Patents

Literature

88results about How to "Crack control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

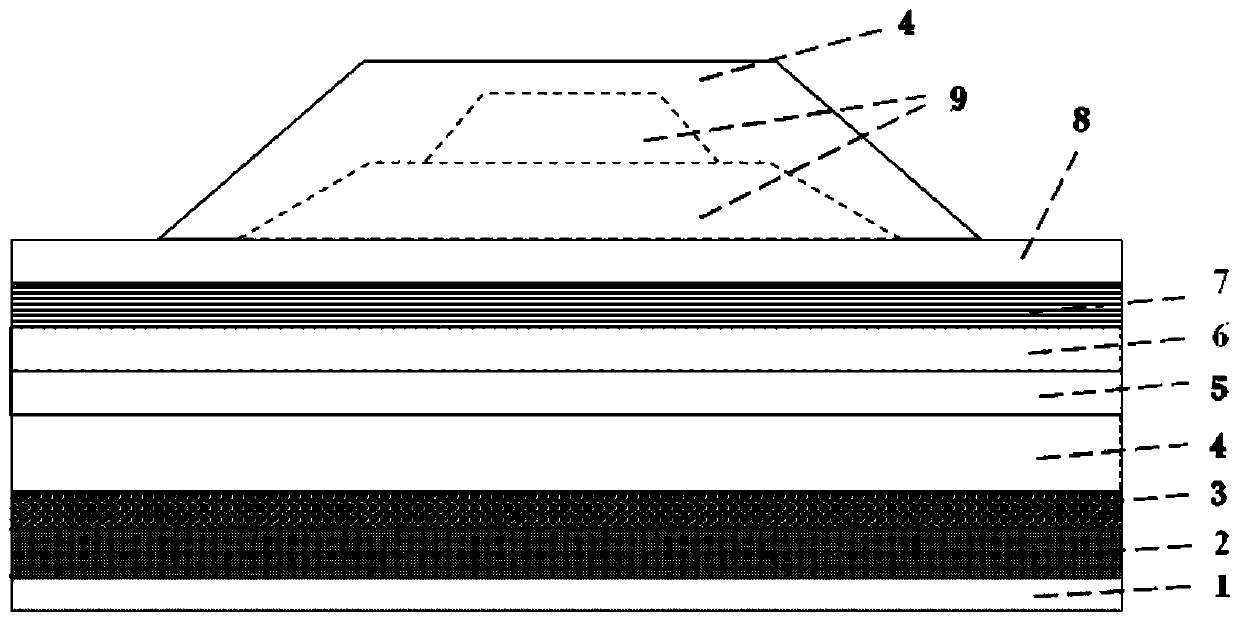

Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

InactiveCN101481930AHigh strengthLimit or improve cracksSolid waste managementBuilding reinforcementsFiberRebar corrosion

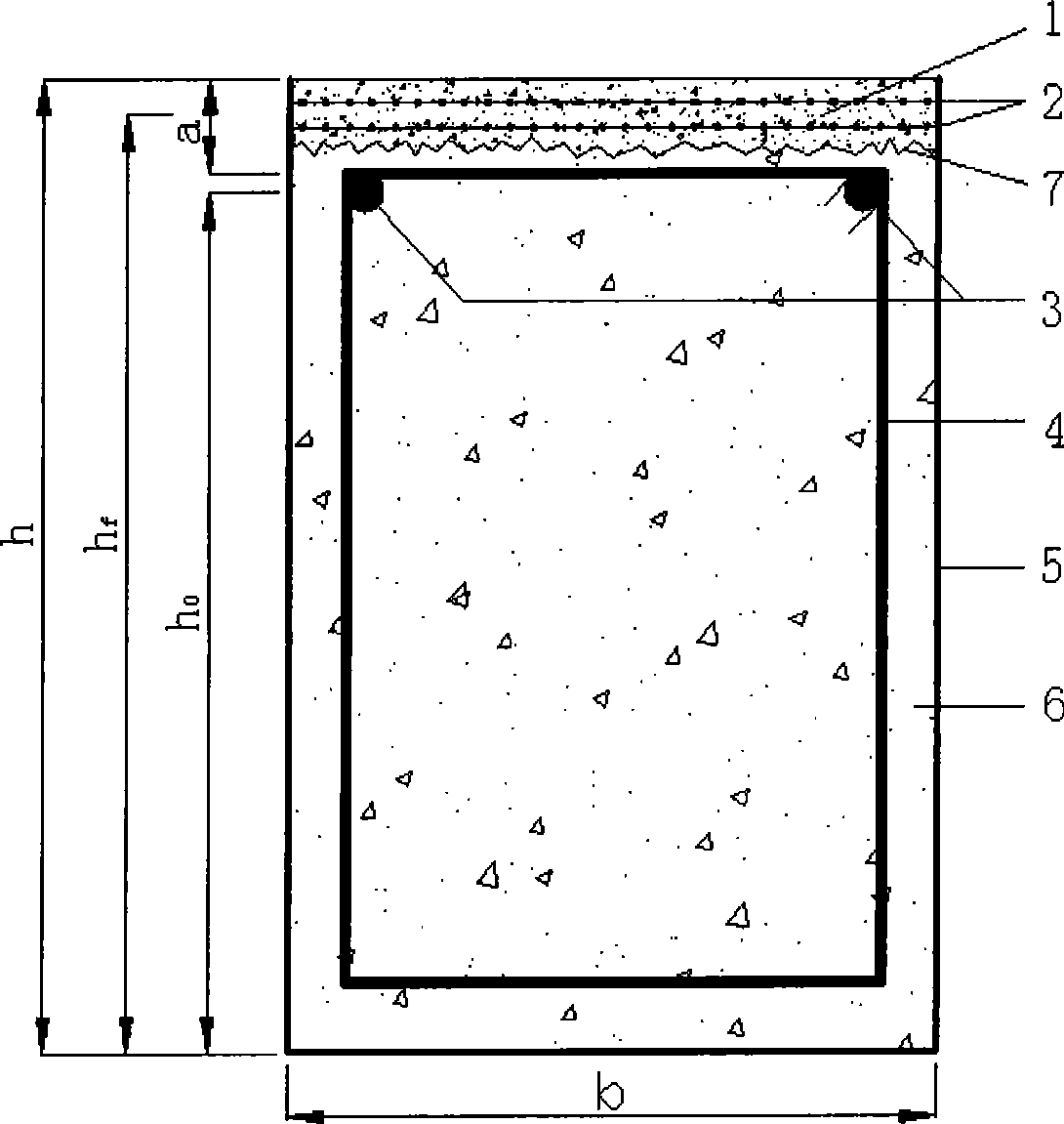

The invention belongs to the technical field of concrete reinforcement, relating to utilizing fiber mesh grids to enhance the concrete strength. The arrangement of structural reinforcing steel, the thickness of concrete protective layers of main stress ribs and the grade of the concrete strength of the invention are designed according to the design criterion of a reinforced concrete structure. The invention is characterized in that before the initial setting of the concrete, fine concrete and the fiber mesh grids are cast on the outer side of the stretched and drawn area of the structure or the external surface of a large-scale integral structure, the total thickness of the fiber mesh grids and the fine concrete ranges from 10mm to 20mm, concrete with equal thickness of external surfaces are replaced, and the fiber mesh grids are evenly distributed in the fine concrete. The grid type or the plate type structure of the invention can adopt the structure of replacing partial reinforcing steel with the fiber mesh grids. The invention can effectively control cracks and solve the problems of concrete cracking and reinforcing steel corrosion, and has the advantages of firm bonding of the boundary surfaces of the fine concrete and the concrete, light self weight, low production cost, corrosion resistance, safe and durable usage, etc.

