Polylactic acid fiber and acetate fiber woven fabric

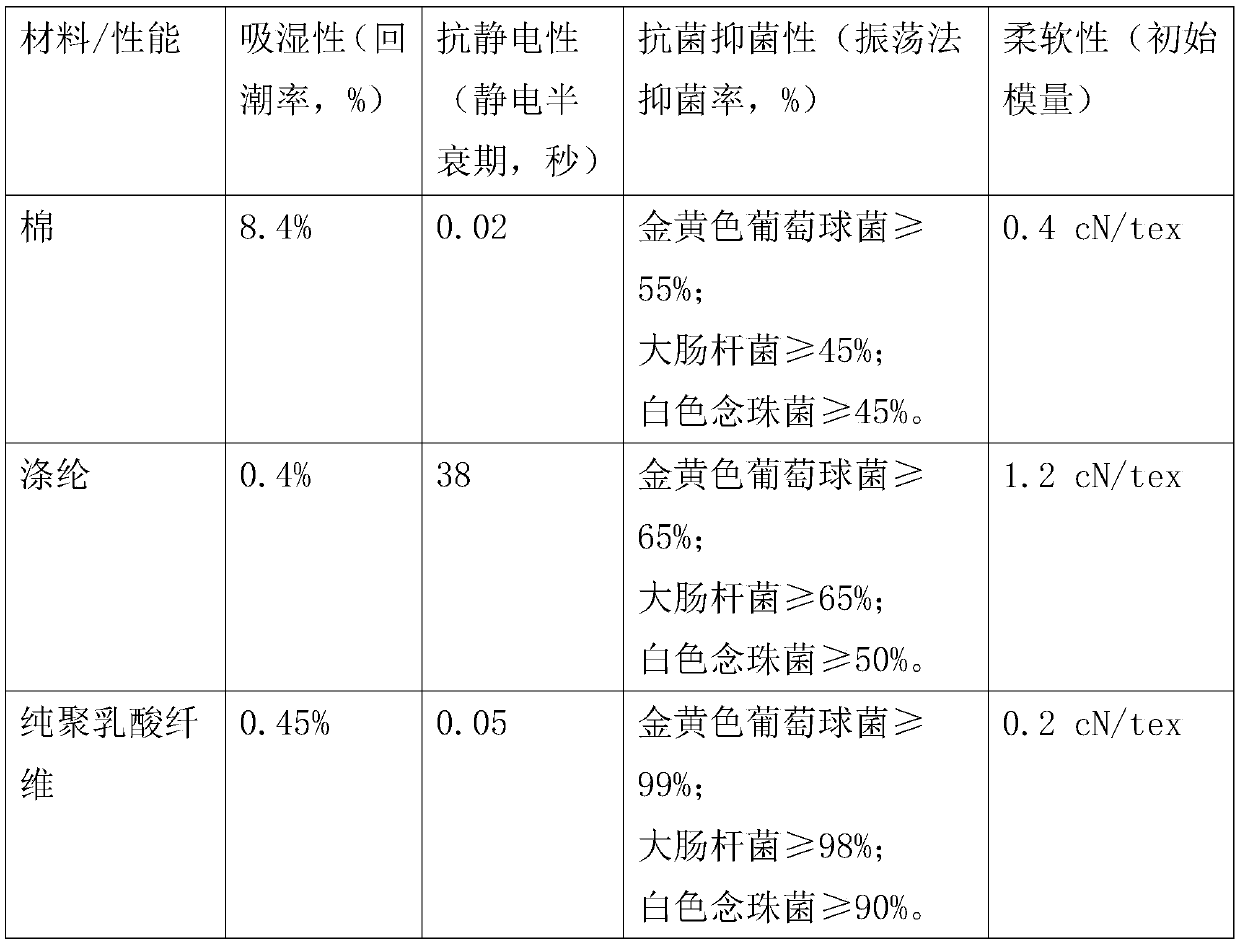

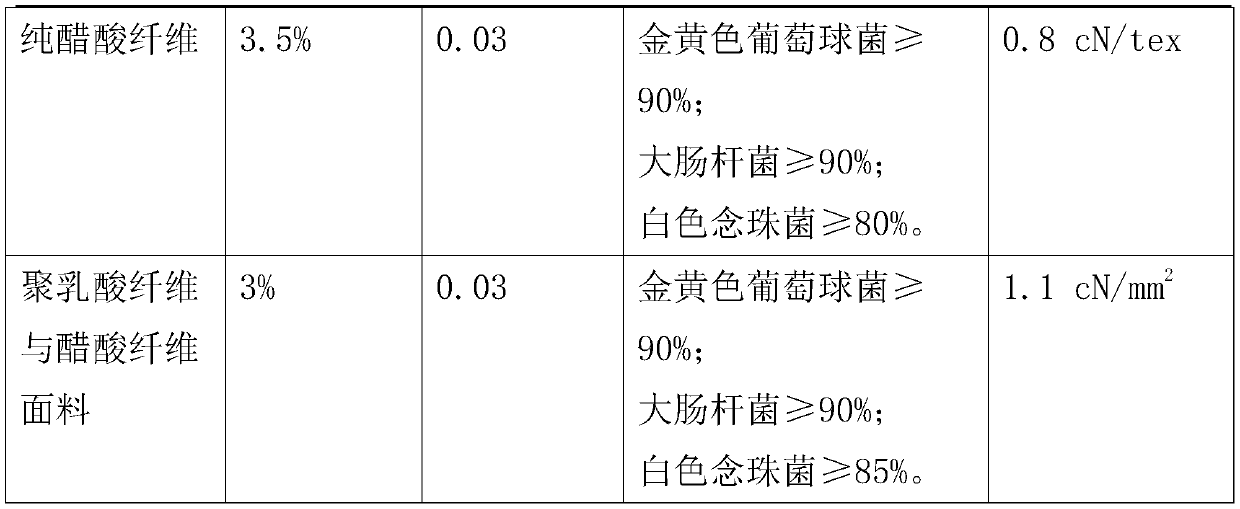

A technology of polylactic acid fiber and acetate fiber, applied in textile, fabric, embossed fabric and other directions, can solve the problems of polylactic acid fiber with hard hand, difficult dyeing, inhibition of large-scale application, etc., and achieves good hygroscopicity, antibacterial and bacteriostatic properties. Good, good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A polylactic acid fiber and acetate fiber woven fabric, which is woven with 70d polylactic acid fiber filaments and 70d acetate fiber filaments. The warp direction is polylactic acid fiber filaments. The direction is acetate filament, the weft density is 310 threads / 10cm, and the jacquard loom is woven into a jacquard women's fabric.

[0033] The weaving method of above-mentioned polylactic acid fiber and acetate fiber woven fabric, comprises the steps:

[0034] S1, twisting; select 70d specification polylactic acid fiber filaments, polylactic acid fiber filament twist is 70-150 twist / 10CM, and acetate fiber filament 70d specification, acetate fiber filament twist is 70-100 twist / 10CM ;

[0035] S2, warping: use batch warping machines for warping, select twisted polylactic acid fiber filaments, or twisted acetate fiber filaments, the warping speed is 800m / min, and the weight of the tension ring is controlled from the back to the bottom. The former is 11.4, 10.6, 9.3, ...

Embodiment 2

[0042] The structure and weaving method of this embodiment and embodiment 1 are basically the same, the difference is that this polylactic acid fiber and acetate fiber woven fabric adopts acetate filament 75D FDY18T / 2S2Z as the warp direction, and the warp density is 420 / 10cm; polylactic acid fiber filament 75D FDY18T / 2S2Z weft density 310 threads / 10cm, woven into elegant and light georgette fabric.

Embodiment 3

[0044] The structure and weaving method of this embodiment and embodiment 2 are basically the same, the difference is that the polylactic acid fiber and acetate fiber woven fabric adopts acetate filament 75D FDY6T / S as the warp direction, and the warp density is 380 strands / 10cm. Polylactic acid fiber filament 100D FDY28T / S, weft density 260 threads / 10cm, woven into crepe fabric for women, has the feel of silk-like fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com