Patents

Literature

55results about How to "Make up for the lack of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Casting method combining investment precise shell-making process with vacuum suction molding technology

InactiveCN104399891AEasy to makeLow production costFoundry mouldsFoundry coresProcess engineeringUltimate tensile strength

The invention discloses a casting method combining an investment precise shell-making process with a vacuum suction molding technology. The casting method comprises the following steps: manufacturing a wax pattern, assembling the wax pattern, coating the surface of a wax pattern cluster with coating, drying, dewaxing and recovering a molding shell, performing low-temperature roasting on the molding shell, binning and moulding the shell, and performing negative pressure pouring. The casting method has the advantages that the manufacturing process of the molding shell is simplified, the manufacturing cost of the molding shell is reduced, the waste discharging volume is reduced, the low-temperature roasting is adopted, energy consumption is reduced greatly, and the problem of insufficient strength of the molding shell is solved through negative pressure pouring.

Owner:温州兰理工科技园有限公司 +2

C90-grade self-compaction high-strength concrete and preparation method thereof

The invention provides C90-grade self-compaction high-strength concrete and a preparation method thereof, and relates to a building material and a preparation method thereof. The C90-grade self-compaction high-strength concrete is prepared from the following materials in the following proportion: the ratio of cement to silicon ash to fly ash to stones to sand to water to a high-efficiency water reducing agent (unit Kg / m<3>) is (440-480) to (25-55) to (55-110) to (580-700) to (1100-1300) to (115-135) to (16-22). Compared with the prior art, a low-carbon environment-friendly architectural concept is integrated, the strength grade is very high and the working performance is good; and the C90-grade self-compaction high-strength concrete is particularly suitable for novel steel pipe high-strength concrete combined structures with limited inner spaces of steel pipes, such as pouring structural steel pipe concrete, hollow interlayer steel pipe concrete, steel pipe concrete overlapped members and dual steel pipe concrete and the like.

Owner:SHENYANG UNIV

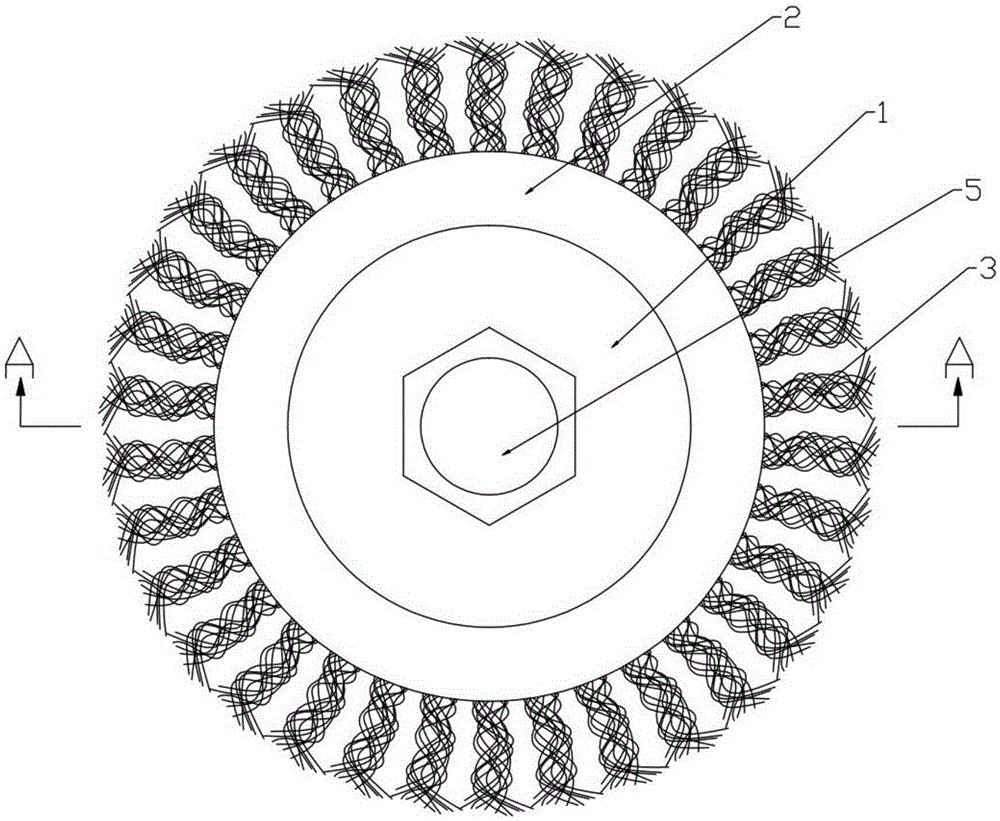

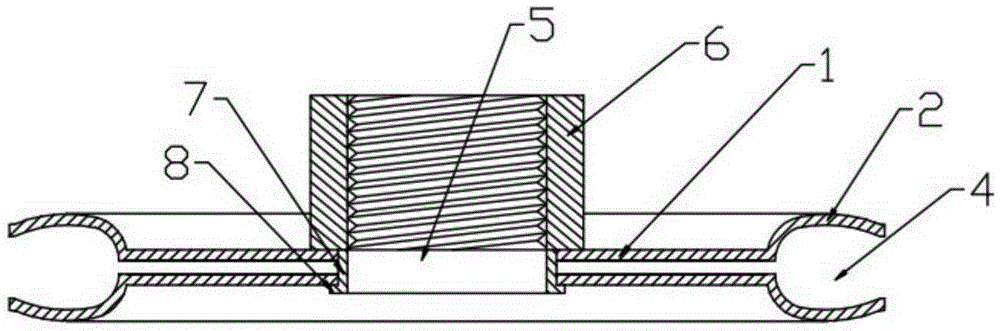

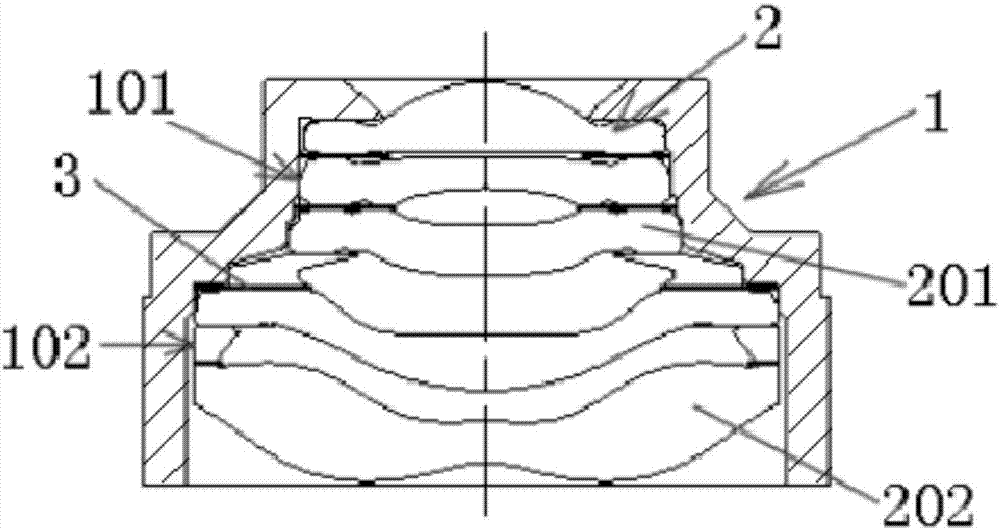

Metal wire polishing wheel

InactiveCN105415212ALight in massReduce quality problemsFlexible-parts wheelsMetallic material coating processesAlloy substrateEngineering

The invention provides a metal wire polishing wheel. The metal wire polishing wheel comprises an upper clamping plate and a lower clamping plate. A plurality of metal wire beams are installed between the edge parts of the upper clamping plate and the lower clamping plate in a central symmetrical mode. A fastener is installed between through holes of the upper clamping plate and the lower clamping plate. A longitudinal installation hole is formed in the middle of the fastener and internally provided with an internal thread. Both the upper clamping plate and the lower clamping plate are divided into the annular sunk parts in the middles and the annular protruding parts at the edges. The annular protruding part of the upper clamping plate and the annular protruding part of the lower clamping plate are symmetrical and form an annular installation groove of the metal wire beams. The metal wire beams are formed by twisting a plurality of metal wires made from an aluminum alloy composite material. The aluminum alloy composite material comprises an aluminum alloy substrate and a ceramic layer arranged on the surface of the aluminum alloy substrate through laser cladding. The metal wire polishing wheel is compact and firm in structure, convenient to install and use and good in thermal conductivity, heat dispersion, mechanical property and usability.

Owner:NINGBO DAHUA GRINDING WHEEL

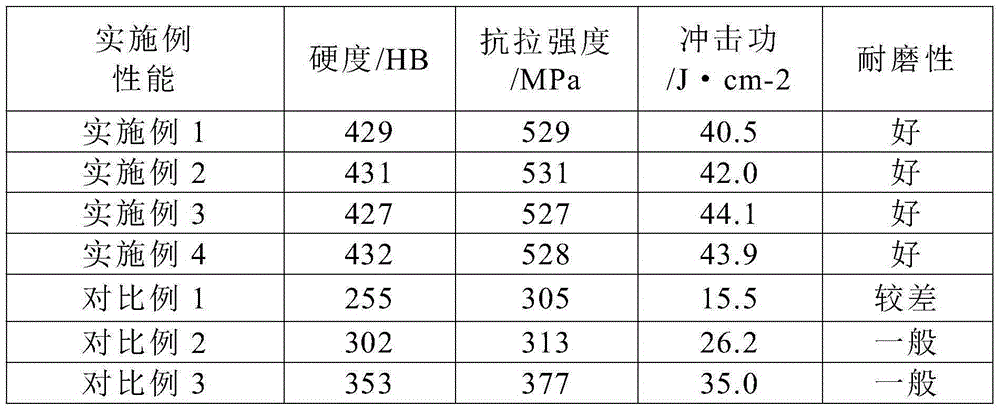

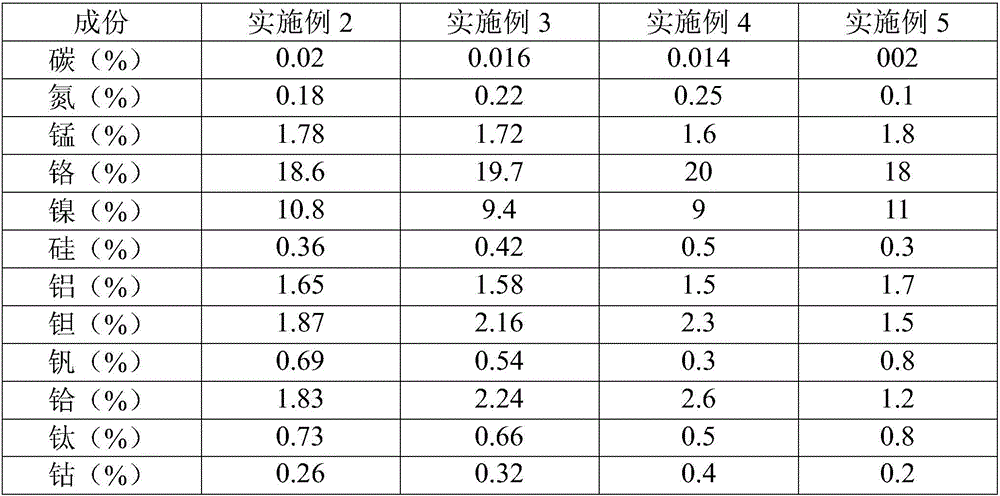

Corrosion-resistance seamless stainless steel pipe and preparation method thereof

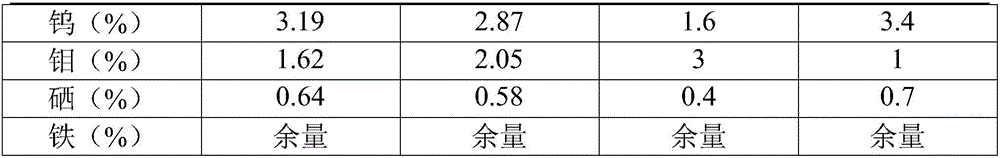

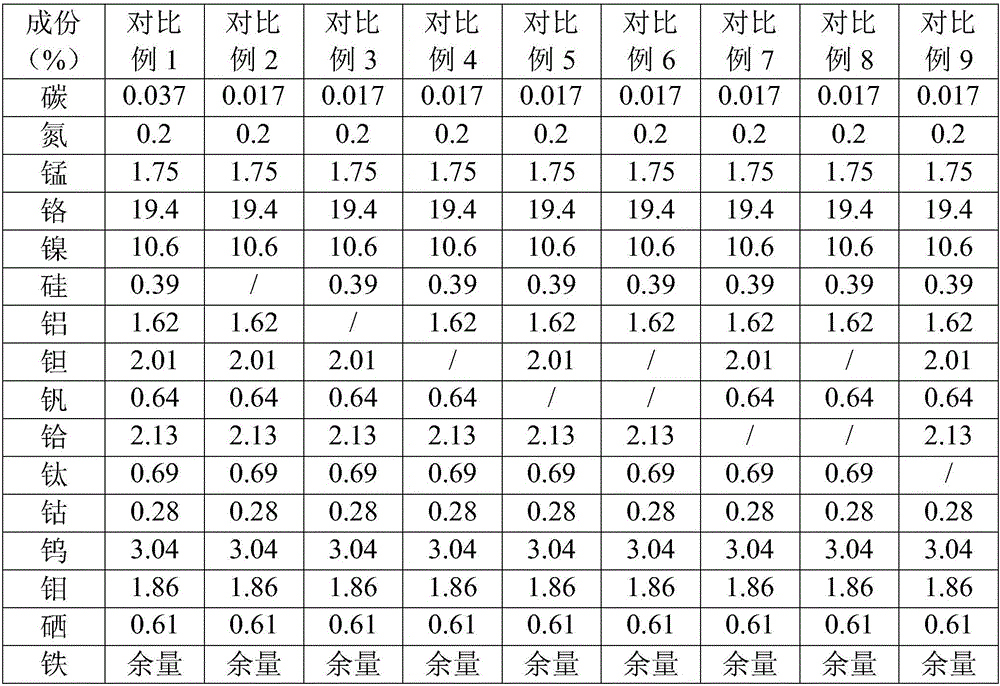

InactiveCN106282845AMake up for the lack of strengthImprove corrosion resistanceFurnace typesHeat treatment furnacesManganeseHafnium

