High temperature and corrosion resistant seamless stainless steel pipe and preparation method of the seamless stainless steel pipe

A stainless steel tube, stainless steel technology, applied in the preparation of seamless stainless steel tube, ultra-low carbon austenitic stainless steel field, can solve the problem of low corrosion resistance, improve corrosion resistance, improve stress corrosion resistance, improve Effect of Intergranular Corrosion Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

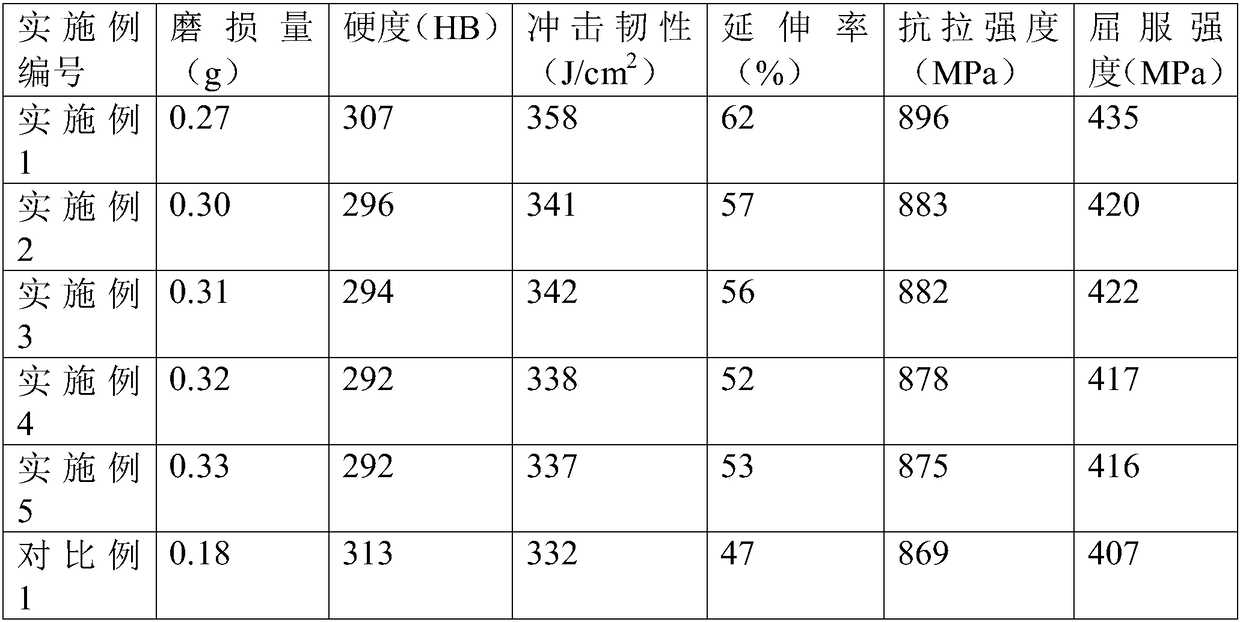

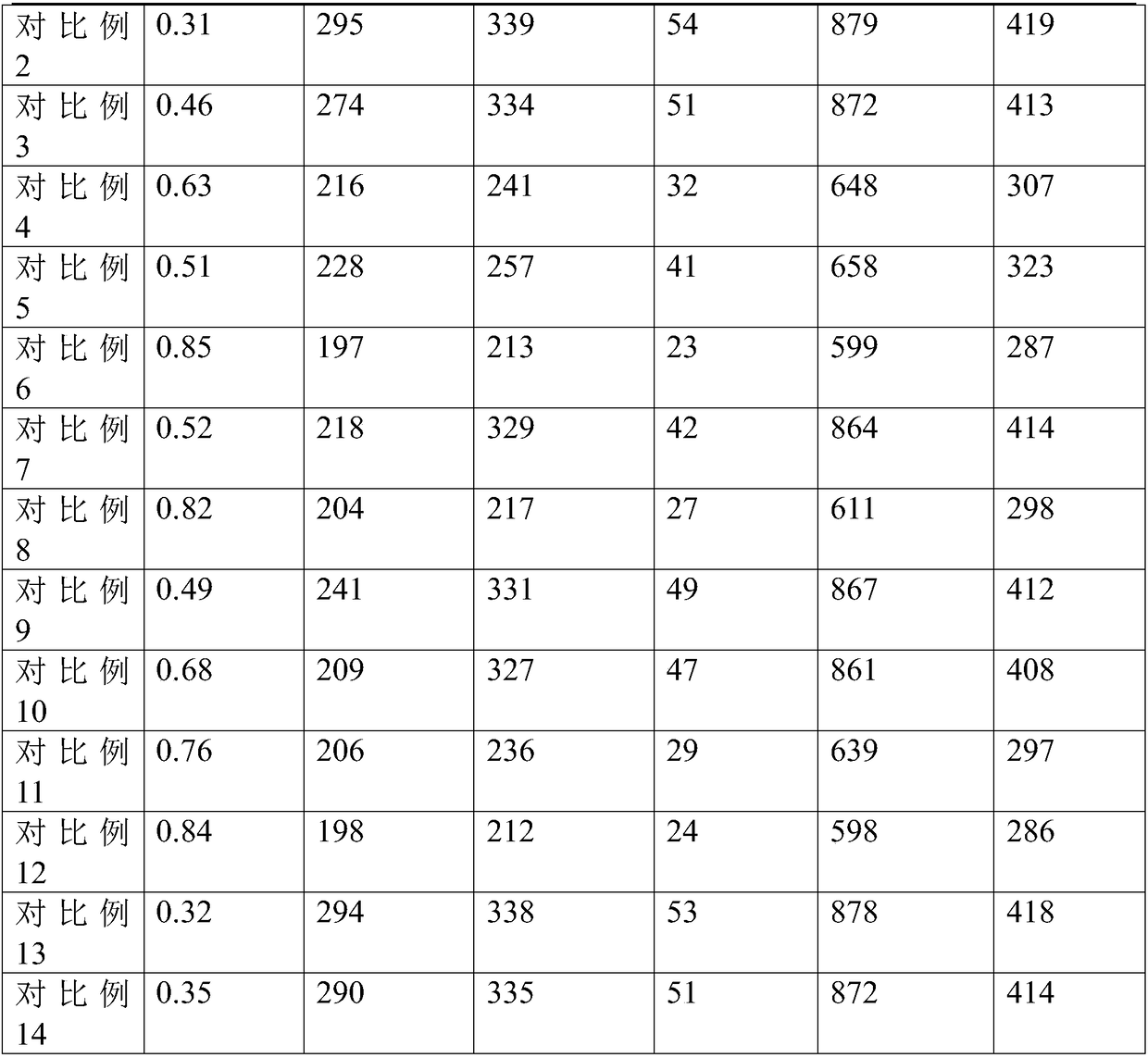

Examples

Embodiment 1

[0063] In this embodiment, an ultra-low carbon austenitic stainless steel has a chemical composition in terms of mass percentage: 0.016% carbon, 0.21% nitrogen, 1.83% manganese, 19.1% chromium, 11.7% nickel, 0.32% silicon, and 1.68% aluminum , tantalum 1.94%, niobium 0.92%, hafnium 2.67%, cobalt 0.21%, tungsten 2.12%, molybdenum 2.15%, tellurium 0.52%, and the balance is iron.

