Patents

Literature

63results about How to "Reduce carbon dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

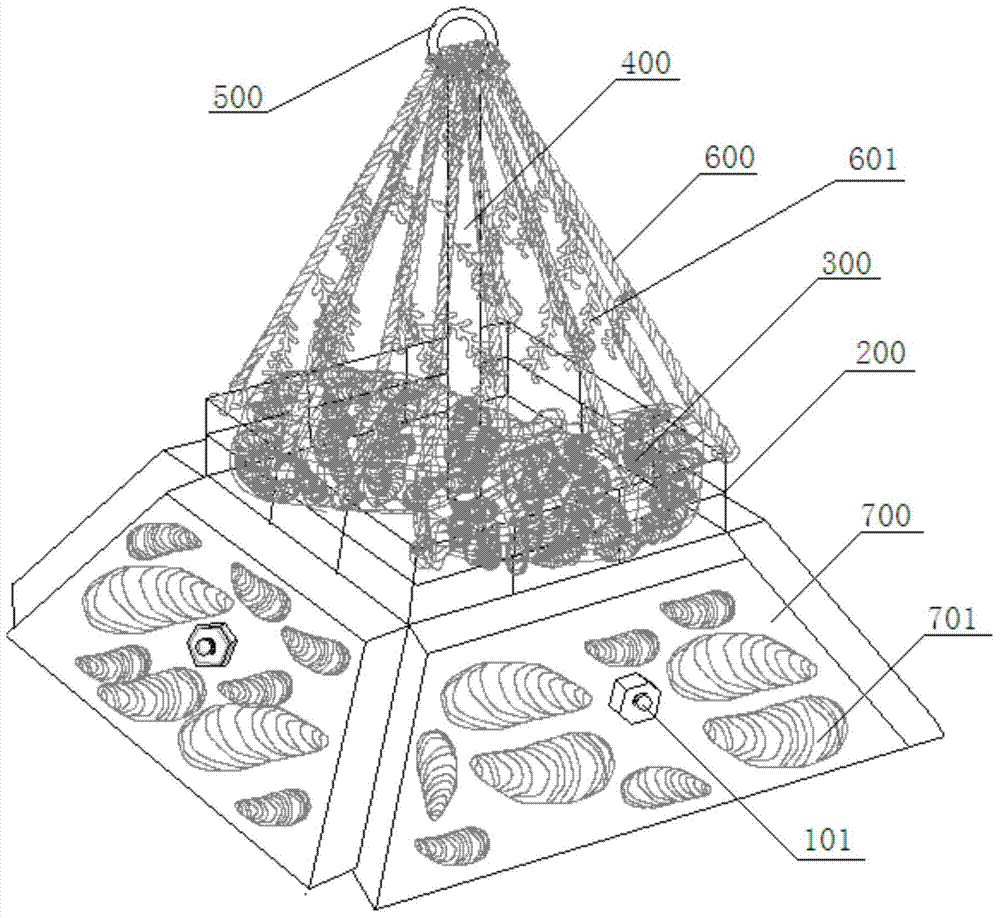

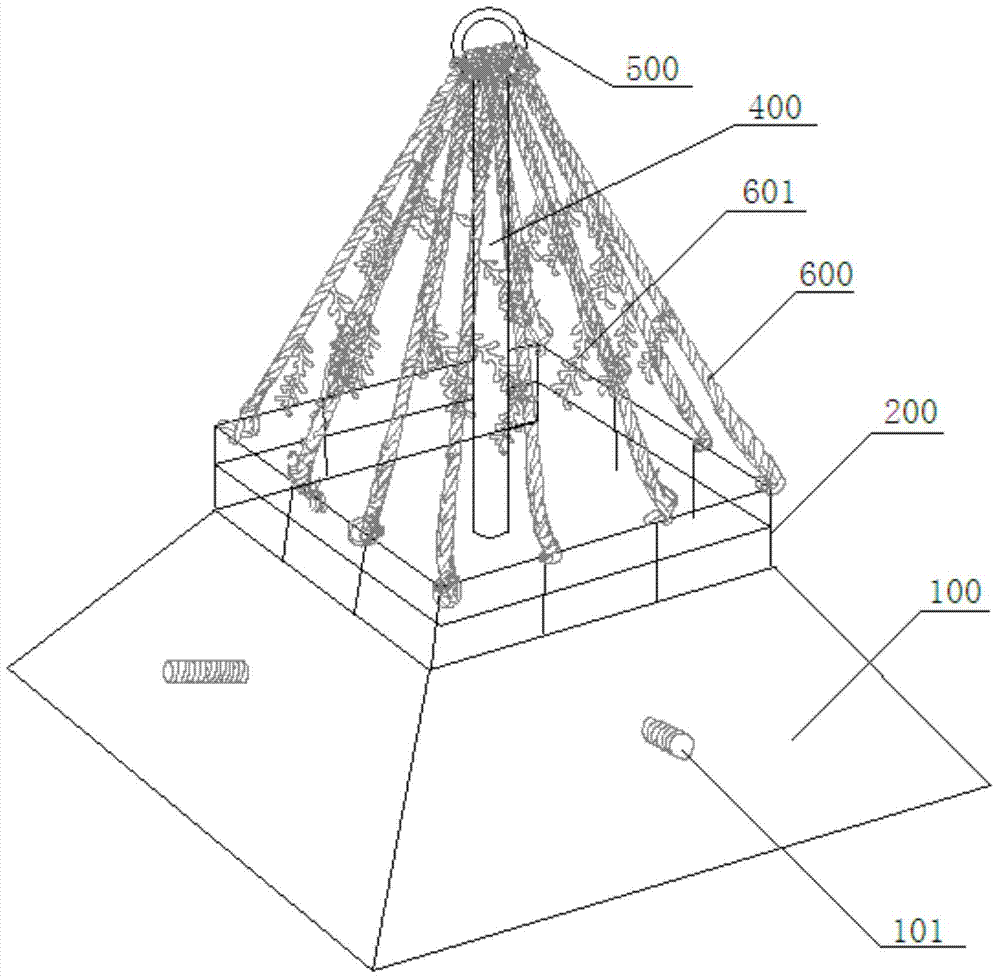

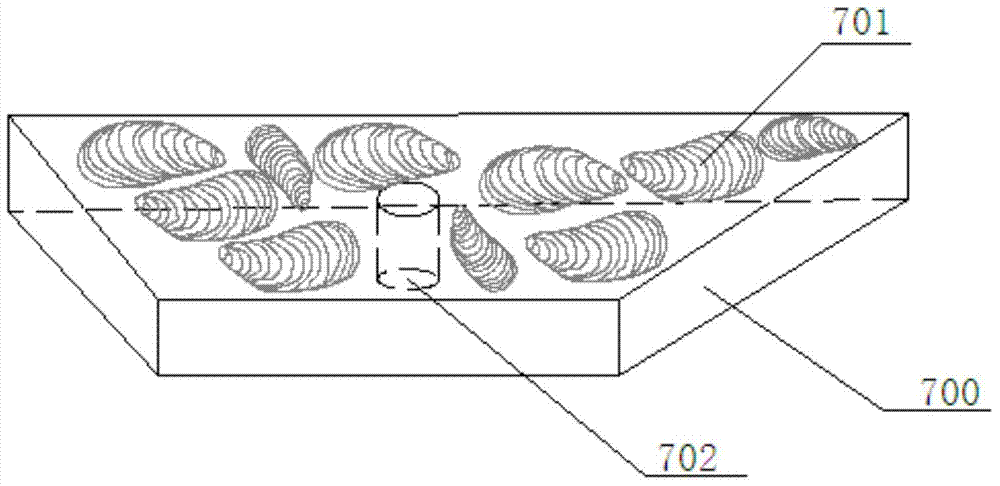

Composite type artificial algal reef

ActiveCN103609424AEasy to carryGuaranteed adhesion effectClimate change adaptationPisciculture and aquariaSporeConch

The invention discloses a composite type artificial algal reef comprising a mature algal reef and a seedling reef. The mature algal reef comprises a solid base. The upper surface of the solid base is embedded with a metal frame, wherein the shape of the metal frame is identical to that of the upper surface of the solid base and the size of the metal frame is identical to that of the upper surface of the solid base. A conch net bag is arranged in the metal frame. The center of the upper surface is embedded with a metal stand column. A steel ring is welded to the upper end of the stand column. A plurality of seedling ropes are fixed between the metal frame and the steel ring. The seedling reef is fixed to the side face of the solid base of the mature algal reef, and algal seedlings are attached to the seedling reef. By the adoption of the composite type artificial algal reef, the attaching effect of alga is guaranteed, the repair period of an algae field is shortened, the success rate of repair and reconstruction of the algae field is improved, the adhesive rate of the seedlings is increased, and the seedling reef is firm, durable, small in size, light, and convenient to carry; the net bag made of waste conches is placed in the metal frame, and a biophile reef can be composed through diffusion and attachment of spores of fronds on the seedling ropes; resource utilization of the waste conches is achieved, and composite type artificial algal reef has the advantages of being economical and easy and convenient to use.

Owner:SHANGHAI OCEAN UNIV

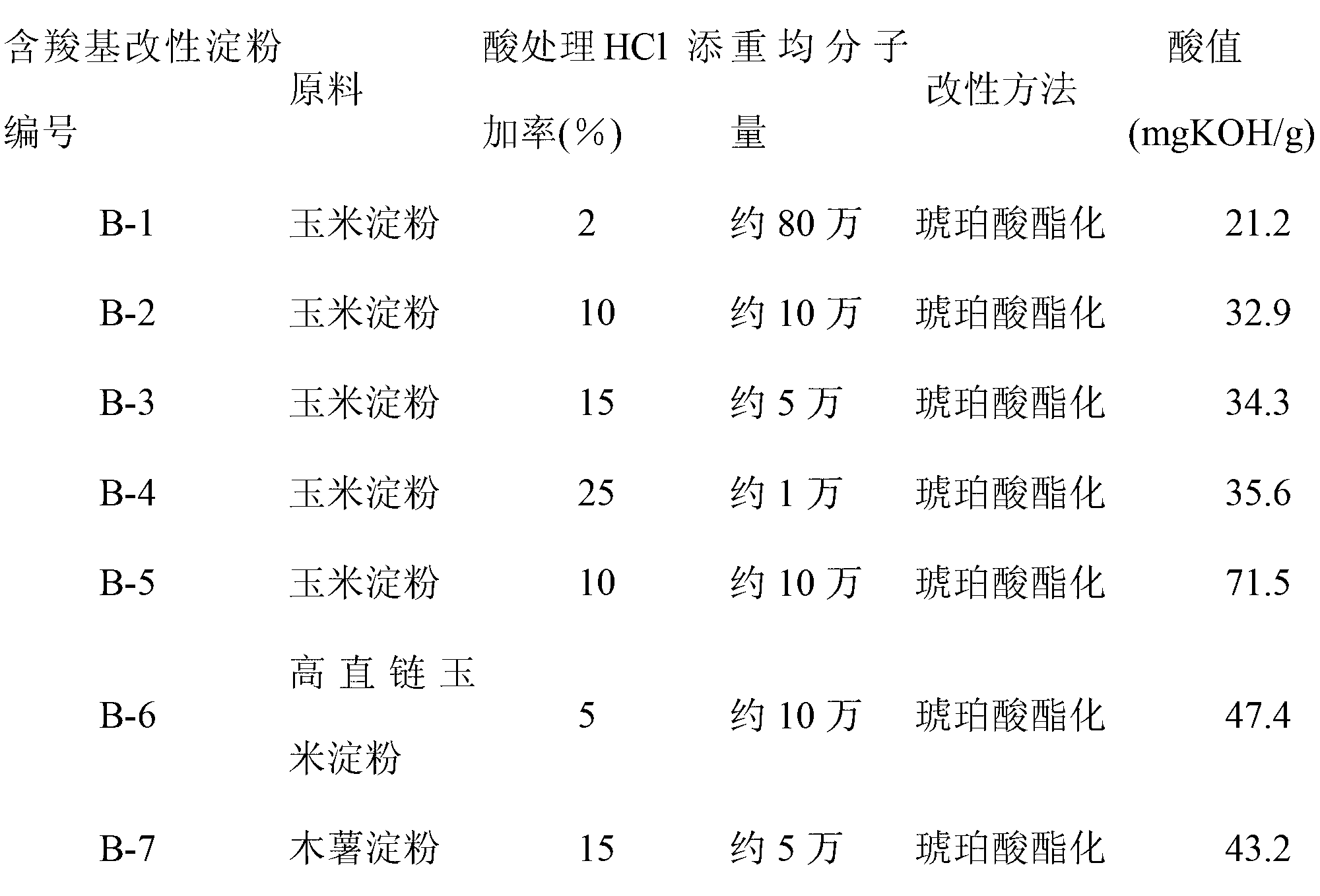

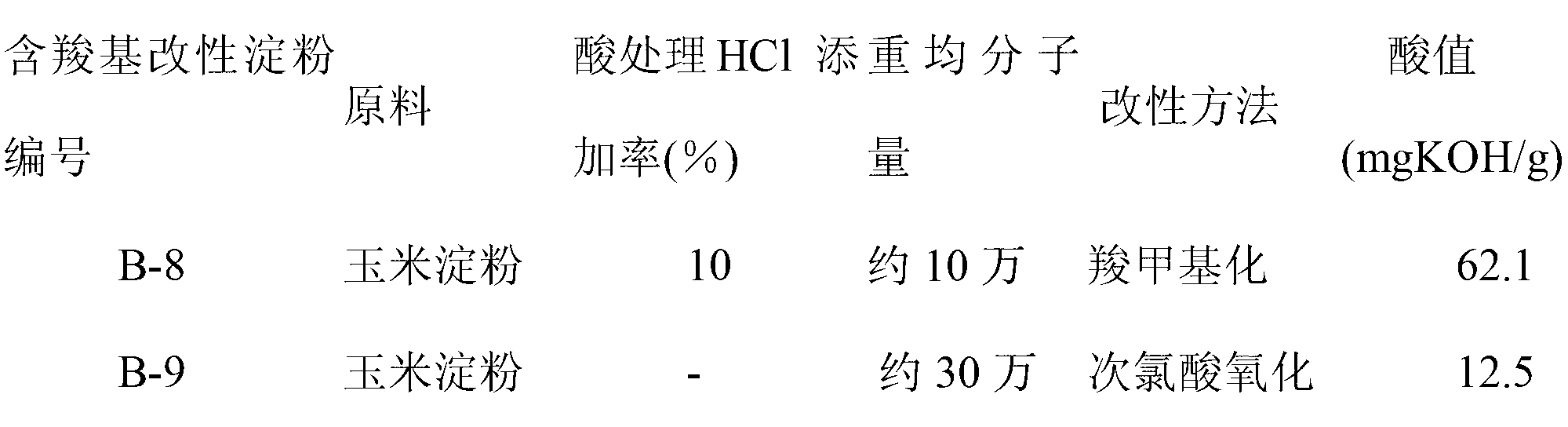

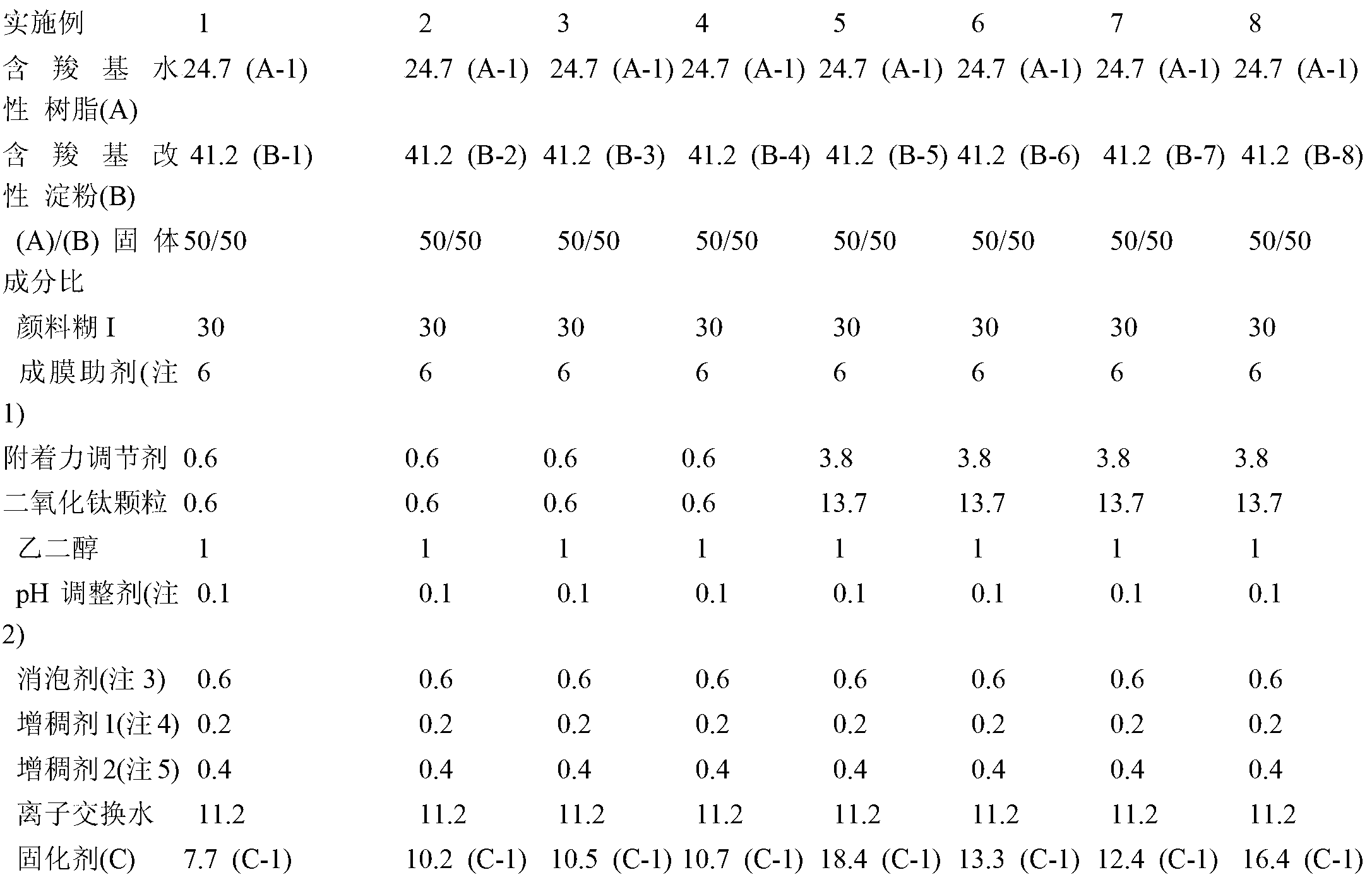

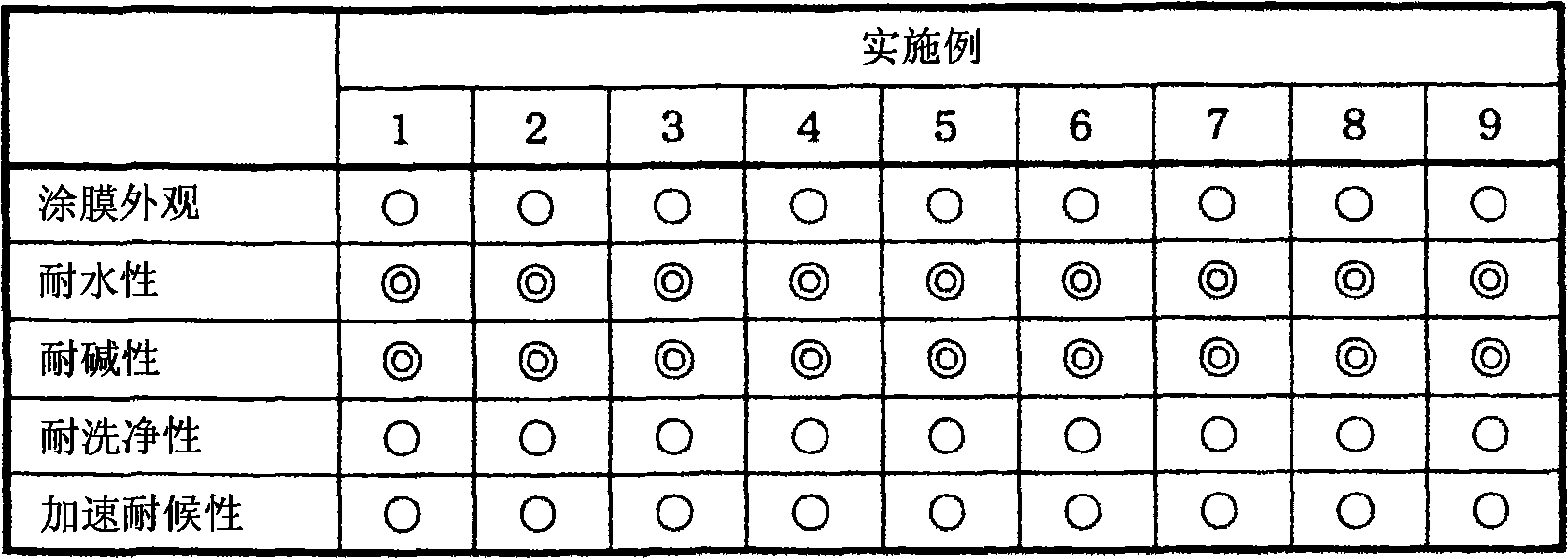

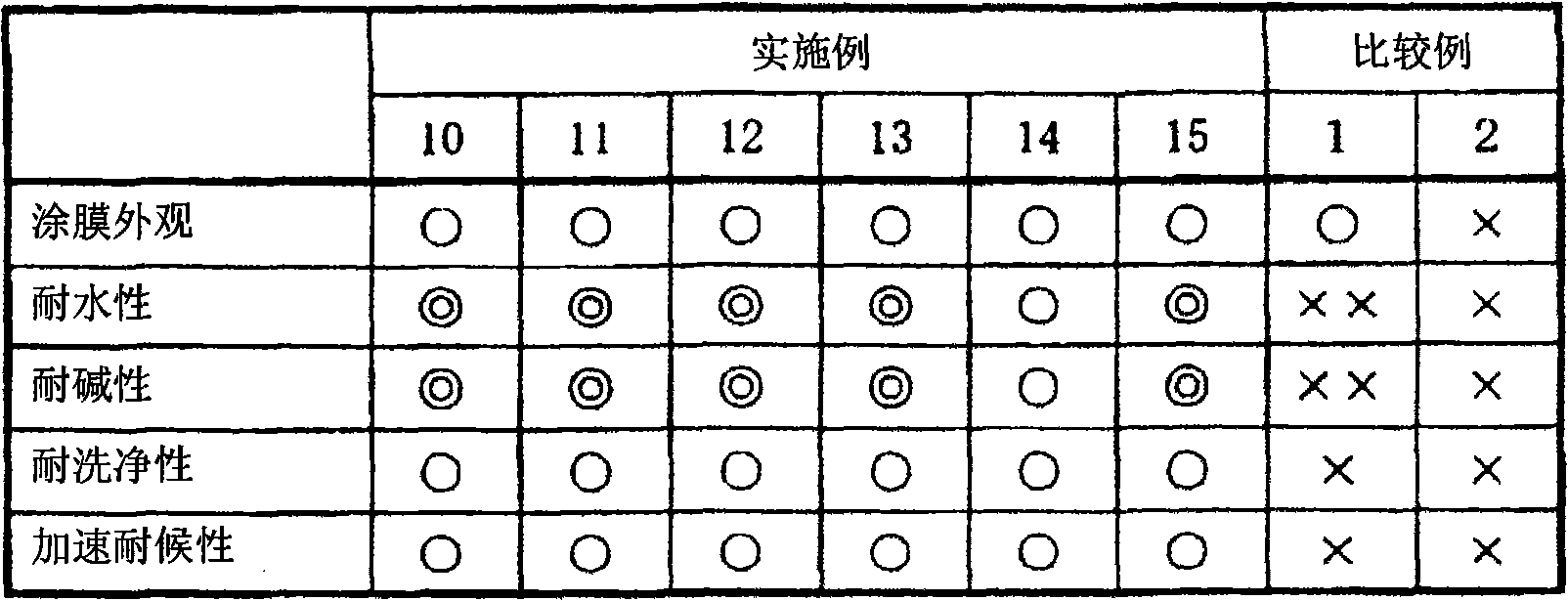

Water paint composition

InactiveCN102827518AGood effectNot easy to surviveStarch dervative coatingsPolyurea/polyurethane coatingsWater basedWear resistance

The invention relates to a water paint composition, containing carboxyl-containing water-base resin, carboxyl-containing modified starch, a curing agent having a functional group for carrying out curing reaction with carboxyl, an adhesion conditioning agent and titanium oxide particles. The water paint composition provided by the invention has the advantages of excellent coating performances, such as biodegradability, water tolerance, alkali resistance, wear resistance, weather fastness, wide range of strippable temperature, and high strippability.

Owner:ANHUI JINDUN PAINT

Respirable multifunctional negative-ion ceramic and manufacturing method and application thereof

ActiveCN106830893AImprove the desorption effectPlay a role in purifying the airCeramic materials productionCeramicwareAfter treatmentSide effect

The invention discloses respirable multifunctional negative-ion ceramic and a manufacturing method and the application thereof. The manufacturing method comprises the following steps: performing after-treatment on a green body raw material to form a green body powder, pressing the green body powder into a green body, and drying the green body to form a semi-finished product; mixing and crushing a first glaze raw material to form a first glaze, and coating the semi-finished product with the first glaze to form a first glaze layer; mixing and crushing a second glaze material to form a second glaze, coating the first glaze layer with the second glaze to form a second glaze layer, and after that, firing. The respirable multifunctional negative-ion ceramic provided by the invention has lots of nanopores and microholes, can adsorb harmful gases with various molecular weights, has a favorable desorption function, further, can release negative ions, can effectively purify air and does not have any side effects.

Owner:清远市美邦陶瓷实业有限公司

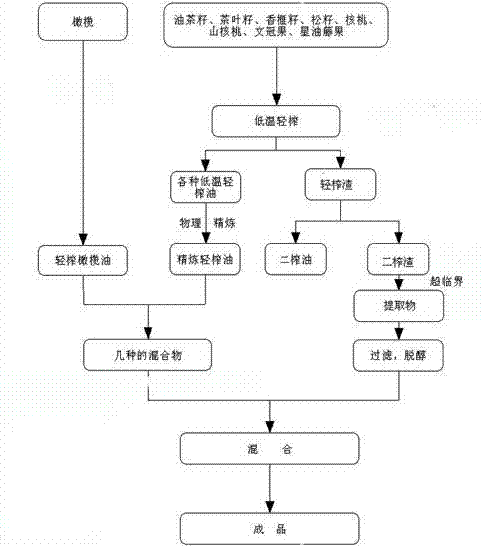

Advanced woody blend oil and production process thereof

ActiveCN103082027ALong growth cycleNutrient accumulationFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesRotary evaporator

The invention relates to a production process of advanced woody blend oil. The production process comprises the following steps of: respectively carrying out virgin expelling on camellia seeds, tea seeds, Chinese torreya seeds, pine nuts, walnuts, hickory nuts, brook feather and plukenetia volubilis fruits under the conditions that the virgin expelling temperature is lower than 150 DEG C, and the oil outlet temperature is lower than 90 DEG C to obtain corresponding virgin oils and virgin slags, wherein the oil yield is 60-70 percent; putting the obtained corresponding secondary expelled slags into a supercritical carbon dioxide kettle, and carrying out extraction to obtain an extract with edible ethanol as an entrainer, wherein the additive amount of the entrainer is 5 percent of the material weight, and extraction is carried out under the conditions that the pressure is 35 MPa and the temperature is 40 DEG C; after filtering the extract, secondarily filtering the extract and removing impurities of the extract by active carbon, and carrying out vacuum removing on ethanol in a rotary evaporimeter under the conditions of 40 DEG C, 8kPa and 25 turns / min to refine the extract; and mixing the virgin oils to obtain a finished product. According to the production process, the camellia seeds, the tea seeds, the Chinese torreya seeds, the pine nuts, the walnuts, the hickory nuts, the brook feather and the plukenetia volubilis fruits are all woody oil seeds and even advanced woody oil seeds, the growth period of the woody oil seeds is long, nutrition is more accumulated, and the woody oil seeds have more nutritive value and functions than herbal oil seeds.

Owner:温州瑞雪农业开发有限公司

Aqueous paint composition

InactiveCN101659815AGood effectNot easy to surviveStarch dervative coatingsPolyurea/polyurethane coatingsWeather resistanceCarboxylic group

The invention provides an aqueous paint composition having good coated film performance such as water resistance, alkali stability, abrasion resistance, weather resistance and the like after a biomassmaterial with the biodegradability is used. The aqueous paint composition contains (A) an aqueous resin containing carboxyl, (B) a modified starch containing carboxyl and (C) a curing agent with a functional grouping the cure reaction with carboxyl.

