Derusting and descaling machine for belt steel

A descaling machine and strip steel technology, applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of environmental pollution, complex process, high cost, etc., to reduce production costs, save acidic materials, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

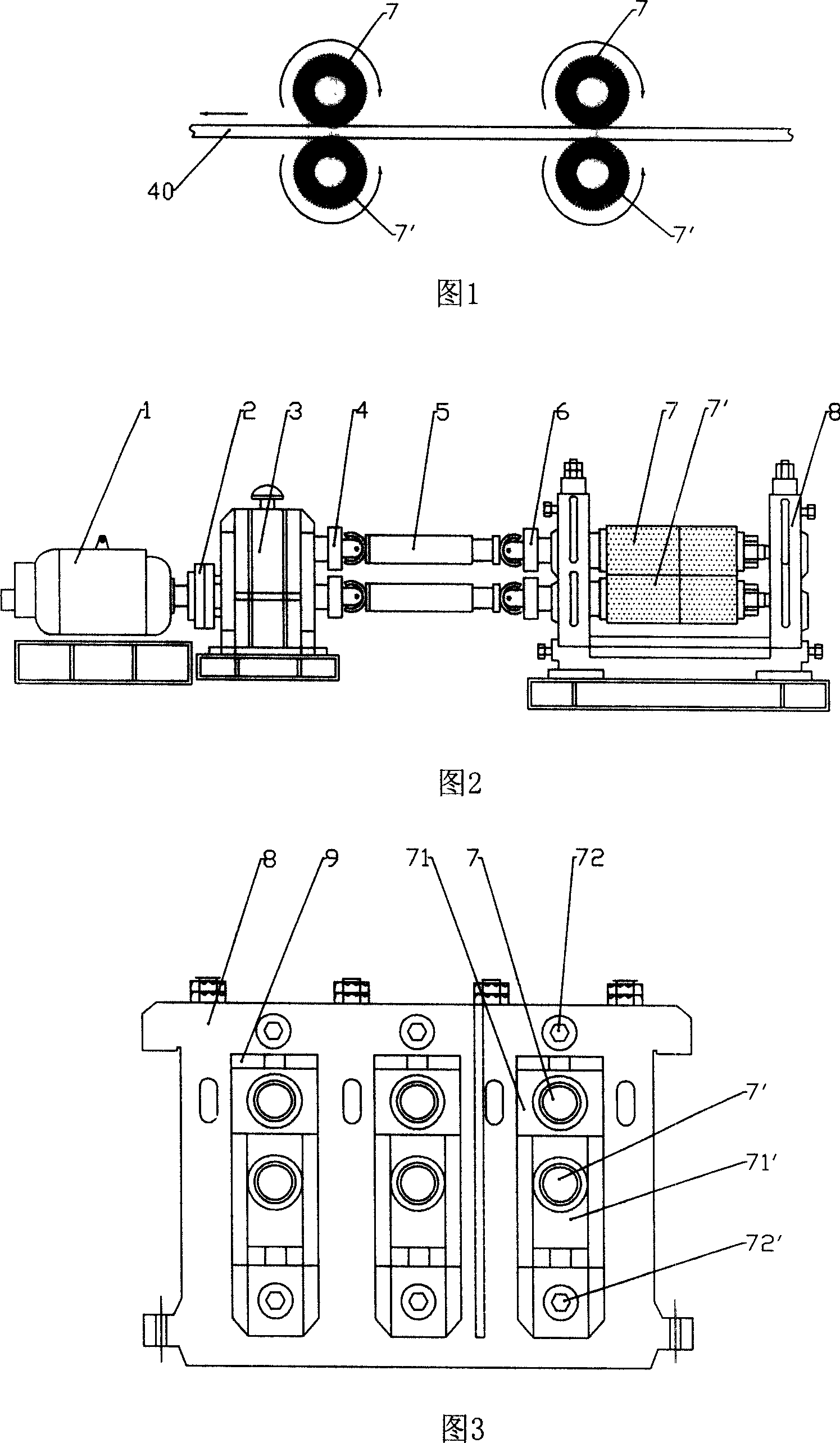

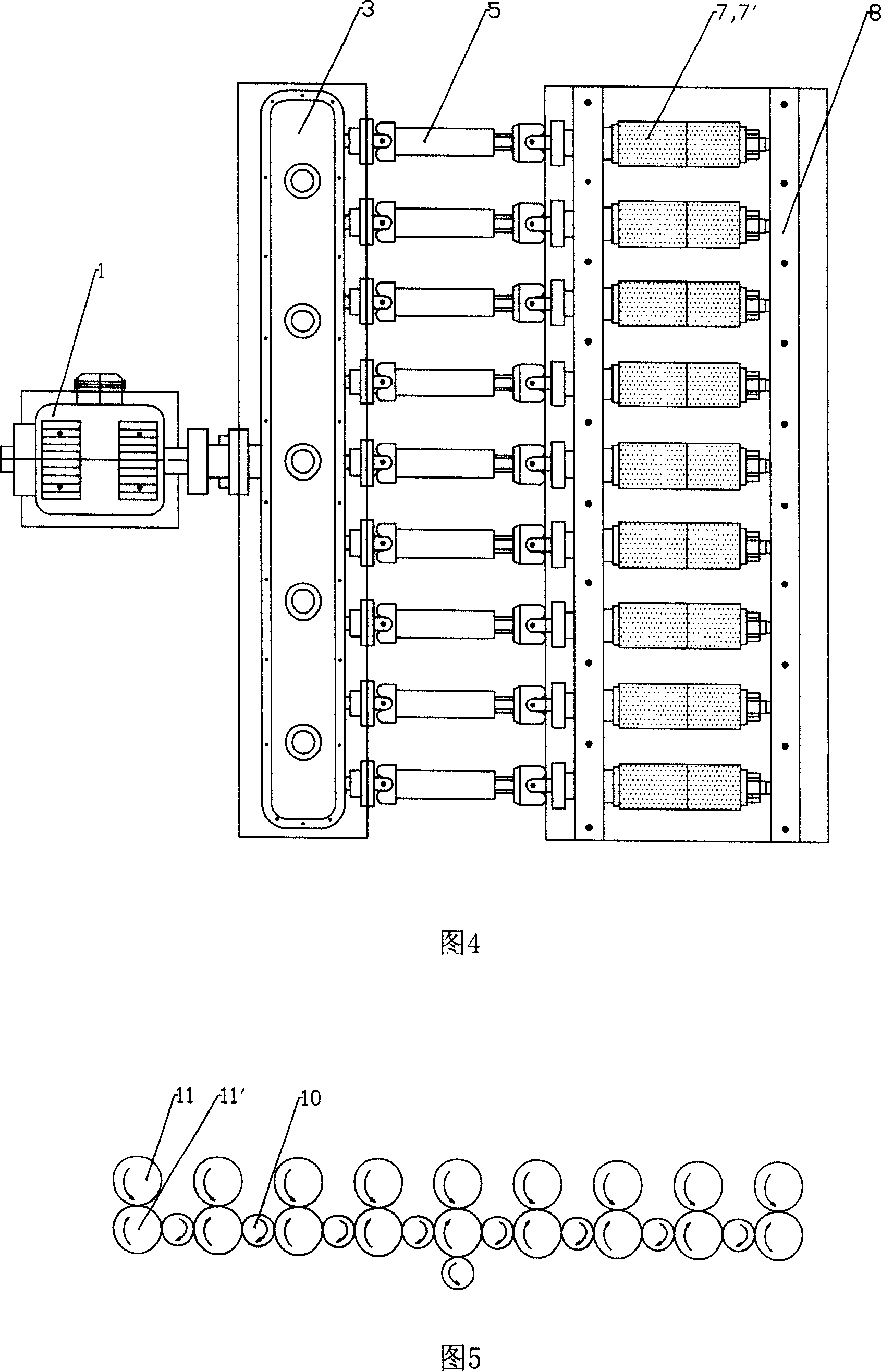

[0014] As shown in Fig. 2 and Fig. 4, it is a strip steel derusting and descaling machine, including a frame 8, and on the frame 8, there are many pairs of steel wire wheels installed and arranged in a linear manner through bearings, that is, many pairs of steel wires The wheels are installed on the same plane to process flat steel strips; each pair of wire wheels is arranged by the upper wire wheel 7 and the lower wire wheel 7', and the two wire wheels 7, 7' are arranged in parallel up and down. A gap passing through the steel plate is reserved between them, and a power device composed of a motor 1 and a combined gearbox 3 is also included, and the power device drives the wire wheels 7, 7' through a transmission device composed of a cardan shaft 5 Rotate, the above steel wire wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com