Processing method for double-sided polished sapphire wafers

A sapphire wafer and processing method technology, applied in stone processing equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of affecting the processing and use of wafers, large sub-surface damage, low processing efficiency, etc. The effect of removing the amount, improving the utilization rate, and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. But it does not constitute any limitation to the present invention.

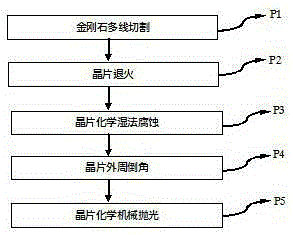

[0021] to combine figure 1 , the present embodiment provides a method for processing a double-sided polished sapphire square wafer. The technological process of described method comprises:

[0022] P1, diamond multi-wire cutting: Paste sapphire block material (square with a cross-section of 52×52mm) on a fixed tooling, use a diamond wire saw with a diameter of 0.22mm to slice, and the median particle size of the diamond particles on the surface is 30-40nm , the thickness of the cut piece is the thickness of the final polished piece plus 0.08-0.1mm reserved for subsequent corrosion and polishing.

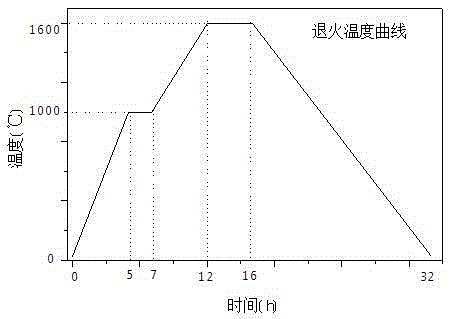

[0023] P2, Wafer annealing: Put the sapphire cutting piece into the high-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com