Owner:DALIAN UNIV OF TECH

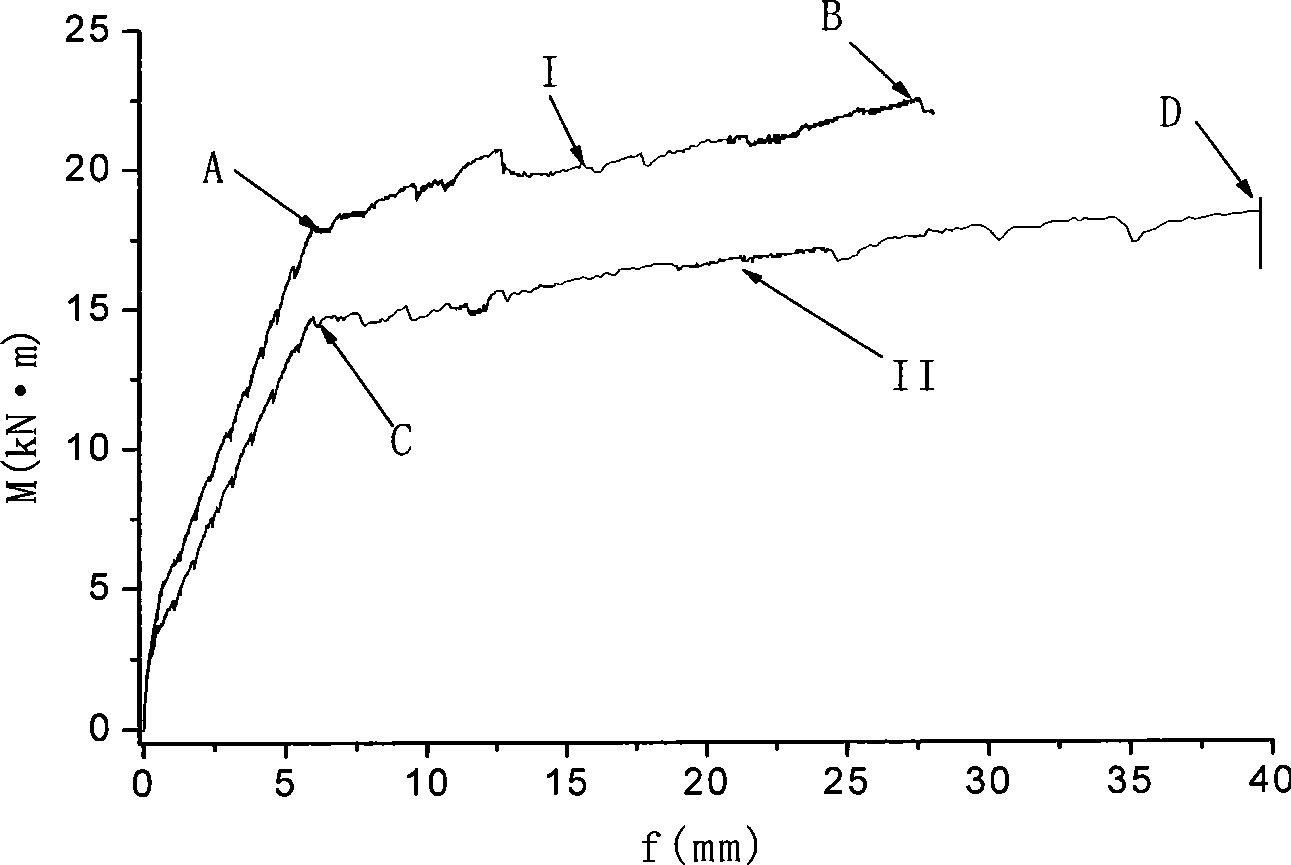

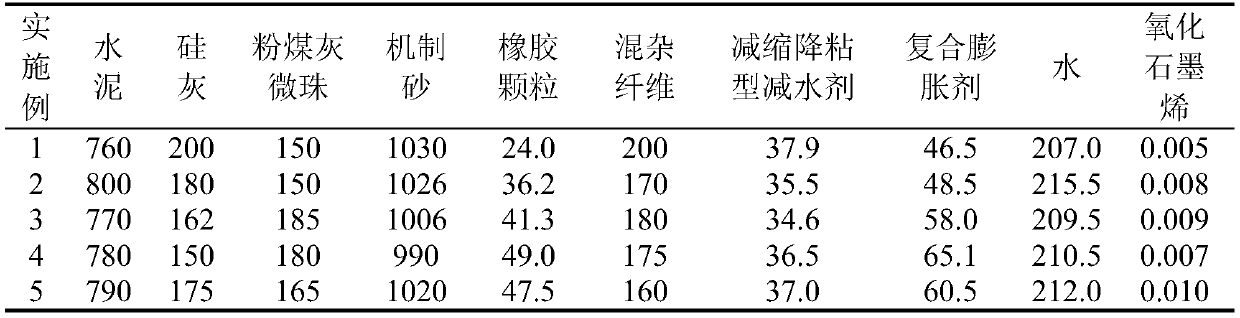

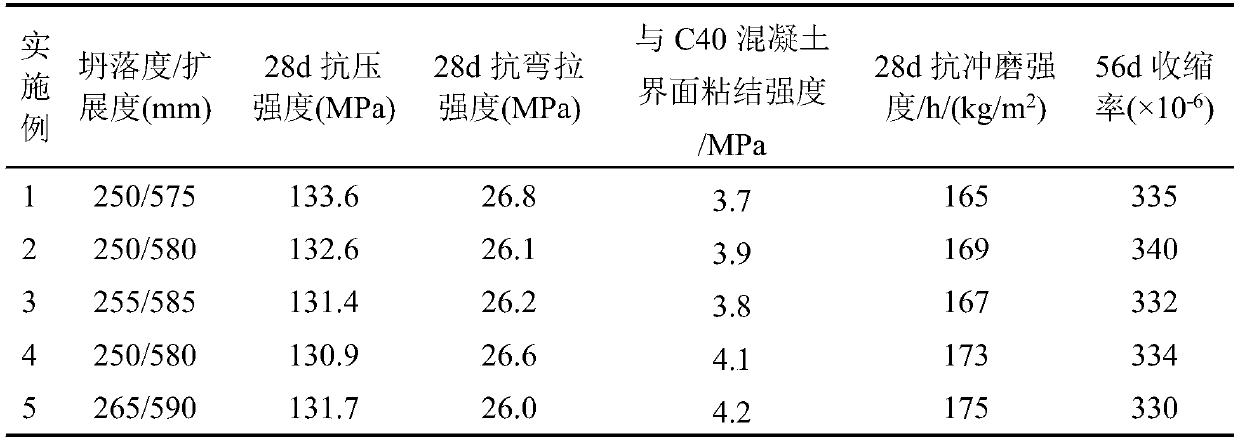

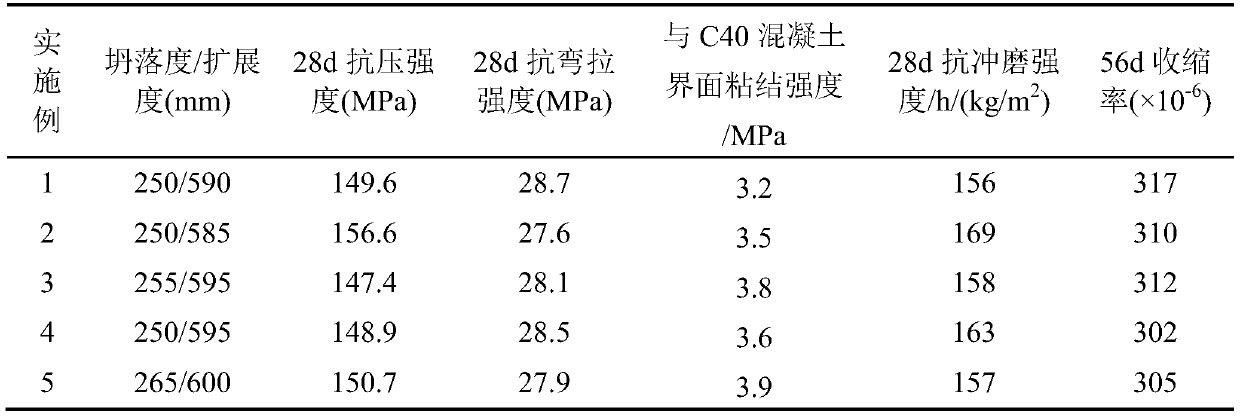

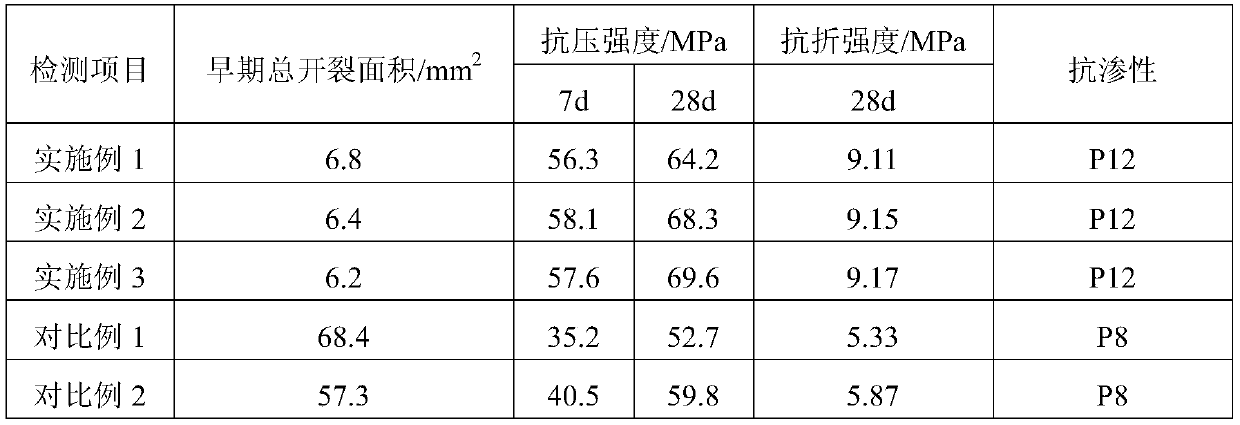

Graphene oxide anti-abrasion ultra-high toughness concrete and preparation method and application thereof

InactiveCN110683809AImprove impact toughnessImprove wear resistanceSolid waste managementWater reducerSilica fume

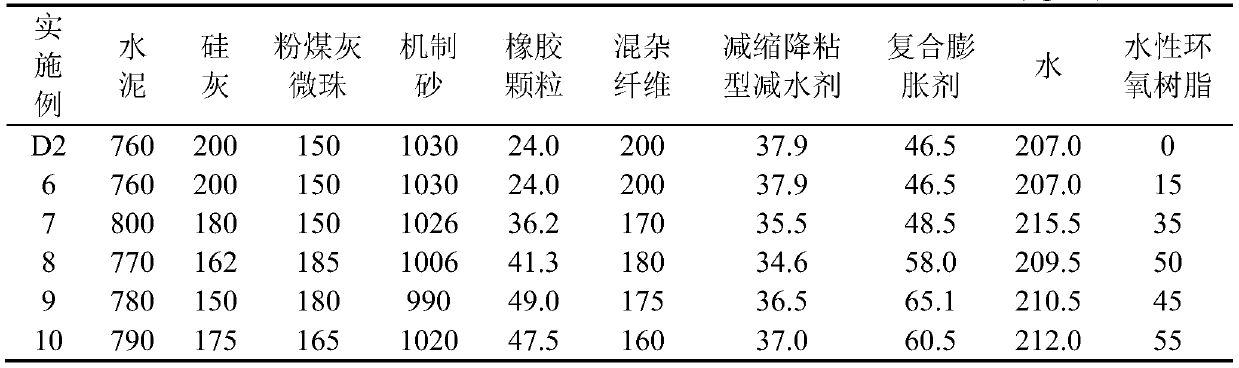

The invention discloses a graphene oxide anti-abrasion ultra-high toughness concrete. The concrete comprises the following raw materials in parts by weight: 700 to 800 parts by mass of cement, 150 to200 parts by mass of fly ash microbead, 150 to 200 parts by mass of silica fume, 900 to 1080 parts by mass of machine-made sand, 23 to 50 parts of hydrophilic rubber particle, 160 to 200 parts of hybrid fibers, 34.5 to 37.95 parts of shrinkage and viscosity reducing water reducing agent, 0.005 to 0.01 part of graphene oxide, 46 to 69 parts of composite expansion agent and 207 to 218.5 parts of water; the hybrid fiber is formed by mixing copper plated flat steel fiber, multi-anchor steel fiber and PVA fiber according to the mass ratio of 6-8: 1-2: 1-2. The graphene oxide anti-impact and anti-wear ultra-high toughness concrete prepared by the invention has excellent impact toughness and anti-wear performance, good volume stability and high interface bonding strength between new and old concrete.

Owner:湖北省高创公路工程咨询监理有限公司 +2

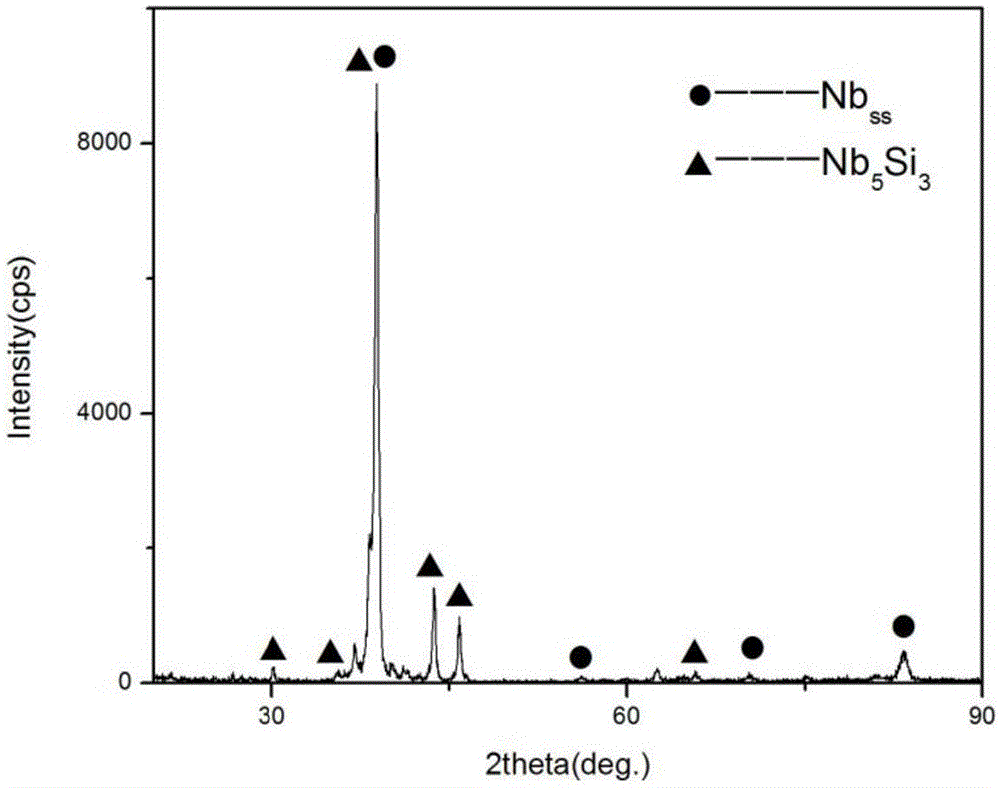

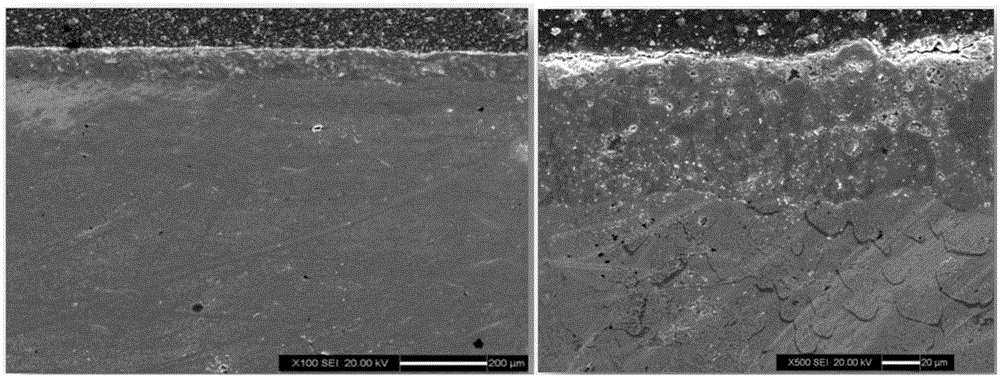

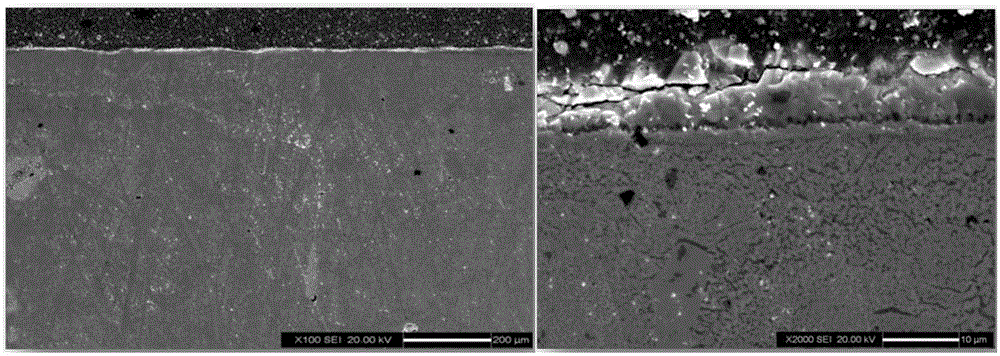

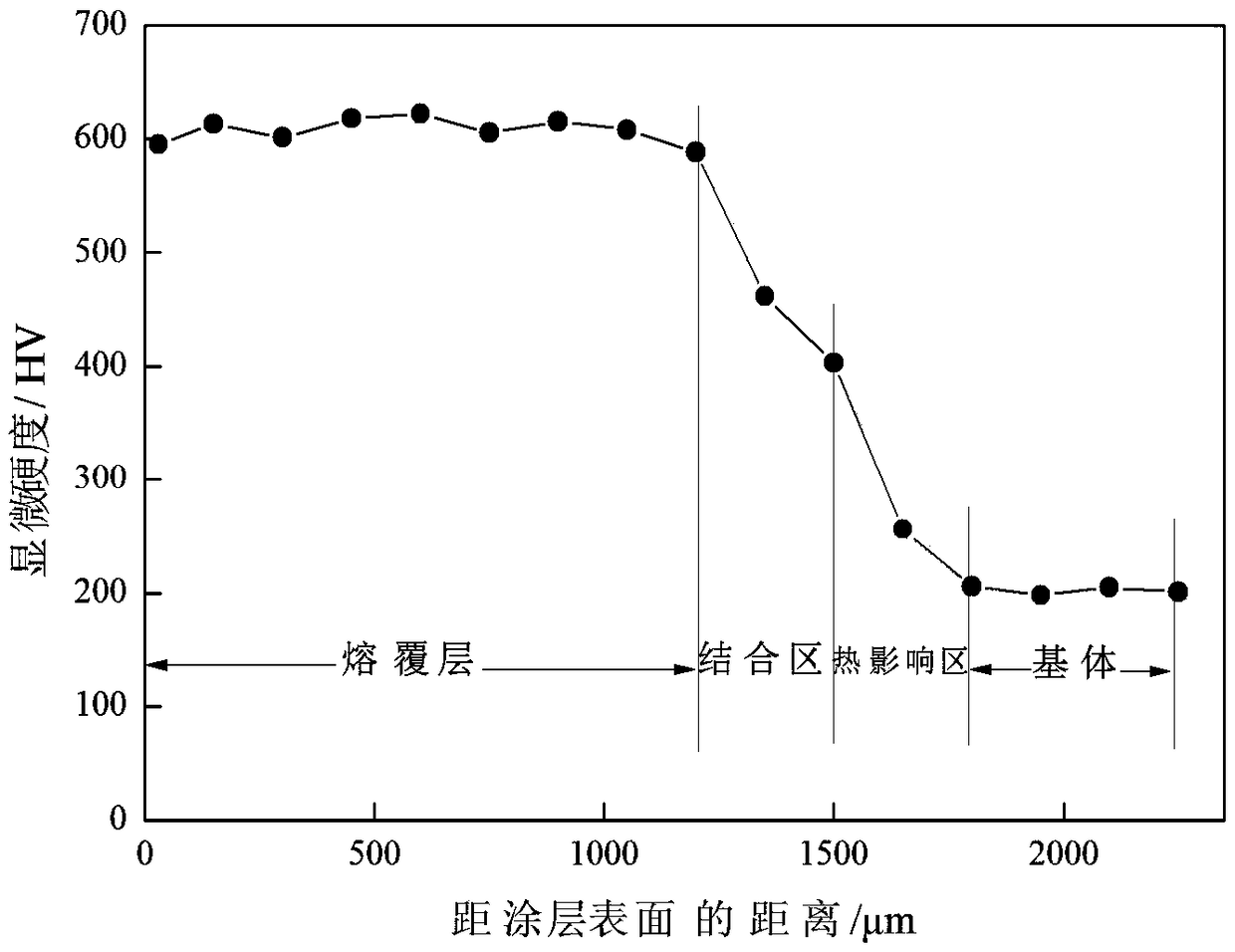

Method for improving high-temperature oxidation resistance of Nb-Si-based multicomponent alloy