Owner:NIPPON PAINT CO LTD +1

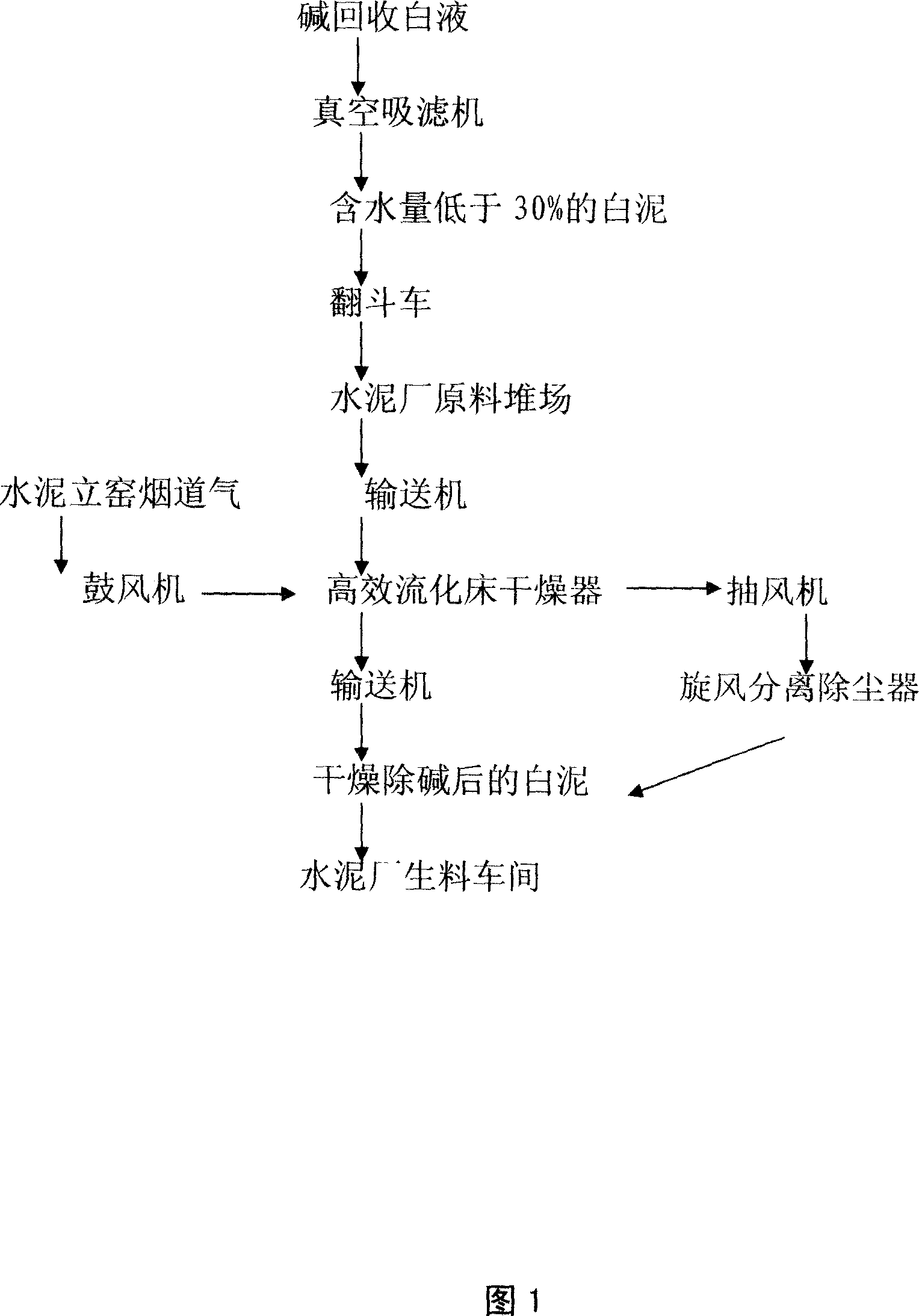

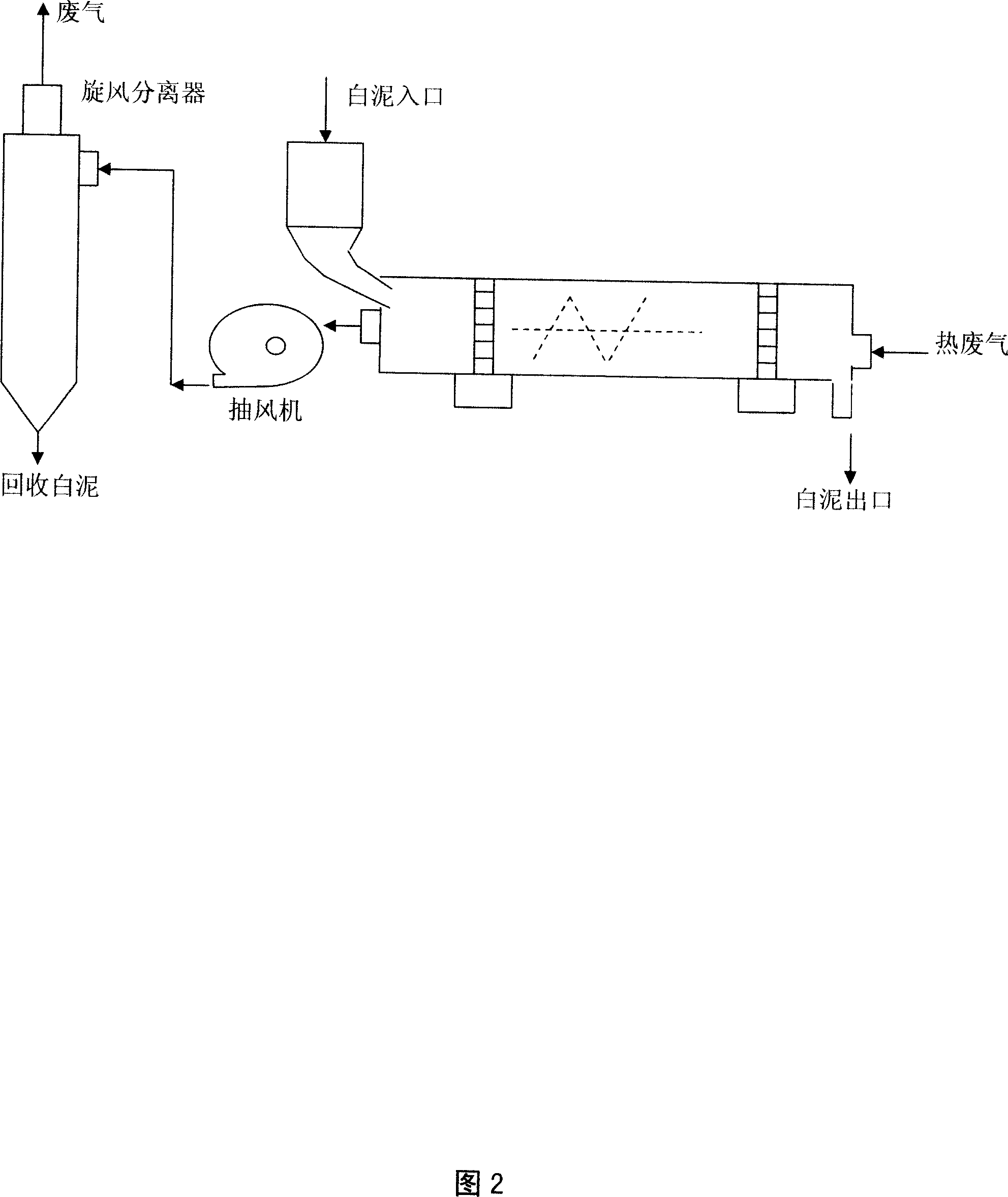

Process of producing cement with papermaking white clay as material

InactiveCN1986472AReduce drying costsReduce pollution hazardsSludge treatment by de-watering/drying/thickeningCement productionFluidized bed dryingSlurry

The process of producing cement with waste papermaking white clay as material includes filtering alkali recovered white fluid in a vacuum suction filter to obtain white clay slurry with water content lower than 30 %, drying through contacting with vertical cement kiln fume inside a fluidized bed drier to obtain alkali-eliminating white clay, and using the white clay as material mixed clay, gypsum, coal and other cement producing material in cement produce shop. The present invention obtains cement material, waste heat and purified cement kiln fume and is environment friendly.

Owner:GUANGXI YUEGUI GUANGYE HOLDINGS CO LTD

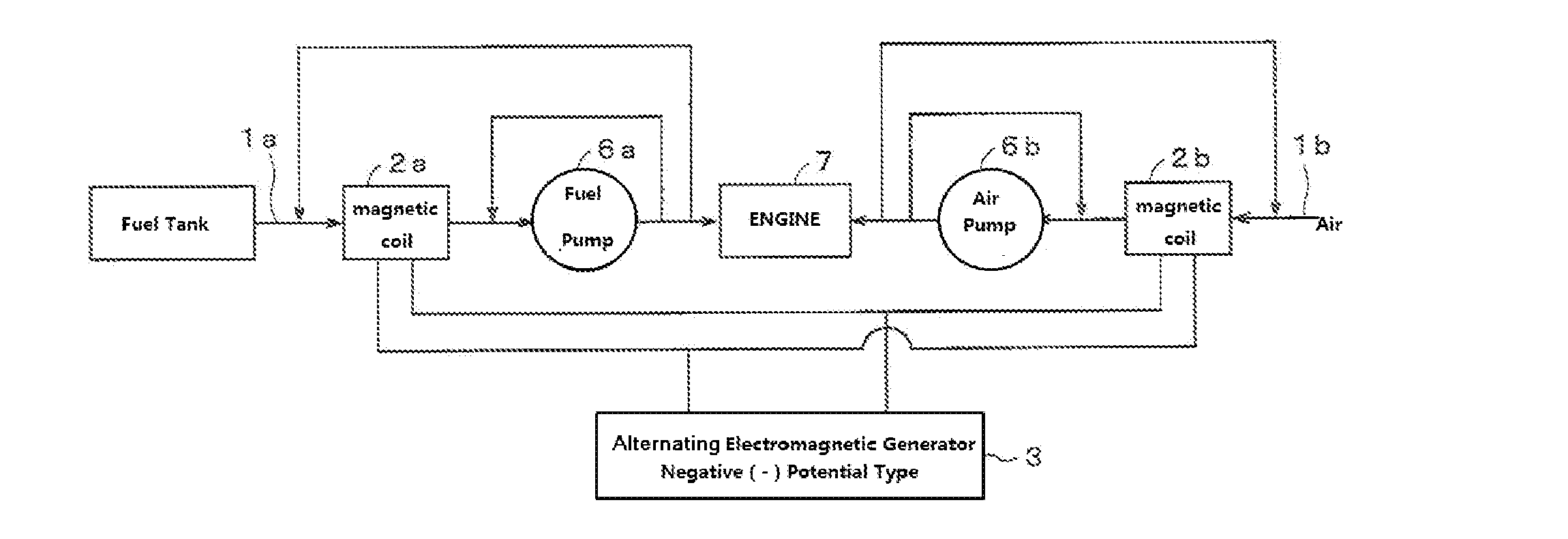

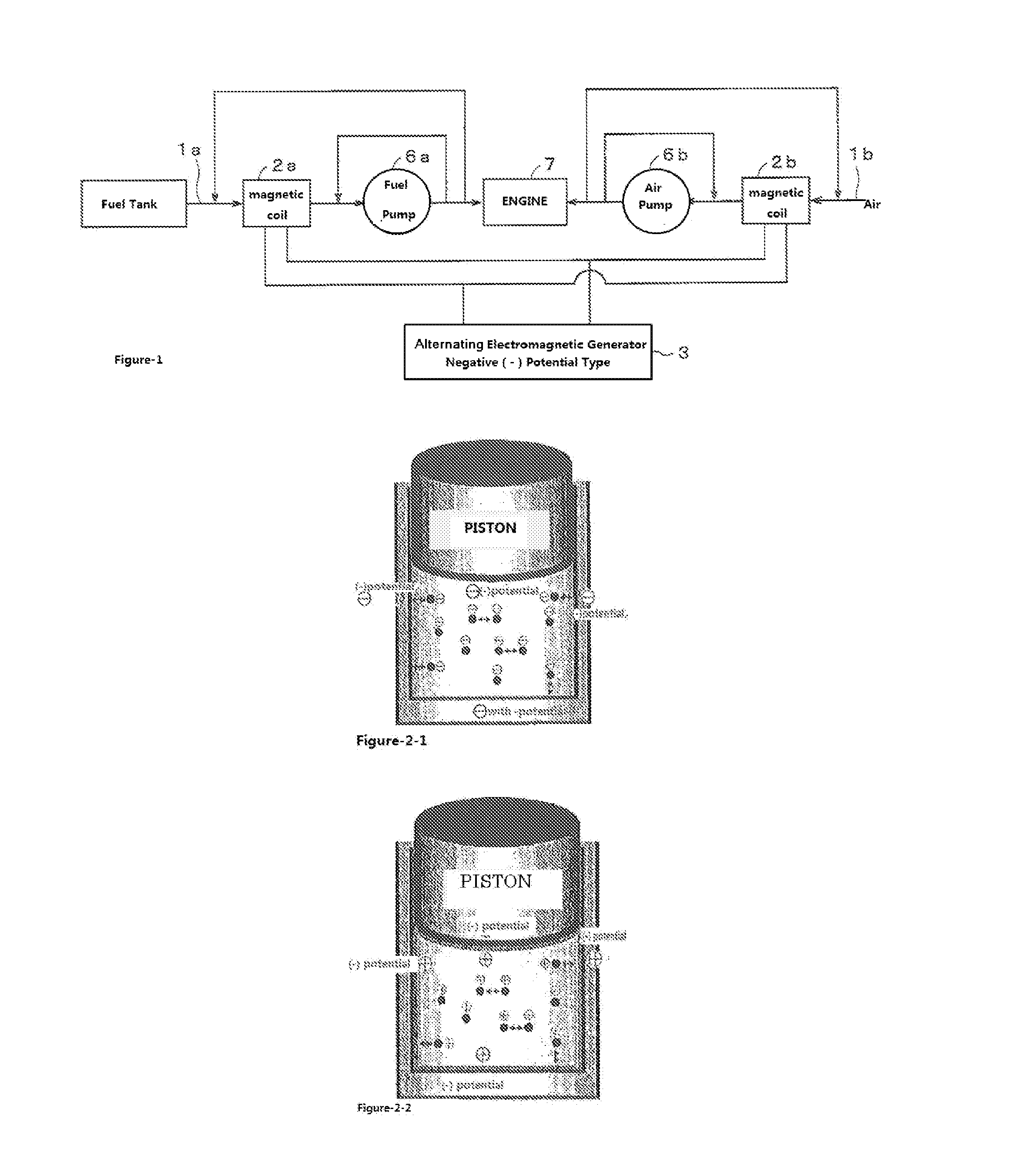

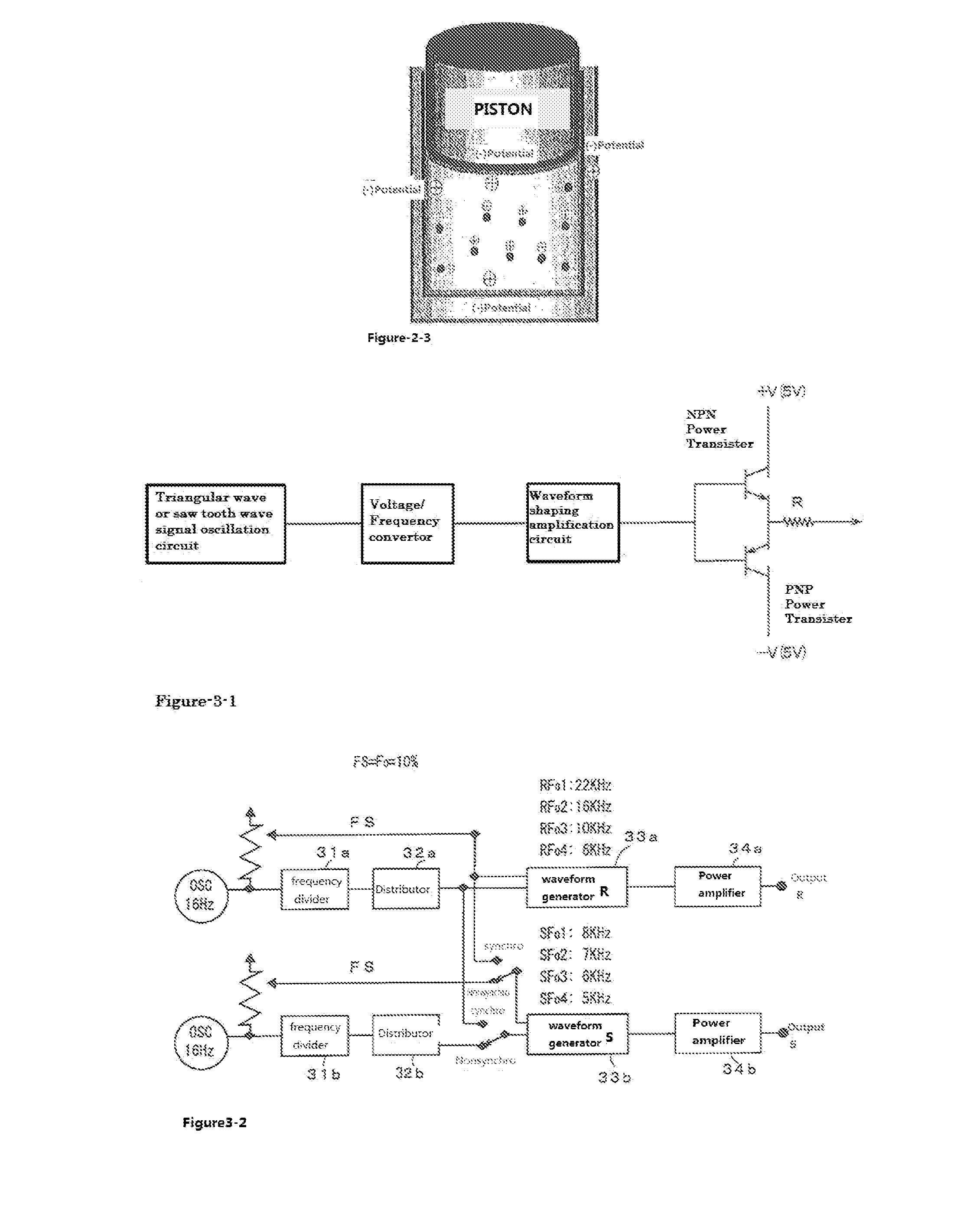

Fuel magnetization treatment method

InactiveUS20140202864A1Fuel ratio can be improvedAvoid pollutionLiquid separation by electricityElectrostatic separationCombustionElectromagnetic coil

A fuel magnetization treatment method includes mounting electromagnetic coils on a supply system through which fuel is supplied to a combustion device of an engine (7), connecting two joints of the electromagnetic coils with an electromagnetic generating device, and providing alternating current to the electromagnetic coils through the electromagnetic generating device so that an alternating current magnetic field is generated by the electromagnetic coils and is used to magnetize the fuel in the engine, where the frequency zone of the alternating current is 4 kHz˜25 kHz. The method can improve the combustion efficiency of various fuels, enhance the power output performance of the engine, inhibit the emission of various pollution gases and prolong the life of engine lubricating oil.

Owner:ZHENJIANG KEYUE ENE TECH

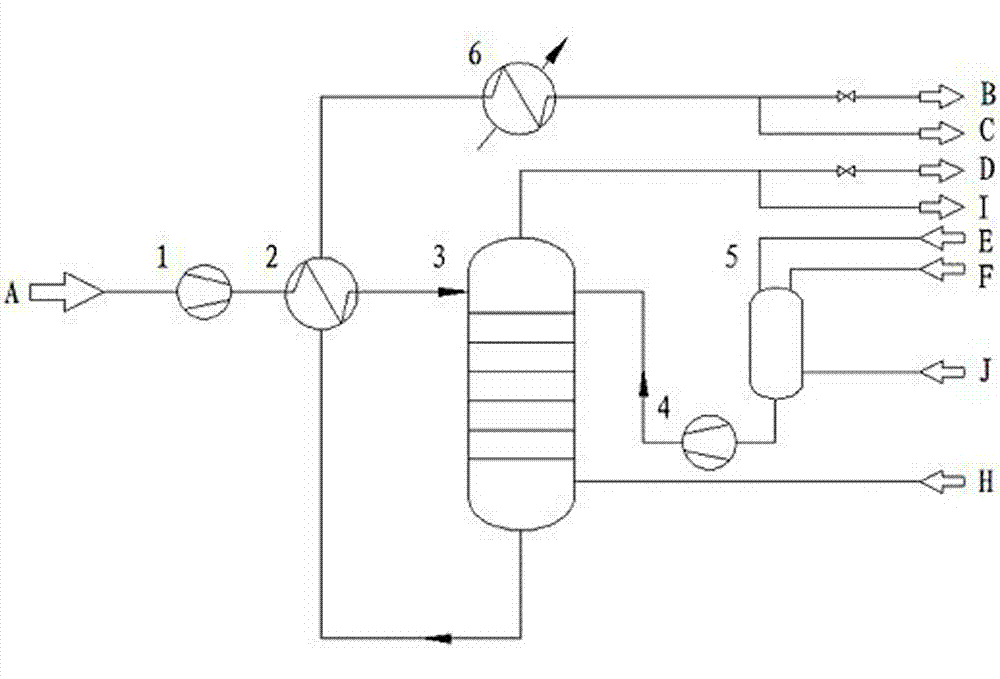

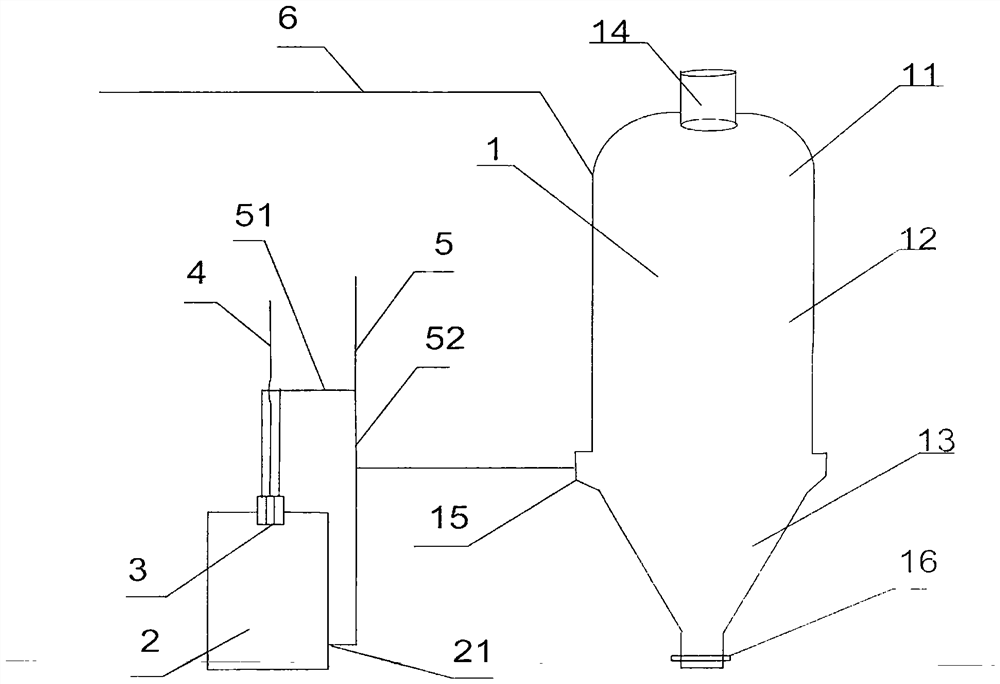

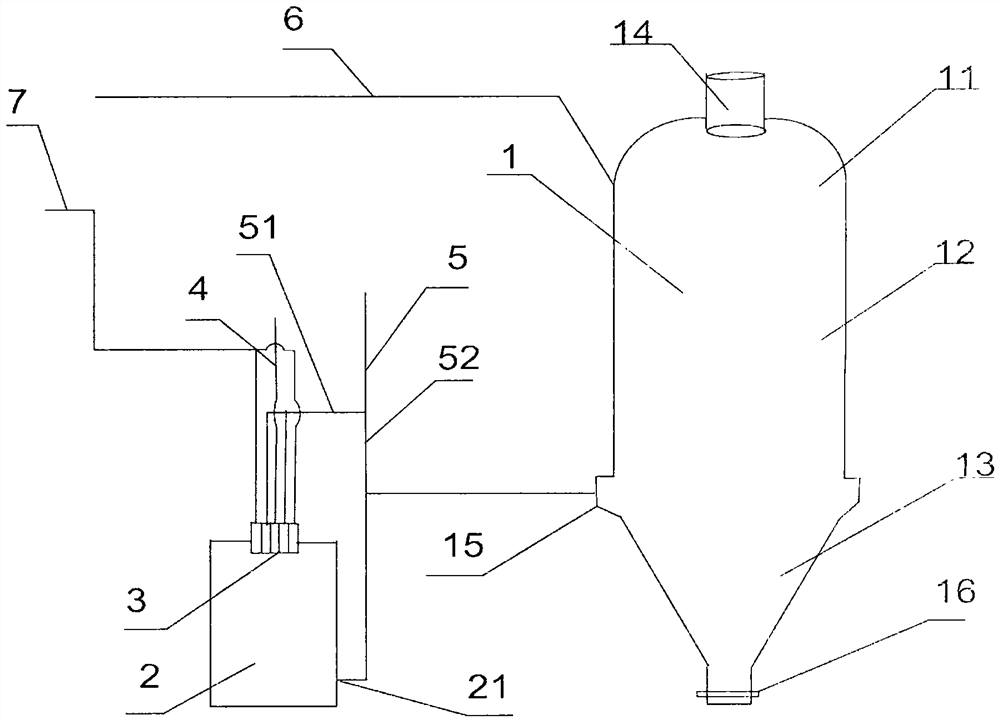

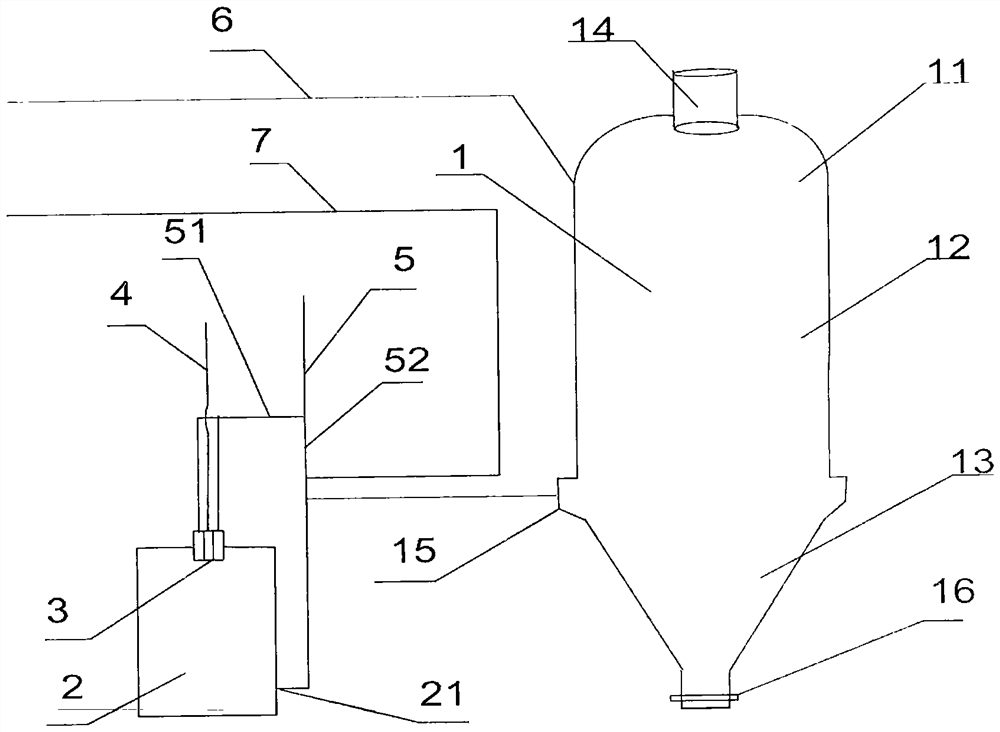

Method and device for treating coal chemical industry production sewage

InactiveCN103496755AImprove the degree of purificationReduce carbon dioxideWater/sewage treatment by heatingWater/sewage treatment by degassingSolubilityHigh pressure

The invention provides a method and a device for treating coal chemical industry production sewage. The method comprises the following steps: allowing medium-pressure overheat steam with the pressure of 3.0 to 4.1 MPa and the temperature of 360 to 420 DEG C to enter a high-pressure steam stripping tower from the bottom of the tower, wherein the medium-pressure overheat steam serves as a heat source; directly heating the coal chemical industry production sewage, which enters the tower from the upper part of the tower and is pressurized to be 3.7 to 4.4 MPa, from bottom to top in a countercurrent manner; resolving soluble gases or volatile substances of the coal chemical industry production sewage; and discharging the generated coal chemical industry treated water from the bottom of the high-pressure steam stripping tower and discharging saturated steam containing resolved gases from the top of the tower. According to the method provided by the invention, an active carbon dephenolizing / CLL ammonia recovering process of coal chemical industry production sewage is changed into a medium-pressure overheat steam stripping process, so the separated pollutants can be recycled and the treated sewage returns a system to be comprehensively utilized.

Owner:TIANJI COAL CHEM IND GROUP

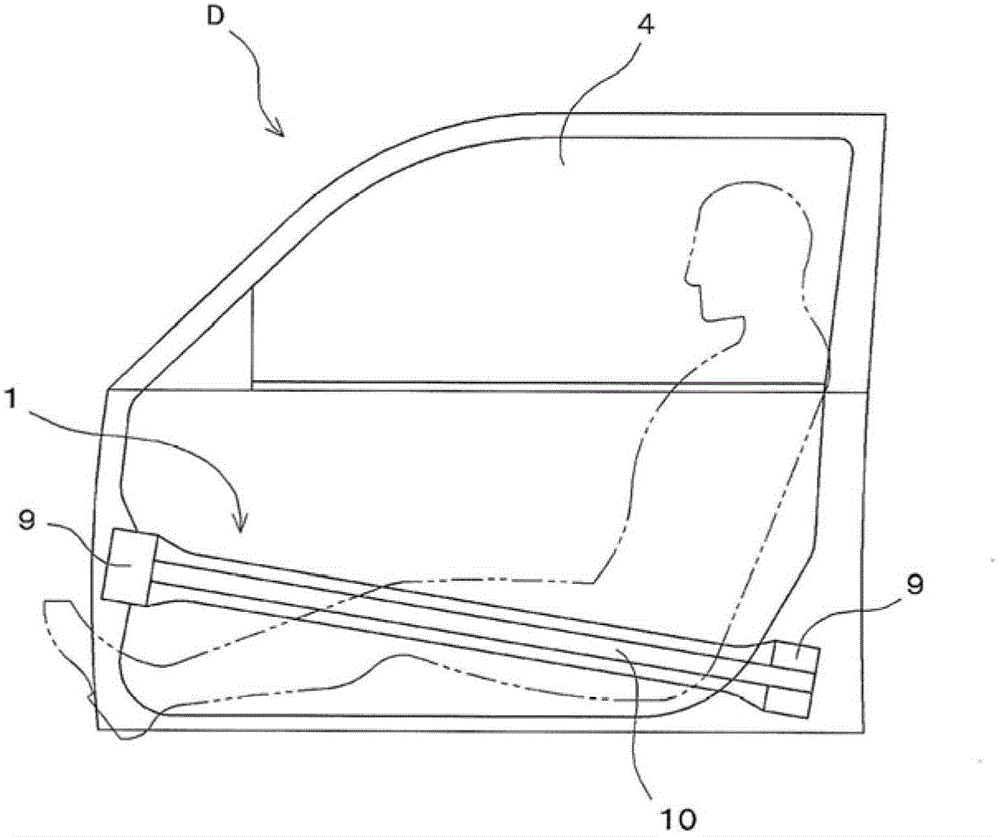

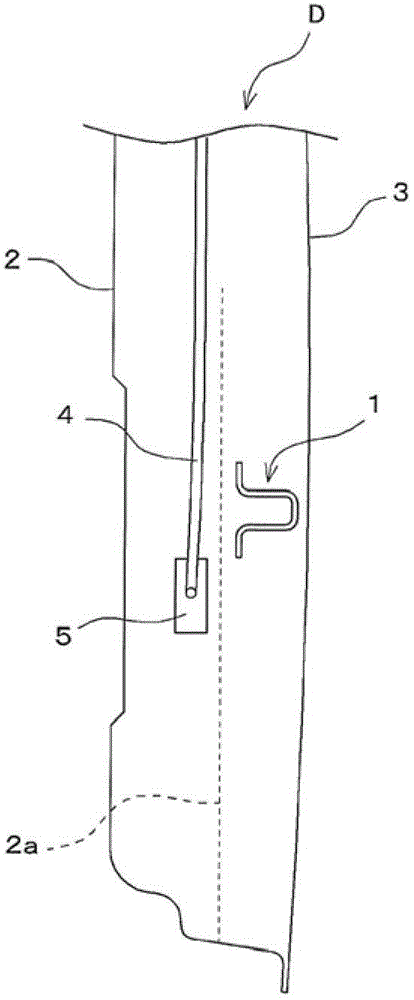

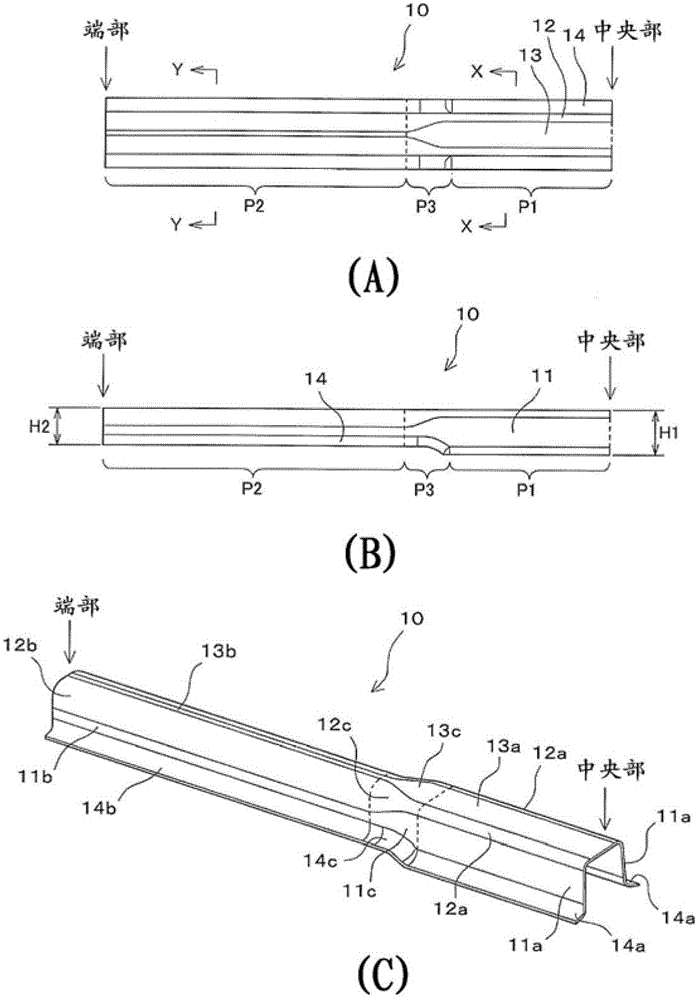

Collision reinforcement material for vehicle

ActiveCN102803024APrevent section fracturePrevents sharp drop in bending rigidityBumpersDoorsFlexural rigidityEngineering

It is an object of the present invention to provide a crash reinforcing member for a vehicle capable of preventing reduction in flexural rigidity as much as possible even if deformation progresses when a load at the time of crash of the vehicle is input. [Solution] A crash reinforcing member for a vehicle (e.g., door impact beam) includes a long body 10. The body 10 has a hat-shaped opened cross-sectional shape by connecting, with one another, a pair of walls 11, a pair of curved corners 12, a center flange 13, and a pair of outer flanges 14. The body 10 is divided into three sections P1, P2 and P3. A width (C1) of the center flange in the section P1 is wider than a width (C2) of the center flange in the section P2. A cross-sectional area of the curved corner 12 in the section P1 is narrower than a cross-sectional area of the curved corner in the section P2. A cross-sectional height (H1) of the section P1 is higher than a cross-sectional height (H2) of the section P2. The section P3 is provided as a gradually changing portion which smoothly connects the section P1 and the section P2 with each other.