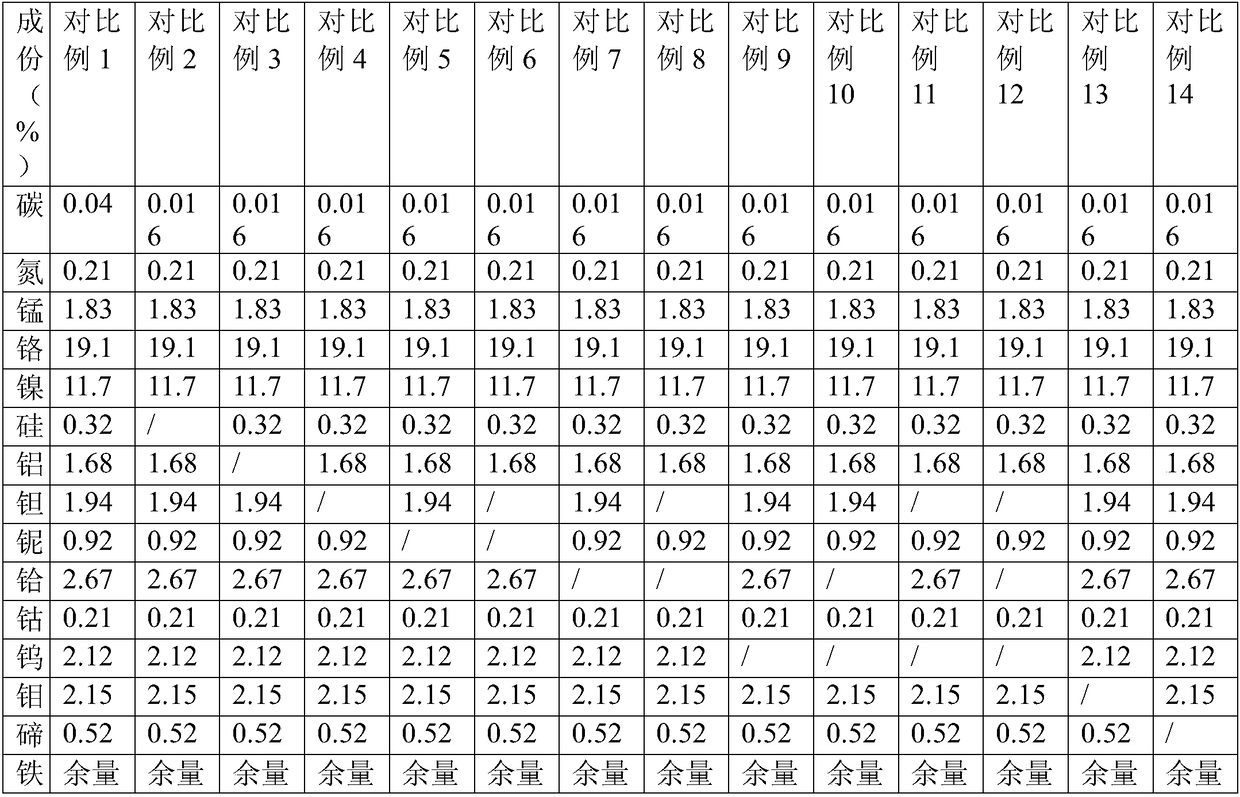

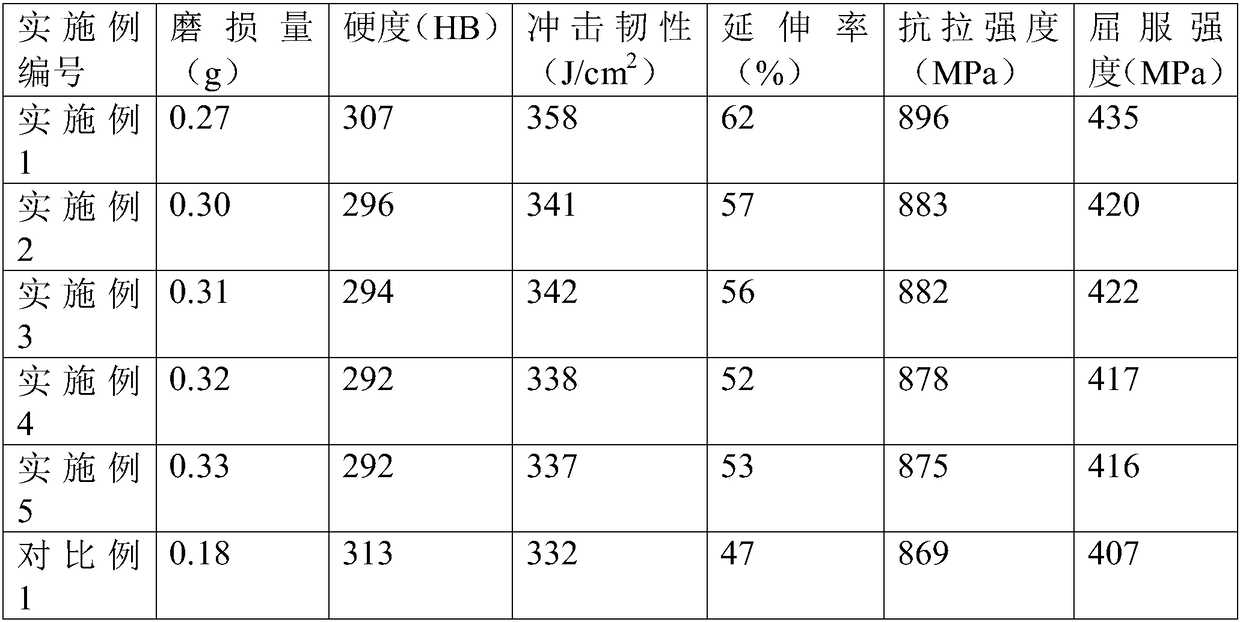

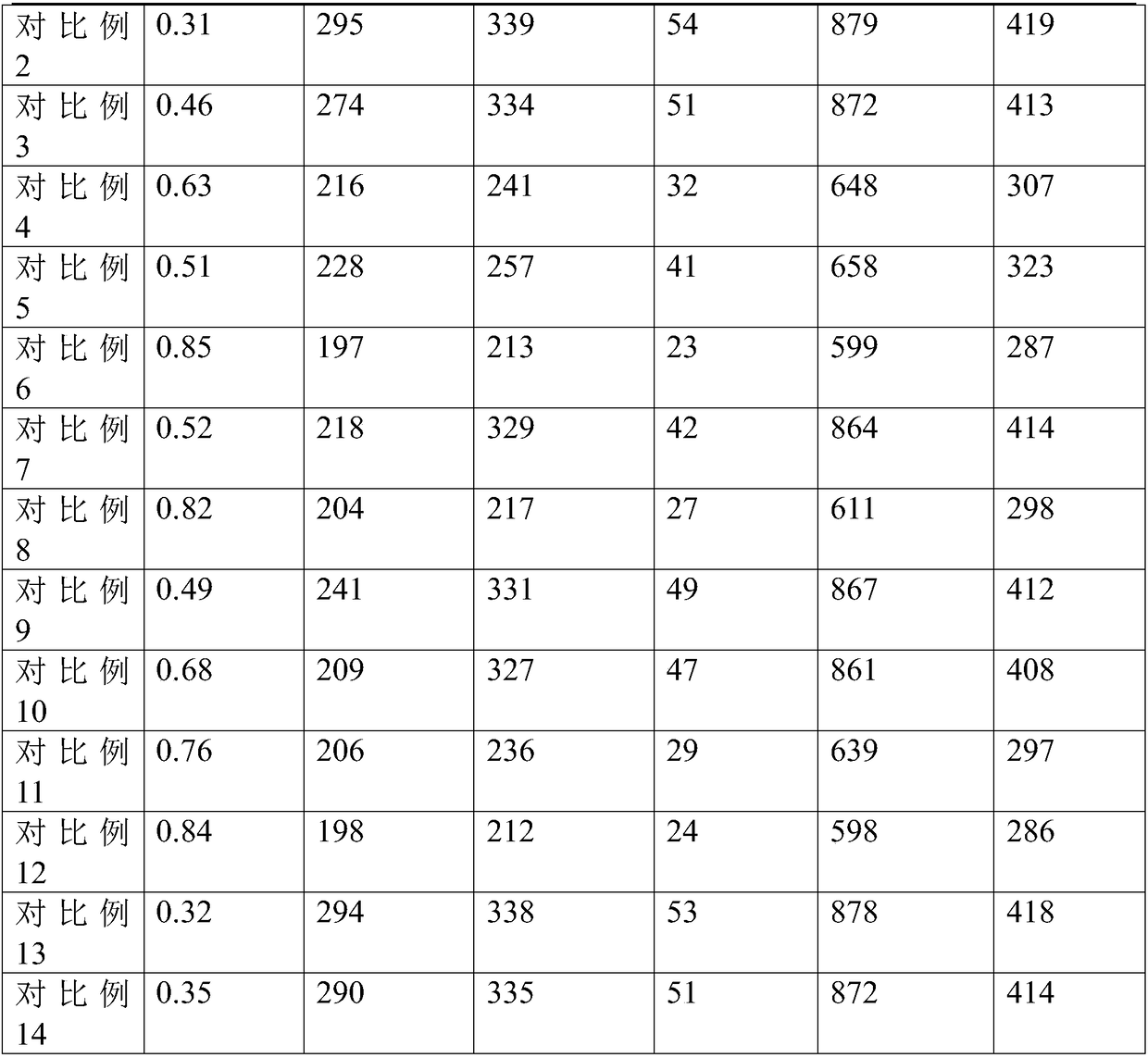

The invention discloses a corrosion-resistance seamless stainless steel pipe and a preparation method thereof. The corrosion-resistance seamless stainless steel pipe comprises the following chemical components in percentage by mass: carbon not more than 0.02%, 0.1-0.25% of nitrogen, 1.6-1.8% of manganese, 18-20% of chromium, 9-11% of nickel, 0.3-0.5% of silicon, 1.5-1.7% of aluminum, 1.5-2.3% of tantalum, 0.3-0.8% of vanadium, 1.2-2.6% of hafnium, 0.5-0.8% of titanium, 0.2-0.4% of cobalt, 1.6-3.4% of tungsten, 1-3% of molybdenum, 0.4-0.7% of selenium, and the balance of iron. Tantalum, hafnium and tungsten are added in austenitic stainless steel, and the chemical components can improve the performances of corrosion resistance, hardness, strength and high-temperature resistance of the austenitic stainless steel, so that the austenitic stainless steel is rich in high ductility and toughness.

Owner:ZHEJIANG HENGYUAN STEEL CO LTD

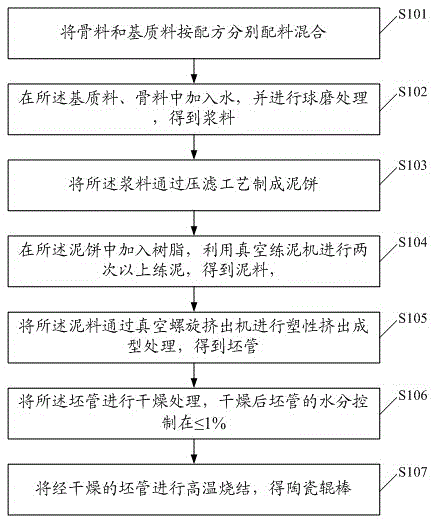

Low cost antibending ceramic roller rod and preparing method thereof

ActiveCN105481349ASolve the problem of easy bending deformationImprove brick walkingCeramic materials productionClaywaresBrickMullite

The invention discloses a low cost antibending ceramic roller rod, comprising aggregate, a matrix material and resin, wherein the aggregate has a main raw material formula of 30-60 parts of ceramic roller rod waste material in parts by weight, the matrix material has a main raw material formula of 15-40 parts of cordierite, 2-15 pars of aluminium oxide, 0.1-8 parts of yttrium oxide and 15-35 parts of clay in parts by weight; the resin selects water soluble resin in 0.1-2 parts by weight. Correspondingly, the invention further discloses a preparing method of the low cost antibending ceramic roller rod. By adopting the low cost antibending ceramic roller rod and the preparing method thereof, the ceramic roller rod waste material is reused, the problem that a corundum-mullite ceramic roller rod easily generates bending and deforming in a quenching belt or a large temperature difference region, and the condition of sliding of a tile in a roller kiln is improved.

Owner:JIN GANG NEW MATERIALS +1

Grade-C60 high-strength recycled concrete and preparation method thereof

The invention relates to field of building materials, in particular to a grade-C60 high-strength recycled concrete and a preparation method thereof.The grade-C60 high-strength recycled concrete is characterized by being prepared according to the specific gravity of cement to silica fume to recycled coarse aggregate to sand to water to a high-efficiency water reducing agent of (480-500) to (25-55) to (950-1100) to (640-680) to (175-190) to (7-8) (unit: Kg / m<3>).Compared with the prior art, the recycled coarse aggregate replacement rate of 100% is taken into consideration for the high-strength recycled concrete, the high-strength recycled concrete is further in line with a green, clean, low-carbon and environmental-protection construction concept, is high in strength grade and excellent in workability and can serve as casting reinforced concrete, steel reinforced concrete, steel tube concrete and a variety of other structural forms.

Owner:SHENYANG UNIV

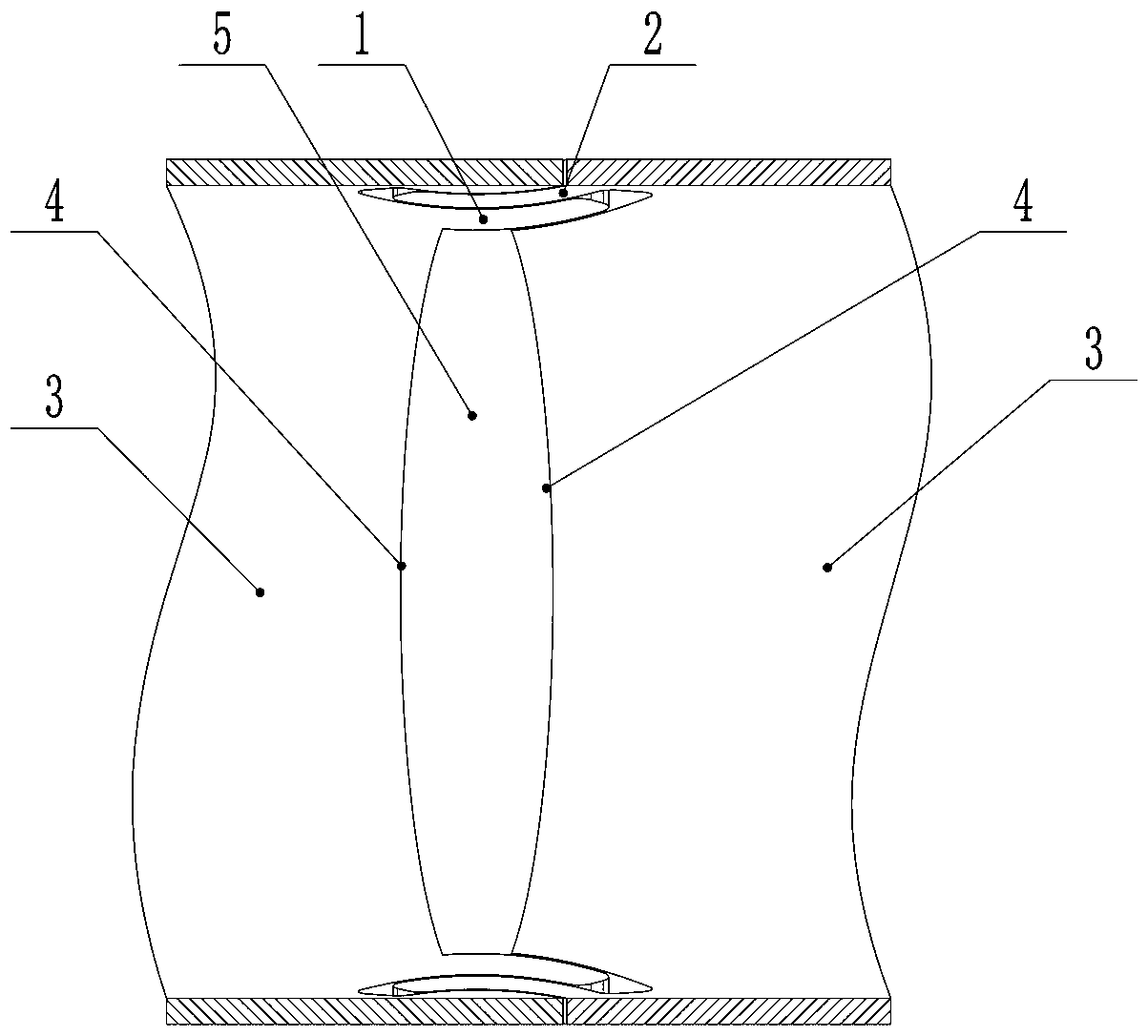

Lens and image pickup module comprising lens

The invention relates to a lens, which comprises a lens tube, a lens group and a light shielding assembly, wherein the lens group is arranged in the lens tube; the light shielding assembly and the lens group are arranged in the lens tube in a corresponding arrangement way; the lens group comprises at least one lens and at least one edge cutting lens alternately arranged with the lens; the edge cutting lens comprises an aspherical work part, a connecting part and at least one longitudinal cutting surface; the connecting part surrounds the aspherical work part and is connected with the aspherical work part; the lens tube comprises a lens installing region and an edge cutting lens installing region; the edge cutting lens installing part comprises at least one longitudinal cutting plate corresponding to the longitudinal cutting surface and an arc-shaped side wall connected with the longitudinal cutting plate; the connecting part comprises an arc-shaped lug boss corresponding to the arc-shaped side wall. The lens provided by the invention has the advantages that the structure is reasonable; the intensity is high; the service life is long; the dimension is small; the screen occupation ratio is high.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