The invention discloses a method for improving the high-temperature oxidation resistance of Nb-Si-based multicomponent alloy and belongs to the field of ultrahigh-temperature alloy materials. According to the method, high-energy laser beams are made to act on the surface of an Nb-Si-based multicomponent alloy sample under the protection of argon gas by means of a laser melting device by conducting preheating and setting melting technological parameters reasonably, so that the surface of the alloy is molten and solidified rapidly, and a surface remelting layer with fine, a uniform and compact structure is formed, and thus the high-temperature oxidation resistance of the Nb-Si-based multicomponent alloy is improved by refining the structure. According to the method, the phenomenon that cracks are generated easily in the rapid solidification process of brittle alloy is avoided effectively by adding the preheating procedure; meanwhile, the surface remelting layer and a base body are combined in a metallurgy mode, falling is unlikely to happen when the alloy is in service, and the practicability is high.

Owner:BEIHANG UNIV

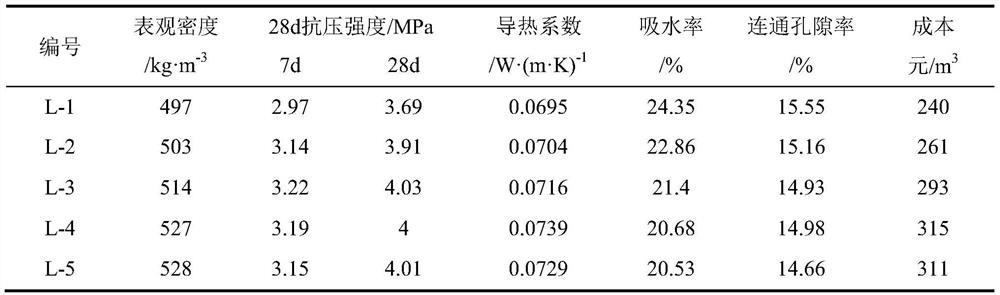

Non-autoclaved lightweight thermal insulation particle aerated concrete block and preparation method thereof

The invention discloses a non-autoclaved lightweight thermal insulation particle aerated concrete block and a preparation method thereof. The aerated concrete block comprises the following components:50 to 100 parts of cement, 0 to 37.5 parts of fly ash, 0 to 12.5 parts of superfine slag powder, 0 to 50 parts of light particles, 2 to 8 parts of a foaming agent, 0 to 5 parts of a coagulation accelerator, 0.025 to 0.175 part of a foam stabilizer, 0.2 to 1.4 parts of a water reducing agent, 0.1 to 0.7 part of a water repellent, 0 to 0.6 part of fibers and 30 to 60 parts of water. The aerated concrete block has the advantages of light weight, heat preservation and insulation, energy conservation, high strength, simple maintenance process and low cost, and solves the problems of non-ideal heatpreservation and insulation performance and complex maintenance process of the existing aerated concrete block.

Owner:CENT SOUTH UNIV +3

Method for reinforcing concrete structural part through fiber grid ribs and early-strength self-compacting mortar

ActiveCN104328924AShort operating timeNot conducive to reinforcementBuilding repairsFiberReinforced concrete

The invention relates to a method for reinforcing a concrete structural part through fiber grid ribs and early-strength self-compacting mortar. The method comprises the following steps of firstly removing floating dust and loose particles on the surface of the reinforced concrete structural part, then carrying out notching processing, and then removing concrete dust and wetting; then smearing or spraying the early-strength self-compacting mortar which is stirred in advance on the surface of the processed concrete structural part, wherein the thickness of the early-strength self-compacting mortar is higher than the surface of the processed concrete structural part; then laying the fiber grid ribs on the early-strength self-compacting mortar; and finally smearing or spraying the early-strength self-compacting mortar which is stirred in advance on the surfaces of the fiber grid ribs to guarantee that the early-strength self-compacting mortar uniformly covers the fiber grid ribs and exceeds the height of the fiber grid ribs. According to the construction process of the invention, the crack distribution of the concrete structural part is effectively improved, the crack propagation of the concrete structural part is effectively controlled, the structural rigidity, the bearing capacity and the durability are improved, and the method can be widely used for the anti-bending, anti-shearing, anti-pressing and anti-seismic reinforcing of concrete structures in various types.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Oil-resistant wear-resistant coating material

InactiveCN105968888AGood antifouling performanceRelieve interface residual stressAntifouling/underwater paintsPaints with biocidesIonWear resistant

The invention discloses an oil-resistant wear-resistant coating material, which is prepared from the following raw materials (by weight): 5-8 parts of aluminium oxide, 12-15 parts of glass glaze, 13-15 parts of triethoxyvinylsilane, 70-80 parts of zirconia ceramic powder, 8-10 parts of alumina sol, 2-3 parts of copper oxide, 6-8 parts of graphene, a proper amount of anhydrous ethanol and a proper amount of deionized water. By ingenious utilization of adhesion property of glass glaze, the coating has good adhesion with a base material. The prepared coating contains no toxic or harmful substances, has high strength, is simple to prepare, is low-cost, and has a wide range of application.

Owner:MAANSHAN JINSHENG IND DESIGN

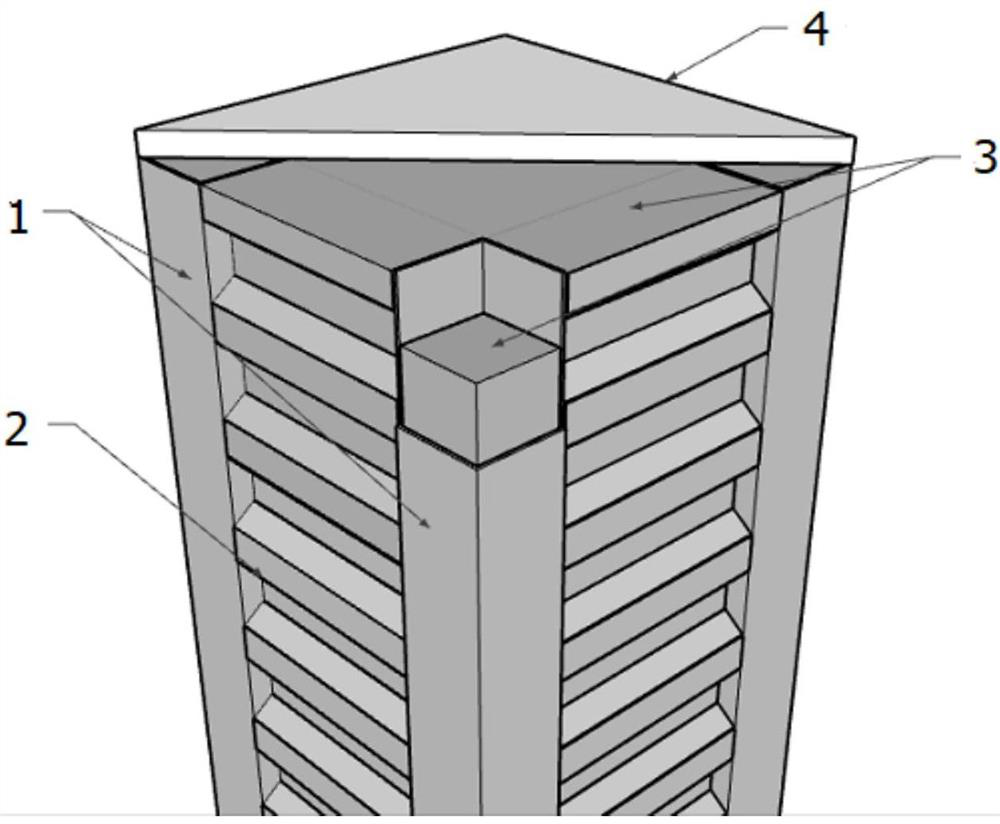

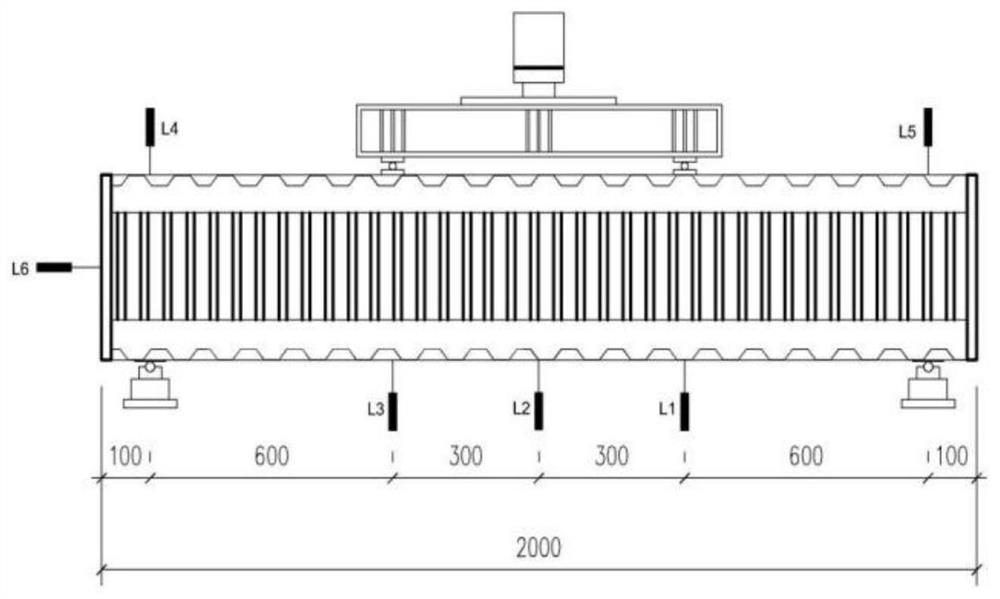

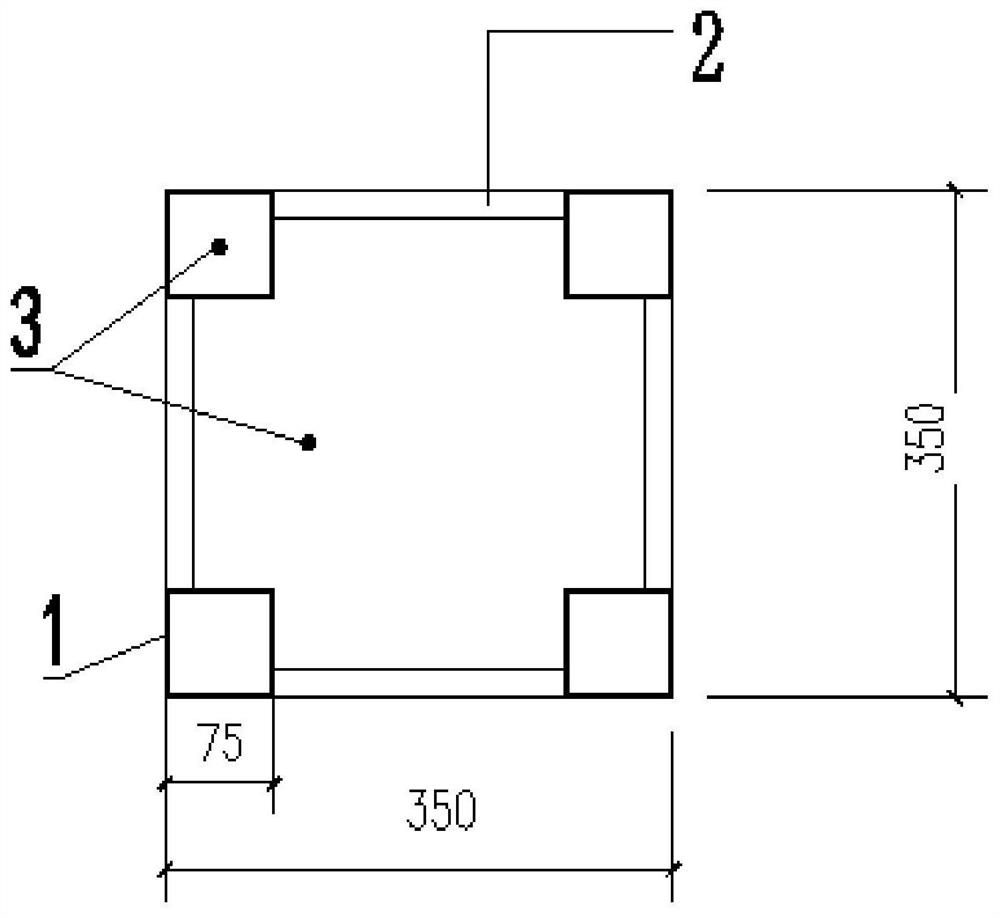

Method for calculating flexural capacity of variable cross-section column

PendingCN111753351AAnti-bending capacity design formula, accurate calculationAccurate calculationGeometric CADDesign optimisation/simulationElement analysisClassical mechanics

The invention discloses a method for calculating the flexural capacity of a variable cross-section column. The method comprises the following steps: S1, calculating and determining a hoop coefficienttheta of a component; and S2, substituting the parameters into a formula to solve the ultimate flexural capacity. The influence of the corrugated plates, the area conversion of the irregular concretesection, the enhancement of the structural constraint effect and other factors are considered, the steel pipe, the corrugated plates and the concrete can be synergistically stressed under the pure bending load, the overall working performance of the combined column is good, and the deflection and cracks of the combined column can be effectively controlled; and the influence of the concrete strength grade on the flexural capacity of the component under the pure bending load is small. The mean value of the ratio of the crustacean column flexural capacity obtained through a calculation formula tothe ultimate bending moment obtained through finite element analysis is 0.999, the variance is 0.009, and the flexural capacity of the crustacean column can be accurately calculated.

