High-speed PCB and difference via hole impedance control method

A technology of PCB board and via hole, which is applied to the formation of electrical connection of printed components, electrical connection of printed components, printed circuit components, etc., can solve problems such as reducing the performance of high-speed PCBs, reducing the performance of electronic products, and discontinuous impedance of transmission lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

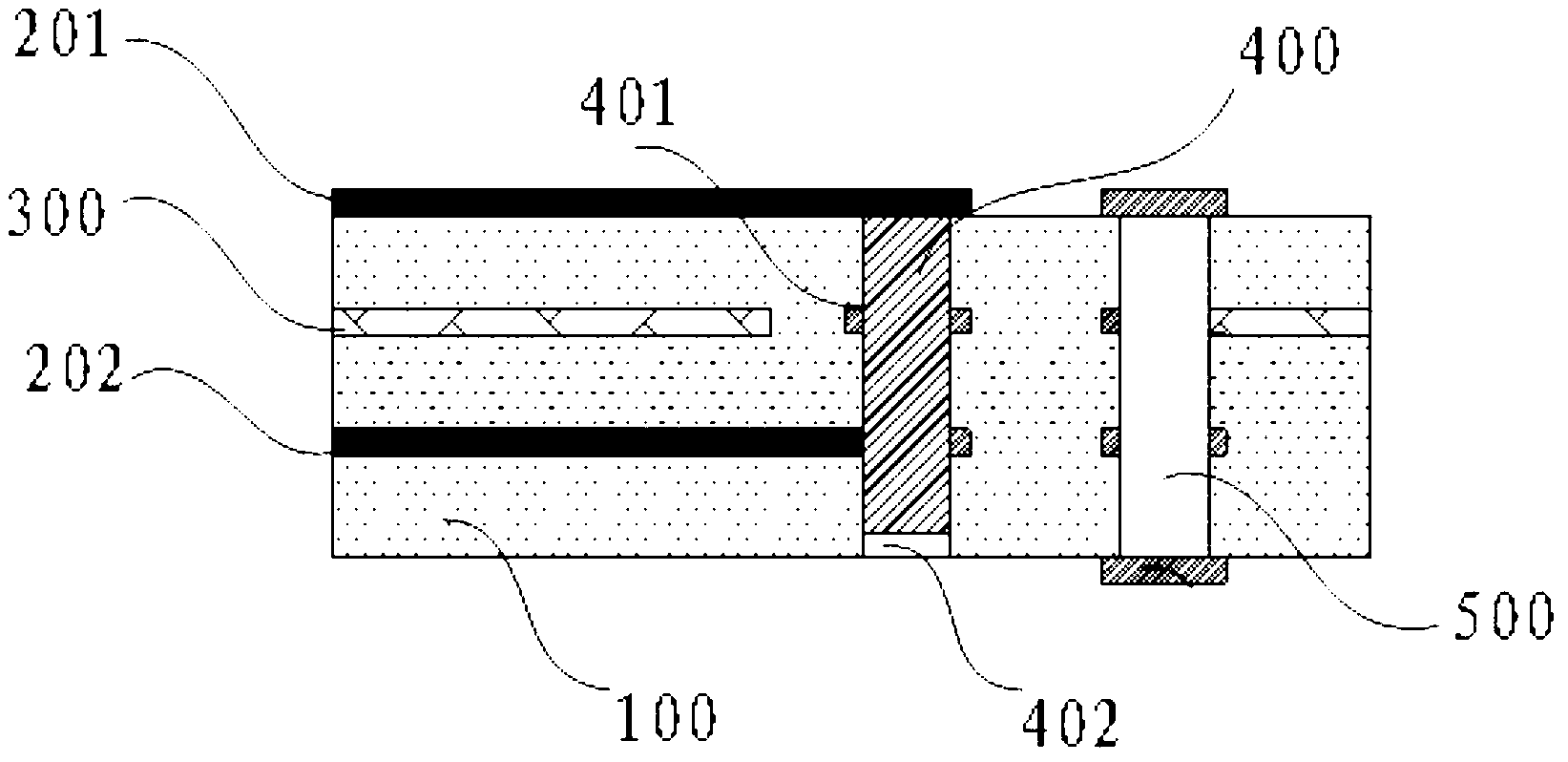

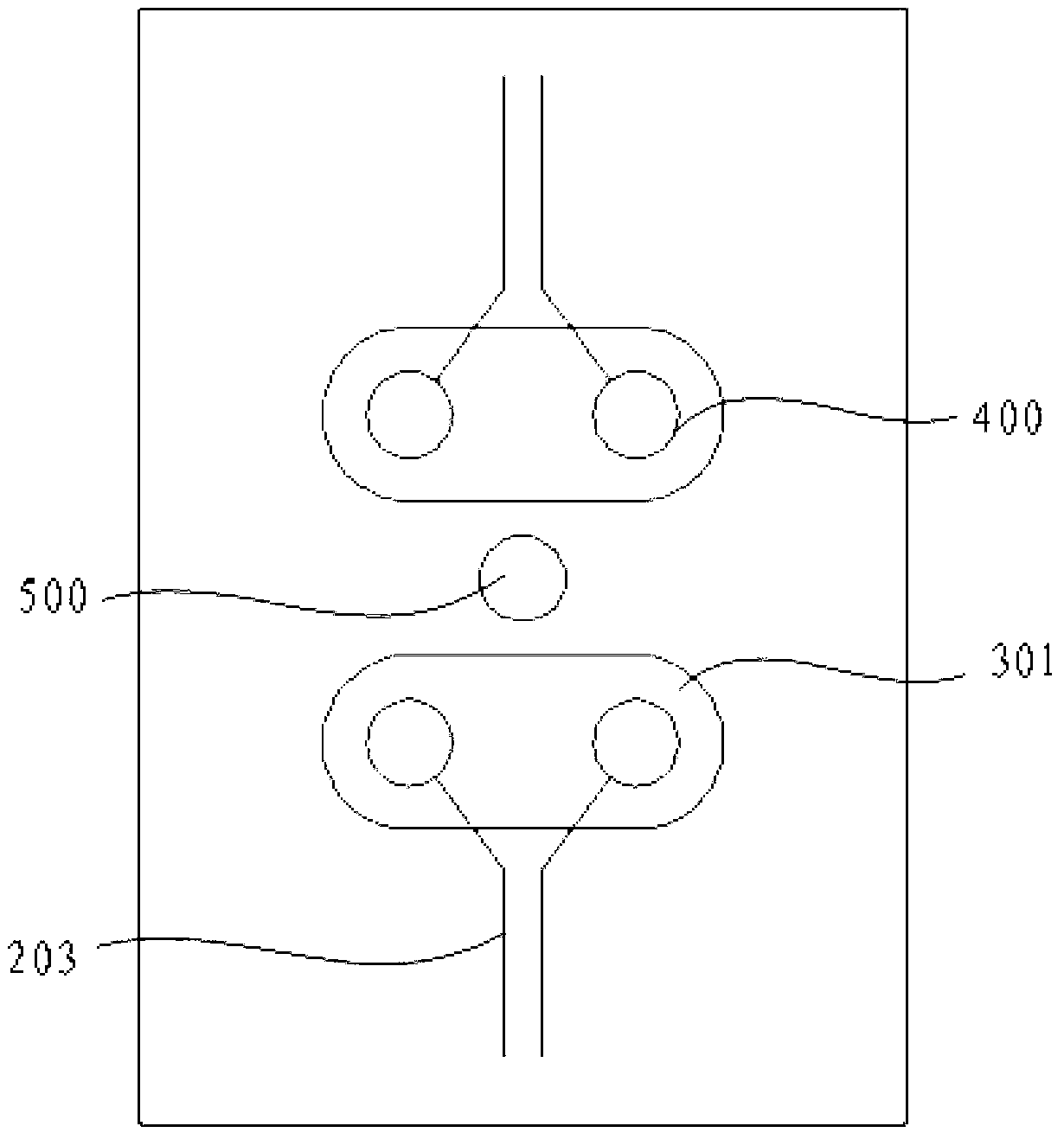

[0028] refer to figure 1 , 2 , in an embodiment of the high-speed PCB board of the present invention, a high-speed PCB board includes an insulating layer 100, a circuit layer, and a reference layer 300, and a differential transmission line 203 is arranged in the circuit layer, and the circuit layer includes a circuit layer arranged on the insulating layer 100. The outer outer circuit layer 201 and the inner circuit layer 202 arranged in the insulating layer 100, the reference layer 300 is arranged between the inner circuit layer 202 and the outer circuit layer 201, the reference layer 300 is provided with an anti-pad 301, and the differential transmission line 203 of each circuit layer is connected through a via hole 400, and a ground shielding hole 500 is provided around the via hole 400, and the via hole 400 is connected between the reference layer 300 and the inner layer circuit layer. A pad is provided at the position 202 , and a stub 402 is provided in the via hole 400 ....