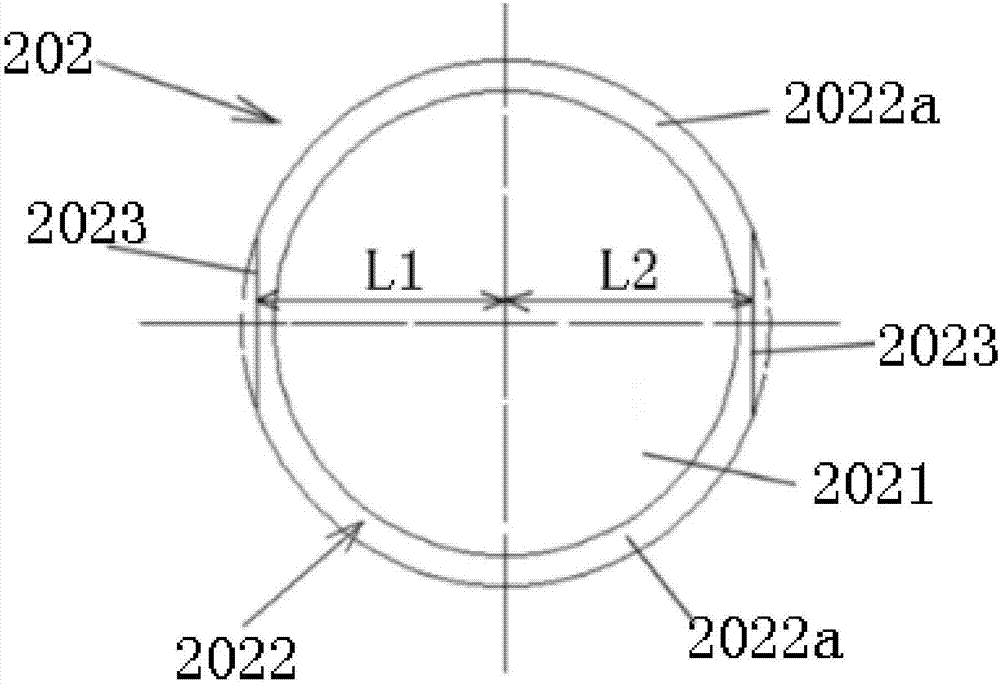

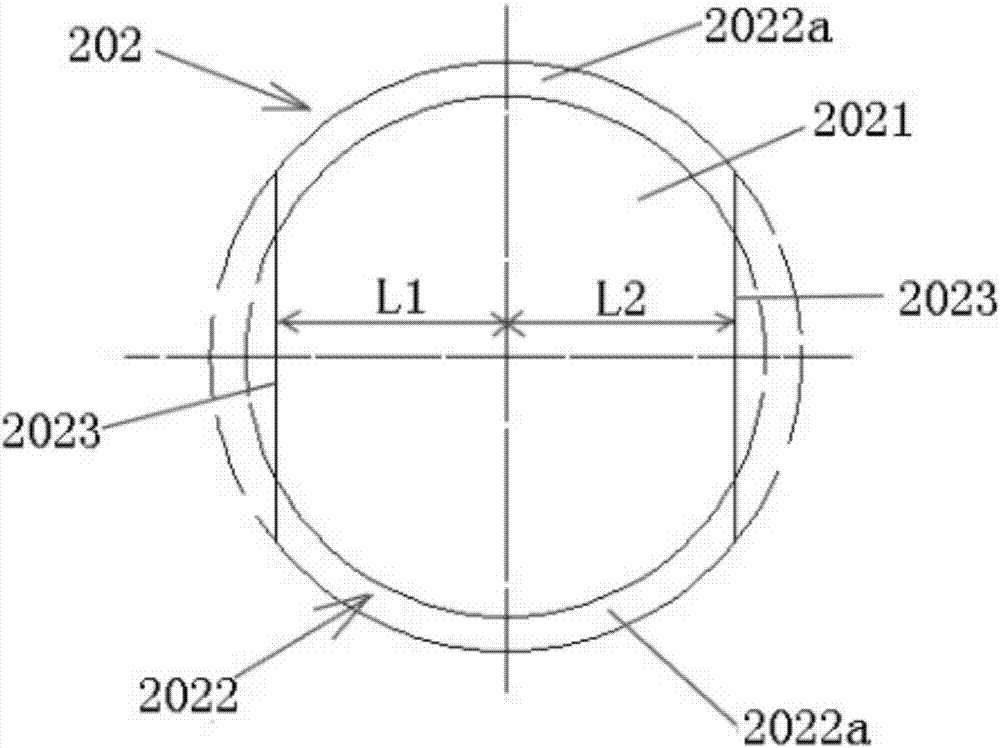

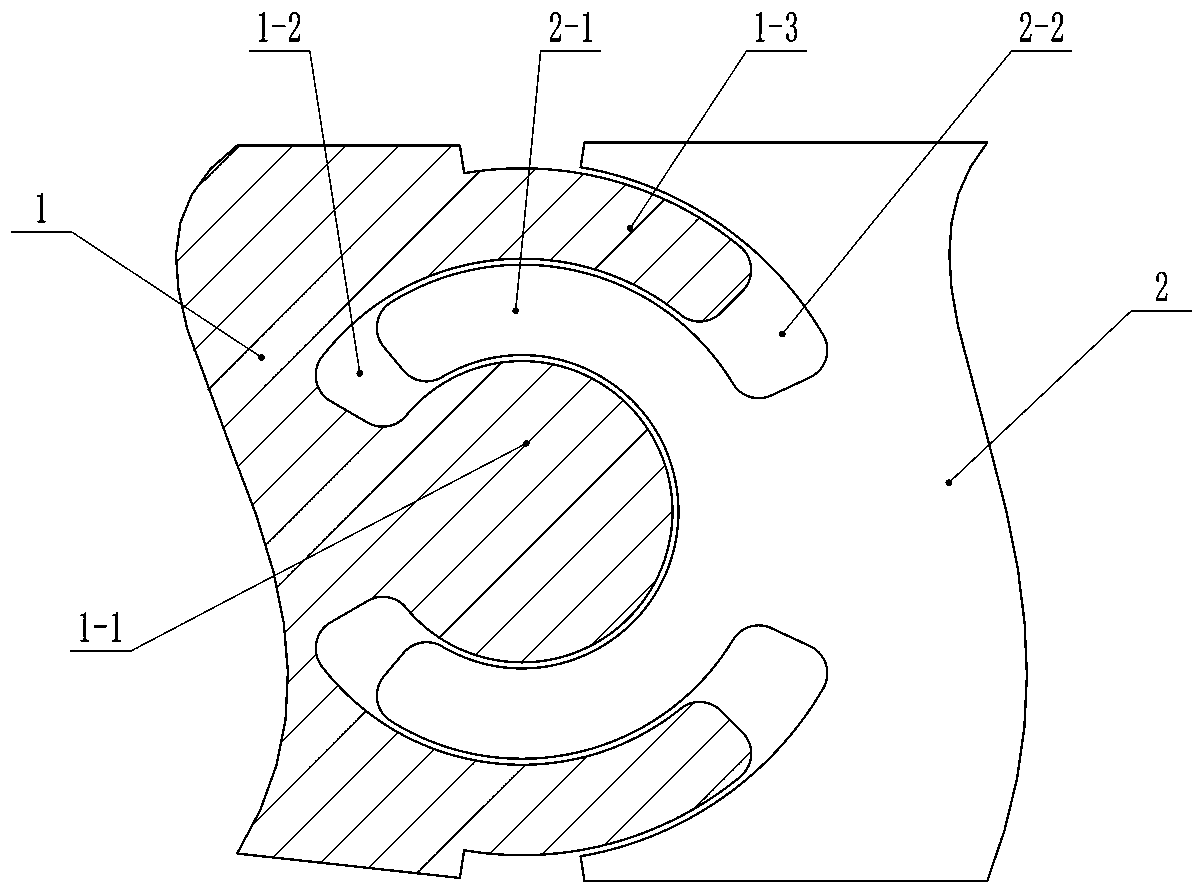

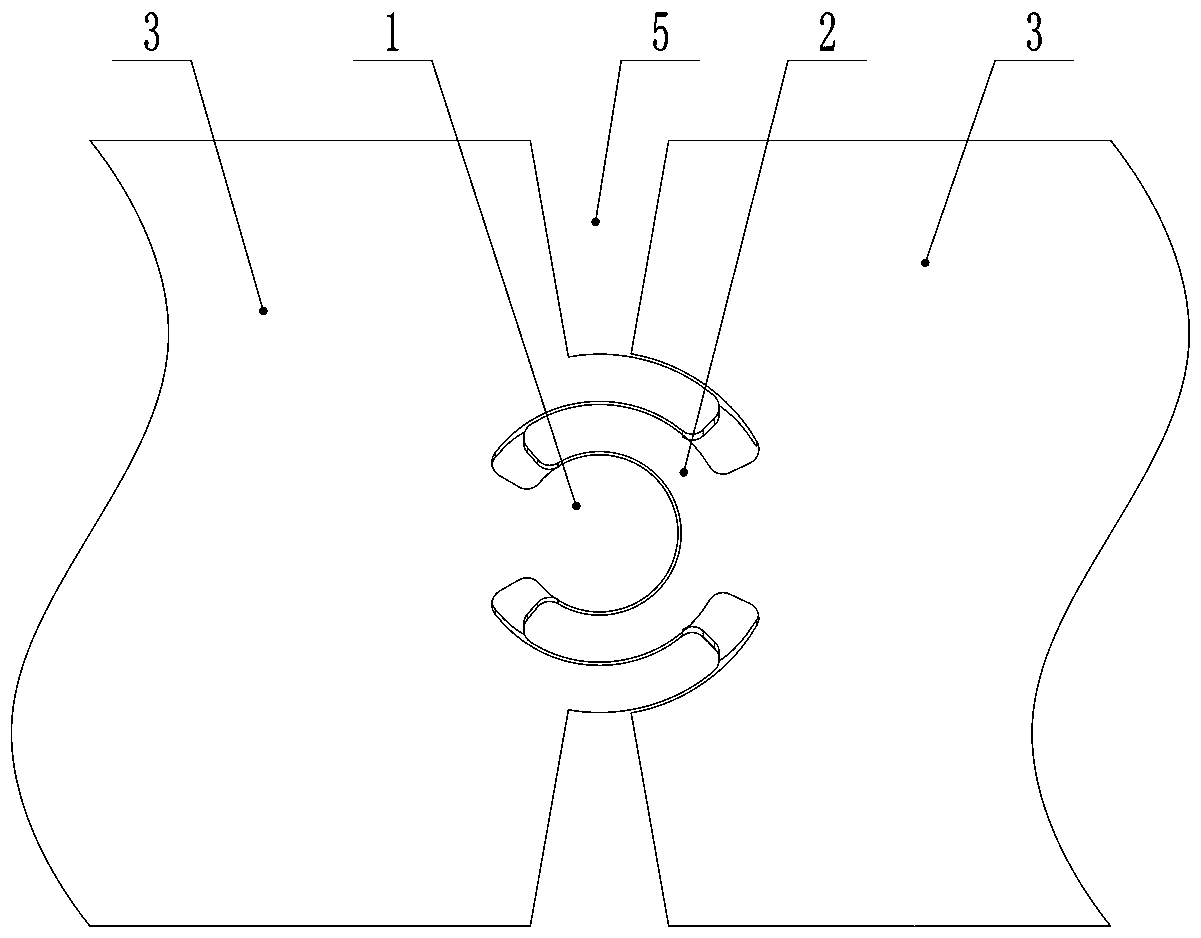

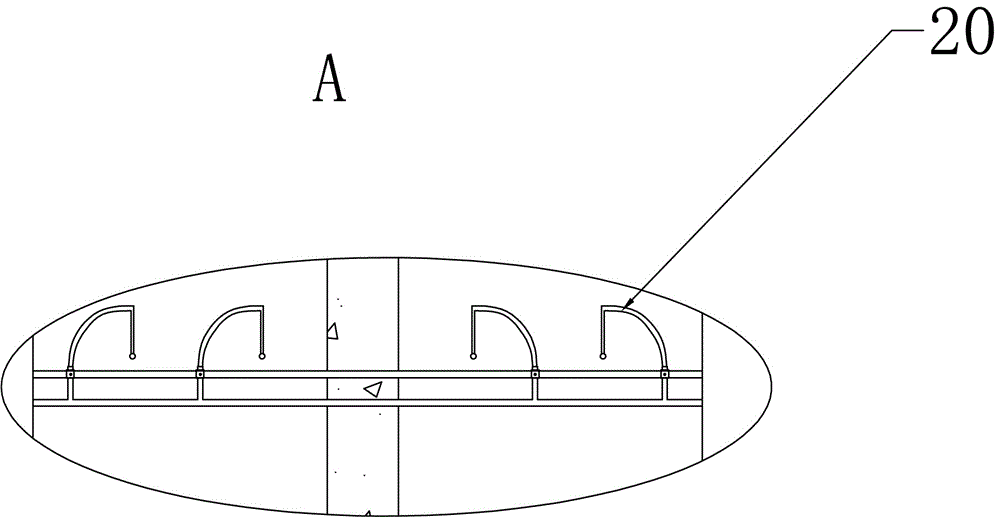

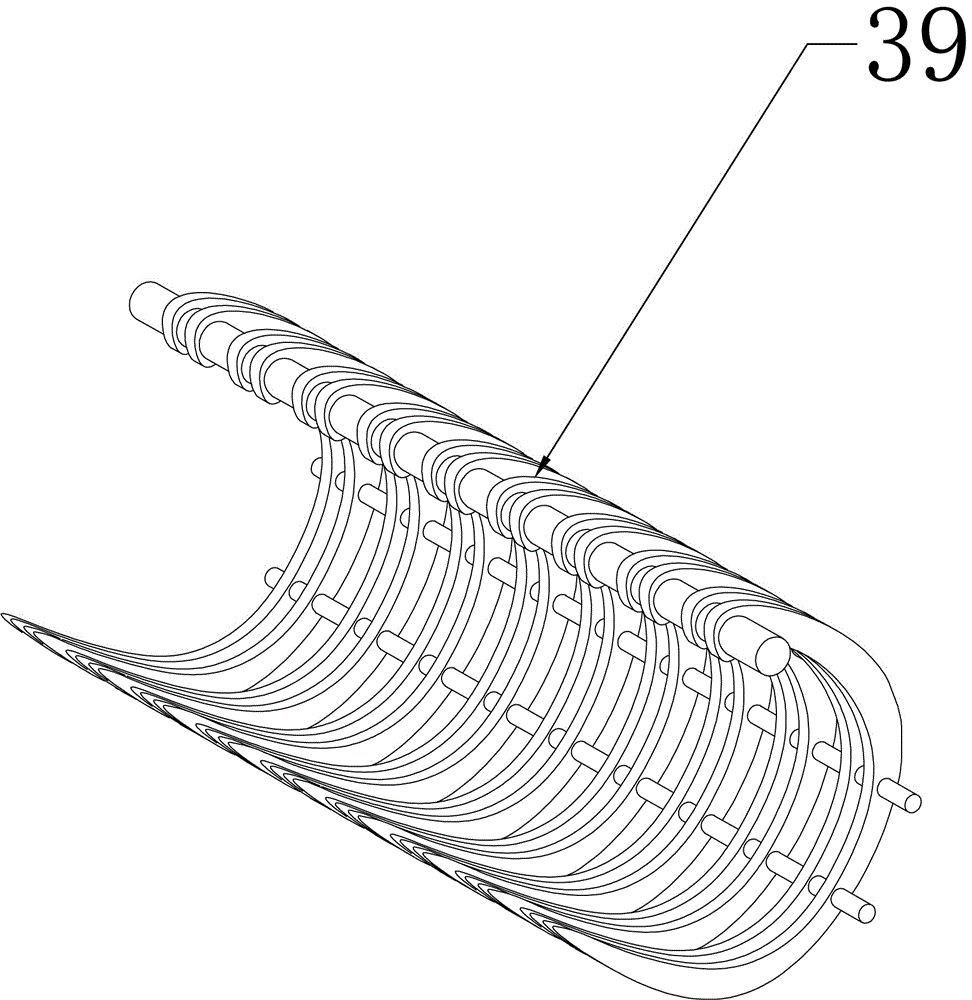

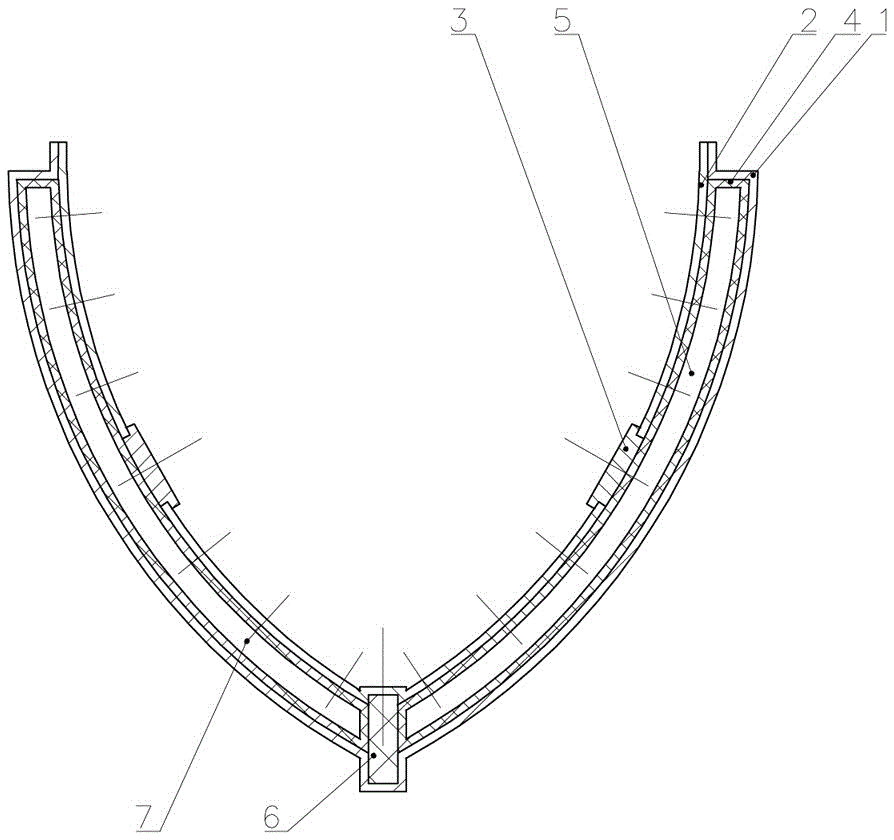

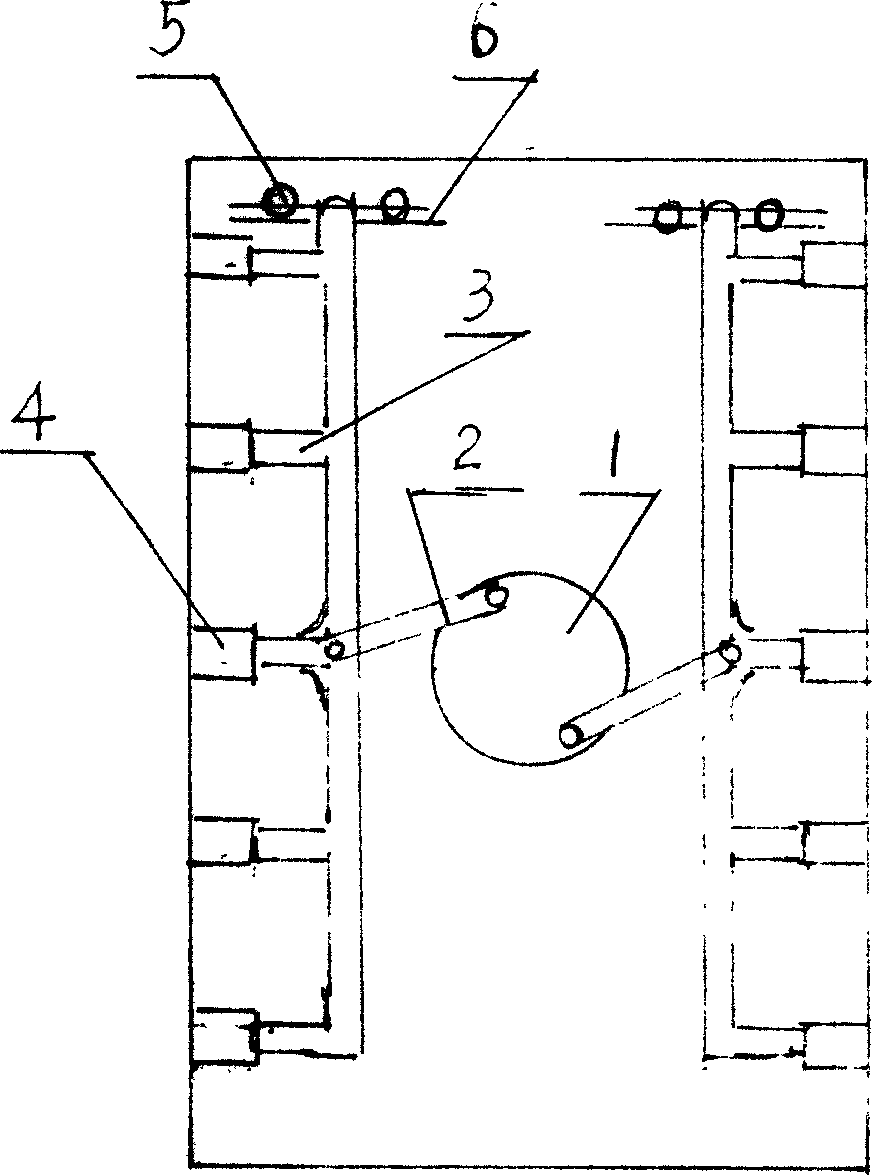

Double-surrounding rotating structure, double-surrounding tube rotating structure, integrated tube rotating structure, snake bone for medical endoscope and endoscope

The invention provides a double-surrounding rotating structure. The double-surrounding rotating structure comprises a primary rotating portion and a secondary rotating portion, wherein the primary rotating portion comprises a circular projection portion, an inner-surrounding annular groove and an outer-surrounding annular projection portion; the secondary rotating portion comprises an inner-surrounding annular projection portion and an outer-surrounding annular groove; the inner-surrounding annular projection portion is arranged in the inner-surrounding annular groove; the outer-surrounding annular projection portion is arranged in the outer-surrounding annular groove, so that the primary rotating portion and the secondary rotating portion can rotate relatively; and the surrounding rotating structure cannot be separated due to multiple limiting structures. According to a double-surrounding tube rotating structure based on this, a rotating travel crack is formed in a relative rotating side, and thus, tubes rotate relatively and are not separated in the axial direction. Furthermore, an integrated tube rotating structure based on the structure is designed, rotating contact surfaces ofthe primary and secondary rotating portions are or comprise radial limiting oblique surfaces, and thus, the two tubes cannot be separated from each other in the radial direction. Finally, a snake bone for a medical endoscope and an endoscope are further provided on the basis of the design, and have the advantages of high stability and low cost.

Owner:ZHENGZHOU RUNDE DELLONSCOPE CO LTD

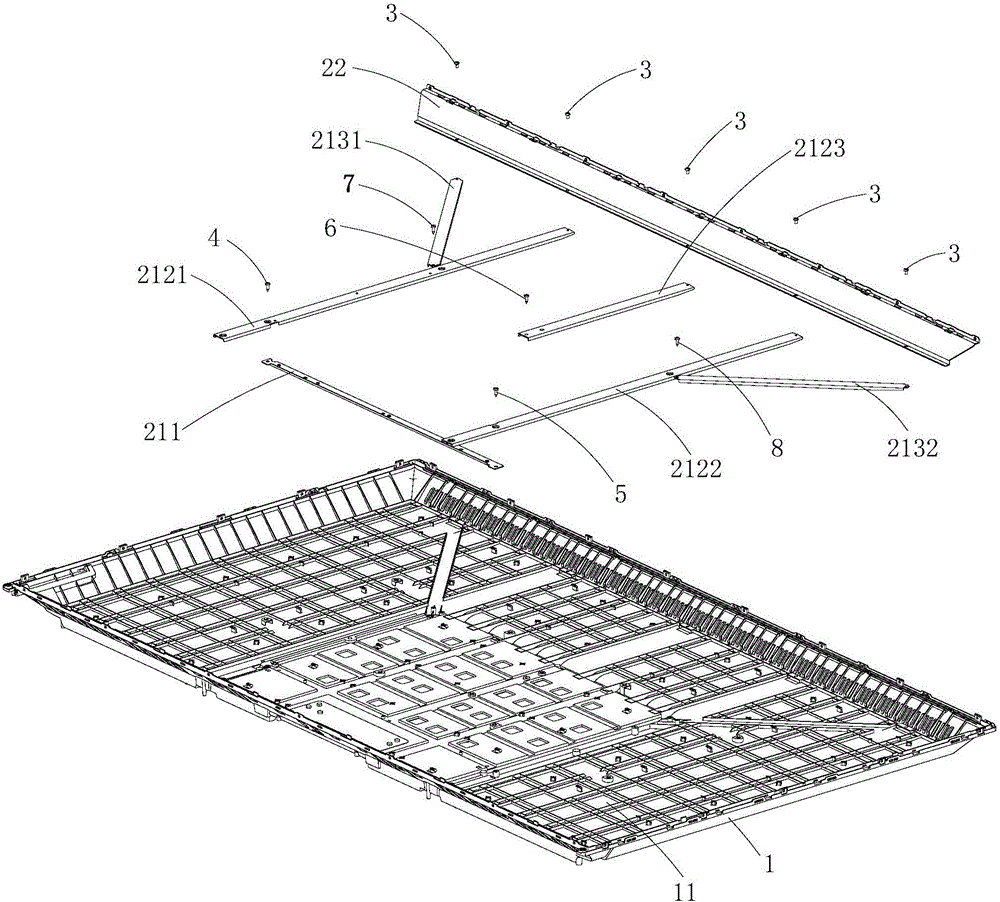

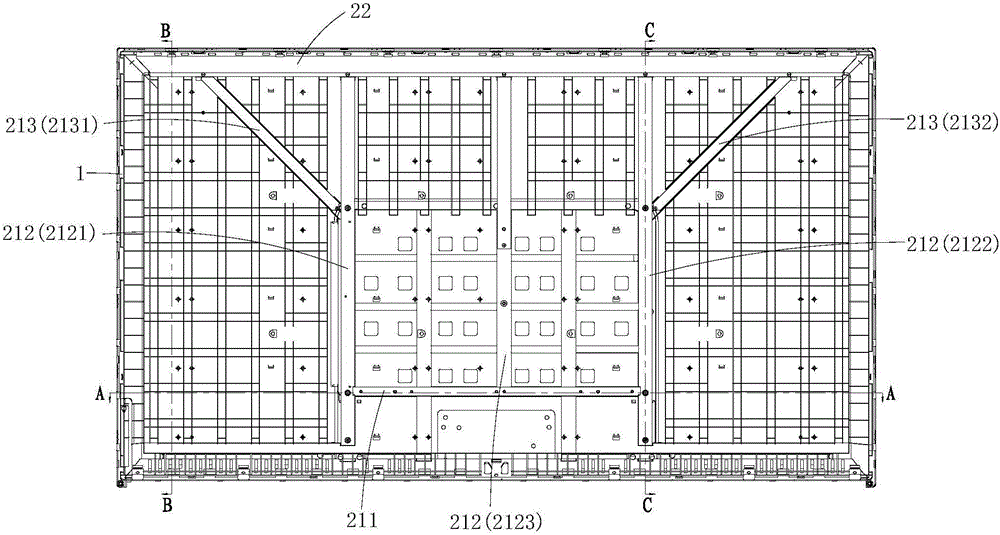

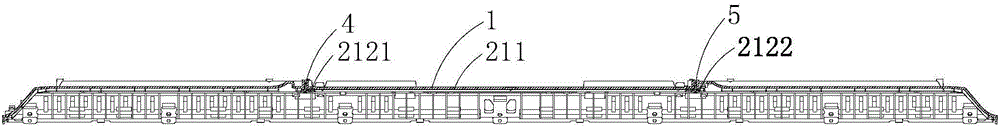

Backboard module of display device

ActiveCN106027927AMake up for the lack of strengthAvoid deformationTelevision system detailsColor television detailsDisplay deviceEngineering

The invention is applicable to the field of a display device, and discloses a backboard module of the display device. The backboard module comprises a plastic backboard body with a concave cavity and a reinforcement rib structure mounted in the concave cavity. The concave cavity is equipped with an open cavity opening, a back cavity wall arranged opposite to the cavity opening, and side cavity walls circularly arranged at the peripheral edges of the back cavity wall. The reinforcement rib structure comprises back reinforcement ribs mounted on the back cavity wall and edge reinforcement ribs mounted on the side cavity wall. According to the backboard module, through adoption of the reinforcement effect of the reinforcement rib structure, the defect that the strength of the plastic backboard body is insufficient is made up; even if the plastic backboard body is applied to a large-size display device, the insufficient strength and deformation problems will not occur. Moreover, the reinforcement rib structure is mounted in the concave cavity of the plastic backboard body, therefore, the arrangement of the reinforcement rib structure will not influence the nice appearance effect of the plastic backboard body, and the strength reliability and nice appearance effect of the large-size display device are taken into effective consideration.