Owner:JIANGNAN UNIV

Novel high-toughness fiber reinforced cement-based composite material and preparation method thereof

The invention discloses a novel high-toughness fiber reinforced cement-based composite material and a preparation method thereof. The composite material is prepared from, by weight, 10-20 parts of composite reinforcing fiber, 30-50 parts of portland cement, 15-25 parts of fly ash, 4-10 parts of fine sand, 1-5 parts of dispersing agent, 2-5 parts of water reducing agent, 0.5-3.5 parts of tougheningagent and 12-18 parts of water. According to the composite material, the toughness and crack resistance of the material are improved, the composite reinforcing fiber is uniformly distributed by the dispersing agent, the mechanical properties are changed, the ability of the material to resist deformation is greatly improved, and the probability of occurrence of cracking and fracture of concrete isreduced.

Owner:合肥市闵葵电力工程有限公司

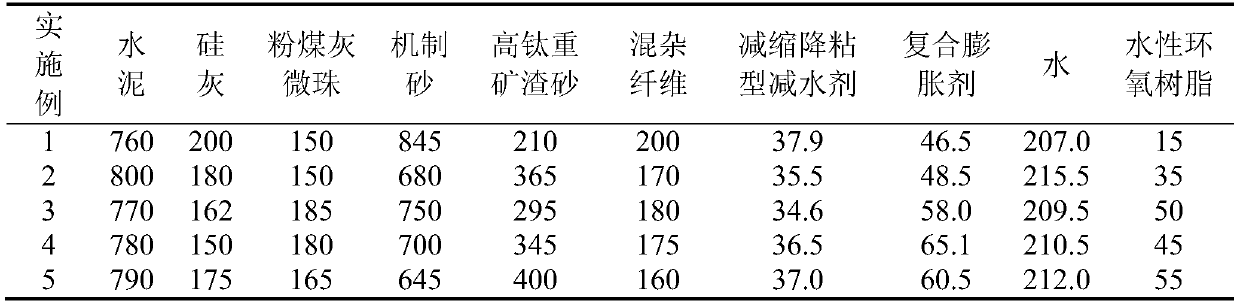

Concrete with low shrinkage, good erosion and abrasion resistance and ultrahigh toughness, and preparation method thereof

The invention discloses a concrete with low shrinkage, good erosion and abrasion resistance and ultrahigh toughness. The concrete is prepared mainly from cement, fly ash microbeads, silica fume, machine-made sand, high-titanium heavy slag sands, hybrid fibers, a waterborne epoxy resin, a composite expansion agent, a shrinkage-reducing and viscosity-reducing water reducer and water. The concrete with low shrinkage, good erosion and abrasion resistance and ultrahigh toughness has the advantages of high mechanical properties, good impact toughness, good abrasion resistance, good interfacial bonding strength of new concrete and old concrete, combination of good working performances and the volume stability, and practical application values.

Owner:WUHAN UNIV OF TECH

Extra-large area concrete floor structure shrinkage control construction technology

The invention relates to an extra-large area concrete floor structure shrinkage control construction technology which effectively controls the extra-large area concrete cracks. When the shrinkage control construction technology is applied, control is mainly performed in the aspects of design and construction technology and comprises design control, material control, construction control and on-site monitoring control. According to the extra-large area concrete floor structure shrinkage control construction technology, the integrality of the floor structure can be effectively ensured, the concrete floor structure durability is improved, construction is reasonably organized, the construction period can be greatly shortened compared with standard arrangement post-cast strip scheme, and the giant economic benefits are brought to engineering projects, particularly industrial projects.

Owner:CHONGQING CONSTR RESIDENTIAL ENG

Anti-crack method for concrete protecting layer

The invention relates to an anti-crack method for a concrete protecting layer and belongs to the field of reinforced concrete construction. The anti-crack method includes: a, preliminarily pouring concrete to a position which is below structural main reinforcement and 10-20mm away from the outermost structural main reinforcement; b, fixing a rebar mesh at a design position after preliminary setting of the concrete and before final setting of the concrete; c, continuing pouring concrete unit pouring is finished; d, leveling and maintaining; wherein the design position is characterized in that the distance between the outer surface of the rebar mesh and the surface of the formed concrete accords to the required minimum protecting layer thickness. By the method which is simple, fast and the like, strength of reinforced concrete can be increased, concrete cracks can be avoided, and concrete appearance quality is increased. In addition, the rebar mesh can be constructed outside a construction site, separated construction is achieved.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

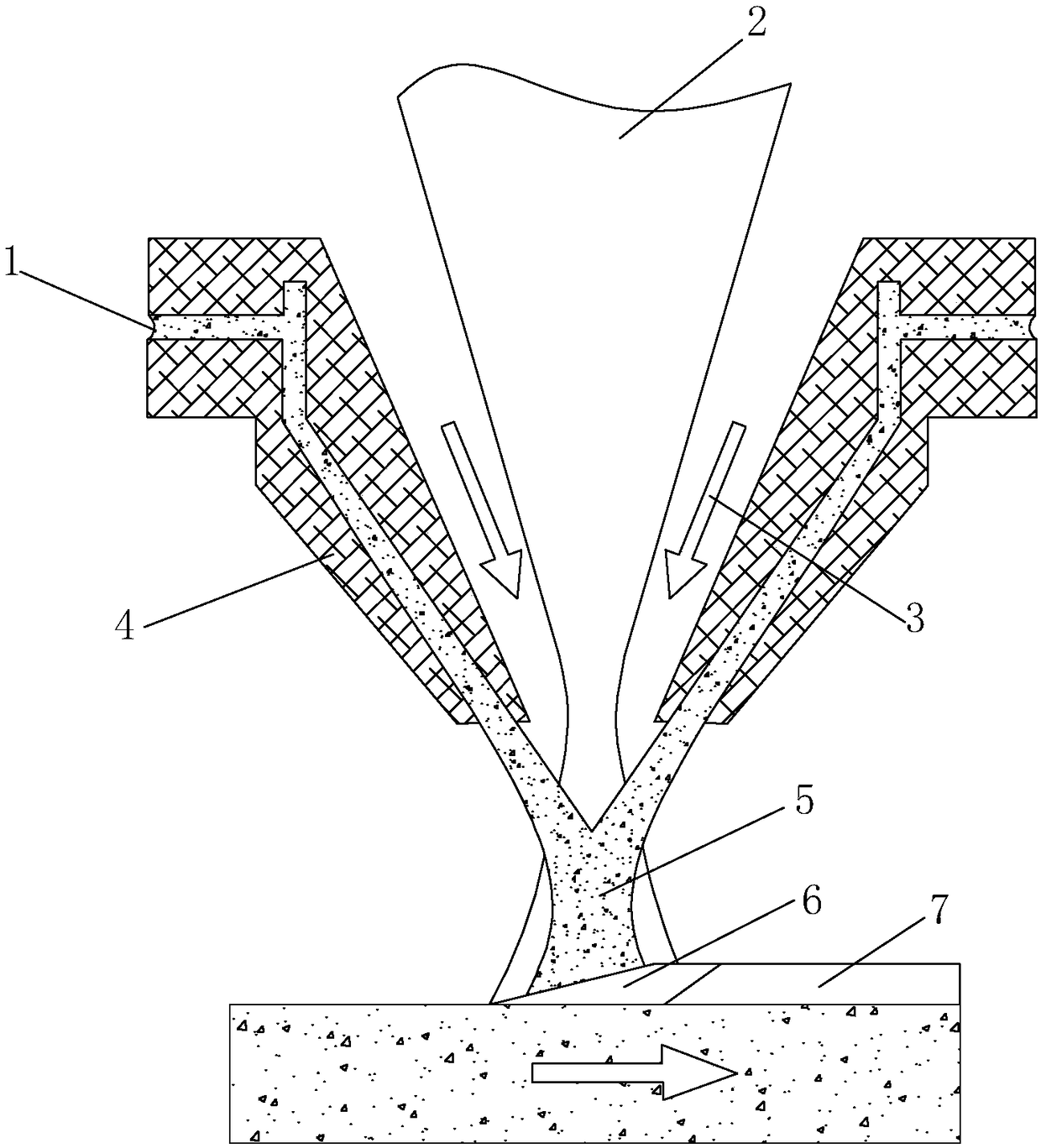

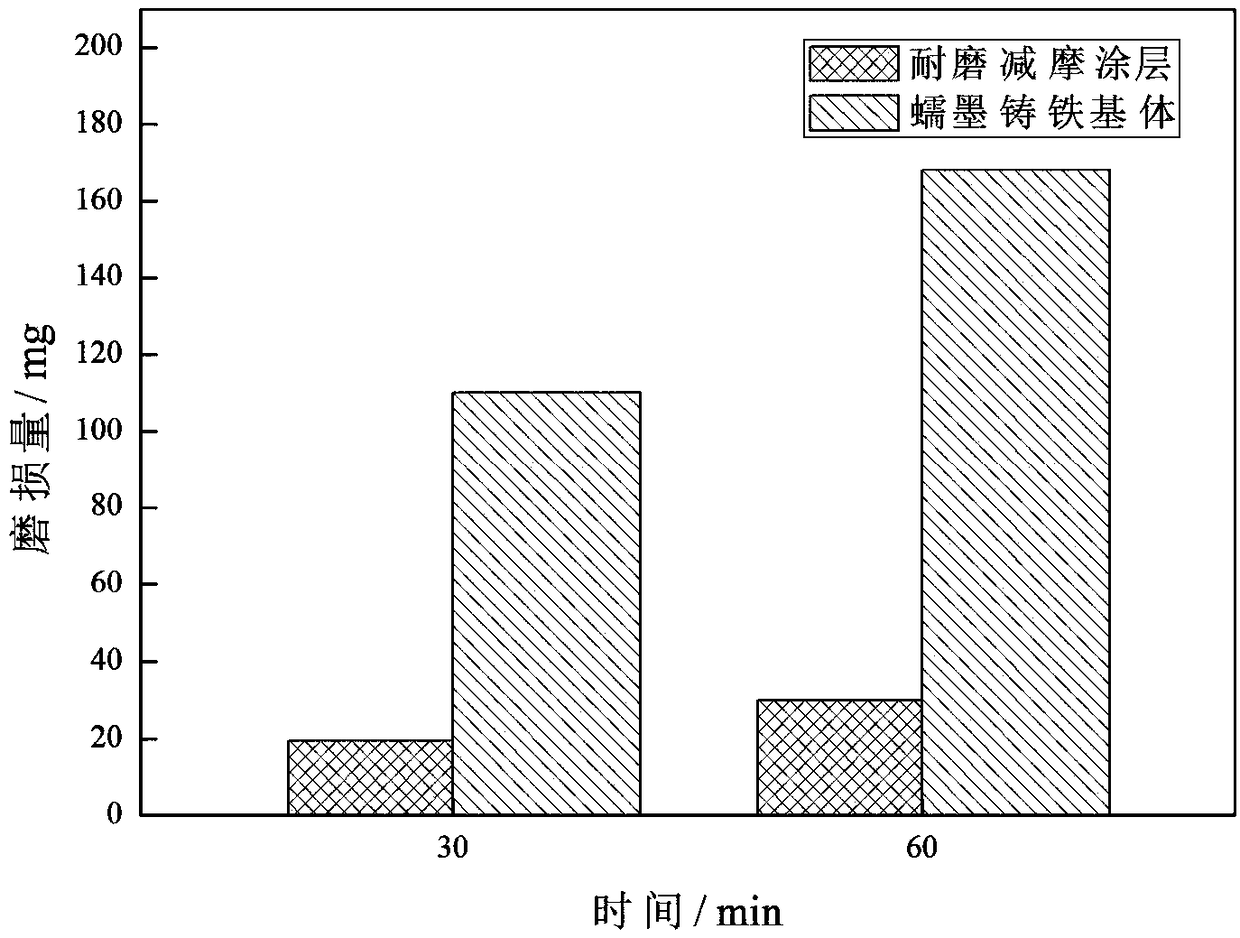

Preparation method for wear-resisting and anti-friction coating on vermicular graphite cast iron surface of cylinder head

InactiveCN109504966AReduce peelingReduce thermal stressMetallic material coating processesCast ironSurface finishing

