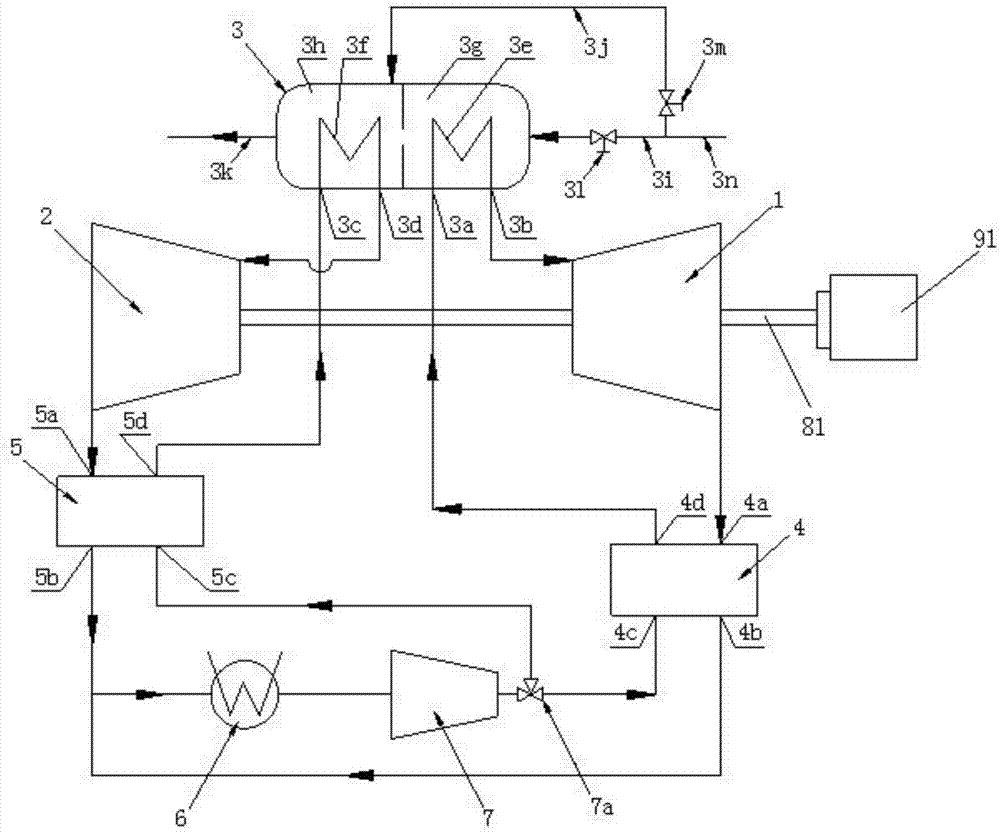

High-and-low-temperature supercritical carbon dioxide waste heat utilization system

A carbon dioxide and supercritical technology, applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as energy waste, inability to fully utilize T2 output capacity, and decrease in turbine efficiency, so as to achieve low economic cost and low pollution The effect of reducing the emission of pollutants and shortening the start and stop time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

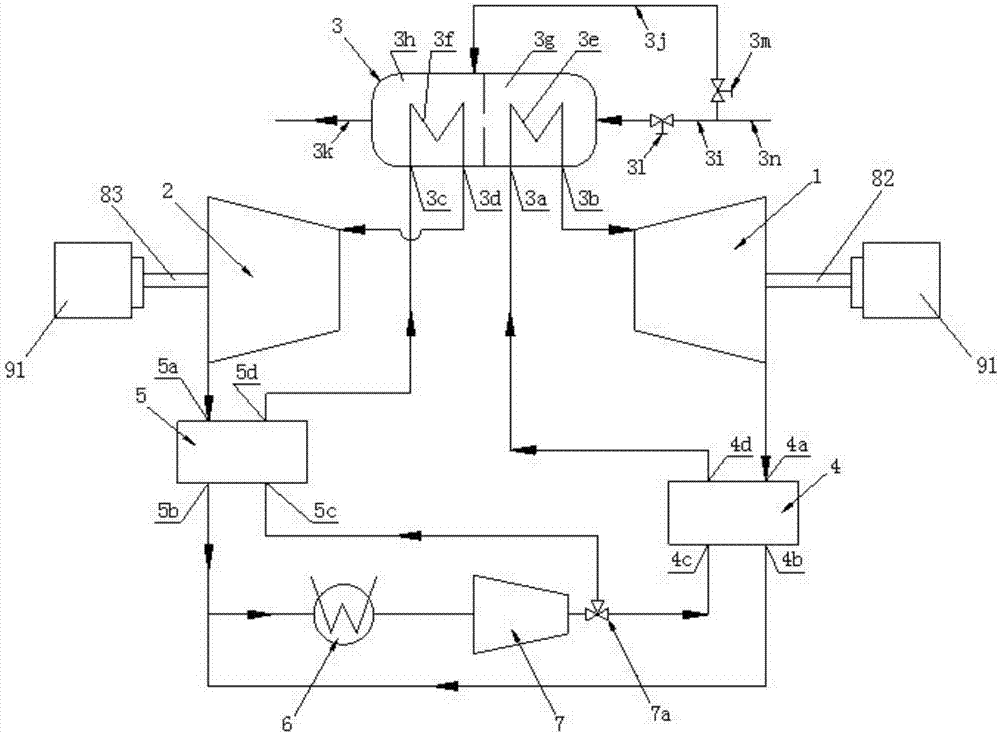

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that the high-low temperature supercritical carbon dioxide waste heat utilization system of this embodiment also includes a high-temperature linkage shaft 82 and a low-temperature linkage shaft 83, and the high-temperature turbine 1 and the low-temperature turbine 2 are connected to the high-temperature linkage shaft respectively. 82 is connected to the low temperature linkage shaft 83, and the output ends of the high temperature linkage shaft 82 and the low temperature linkage shaft 83 are respectively connected to two external devices 91. The high-temperature linkage shaft 82 and the low-temperature linkage shaft 83 are biaxial structures, and the high-temperature linkage shaft 82 and the low-temperature linkage shaft 83 respectively drive corresponding external devices 91 to work.

[0063] When the heat source gas is a medium and low temperature heat source gas such as industrial medium and low temperature flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com