Low-carbon energy-saving noise-reducing lightweight water-permeable brick containing bamboo aggregate and concrete

A technology for permeable bricks and concrete, applied in the field of permeable bricks, can solve the problems of poor water filtering performance, poor noise reduction effect, large energy consumption, etc., and achieve the effects of excellent water permeability, reducing road water accumulation and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A low-carbon, energy-saving, noise-reducing lightweight permeable brick made of bamboo aggregate concrete. The raw material components are as follows: 28.5 parts of Portland cement, 26.4 parts of modified bamboo 11 parts of neutral water, prepared by stirring, molding, curing, demoulding and re-curing, and then spraying green pigment on the surface. The water permeability coefficient and sound absorption coefficient of the bamboo aggregate concrete low-carbon energy-saving and noise-reducing lightweight permeable brick are shown in Table 1.

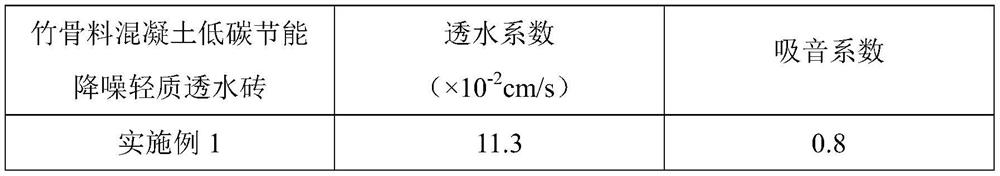

[0020] The water permeability coefficient and the sound absorption coefficient of the bamboo aggregate concrete low-carbon energy-saving and noise-reducing lightweight permeable bricks of Table 1 Example 1

[0021]

Embodiment 2

[0023] A low-carbon energy-saving and noise-reducing lightweight permeable brick made of bamboo aggregate concrete. 11 parts of neutral water, prepared by stirring, molding, curing, demoulding and re-curing, and then spraying green pigment on the surface. The water permeability coefficient and sound absorption coefficient of the bamboo aggregate concrete low-carbon energy-saving and noise-reducing lightweight permeable brick are shown in Table 2.

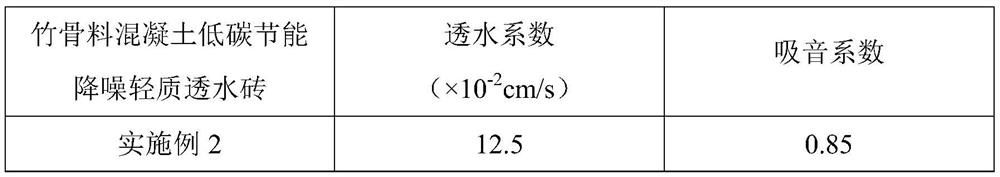

[0024] Water permeability coefficient and sound absorption coefficient of bamboo aggregate concrete low-carbon energy-saving and noise-reducing lightweight permeable brick of table 2 embodiment 2

[0025]

Embodiment 3

[0027] A low-carbon, energy-saving, noise-reducing lightweight permeable brick made of bamboo aggregate concrete. The raw material components are as follows: 28.5 parts of Portland cement, 26.4 parts of modified bamboo 11 parts of neutral water, prepared by stirring, molding, curing, demoulding and re-curing, and then spraying green pigment on the surface. The water permeability coefficient and sound absorption coefficient of the bamboo aggregate concrete low-carbon energy-saving and noise-reducing lightweight permeable brick are shown in Table 3.

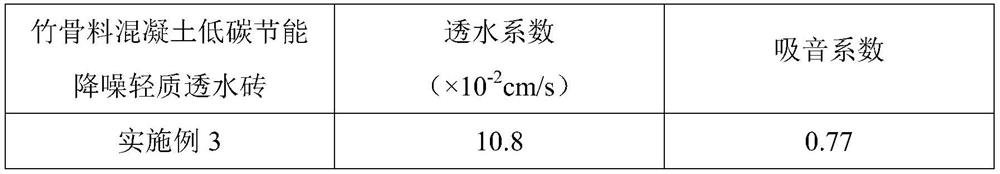

[0028] Water permeability coefficient and sound absorption coefficient of the bamboo aggregate concrete low-carbon energy-saving noise-reduction lightweight permeable brick of table 3 embodiment 3

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com