System for coupling aerobic composting and dry type anaerobic straw fermentation

A dry anaerobic fermentation and aerobic composting technology is applied in the fields of organic fertilizers, fertilization devices, and preparation of organic fertilizers. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

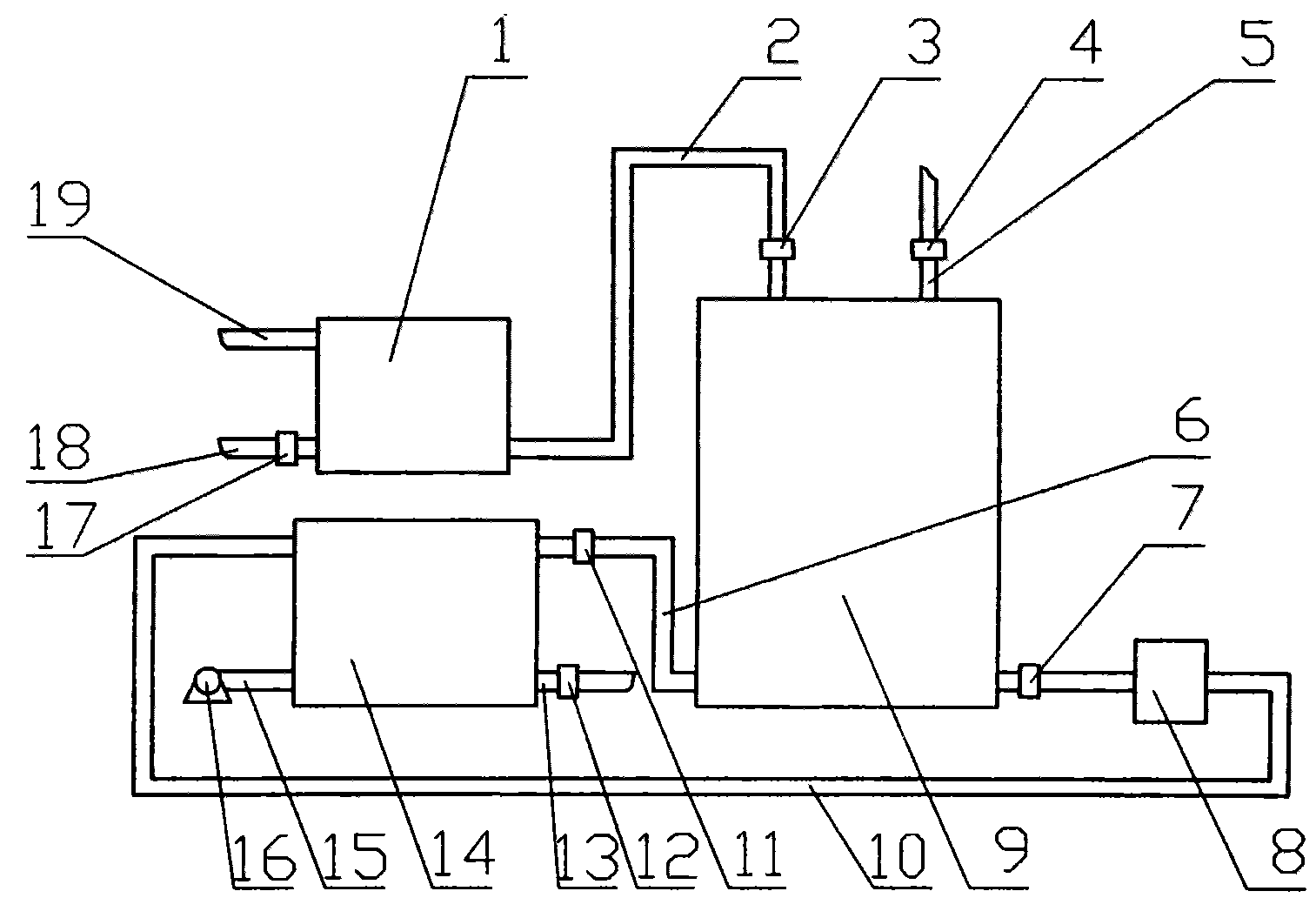

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An aerobic composting and straw dry anaerobic fermentation coupling system includes a biochar waste gas purifier 1, a straw dry anaerobic fermenter 9 and an aerobic composter 14; the biochar waste gas purifier 1 is connected and installed to clean Exhaust gas discharge pipe 19 and waste biological carbon material discharge pipe 18 with waste gas bio-carbon material discharge valve 17; Air pump 16 is communicated with aerobic composter 14 through inlet pipe 15, and on described aerobic composter 14, equipped with The decomposed organic fertilizer discharge pipe 13 of the decomposed organic fertilizer discharge valve 12; the straw dry anaerobic fermenter 9 is connected to the biogas output pipe 5 with the third gas valve 4; the first waste gas equipped with the first gas valve 11 The conveying pipe 6 connects the aerobic composter 14 with the straw dry ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com