Embodiment 2~5

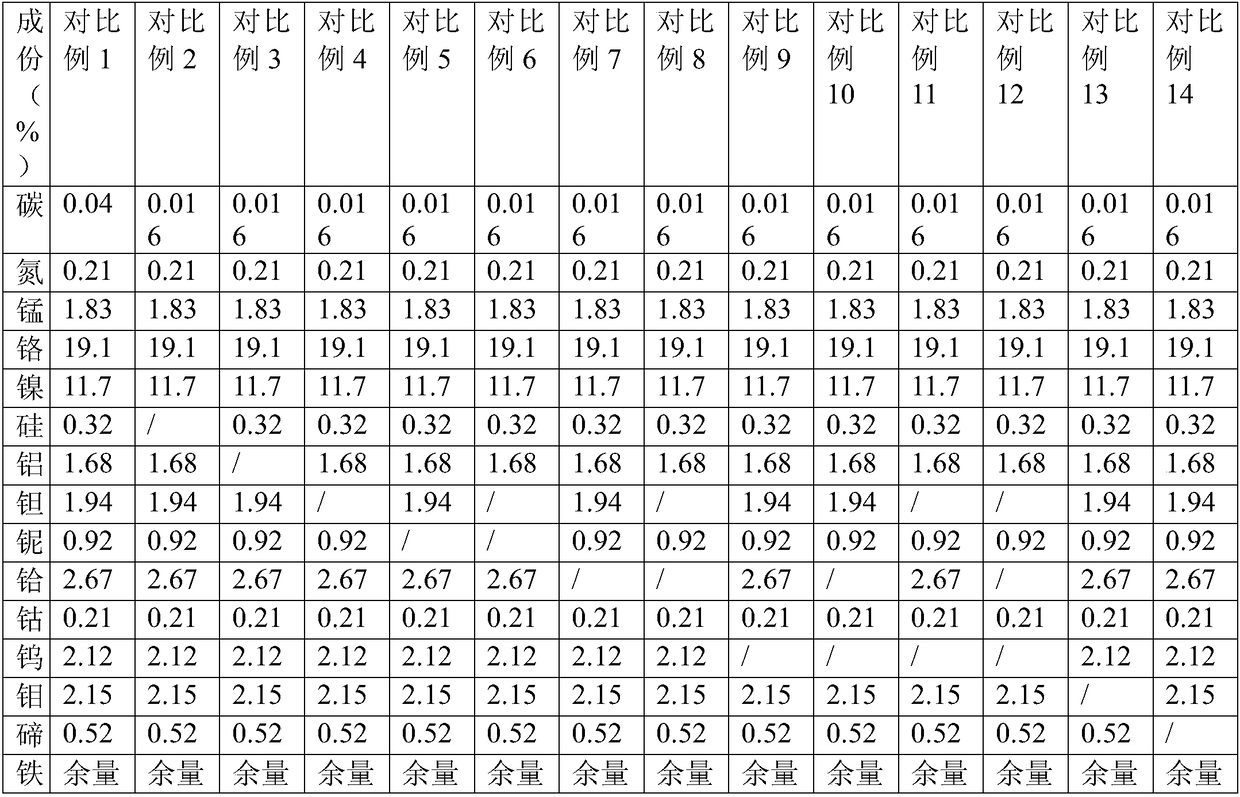

[0065] The chemical composition of the ultra-low carbon austenitic stainless steel in Examples 2-5 is shown in Table 1 in terms of mass percentage.

[0066] The chemical composition table of the ultra-low carbon austenitic stainless steel of table 1 embodiment 2~5

[0067] ingredients

Embodiment 6

[0073] Using the austenitic stainless steel materials of Examples 1-5 and Comparative Examples 1-13 to prepare high-temperature-resistant and corrosion-resistant seamless stainless steel pipes, the steps include the following steps:

[0074] (1) primary refining

[0075] ①: According to the preset mass percentage, put manganese, nickel, chromium, molybdenum, tellurium, aluminum and iron in an electric furnace or a converter, and smelt at 1350-1400°C until all components are completely melted to obtain smelting solution A;

[0076] ②: Put tantalum, hafnium, tungsten, niobium and cobalt in an electric furnace or a converter according to the preset mass percentage, and smelt them at 1500-1600°C until all components are completely melted to obtain smelting liquid B;

[0077] ③: Raise the temperature of smelting liquid B to 1550-1750°C, and add carbon, nitrogen and silicon to smelting liquid B according to the preset mass percentage, and continue smelting for 3 to 4 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com