Owner:AISIN TAKAOKA CO LTD

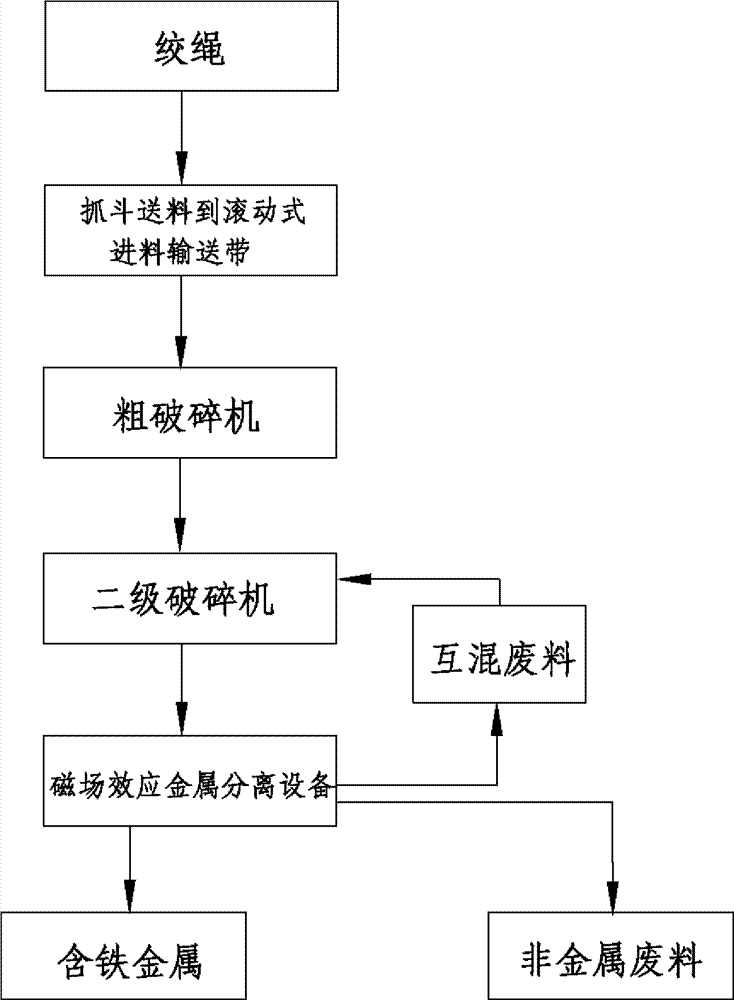

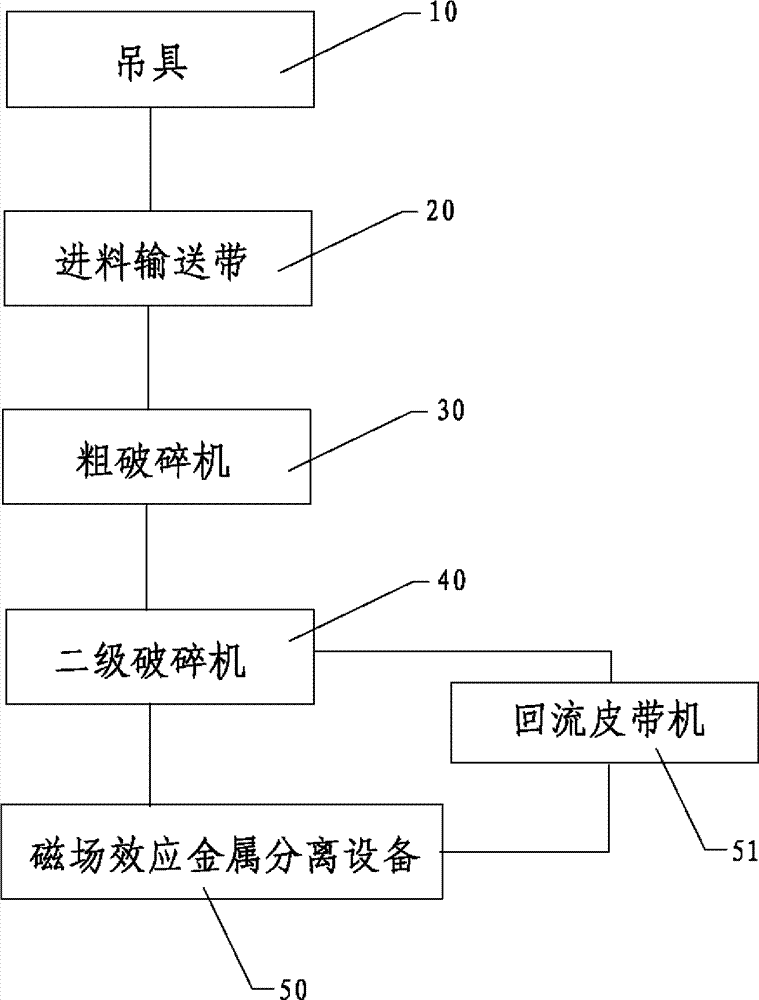

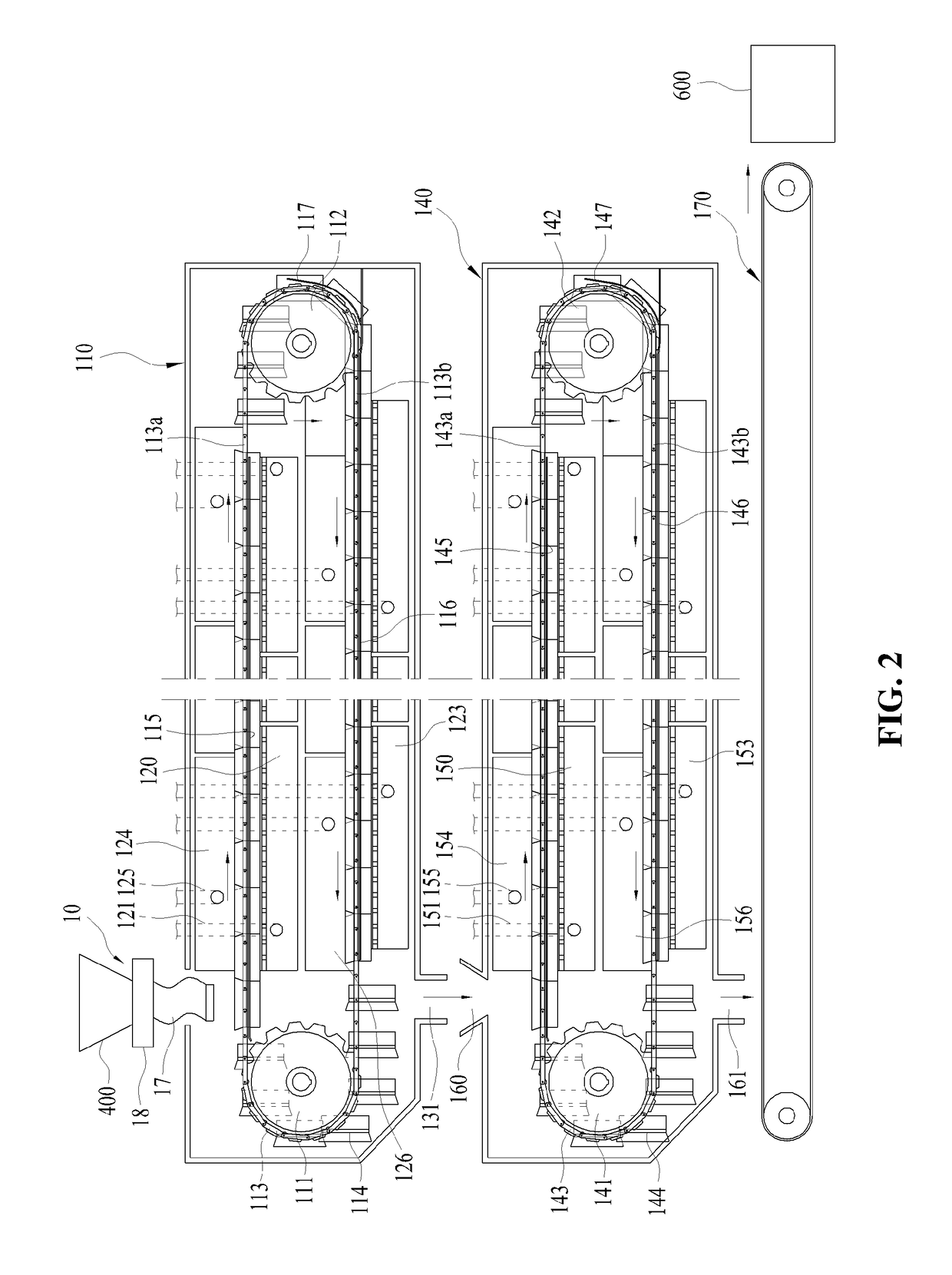

Method and system for crushing and recycling twisted ropes

ActiveCN103240158ASimple structureIncrease profitMagnetic separationGrain treatmentsSocial benefitsEconomic benefits

The invention relates to the technical field of paper-making machinery, and in particular relates to a method and a system for crushing and recycling twisted ropes. The recycling method comprises the following process steps of: feeding materials, namely, feeding the twisted ropes to a feeding conveyer belt by using a hanger; roughly crushing, namely, conveying the twisted ropes to a rough crusher to crush so as to make strip rough materials which is 16-25cm long and 5-10cm wide; secondarily crushing, namely, feeding the strip rough materials into a secondary crusher to crush so as to make strip fine materials which are 5-10cm long and 2-8cm wide; and separating and recycling, namely, conveying the strip fine materials to magnetic field effect metal separation equipment to separate, and collecting so as to obtain ferrous metals and non-metal waste. The method and the system have the advantages that the process is simple and developed, the operation is simple, the utilization rate of the raw material is high, and the economic benefits and the social benefits are good.

