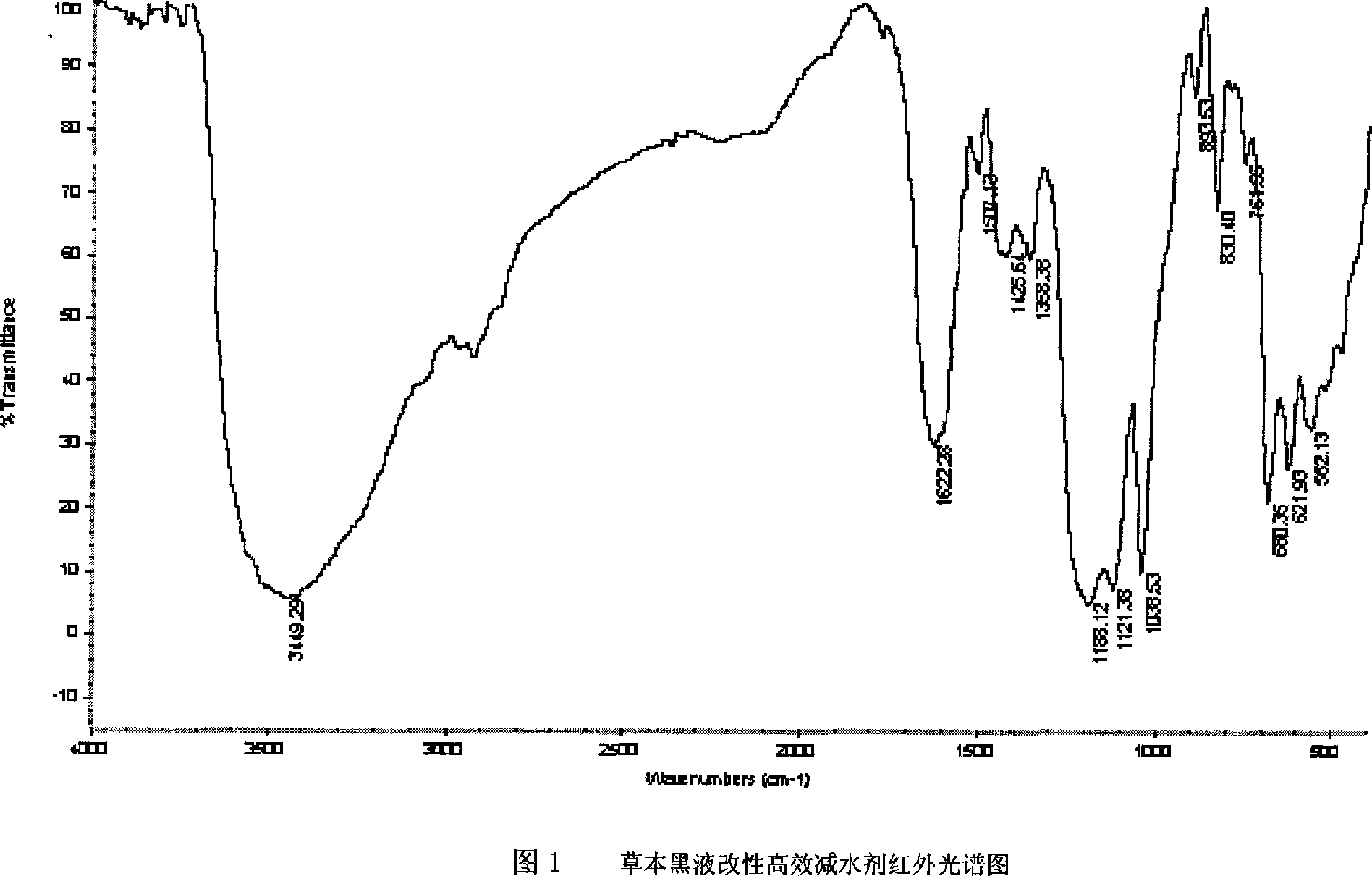

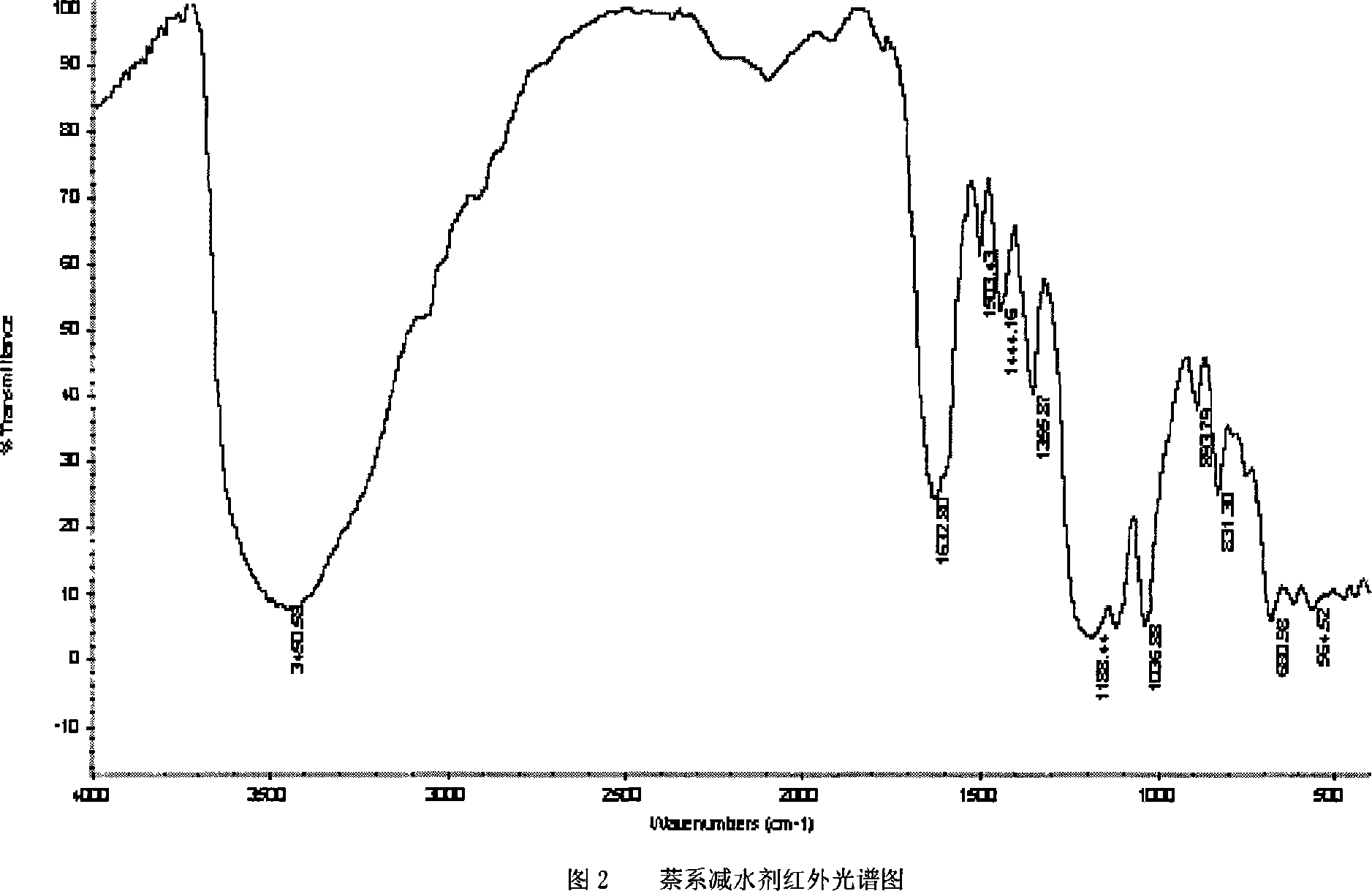

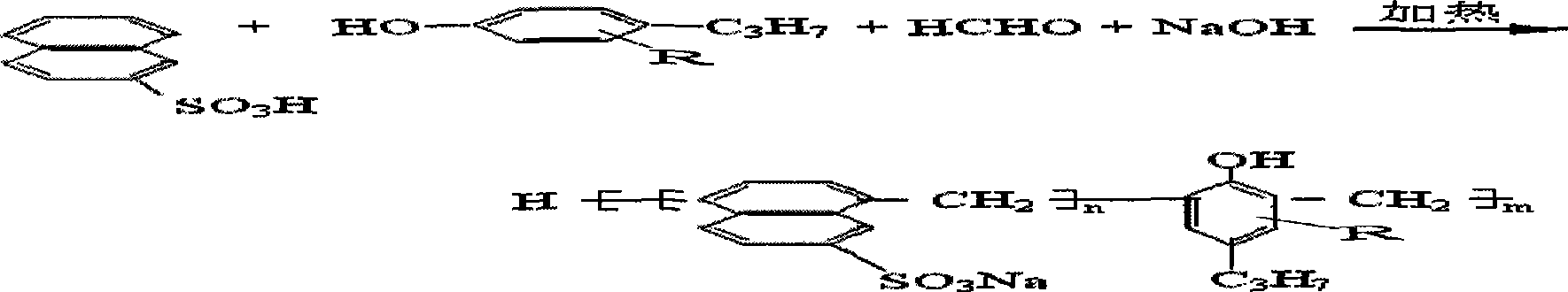

Method for producing herbage black liquor modified high efficiency water reducing agent

A high-efficiency water reducer and production method technology, applied in the field of building materials, can solve problems such as air pollution, construction performance is not easy to be guaranteed, and slump loss is fast, so as to achieve the effect of solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Put 1300Kg of industrial naphthalene into the reaction kettle, heat and melt; then raise the temperature to 140°C while stirring, add 1700Kg of 98% concentrated sulfuric acid, and sulfonate at 160-165°C for 2 hours; cool the reactant to 95°C, add 37% 780Kg of formaldehyde, after