Stretched iron end cover structure used for roller washing machine series excited motor

A technology for a drum washing machine and a series excitation motor, which is applied in the directions of electromechanical devices, electrical components, and electric components, can solve the problems of the impact of end cap strength, the limited reduction in the cost of end cap raw materials, and environmental pollution, and achieve the effect of reducing material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

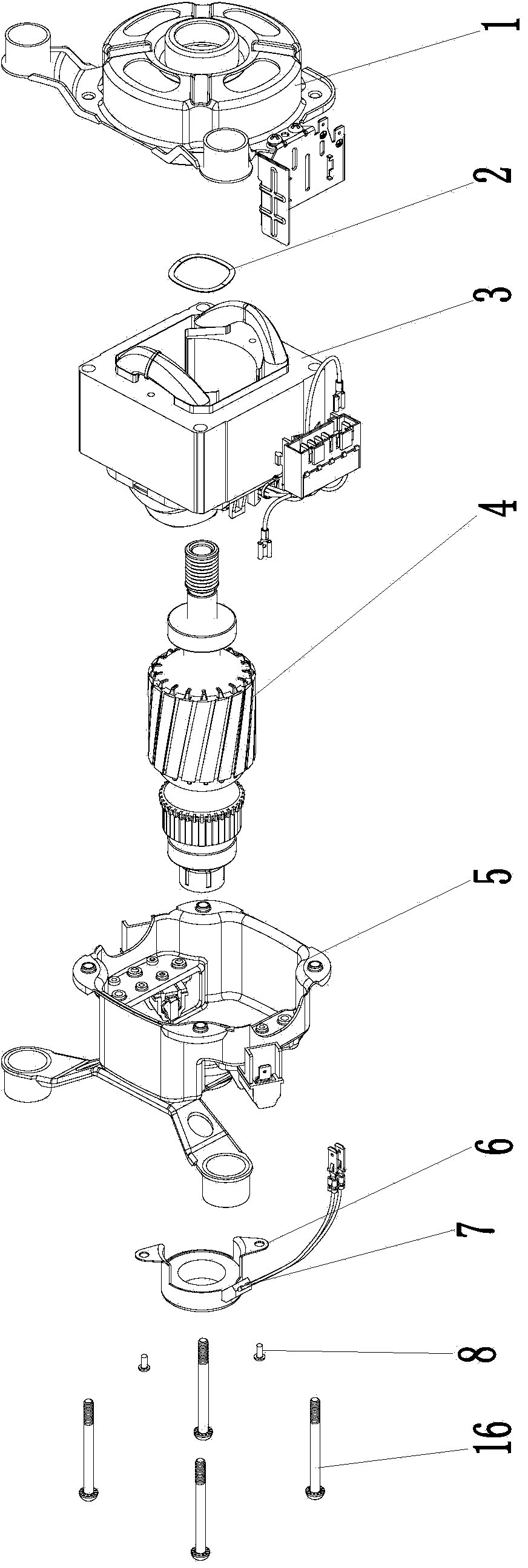

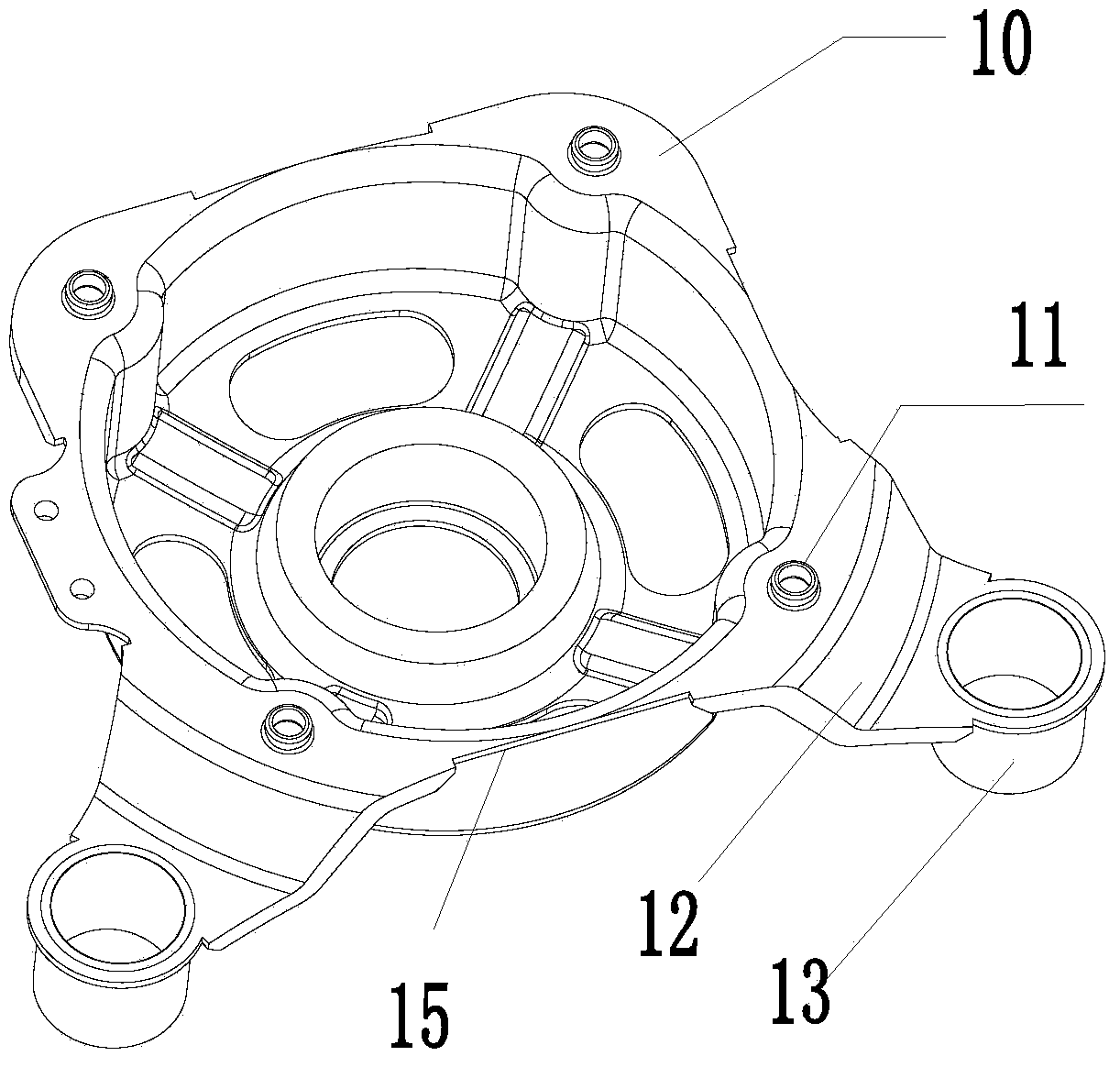

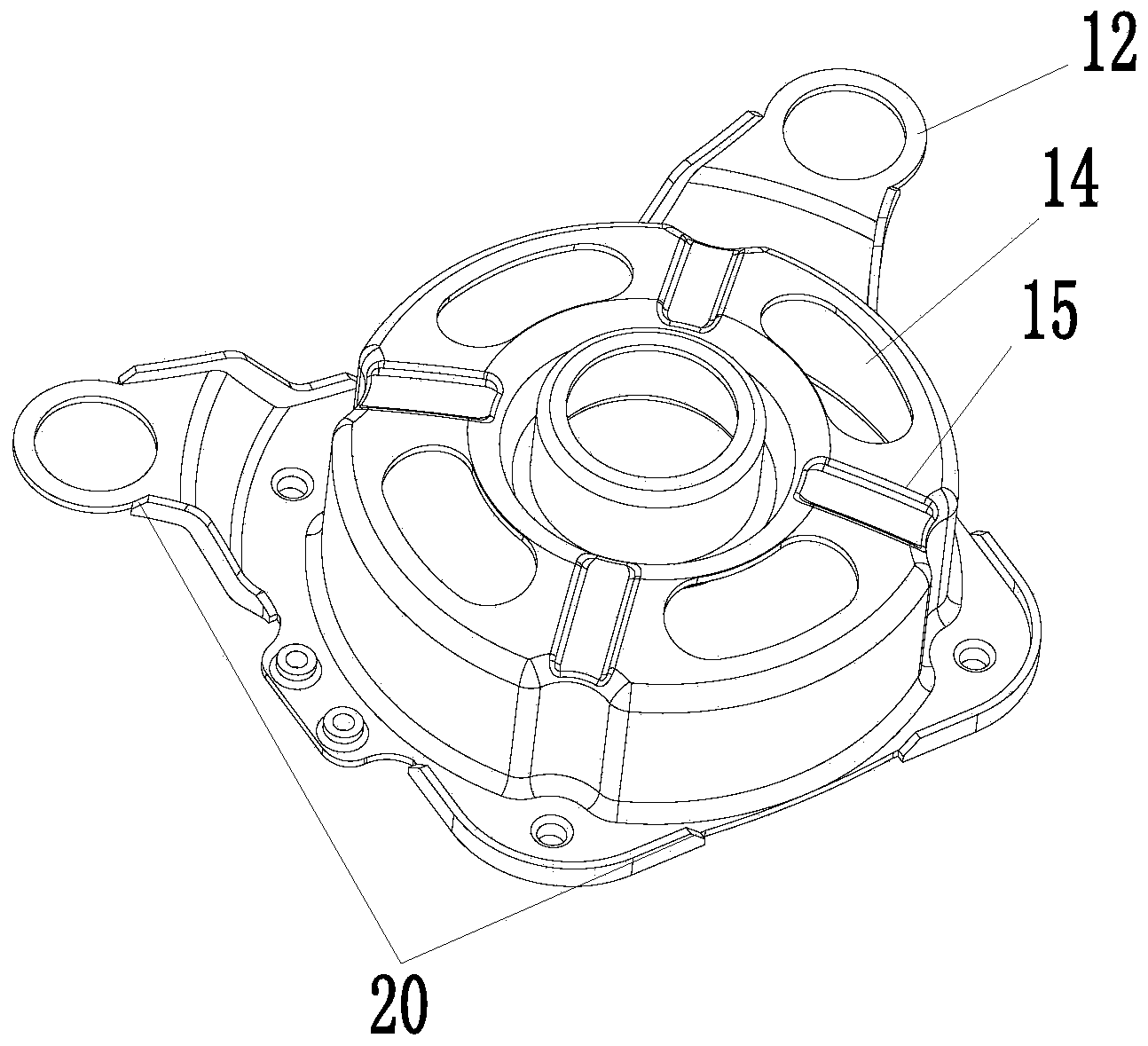

[0022] Example. A stretched iron end cover structure for the series excitation motor of the drum washing machine, including the front end cover 10 and the rear end cover 28 processed and manufactured by the cold plate drawing process, which are used to assemble the front end cover when assembling the series excitation motor 1. Wave washer 2, stator assembly 3, rotor assembly 4, rear end cover assembly 5, tachometer assembly 6 (including tachometer 7 and tachometer positioning bracket 26), screws 8 and other components are assembled in a conventional manner, and the characteristics are: The front end cover 10 comprises a front end cover body 15 and a front mounting foot support 12, the front end cover body 15 and the front installation foot support 12 are integrally structured, and the front installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com