Owner:NINE DRAGONS PULP PAPER LESHAN CO LTD

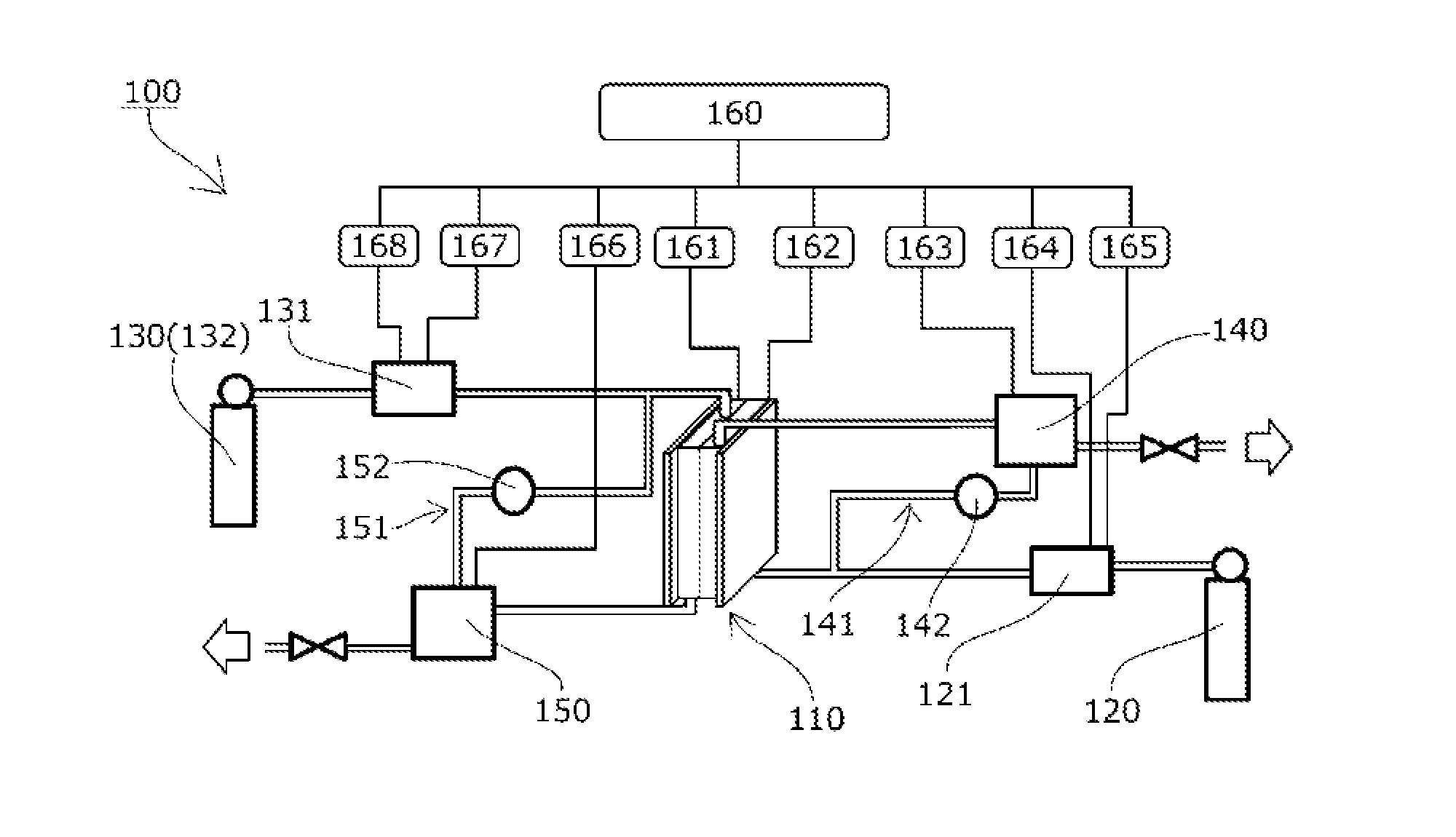

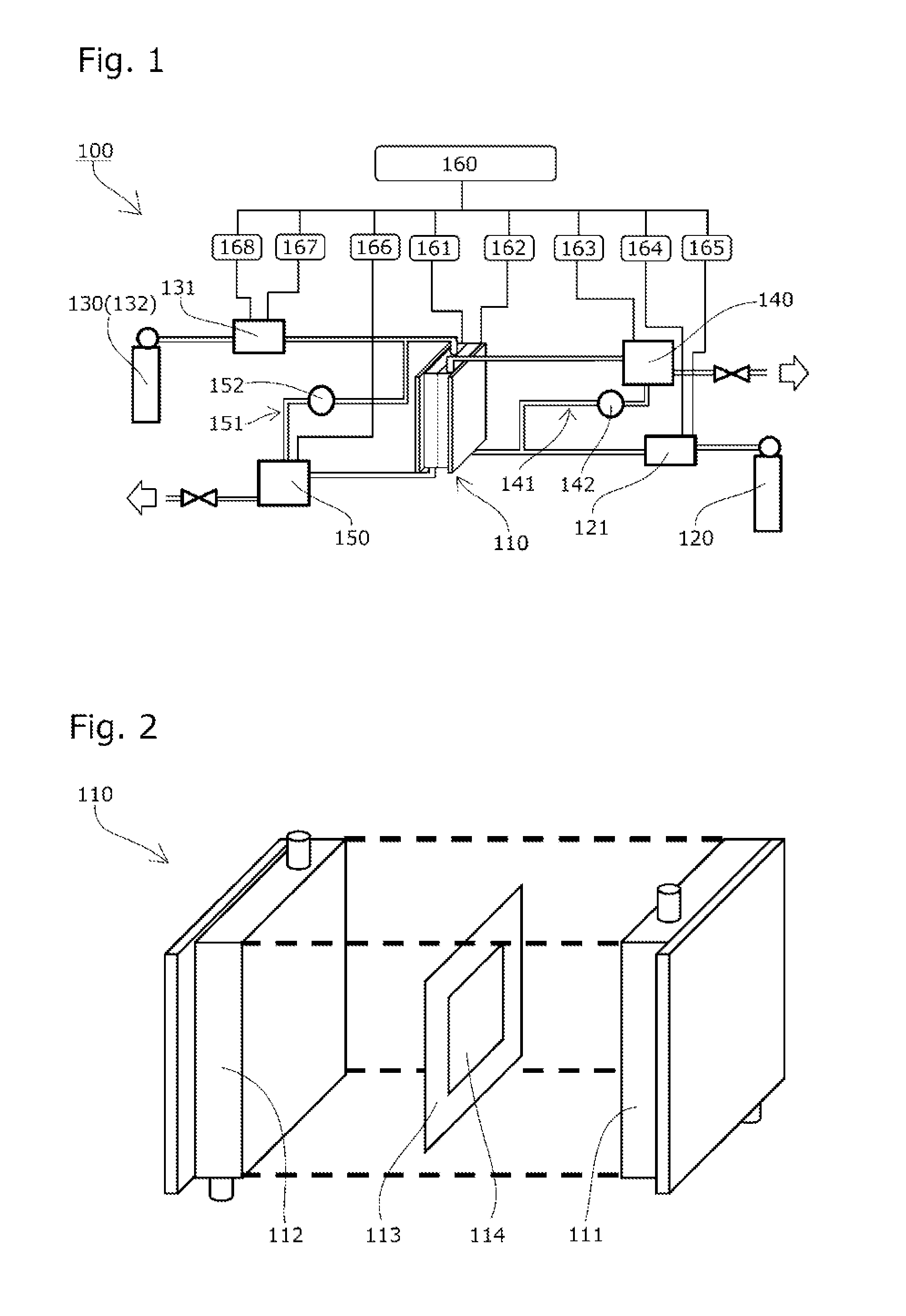

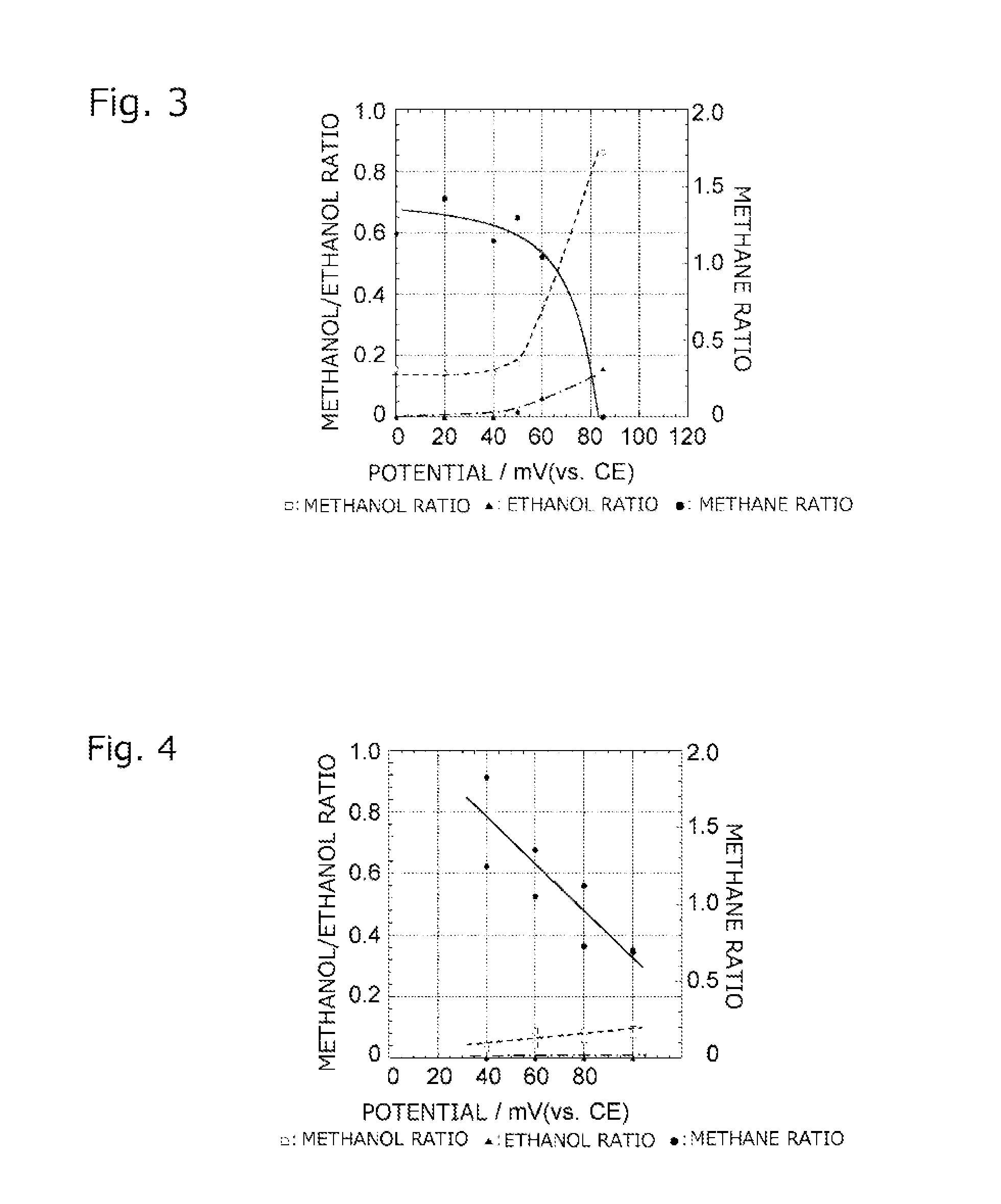

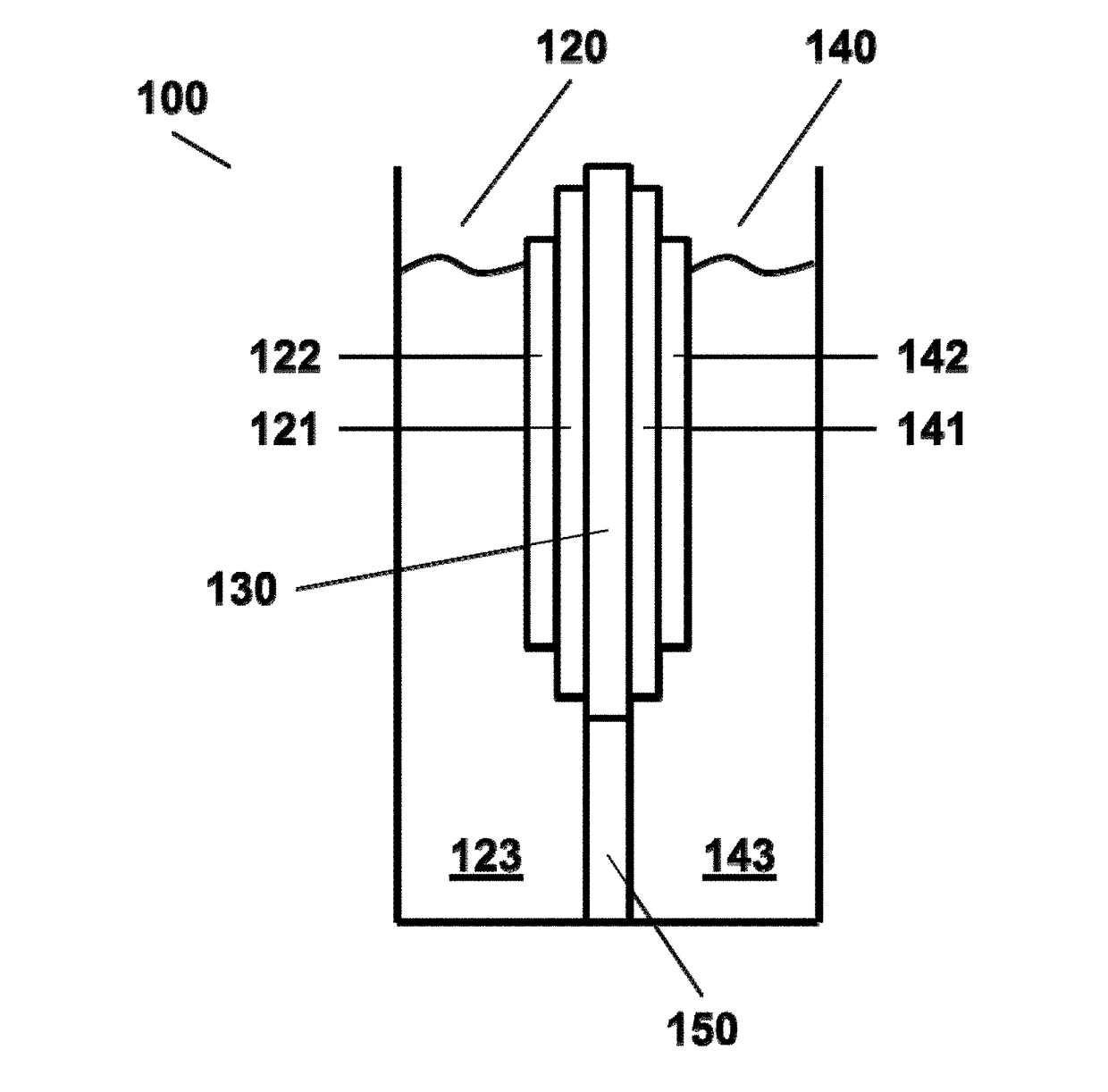

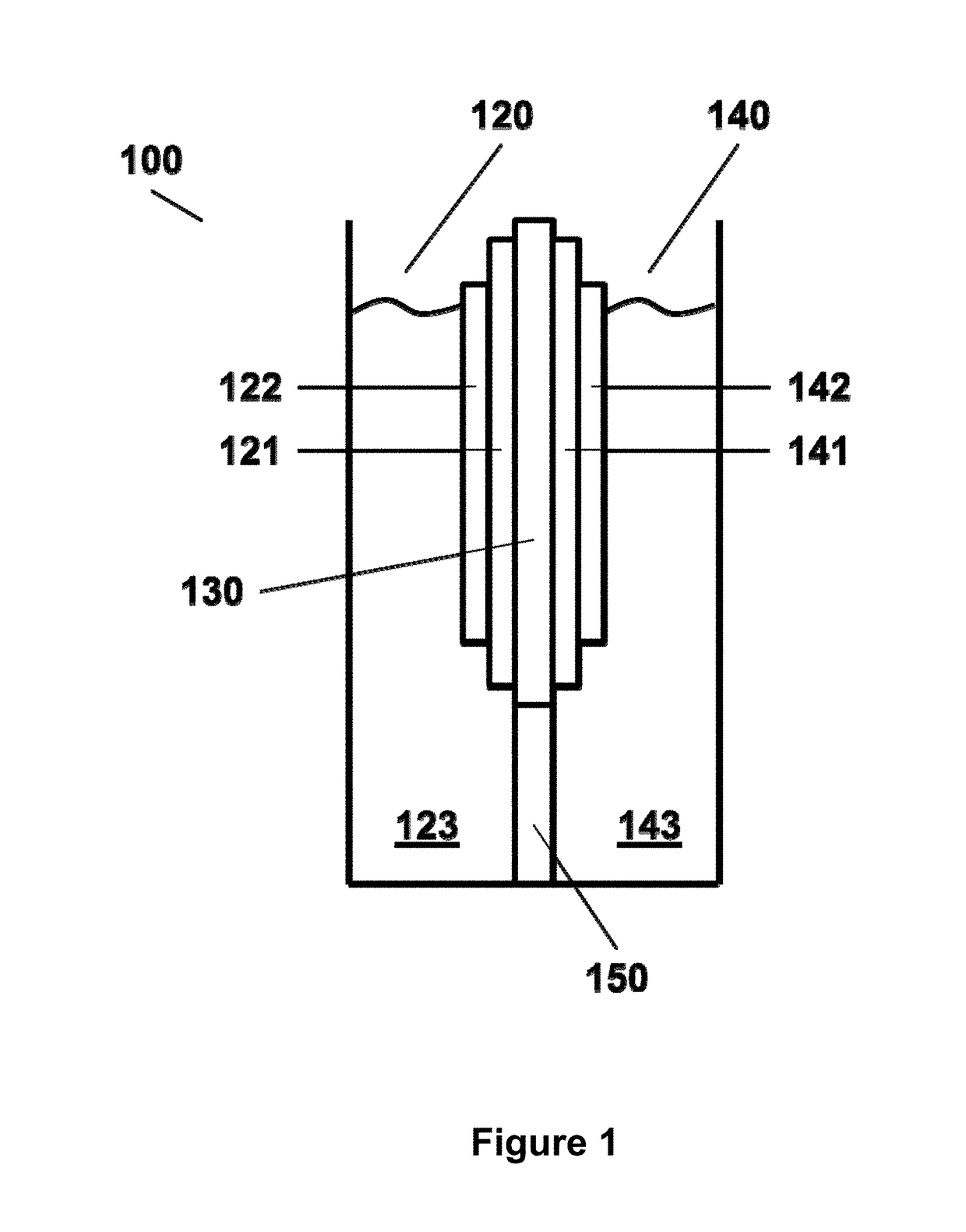

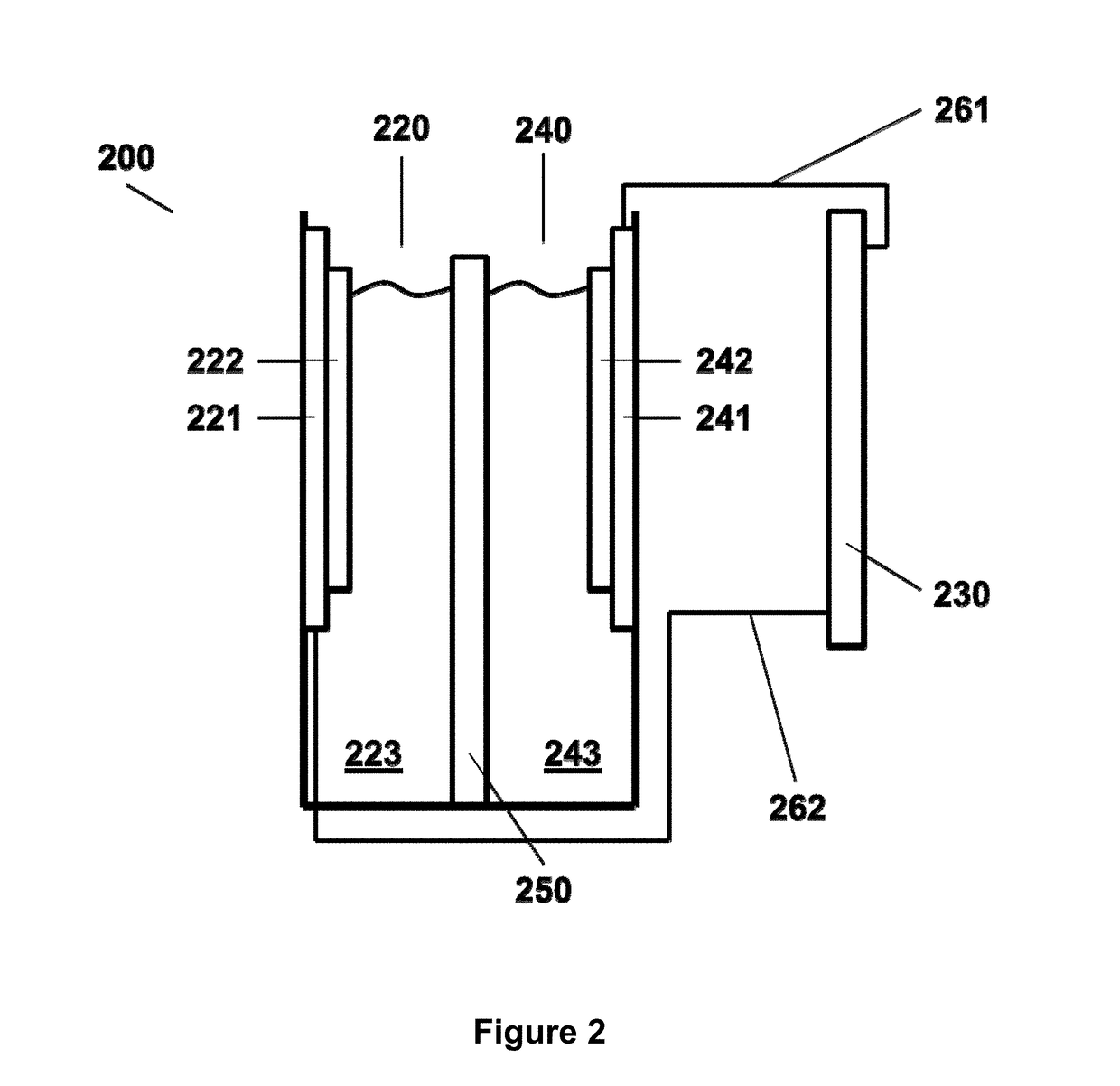

Solid polymer power generation or electrolysis method and system

ActiveUS20160226090A1Reduce carbon dioxideImprove utilization efficiencyCellsSolid electrolytesElectrolysisHydrogen supply

There are provided: a solid polymer power generation or electrolysis method that does not require injection of energy from the outside and maintenance of a high temperature, and is capable of converting carbon dioxide to a useful hydrocarbon while producing energy, controlling the production amounts of the hydrocarbons or the like and a ratio sorted by kind of the hydrocarbons, improving utilization efficiency of a product, and simplifying equipment for separation and recovery; and a system for implementing the solid polymer power generation or electrolysis method. Carbon dioxide is supplied to the side of one electrode 111 of a reactor 110 having a membrane electrode assembly 113, hydrogen is supplied to the side of the other electrode 112, and the amounts of the hydrocarbons produced per unit time and the ratio sorted by kind of the hydrocarbons are changed by controlling a power generation voltage of the reactor 110.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

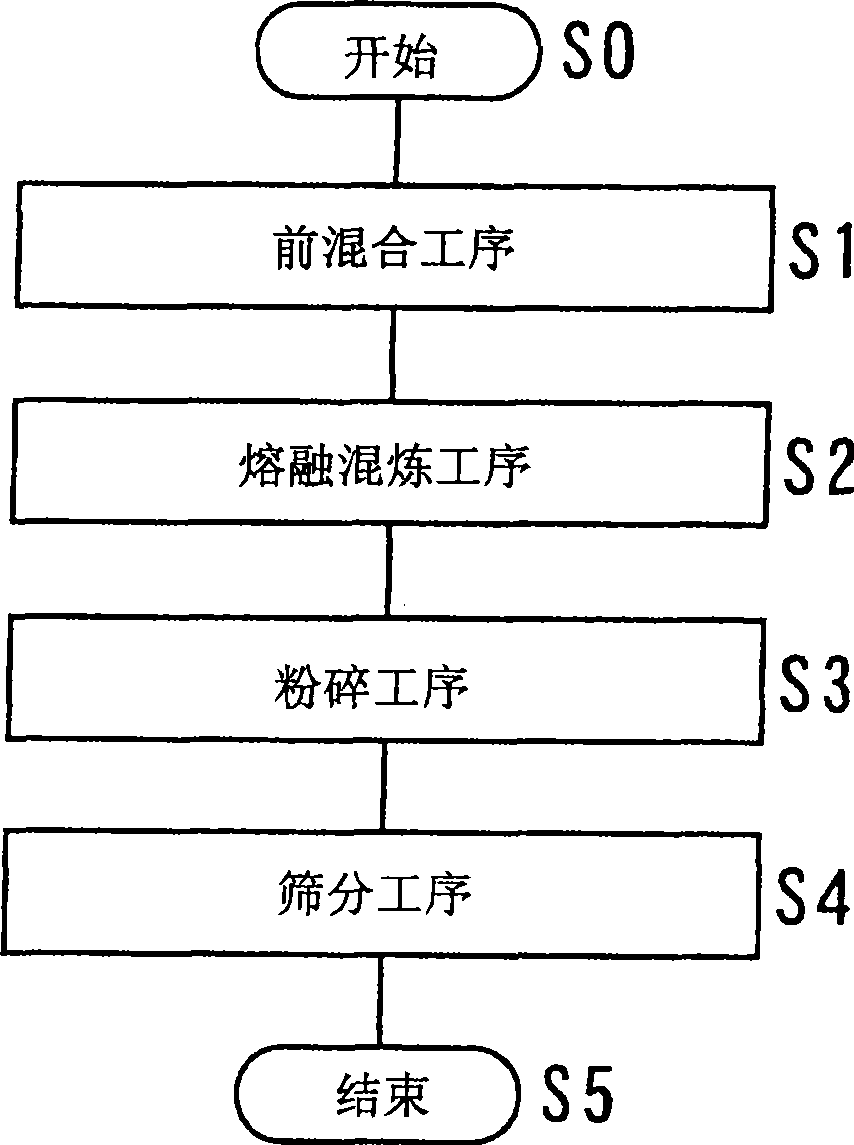

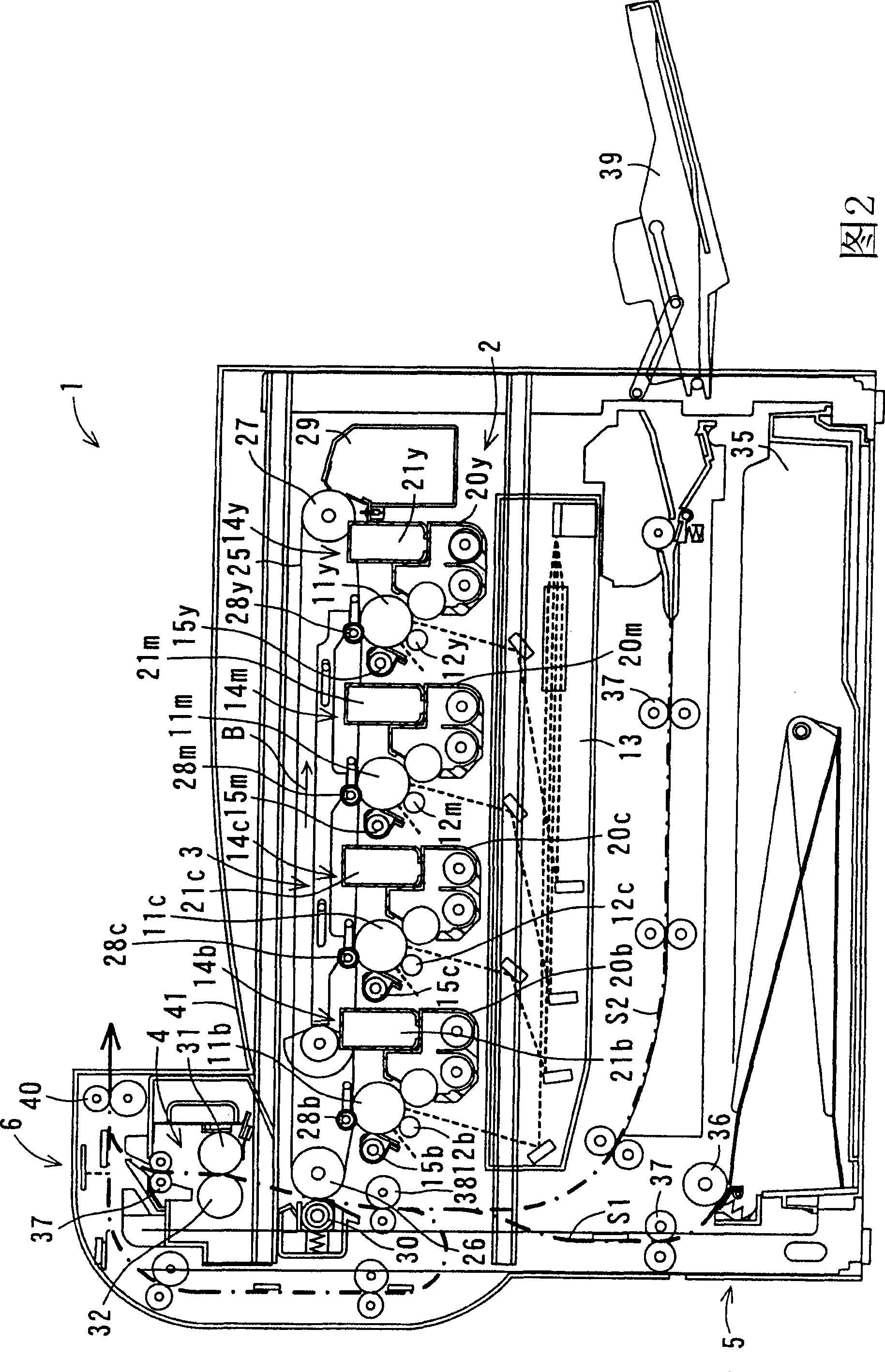

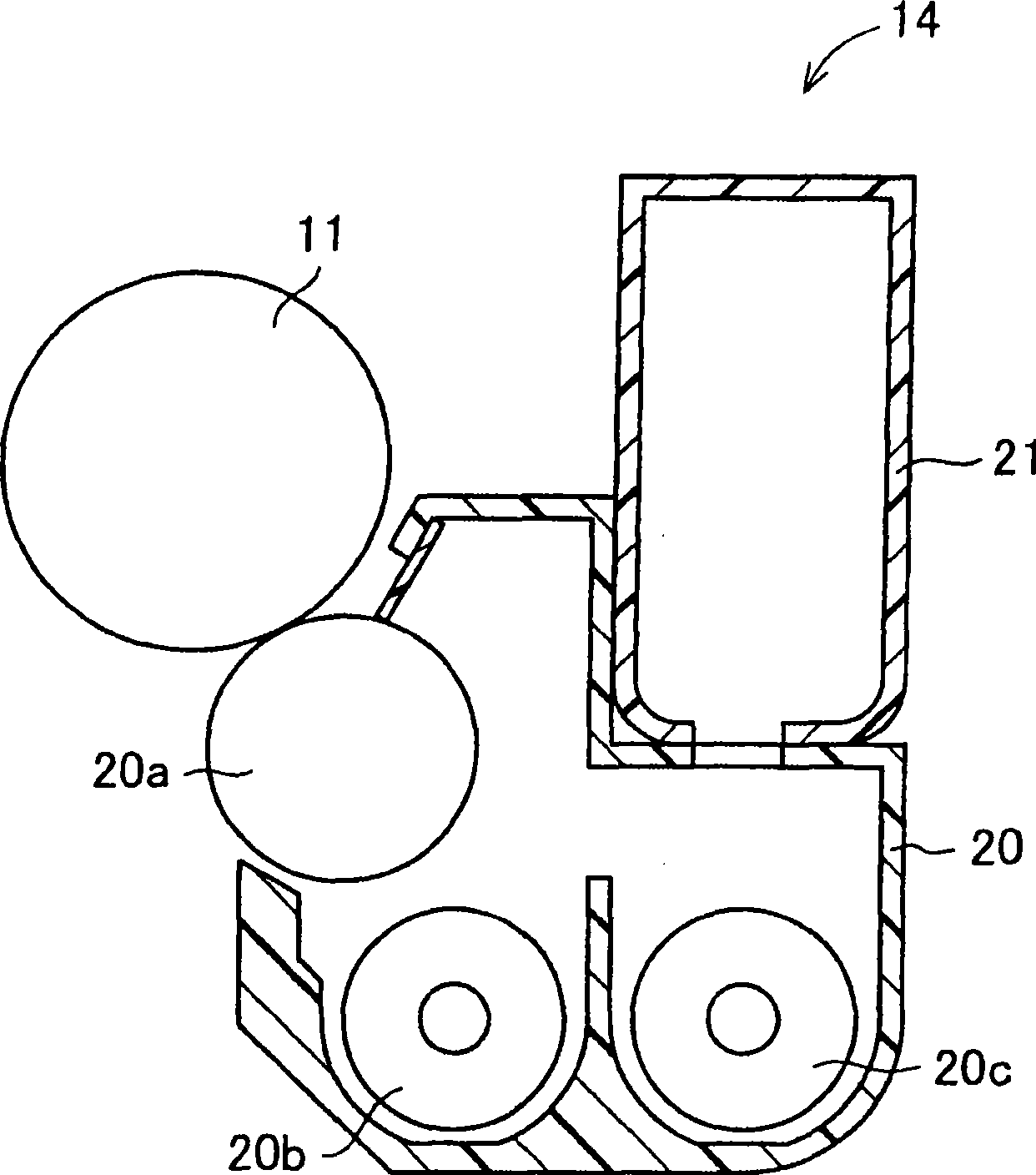

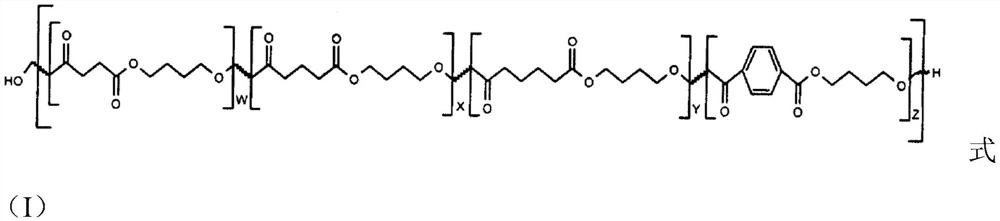

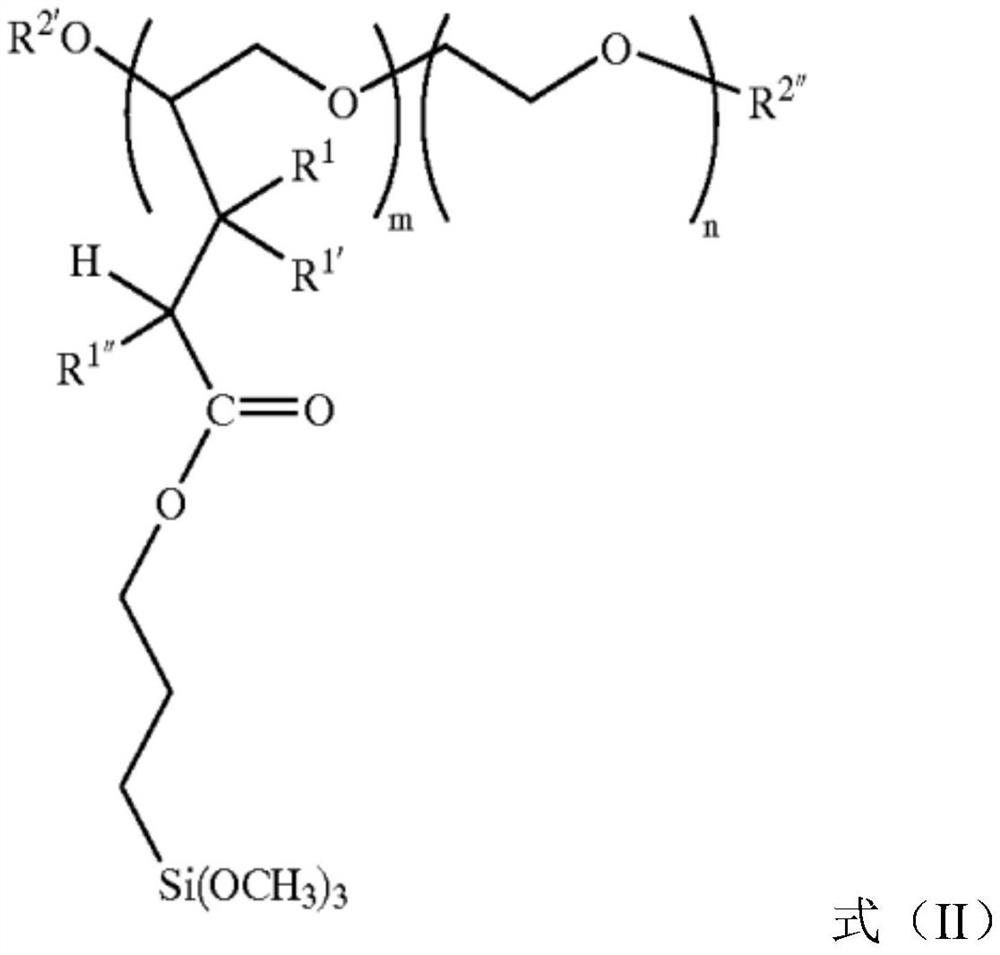

Toner and method for manufacturing the toner, two-component developer, developing device and image forming apparatus

InactiveCN101446782AImprove environmental safetyReduce carbon dioxideDevelopersElectrographic process apparatusTransmittanceImage formation

A toner which takes into account preservation of the global environment and which is excellent in fixability and storage stability and moreover, good in light transmittance and a method for manufacturing the toner, a two-compartment developer, a developing device and an image forming apparatus are provided. In toner including at least a binder resin and a colorant, the binder resin includes a resin which is a major component and a biomass-containing crystalline resin; and the crystalline resin is contained in an amount of 1 part by weight or more and 50 parts by weight or less based on 100 parts by weight of the binder resin, and a melting point of the crystalline resin is higher by a temperature of from 5 DEG C. to 10 DEG C. than a temperature at which a loss modulus G'' of the toner at a frequency of 1 Hz is 103 Pa.

Owner:SHARP KK

Probiotic fermentation bed for breeding livestock and poultry

InactiveCN104620996ASolve pollutionRapid and effective degradationBio-organic fraction processingFood processingWater sourceAntibiotic Y

The invention relates to an ecological cultivation method with health care fermented feed matched with a probiotic fermentation bed. The method includes the steps that first, probiotic fermentation is carried out, wherein the probiotic fermentation comprises anaerobic fermentation of anaerobes and aerobic fermentation of aerobic microorganisms; second, the probiotic fermentation bed is prepared, wherein various raw materials for preparing the material of the fermentation bed are evenly mixed so as to obtain organic bedding, bacterium solution is inoculated for fermentation, and the organic bedding contains saw dust, rice husks, bran and first compound Chinese herbal medicine; third, the fermented feed contains corn, bean pulp, vitamins, microelements, mineral substances, amino acids, other additives, second compound Chinese herbal medicine and the like, and microorganisms are added into the feed components for fermentation. The ecological cultivation method has the advantages that water can be purified, and hidden danger to health of hogs caused by a water source is blocked; the using amount of the microelements is reduced, resources are saved, emissions are reduced, and the environment is protected; no antibiotics or residue exists, and food safety and human health are guaranteed; the Chinese herbal medicines have the functions of being resistant to disease and promoting growth and can replace antibiotics.