dripping for about 3 hours, gradually add 2600Kg of 35% herbal plant lignosulfonate, keep warm at 100°C for 5 hours; then neutralize with alkali to pH7~8.

Embodiment 2

[0011] In the reaction kettle, put 1300Kg of industrial naphthalene into it, heat and melt it; then raise the temperature to 145°C while stirring, add 1650Kg of 98% concentrated sulfuric acid, and sulfonate at 160-165°C for 2.5h; cool the reactant to 98°C, add 37 % formaldehyde 800Kg, after dripping for about 2.5 hours, then gradually add 35% herbal plant lignosulfonate 3700Kg, keep warm at 100°C for 4.5 hours; then use alkali to neutralize to PH7-8.

Embodiment 3 ,1300Kg,; to 140℃,98%1600Kg,160~165℃2.5h; to 98℃,37%780Kg,2h,35%4460Kg,100℃6h; and to PH7~8。 Embodiment 4

[0012] Example 3: Put 1300Kg of industrial naphthalene into the reaction kettle, heat and melt; then heat up to 140°C while stirring, add 1600Kg of 98% concentrated sulfuric acid, sulfonate at 160-165°C for 2.5h; cool the reactant to 98°C , 780Kg of 37% formaldehyde was added dropwise, and after about 2 hours of dripping, 4460Kg of 35% herbaceous lignosulfonate was gradually added, and kept at 100°C for 6 hours; then neutralized with alkali to pH 7-8. Embodiment four: detection result

[0013] ① Hazardous substance detection (see Table 1)

[0014] Test items

Herbal black liquor modified superplasticizer

Heavy

gold

belongs to

Pb

≤0.05ppm / l

≤0.05ppm / l

Cd

≤0.05ppm / l

≤0.05ppm / l

Cr

0.38ppm / l

0.65ppm / l

Hg

0.016ppm / l

0.060ppm / l

As

0.006ppm / l

0.003ppm / l

0.03%

≤0.1%

Formaldehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com