Owner:HEFEI HUIKE JINYANG TECH

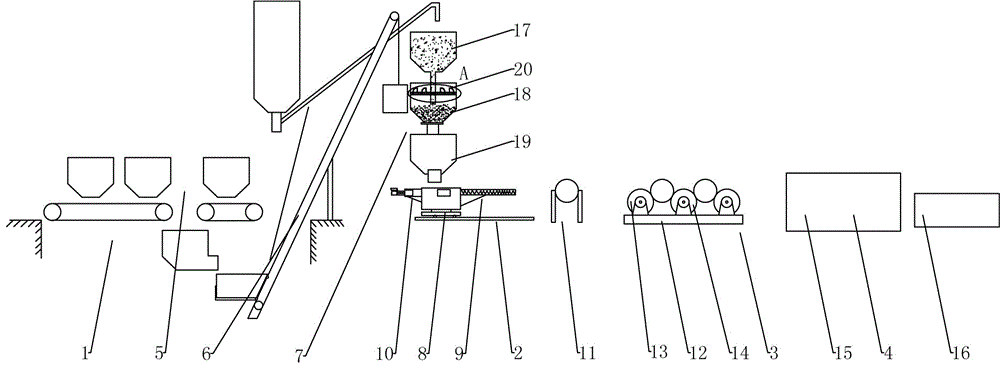

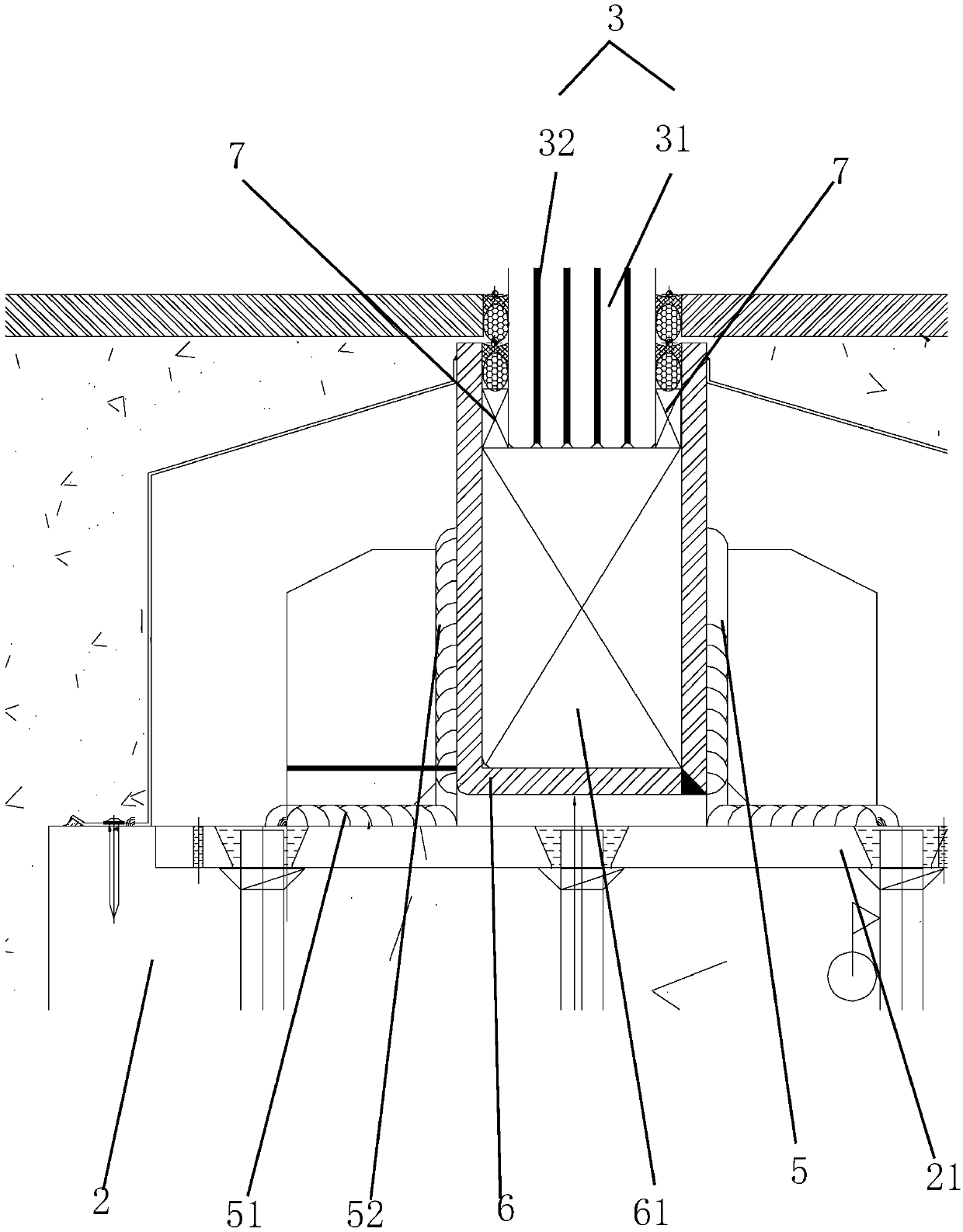

Production system and method for steel fiber reinforced concrete electric pole

InactiveCN105881728AReduce labor intensityCompact structureMouldsMixing operation control apparatusEngineeringFiber-reinforced concrete

The invention discloses a production system and method for a steel fiber reinforced concrete electric pole. The production system for the steel fiber reinforced concrete electric pole comprises a concrete mixing transportation device, a feeding device, a centrifugation device and a maintenance device, wherein the concrete mixing transportation device comprises a weighing transportation mechanism; the weighing transportation mechanism is connected with a multi-stage mixing stirring mechanism; the feeding mechanism comprises a walking rotating mechanism; a primary centrifugal feeding mechanism and a secondary centrifugal feeding mechanism are respectively arranged on the two sides on the walking rotating mechanism; the centrifugation device comprises a base; at least one group of fixed supporting wheels and a group of movable supporting wheels are arranged on the base; the maintenance device comprises a steam maintenance pool; a vertical mounting frame is arranged inside the steam maintenance pool; and a hydration pool is arranged on one side of the steam maintenance pool. According to the production system and the method for the steel fiber reinforced concrete electric pole provided by the invention, through arranging the concrete mixing transportation device, the feeding device, the centrifugation device and the maintenance device, the automatic operation is achieved, the defects in the production process of the steel fiber reinforced concrete electric pole are overcome, and the integral strength of the electric pole is improved.

Owner:湖北红业建材科技开发有限公司

Dumplings containing ampelopsis grossedentata and tartary buckwheat, and preparation method of dumplings

InactiveCN104381754AEnhance nutrition and health careImprove toughnessFood coatingFood preparationPolygonum fagopyrumSaccharum

The invention discloses dumplings containing ampelopsis grossedentata and tartary buckwheat, and a preparation method of the dumplings. Dumpling wrappers are prepared from the following raw materials in parts by weight: 80-100 parts of wheat flour, 10-30 parts of tartary buckwheat powder, 2-3.5 parts of ampelopsis grossedentata powder, 3-8 parts of vital gluten, 0.5-1 part of calcium lactate gluconate, 1-2 parts of sorbitol, 1-2 parts of sucrose ester and 25-40 parts of water; the filling for the dumplings comprises the following components in parts by weight: 80-115 parts of meat, 30-300 parts of vegetables or edible fungi, 3-5 parts of ampelopsis grossedentata powder and 15-45 parts of auxiliary materials. The preparation method comprises the steps of preparing the dumpling wrappers, namely, mixing the wheat flour, the tartary buckwheat powder, the ampelopsis grossedentata powder, the vital gluten, the calcium lactate gluconate, the sorbitol and the sucrose ester, feeding water into the mixture, kneading dough, and rolling into the wrappers; preparing the filling for the dumplings, namely, cleaning the vegetables or edible fungi, and treating for 5-30 minutes by steam with the temperature of 40-55 DEG C; mincing the meat into meat paste, feeding the vegetables or edible fungi, the ampelopsis grossedentata powder and the auxiliary materials, and evenly mixing to obtain the filling for the dumplings; wrapping the filling for the dumplings by the dumpling wrappers. The dumplings containing the ampelopsis grossedentata and the tartary buckwheat are unique in mouth feel, rich in nutrition, bright in color and boiling-resistant, are smooth in surfaces after being boiled in water, and have health care effects.

Owner:ANHUI SCI & TECH UNIV

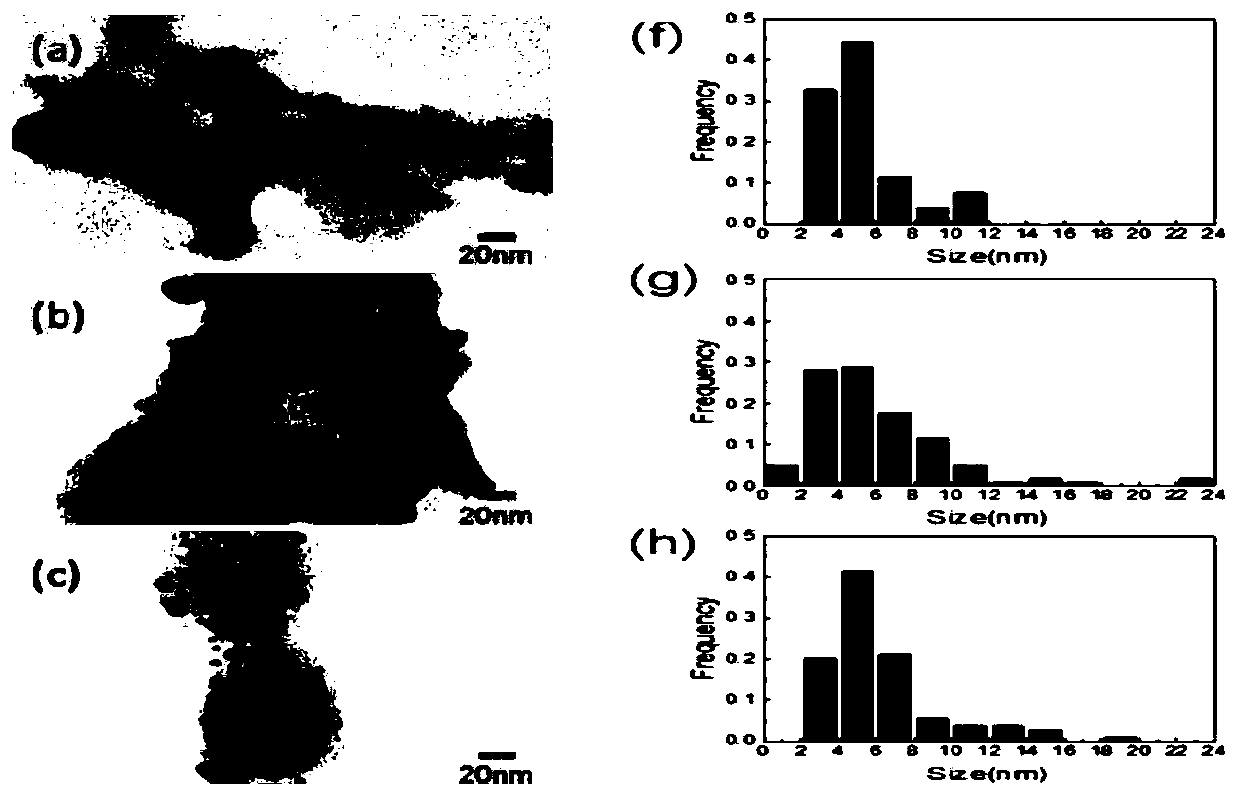

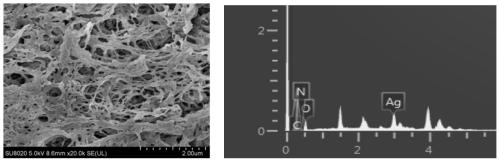

Silver-carried chitosan high-strength antibacterial material and preparation method thereof

The invention discloses a silver-carried chitosan high-strength antibacterial material and a preparation method thereof. The silver-carried chitosan high-strength antibacterial material is prepared through the steps that chitosan is dissolved at a low temperature, low-temperature regeneration is conducted, chitosan hydrogel composed of a nanofiber network is obtained and services as base material,and nanosilver elements are uniformly loaded on the fiber network of the base material; the silver elements are obtained through reduction of an amino group on large specific surface area chitosan nanofiber, and plays a role of cross-linking antibiosis and antibiosis to enhance the mechanics. The regenerated chitosan nanofiber network hydrogel has the very large specific surface area and the fully exposed amino group, the silver element are prepared by means of amino reduction, a chemical reducing agent is not needed, and pollution is reduced. Nano silver particles on a silver-carried chitosan high-strength antibacterial film prepared through the method are small in size and uniform in dispersion, and by means of the cross-linking action of silver and the amino group, the film strength isimproved, so that the film is high in mechanical strength and resistant to stretching and tear. The material has broad application prospects in the industries of antibacterial wound dressings, food packaging and the like.

Owner:HEFEI UNIV OF TECH

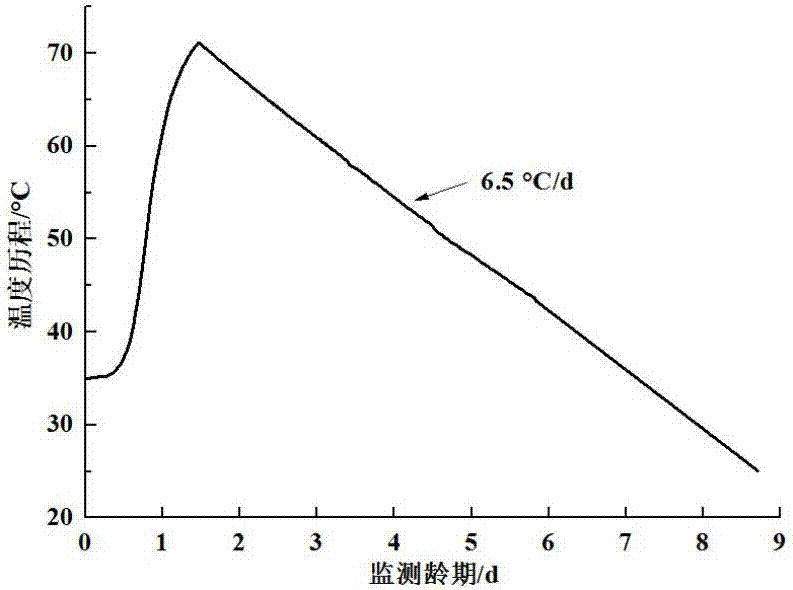

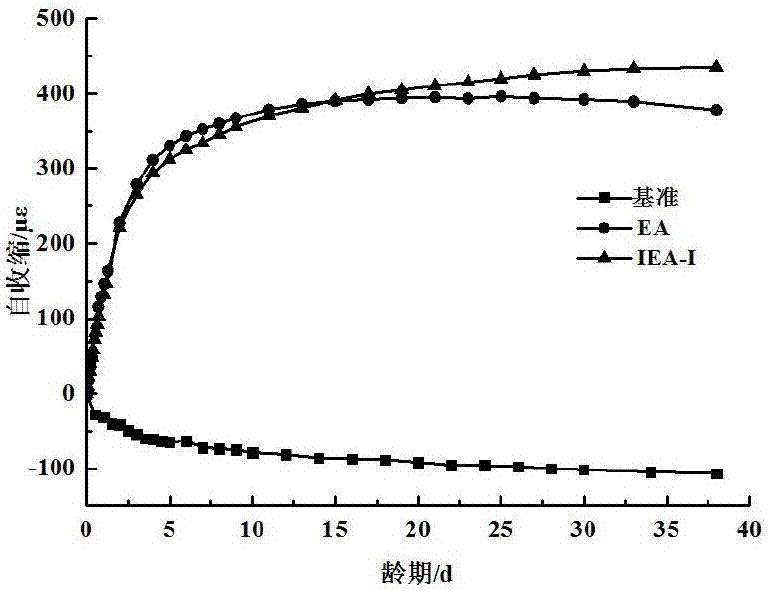

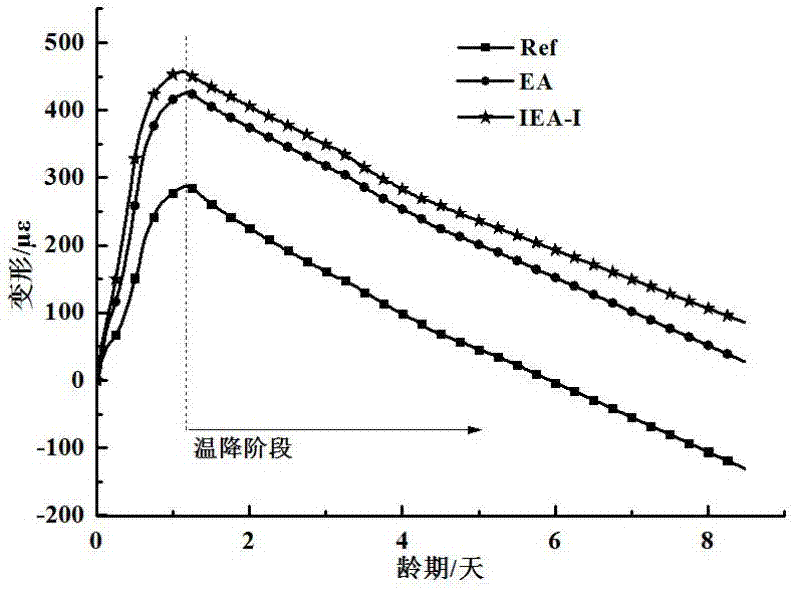

Internal-curing type expanding agent for concrete and preparation method thereof

The invention discloses an internal-curing type expanding agent for concrete and a preparation method thereof. The internal-curing type expanding agent for concrete is composed of expanding clinker and a porous micro-medium, wherein the expanding agent compensates for shrinking; and the porous micro-medium achieves the effect of reducing shrinkage in internal curing and optimizing the hydration process of the expanding agent by regulating and controlling humidity, and also functions as a dispersion carrier of the expanding clinker. The prepared internal-curing type expanding agent takes full advantage of the synergistic effect between the expanding clinker and the porous micro-medium and can effectively reduce the self-shrinkage and drying shrinkage of the concrete, decrease thermal shrinkage in a temperature dropping stage after temperature rise of the concrete, improve the hydration degree of the concrete and overcome the disadvantage of reduced strength of an internally doped expanding agent.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