The invention discloses a preparation method for a wear-resisting and anti-friction coating on a vermicular graphite cast iron surface of a cylinder head. The preparation method for the wear-resistingand anti-friction coating on the vermicular graphite cast iron surface comprises the following steps that firstly, vermicular graphite cast iron after surface treatment is subjected to moderate pre-heat treatment; then a Co-based alloy, Cr3C2 and MoS2 powder are mixed evenly and dried according to the proportion; the laser cladding technology is used to deposit the dried powder on the vermiculargraphite cast iron surface in the form of multi-channel overlap to form a Co-based composite coating; and finally, the Co-based composite coating is subjected to subsequent heat treatment to obtain awear-resisting and anti-friction cladding layer. The advantages are that the probability of peeling, separating and exfoliating can be greatly reduced by good metallurgical bonding, the damage to a matrix material is small, and the matrix deformation and strength loss are smaller; a vermicular graphite cast iron matrix is subjected to pre-heat treatment so that the thermal stress can be effectively reduced, and thus the crack initiation is controlled; the wear-resisting and anti-friction coating prepared is subjected to subsequent heat treatment, so that residual stress after laser cladding isreduced and eliminated, and cracks in the using process of the coating are avoided; the coating prepared has excellent performance, both wear-resisting and anti-friction performance; and the claddingefficiency is high.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

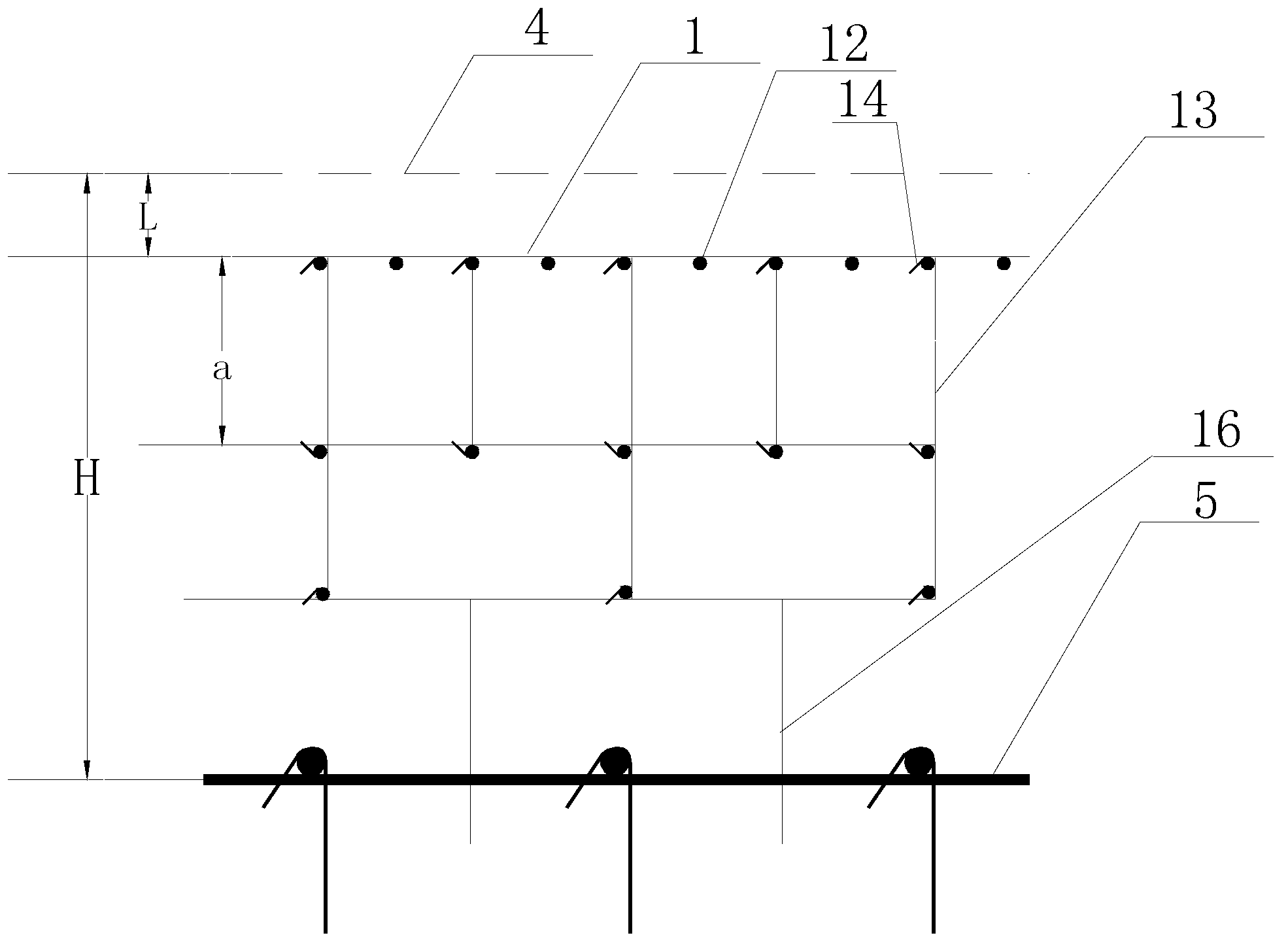

Seasonal frozen soil region subgrade structure and construction method thereof

InactiveCN110184872AGood overall mechanical performanceAvoid uneven settlementRoadwaysClimate change adaptationFreeze thaw resistanceCushion

The invention discloses a seasonal frozen soil region subgrade structure and a construction method thereof. The subgrade structure sequentially comprises a light foam layer, a low-liquid-limit clay layer, a composite geomembrane layer, a subgrade filling layer, a gravel layer, a metalling layer, a medium coarse sand layer and a composite heat preservation cushion layer from bottom to top, whereina fiber concrete layer is arranged on the upper surface of the composite heat preservation cushion layer, the section of the fiber concrete layer is in a double-layer trapezoid shape, and the fiber concrete is coated with a subgrade filler. According to the structure and the method, the service life of the subgrade is prolonged, the overall long-term stability of the subgrade structure of the seasonal frozen soil area is ensured, and the defects of insufficient toughness, poor freeze thawing resistance, easy cracking and weak seepage resistance of plain concrete are overcome.

Owner:JIAMUSI UNIVERSITY

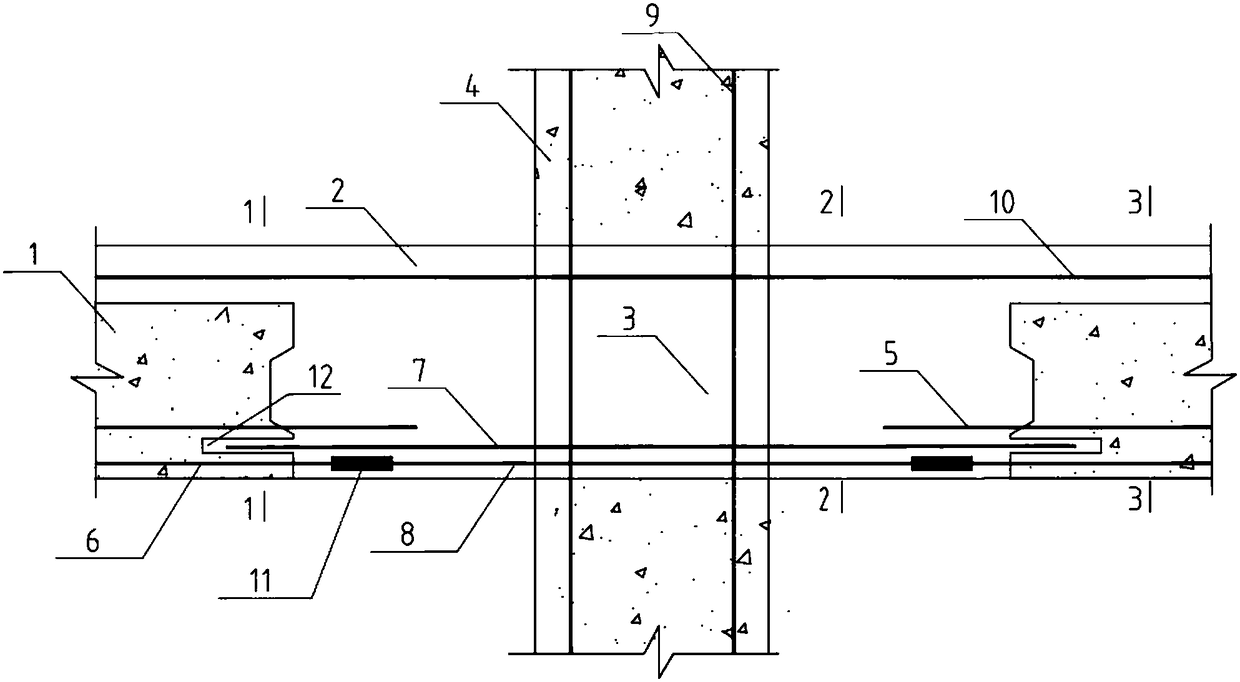

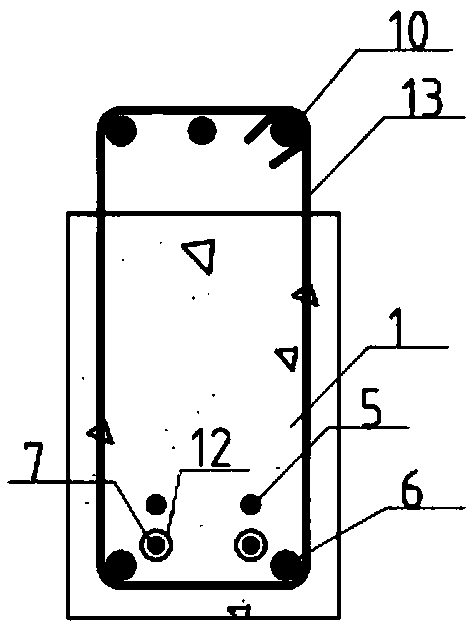

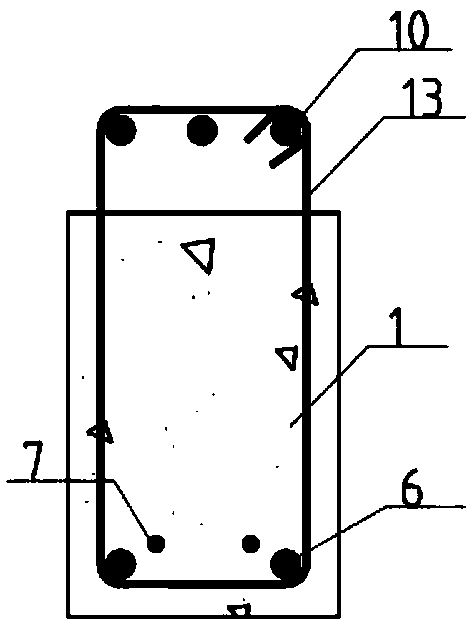

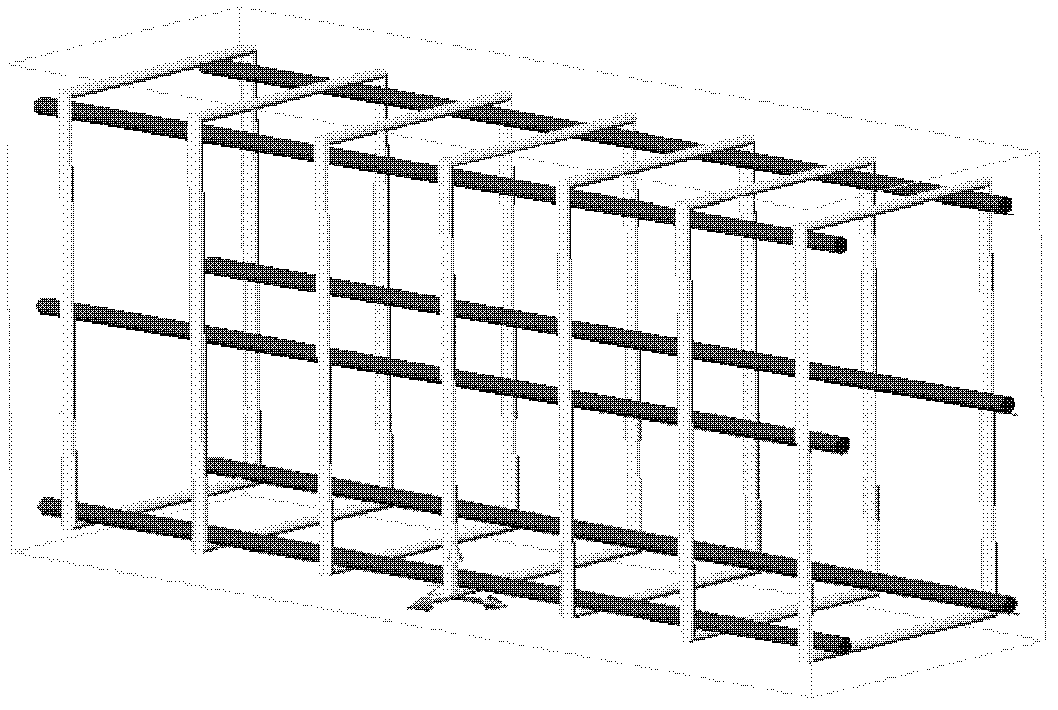

Prefabricated prestress concrete frame beam-column joint with additionally-arranged steel bars and sleeves

InactiveCN108487461AIncrease the reinforcement ratioCrack controlBuilding reinforcementsRebarEngineering

The invention discloses a prefabricated prestress concrete frame beam-column joint with additionally-arranged steel bars and sleeves. The prefabricated prestress concrete frame beam-column joint comprises a beam-column joint post-cast area, prefabricated concrete beams arranged on the horizontal two ends of the beam-column joint post-cast area, prefabricated concrete columns arranged at the upperend and the lower end of the beam-column joint post-cast area, and a superposed beam cast-in-situ area arranged above the prefabricated concrete beams and the beam-column joint post-cast area. Anti-seismic steel bars and the additionally-arranged steel bars are horizontally arranged on the lower portion of the beam-column joint post-cast area, the anti-seismic steel bars and stirrups in the beam-column joint post-cast area are connected, and the superposed beam cast-in-situ area and the beam-column joint post-cast area are cast into a whole. Longitudinal ordinary stress steel bars on the lowerside and the anti-seismic steel bars are connected through sleeves, and the additionally-arranged steel bars extend into bar inserting holes of the ends of the prefabricated concrete beams. Accordingto the prefabricated prestress concrete frame beam-column joint, the on-site construction difficulty is reduced, the size of a beam section and the steel using quantity are reduced, and the development and rotation performance of beam end plastic hinges and the anti-seismic performance such as integrity and ductility of the beam-column joint are ensured.

