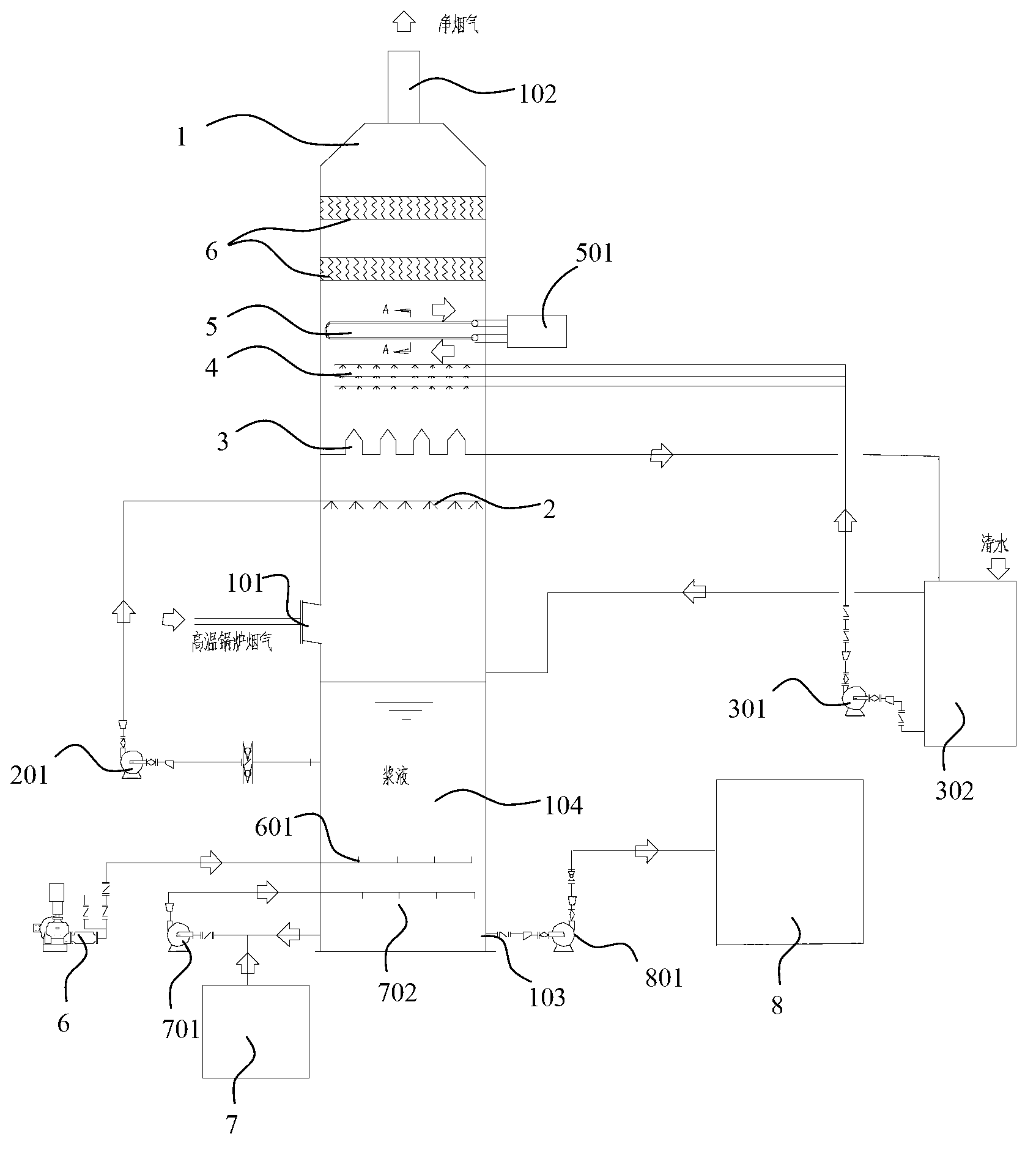

SEPARATION OF AQUEOUS AMMONIA COMPONENTS FOR NOx REDUCTION

InactiveUS20080196588A1Efficient implementationAchieve energy efficiencyGas treatmentLiquid degasificationFlue gasPhysical chemistry

Methods and apparatus for generating a vapor to be injected into a flue gas stream are described. Apparatus comprises a fluid vaporization and injection assembly further comprising: a stripper for producing first ammonia vapor and a first aqueous ammonia solution from a second aqueous ammonia solution; a reflux tank for producing a second ammonia vapor and the second aqueous ammonia solution from the first ammonia vapor and the first aqueous ammonia solution; and a first outlet for outputting the second ammonia vapor for introduction into the flue gas.

Owner:HITACHI POWER SYST AMERICA

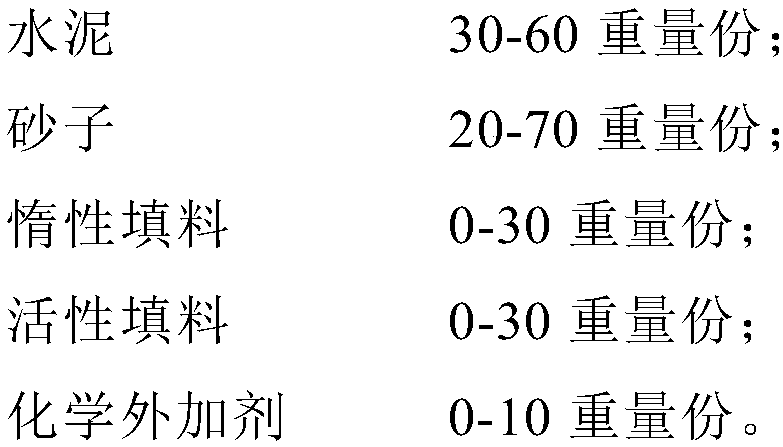

Environmentally-friendly odor removing dual-component cement-based waterproof material

InactiveCN107686297APromote environmental protectionGood physical propertiesChemical admixtureAmmonia

The invention discloses an environmentally-friendly odor removing dual-component cement-based waterproof material, which is prepared from the following ingredients in parts by weight: 1 part of liquidmaterial ingredient and 1-6 parts of powder material ingredient, wherein the powder material ingredient comprises cement, sand, inert filler, active filler and chemical additive; the liquid materialingredient comprises polymer emulsion, defoamer, bactericide and water. The environmentally-friendly odor removing dual-component cement-based waterproof material has the characteristics of extremelylow ammonia content, odor removal, good environment protection performance, good physical performance, good construction hand feeling and convenience in use and is suitable for various construction technologies including spraying, rolling and brushing, and VOC (volatile organic compounds), formaldehyde and harmful heavy metal powder can not be detected.

Owner:NIPPON PAINT CHINA

Hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil

ActiveCN104611037AEffectively play an active roleBroaden sources of raw materialsTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenNitrogen

The present invention discloses a hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil. According to the method, poor-quality heavy distillate oil and hydrogen gas enter a first-stage reaction zone to carry out a hydrorefining reaction, the reaction effluent is separated, the obtained liquid enters a second-stage reaction zone to carry out a hydrorefining reaction, the second-stage reaction effluent enters a third-stage reaction zone to carry out a hydrocracking reaction, the hydrocracking effluent is separated, and at least part of the tail oil and new hydrogen are mixed and then are subjected to an isomerizing dewaxing and finishing reaction to obtain various lubricating oil base oils. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the hydrorefining temperature is substantially reduced so as to increase the operation period of the device and process the poor-quality raw material, or increase the processing capacity of the device in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

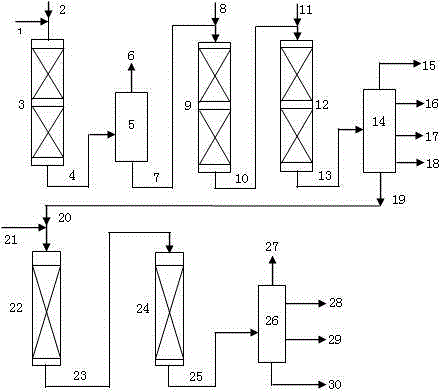

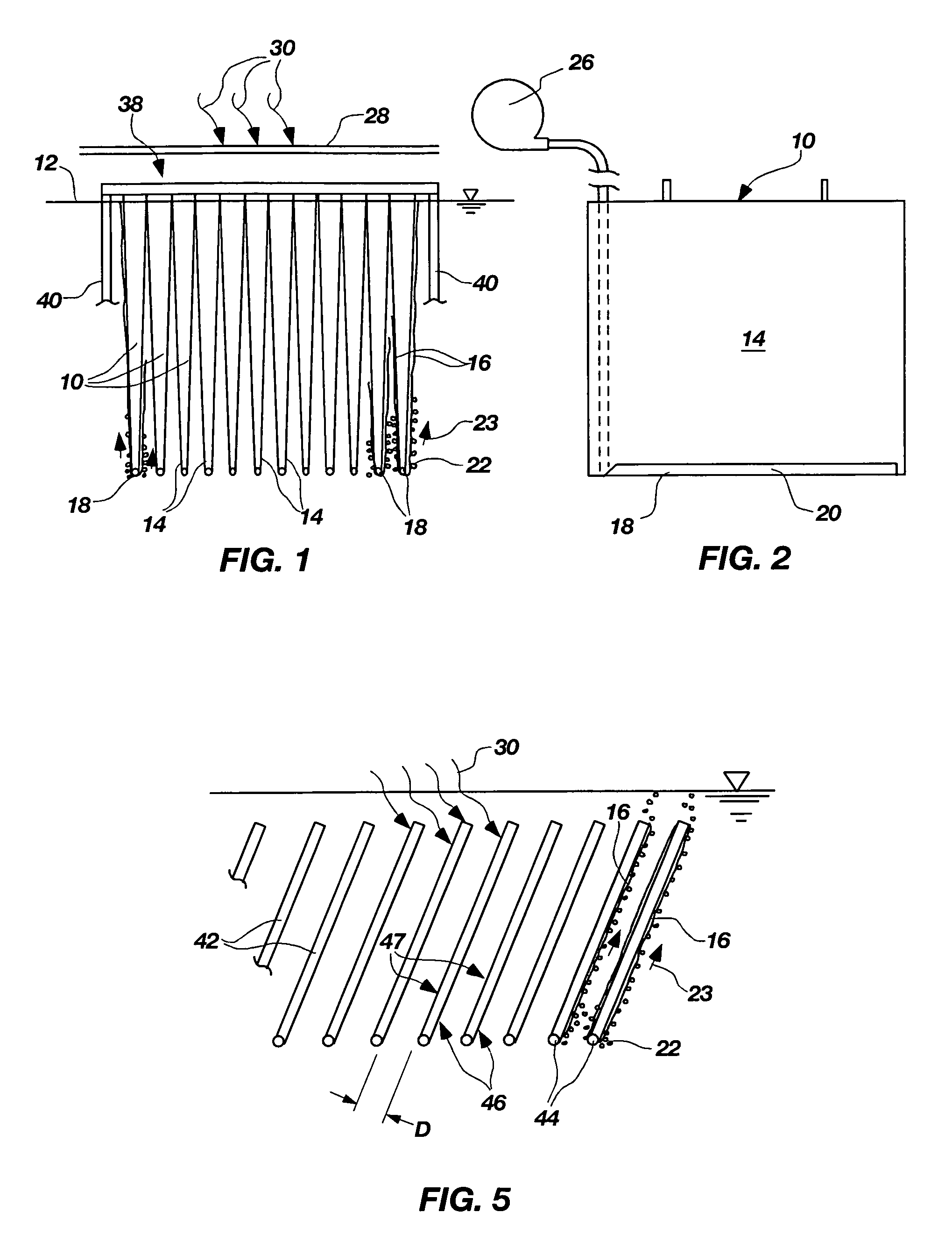

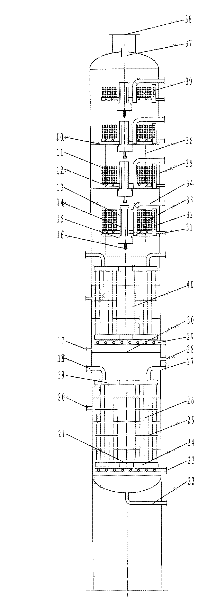

Submerged ammonia removal system and method

ActiveUS7008539B2Simple and reliable systemReduce ammonia contentTreatment using aerobic processesWater contaminantsChemistryAir bubble

A system and method for reducing the content of ammonia in water provides a submerged surface having a growth of nitrifying bacteria thereon. An aeration system creates air bubbles that travel along the surface as they rise to create aerobic conditions on the surface, and to circulate the water along the surface to allow the nitrifying bacteria to remove ammonia from the water.