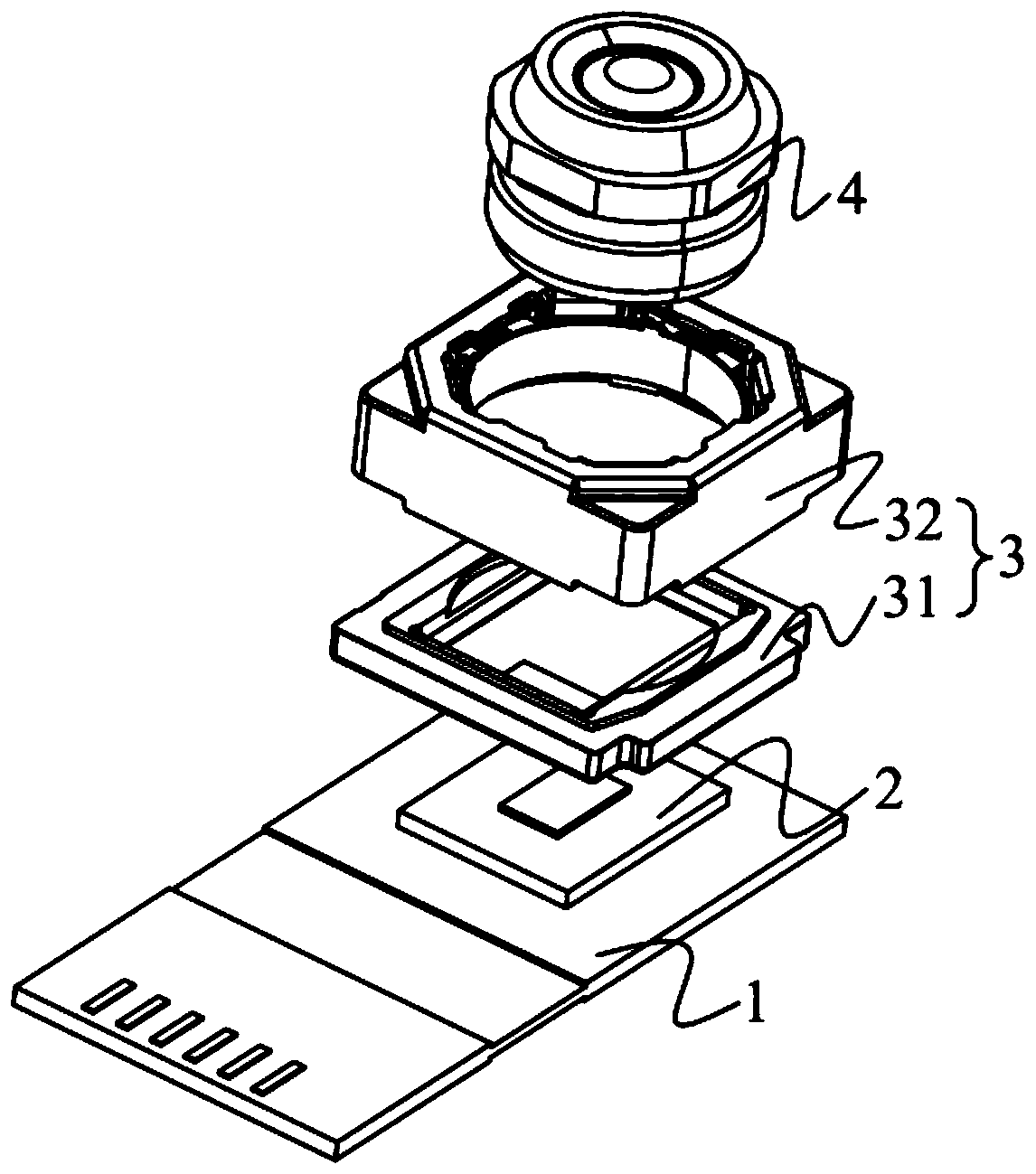

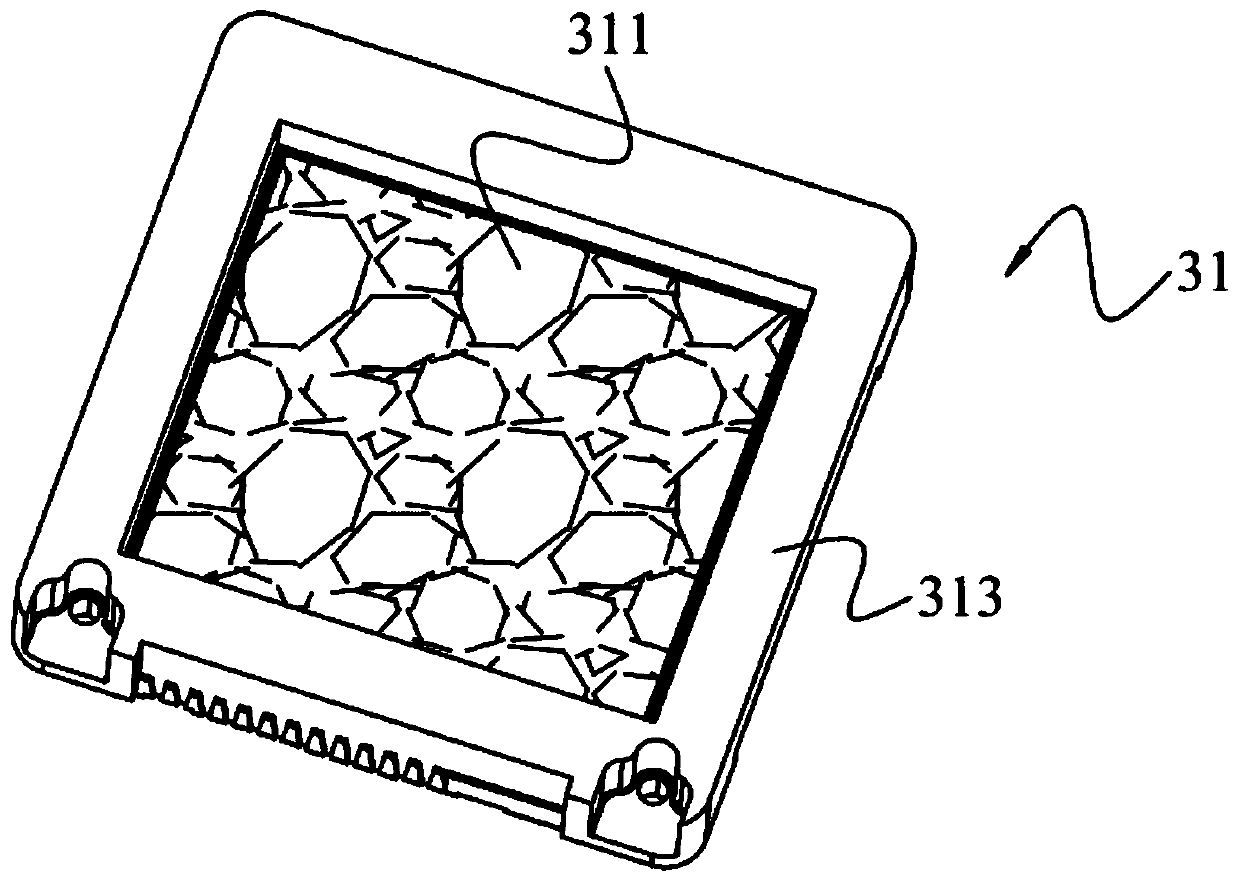

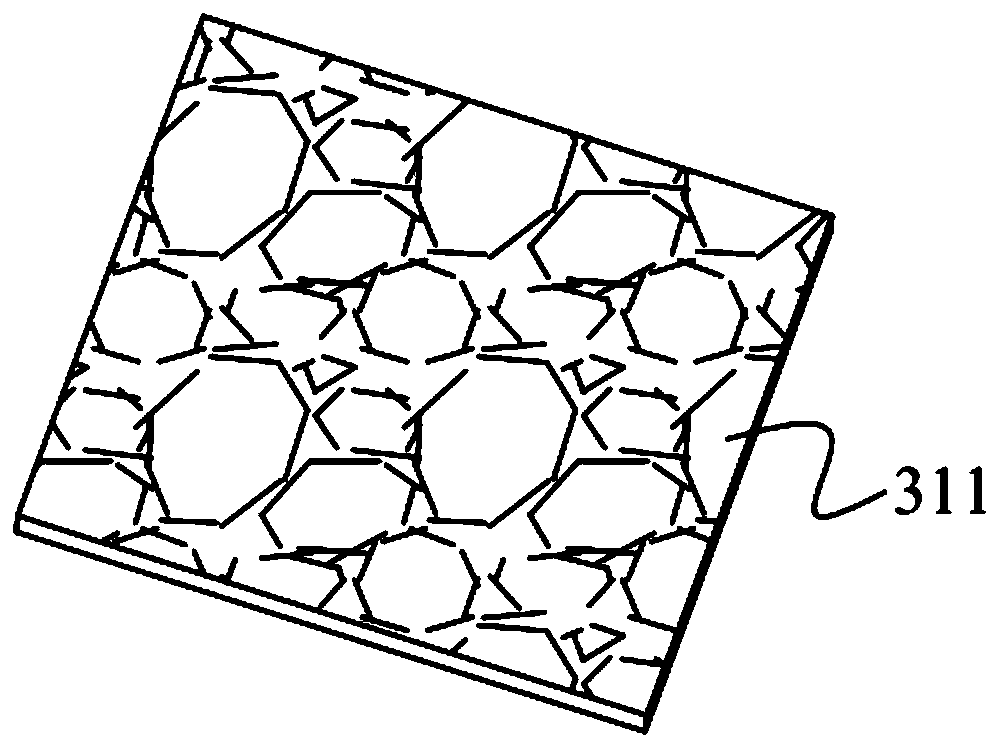

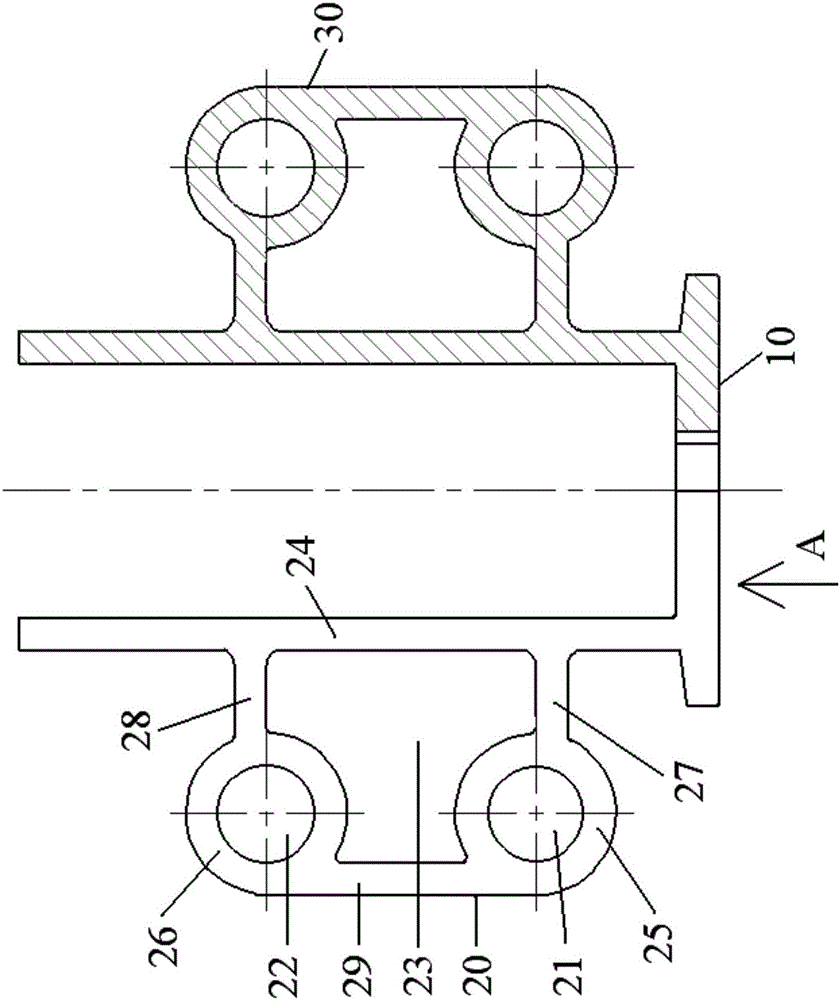

Voice coil motor base, voice coil motor and camera module

InactiveCN109819151AReduce the overall heightReduce manufacturing costTelevision system detailsColor television detailsEngineeringCamera module

The invention discloses a voice coil motor base, a voice coil motor and a camera module, and relates to the technical field of electronic equipment. The voice coil motor base comprises a metal plate,an optical filter and a plastic base, wherein a through hole is formed in the metal plate; The optical filter is fixed on the metal plate and shields the through hole, and the metal plate and the optical filter form an assembly; And the plastic seat is formed by injection molding of the edge position of the assembly. According to the voice coil motor base, the optical filter is embedded in the plastic base in an injection molding mode, the optical filter does not need to be positioned when the camera module is assembled, the positioning and assembling cost of the optical filter can be saved, and the influence on the quality of the camera module due to poor positioning of the optical filter is avoided; A supporting seat can be omitted, so that the height and the manufacturing cost of the camera module can be reduced; The metal plate increases the strength of the voice coil motor base, and the thickness of the plastic base can be properly reduced, thereby reducing the height of the camera module, and making up the problem of insufficient strength caused by the reduction of the plastic base.

Owner:SUZHOU GYZ ELECTRONICS TECH CO LTD

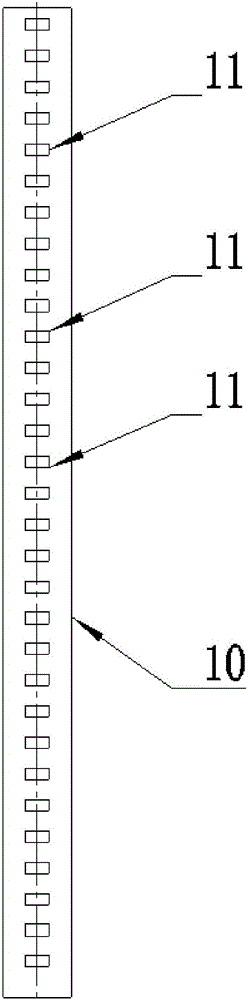

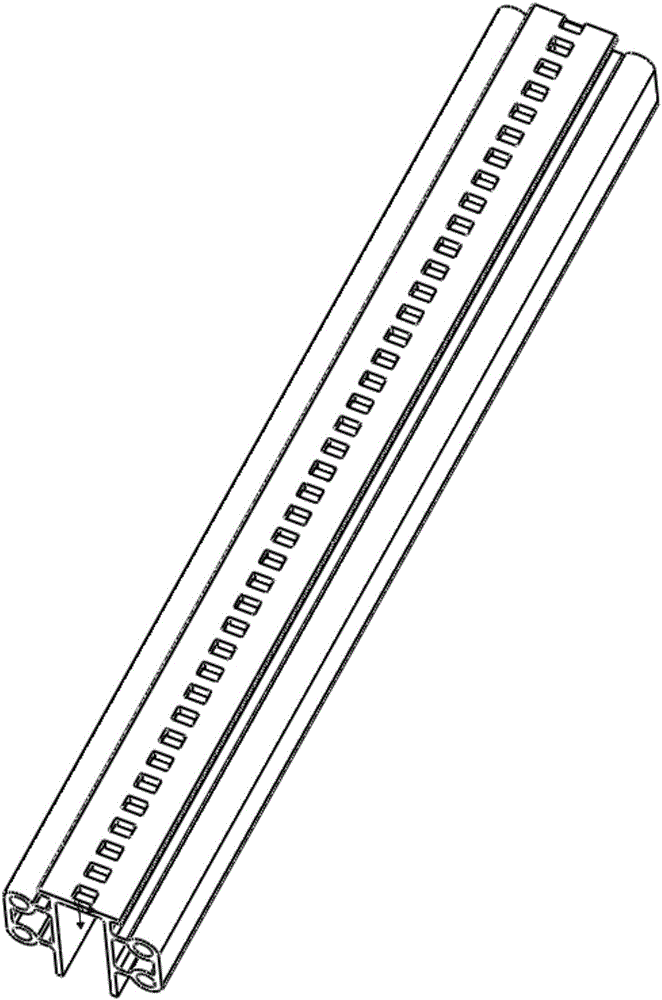

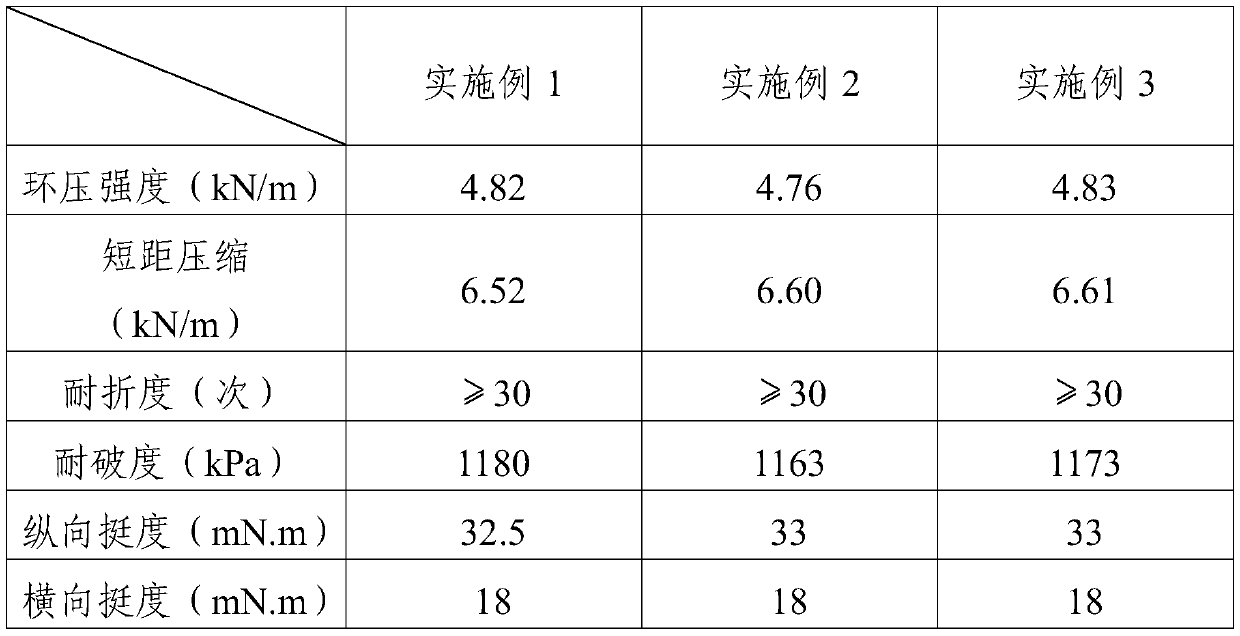

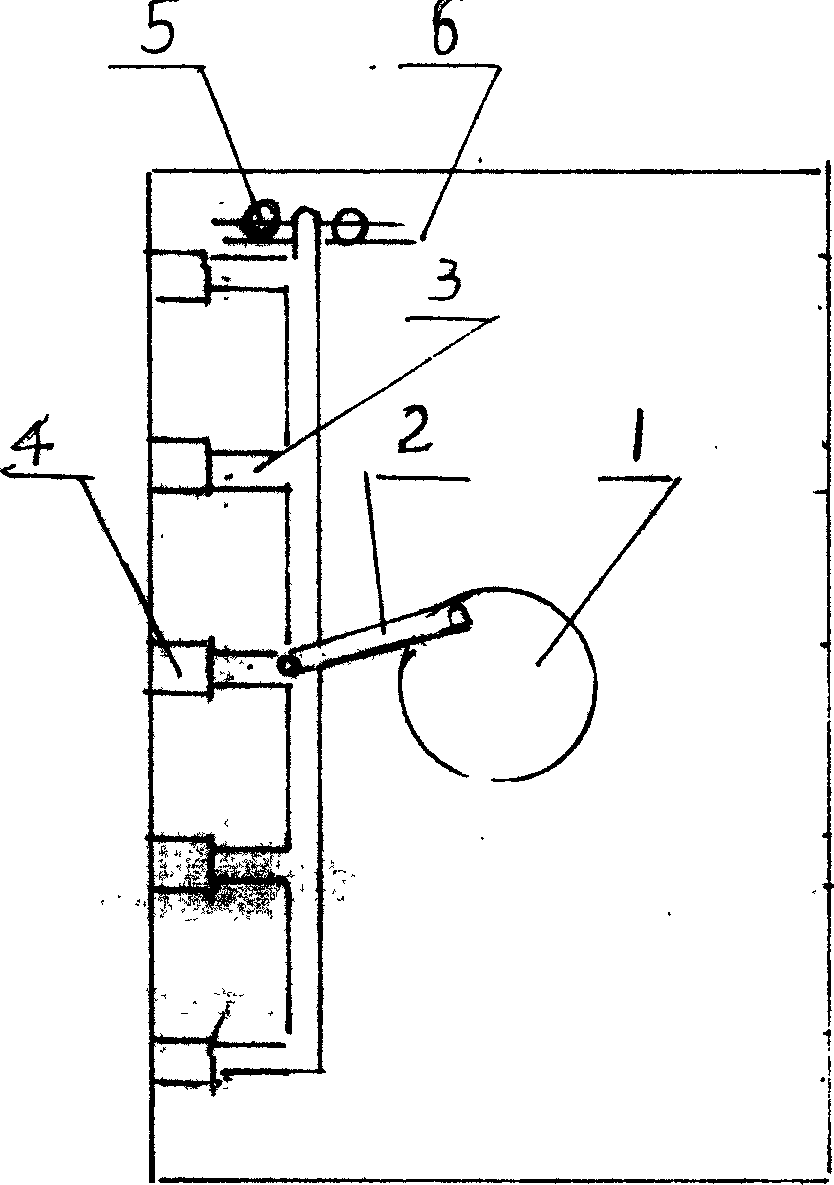

Guide rail unit used on transmission tower and guide rail

ActiveCN105819304ASmall wind blocking coefficientImprove lack of strengthElevatorsTransmission towerEngineering

