High-resistance mechanical load solar energy battery component and manufacturing method thereof

A technology of solar cells and solar cells, which is applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high conversion efficiency that cannot be fully reflected and high power loss, and achieve optimized battery layout, reduced operation and maintenance costs, and failure The risk reduction effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

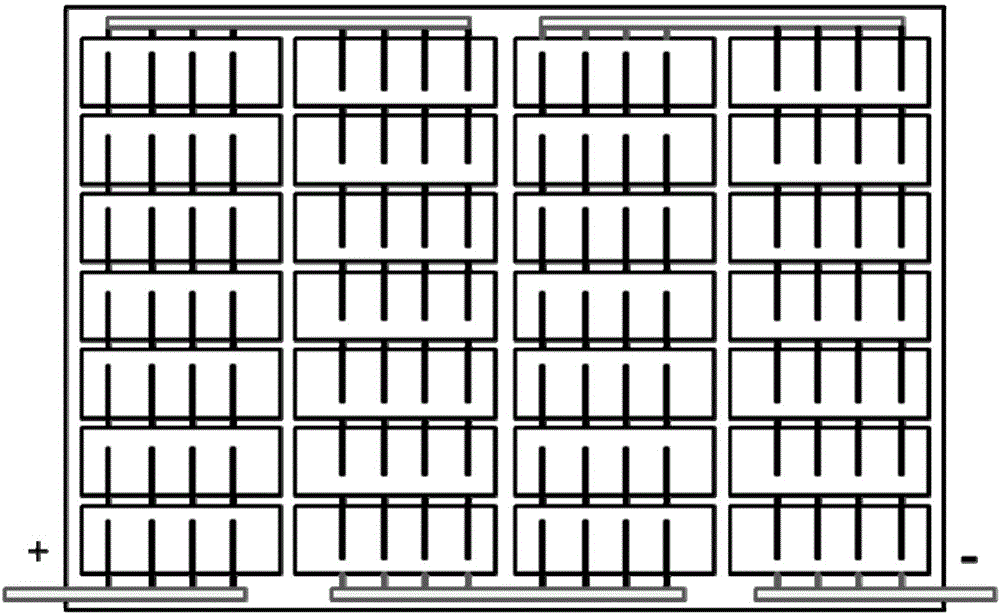

Embodiment 1

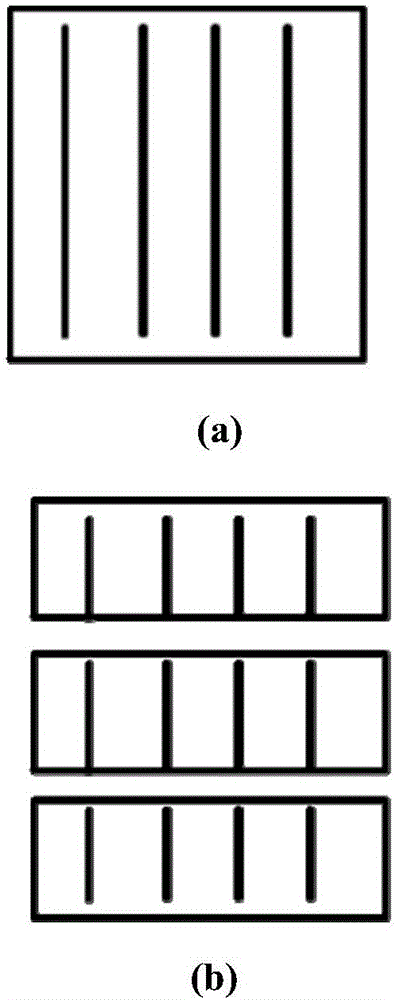

[0034] The high mechanical load resistance solar cell assembly provided in this embodiment includes a cover plate material, EVA and / or POE, battery strings, EVA and / or POE and a backsheet material, and the battery strings are formed by connecting multiple battery strings, The battery string is composed of a plurality of small cells connected in series. The small cells are cut from p-type solar cells. After cutting, a number of small cells with the same width are obtained. The length and width of each small cell are different. (each A small battery sheet) includes long sides and short sides, and the length and width of the cover material are different, and its (cover material) also includes long sides and short sides.

[0035] Among them, the p-type solar cell adopts a right-angle p-type conventional polycrystalline cell with single-sided light transmission. The front side of the cell is the emitter, and the back side is the aluminum back field. The length and width of the p-typ...

Embodiment 2

[0046] The structure of the solar cell assembly with high mechanical load resistance provided in this example is the same as that in Example 1, the difference is that this example uses a p-type conventional back passivated cell to make the assembly, the front side of the cell is the emitter, and the back side is the local contact Back passivation structure, the battery slices are connected in series along the direction parallel to the long side of the small battery slices.

[0047] Among them, the p-type solar cell adopts a right-angle p-type conventional back passivation cell with single-sided light transmission. The front side of the cell is the emitter, and the back side is a partial contact back passivation structure. The size is 156mm×156mm.

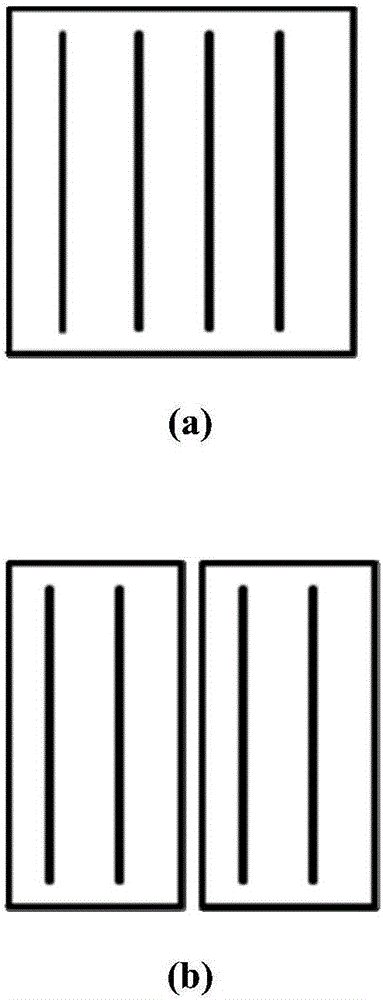

[0048] Cut each solar cell into 2 small cells (of the same size), where the length and width of each small cell after cutting are inconsistent, including the long side and the short side, the size of the long side is 156mm, and the ...

Embodiment 3

[0057] The structure of the solar cell module with high mechanical load resistance provided in this example is the same as that in Example 1, the difference is that this example uses an n-type double-sided light-transmitting round corner single crystal cell, and the specific size is 156.75mm×156.75mm , to make components, the positive and negative electrodes of the battery are distributed on the front and back of the battery, and the front and back of the battery are respectively provided with 4 busbars, and the serial connection direction of the battery is parallel to the short side of the small battery.

[0058] Cut each solar cell into two small cells of the same size. The length and width of each small cell after cutting are inconsistent, including the long side and the short side. The width of the long side is 156.75mm, and the width of the short side is 78.38mm.

[0059] The distance between two adjacent small cells is 5mm.

[0060] The cut 12 small battery pieces are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com