Internal-curing type expanding agent for concrete and preparation method thereof

A technology of concrete internal and expansive agent, which is applied in the field of building materials, can solve the problems of ineffective control of cracks, limited compensation for shrinkage, and reduction of concrete strength, etc., and achieves low cost of comprehensive anti-cracking, simple preparation and use methods, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The commercially available calcium oxide expanded clinker is crushed into a specific surface area of 200m 2 / kg of powder, choose rice husk ash with an average particle size of 20 μm, mix thoroughly according to the ratio of 40% calcium oxide clinker and 60% rice husk ash, and prepare 10kg of concrete internal curing expansion agent IEA-I.

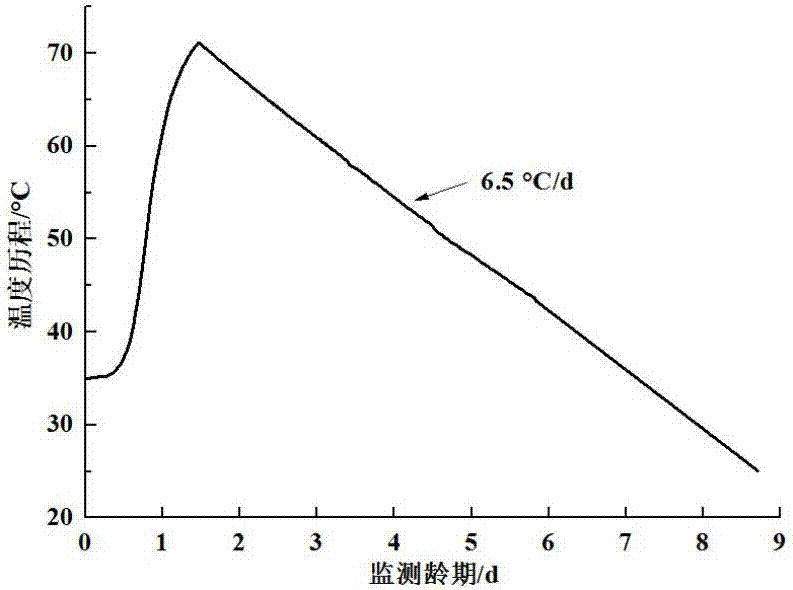

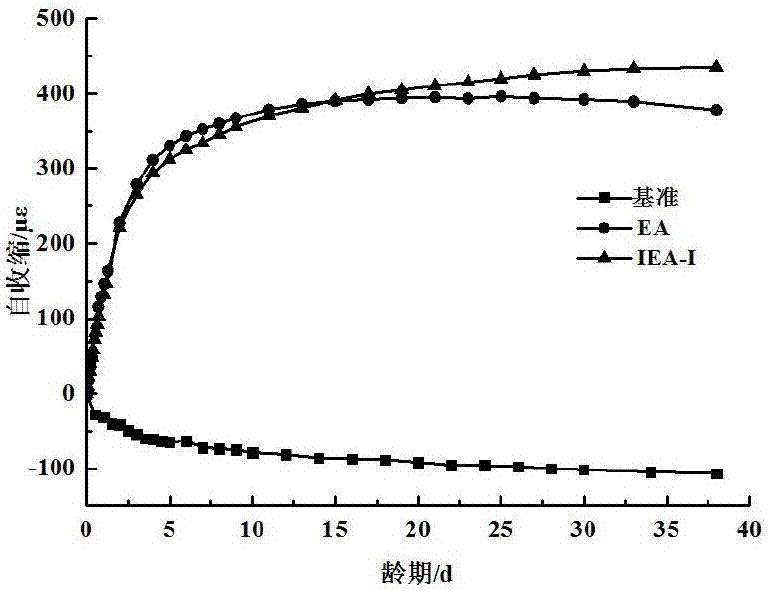

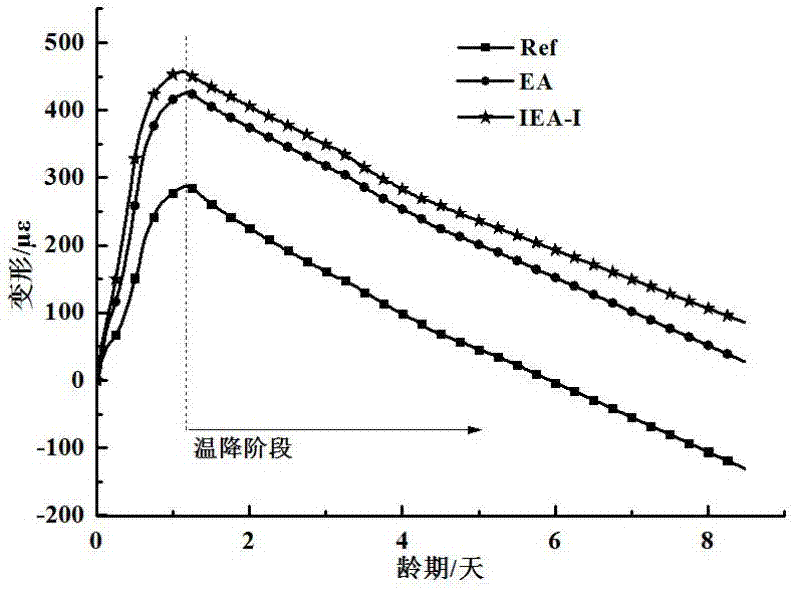

[0037] Concrete was prepared according to the concrete mix ratio of the subway station side wall of a certain rail transit project shown in Table 1, wherein the reference group was without adding any expansion agent, the EA group was mixed with commercially available calcium oxide expansion agent, and the IEA-I group was mixed with Add the internal curing type expansion agent IEA-I prepared by the present invention, and the two kinds of expansion materials are all added to the concrete in the form of internally admixing instead of the cementitious material, and the admixture is 8%, wherein, according to the 24h water absorption rat...

Embodiment 2

[0047] The commercially available calcium oxide expanded clinker is crushed into a specific surface area of 400m 2 / kg of powder, choose 700 grade shale light aggregate, crush it to a particle size range of 5-80 μm, and its 24h liquid absorption rate is 23.5%, according to calcium oxide clinker 40%, ground light aggregate 60 The ratio of % is fully mixed to prepare 10kg of concrete internal curing expansion agent IEA-II.

[0048] Concrete was prepared according to the mix ratio of the side wall concrete of a rail transit project subway station shown in Table 3, wherein the benchmark group was without adding any expansion agent, the EA group was mixed with commercially available calcium oxide expansion agent, and the IEA-II group was mixed with Add the internal curing expansion agent IEA-II prepared by the present invention, and the two kinds of expansion materials are all added to the concrete in the form of internal admixture instead of the cementitious material, and the ad...

Embodiment 3

[0057] The commercially available calcium oxide expanded clinker is crushed into a specific surface area of 300m 2 / kg powder, choose 900 grade shale light aggregate, crush it to a particle size range of 80-160μm, and its 24h liquid absorption rate is 15.6%, according to calcium oxide clinker 30%, ground light aggregate 70 The ratio of % is fully mixed to prepare 10kg of concrete internal curing expansion agent IEA-III.

[0058] Concrete was prepared according to the concrete mix ratio of the subway station floor of a certain rail transit project shown in Table 5, wherein the reference group was without adding any expansion agent, the EA group was mixed with commercially available calcium oxide expansion agent, and the IEA-III group was mixed with According to the concrete internal curing expansion agent IEA-III prepared in the present invention, two kinds of expansion materials are added into the concrete in the form of internally admixing instead of the cementitious materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com