Environmentally-friendly odor removing dual-component cement-based waterproof material

A waterproof material and cement-based technology, which is applied in the field of environmentally friendly and odorless two-component cement-based waterproof materials to achieve the effects of good environmental protection, good construction and good impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

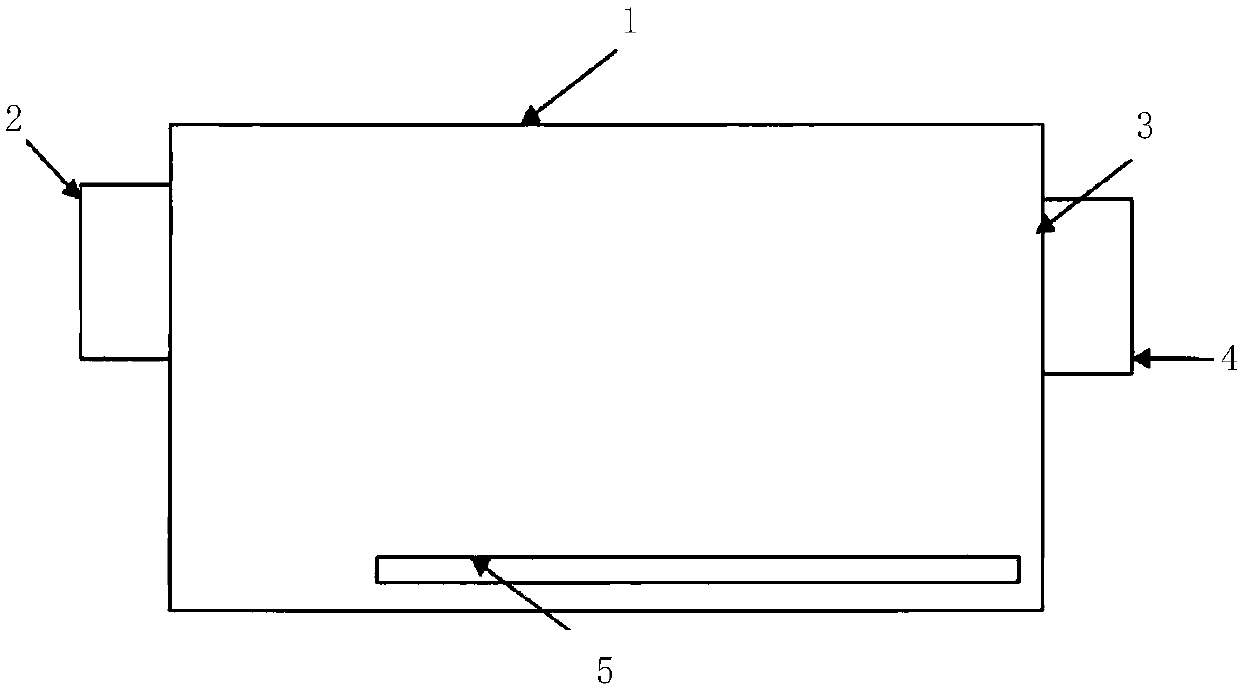

Image

Examples

Embodiment 1

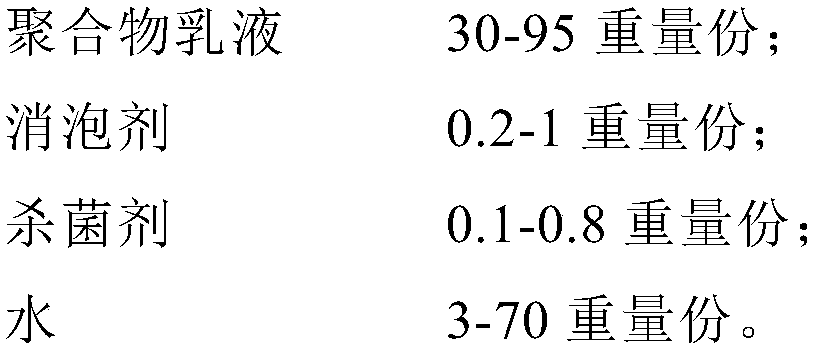

[0065] In the present embodiment, liquid material component is:

[0066]

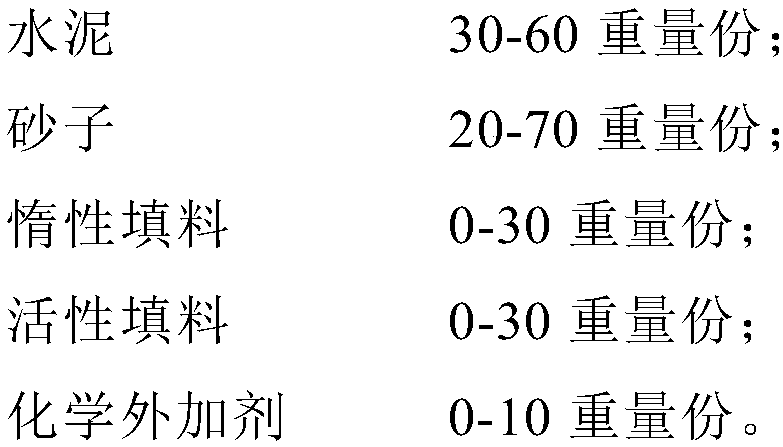

[0067] The powder components are:

[0068]

[0069] The liquid-to-powder ratio of the formula is 1:3.3, according to the enterprise standard >, "JC / T 1066-2008 Limits of Harmful Substances in Architectural Waterproof Coatings" and "JC / T 984-2011 Polymer Cement Waterproof Mortar" to test and evaluate the formula.

[0070] Table 3 shows the odor test results of the waterproof material prepared by the formula of Example 1 (ie the example formula 1 in the table) and common waterproof materials on the market.

[0071] Table 3 Odor test results

[0072]

[0073] The results of the odor test show that the odor of the waterproof material formulated in Example 1 can reach level 2 in the first odor test, while the odor of ordinary waterproof material products on the market can only reach level 2 after the fourth cycle.

[0074] The harmful substance detection result of example formula 1 is shown in t...

Embodiment 2

[0083] In the present embodiment, liquid material component is:

[0084]

[0085] Powder formula:

[0086]

[0087] The liquid-to-powder ratio of the formula in this example is 1:2.5, according to the enterprise standard >, "JC / T 1066-2008 Limits of Harmful Substances in Architectural Waterproof Coatings" and "GB / T 23445-2009 Polymer Cement Waterproof Coating" tests and evaluates this formula.

[0088] Table 6 shows the odor test results of the waterproof material prepared by the formula of Example 2 (ie the example formula 2 in the table) compared with common waterproof materials on the market.

[0089] Table 6 Odor test results

[0090]

[0091] The results of the odor test show that the example formula 2 can reach the odor intensity level 2 after 3 cycles, while the common waterproof materials on the market cannot meet the requirement of clean odor.

[0092] The harmful substance detection result of example formula 2 is shown in table 7.

[0093] Table 7 Hazard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com