Owner:BEIJING HUAMU GREAT EXPLOIT SCI & TECH +1

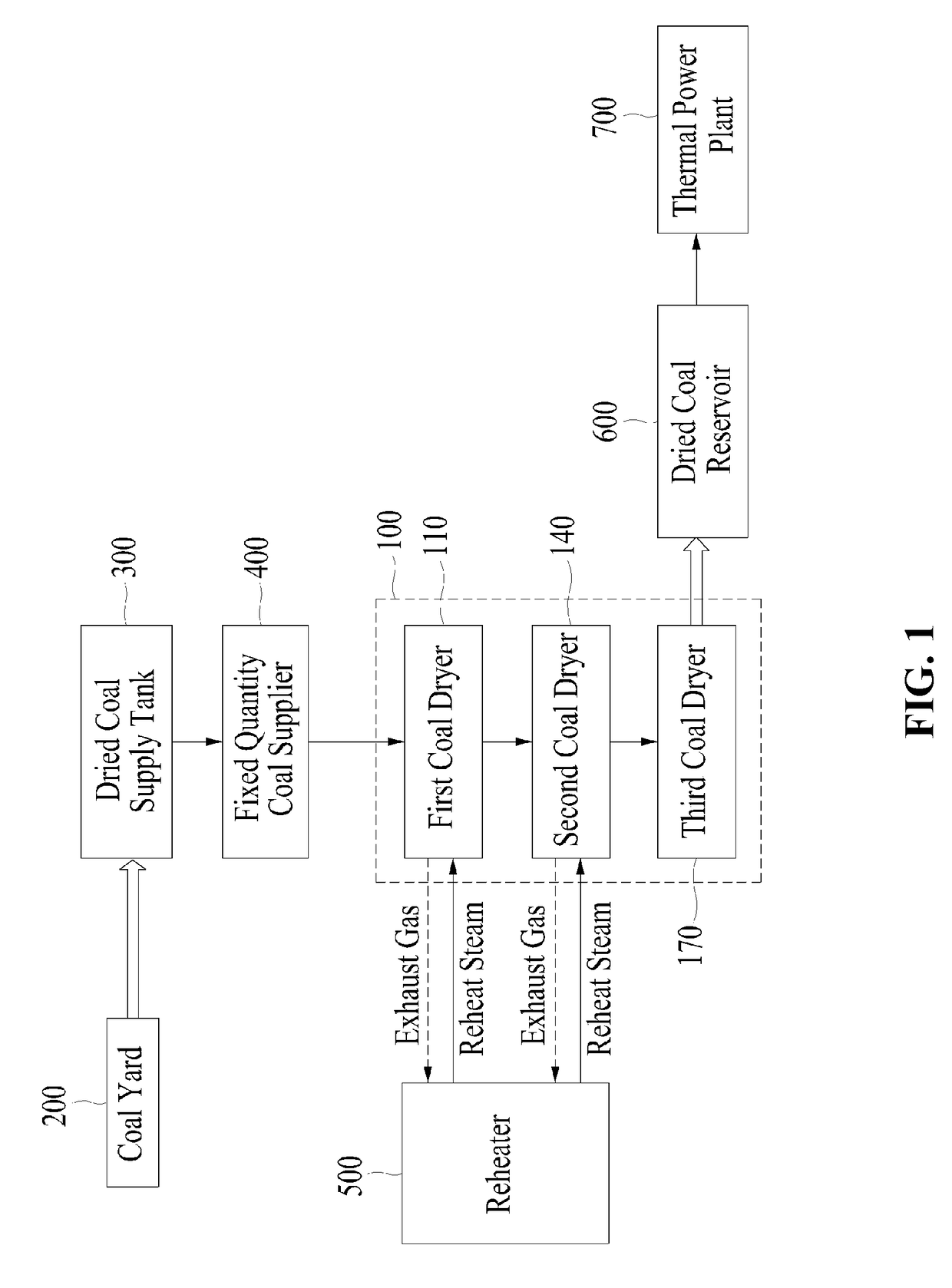

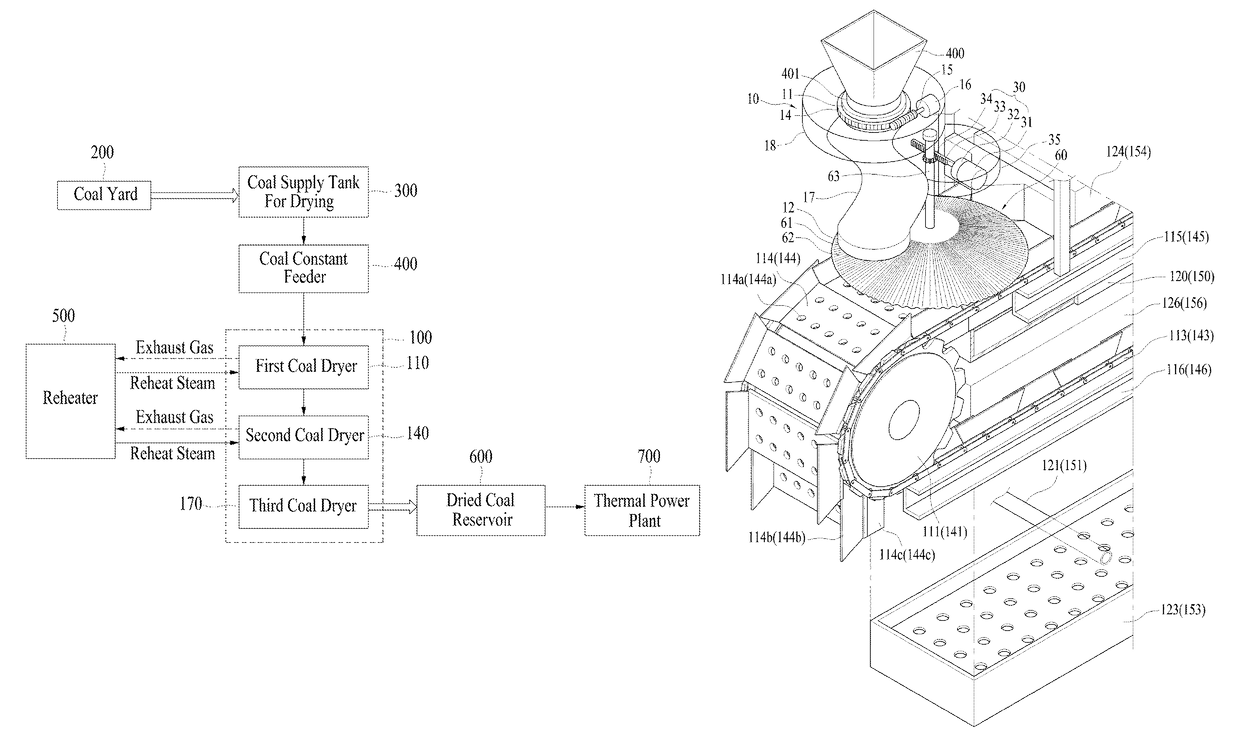

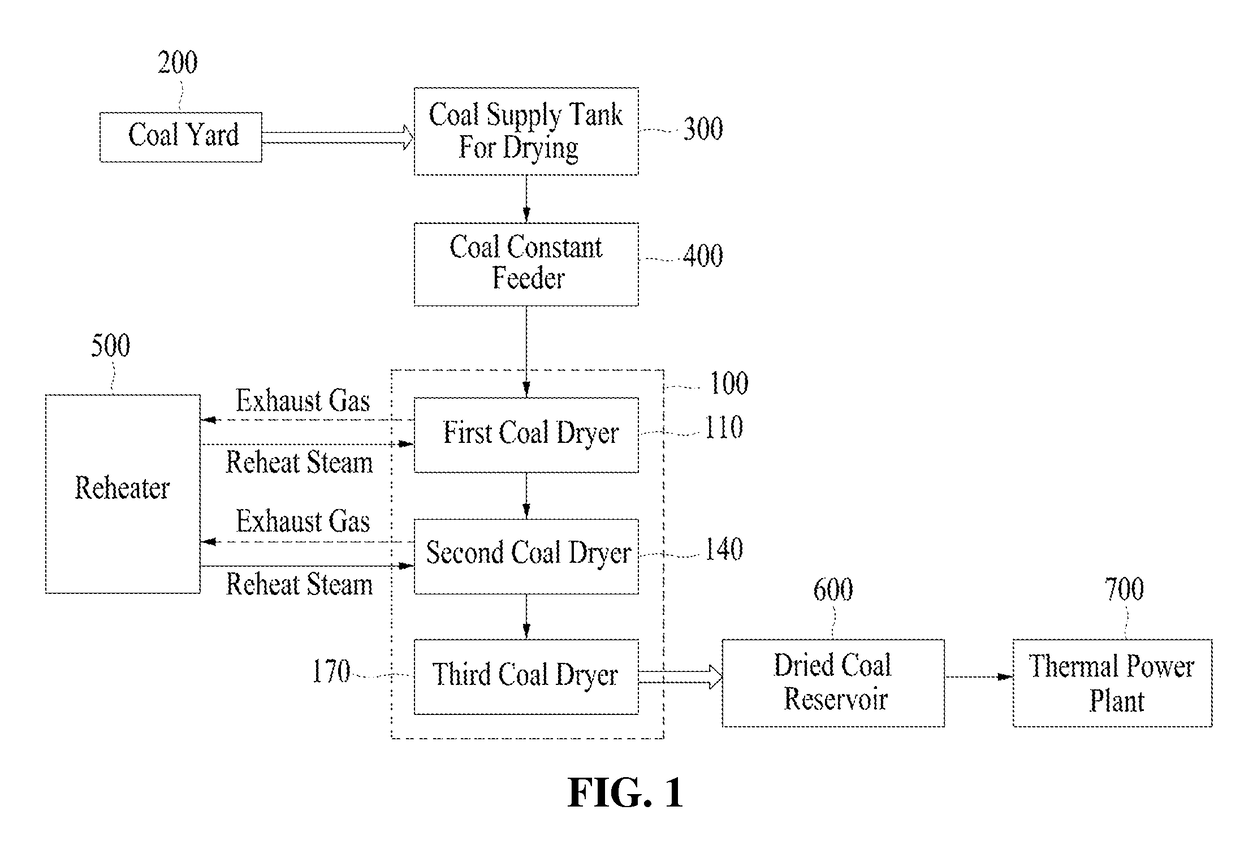

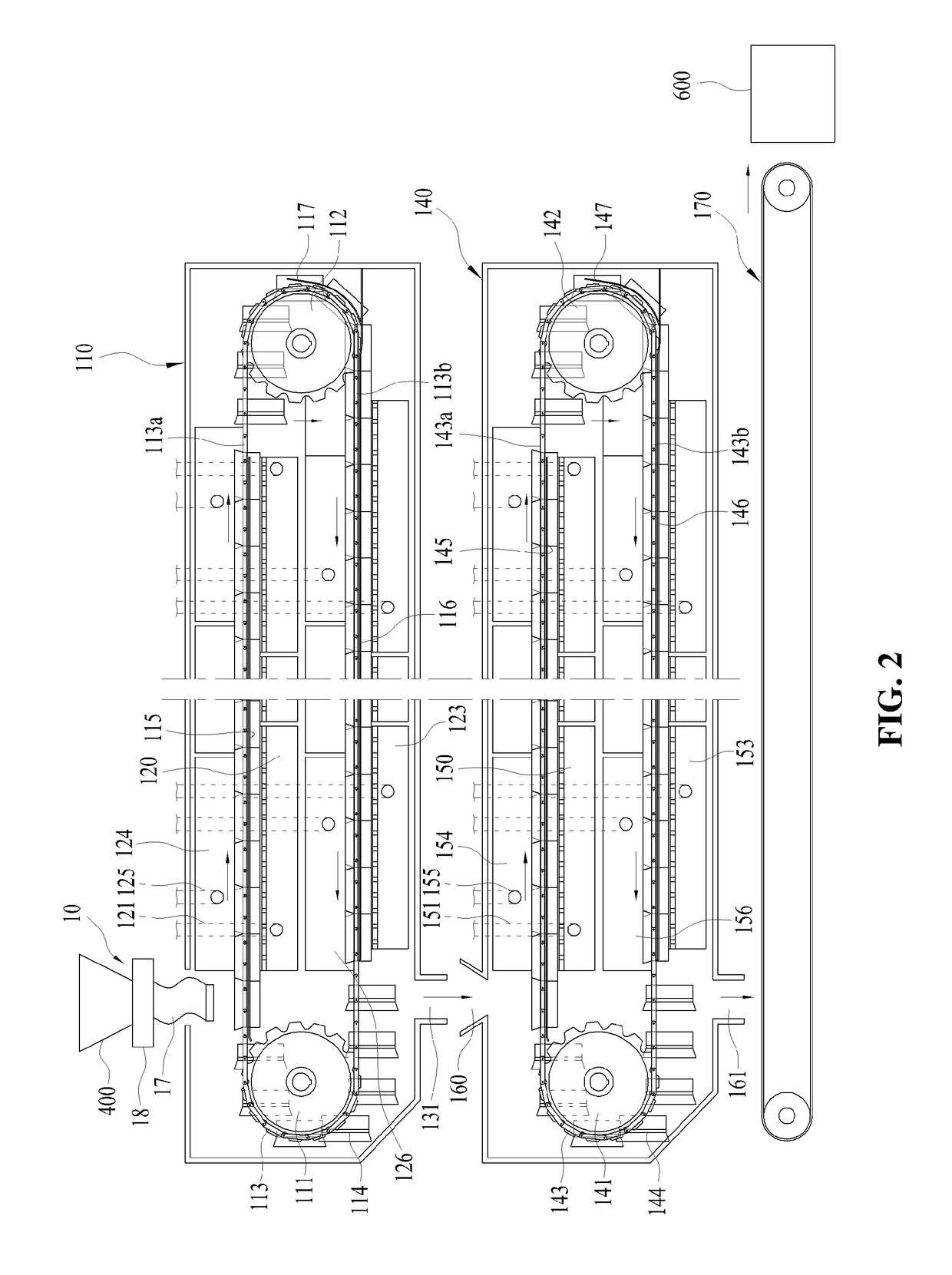

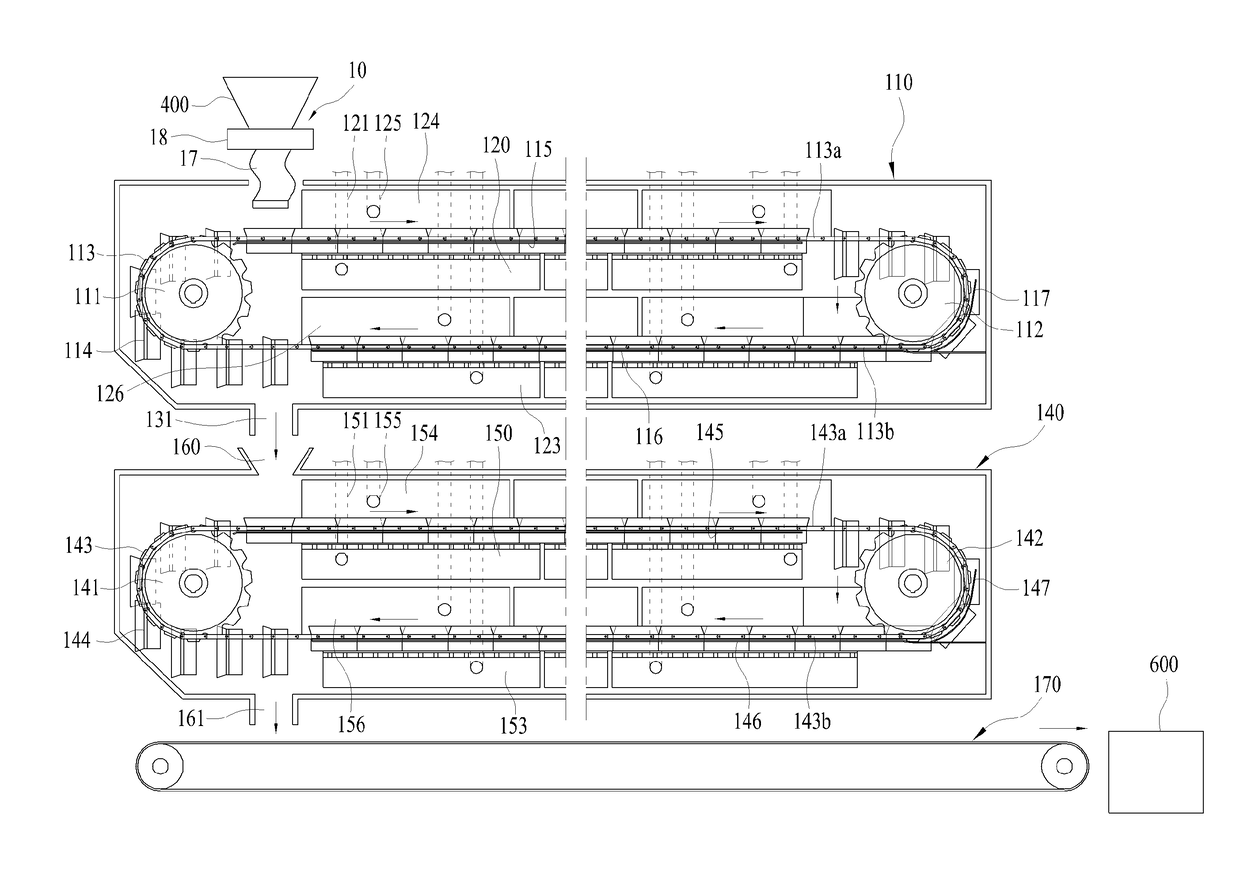

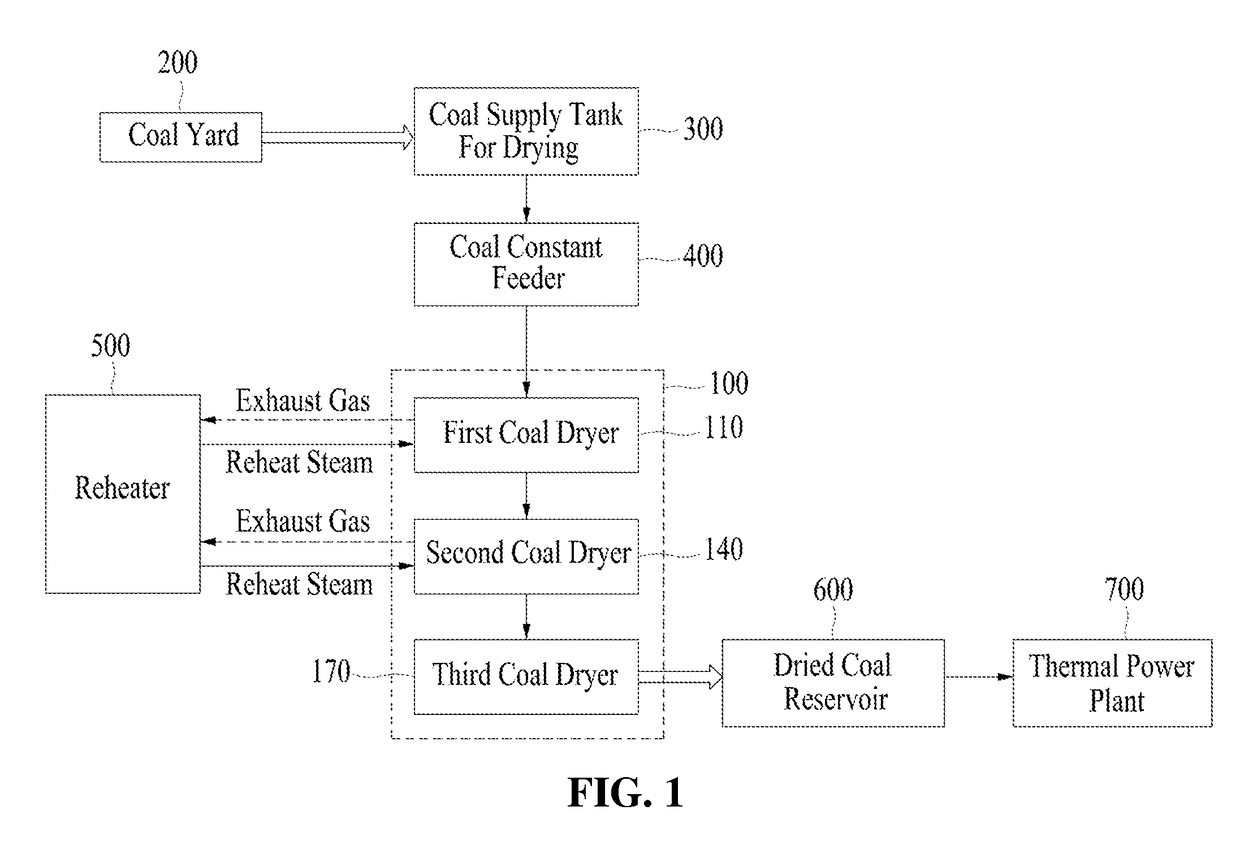

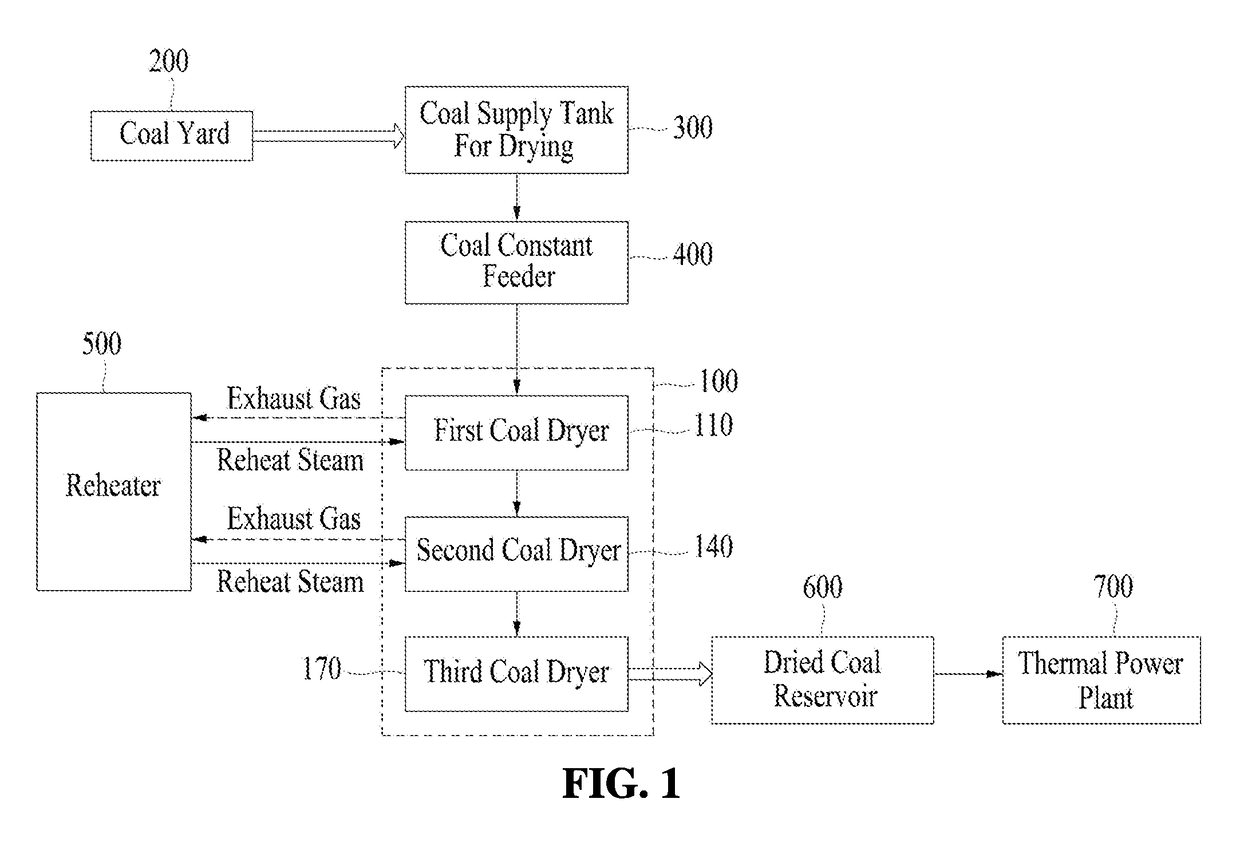

Apparatus for preventing spontaneous ignition of transferred coal in apparatus for drying coal using reheat steam

InactiveUS20170145315A1Maximize useMinimize occurrenceDrying solid materials with heatCoke ovensFour-way valveNitrogen

The present invention relates to an apparatus for preventing, in a multi-stage dryer for drying coal using reheat steam, spontaneous ignition caused by oxidation of coal when coal is transferred to the multi-stage dryer from a fixed quantity coal supplier by way of a pulverizer. The present invention relates to an apparatus for drying coal using reheat steam, the apparatus being configured so that coal which has been dried primarily in a first coal dryer is inputted into a second coal dryer and thus is secondarily dried, wherein reheat steam generated from a reheater is supplied through a reheat steam supply pipe; a nitrogen supplier supplies nitrogen through a nitrogen supply pipe; saturated steam generated from a saturated steam generator is supplied through a saturated steam supply pipe; the reheat steam supply pipe, the nitrogen supplier, and the saturated steam supply pipe are connected to a 4-way valve; and the 4-way valve supplies nitrogen and saturated steam, or nitrogen or saturated steam, along with reheat steam, to first to fourth steam chambers through the steam supply pipe, and injects steam into coal which is transferred to a first transfer plate and a second transfer plate so that spontaneous ignition of coal is prevented in the course of drying and transferring coal.

Owner:HANKOOK TECH

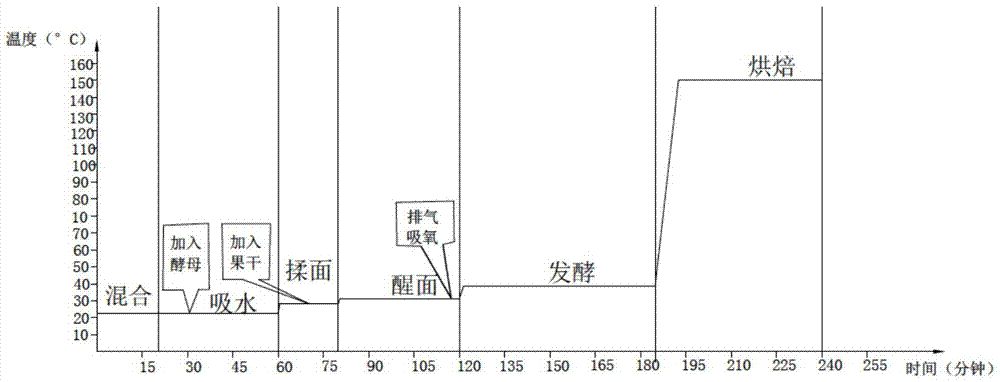

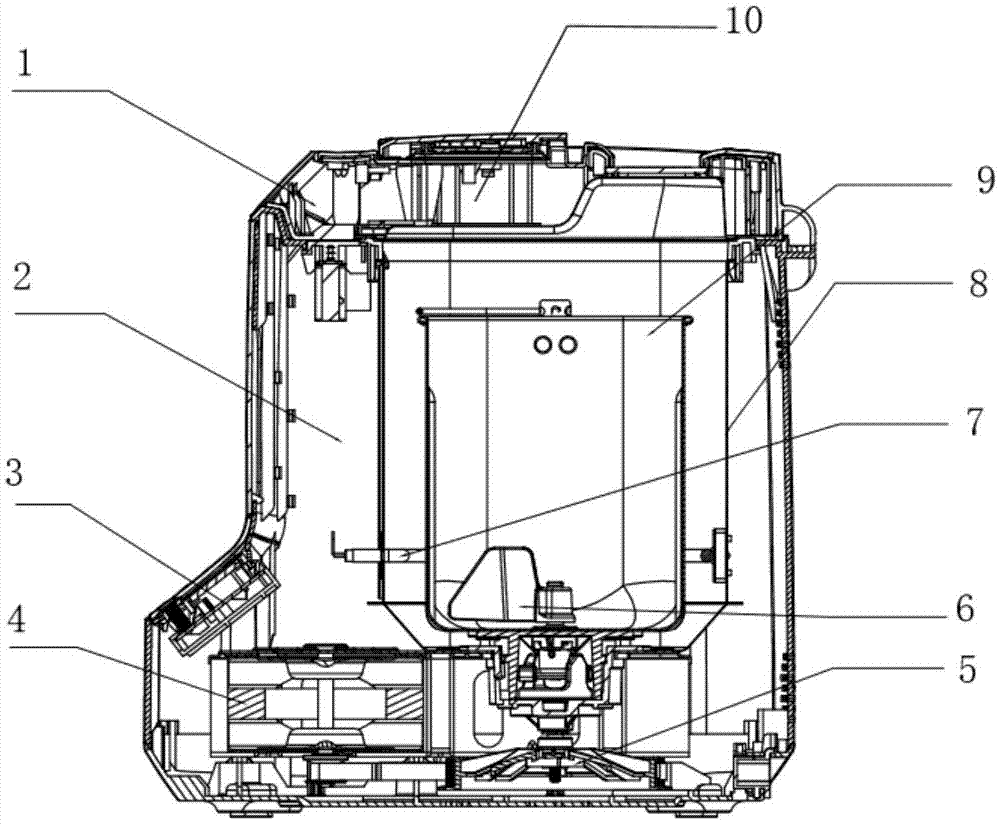

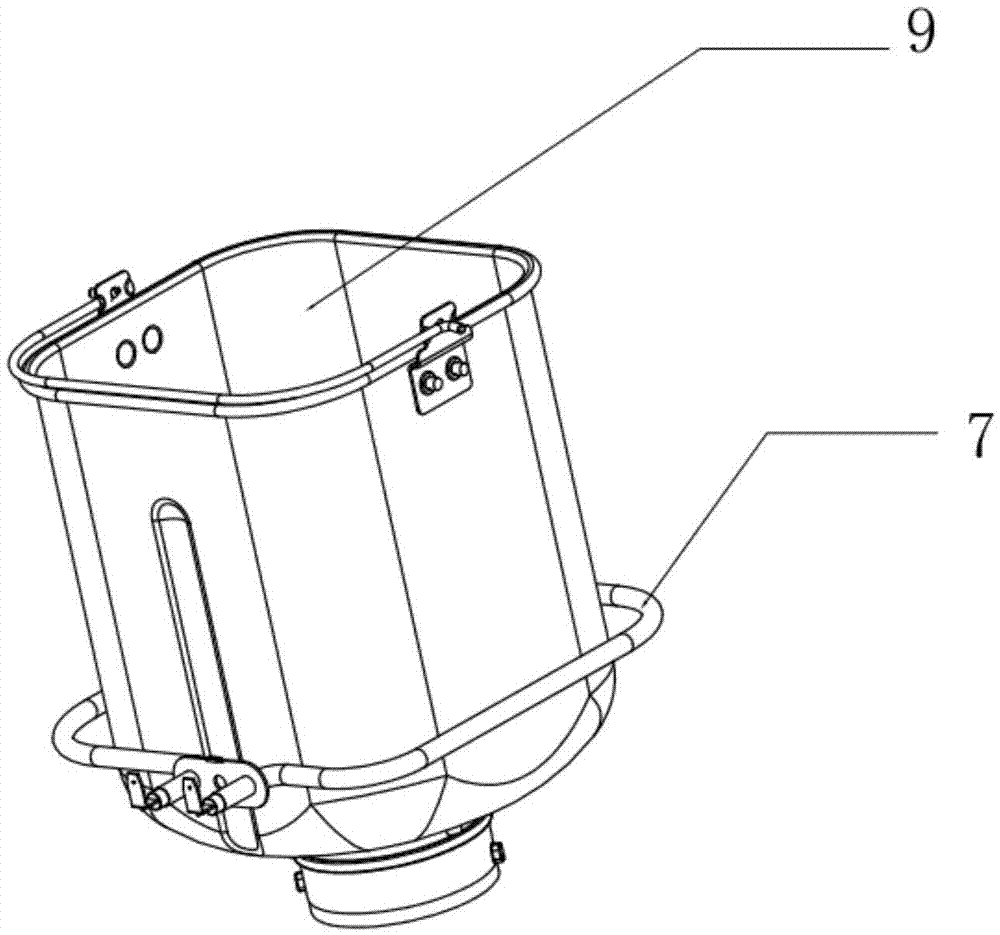

Method for making bread through bread maker

ActiveCN107232262AShorten fermentation timeIncreased softnessBakery productsBread-toastersEngineeringHeating element

The invention relates to a method for making bread through a bread maker. The bread maker comprises a bread barrel, a motor and a heating element, wherein a stirring mechanism connected with the motor is arranged in the bread barrel. The making method comprises the following steps of S1, a mixing stage; S2, a water absorption stage, wherein yeast is added; S3, a dough kneading stage; S4, a fermentation stage and S5, a baking stage. According to the method disclosed by the invention, a reasonable preparation technology is adopted, so that the made bread has the advantages of being good in mouth feel, rich in nutrition and the like, besides, the preparation method is simple to operate, and repeated fermentation is not needed, so that the time is saved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