Owner:UNIV OF UTAH RES FOUND

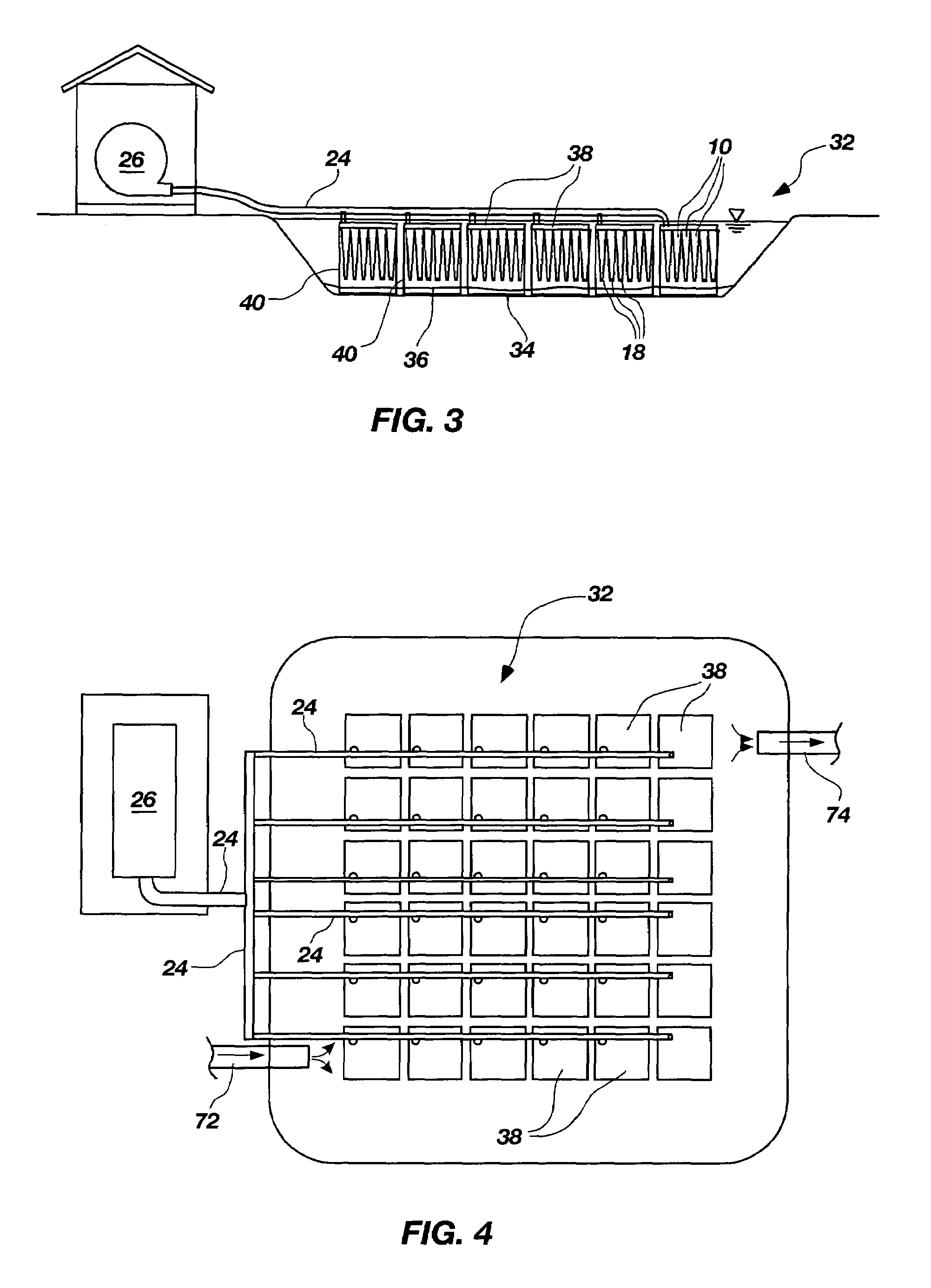

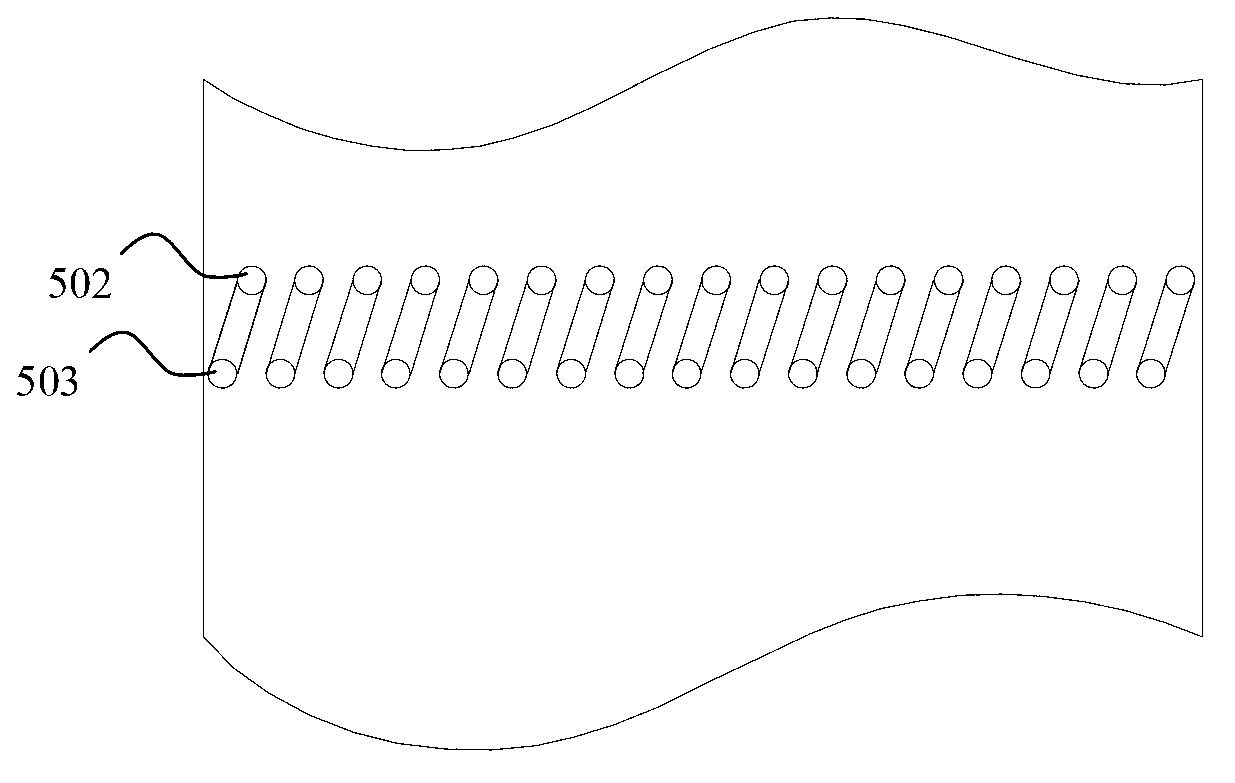

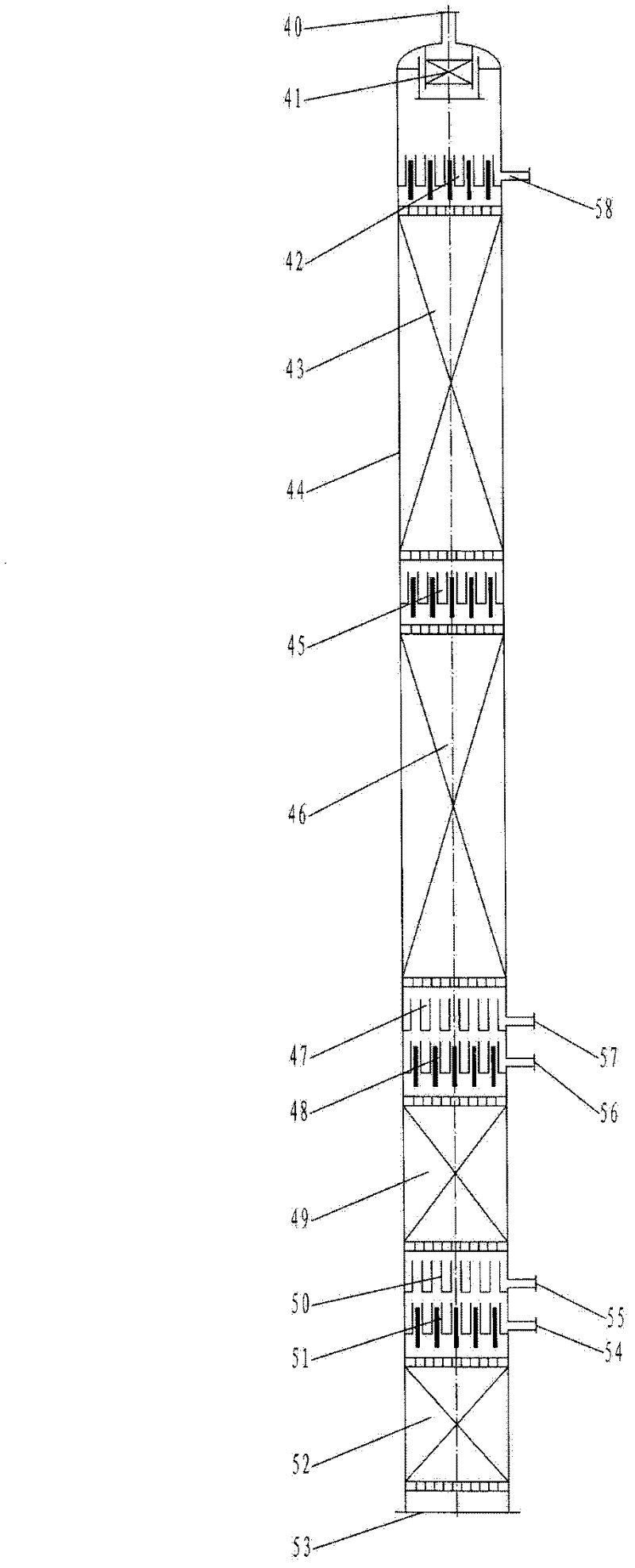

Desulfurization system and desulfurization process thereof

InactiveCN103252158AReduce consumptionUniform flow rateDispersed particle separationEscape rateSaturated water vapor

The invention discloses a desulfurization system comprising a tower body, wherein a smoke inlet is arranged in the middle of the tower body; a pure smoke outlet is arranged at the top of the tower body; a slurry pool for containing slurry is formed on the lower part of the tower body; the slurry pool is provided with a mixed liquid outlet; a slurry spraying layer, a rising air gap and a clean water spraying layer are sequentially arranged from the smoke inlet to the pure smoke outlet from bottom to top; the bottom of the slurry pool is respectively connected with an oxidization mechanism and an ammonia supplying mechanism; and the desulfurization system further comprises a slurry circulating mechanism and a clean water circulating mechanism. The invention further provides a desulfurization process; and the process is low in water consumption amount so that the amount of saturated steam in pure smoke is reduced by 30-40% and consumption of external clean water is reduced. According to the desulfurization system and the desulfurization process disclosed by the invention, the operation cost is low; and the consumption of the steam is 20% of that of an ammonia-fertilizer method process and the consumption of power is 40% of that of the ammonia-fertilizer method process. The escaping rate of ammonia is low; the content of the ammonia in the pure smoke is less than 8mg / Nm<3>; no three wastes are discharged; and secondary pollution to an environment is not caused.