Embodiment 2

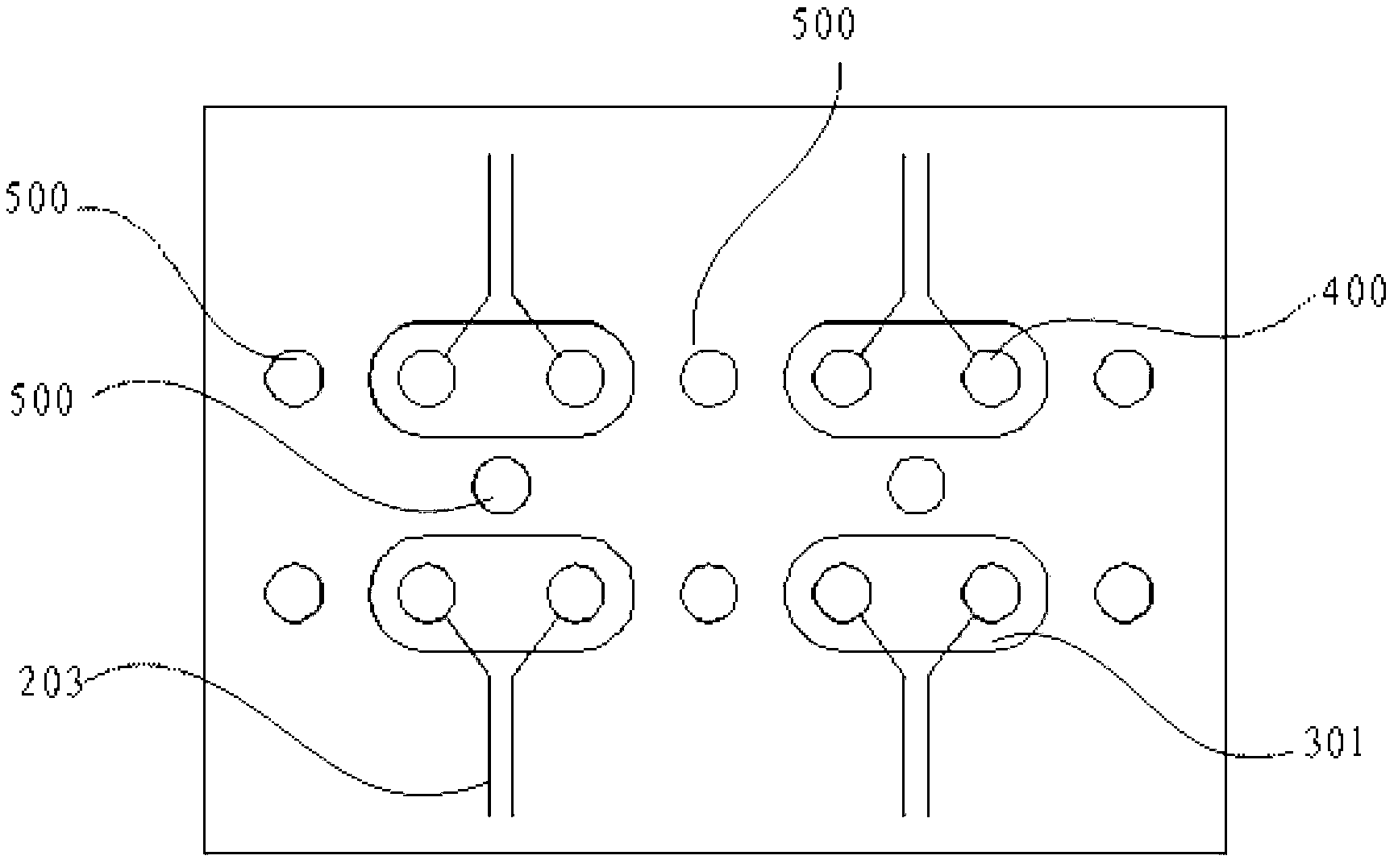

[0031] Such as image 3 As shown, there are three ground shielding holes 500 . The three ground shielding holes 500 are arranged in a triangle around the via hole 400 .

[0032] When the signal passes through the via hole 400, coupling will occur, thereby reducing the integrity of the signal. By setting the ground shielding hole 500 around the via hole 400, the coupling of the via hole can be reduced, thereby reducing the transmission loss of the via hole 400 and improving the integrity of the signal. , the non-connection pads 401 and stubs 402 will affect the impedance of the via hole 400, and the impedance of the via hole 400 can be compared with the impedance of the differential transmission line 203 through a suitable number of non-connection pads 401 and short columns 402 of a suitable size. Consistent, thereby reducing signal reflection and improving signal integrity.

[0033] A controllable design method for differential via impedance of high-speed PCB board:

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com