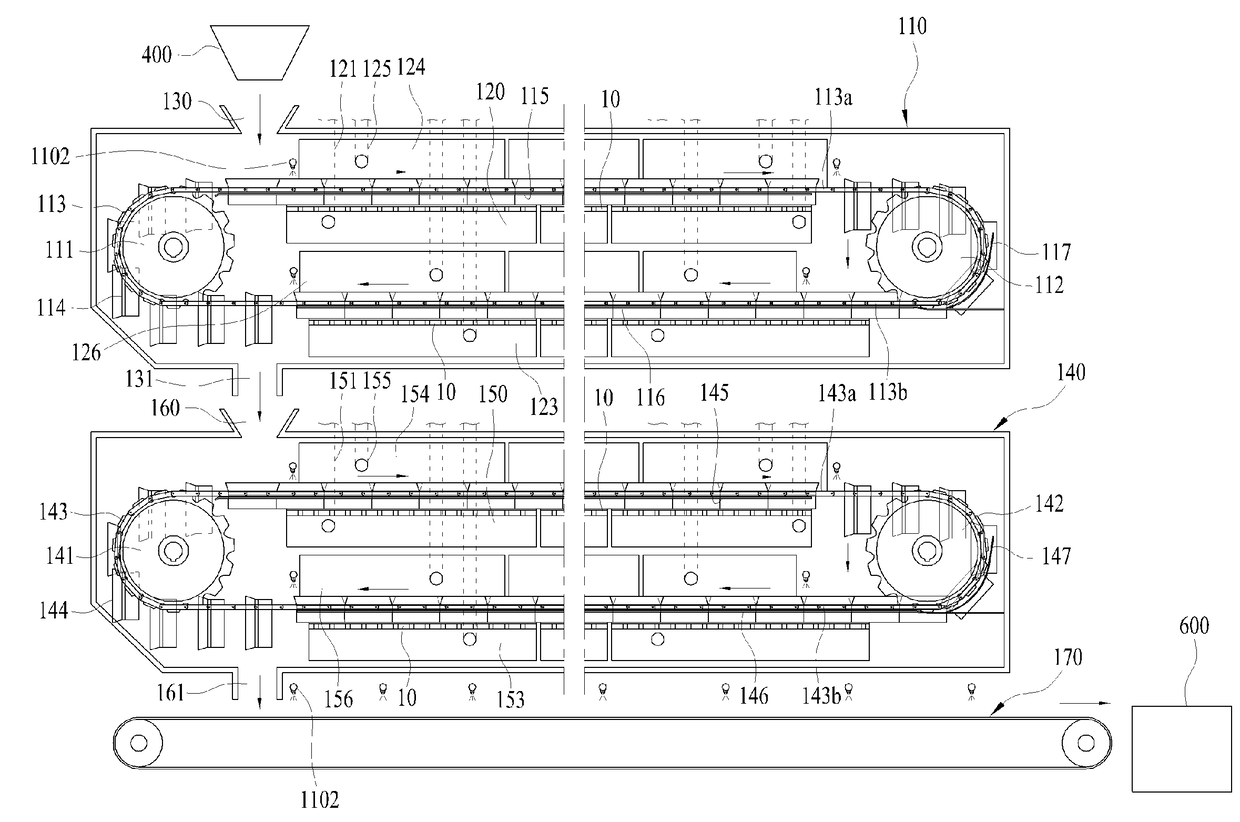

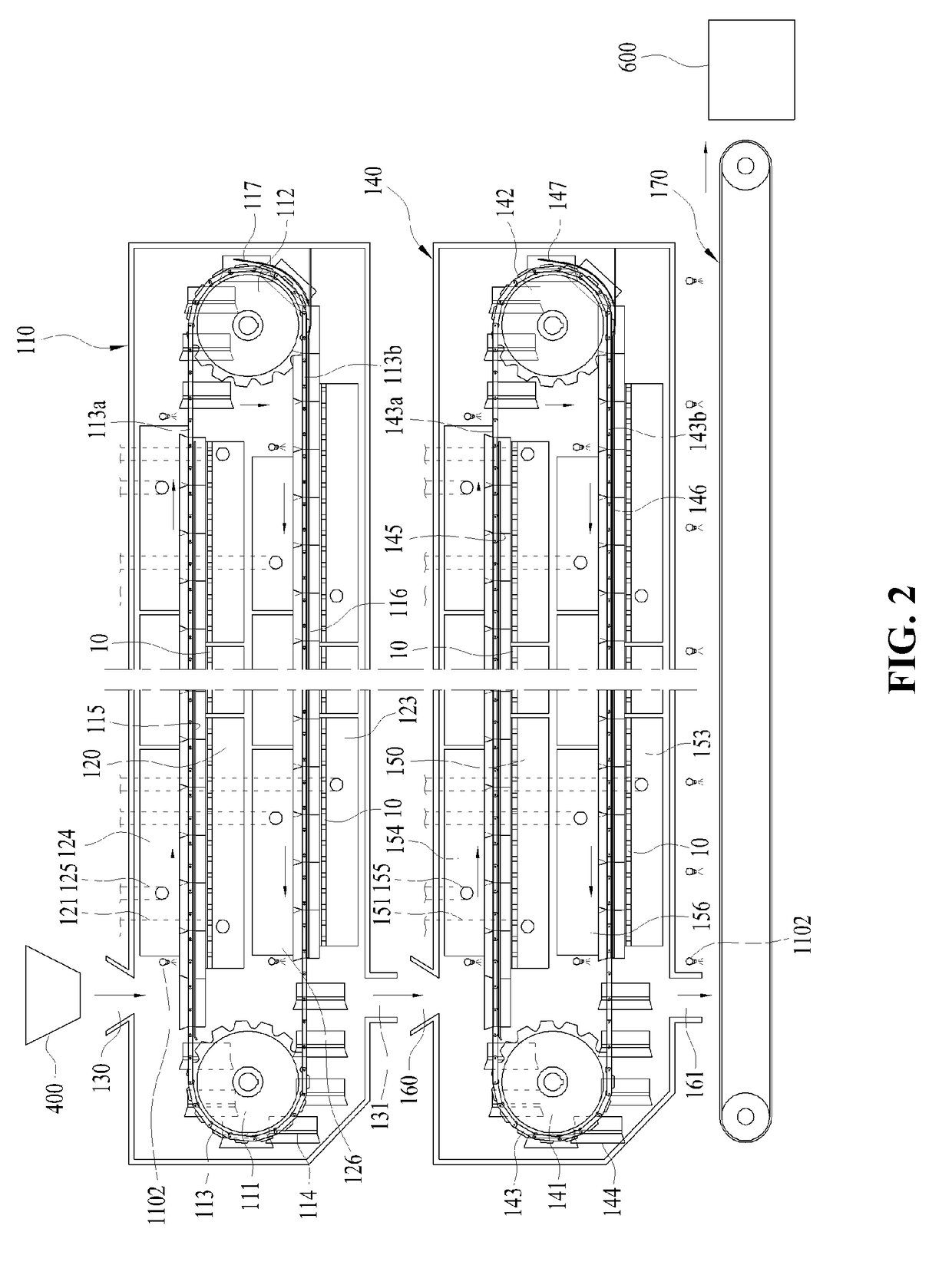

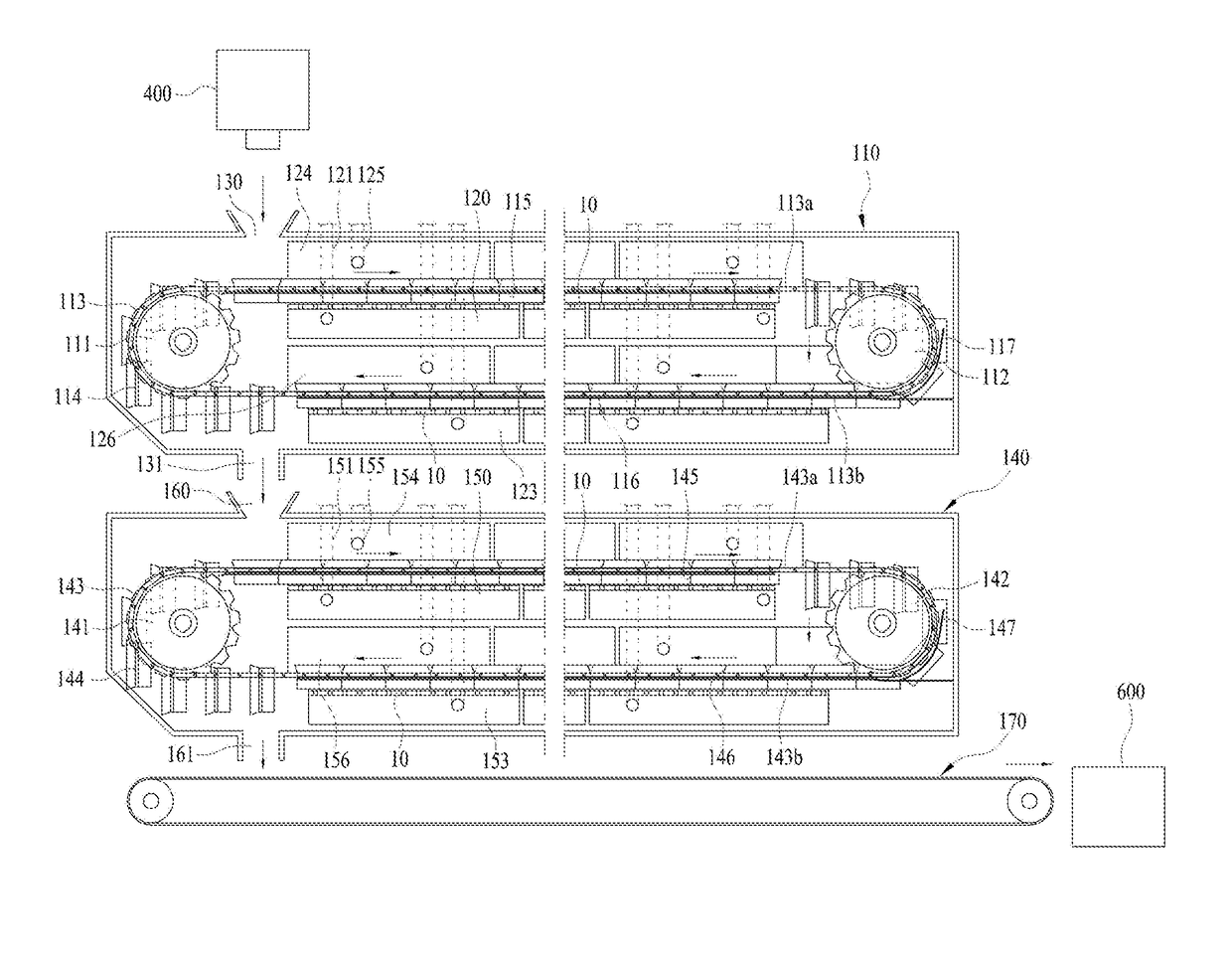

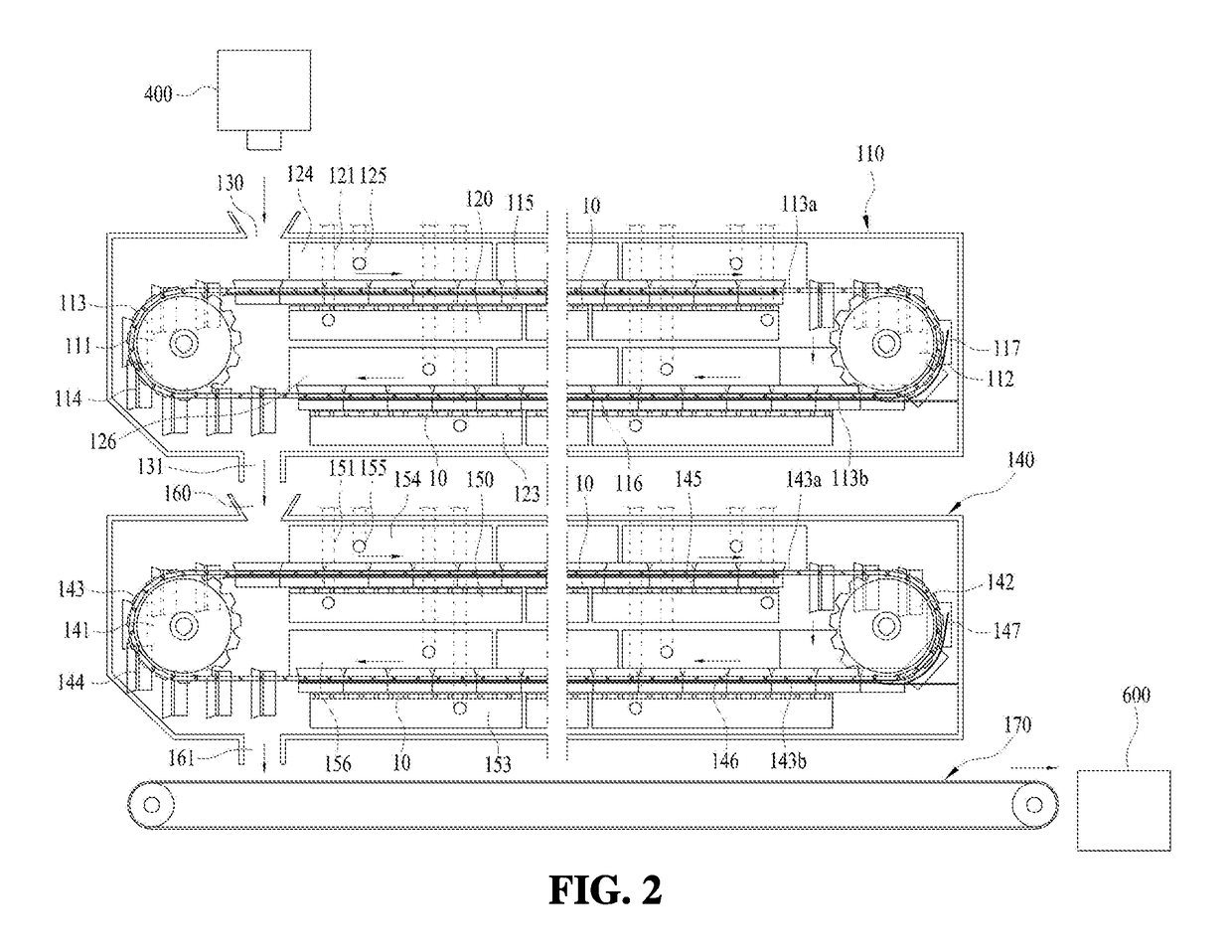

Apparatus for dust reduction and dispersion supply of input coal in system for drying coal using reheat steam

InactiveUS9890344B2Efficiently drying hot reheat steamReduce dustDrying solid materials with heatDrying gas arrangementsReducerCoal

The present invention relates to a coal supply device for reducing dust of coal input for dry and supplying dispersing and supplying the coal in a system for drying coal using reheat steam, and more particularly, to a device to minimize dust when the coal is supplied to a multi-stage dryer from a coal constant feeder through a pulverizer in a multi-stage dryer for drying coal using reheat steam and disperse and supply the coal to a transfer device and a coal drying system in which coal which is primarily dried in the first coal dryer is inputted into the second coal dryer and thus is secondarily dried, includes a coal constant feeder supplying a predetermined amount of coal onto the upward surface of the first transfer plate; and a dust reducer constituted by an inlet pipe coupled to an outlet of the coal constant feeder by a bearing, a worm wheel coupled onto the outer periphery of the inlet pipe, a worm gear-coupled with the worm wheel and rotating with rotary force transferred from a motor, a curved pipe of which the top is coupled to the inlet pipe, and an outlet pipe coupled to the end of the curved pipe, wherein the dust reducer which rotates at the predetermined velocity reduces the velocity of the coal supplied by the coal constant feeder to minimize generation of dust from the coal input onto the upward surface of the first transfer plate.

Owner:HANKOOK TECH

Apparatus for dust reduction and dispersion supply of input coal in system for drying coal using reheat steam

InactiveUS20170130151A1Easily contactSave on fuel costsDrying solid materials with heatDrying gas arrangementsReducerCoal

The present invention relates to a coal supply device for reducing dust of coal input for dry and supplying dispersing and supplying the coal in a system for drying coal using reheat steam, and more particularly, to a device to minimize dust when the coal is supplied to a multi-stage dryer from a coal constant feeder through a pulverizer in a multi-stage dryer for drying coal using reheat steam and disperse and supply the coal to a transfer device and a coal drying system in which coal which is primarily dried in the first coal dryer is inputted into the second coal dryer and thus is secondarily dried, includes a coal constant feeder supplying a predetermined amount of coal onto the upward surface of the first transfer plate; and a dust reducer constituted by an inlet pipe coupled to an outlet of the coal constant feeder by a bearing, a worm wheel coupled onto the outer periphery of the inlet pipe, a worm gear-coupled with the worm wheel and rotating with rotary force transferred from a motor, a curved pipe of which the top is coupled to the inlet pipe, and an outlet pipe coupled to the end of the curved pipe, wherein the dust reducer which rotates at the predetermined velocity reduces the velocity of the coal supplied by the coal constant feeder to minimize generation of dust from the coal input onto the upward surface of the first transfer plate.

Owner:HANKOOK TECH

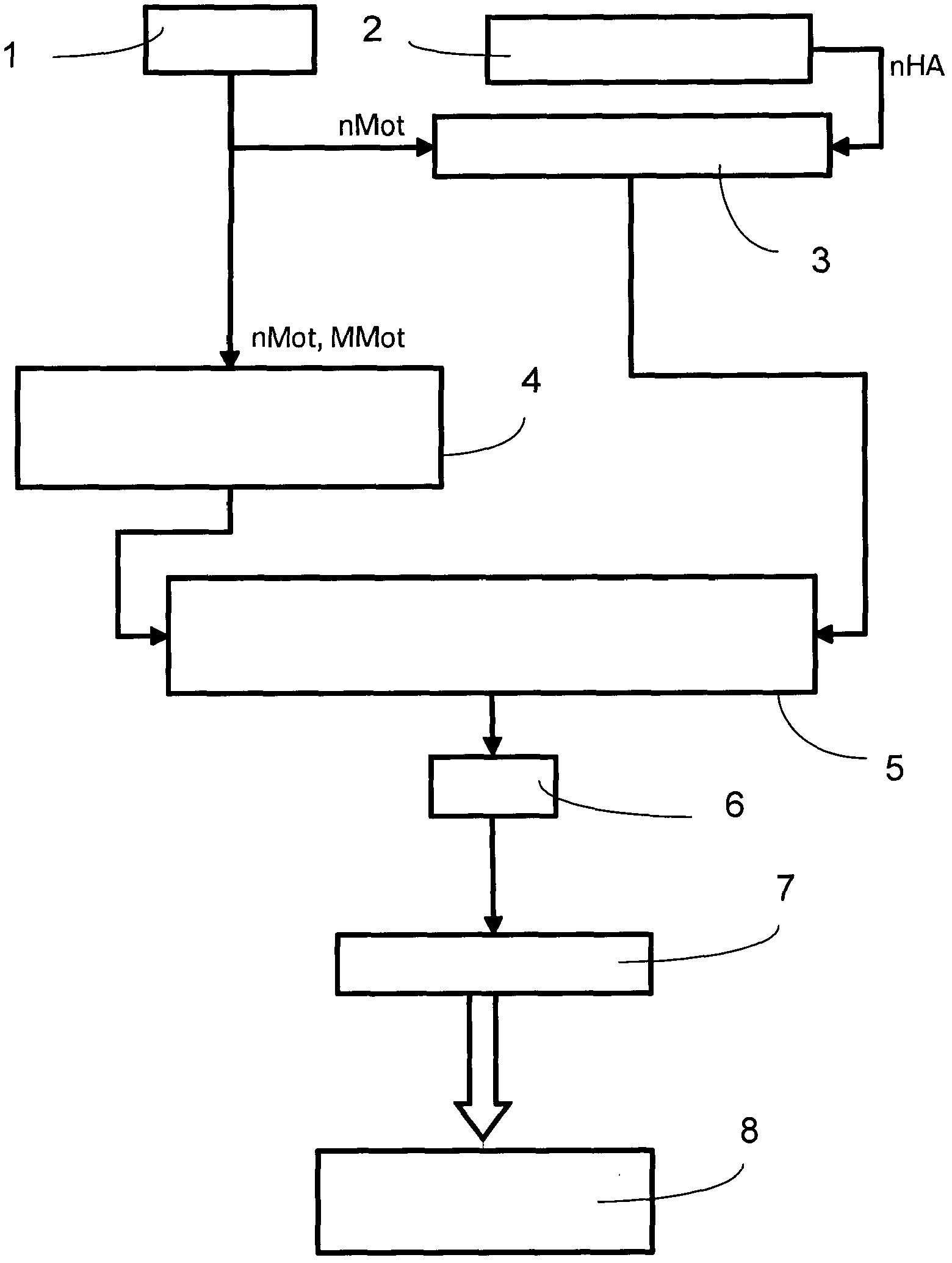

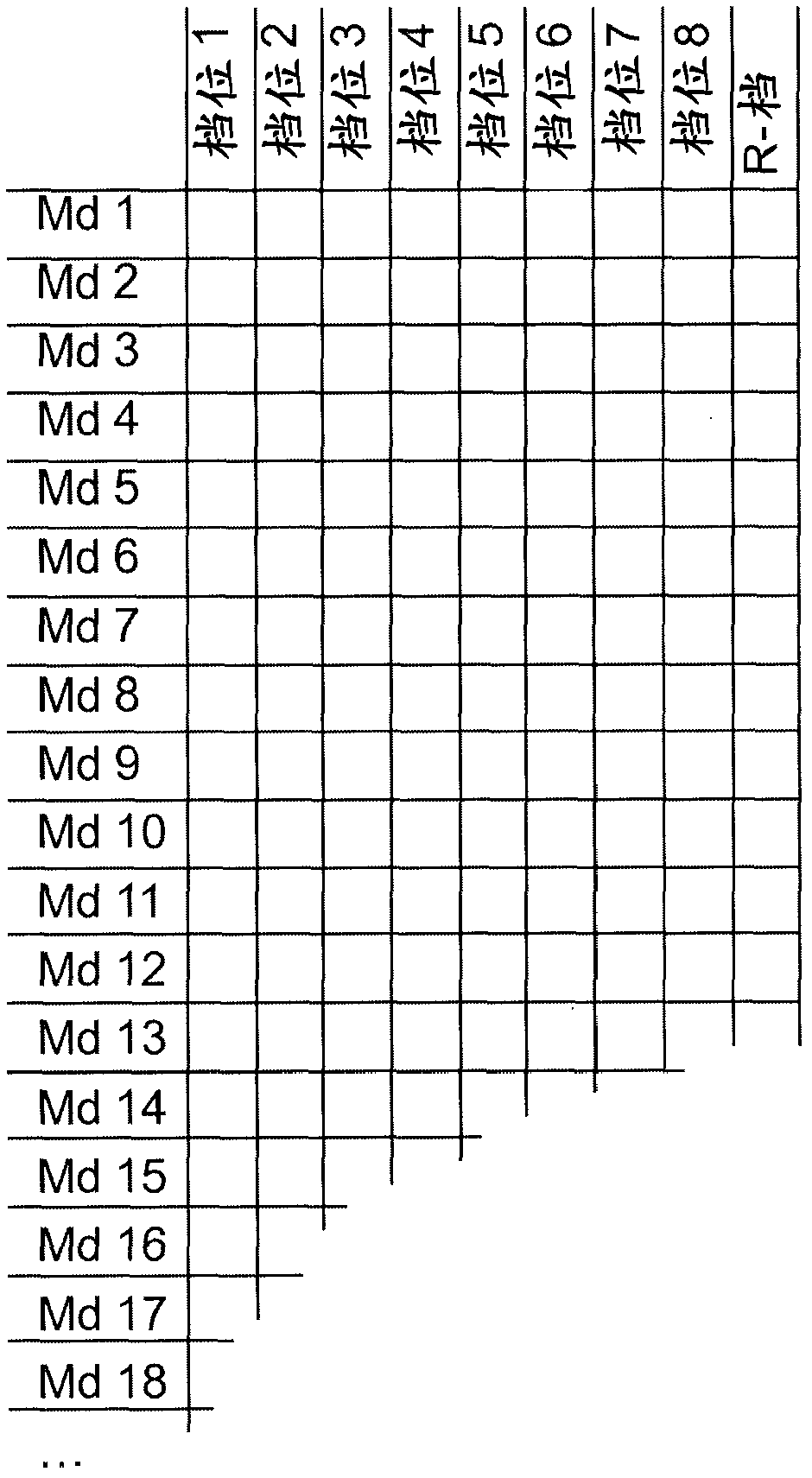

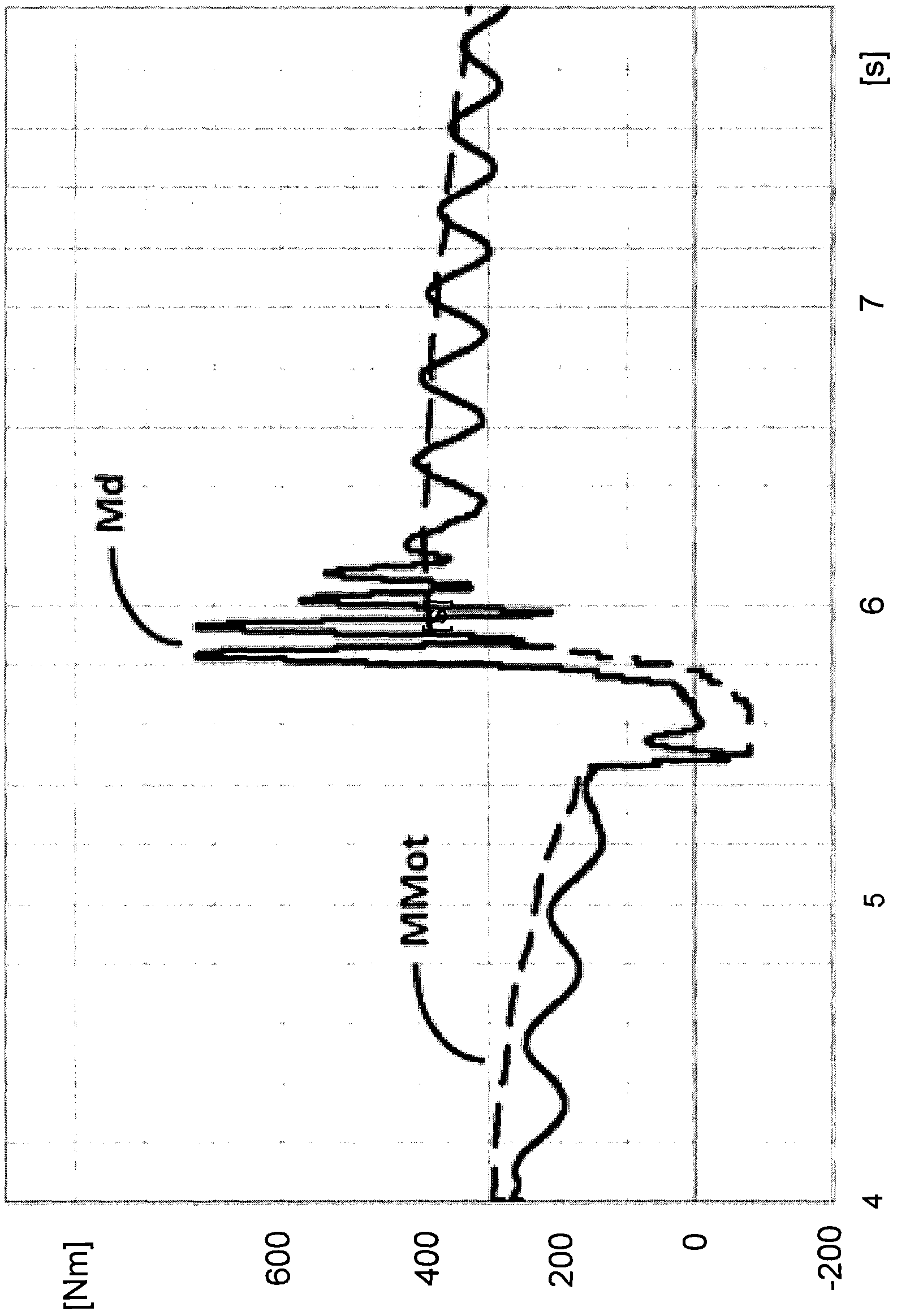

Method and device for determining load spectrum for transmission in motor vehicles

ActiveCN102326186BReduce carbon dioxideRegistering/indicating working of vehiclesGearing controlControl theoryVolatile memory

According to the invention, for determining the load spectrum of a transmission for motor vehicles, the transmission torque at the transmission input is calculated continuously from prescribed operating parameters. A matrix is generated from the continuously calculated transmission torque values, in which the frequency of occurrence of a transmission torque in a defined transmission torque class is entered and stored for each gear. The stored values in the matrix are preferably saved in a non-volatile memory for each shifting procedure during motor vehicle operation, and evaluated external to the vehicle for new development of transmissions.

Owner:BAYERISCHE MOTOREN WERKE AG

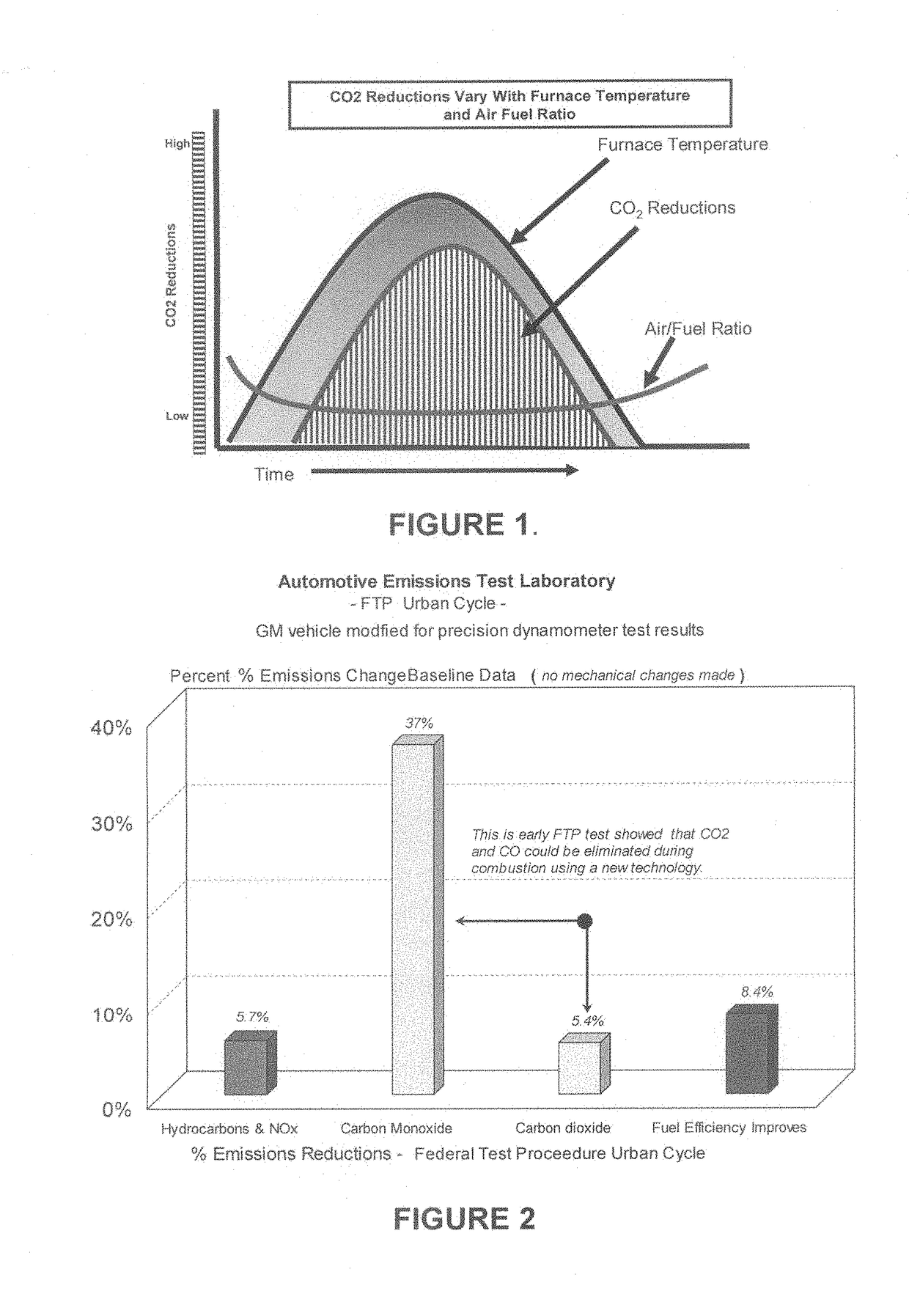

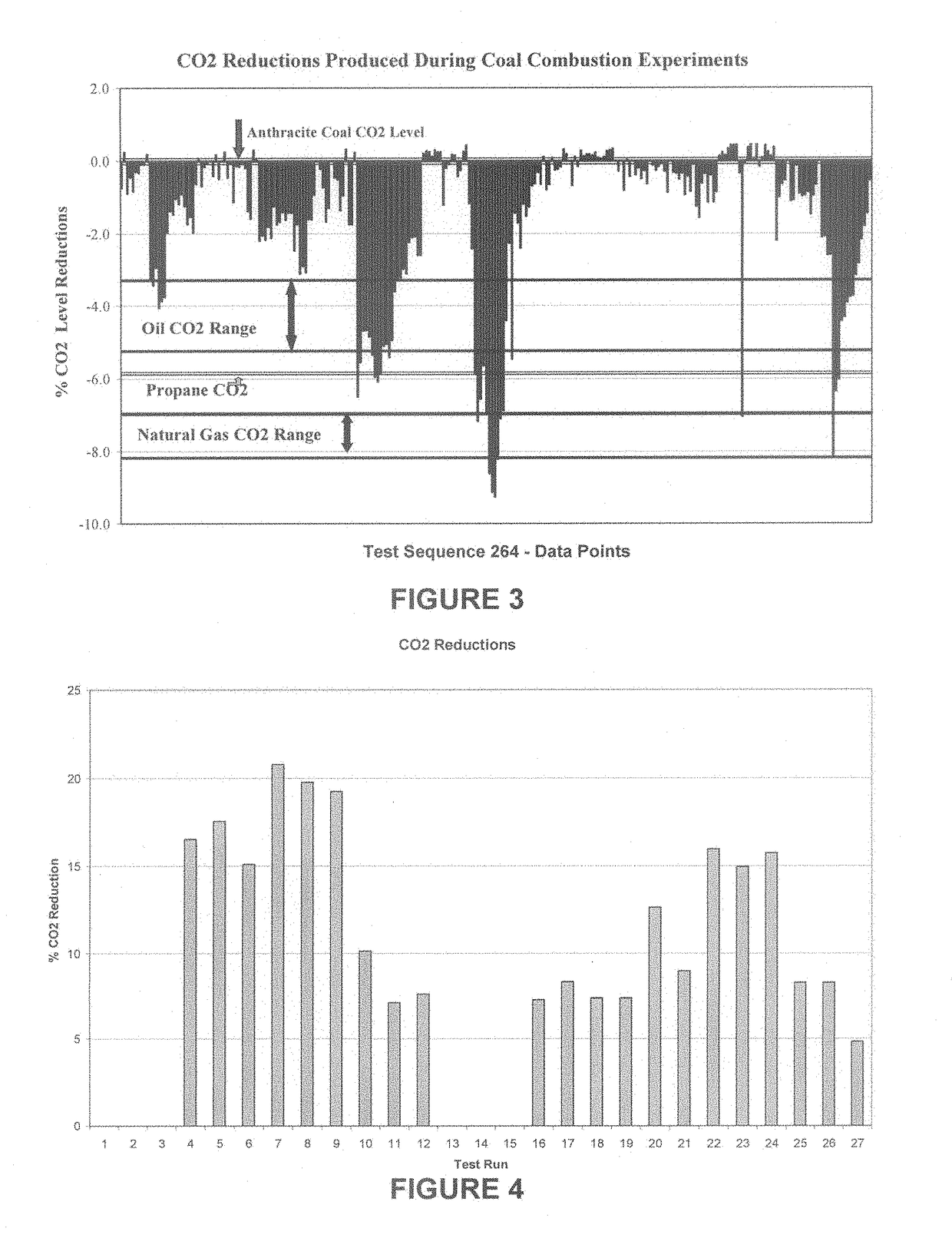

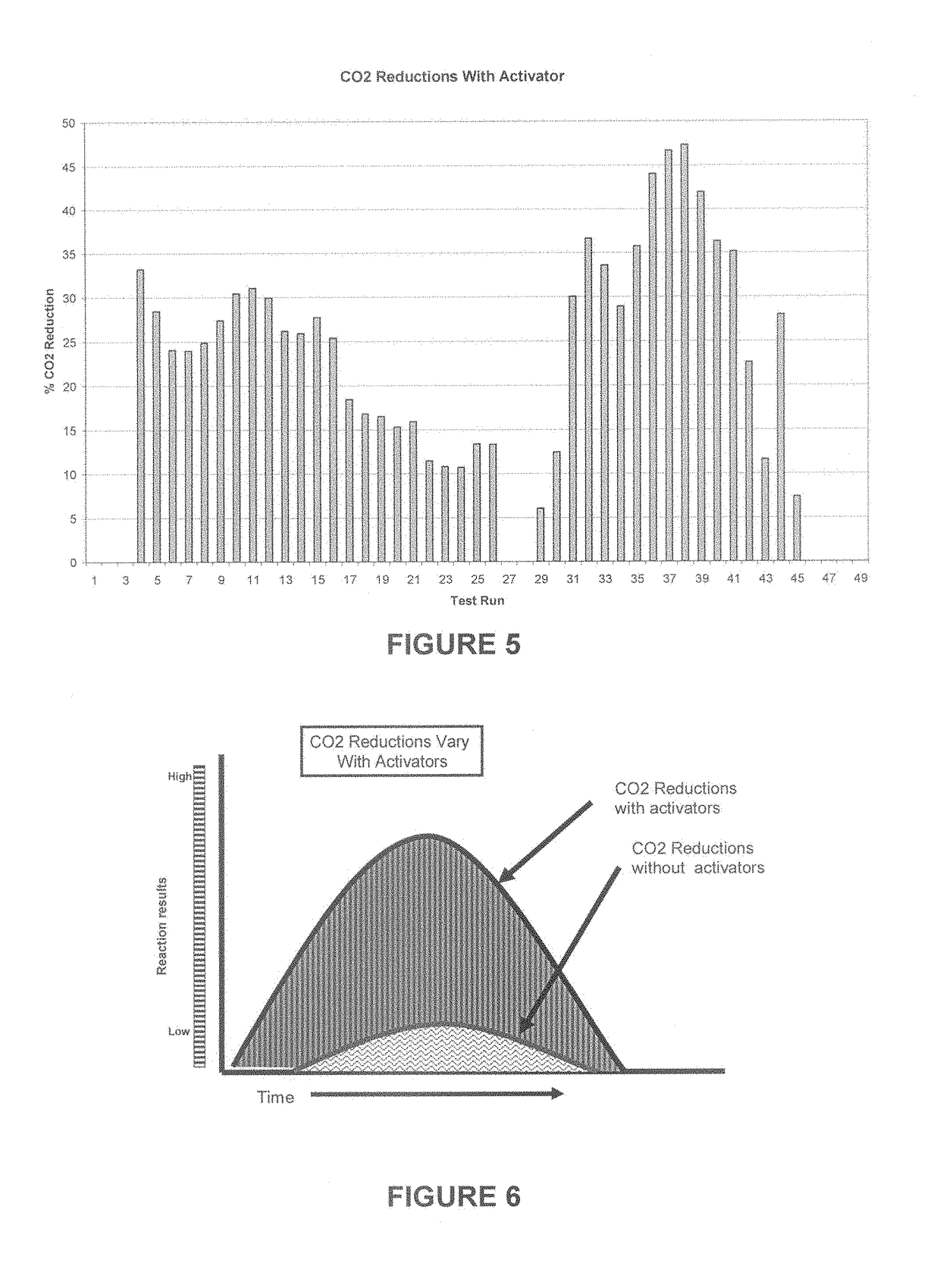

System for combustion of fuel to provide high efficiency, low pollution energy

ActiveUS20190024884A1Reduce carbon dioxideReduce CO2Fuel supply regulationEmission preventionCombustion systemLithium

An afterburner system and method for reducing the CO2 and other pollutants produced by the combustion of a fuel in a combustion chamber while maintaining or increasing the efficiency of said combustion includes feeding a catalyst, preferably lithium and / or boron to the afterburner, or a preconditioning afterburner, along with the exhaust from the combustion chamber. The presence of the catalyst in the after burner results in further reduction of pollutants generated by the combustion in the combustion chamber.