Owner:九美科技有限公司

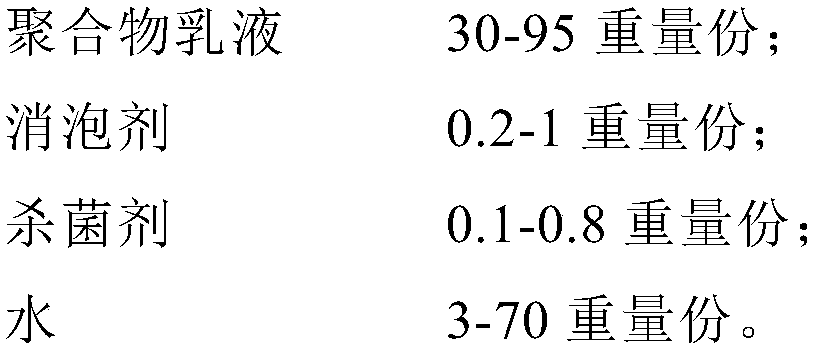

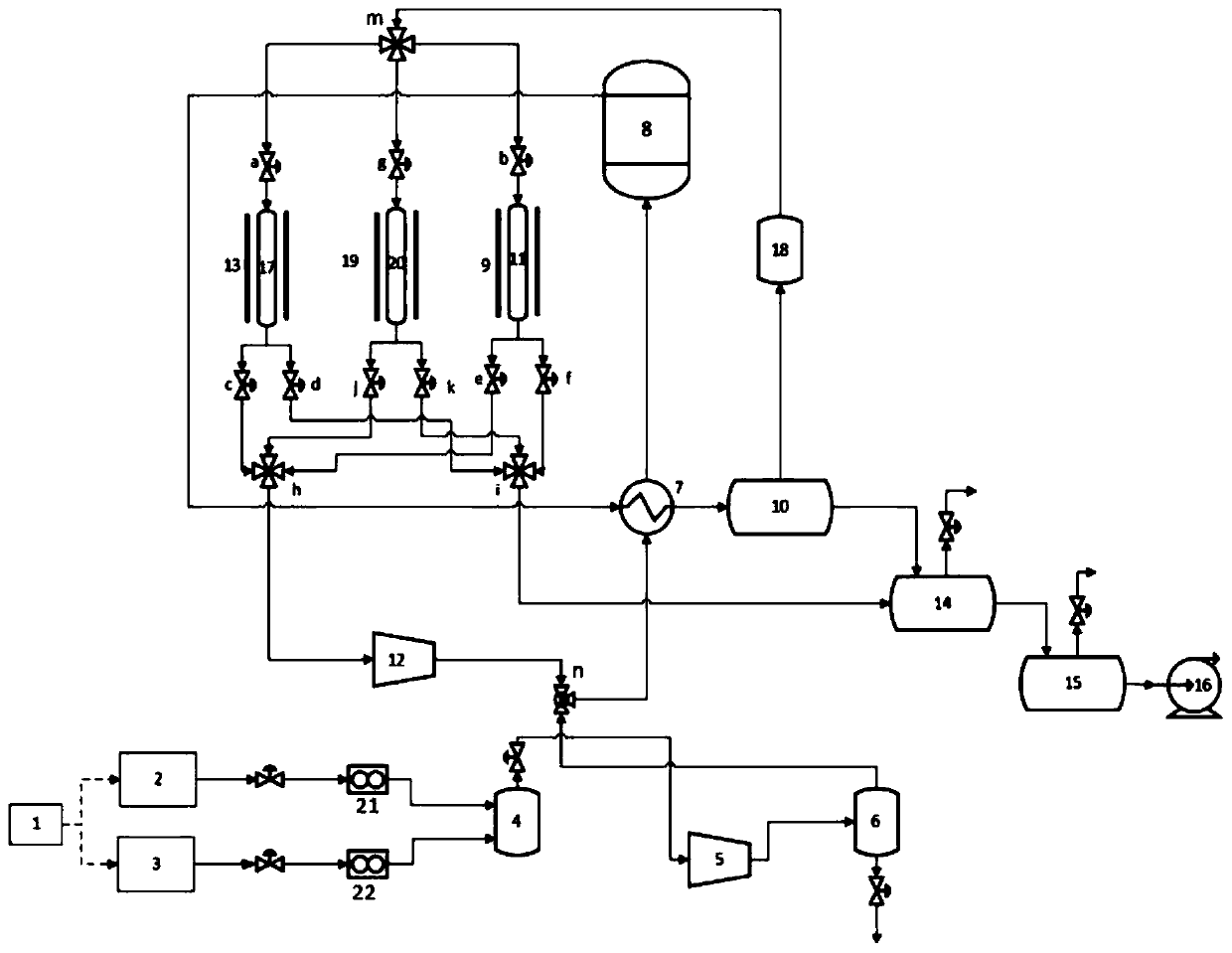

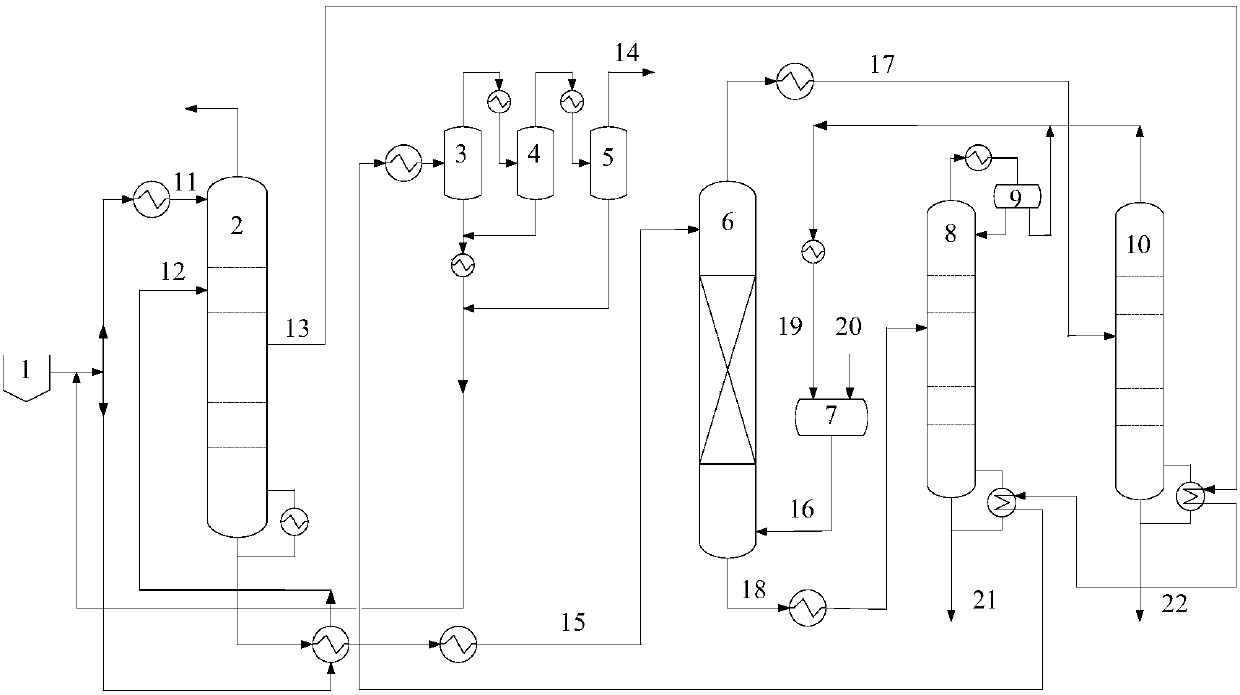

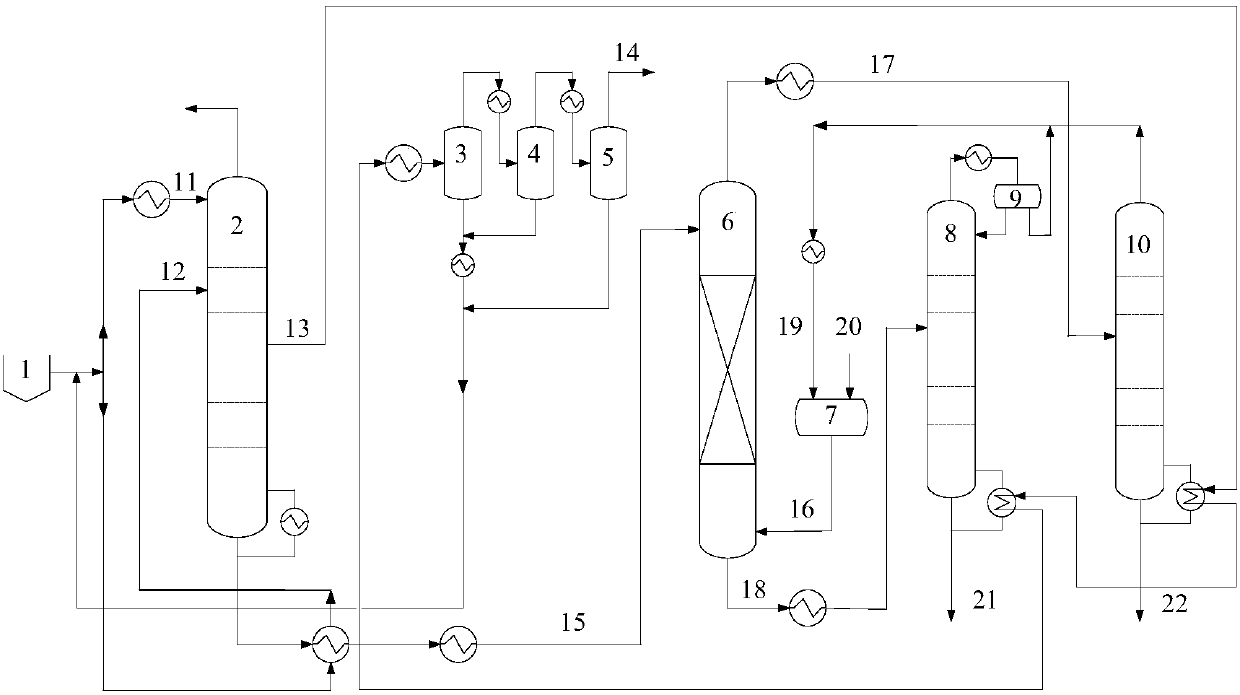

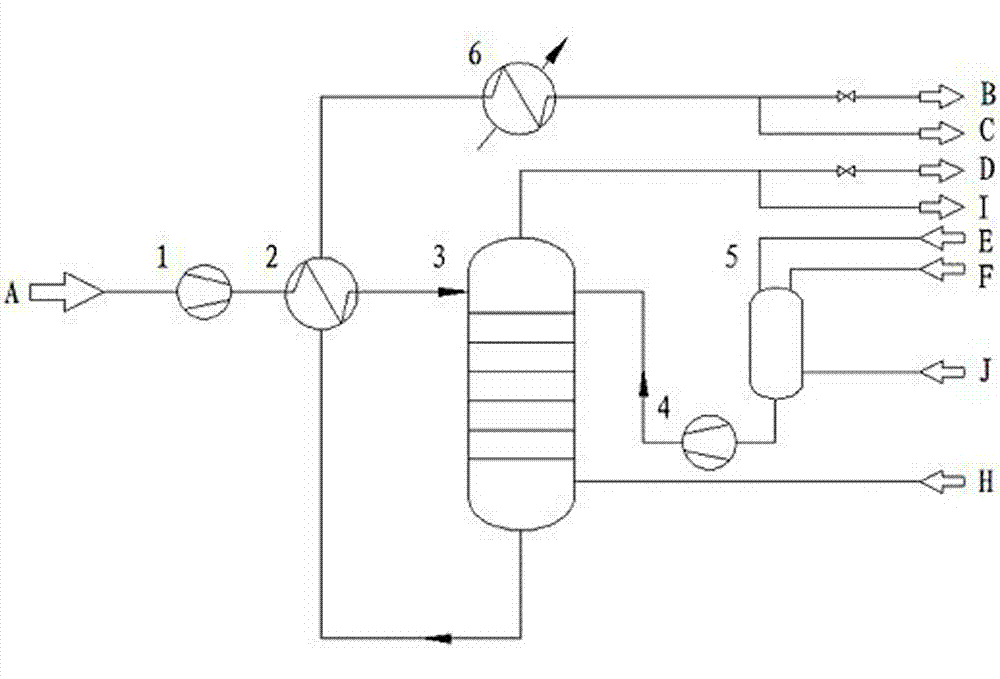

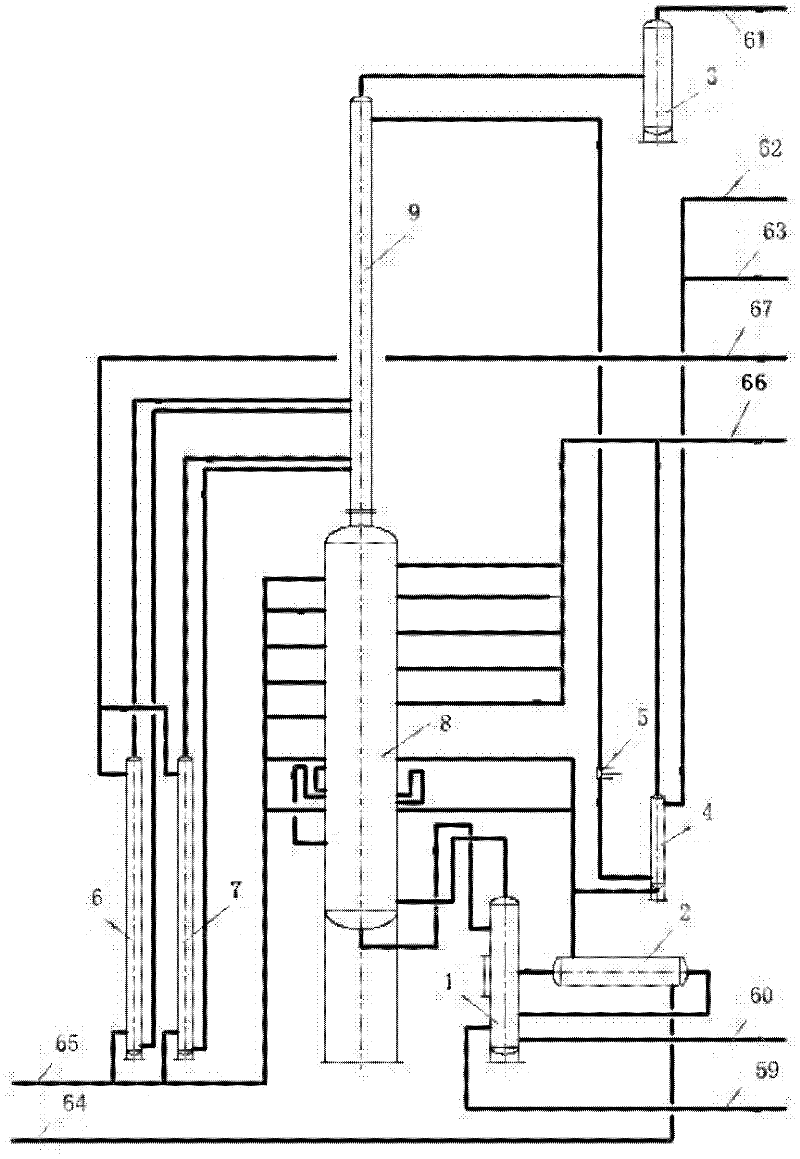

