Degradable bioplastic composite paper and preparation process thereof

A bioplastic and composite paper technology, applied in the field of papermaking, can solve problems such as high equipment and process requirements, increased environmental pollution pressure, poor degradability, etc., and achieve the effect of meeting strength requirements, meeting environmental protection requirements, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

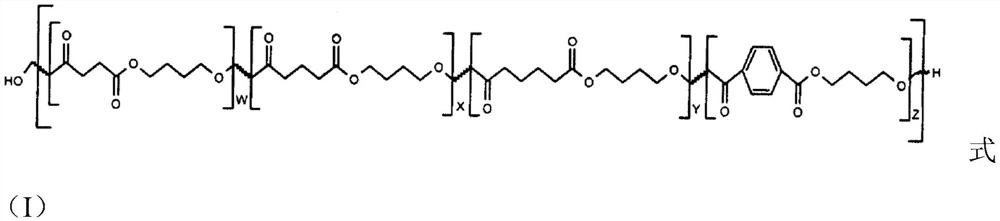

[0054] After replacing the air in the 500mL round bottom flask with nitrogen, add 81.9g of succinic acid, 128.0g of 1,4-butanediol, 12.6g of lactic acid, and 88.4g of dimethyl terephthalate; Increase the temperature, react at 180°C for 4 hours, and remove the water generated during the reaction; after that, add 0.10g antimony acetate, 0.15g tributyltin oxide and 0.07g tetrabutyl titanate as catalysts and 0.2g Trimethyl phosphate was used as a stabilizer; subsequently, the temperature was raised to 246° C. and a polycondensation reaction was performed at this temperature and a reduced pressure of 0.3 Torr for 180 minutes. After the reaction, it was detected that the melt index (190°C, 2160g) of the degradable resin was 12.6g / 10min, the number average molecular weight was 39,000, and the melting point measured by DSC was 86°C.

[0055] Mix the degradable resin prepared above with starch (Shandong Fengtai Environmental Protection Technology Co., Ltd.) in a weight ratio of 7:3, fu...

Embodiment 2

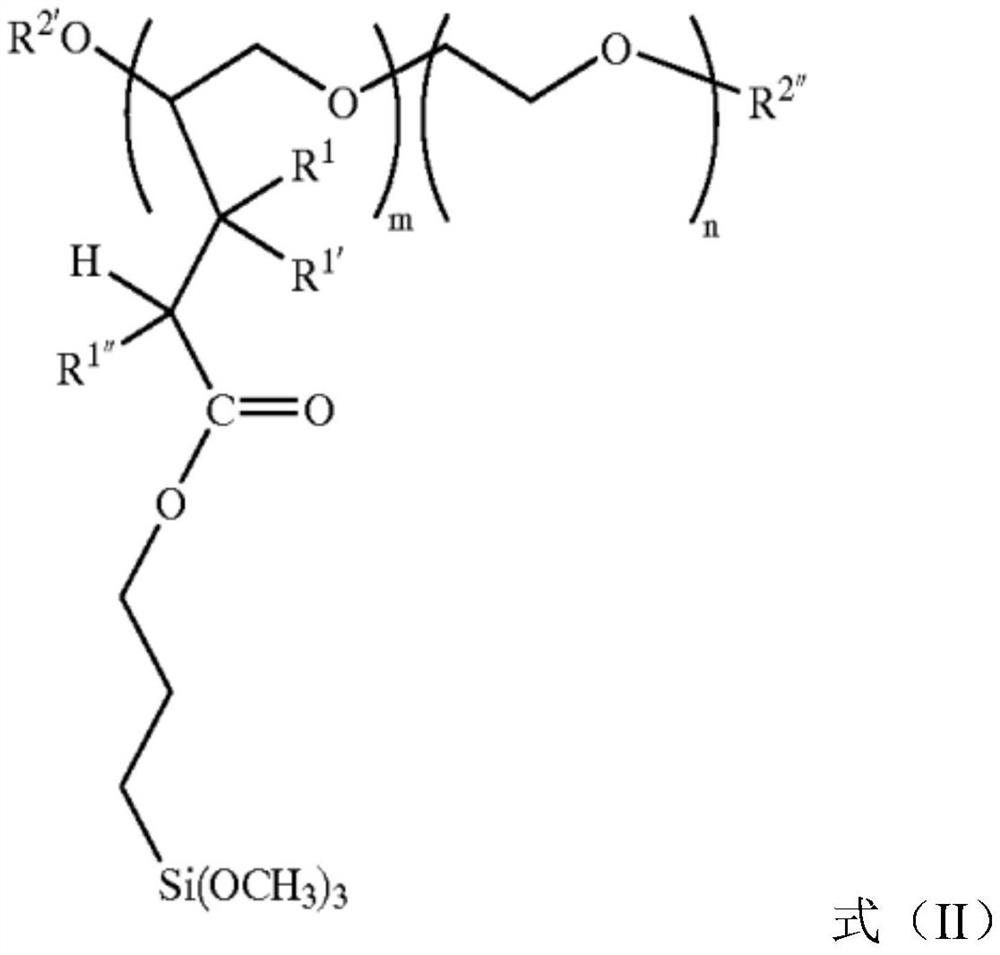

[0057] According to the HJ / T340-2007 standard, the kraft chemical wood pulp production process (with reference to the method of CN104452467A embodiment 1, wherein the wood raw material adopts coniferous wood) is added to the pulp by adding a strength enhancer shown in 0.1wt% formula (II), A lightweight paper is produced with a density of 18.2 g / m 2 .

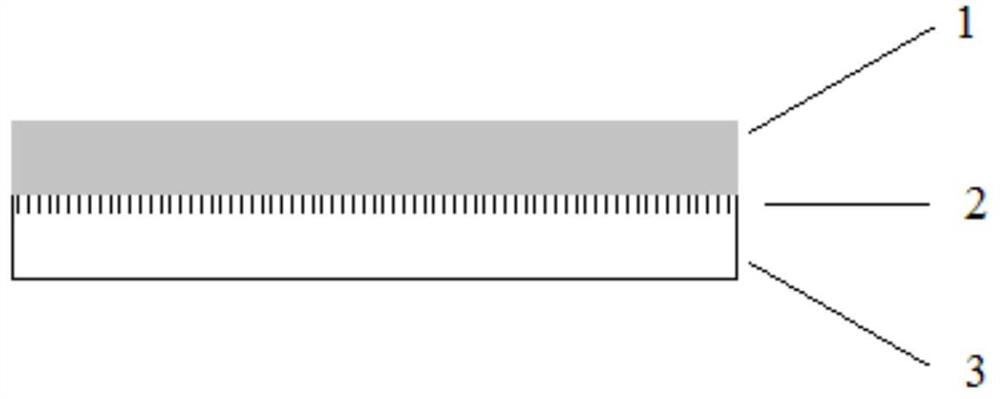

[0058] The bioplastic film obtained in Example 1 and the lightweight paper obtained in Example 2 are fed into the manufacturing equipment and adhered together to produce degradable bioplastic composite paper. The specific process is: the bioplastic film can be passed through The first feed roll is drawn into the system, the light weight paper can be drawn in with the second feed roll, and the paper is then passed through bonding rolls which apply a coating of soy protein as a binder to the paper One side of the paper so that the lightweight paper with a soy protein adhesive coating and the bioplastic film can be attached togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com