Owner:TAPLIN JR HARRY R

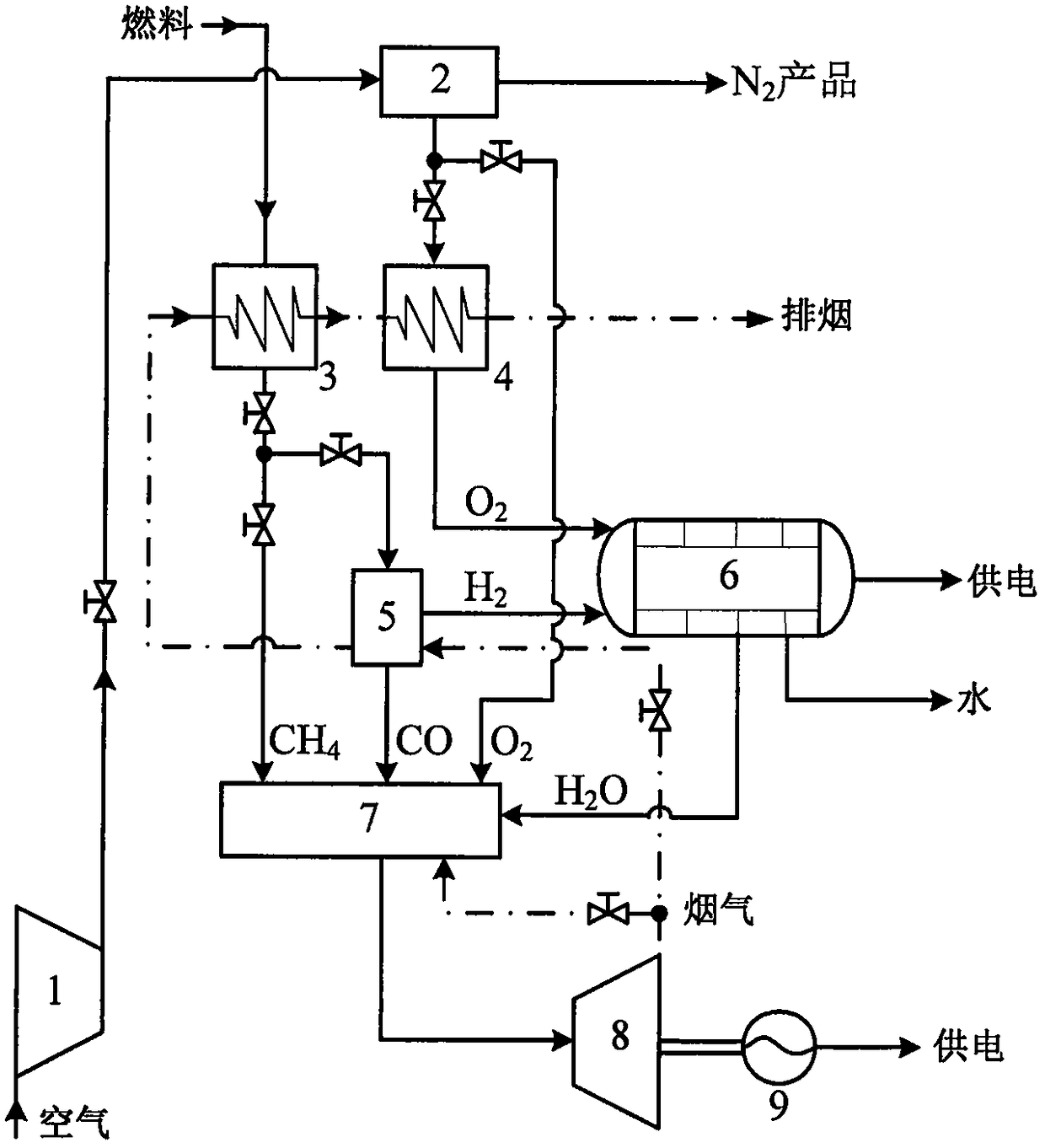

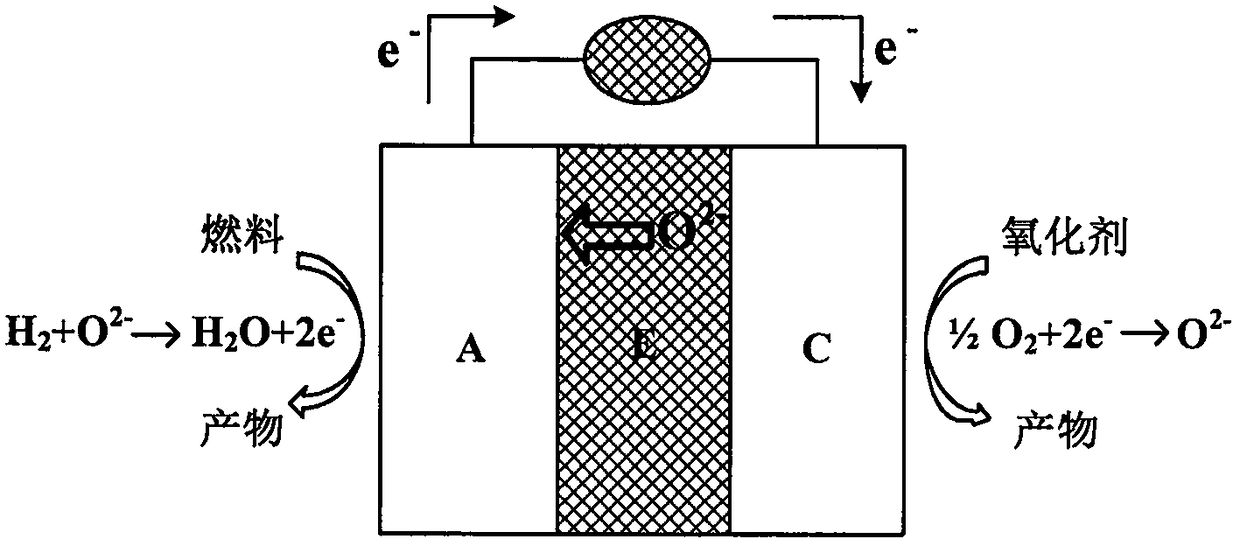

Oxygen-enriched combustion and solid oxide fuel cell hybrid power generating system

PendingCN108306027AReduce carbon dioxideReduce pollutionFuel cell heat exchangeFuel cell applicationsCombustion chamberElectric generator

The invention relates to an oxygen-enriched combustion and solid oxide fuel cell hybrid power generating system, and belongs to the field of power generating systems. The system includes a solid oxidefuel cell, a reformer, a combustion chamber, an electric generator and the like. Air separation is performed to obtain O2 and N2, and a CH4-based fuel is reformed to obtain H2 and CO; H2 and O2 are reacted in the solid oxide fuel cell to form a solid oxide fuel cell power generating system; and a fuel-based gas undergoes oxygen-enriched combustion in the combustion chamber, and generated high-temperature flue gas enters a turbine and does work through expansion to form an oxygen-enriched combustion power generating system. The hybrid power generating system can ensure the power demand of thesystem, also fully utilizes the energy, and improves the power generating efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Apparatus for adjusting steam pressure in a system for drying coal using reheat steam

InactiveUS20170130152A1Emission reductionIncrease calorie valueDrying solid materials with heatDrying gas arrangementsSteam pressureEngineering

The present invention relates to a system for drying coal using reheat steam, and more particularly, to an apparatus for enhancing drying efficiency by adjusting reheat steam to be injected to coal input and transferred onto a transfer device at predetermined pressure in a multi-stage dryer drying the coal by using reheat steam and in the apparatus for adjusting steam pressure in a system for drying coal using reheat steam, a steam supply pipe supplying the reheat steam generated by a reheater is connected to one side of each of the first steam chamber, the second steam chamber, the third steam chamber, and the fourth steam chamber and a first steam distribution perforated plate with a plurality of steam injection holes is coupled to and installed in the inner upper part of each of the first steam chamber, the second steam chamber, the third steam chamber, and the fourth steam chamber to inject the reheat steam at uniform pressure through the first steam injection holes.

Owner:HANKOOK TECH

Gas-based shaft furnace direct reduction method for hydrocarbon-rich gas and reduction system thereof

The invention discloses a hydrocarbon-rich gas gas-based shaft furnace direct reduction method and a reduction system thereof, and belongs to the field of direct reduction. Reducing gas is hydrocarbon-rich gas, the hydrocarbon-rich gas and an oxidizing agent are heated to 1100-1350 DEG C in a heating device, then unheated hydrocarbon-rich gas is injected to form mixed gas, then the mixed gas is sprayed into the gas-based shaft furnace, a lining of the heating device is a refractory material, and the oxidizing agent is one or a mixture of more than two of O2, H2O and CO2. The reduction system comprises a gas-based shaft furnace and a gas heating device, a partial oxidation converter is adopted as the gas heating device, hydrocarbon-rich gas is divided into two pipelines, one pipeline is communicated with an inlet of the partial oxidation converter heating device, and the other pipeline is connected with an outlet pipeline of the partial oxidation converter heating device in parallel and then is communicated with the partial oxidation converter heating device. And then communicating with a reducing section tuyere of the strange furnace body. The invention has the advantages of low overall investment, high utilization rate of feed gas and high conversion rate of hydrocarbon-rich gas, and solves the problem of efficient utilization of coal gases with different properties in iron and steel combined enterprises.

Owner:李伟

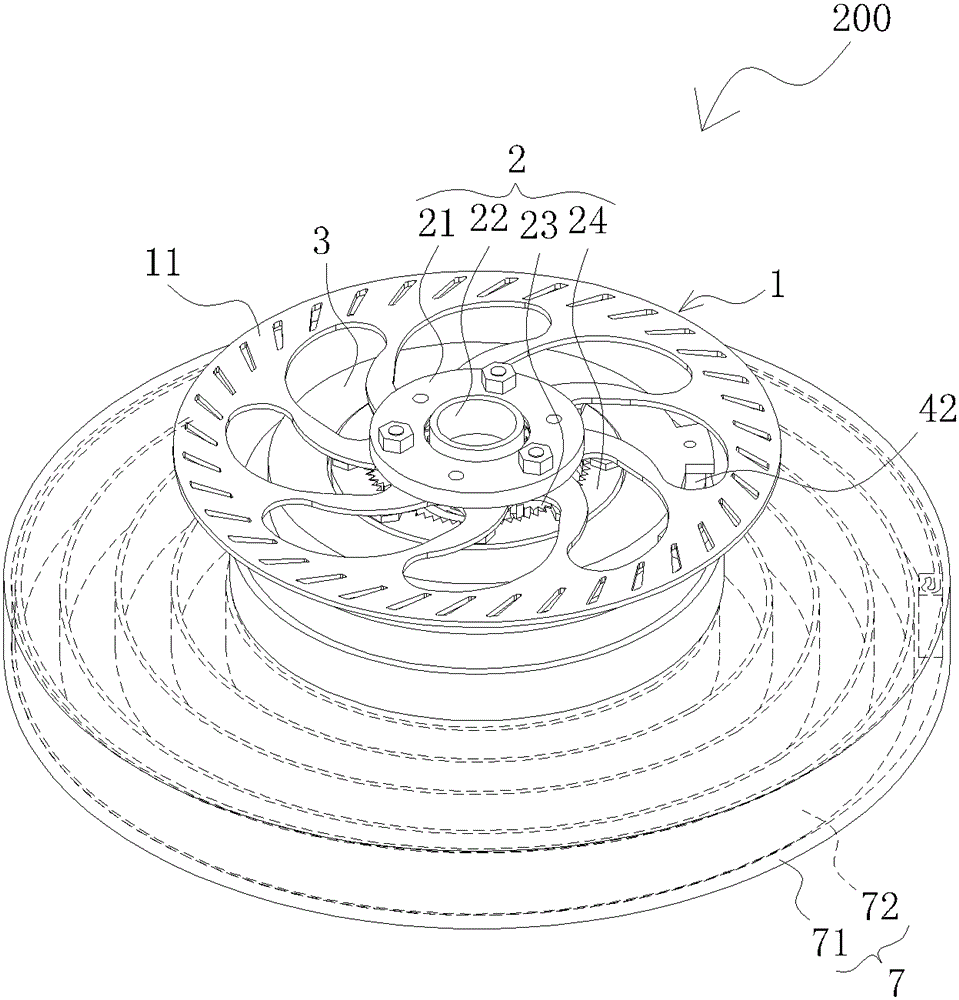

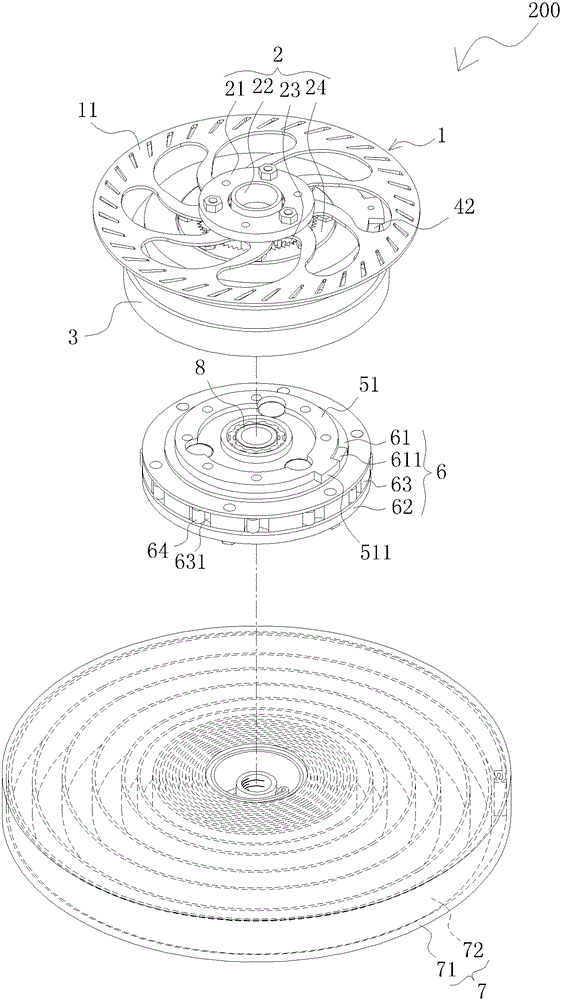

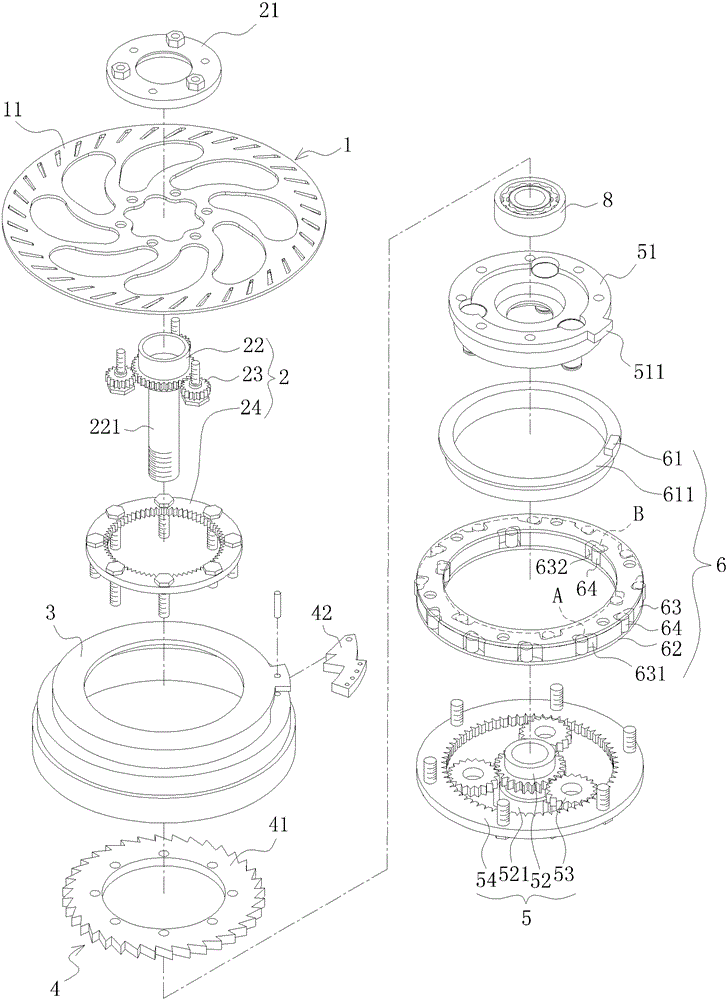

accumulator

The invention aims at providing an energy accumulator which can store originally useless kinetic energy and convert the kinetic energy into auxiliary power. The energy accumulator comprises a braking part, a first planetary gear group, a gearbox, a ratchet device, a second planetary gear group, a compound ratchet and an energy accumulation part. The compound ratchet is composed of a sliding ring, a locating piece and a main ring. The external diameter of the main ring is smaller than the internal diameter of the corresponding position of an accommodating space, the internal diameter of the main ring is larger than the external diameter of the sliding ring, a plurality of outer grooves are annularly arranged at the position of the ring edge of the outer side of the main ring, and a plurality of inner grooves are also annularly arranged at the position of the ring edge of the inner side of the main ring. The outer grooves and the inner grooves are oppositely arranged, the higher side ends of and the lower side ends of both a first inclined plane and a second inclined plane are same in direction, and rolling columns capable of rolling in the outer grooves and the inner grooves are respectively movably embedded in the outer grooves and the inner grooves. In addition, a one-way bearing is further arranged at the joint of a first sun gear and a second planet carrier.

Owner:游大庆

M55 low-carbon clean gasoline

InactiveCN104560229ANo corrosionNo swellingLiquid carbonaceous fuelsFuel additivesSolventOil soluble

The invention relates to M55 low-carbon clean gasoline. The M55 low-carbon clean gasoline comprises the following components: 550kg of methanol, 400kg of No.93 gasoline, 15kg of methyl tert-butyl ether, 5kg of isopropyl ether, 5kg of isopropanol, 7kg of petroleum ether, 10kg of solvent oil, 2kg of ethanolamine, 5kg of a clean dispersant, 0.5kg of benzotriazole, 0.5kg of an antioxidant 501 and 10g of oil-soluble yellow. The M55 low-carbon clean gasoline is an environment-friendly fuel and has the characteristics of low carbon, environment friendliness, burning resistance, oil conservation and no corrosion, and carbon monoxide and carbon dioxide are reduced. The M55 low-carbon clean gasoline can be used with gasoline at any blending ratio, a vehicle using a fuel can use the gasoline without needing to change an engine, and thus the difficult problem that a vehicle driver is inconvenient to add fuel to the vehicle is solved. By the M55 low-carbon clean gasoline, the emission of carbides can be reduced. The M55 low-carbon clean gasoline is non-corrosive and free of swelling, air resistance is avoided in summer, and the vehicle is easy to start in winter.

Owner:郝德厚

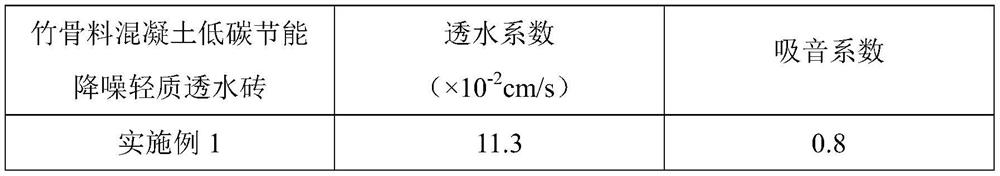

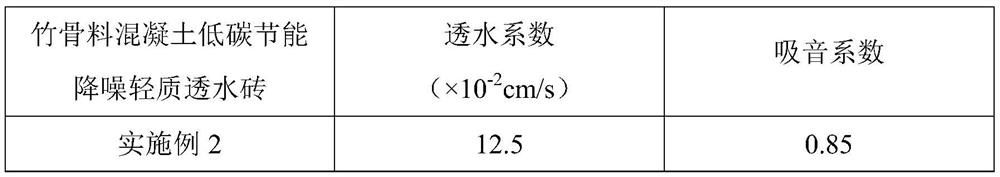

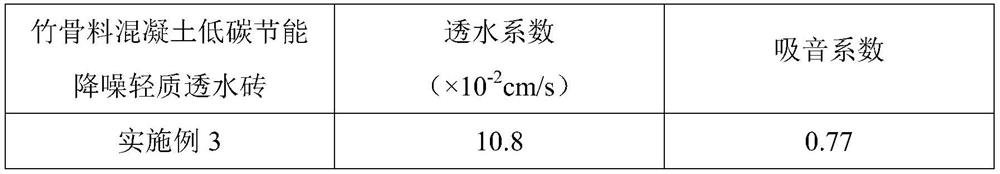

Low-carbon energy-saving noise-reducing lightweight water-permeable brick containing bamboo aggregate and concrete

PendingCN113548860APromote sustainable economic developmentReduce carbon dioxideSolid waste managementSingle unit pavingsBrickPortland cement

The invention discloses a low-carbon energy-saving noise-reducing lightweight water-permeable brick containing bamboo aggregate and concrete. The water-permeable brick is composed of the bamboo aggregate and cement mortar, and specifically comprises the following components: 18.2 to 29.3 parts of Portland cement, 25.2 to 40.1 parts of modified bamboo aggregate, 13.5 to 20.8 parts of medium sand, 0.5 to 1.5 parts of a recombination admixture, and 10 to 20 parts of neutral water. The water-permeable brick has the following characteristics that the water-permeable brick is high in freezing resistance, compression resistance and corrosion resistance; the porous material, namely the bamboo aggregate is environment-friendly and renewable; the internal porosity of the water-permeable brick is high, so the problem of surface water accumulation is effectively solved, the water-permeable brick has super-strong water permeability, and meanwhile, pavement noise can be reduced by 3-5 decibels; and in addition, due to the fact that the bamboo aggregate replaces traditional stone aggregate, the brick is 30-40% lighter than a common concrete brick under the same size, and is low in price compared with similar products. The low-carbon energy-saving noise-reducing lightweight water-permeable brick containing the bamboo aggregate and the concrete can be widely applied to non-motor vehicle roads, parking lots, scenic spots, gardens, sidewalks and the like.

Owner:无锡贝通环保新材料有限公司

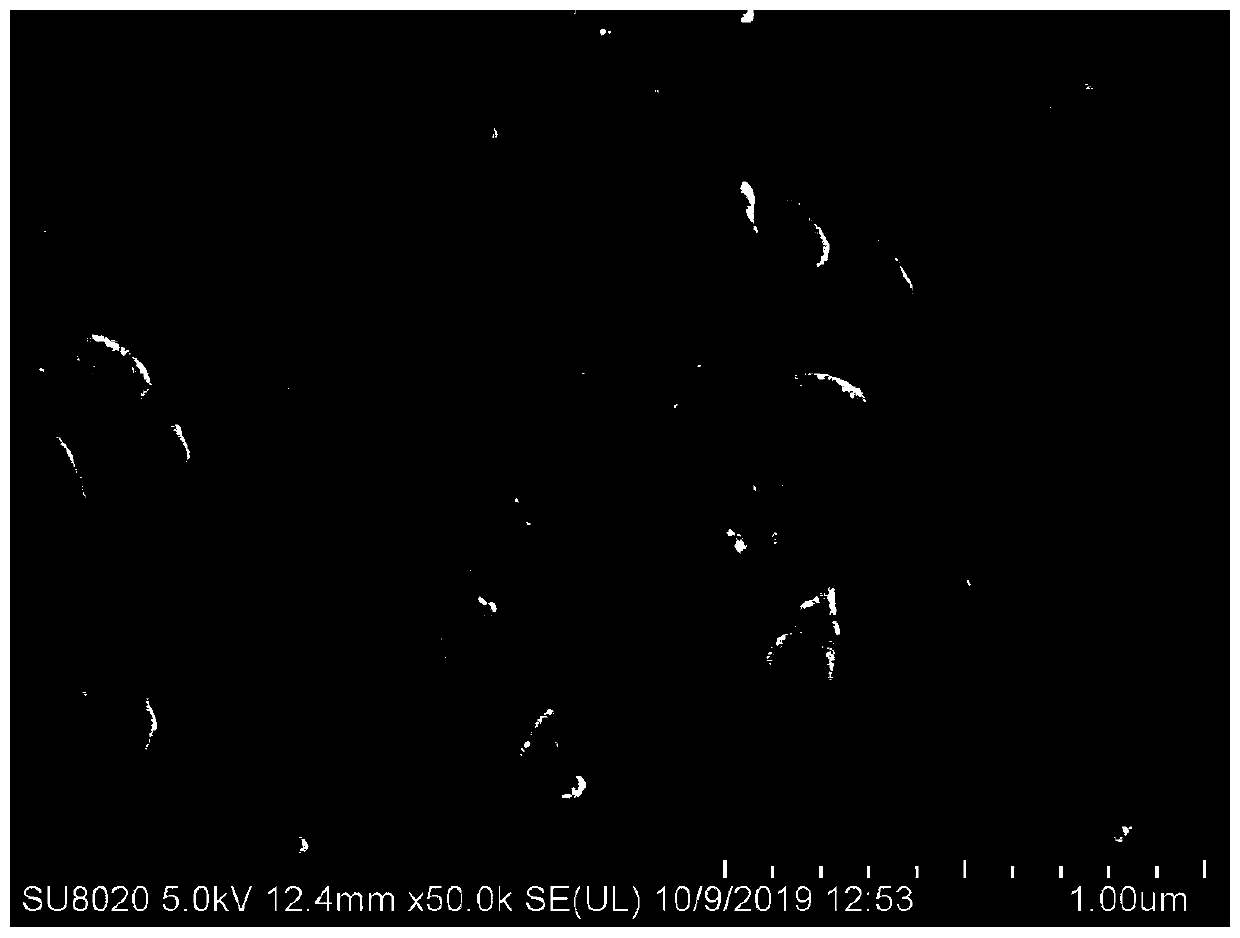

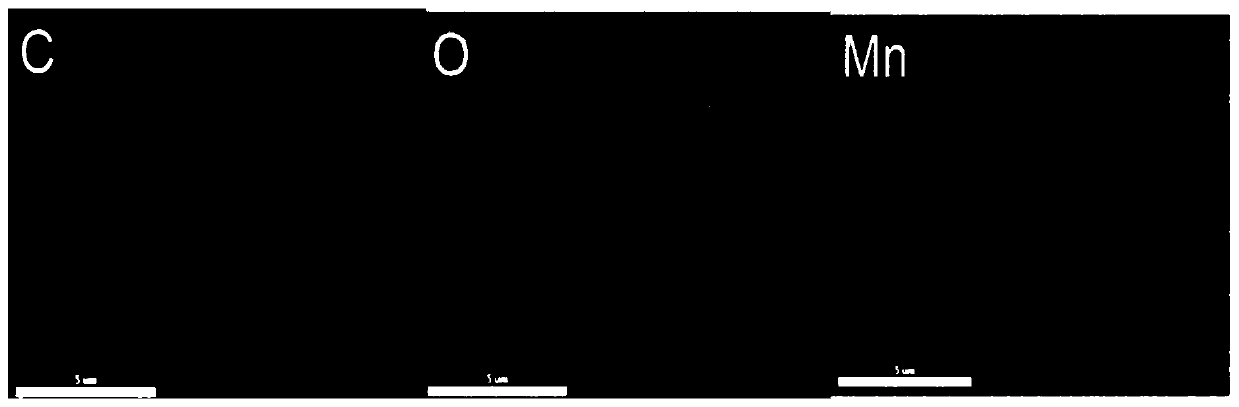

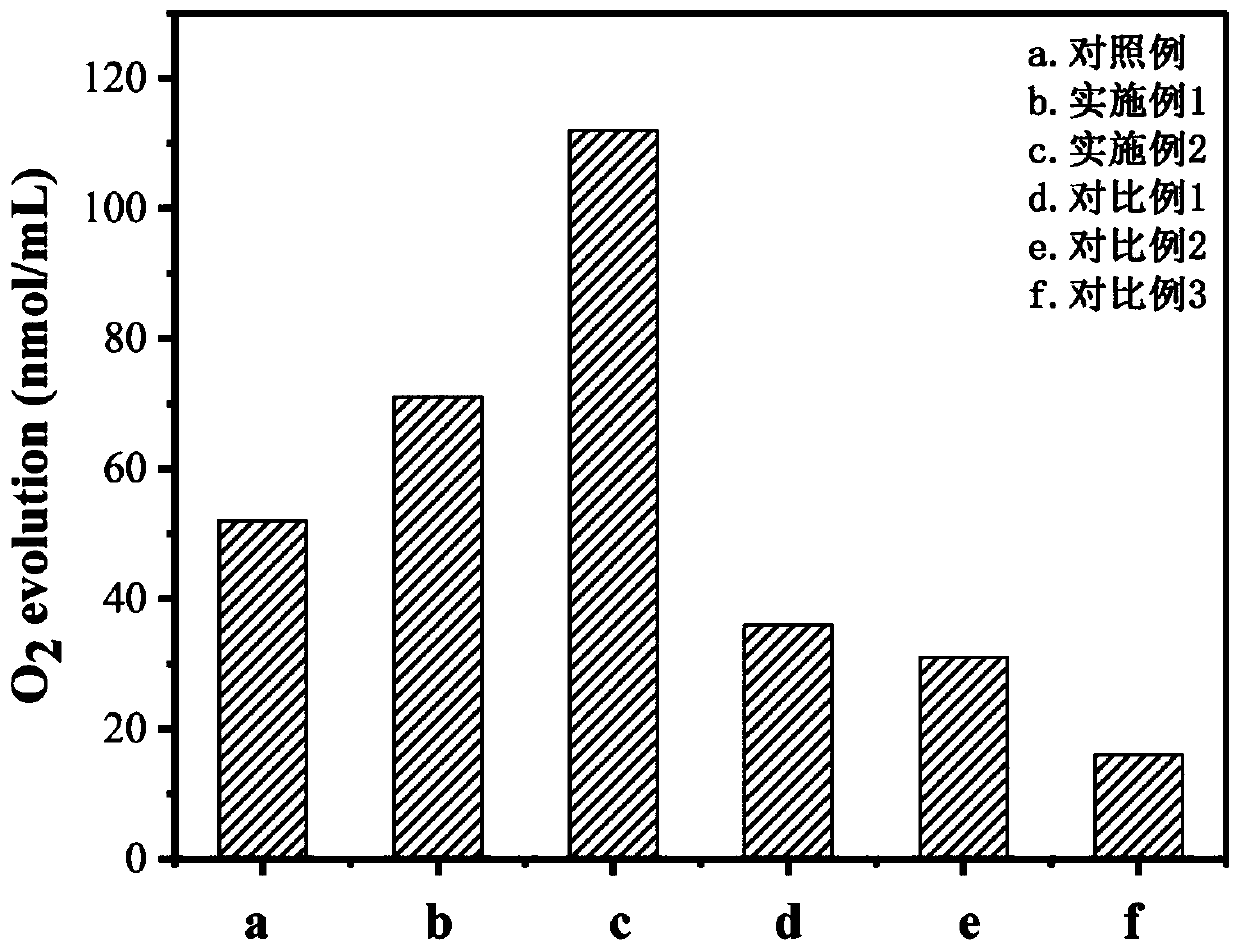

Photocatalytic material capable of rapidly capturing carbon dioxide and releasing oxygen

InactiveCN110721675AMix directlyReduce carbon dioxideOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsAir decontaminationManganese

The invention discloses a photocatalytic material capable of rapidly capturing carbon dioxide and releasing oxygen. According to the invention, a thylakoid / manganese-based light-capturing oxygen-releasing composite material is prepared by utilizing photocatalytic oxygen-releasing properties of extracted in-vitro thylakoid and manganese dioxide through a material compounding preparation method, sothat the photosynthesis efficiency of the thylakoid is further improved; and the material has advantages of easy obtaining, simple preparation method, mild preparation condition, environmental protection, no pollution, biodegradability and the like, and has potential application prospects in the field of environmental protection, especially air purification.