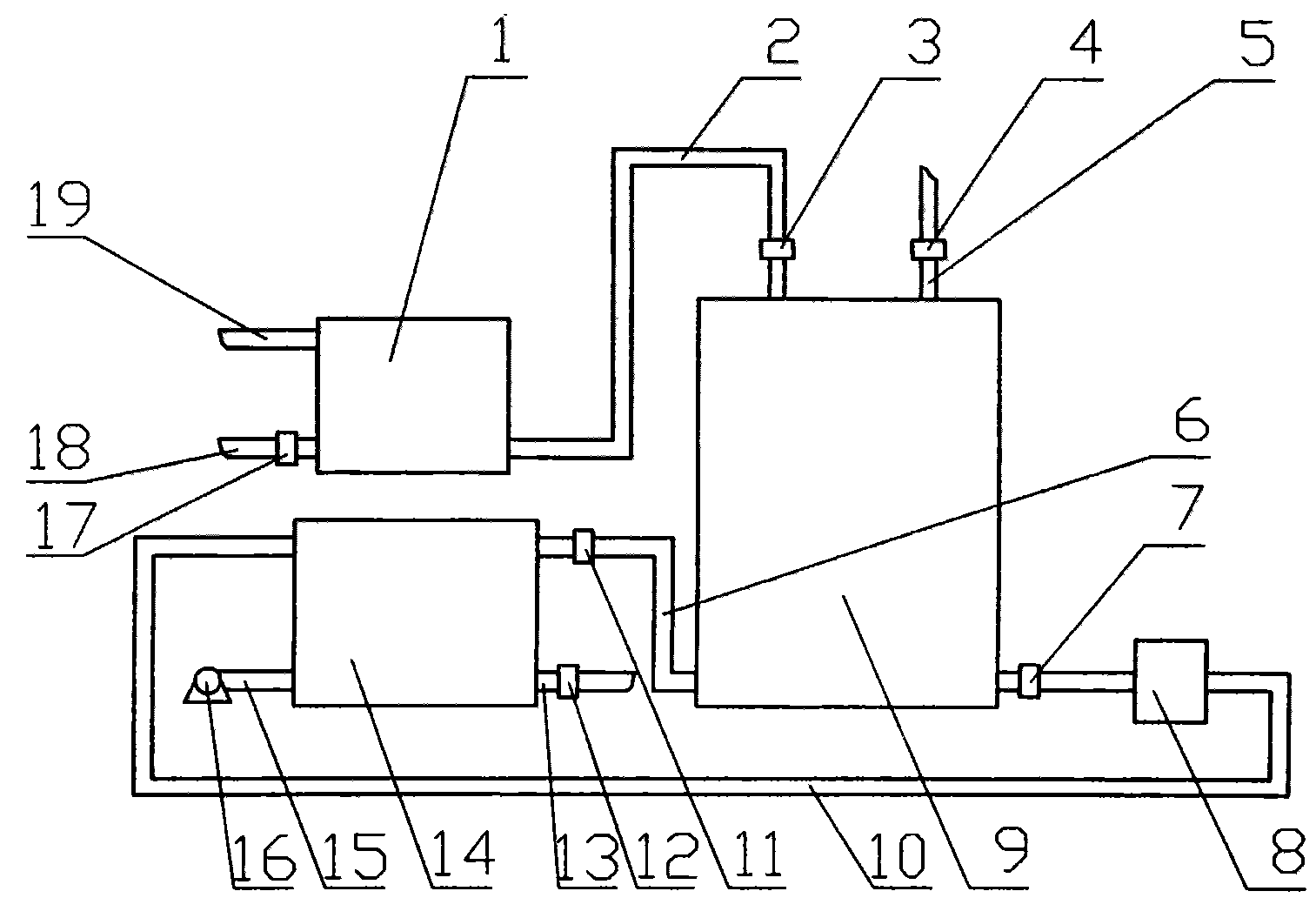

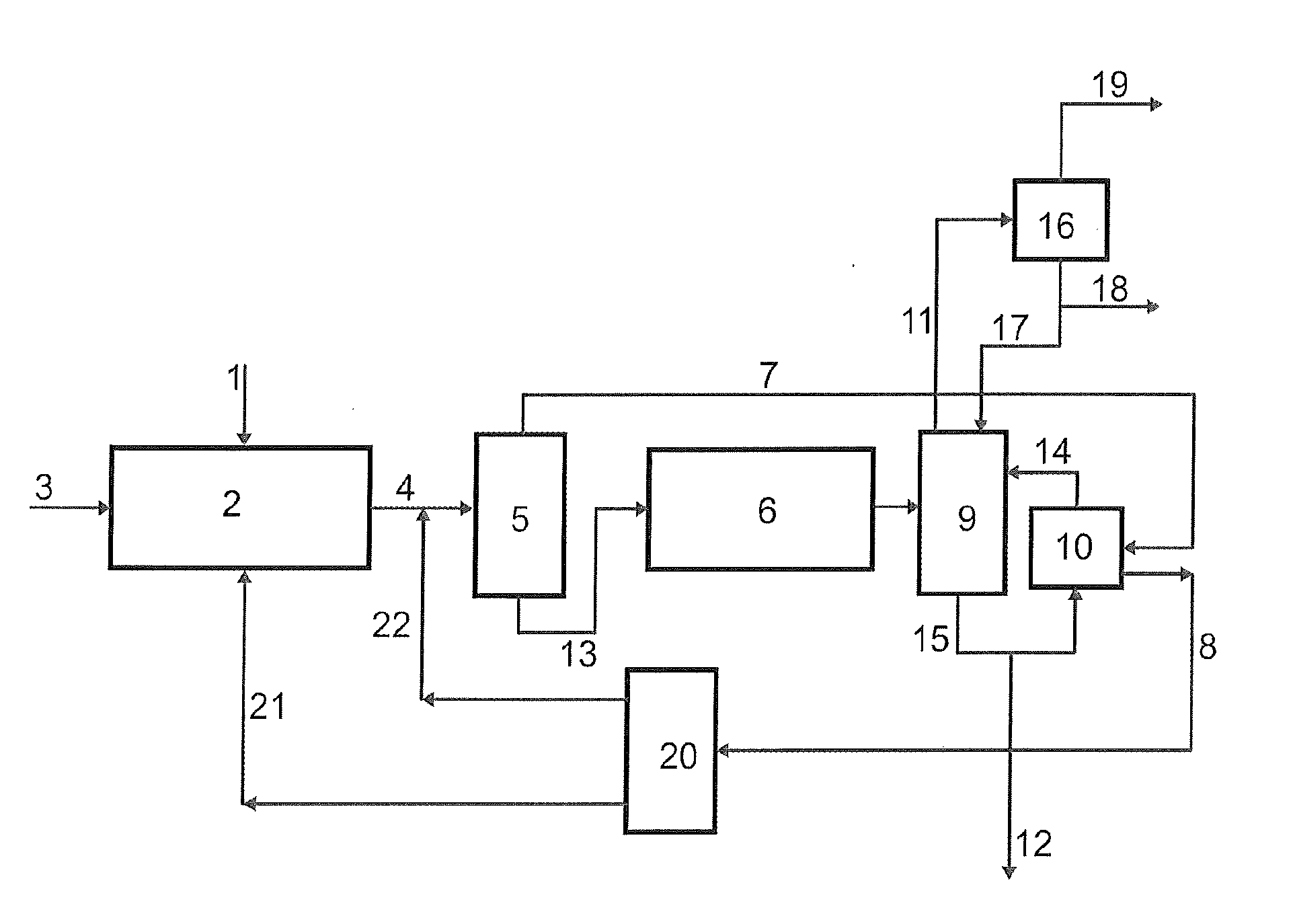

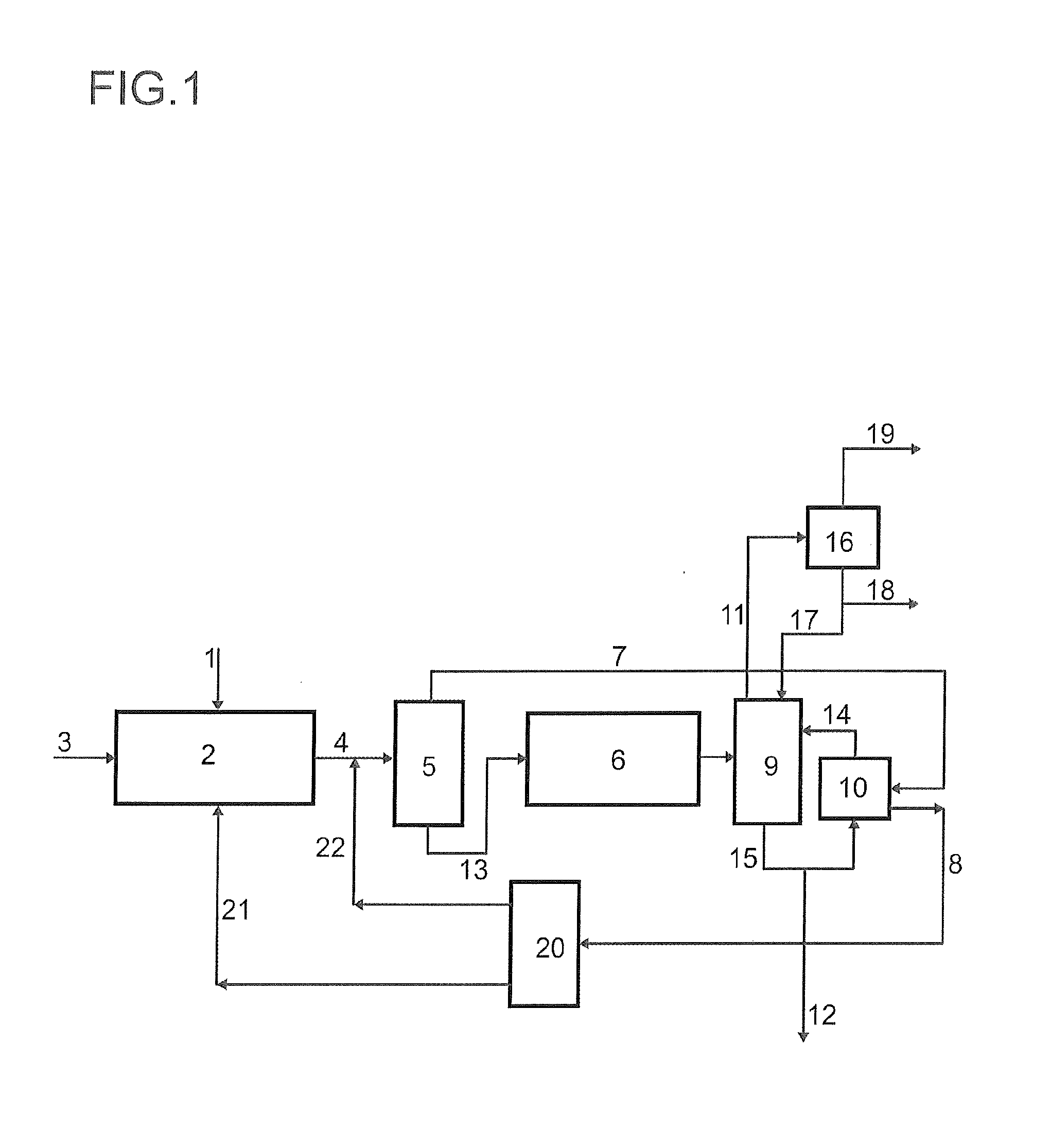

Renewable energy synthesis ammonia device and method

ActiveCN111498868AAchieve productionSmall scaleNitrogen purification/separationElectrolysis componentsMicrogridNitrogen gas