The invention provides a guide rail unit used on a transmission tower and a guide rail. The guide rail unit is of a profile structure, and the guide rail unit used on the transmission tower comprises a rack (10), a left guide rod (20) and a right guide rod (30); the left guide rod (20) and the right guide rod (30) are mutual mirror images, a first inserting hole (21) and a second left side inserting hole (22) are formed in the left guide rod (20), and a first sealed cavity (23) is further contained in the left guide rod (20); and according to the guide rail unit used on the transmission tower and the guide rail, the guide rods and the rack are designed to be of an integrated profile structure, the problem that strength of the connecting position of an existing guide rail unit steel framework is insufficient is well solved, assembly errors are reduced, a whole frame body has no obvious weak points, the whole strength is higher, machining precision of the fixed-length guide rail unit is easily controlled, and scale production is facilitated.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV

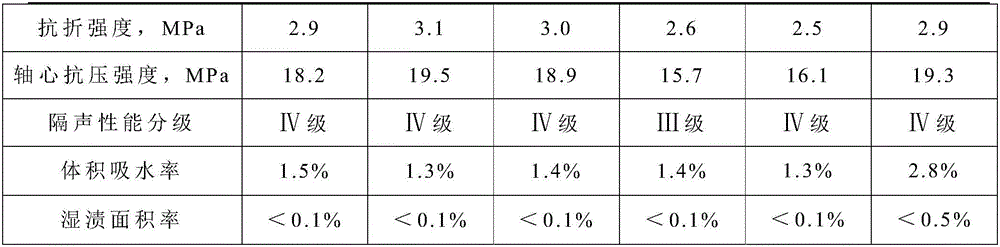

Environmental-friendly soundproof waterproof concrete wall brick and preparation method thereof

The invention relates to an environmental-friendly soundproof waterproof concrete wall brick and a preparation method thereof, and belongs to the technical field of a building material. The method comprises: firstly, carrying out processing of crushing, sorting and the like on building waste to obtain recycled coarse and fine aggregate; then carrying out batching on cement, the recycled coarse aggregate, haycite, the recycled fine aggregate, bamboo fibers, silica sol, a water reducing agent and water, and uniformly stirring; after sufficiently foaming a foaming agent by a foaming machine, mixing foam and slurry to prepare foam concrete; then carrying out pumping, injection molding and maintenance and demoulding to take the brick; finally, coating the surface with a modified polyurethane waterproof paint. The method is simple to operate; used raw materials are nonhazardous; the problem of the building waste can be effectively solved; the obtained concrete wall brick has the advantages of high intensity, good soundproof effect, excellent waterproof performance and the like.

Owner:龚家红

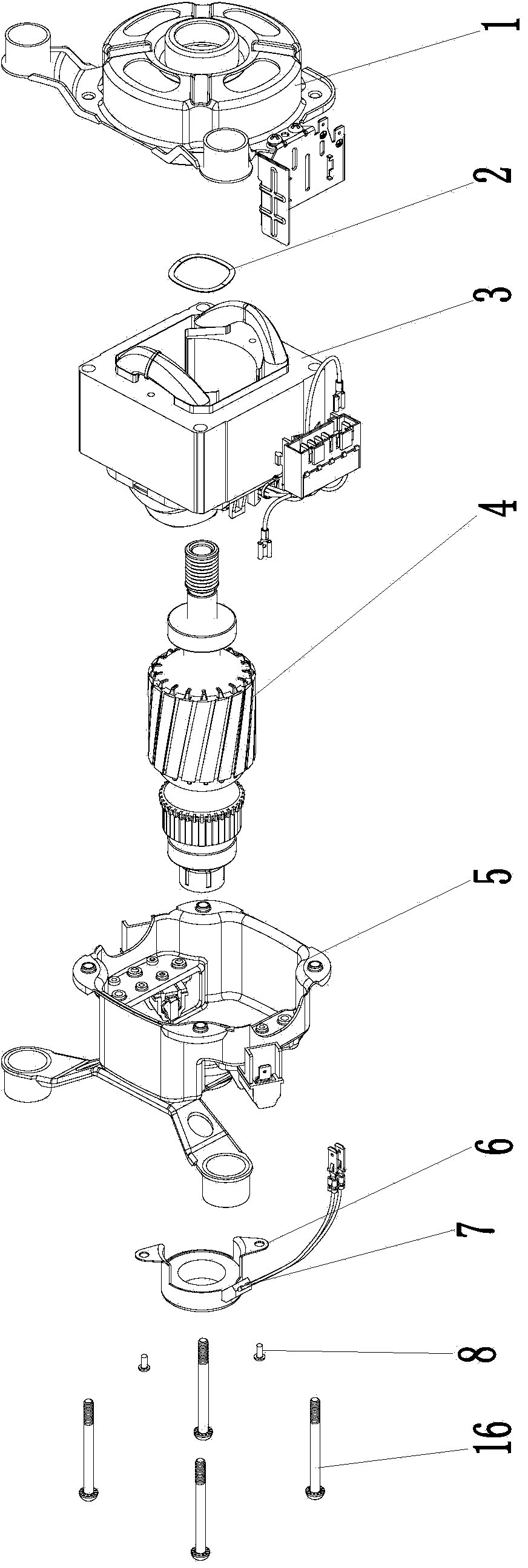

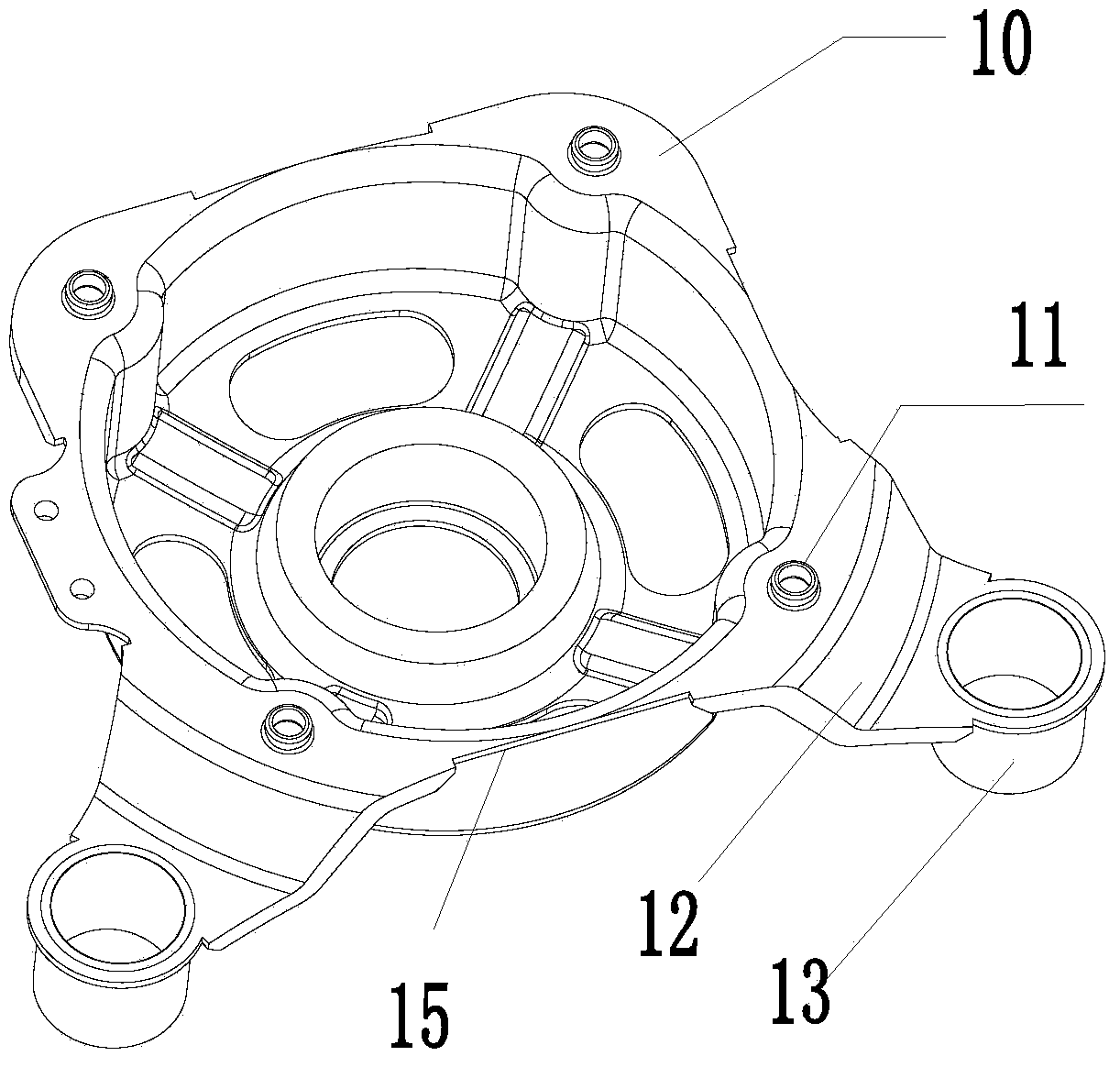

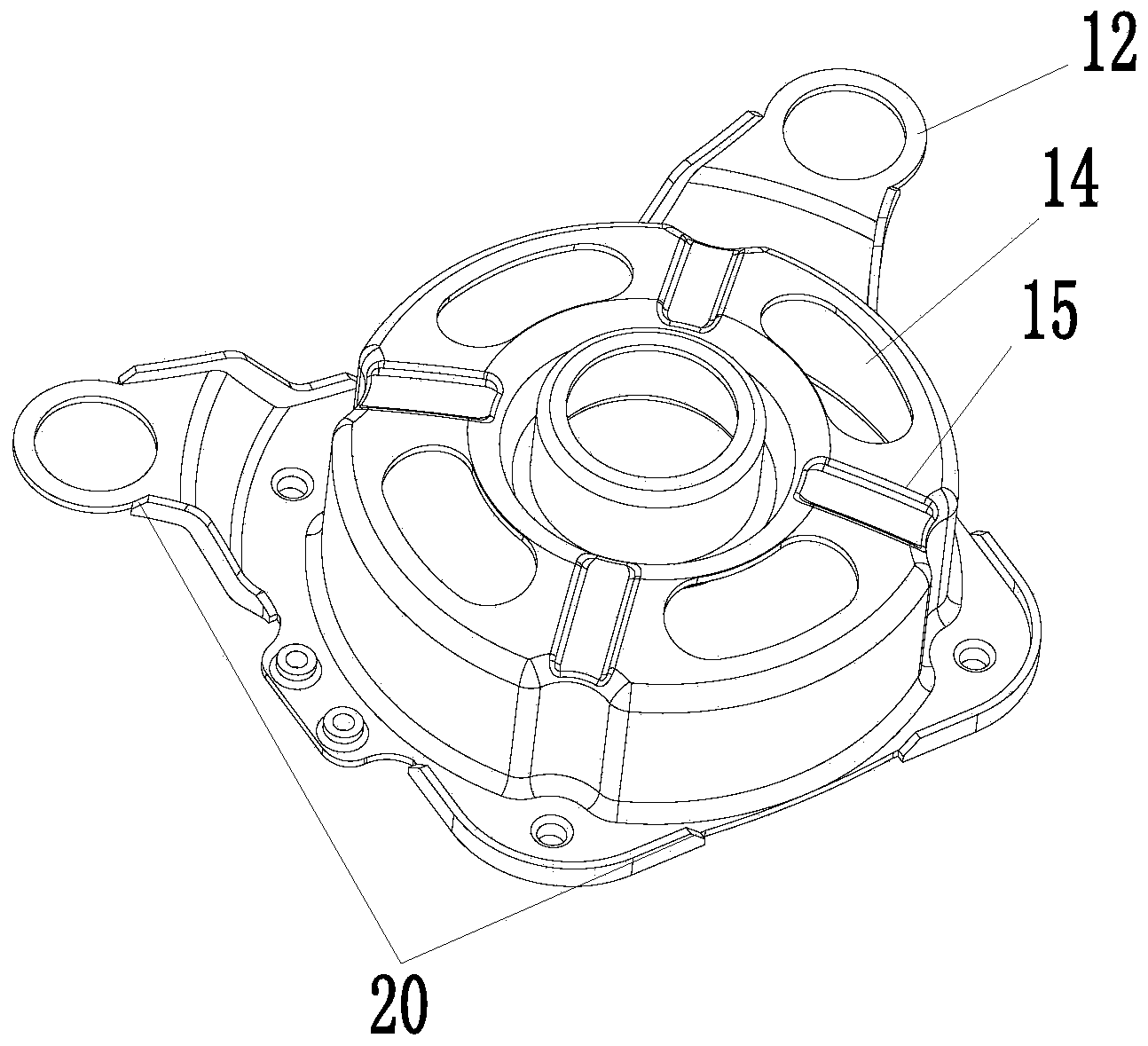

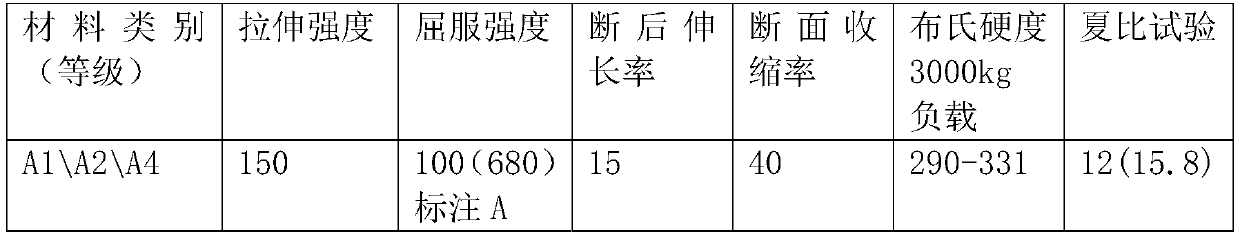

Stretched iron end cover structure used for roller washing machine series excited motor

ActiveCN104079104AReduce material costsMake up for the lack of strengthSupports/enclosures/casingsEngineeringUltimate tensile strength

The invention discloses a stretched iron end cover structure used for a roller washing machine series excited motor. The stretched iron end cover structure comprises a front end cover and a rear end cover which are manufactured with the cold plate stretching technology. The front end cover comprises a front end cover body and front installation pin supports. The front end cover body and the front installation pin supports are of an integrated structure. Front installation pin steel pipes are welded to the front installation pin supports. The rear end cover comprises a rear end cover body and a rear installation pin support. Rear installation pin steel pipes are welded to the two ends of the rear installation pin support. The rear installation pin support is fixed to the rear end cover body through rivets. According to the stretched iron end cover structure, the front end cover and the rear end cover are ingeniously decomposed, the end cover structure is accordingly achieved by drawing cold plates, aluminum end covers universal on the existing market can be directly replaced under the condition that the structure size of any other existing part is not changed, the defect that the strength of BMC case end covers is insufficient can be overcome, and the material cost of the end covers is reduced; meanwhile, the national environment protection requirement is met, and the aim of achieving three functions is achieved.

Owner:湖州鸿德电机有限公司

Alloy ring forge piece for ultra-high pressure turbine and manufacturing method of alloy ring forge piece

InactiveCN110358895AImprove corrosion resistanceMake up for the lack of strengthFurnace typesEngine componentsUltra high pressureHafnium

The invention discloses an alloy ring forge piece for an ultra-high pressure turbine and a manufacturing method of the alloy ring forge piece. The alloy ring forge piece is manufactured from the chemical components of carbon, nitrogen, manganese, chromium, nickel, silicon, copper, aluminum, tantalum, niobium, hafnium, cobalt, tungsten, molybdenum, titanium, tin, tellurium, lutetium, scandium and iron; and the forge piece is a 2Cr11MoVNbN forge piece. The manufacturing method comprises the following stepsofblanking, heating, forging, machining, tempering heat treatment and stress relief annealing, specifically, the tempering step includes the steps ofa, carrying out scanning irradiation on the surface of a rolled ring piece by using a laser beam emitted by a laser heat treatment machine; b,heating the ring piece obtained after laserscanningand irradiationto 620-640 DEG C at a temperature rising speed beingless than or equal to 150 DEG C per hour, keeping the temperature for primary tempering for 16 hours, and then preforming air cooling; and c, again, heating the ring piece to 620-640 DEG C at the temperature rising speed beingless than or equal to 150 DEG C per hour, keeping the temperature for secondary tempering for 16 hours, and performing air cooling. According to the ring forge piece and the manufacturing method, the ring forge piece has good high-pressure resistance, themechanical property of the ring piece can be remarkably improved, the machining and manufacturing cost is low, and the machining process is simple.