Owner:SHAANXI NORMAL UNIV

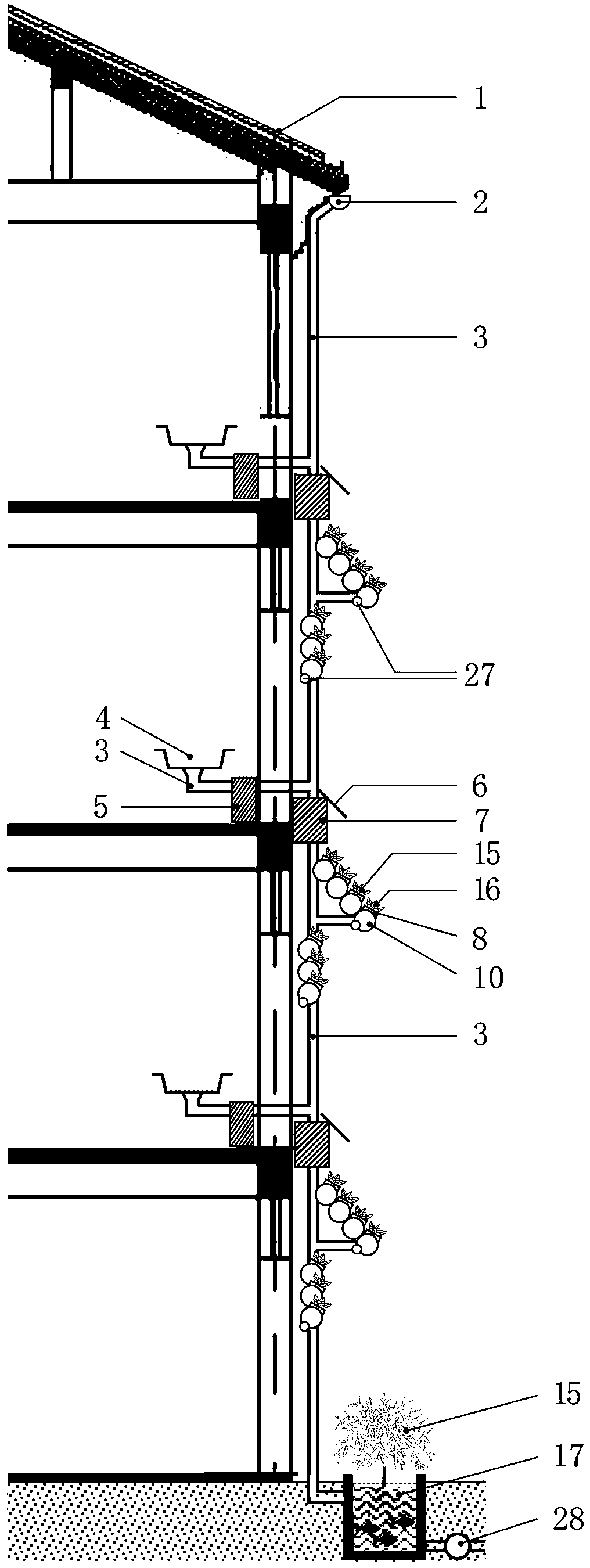

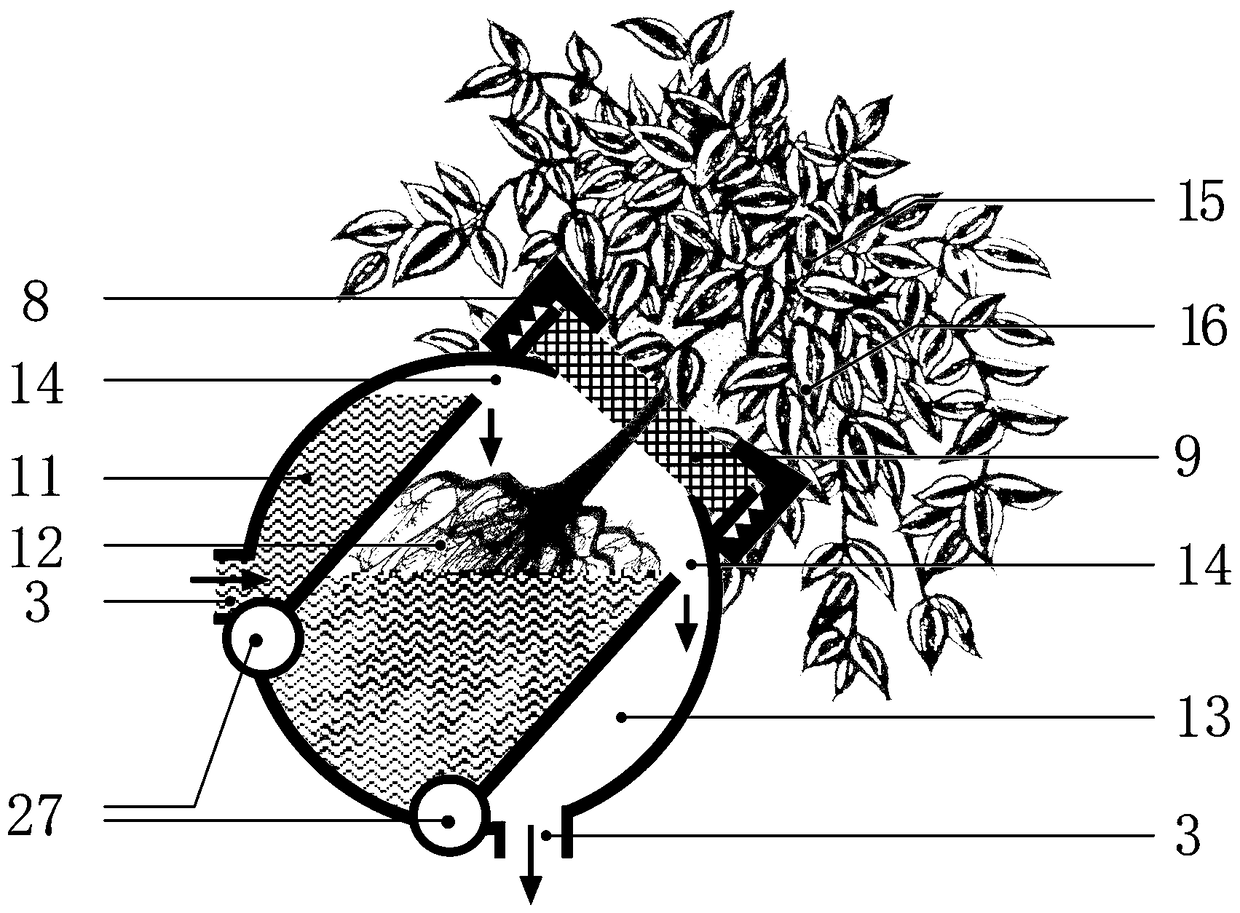

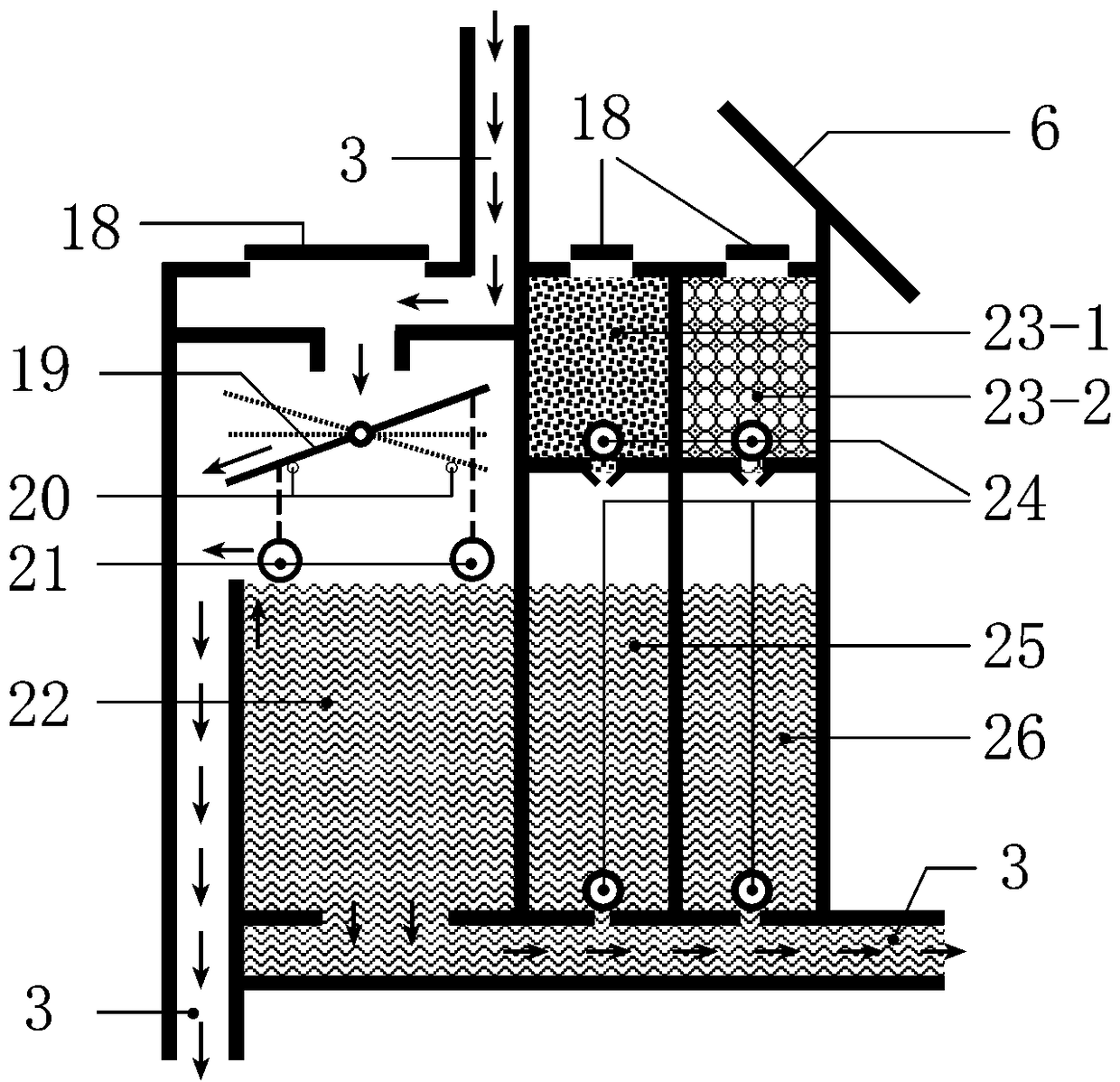

Constructing the ecological greening system of the external wall pipe network of the secondary water reuse building in the sponge city

ActiveCN106922418BPowerful three-dimensional ecosystemGreen ecological environmentRoof improvementGeneral water supply conservationInteraction systemsEcological environment

An external building wall pipe network ecological greening system for secondary water reuse in a sponge city, comprising: a rooftop (1), a rainwater collection box (2), water drainage pipes (3), wash basins (4), filters (5), solar panels (6), a computer / mobile phone smart automatic / manual control organic nutrient solution, particle fertilizer / water quality improvement chemical additive and particle / drop box cloud application interaction system (7-1-2), plant growth covers (8), three-chamber pipe-linked pipe-type water circulating plant growth pipe disks (10), optimally cultivated terrestrial and aquatic plants suitable for growing in secondary city water; water channels surrounding the city / water channels surrounding buildings as well as the optimally cultivated terrestrial and aquatic plants suitable for growing in secondary city water, and excess water being discharged to an underground city pipe network after the secondary water is purified by means of plant growth are effective approaches to and provide strong support for the construction of a sponge city.

Owner:汤疆平

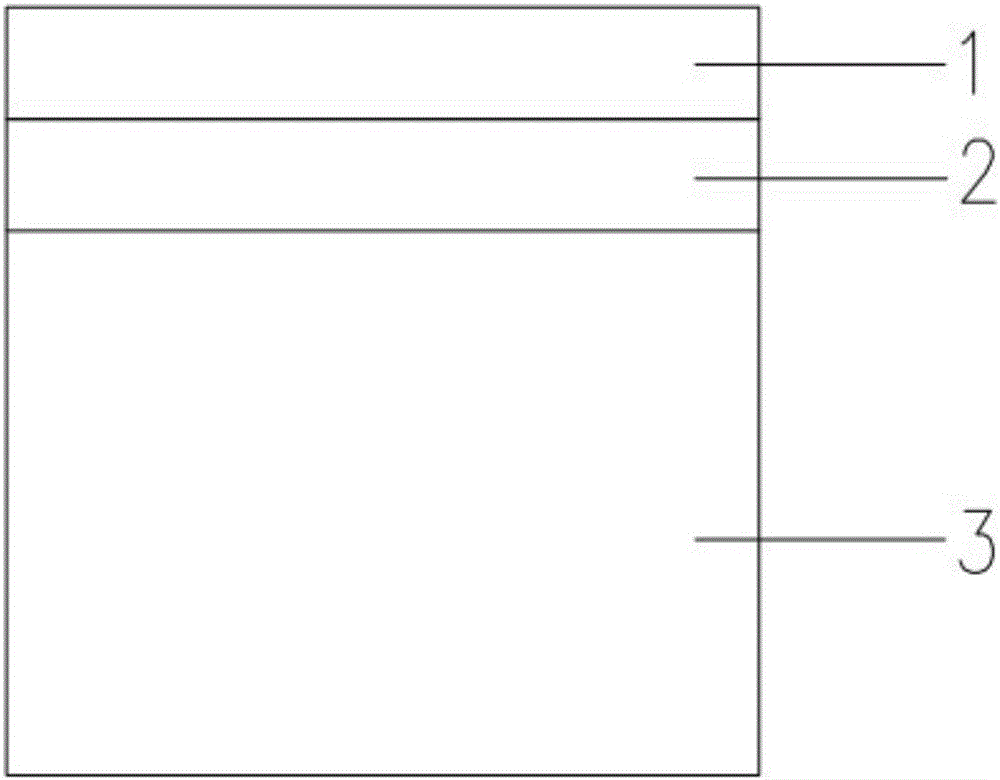

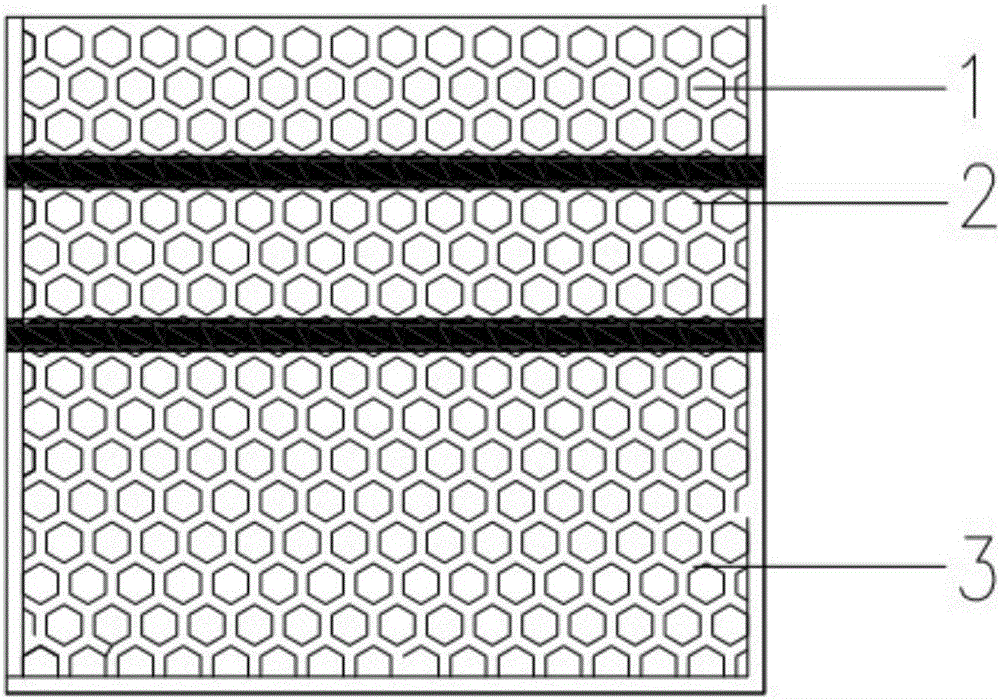

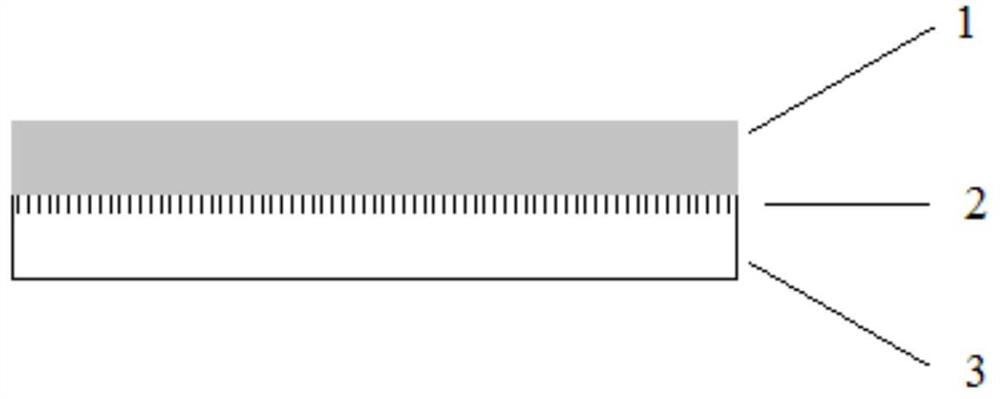

Degradable bioplastic composite paper and preparation process thereof

ActiveCN111730943AReduce carbon footprintHigh strengthFlexible coversWrappersPolymer scienceWet strength

The invention provides degradable bioplastic composite paper and a preparation process thereof. The degradable bioplastic composite paper at least comprises a first layer (1) containing bioplastic anda paper layer (3) as a second layer, and the first layer and the second layer are bonded together through an adhesive layer (2). The degradable biological plastic composite paper can overcome the adverse environmental influence caused by high-content plastic, and has excellent tensile strength performance and wet strength.

Owner:新疆弘瑞达纤维有限公司

Photoelectrochemical cell for carbon dioxide conversion

InactiveUS20180171492A1Reduce carbon dioxideCellsEnergy inputPhotoelectrochemical cellElectrochemical cell

the present disclosure relates to photoelectrochemical cells and methods for using such for reduction of carbon dioxide and oxidation of water. In one aspect, the disclosure provides a method of electrochemically reducing carbon dioxide in an electrochemical cell, comprising contacting the carbon dioxide with at least one transition metal dichalcogenide in the electrochemical cell and at least one helper catalyst and applying a potential to the electrochemical cell.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

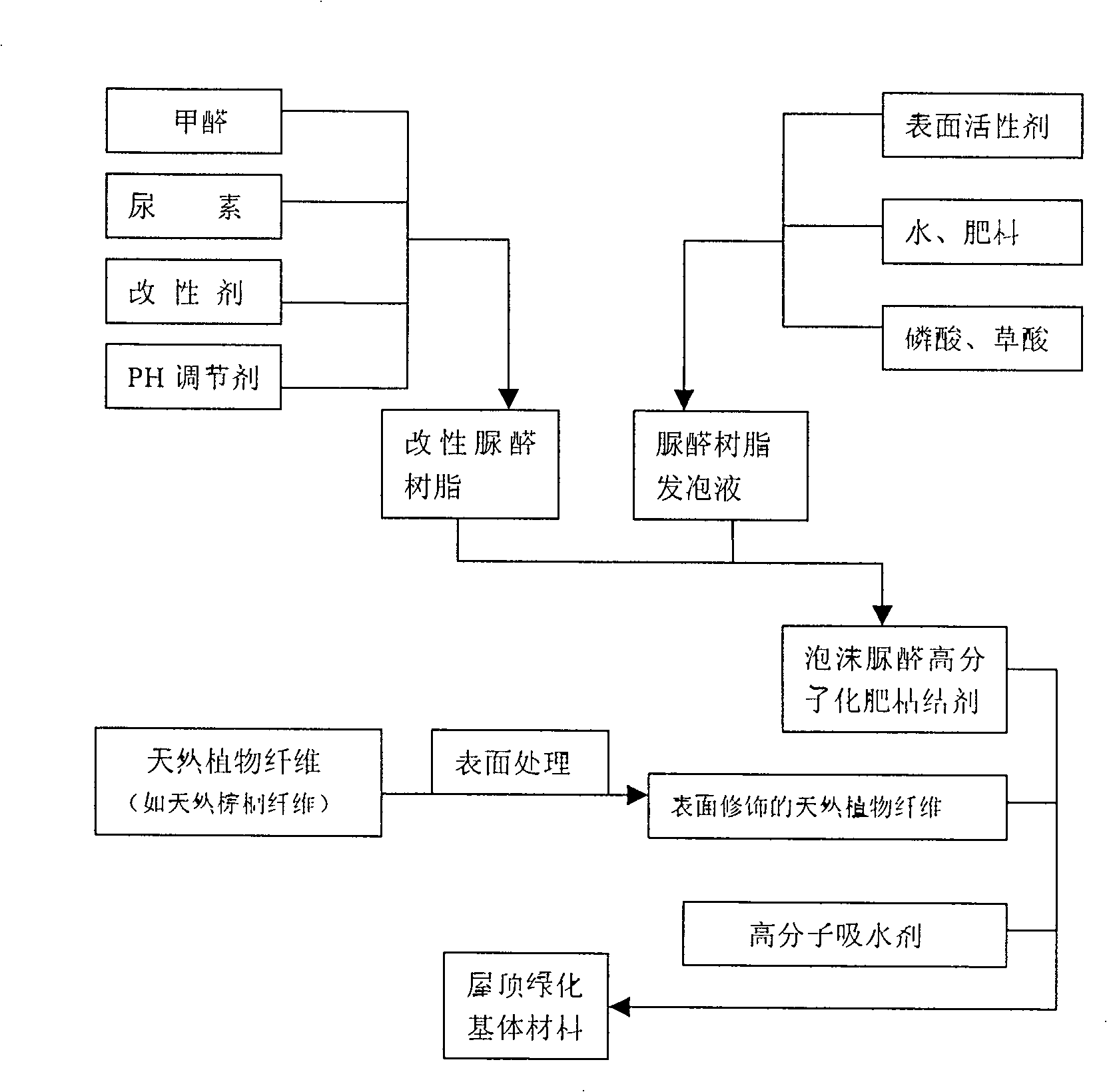

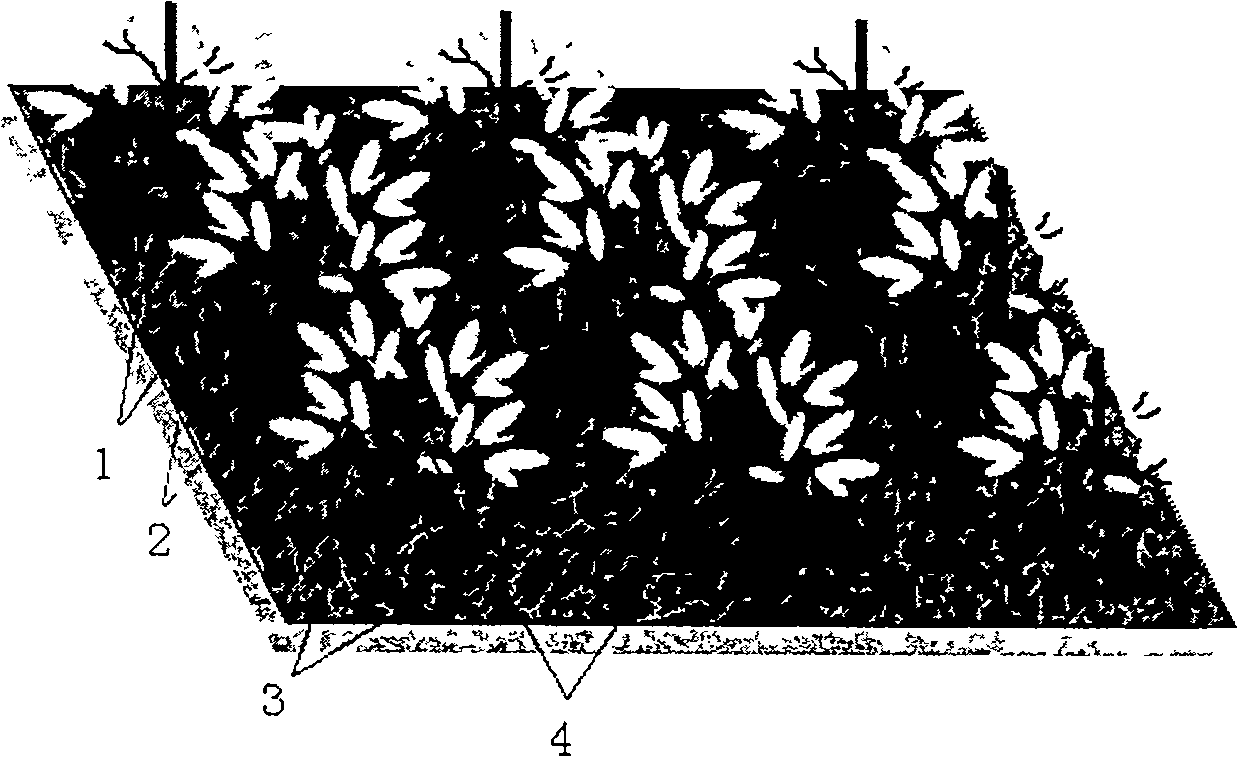

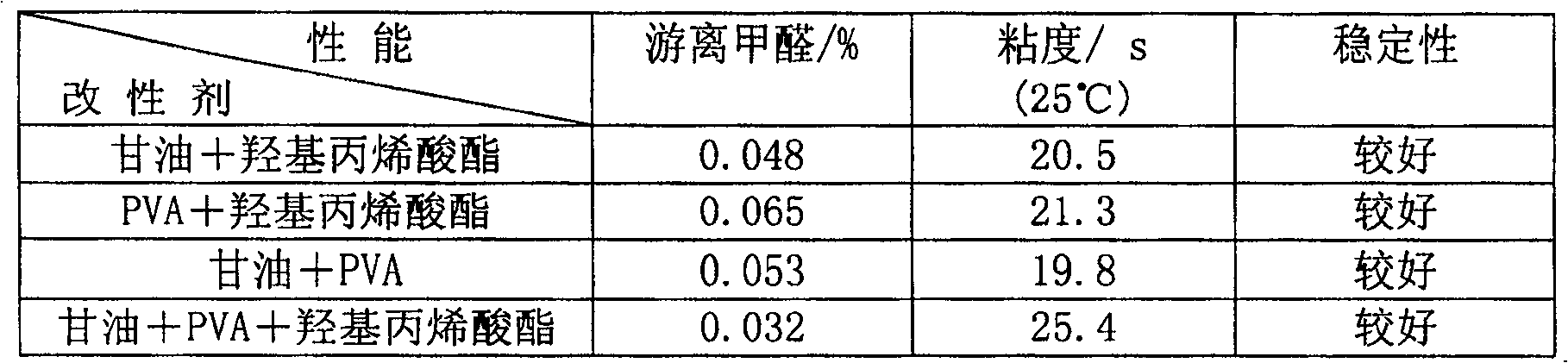

Matrix material for making green by planting on housetop and preparation process thereof

InactiveCN100419021CImproved microclimate aboveReduce thermal expansion and contractionCultivating equipmentsSoilless cultivationFiberBlowing agent

This invention relates to a roofing greening base material and the method. Its main primary materials includes 10-35 portions foam urea formaldehyde fertilizer adhesive, 40-95 portions natural fabric, 1-5 portions polymer water absorption agent. The foam urea formaldehyde fertilizer adhesive is made by frothing modified urea-formaldehyde resin and urea-formaldehyde resin blowing agent in frother, at a quality proportion of 100-150:40-60.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com