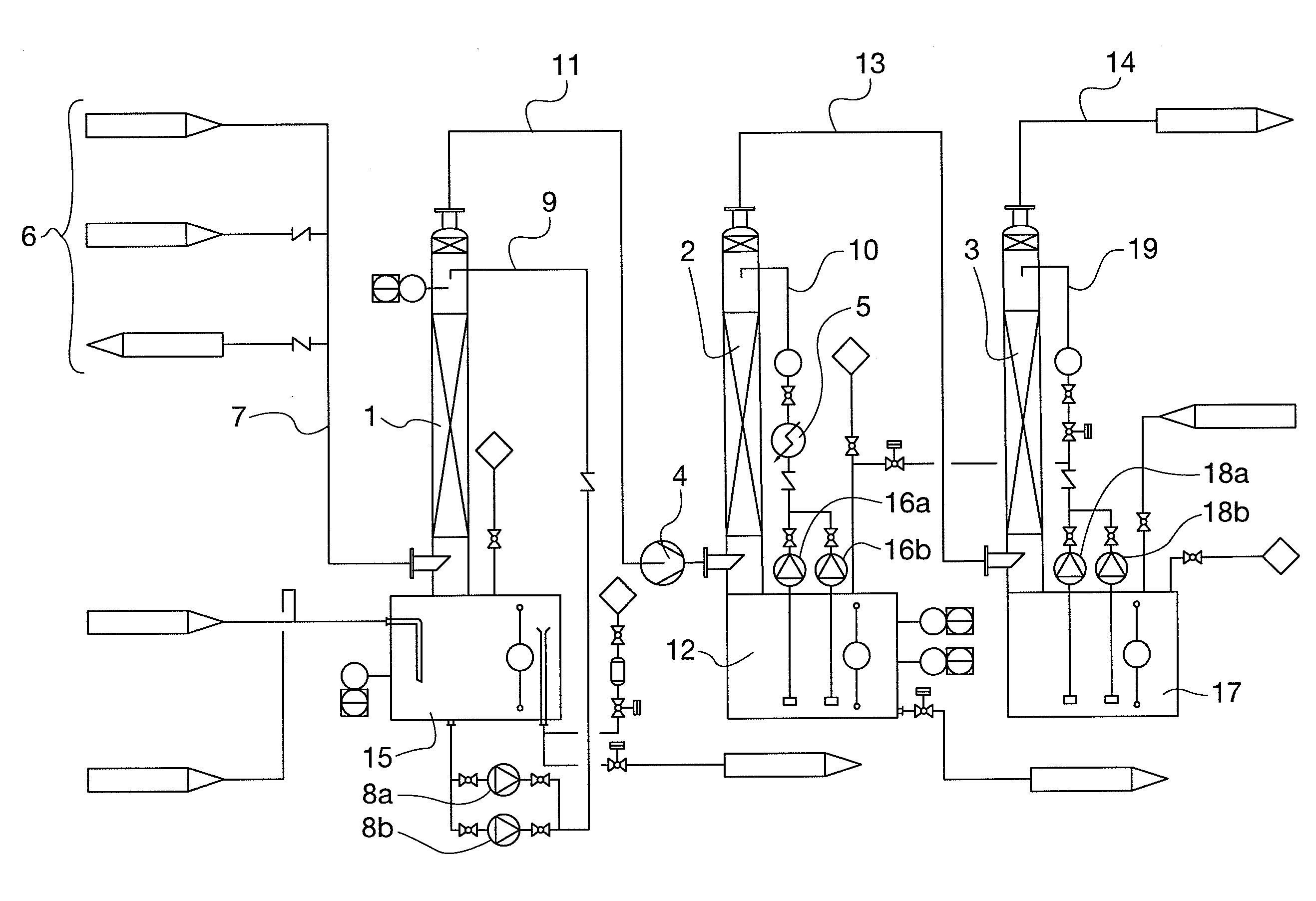

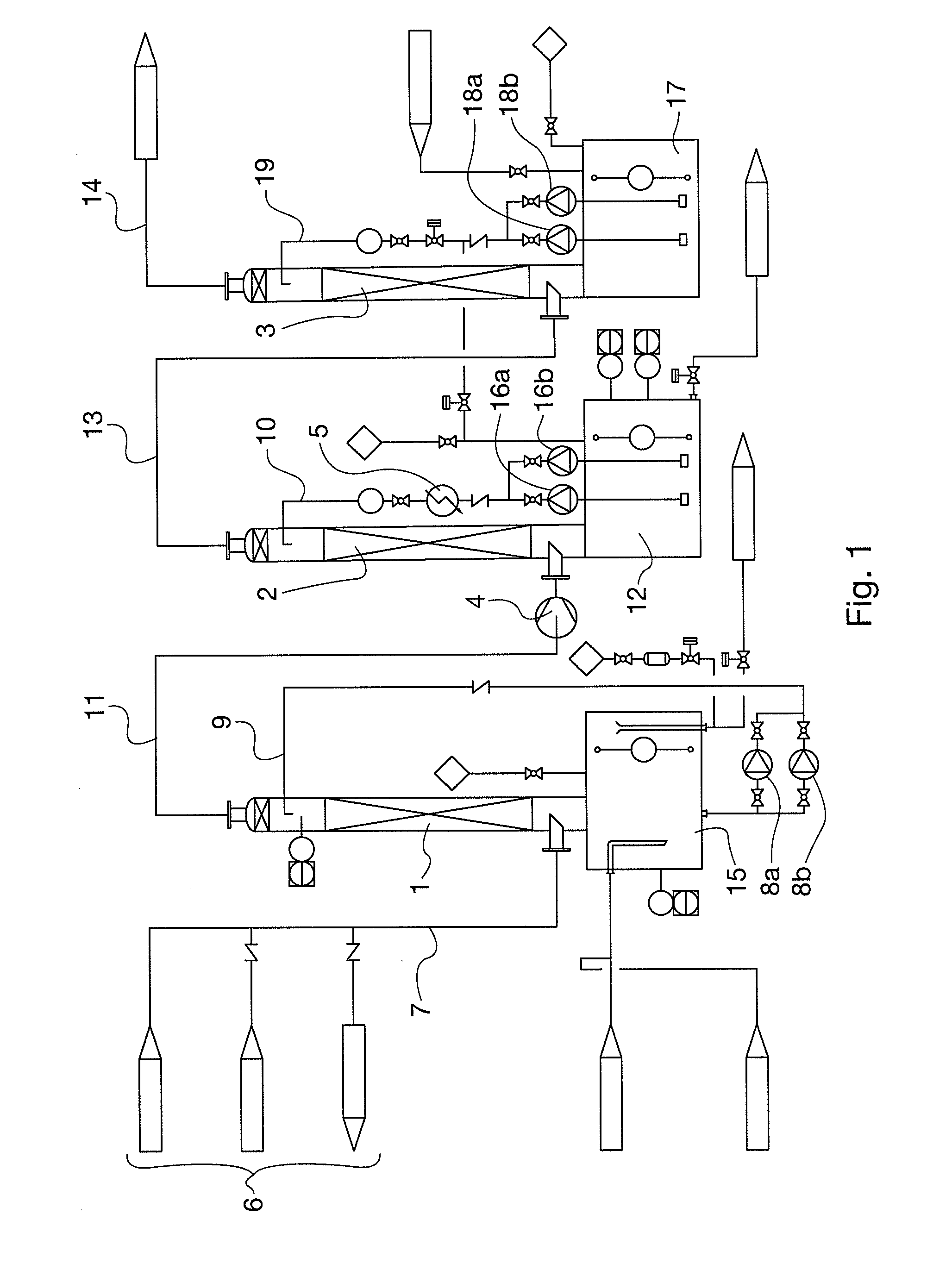

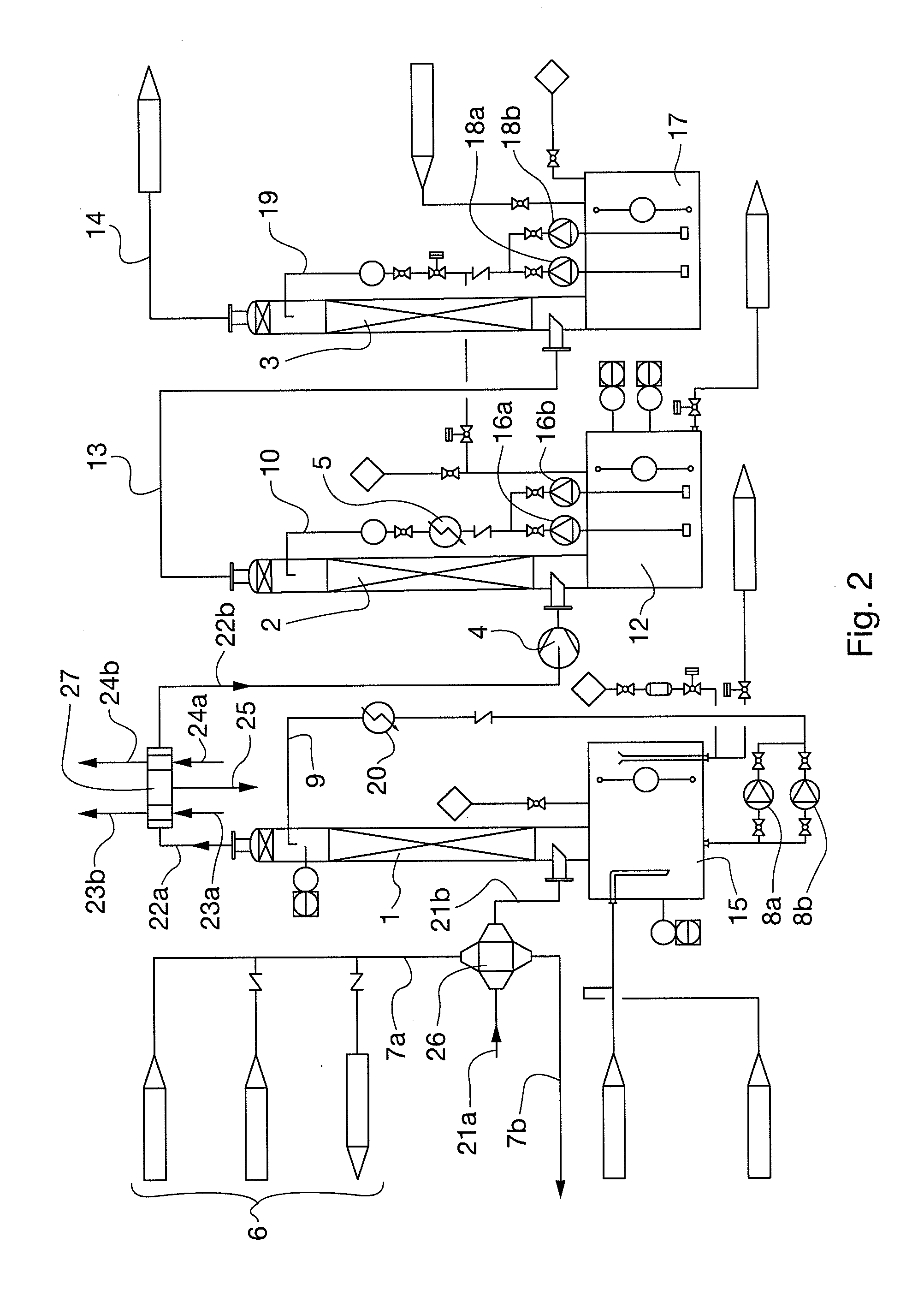

The invention provides a device and a method for synthesizing ammonia by utilizing renewable energy sources, and relates to the technical field of ammonia synthesis. The device provided by the invention comprises an energy microgrid 1, a water electrolysis hydrogen production device 2, an air separation device 3, a first buffer tank 4, a first compressor 5, a second buffer tank 6, a third buffer tank 18, a heat exchanger 7, a reaction tower 8, a first adsorption column 17, a second adsorption column 11, a third adsorption column 20, a first flash tower 10, a second flash tower 14, a third flash tower 15, a liquid ammonia pump 16, a second compressor 12 and valves. According to the invention, the energy microgrid is used for providing a renewable energy source for hydrogen production by water electrolysis and nitrogen production by air separation, then the prepared hydrogen and nitrogen are mixed and then subjected to a synthetic reaction, and the generated high-temperature outlet gas is subjected to adsorption separation again after flash evaporation, condensation and separation, so that ammonia is obtained. The method can realize production of carbon-free ammonia, and the method combining adsorption separation and condensation separation can improve the nitrogen-hydrogen conversion rate and the ammonia synthesis rate in the ammonia synthesis reaction.

Owner:XIAMEN UNIV

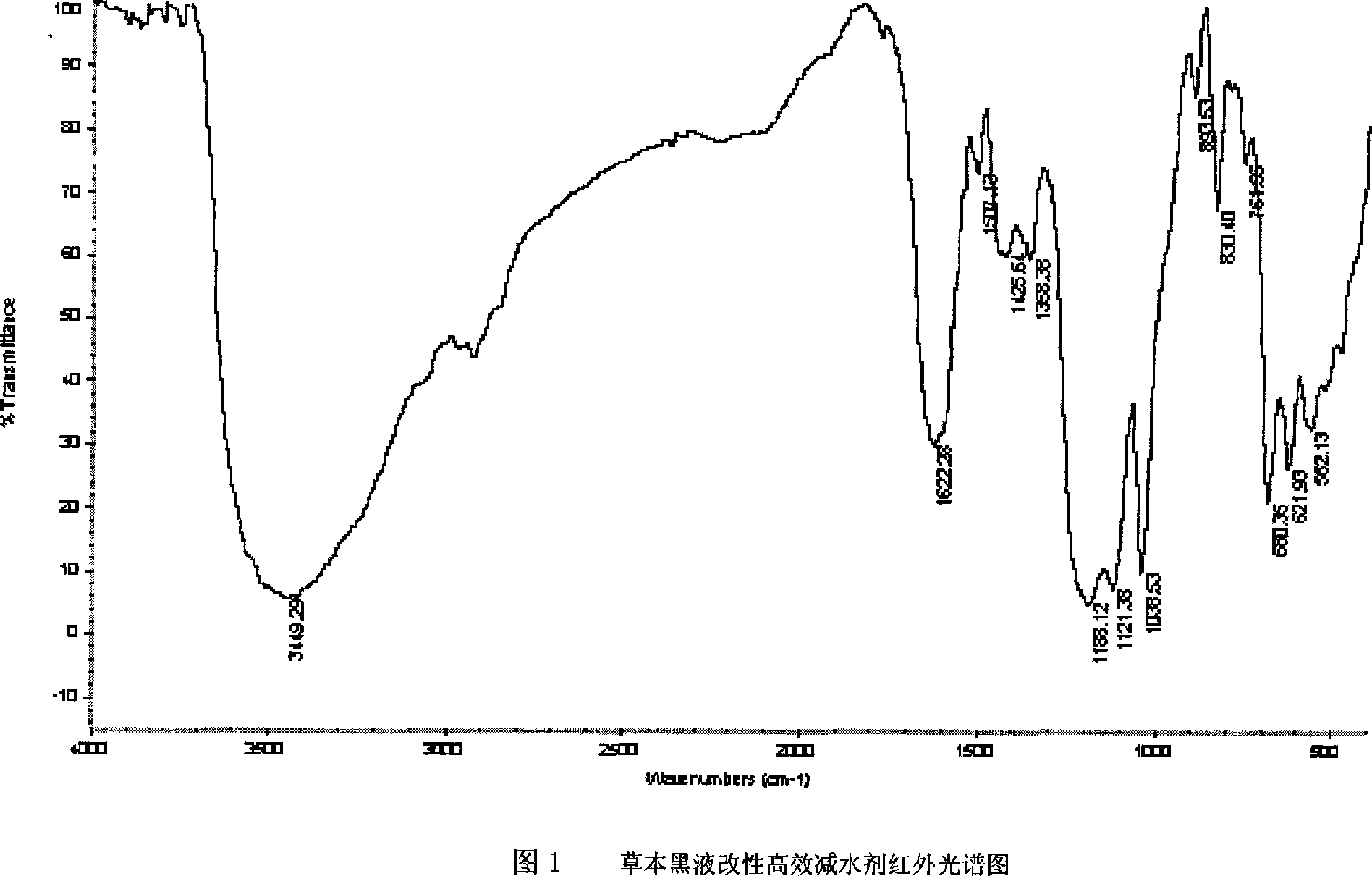

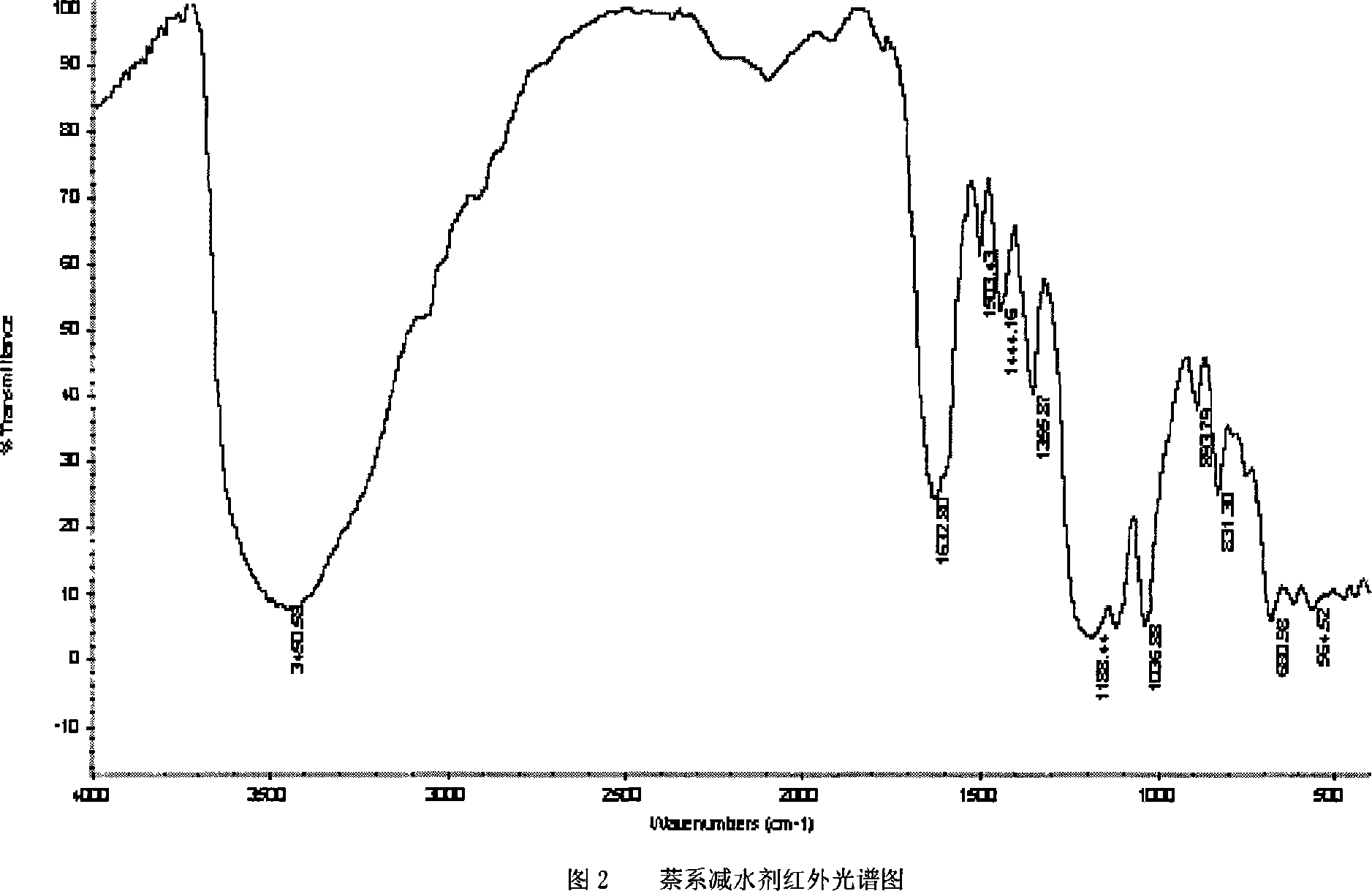

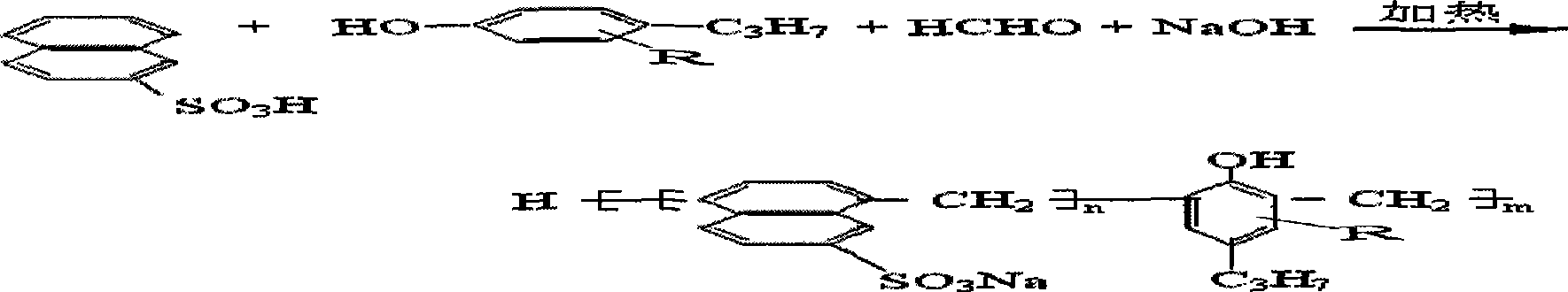

Method for producing herbage black liquor modified high efficiency water reducing agent

A preparation method of herb black liquor modified high-effective water-reducing agent comprises a graft polymerization reaction by adding herbal lignin sulfonate with 20%-240% weight of reactant naphthaline in naphthalene sulfonic acid. The water-reducing rate of herb black liquor modified high-effective water-reducing agent gets to 20%-26%, other performances such as bleeding rate and concrete time-dependent loss are better than naphthalene high-effective water-reducing agent; production cost is reduced lower than that of naphthalene high-effective water-reducing about 25%; ammonia content is low, free formaldehyde content is approximately 1 / 70 of naphthalene high-effective water-reducing agent, ammonia and formaldehyde pollution is not existed basically. The technology is a environmental protection technology, which can solve pollution problem of herb black liquor, lignin and alkali of black liquor as material are used fully, which is uncapable of generating other rejected products.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

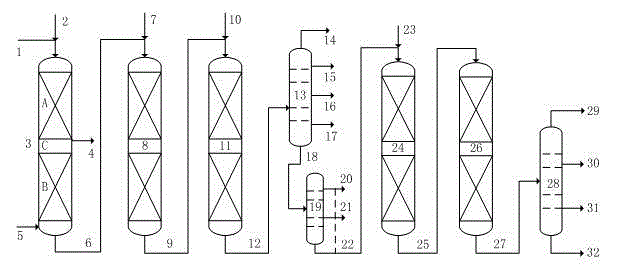

Coal gasification wastewater phenol and ammonia recovery process

ActiveCN106698785ADoes not affect the processing effectLow operating pressureWater contaminantsMultistage water/sewage treatmentCoal gasification wastewaterTreatment effect

The invention relates to the technical field of wastewater treatment, in particular to a coal gasification wastewater phenol and ammonia recovery process. The process comprises the following steps that feeding wastewater is divided into cold feeding materials and hot feeding materials to respectively enter an acid water stripping tower from the tower top and the tower middle upper part; the tower top pressure is set to be 0.9 to 1.2MPa; the tower top temperature is 50 to 80 DEG C; the tower kettle pressure is set to be 0.92 to 1.25 MPa; the tower kettle temperature is 178 to 188 DEG C; acid gas is produced at the tower top; ammonia water vapor is produced at the lateral line; the ammonia water vapor is sequentially used as a heat source of a phenol tower and a solvent stripping tower, and then enters a three-stage segregated system to be concentrated into crude ammonia gas; kettle liquid of the acid water stripping tower enters an extraction device to be subjected to phenol removal; an extraction phase enters the phenol tower; an extracting agent and crude phenol are separated through rectification; a raffinate phrase enters a solvent steam extraction tower; the extracting agent dissolved in the wastewater is stripped out and returns to an extraction tower. By using the process provided by the invention, the steam consumption can be greatly reduced; in addition, the good treatment effect can be ensured.