Owner:SOUTHEAST UNIV

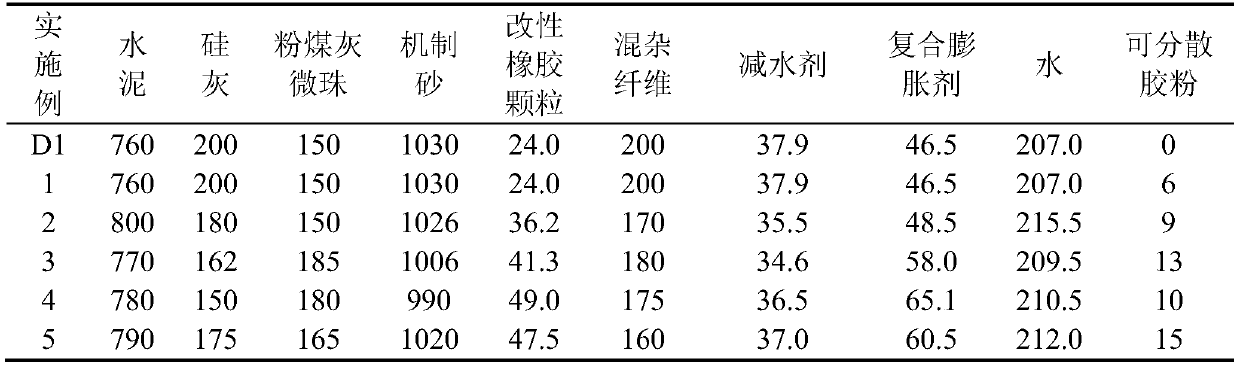

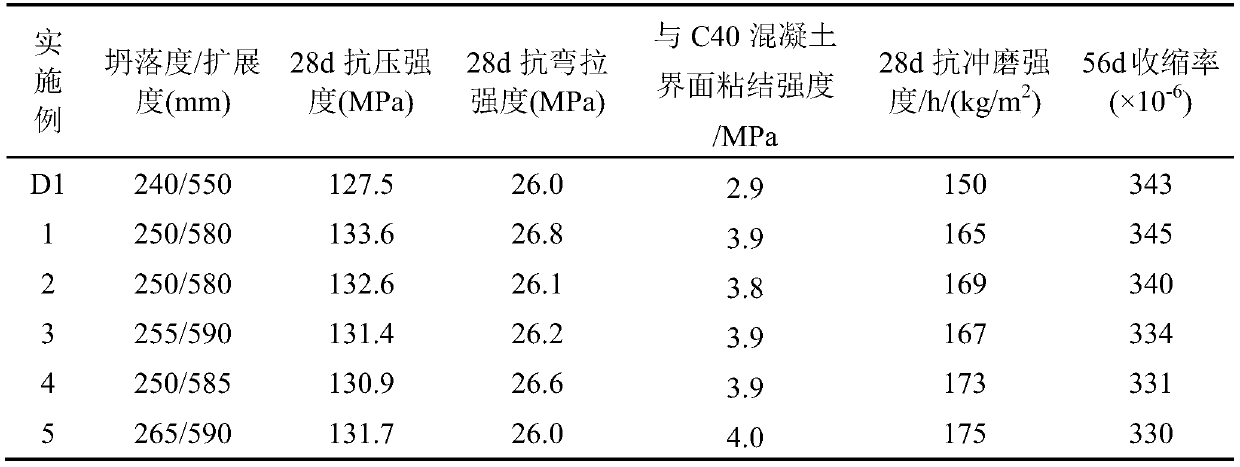

Modified rubber particle impact-resistant abrasion-resistant ultrahigh-toughness concrete and preparation method thereof

InactiveCN110981327AImprove impact toughnessGood working performanceSolid waste managementSilica fumeRiver sand

The invention discloses modified rubber particle impact-resistant abrasion-resistant ultrahigh-toughness concrete, which is prepared from the following main raw materials: cement, fly ash micro-beads,silica fume, machine-made sand, modified rubber particles, hybrid fibers, an interface enhancer, a composite expanding agent, a shrinkage-reducing viscosity-reducing water reducing agent and water. According to the invention, the modified rubber particle impact-resistant abrasion-resistant ultrahigh-toughness concrete has advantages of excellent impact toughness, excellent corrosion resistance, good volume stability and high interface bonding strength of new and old concrete, can be widely applied to the field of construction, repair and reinforcement of hydraulic structures such as bridge piers and the like, can improve the bearing capacity and the service life of hydraulic structures such as the piers and the like, reduce the maintenance cost, achieve effective utilization of wastes andsolve the problems of shortage of quartz sand and river sand resources and the like in China, and has important economic and environmental benefits.

Owner:徐思钰

Nickel-based high temperature alloy and design method thereof

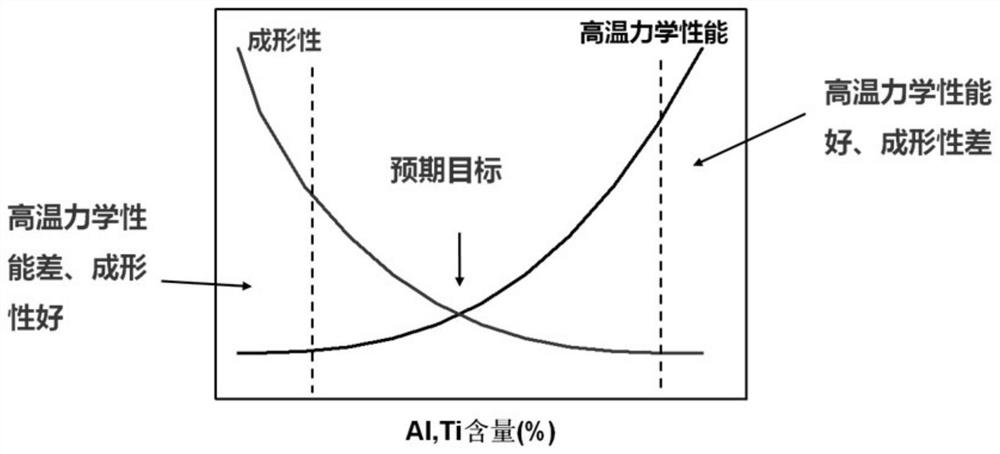

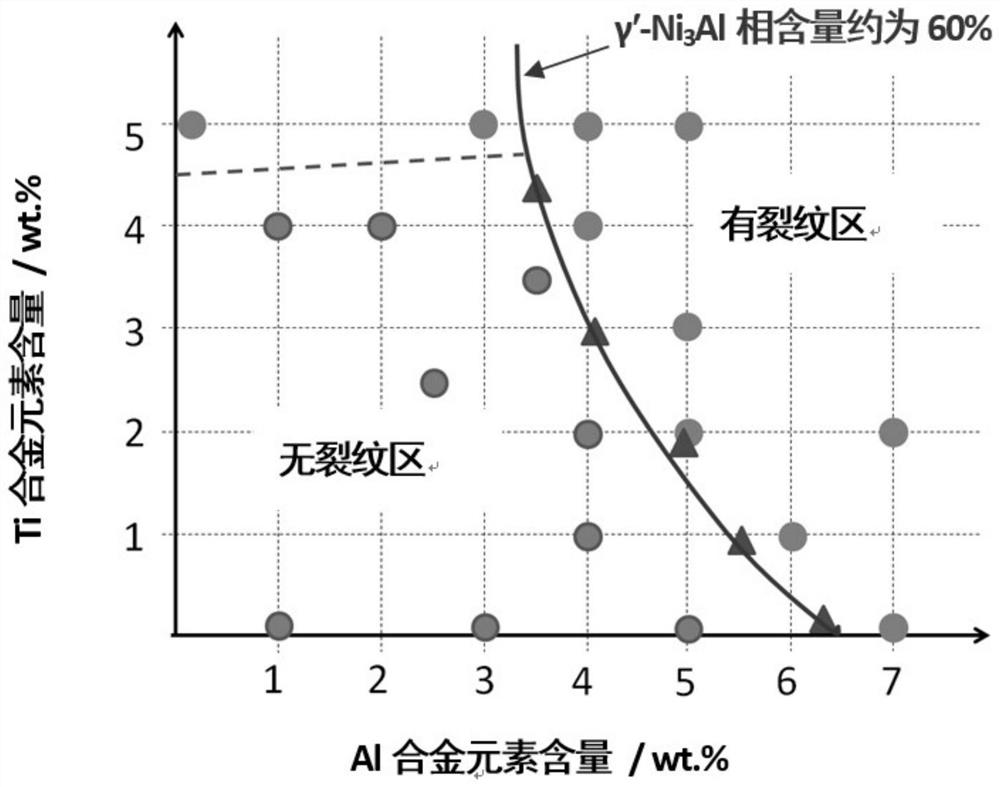

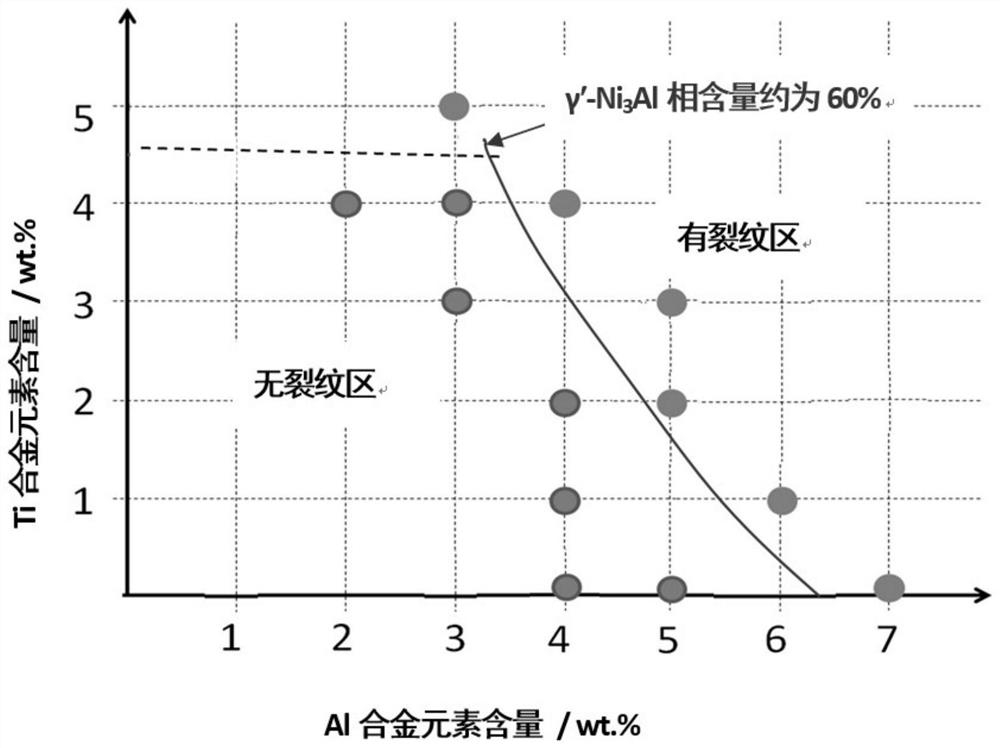

ActiveCN113201667AGuaranteed mechanical propertiesControl crack contentAdditive manufacturing apparatusSuperalloyAdditive layer manufacturing

The invention relates to a nickel-based high temperature alloy and a design method thereof, and relates to the technical field of alloy design and additive manufacturing. According to the main adopted technical scheme, the nickel-based high temperature alloy is prepared through an additive manufacturing process, and the contents of alloy elements, used for promoting precipitation of a gamma'-Ni3Al second phase, in the nickel-based high temperature alloy meet the conditions that the volume fraction of the gamma'-Ni3Al second phase in the nickel-based high temperature alloy ranges from 45% to 60%, and the content of a Ti element in the nickel-based high temperature alloy ranges from 0 to 4 wt%; and the alloy elements, used for promoting precipitation of the gamma'-Ni3Al second phase, in the nickel-based high temperature alloy comprise an Al element, and preferably, the alloy elements further comprise the Ti element and / or a Ta element. According to the nickel-based high temperature alloy, the content of the gamma'-Ni3Al second phase in the nickel-based high temperature alloy serves as a key parameter for balancing the high-temperature mechanical property and the additive manufacturing formability, the gamma'-Ni3Al phase content is controlled within the range of 45%-60%, and therefore the mechanical property and the formability of the nickel-based high temperature alloy are both considered. A guiding idea can be provided for research and development of the high-performance nickel-based high temperature alloy special for additive manufacturing.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