Owner:JIANGYIN HENGRUN RING FORGING

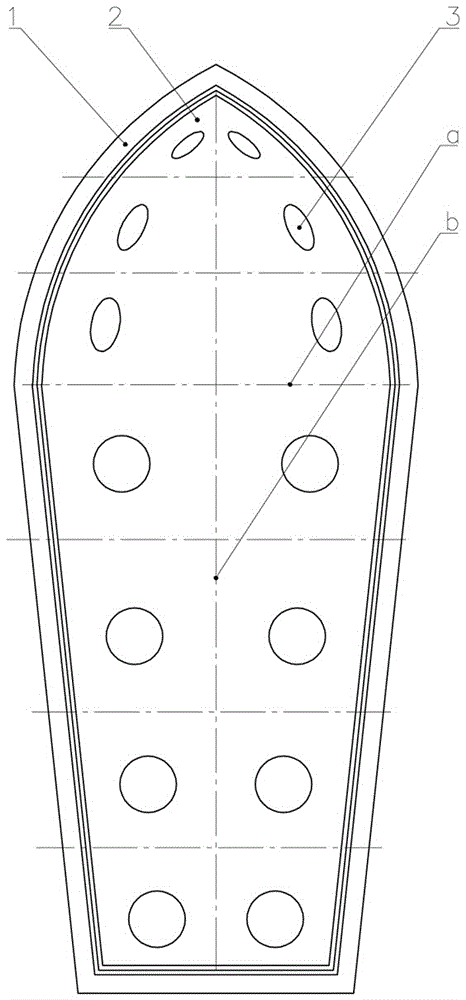

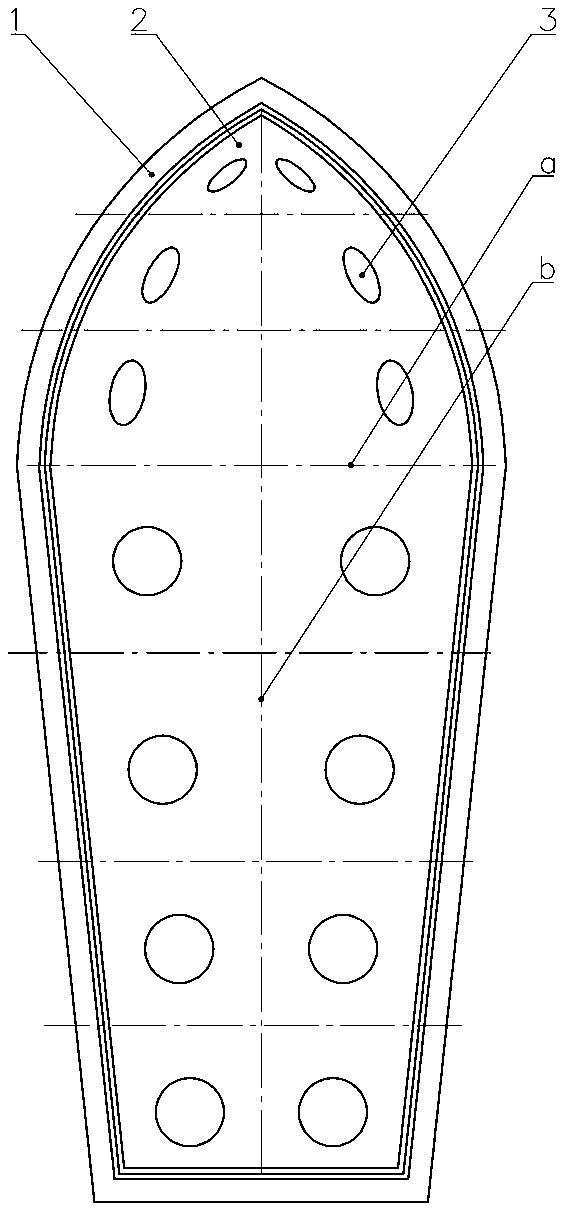

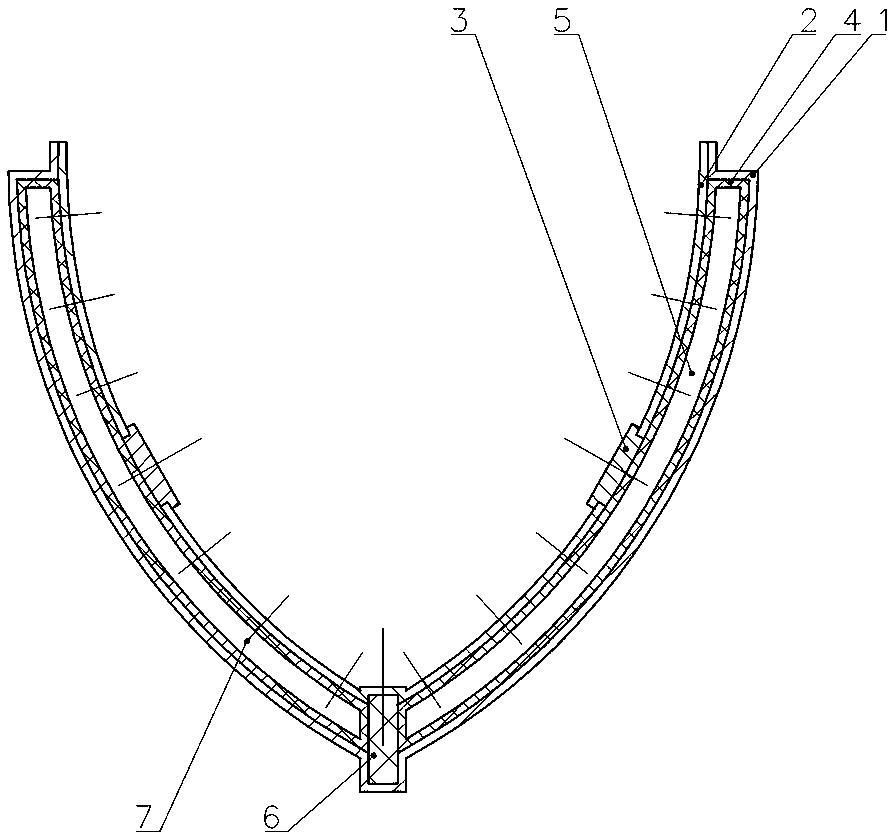

Rotational molding manufacturing method for double-layer all-plastic ship

The invention provides a rotational molding manufacturing method for a double-layer all-plastic ship. The method includes the process that after an inner mold body and an outer mold body are combined, plastic and other raw materials are added through a feed port, the mold bodies are heated and rolled, the plastic and other raw materials are melted, mixed and arranged on the inner walls of the mold bodies in a coating mode, and finally cooling and demolding are conducted; before the inner mold body and the outer mold body are combined, a supporting frame is fixed between the inner mold body and the outer mold body through a supporting frame fixing device, and the distance between the surface of the supporting frame and the inner walls of the inner mold body and the outer mold body is within the design thickness of a hull shell. Compared with the prior art, the supporting frame is arranged between the inner layer and the outer layer of the hull shell, the defects that no keel is arranged, and a rib hull is insufficient in strength are overcome, the hull is firm and stable and is not prone to deformation, re-modification worries are avoided, and the defects that labor and materials are wasted due to the fact that reinforcing ribs are additionally welded or a hollow interlayer is filled with foam materials are overcome.

Owner:王海平

Preparation method for lead-zinc-silver tailing low-temperature-sintered encaustic brick glaze

The invention relates to a preparation method for a lead-zinc-silver tailing low-temperature-sintered encaustic brick glaze. A purple chrome-tin pigment, cryolite and mullite are adopted as main raw materials of the glaze, the same glaze additive capable of reducing the sintering temperature, nanometer alumina, nanometer titania, Ca3(VO4)2, zinc oxide, lithium carbonate, sodium tetraborate decahydrate, a solvent capable of improving hydrophobicity, aging resistance and brushing resistance of the glaze and an additive thereof, phosphoric acid, n-pentyl alcohol, ethanol, zirconium silicate, methyl cellulose and water are adopted, and glazing can be implemented to obtain an encaustic brick at the sintering temperature of 600 to 730 DEG C; in addition, the prepared encaustic brick has good crystallization effects, the physicochemical performance of pressure resistance and the like meets requirements for use, and the glaze is crystal clear, strong in stereoscopic sensation and bright in color, and can be sintered to obtain ceramics at low temperature; moreover, the solvent is optimized to achieve higher hydrophobicity and high aging resistance and brushing resistance.

Owner:叶国强

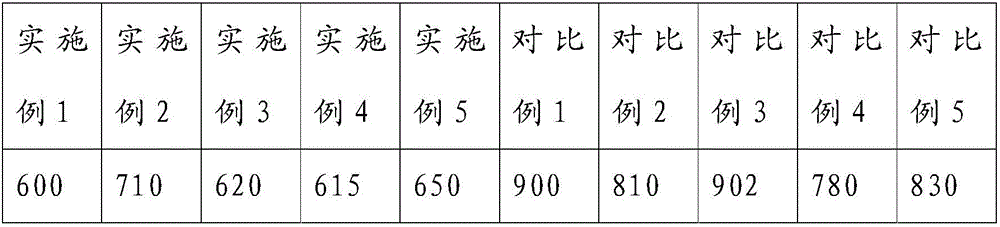

Preparation method of low-cost paper environment-friendly take-out meal box

InactiveCN111150198AImprove mechanical propertiesImprove heat resistanceOther accessoriesNon-woven fabricsProcess engineeringSodium hydroxide

The invention provides a preparation method of a low-cost paper environment-friendly take-out meal box, and relates to the field of meal box materials, and the preparation method comprises the following steps: preparing wheat straw fibers; preparing ramie fibers; preparing hard cloth; adding waste corrugated paper into a crusher; crushing for 30-50 minutes at the speed of 2,000-2,500 r / min to obtain corrugated paper powder; soaking the corrugated paper powder in water for 25-30 hours; adding rice straw powder, calcium carbonate and starch; mechanically stirring at 1200-1500r / min for 2-5h, andadjusting the pH value of the system to 10 by using a sodium hydroxide solution to obtain thick slurry; heating and raising the temperature to 40 to 50 DEG C; soaking the hard cloth for 5 to 10min andthen fishing out the hard cloth; drying at the temperature of 70-80 DEG C to obtain sheets, taking a plurality of sheets for hot press molding to obtain a meal box body, adhering a layer of high-temperature-resistant film to the inner surface of the meal box body, and heating and curing at the temperature of 50-60 DEG C. According to the paper environment-friendly take-out meal box, the excellent mechanical property, heat resistance and water resistance of the meal box can be guaranteed while the low cost is guaranteed.

Owner:安徽硕通网络科技有限公司

Transparent curtain wall system free from ribbed plates and installation method thereof

The invention discloses a transparent curtain wall system free from ribbed plates and an installation method thereof. The curtain wall system comprises a building top structure, a building bottom structure and a glass panel; two first through-connection parts are fixedly arranged on the bottom surface of a structure top beam of the building top structure, cross sections of the first through-connection parts are in inverted-L shapes, and a first installation groove is formed between two first side boards of the first through-connection parts; two second through-connection parts are fixedly arranged on the top surface of a structure bottom beam of the building bottom structure, cross sections of the second through-connection parts are in L shapes, and the second through-connection parts comprise bottom boards and second side boards; the bottom boards and the structure bottom beam are fixedly connected, a second installation groove is formed between the two second side boards in a fixed mode, and a cross section of the second installation groove is in a U shape; the glass panel is laminated tempered glass, and comprises multiple glass panes, and adhesive sheets are arranged among theadjacent glass panes; the top of the glass panel is located in the first installation groove, and a horizontal fixing bolt penetrates the top of the glass panel; the glass panel and two first side boards are fixed together by the fixing bolt; the bottom of the glass panel is located in the second installation groove.

Owner:BEIJING JANGHO CURTAIN WALL SYST ENG

Production method for secure sliding window resistant to deformation

InactiveCN110561037AMake up for the lack of strengthReduce easy deformationMetallic material coating processesWaxLacquer

The invention provides a production method for a secure sliding window resistant to deformation. The method comprises the steps that a window frame base part is manufactured, and a window frame is assembled, welded and processed; a sliding window base part and edge sealing bars are manufactured; the edge sealing bars are soaked in a colloid pool and de-oiled; the window frame and the sliding window base part are reinforced; the edge sealing bars, the window frame and the sliding window base part are grinded, soaked and dried; a sliding window blank body is formed by welding, sprayed with waterproof glue, sprayed with a varnish paint for baking; and the sliding window is manufactured after polishing treatment. In comparison with the prior art, the method provided by the invention has the beneficial effects that the window frame and the sliding window base part are reinforced, so the defect in insufficient strength of the sliding window is remedied, and easy deformation in reuse is reduced; and the sliding window blank body is sprayed with the waterproof glue, then sprayed with the varnish paint by electric spraying and baked, and is finally polished with polishing wax, so processingaccuracy is increased and current people's use demands are satisfied.

Owner:TIANJIN SHIDE NEW BUILDING MATERIAL SCI & TECH

Safety door-bolt mechanism

InactiveCN1814977AHigh strengthIdeal insertion depthConstruction fastening devicesPush and pullLeft direction

Present invention discloses a safety door bolt mechanism. It contains crank rotation in said mechanism, uniformity or no uniformity distributed n>=2 number of door bolt along single side or two sides of door edge on right and left direction of door, under crank push and pull action, the door bolt making locking and unlocking movement to realize the door open and close. Said safety door bolt mechanism increases breaking door hardness, effectively raise overall strength of door and safety, and even if at high temperatures of hundred of degree, said door still can be smoothly opened.

Owner:姜仁忠

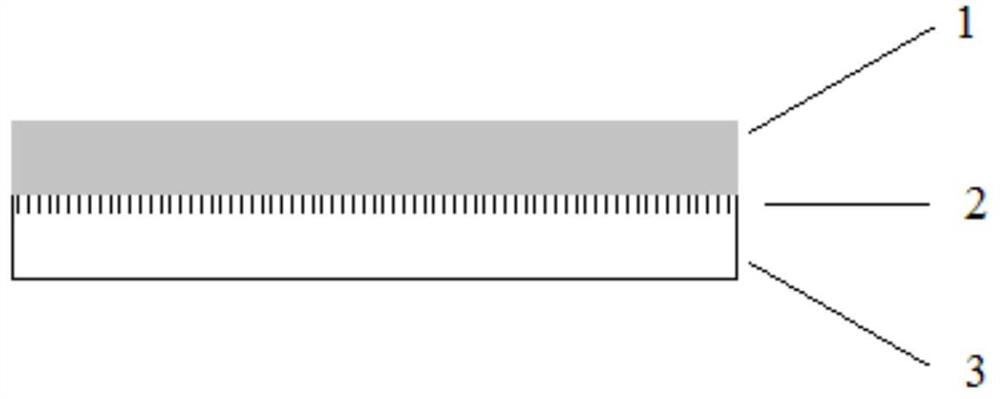

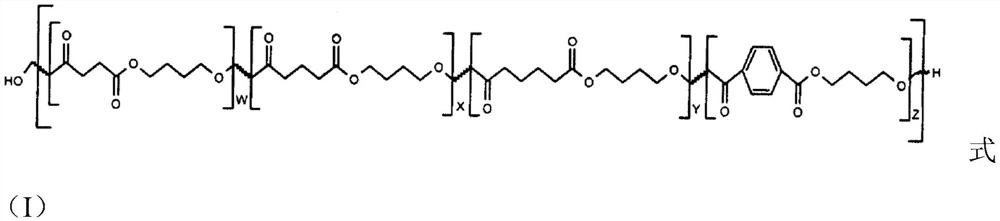

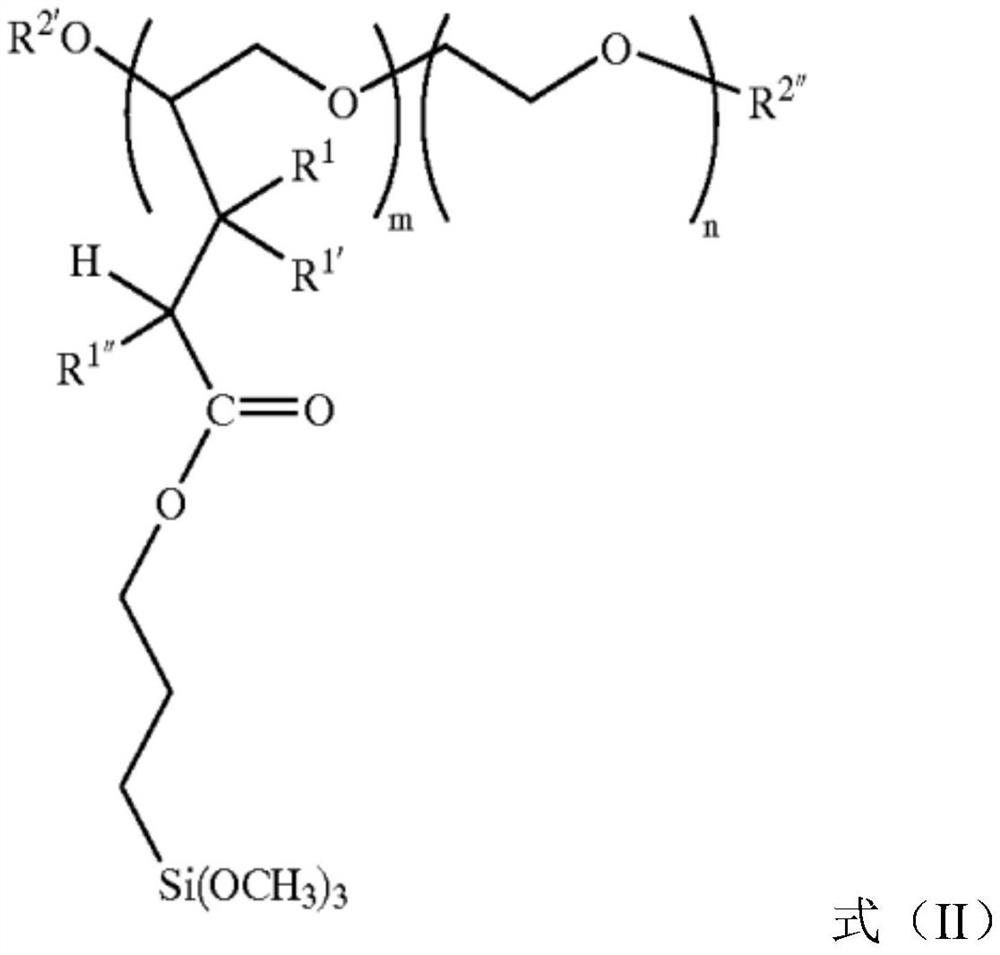

Degradable bioplastic composite paper and preparation process thereof

ActiveCN111730943AReduce carbon footprintHigh strengthFlexible coversWrappersPolymer scienceWet strength

The invention provides degradable bioplastic composite paper and a preparation process thereof. The degradable bioplastic composite paper at least comprises a first layer (1) containing bioplastic anda paper layer (3) as a second layer, and the first layer and the second layer are bonded together through an adhesive layer (2). The degradable biological plastic composite paper can overcome the adverse environmental influence caused by high-content plastic, and has excellent tensile strength performance and wet strength.

Owner:新疆弘瑞达纤维有限公司

Double-layer all-plastic ship rotational molding manufacturing method

The invention provides a rotational molding manufacturing method for a double-layer all-plastic ship. The method includes the process that after an inner mold body and an outer mold body are combined, plastic and other raw materials are added through a feed port, the mold bodies are heated and rolled, the plastic and other raw materials are melted, mixed and arranged on the inner walls of the mold bodies in a coating mode, and finally cooling and demolding are conducted; before the inner mold body and the outer mold body are combined, a supporting frame is fixed between the inner mold body and the outer mold body through a supporting frame fixing device, and the distance between the surface of the supporting frame and the inner walls of the inner mold body and the outer mold body is within the design thickness of a hull shell. Compared with the prior art, the supporting frame is arranged between the inner layer and the outer layer of the hull shell, the defects that no keel is arranged, and a rib hull is insufficient in strength are overcome, the hull is firm and stable and is not prone to deformation, re-modification worries are avoided, and the defects that labor and materials are wasted due to the fact that reinforcing ribs are additionally welded or a hollow interlayer is filled with foam materials are overcome.