Owner:QINGDAO JUNYANG CHEM TECH

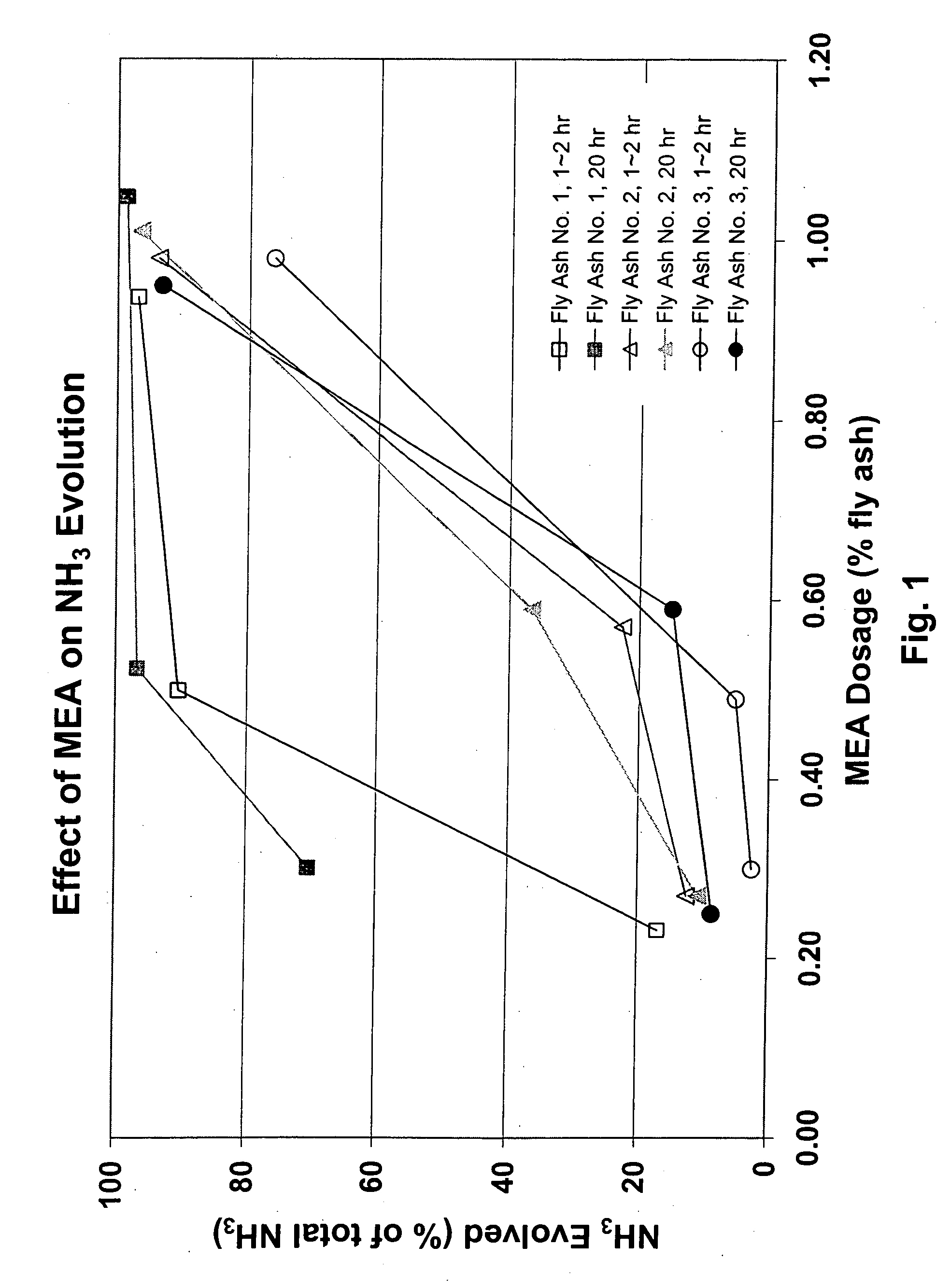

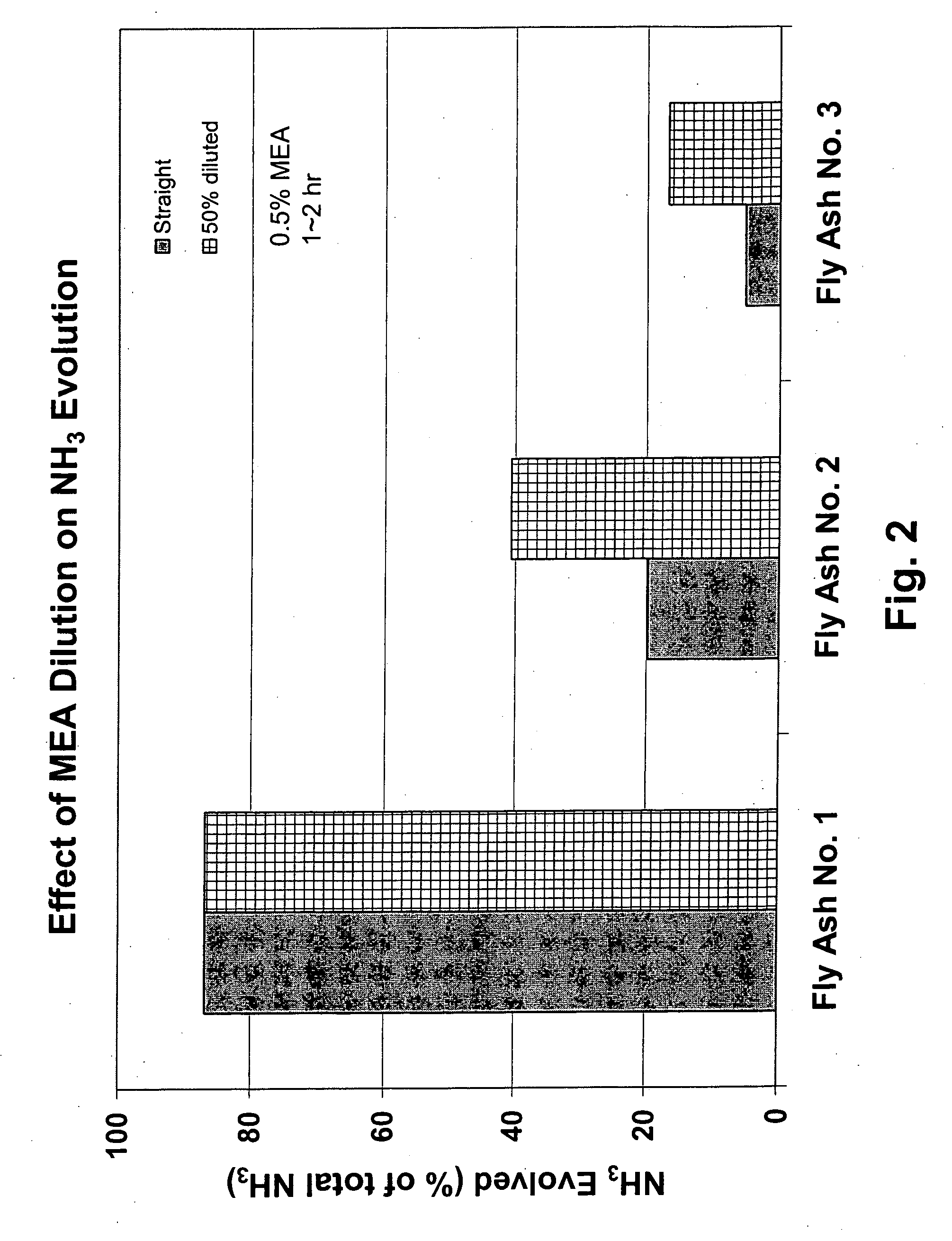

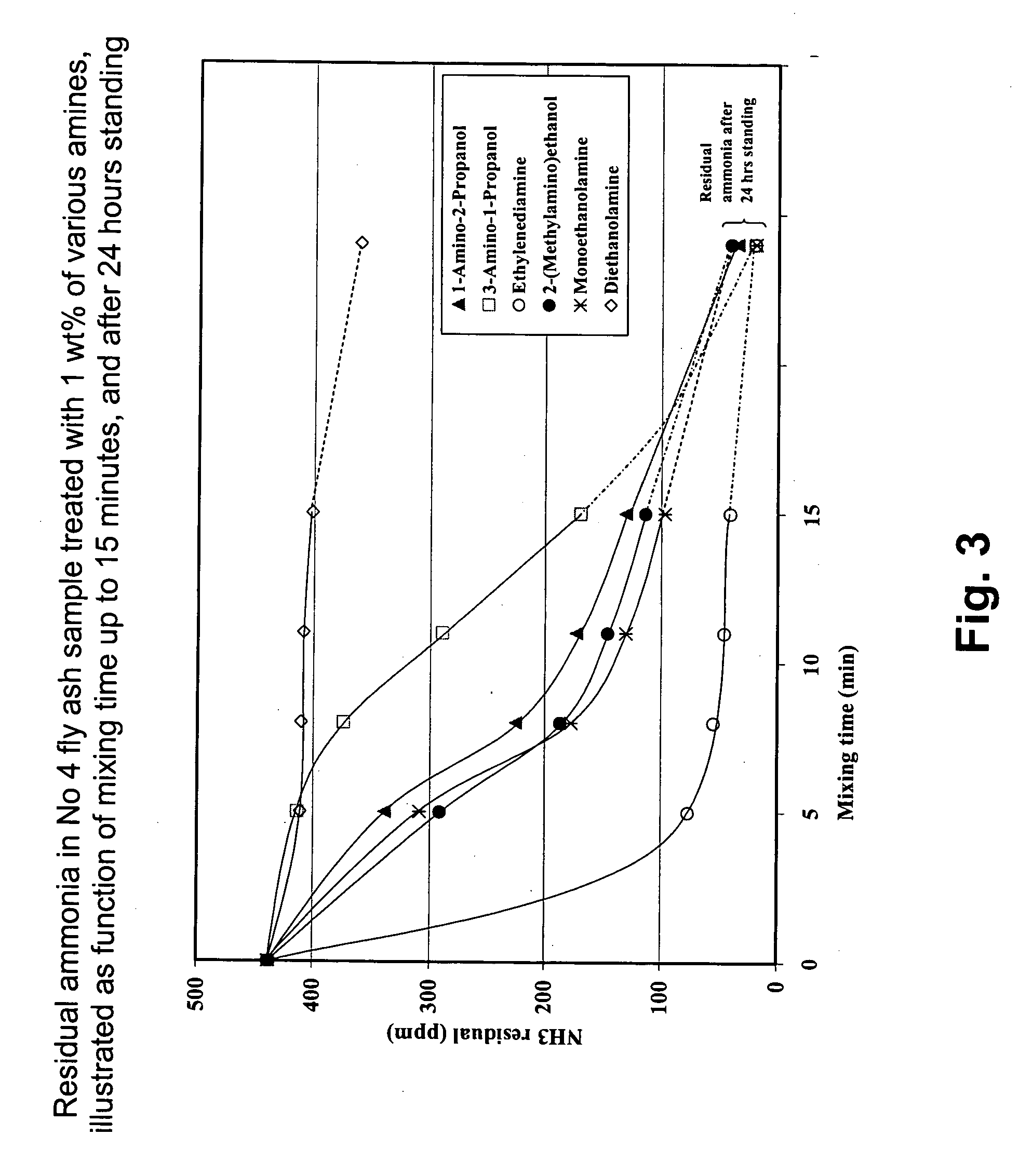

Method of removing ammonia from fly ash and fly ash composition produced thereby

ActiveUS20070051277A1Reduce ammonia contentImprove responseCyanogen compoundsNitrogen compoundsOrganic baseEnvironmental engineering

A method of treating fly ash and fly ash treated thereby, the method involving contacting ammonia-laden fly ash with an organic base-containing treatment composition, where the organic base causes the ammonia within the fly ash to evolve from the fly ash. The treatment composition preferably includes an effective amount of one or more amines. The treatment compound may be applied to the fly ash in any manner effective to disperse the treatment compound among the fly ash.

Owner:EM RESOURCES LLC

Waterproof concrete compacting agent and preparation method thereof

The invention discloses a waterproof concrete compacting agent and a preparation method thereof. The compacting agent consists of the following raw material components in percentage by weight: 10 to 13 percent of potassium hydroxide, 0.5 to 1 percent of volcanic ash, 0.5 to 1 percent of potassium oleate, 10 to 12 percent of sulfur, 0.5 to 1 percent of glycerol, 3 to 5 percent of triethanolamine, 0.5 to 1 percent of citric acid, 0.5 to 1.5 percent of ferric oxide, 0.5 to 1 percent of sodium fluosilicate, and the balance of water. Chemical crystal or colloid generated by chemical reaction of components in the compacting agent and silicon, calcium, sodium, magnesium and the like in cement can effectively prevent permeation of water molecules and effectively control cracking. The compacting agent contains extremely low harmful substances, particularly has extremely low chlorine ion content and ammonia content, reduces damage to steel bars and concrete, and is beneficial to environmental protection.