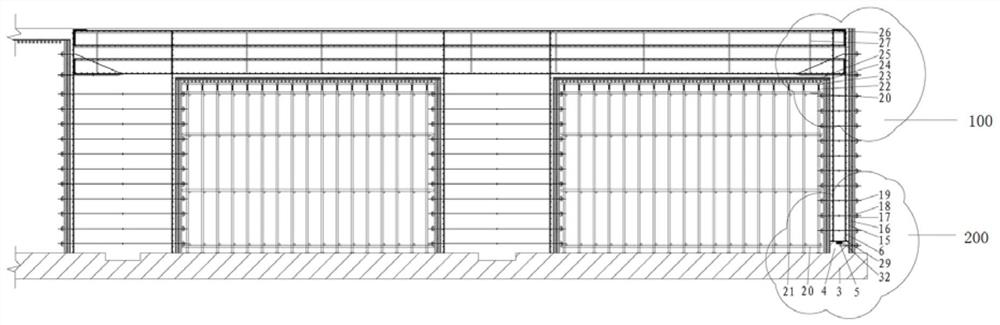

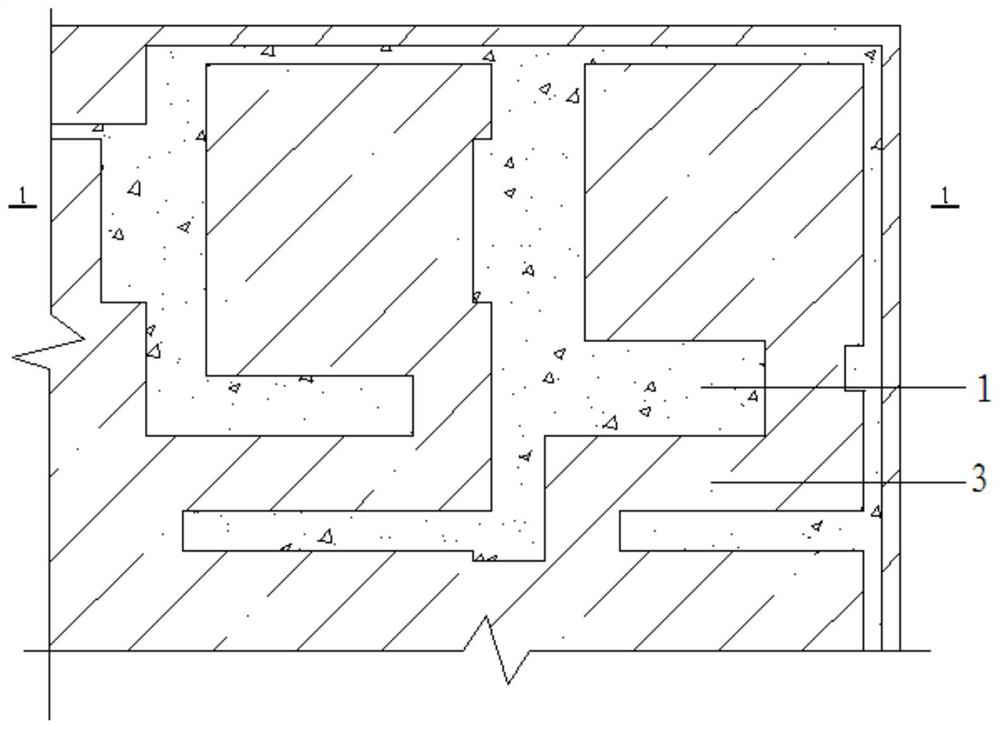

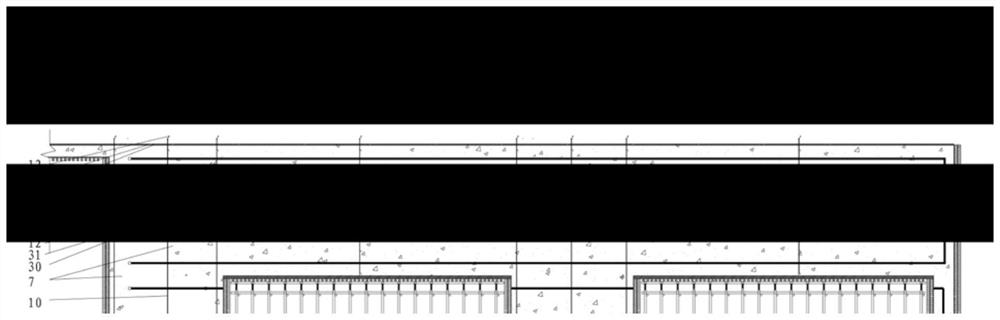

Linear accelerator radiotherapy room structure and construction method thereof

PendingCN112031479ACrack controlAccurate and fast temperature monitoringHospitalsForms/shuttering/falseworksEngineeringRebar

The invention provides a linear accelerator radiotherapy room structure and a construction method thereof. The linear accelerator radiotherapy room structure comprises a wall body, a top plate, a bottom plate and an outer wall guide wall, wherein the bottom plate is located on a basement bottom plate, the bottom plate and the basement bottom plate are connected into a whole, and the outer wall guide wall and a basement outer wall are connected into a whole; the wall body and the top plate are each internally provided with a heat preservation formwork system and a concrete temperature drop andmeasurement system, and the wall body heat preservation formwork system comprises wall body steel bars, an extruded sheet and wood formworks arranged on the two sides of the extruded sheet; the top plate heat preservation formwork system comprises top plate steel bars, a keel and a top plate wood formwork arranged at the top of the keel; and the concrete temperature drop and measurement system comprises temperature drop pipes and a temperature measurement system, the temperature drop pipes are arranged in the wall body and the top plate at equal intervals in a layered mode, the temperature measurement system comprises auxiliary steel bars, the auxiliary steel bars are vertically arranged according to the positions of temperature measurement points, and sensors are evenly distributed. The linear accelerator radiotherapy room structure is used for guaranteeing the construction quality of mass concrete and the radiation protection requirement of the structure.

Owner:MCC TIANGONG GROUP

Concrete porous energy-saving brick and preparation method thereof

The invention discloses a concrete porous energy-saving brick and a preparation method thereof. The concrete porous energy-saving brick is prepared from, by weight, 10-20 parts of silicate cement, 30-50 parts of colliery powder, 5-10 parts of slag powder, 4-8 parts of modified plant straw powder, 2-4 parts of fly ash, 1-3 parts of glazed hollow beads, 2-4 parts of fibers, 1-3 parts of dispersiblelatex powder, 0.5-1.5 parts of cellulose ether, 0.3-0.7 part of macromolecule binding agents, 0.2-0.6 part of pore forming agents, 0.5-2 parts of water reducing agents and 25-35 parts of deionized water. The concrete porous energy-saving brick is light in weight, high in strength, good in heat insulation performance, excellent in crack resistance, simple in preparation method and easy to implementand has a good application prospect.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