Owner:王海平

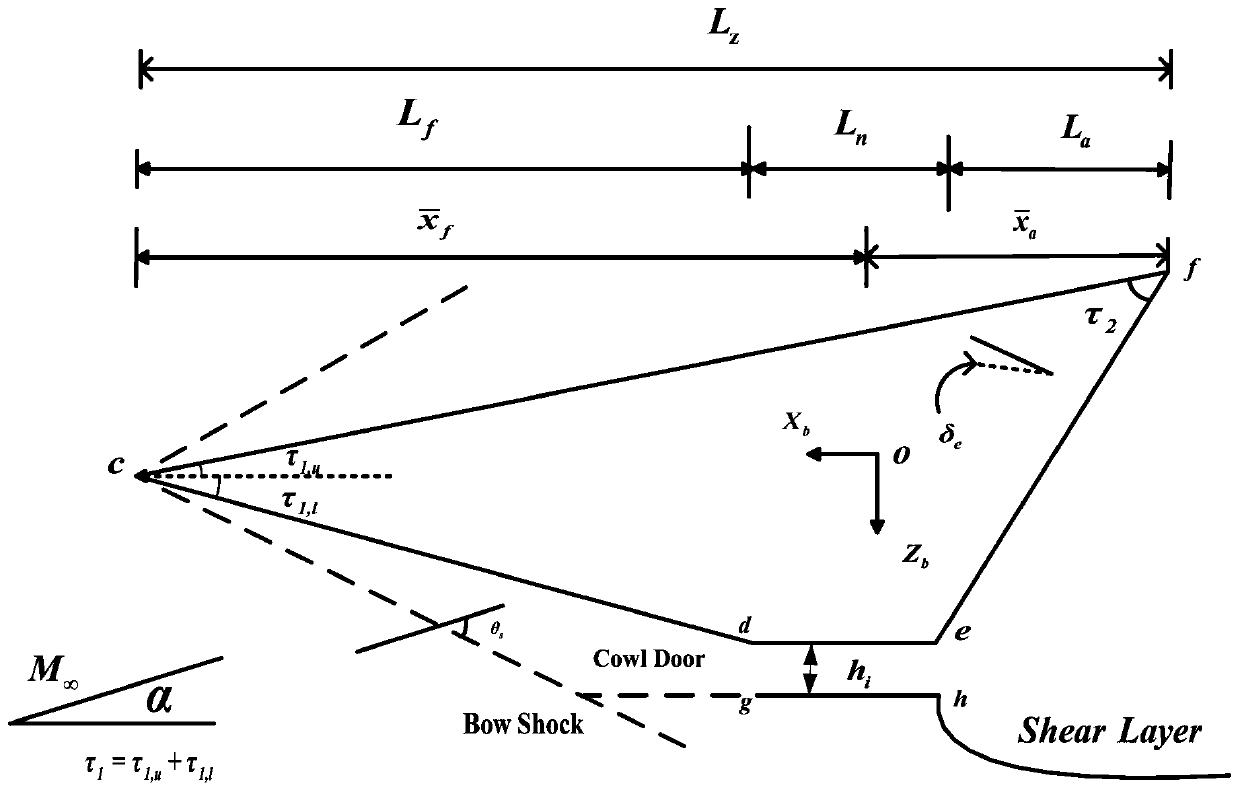

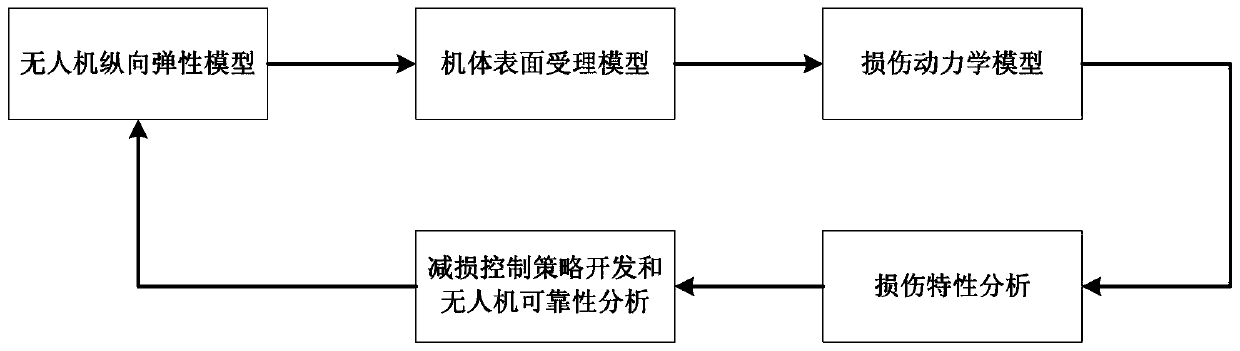

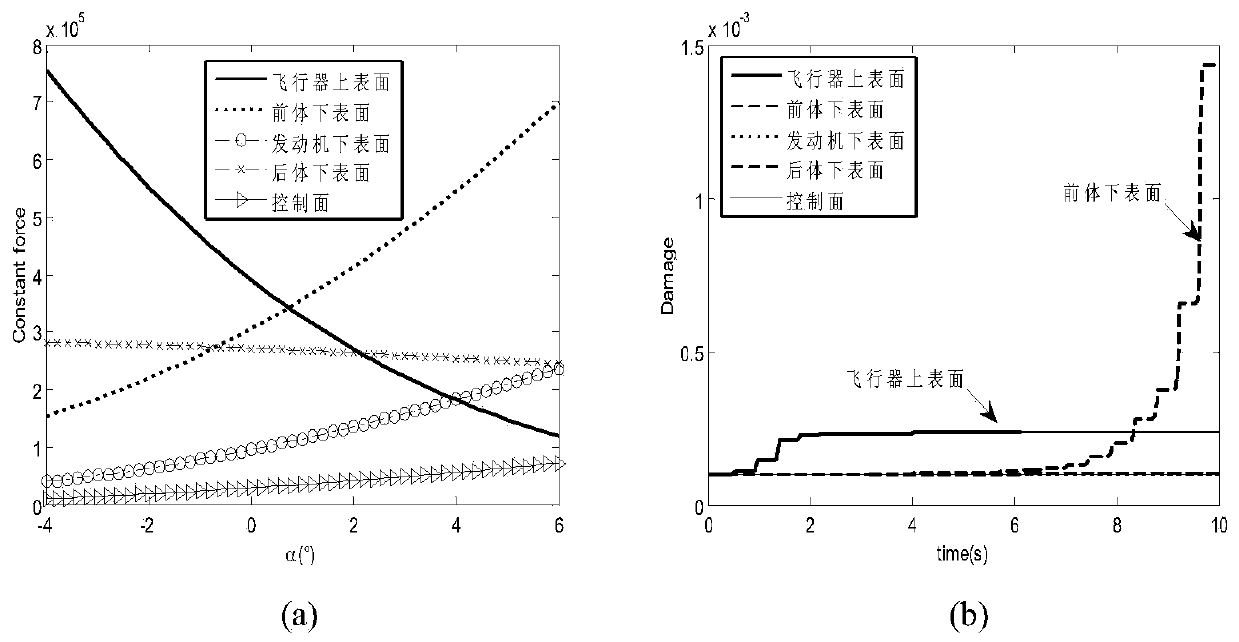

Air-breathing hypersonic unmanned aerial vehicle damage characteristic analysis method

ActiveCN111159812AMake up for the defect that the simulation considers the force of the elastic factorMake up for the lack of strengthGeometric CADDynamic modelsClassical mechanics

The invention discloses an air-breathing hypersonic unmanned aerial vehicle damage characteristic analysis method, which comprises the steps of establishing an unmanned aerial vehicle full-fuselage stress model considering elastic factors, and analyzing unsteady aerodynamic force; according to the obtained stress information, establishing a whole-body damage dynamic model of the unmanned aerial vehicle; establishing an unmanned aerial vehicle longitudinal elastic model, analyzing the key difference between the unmanned aerial vehicle longitudinal elastic model and the longitudinal rigid body model, and demonstrating the necessity of considering the aerodynamic elasticity when the damage characteristics of the air-breathing hypersonic unmanned aerial vehicle are studied; for different flight states, analyzing damage characteristics of each surface of the unmanned aerial vehicle, and determining key variables influencing damage evolution. According to the method, the whole unmanned aerial vehicle body serves as a research object, the influence caused by elastic vibration of the unmanned aerial vehicle in the flight process is fully considered, a damage model and unmanned aerial vehicle flight are dynamically combined, the influence of the attack angle, the flight speed, the height and the rudder deflection angle of the unmanned aerial vehicle on fuselage damage accumulation is analyzed, and key variables influencing fuselage damage are found out.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

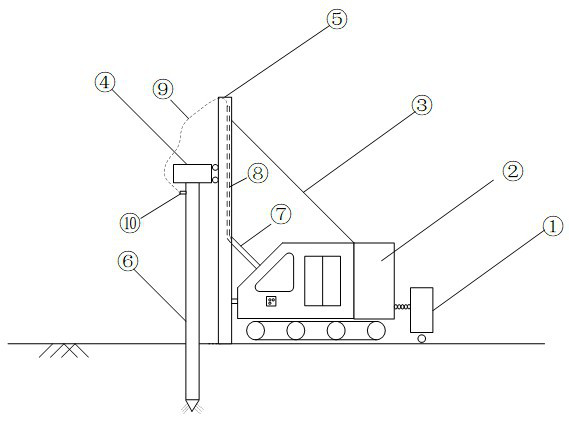

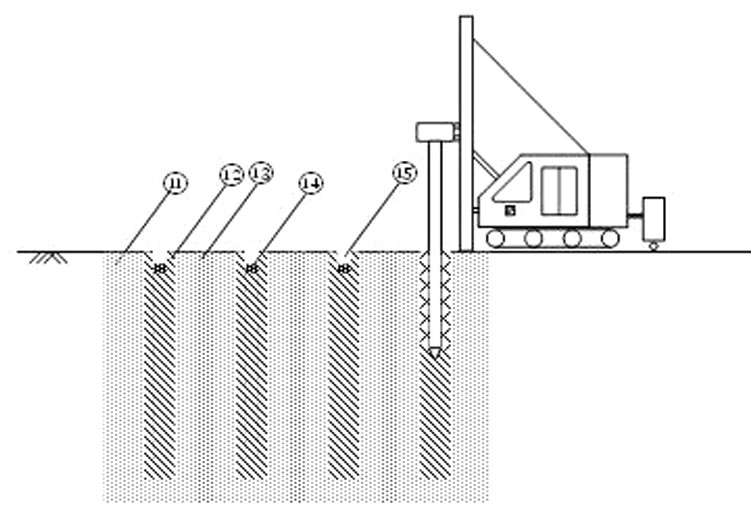

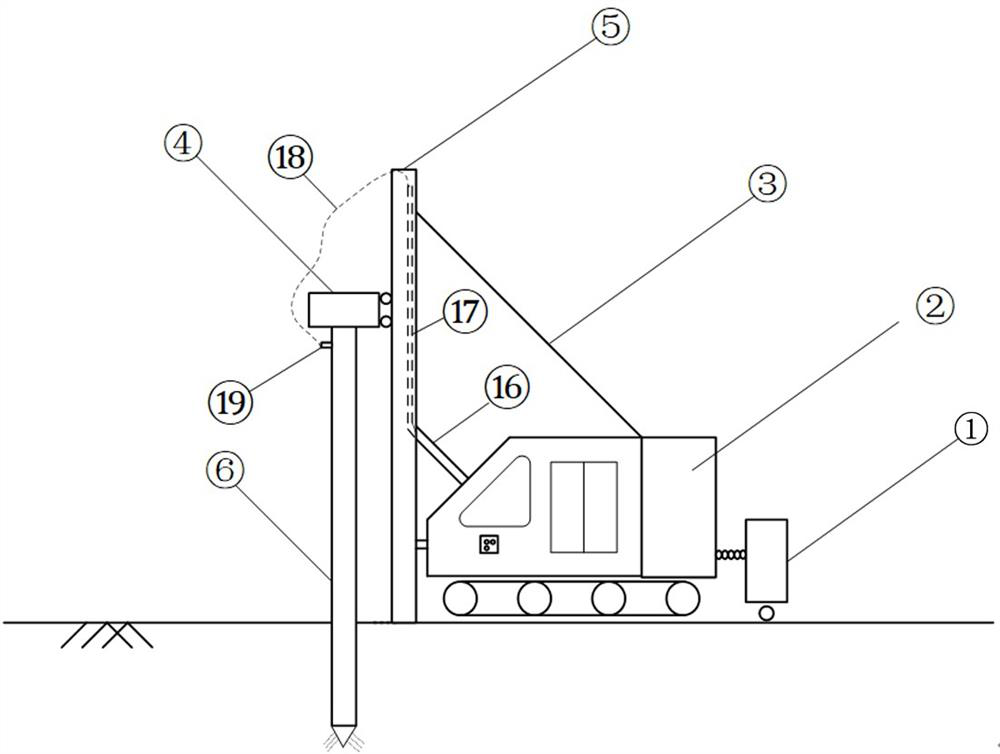

Device and method for deep resonant compaction and reinforcement of miscellaneous fill foundation

The device and method for deep resonant compaction and reinforcement of miscellaneous fill foundation, after sinking the vibrating rod into the soil, adjust the frequency of the vibrating hammer to the resonant frequency of the vibrating rod-soil system, and use the principle of resonance amplification to effectively transfer the vibration energy to the deep miscellaneous Filling, forming a resonant compacting area of miscellaneous fillings, plus the mixed area of solidifiable slurry and miscellaneous fillings for auxiliary reinforcement, the vibrating hammer drives the vibrating rod to freely fall to compact the compacted area formed by the loose soil inside the vibrating hole Reinforce miscellaneous fill foundation; effectively solve the shortcomings of traditional methods such as poor effect of reinforcing deep miscellaneous fill, low economic benefits, and complicated construction techniques.

Owner:ZHENGZHOU UNIV

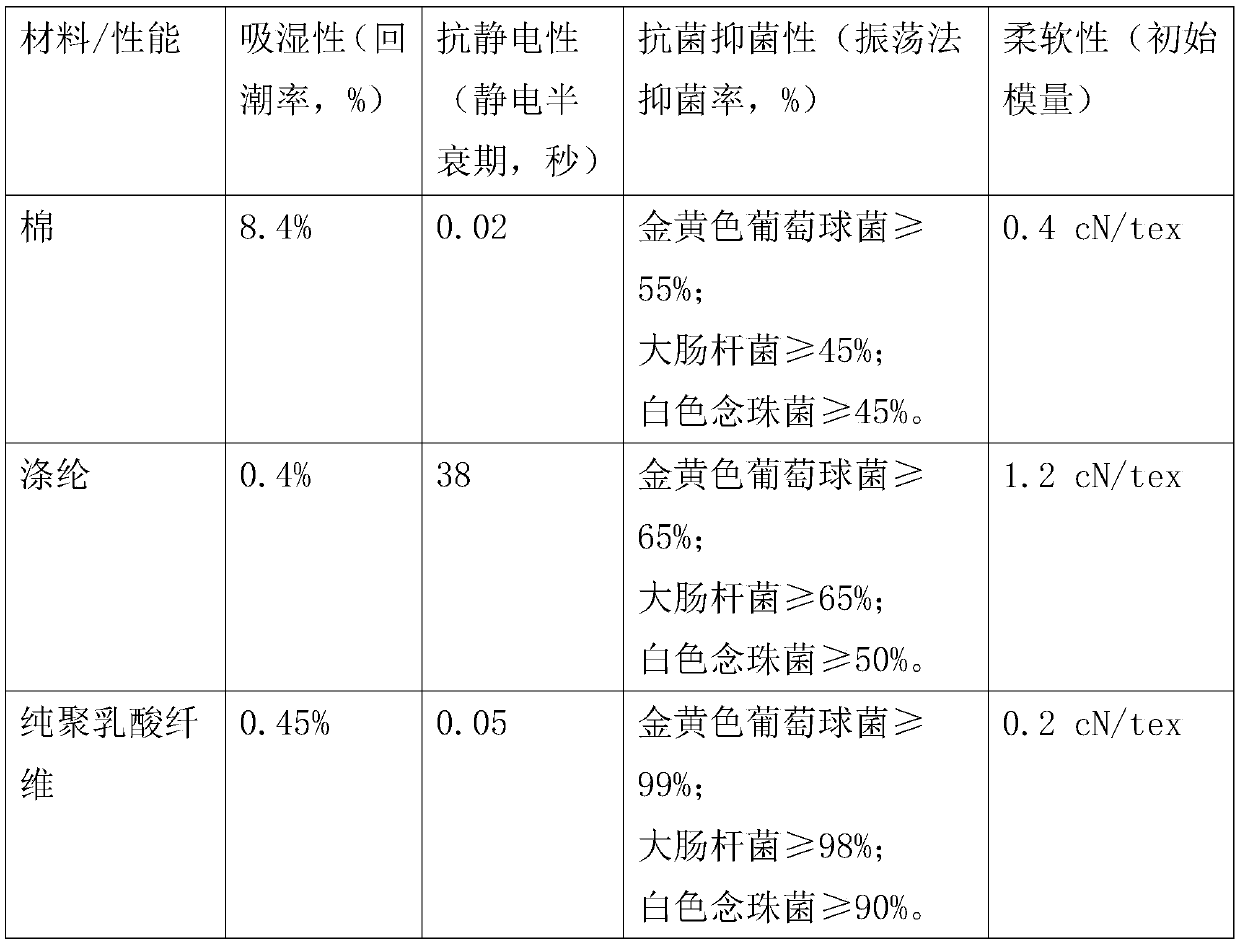

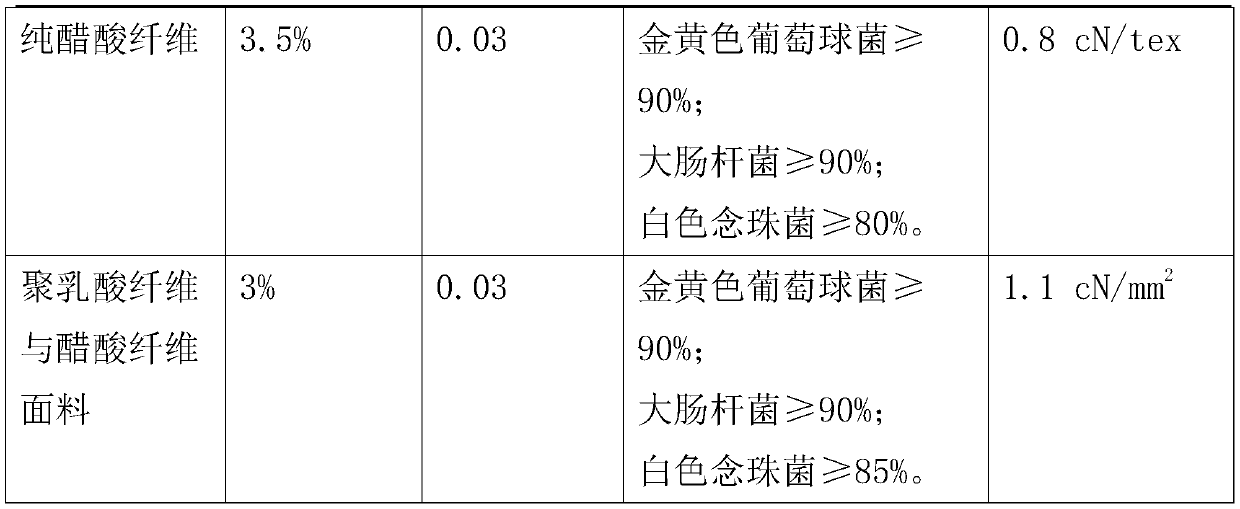

Polylactic acid fiber and acetate fiber woven fabric

InactiveCN110438622AStrong and goodStronger than acetate fiber, good in tensile strengthSwivel-woven fabricsLappet-woven fabricsTextile technologyPolylactic acid

The invention relates to a polylactic acid fiber and acetate fiber woven fabric, belongs to the technical field of textile, and solves the problems of poor strength and wearability of acetate fibers in the prior art. According to the woven fabric, polylactic acid fiber filaments / yarns and acetate fiber filaments / blended yarns are tatted to form the polylactic acid fiber and acetate fiber woven fabric, and a tatting mode is one or more of plain weave, twill weave, satin weave and variation, combination and complex weave or jacquard weave of the plain weave, the twill weave and satin weave. Polylactic acid fibers and acetate fibers are environment-friendly and degradable materials, good in environmental-friendly performance, applicable to a normal-temperature disperse dyeing process and convenient to dye, the polylactic acid fibers and the acetate fibers are combined, performance complementation is formed, subsequent dyeing and finishing processes are similar, the advantages of the polylactic acid fibers and the acetate fibers are amplified, and the defects of the polylactic acid fibers and the acetate fibers are remedied.

Owner:润益(嘉兴)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com