Owner:北京龙阳伟业科技股份有限公司

Pet deodorizing tablet and preparation method thereof

InactiveCN104957399AEliminate bad breathEliminate body odorAnimal feeding stuffPhytaseMagnesium stearate

The present invention provides a pet deodorizing tablet which is mainly prepared by using the following components in parts by weight: complex enzymes 8-21 parts, yucca saponin 5-10 parts, green tea extract 20-30 parts, probiotics 8-28 parts, dextrin 5-30 parts, aspartame 1-3 parts, starch 5-15 parts, magnesium stearate 0.5-2 parts, and the complex enzymes comprise the following components: papain 1500-2000 u / g, bromelain 3000-4000 u / g, phytase 1000-1680 u / g, cellulase 600-750 u / g, beta-glucanase 1500-2300 u / g and trypsin 1800-2560 u / g. The pet deodorizing tablets can comprehensively eliminate pets' bad breath, shit smell and other body odors, have a more comprehensive and effective deodorizing effect, and can effectively improve the gastrointestinal function, immunity and health condition of pets.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

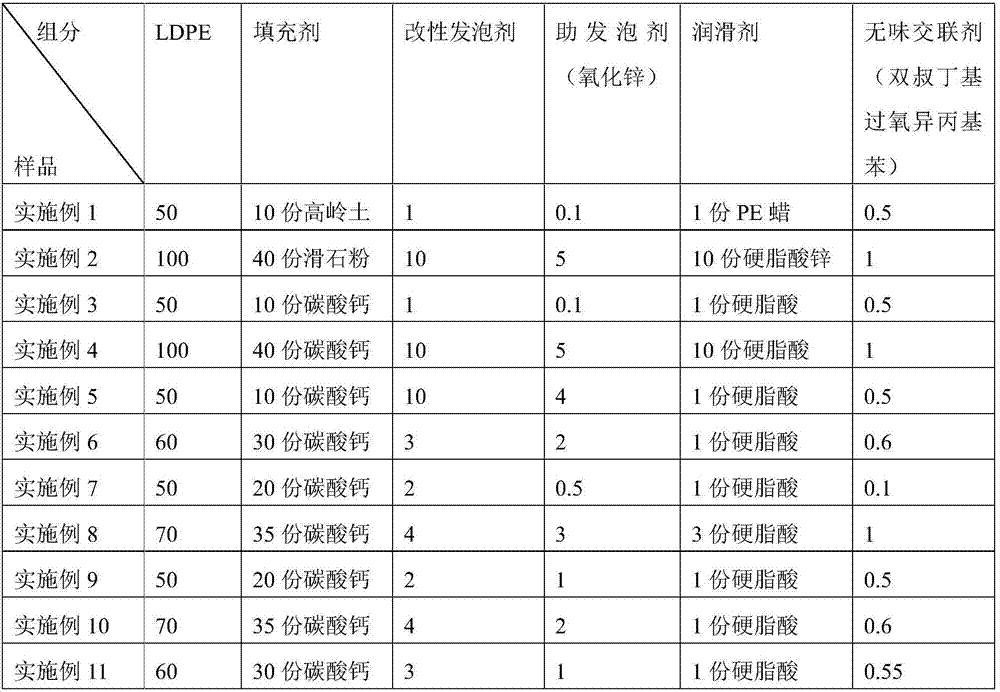

Odorless PE foam material and preparation method thereof

The invention discloses an odorless PE foam material and a preparation method thereof. The odorless PE foam material is mainly prepared from raw materials in parts by weight as follows: 50-100 parts of LDPE, 10-40 parts of a filling agent, 1-10 parts of a modified foaming agent, 0.1-5 parts of an auxiliary foaming agent, 0.1-10 parts of a lubricant and 0.5-1 part of an odorless crosslinking agent. The preparation method of the odorless PE foam material comprises steps as follows: material mixing, open-milling, slice discharging, curing and foaming as well as cooling and forming. The modified foaming agent is added to the PE foam material, the content of ammonia gas is smaller than 30 ppm, and compared with a traditional PE foam material, the odorless PE foam material is odorless, environment-friendly and non-toxic.

Owner:SANSD JIANGSU ENVIRONMENTAL PROTECTION TECH

Process for stripping and recovering ammonia from digested wastes and plant for carrying out said process

InactiveUS20110048230A1Reduce nitrate levelsEmission reductionWater treatment parameter controlGas treatmentGas phaseAbsorption column

A process for reducing ammonia from digested wastes (9), in which the stripping of ammonia by counter-current air / liquid extraction inside a stripping column (1) and the subsequent recover of ammonia by counter-current contact of the gas phase (11) exiting said stripping column (1) with a first sulphuric acid solution (10) inside a first absorption column (2) are provided.

Owner:STURLA VITTORIO +1

Novel safe environmentally-friendly feed additive

InactiveCN102845620AReduce moisture contentReduce generationAnimal feeding stuffBetaineFeed conversion ratio

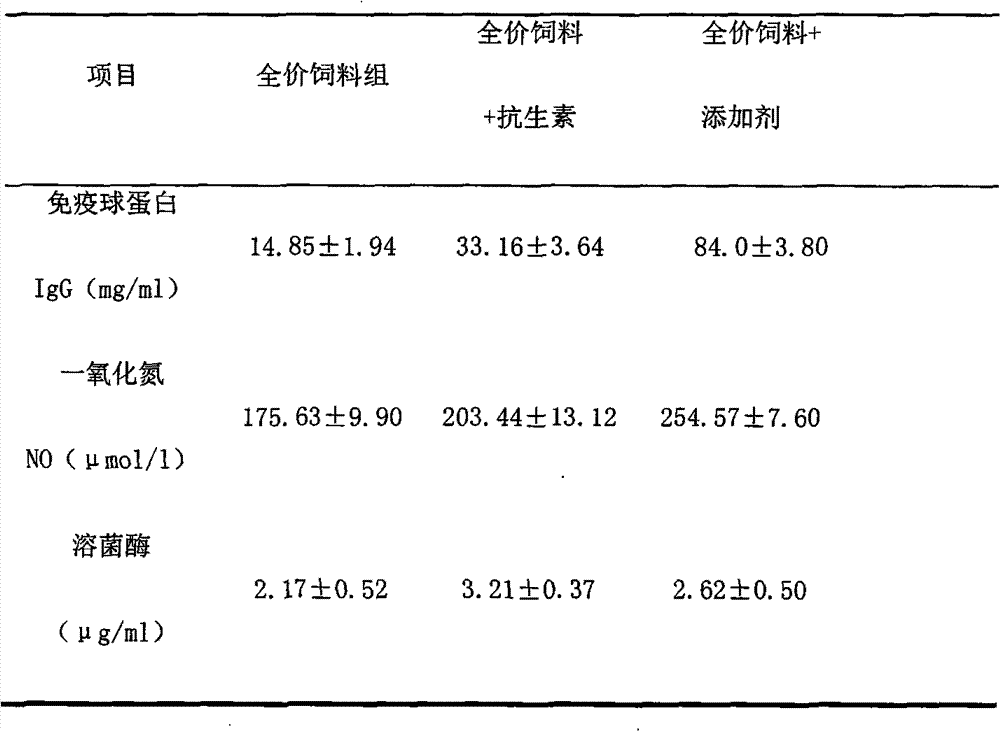

The invention discloses a novel safe environmentally-friendly feed additive for the livestock and poultry industry. The novel safe environmentally-friendly feed additive is prepared from pheophytin, betaine, metaplexis japonica extract, oxidized matrine, yucca saponin, rose-boot extract, flos caryophylli powder, clinoptilolite powder and illite powder according to a scientific ratio. The novel safe environmentally-friendly feed additive has activation, adjustment and quick-acting functions, improves animal immunity, maintains the balance of florae in a livestock intestinal tract, improves muscle quality, a culture environment and an organic decomposition rate, reduces an ammonia concentration of air in an animal house and realizes deodorization. In breeding, the novel safe environmentally-friendly feed additive can fully avoid antibiotic medicines, reduce mycotoxins, prevent enterorrhea and diarrhea, resist stress and coccidium, improve a feed conversion ratio and an egg yield, and eliminate heavy metal and drug residues.

Owner:王茜 +1

Method and device for treating coal chemical industry production sewage

InactiveCN103496755AImprove the degree of purificationReduce carbon dioxideWater/sewage treatment by heatingWater/sewage treatment by degassingSolubilityHigh pressure

The invention provides a method and a device for treating coal chemical industry production sewage. The method comprises the following steps: allowing medium-pressure overheat steam with the pressure of 3.0 to 4.1 MPa and the temperature of 360 to 420 DEG C to enter a high-pressure steam stripping tower from the bottom of the tower, wherein the medium-pressure overheat steam serves as a heat source; directly heating the coal chemical industry production sewage, which enters the tower from the upper part of the tower and is pressurized to be 3.7 to 4.4 MPa, from bottom to top in a countercurrent manner; resolving soluble gases or volatile substances of the coal chemical industry production sewage; and discharging the generated coal chemical industry treated water from the bottom of the high-pressure steam stripping tower and discharging saturated steam containing resolved gases from the top of the tower. According to the method provided by the invention, an active carbon dephenolizing / CLL ammonia recovering process of coal chemical industry production sewage is changed into a medium-pressure overheat steam stripping process, so the separated pollutants can be recycled and the treated sewage returns a system to be comprehensively utilized.

Owner:TIANJI COAL CHEM IND GROUP

Process method for producing lubricating oil base oil through poor-quality raw material

ActiveCN104611047AFully activeExpand sourceTreatment with hydrotreatment processesLubricant compositionCounter flowHydrogenation reaction

The present invention discloses a process method for producing lubricating oil base oil through a poor-quality raw material. According to the process method of the present invention, a poor-quality raw material firstly enters a first-stage reaction zone to carry out a hydrorefining reaction, a co-current flow process and a counter flow process are concurrently adopted in the first stage, the generated oil obtained in the first stage enters a second-stage reaction zone to carry out a deep hydrogenation reaction, and the second-stage reaction effluent is subjected to hydrocracking; and the cracking tail oils are subjected to cutting pre-fractionation to obtain the suitable tail oil distillate, and the suitable tail oil distillate is subjected to an isomerizing dewaxing and finishing reaction to obtain the lubricating oil base oil distillate. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the operation period of the device can be increased and the poor-quality raw material can be processed, or the processing capacity of the device can be increased in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

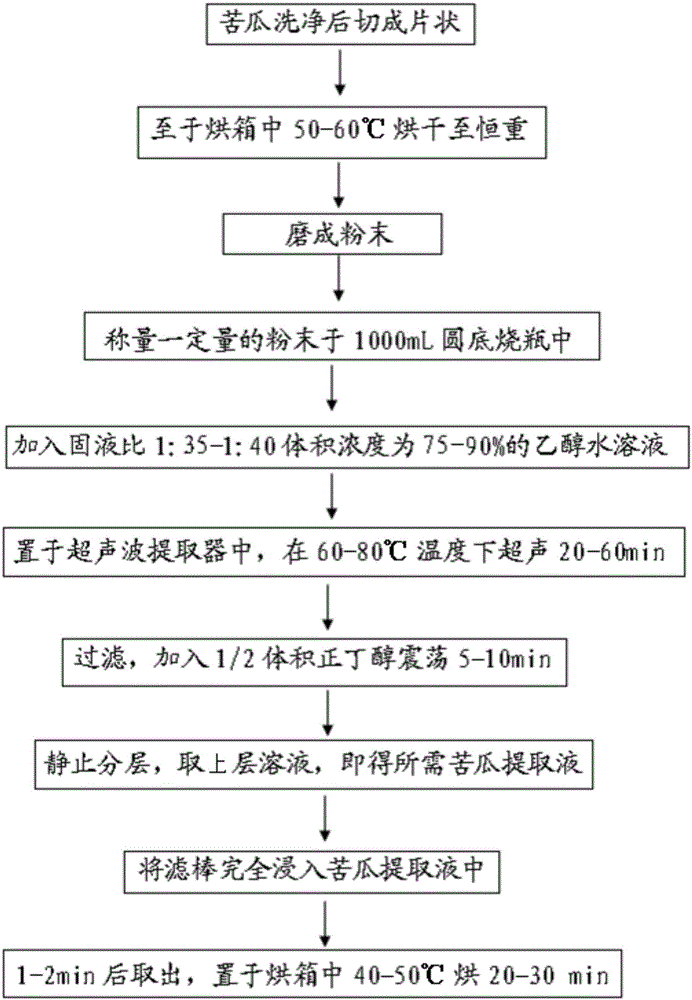

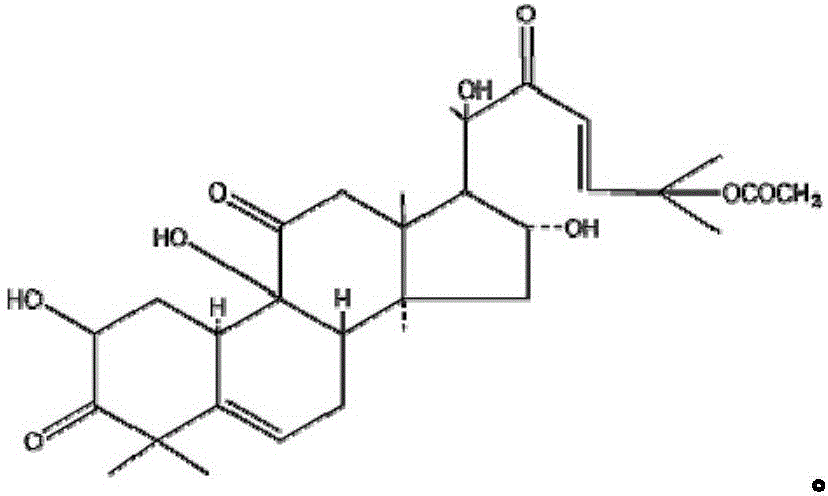

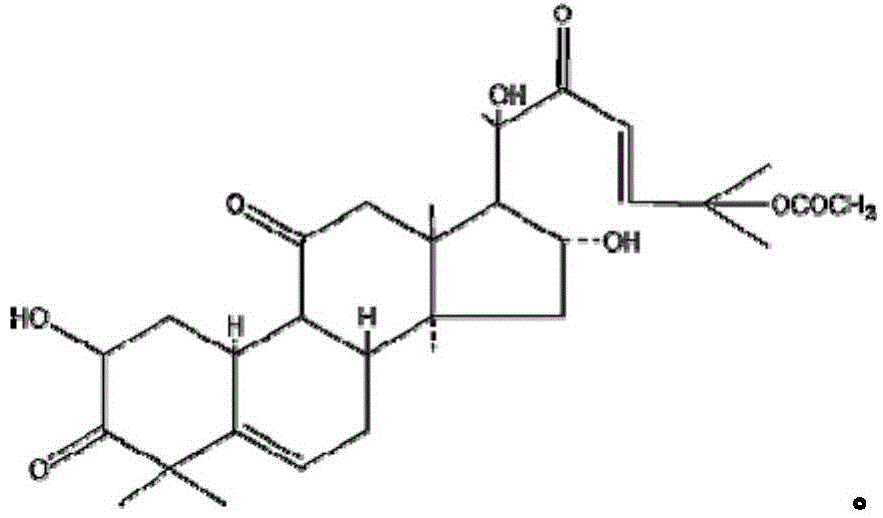

Method for preparing extract of momordica charantia, extract of momordica charantia and application of extract of momordica charantia

InactiveCN106174696AReduce ammonia contentUnique sense of body fluidTobacco smoke filtersNicotiana tabacumMedicine

The invention belongs to the field of a tobacco product, and particularly relates to a method for preparing extract of momordica charantia. The method comprises the following steps of: (1) leaching a momordica charantia sample by ethanol solution, and separating to obtain original leaching solution; (2) carrying out extraction on the original leaching solution by n-butyl alcohol, and separating to obtain extraction liquid. The invention further relates to extract of momordica charantia, a composition for tobacco and application of the extract of momordica charantia. When one or more of momordica saponins A, momordica saponins B, the extract of momordica charantia disclosed by the invention and the composition for tobacco, which is disclosed by the invention, are added into a cigarette holder, a filter tip or a filter stick to produce a cigarette, ammonia content in mainstream smoke of the cigarette can be obviously reduced.

Owner:CHINA TOBACCO FUJIAN IND

Powerless low-temperature isobaric ammonia recovering method and isobaric ammonia recovering device

InactiveCN102389689ASave powerSimple process conditionsDispersed particle separationAmmonia preparation/separationAmmonia productionDissolution

The invention relates to an ammonia recovering process and ammonia recovering equipment, namely a method and a device for recovering ammonia from gas from ammonia production plants at a low temperature and isobaric pressure. Several or all coolers of the isobaric ammonia recovering device cool ammonia water and absorb water used by ammonia by using liquid ammonia of which the temperature is lower than that of cooling water. The coolers include a double-travel internal cooler in a bubbling absorber, a coil tube type cooler, an out-tower ammonia water cooler, a demineralized water cooler, a first out-tower small ammonia water cooler, a second out-tower small ammonia water cooler. In the invention, ammonia water is cooled without using cooling water, and power is saved; the cooling area of the out-tower ammonia water coolers and the cooling area of the coolers on all layers of tower plates increase gradually from top down and are allocated according to different ammonia absorbing capacities and different dissolution heat released on all layers of tower plates and the cooler loads on the coolers on the layers of tower plates; and thus, the required cooling area is guaranteed and does not wasted, and the ammonia absorbing capacities on all layers of tower plates are fully played.

Owner:刘军

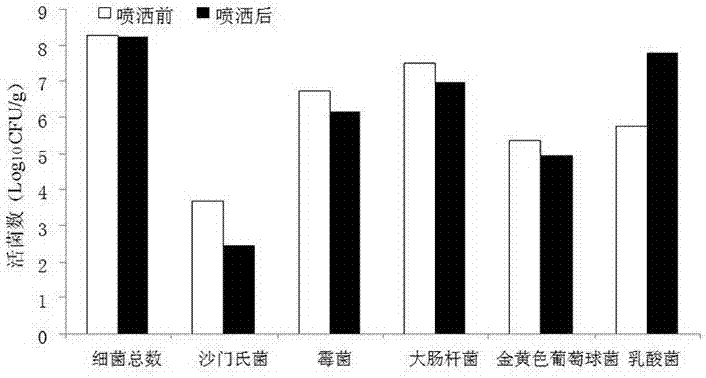

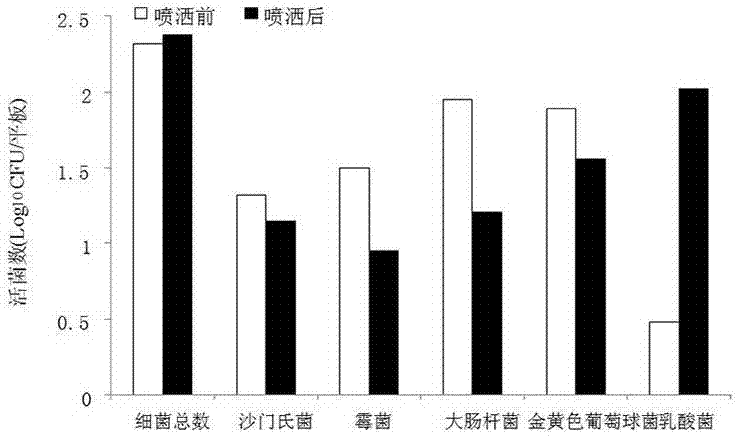

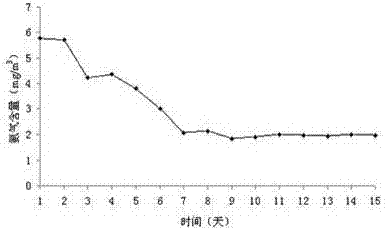

Novel environmental modifier for livestock housing as well as preparation method and application of novel environmental modifier

The invention belongs to the technical field of breeding environment improvement and purification based on probiotics and relates to a novel environmental modifier for livestock housing as well as a preparation method and an application of the novel environmental modifier. According to the preparation method, first-grade shake-flask seeds are prepared from Enterococcus faecium WEI-19, Lactobacillus plantarum WEI-12 and Bacillus coagulans WEI-125 and cultured in a seed tank and a fermentation tank, and the livestock housing environmental modifier containing thalli and fermentation products is obtained. When the environmental modifier for the livestock housing is sprayed to excrement and air of the livestock housing, ammonia gas content of the livestock housing can be reduced by 80%, contentof pathogenic bacteria in excrement is reduced by 90%, content of pathogenic bacteria in air is reduced by 70%, infection probability of bacterial livestock diseases is reduced, and an excellent growth environment is provided for the livestock.

Owner:BEIJING DAWEIJIA BIOTECH SHARE CO LTD +1

System for coupling aerobic composting and dry type anaerobic straw fermentation

ActiveCN104261925ASpeed up fermentationImprove degradation rateBio-organic fraction processingClimate change adaptationSlagEnvironmental engineering

The invention provides a system for coupling aerobic composting and dry type anaerobic straw fermentation, and belongs to a biomass fermentation technology. The system comprises a biological carbon waste gas purifier, a dry type anaerobic straw fermenter and an aerobic composting device, wherein the aerobic composting device is communicated with the dry type anaerobic straw fermenter through a first waste gas conveying pipe equipped with a first gas valve; two ends of a biogas residue conveying pipe equipped with a biogas residue discharge valve are connected with a slag discharge port of the dry type anaerobic straw fermenter and a slag inlet of the aerobic composting device respectively; the biogas residue conveying assembly is assembled on the biogas residue conveying pipe; and the dry type anaerobic straw fermenter and the biological carbon waste gas purifier are communicated through a second waste gas conveying pipe equipped with a second gas valve. The system is simple in overall configuration, the technological process is novel and reasonable, the straw fermentation speed is high, the straw degradation rate is high, the production cost is low, and the environment pollution is low.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Process for purifying wastewaters from the workup of crude aromatic nitro compounds

InactiveUS20120205308A1Improve economyGreat ecological advantageSolid sorbent liquid separationWater/sewage treatment by ion-exchangeNitro compoundSimple Organic Compounds

The invention relates to a process for working up wastewaters which are obtained in the purification of crude aromatic nitro compounds after the nitration of aromatic compounds, comprising the following steps:(a) single-stage or multistage washing of the crude aromatic nitro compound to obtain at least one organic phase and at least one aqueous phase, and removal of the aqueous phase or of the aqueous phases, step (a) comprising the addition of a base other than ammonia, and then(b) optional removal of organic constituents from at least a portion of the aqueous phase or aqueous phases obtained in step (a) by stripping, preferably with steam, then(c) removal of organic compounds from at least a portion of the aqueous phase or aqueous phases resulting from step (a) or step (b) by thermal and / or oxidative degradation, then(d) distillative depletion of ammonia from at least a portion of the aqueous phase or aqueous phases resulting from step (c), and then(e) optional supply of at least a portion of the aqueous phase resulting from step (d) to a biological wastewater treatment.

Owner:BASF AG

Synthetic ammonia waste gas recovering and utilizing device and recovering and utilizing method thereof

The invention discloses a synthetic ammonia waste gas recovering and utilizing device and a recovering and utilizing method thereof. The device comprises an ammonia tank purge gas pipeline and a synthetic exhausted gas inlet pipeline; the ammonia tank purge gas pipeline is connected to a membrane separation device through a first ammonia purifying tower, a second ammonia purifying tower, a first T joint, and an ammonia washing tower; the top of the membrane separation device is connected to a synthetic ammonia system through a hydrogen gas pipeline, and the bottom of the membrane separation device is connected to a LNG storage device through a pipeline. The provided device has the advantages of simple structure and reasonable design, the energy conversion of high pressure gas can be achieved by an expanding machine, and the goals of no pollution and zero discharge can be realized.

Owner:HENAN XINLIANXIN FERTILIZER +2

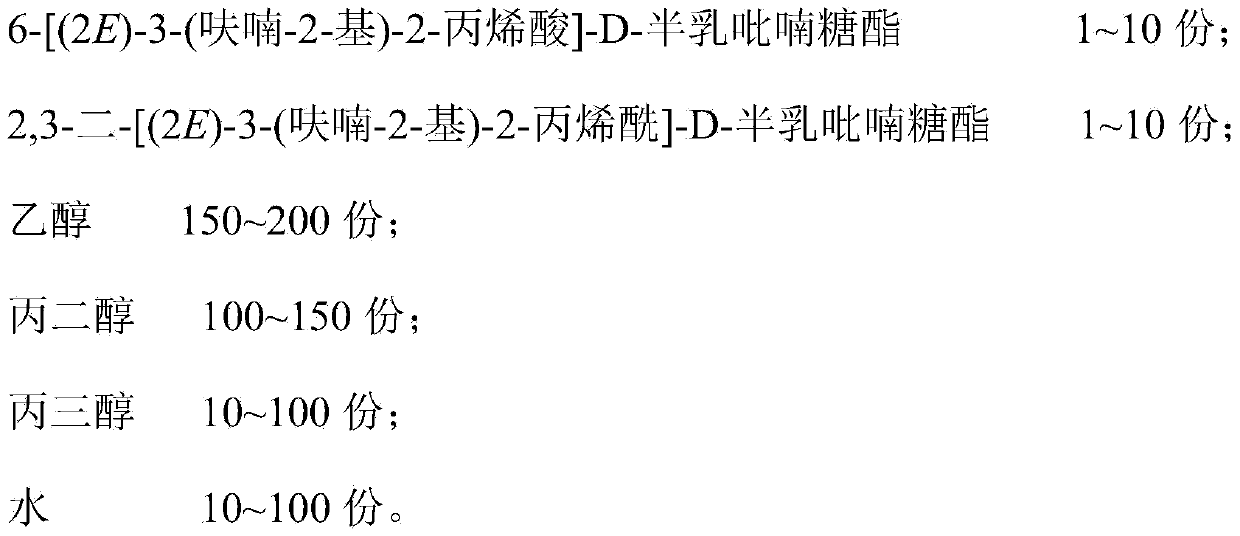

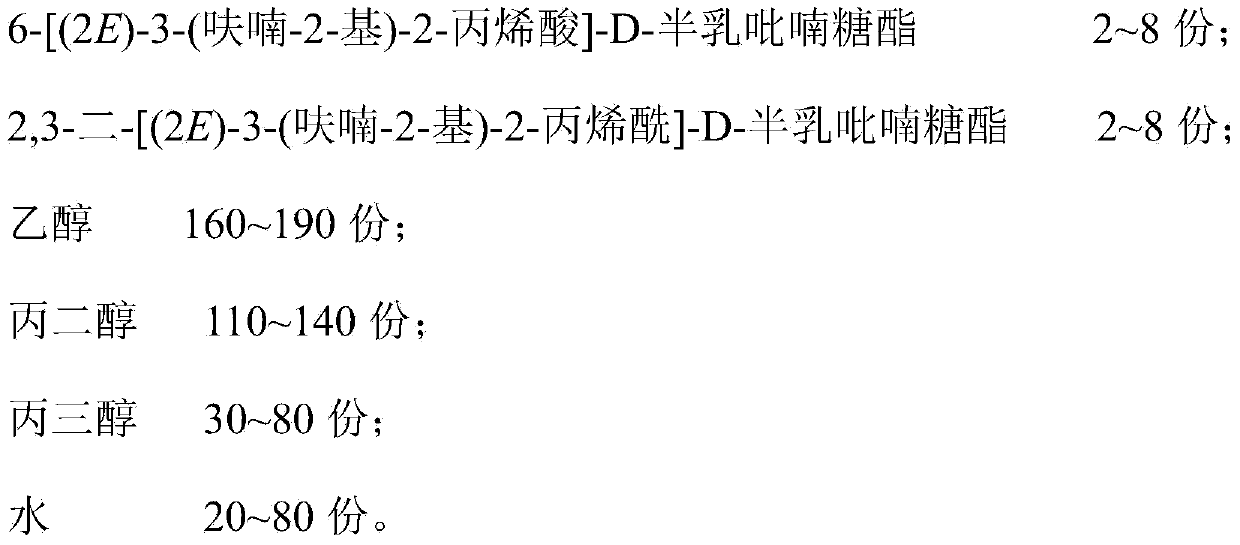

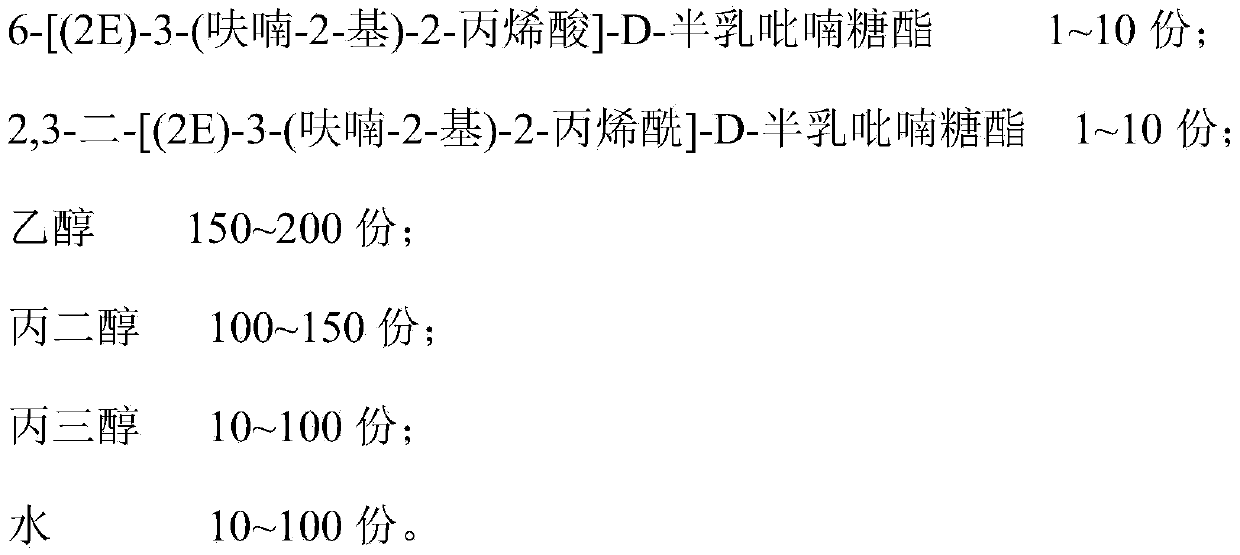

Adsorbing agent for reducing content of ammonia in cigarette smoke and preparation method and application thereof

InactiveCN104190365AReduce ammonia contentSmoke irritation and miscellaneous gas reductionOther chemical processesTobacco smoke filtersChemistryGlycerol

The invention discloses an adsorbing agent for reducing the content of ammonia in cigarette smoke and a preparation method and application thereof. The adsorbing agent is prepared from 6-((2E)-3-(2-furyl))-2-acrylic acid)-D-galapyranose ester, 2,3-bis-((2E)-3-(2-furyl))-2-acrylic acid)-D-galapyranose ester, ethanol, propanediol, glycerol and water in a certain ratio. The adsorbing agent is applied to a cigarette filter stick to manufacture a filter stick in trial, and the filter stick in trial can be further applied to a cigarette to manufacture a cigarette in trial, and then the detection of the ammonia content and the sensory evaluation are carried out on main smoke of the cigarette in trial. The results show that the adsorbing agent has the effects of reducing the content of ammonia in main smoke of the cigarette and preserving sensory humidity.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com