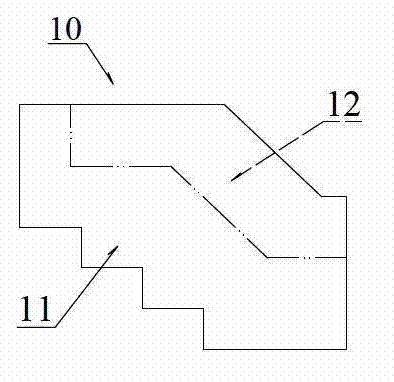

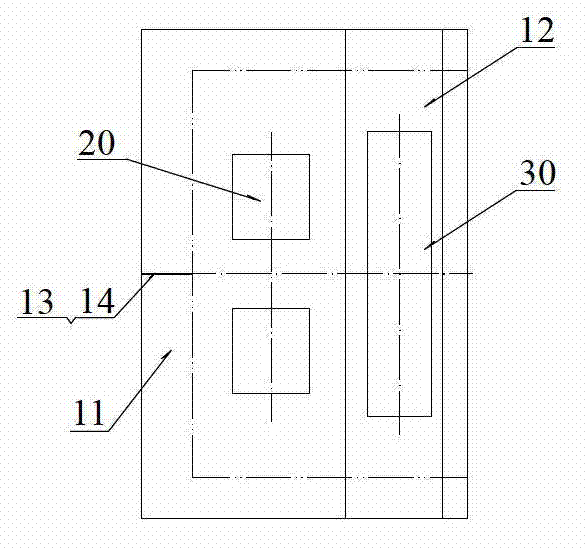

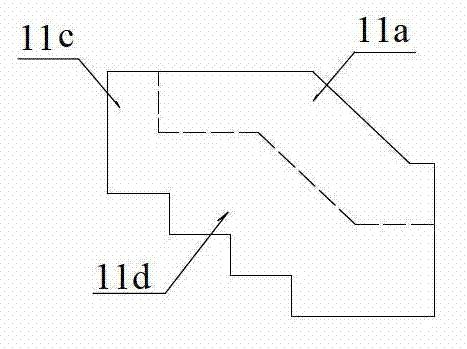

Bridge bulk mass concrete skewback structure

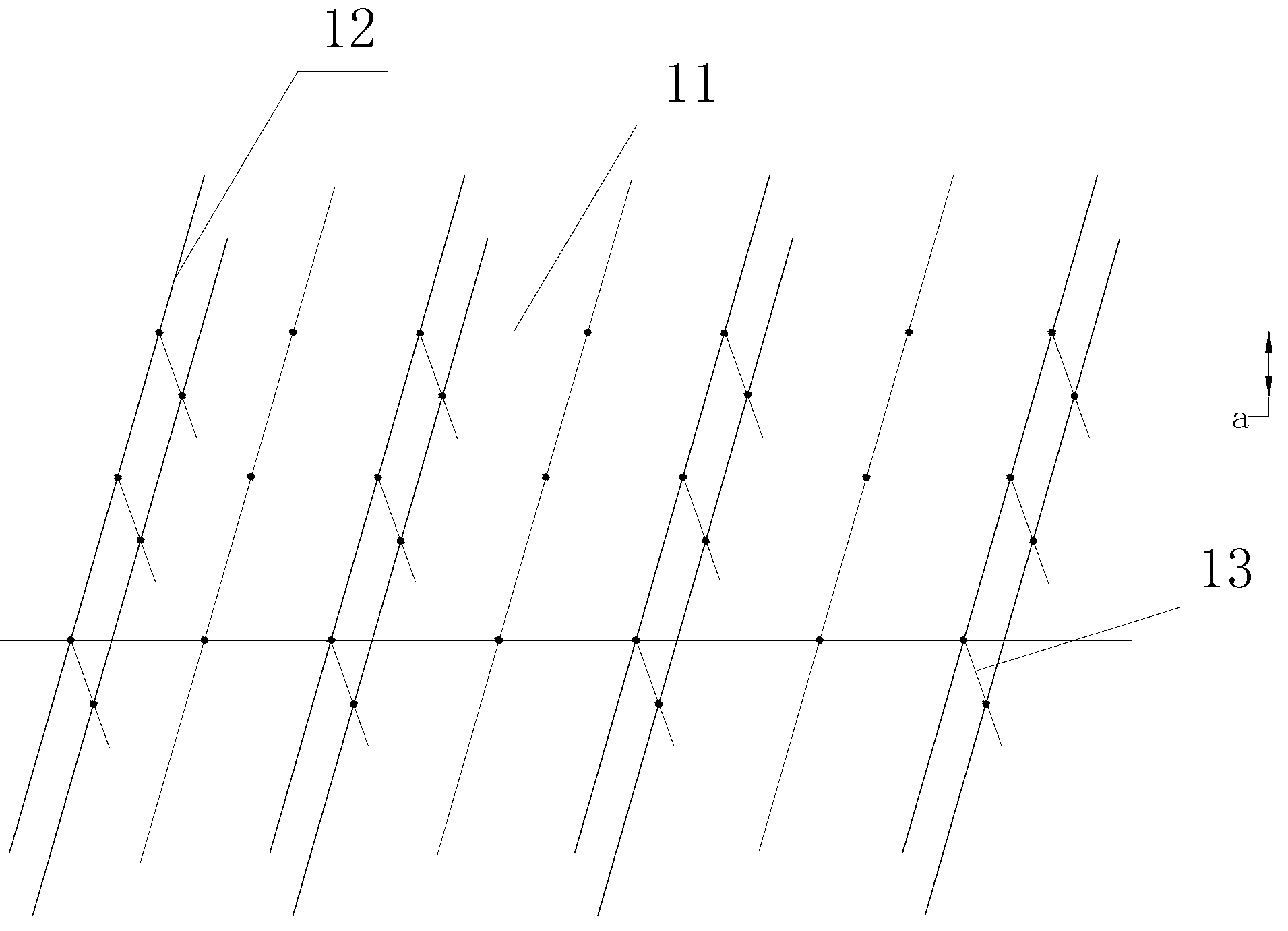

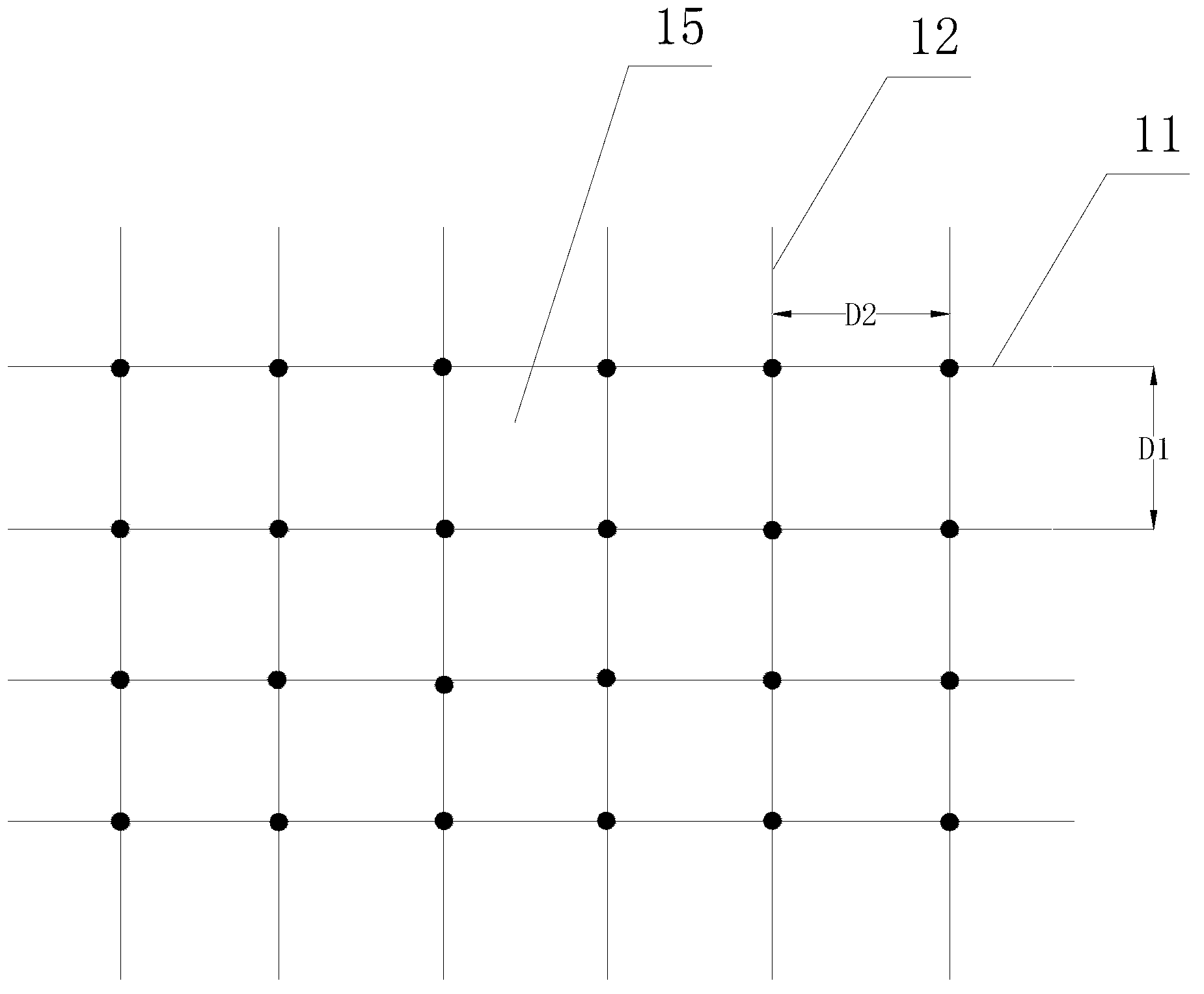

A bridge bulk mass concrete skewback structure has the advantages of being concise in structure, clear in stress, simple and convenient to construct, economical and reasonable, and can not only well meet the longitudinal and transversal stressing requirements of the skewback structure, but also simultaneously lower influence brought by heat of hydration and concrete shrinkage during construction process. The bridge bulk mass concrete skewback structure comprises a skewback (10) which supports and fixedly connecting a border pier (20) and an arch ring (30), and the whole of the skewback (10) is in a transversal uniform-section step shape and composed of a lower-portion plain concrete casting body (11) and an upper-portion reinforced concrete casting body (12). A transversal breaking joint (13) is arranged in the middle of the plain concrete casting body (11), and steel plates (14) are filled in the transversal breaking joint (13). The border pier (20) and the arch ring (30) are cast on the upper-portion reinforced concrete casting body (12).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

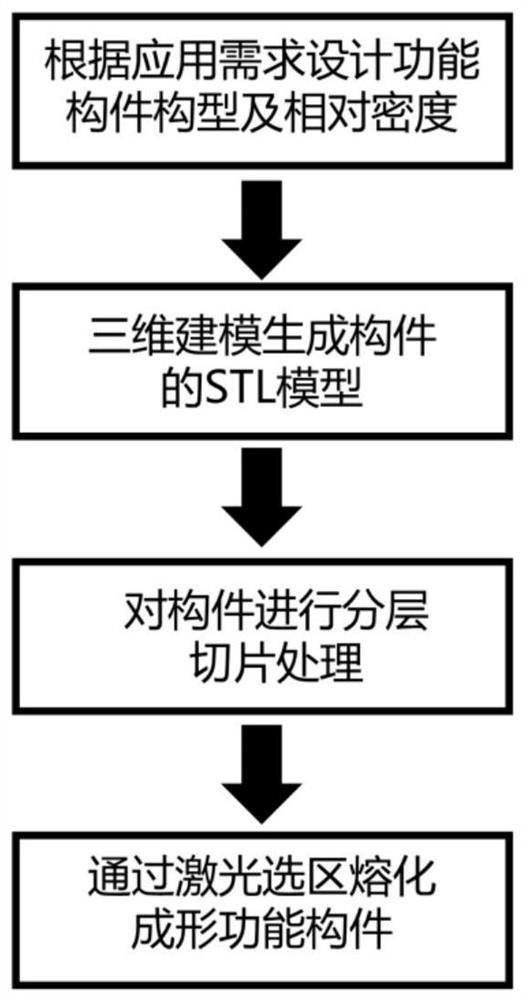

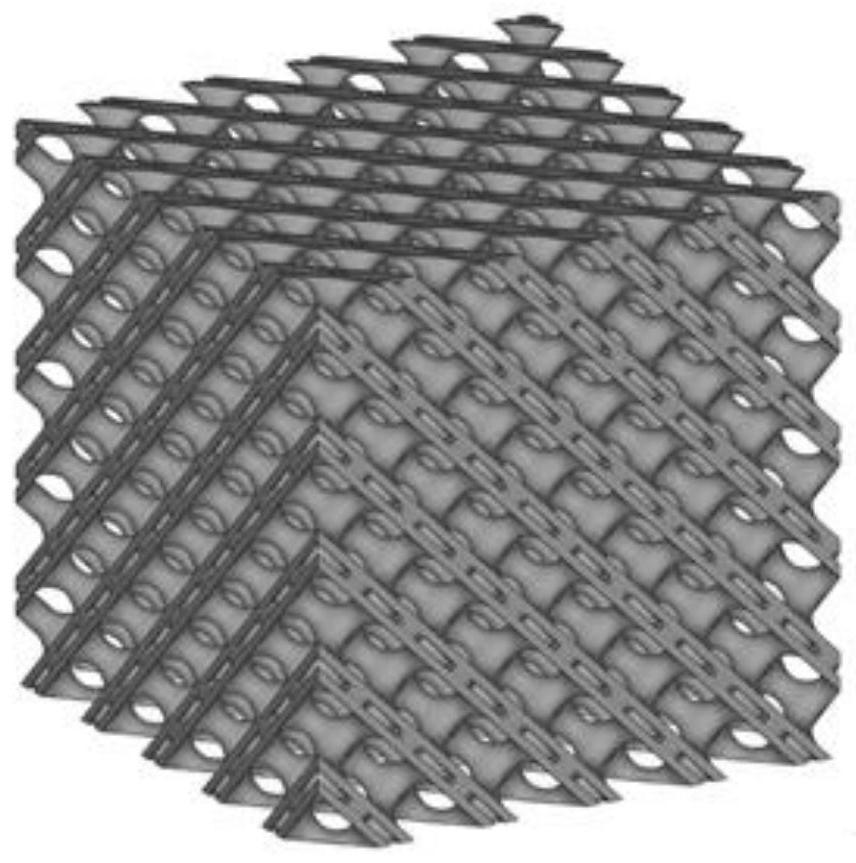

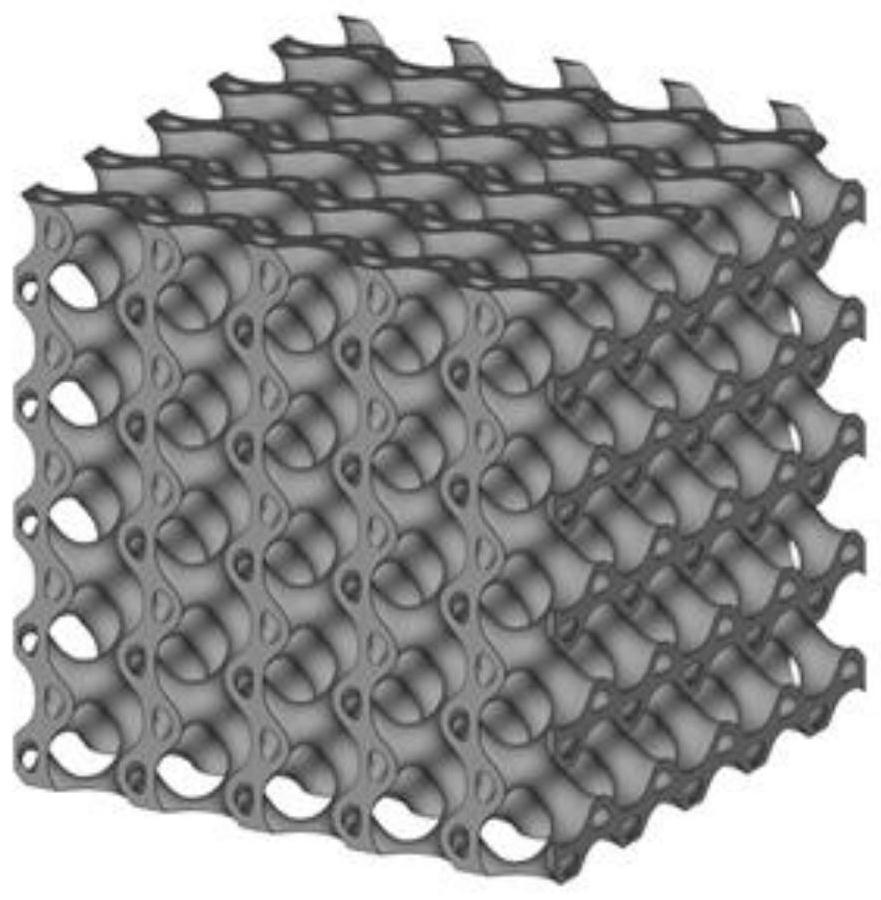

4D forming method for nickel-titanium alloy member with deformation recovery rapid response and product

ActiveCN112475319AIncrease surface areaHigh phase transition temperatureAdditive manufacturing apparatusSelective laser meltingLarge deformation

The invention belongs to the related technical field of metal additive manufacturing, and discloses a 4D forming method of a nickel-titanium alloy member with deformation recovery rapid response and aproduct. The 4D forming method of the nickel-titanium alloy member with deformation recovery rapid response comprises the following steps of S1, determining the deformation amount and deformation recovery speed requirements of the to-be-formed member, constructing a lattice structure SA and a lattice structure SB with different relative densities by adopting a three-period minimal curved surface,and performing Boolean differencing operation on the lattice structure SA and the lattice structure SB to remove the same parts in the lattice structures so as to obtain a shell lattice structure; S2, adjusting the parameters of the lattice structures SA and SB till the deformation amount and deformation recovery speed requirements of the to-be-formed member are met, and a three-dimensional modelis obtained; and S3, forming the three-dimensional model through selective laser melting so as to obtain the needed to-be-formed member. By means of the 4D forming method of the nickel-titanium alloymember with deformation recovery rapid response, the forming quality of the nickel-titanium alloy is effectively controlled, and the response speed of large deformation and deformation recovery of the obtained product is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Additive for improving carbonization resistance of concrete as well as preparation method and application of additive

The invention provides an additive for improving carbonization resistance of concrete as well as a preparation method and application of the additive, and belongs to the technical field of concrete. The additive provided by the invention is prepared from the following components in parts by mass: 8-12 parts of mineral substance fine powder, 3-5 parts of silica fume, 10-15 parts of metakaolin, 3-5 parts of methyl silicate, 2-3 parts of an expanding agent, 5-8 parts of a super plasticizer and 6-12 parts of a self-healing expanding fiber anti-crack waterproof agent. Results of the embodiment show that the additive provided by the invention can reduce the internal porosity of concrete by 50% or more, and reduce the number of capillary pores and macropores. The strength of the prepared concrete can be improved by 70% in 3 days, the strength of the prepared concrete can reach the original strength on the 28th day in 7 days, and the strength can be improved by about 20% in 28 days. Energy spectrum analysis before and after concrete carbonization shows that the carbon content of concrete is relatively low even if the concrete is carbonized, which indicates that the additive has very good carbonization resistance.

Owner:CCCC FOURTH HIGHWAY ENG

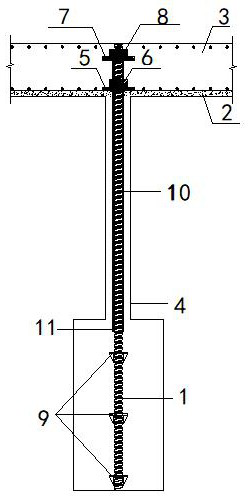

PSB finish-rolled deformed steel bar anti-floating anchor rod structure and construction method thereof

PendingCN112392043AIncreased durabilityCrack controlProtective foundationBulkheads/pilesPre stressEngineering

The invention provides a PSB finish-rolled deformed steel bar anti-floating anchor rod structure and a construction method thereof. The PSB finish-rolled deformed steel bar anti-floating anchor rod structure comprises a PSB finish-rolled deformed steel bar anchor rod body, a first anchor plate, a first anchor head, a second anchor plate and a second anchor head. After an anchoring body reaches thestrength required by tensioning, the PSB finish-rolled deformed steel bar anchor rod body can be tensioned and fixed through the first anchor plate and the first anchor head, the generated prestresscan enable the anchoring body to be in a pressed state, so that the anchoring body of the anchor rod is effectively controlled from generating cracks, the durability of the anti-floating anchor rod isimproved, and the anti-floating effect is consolidated. According to the construction method of the PSB finish-rolled deformed steel bar anti-floating anchor rod structure, prestress can be generatedonly by tensioning the anchor rod and additionally arranging the first anchor plate and the first anchor head to achieve the anti-cracking effect, and the construction method is simple and easy to operate.

Owner:北京基泰科技有限公司

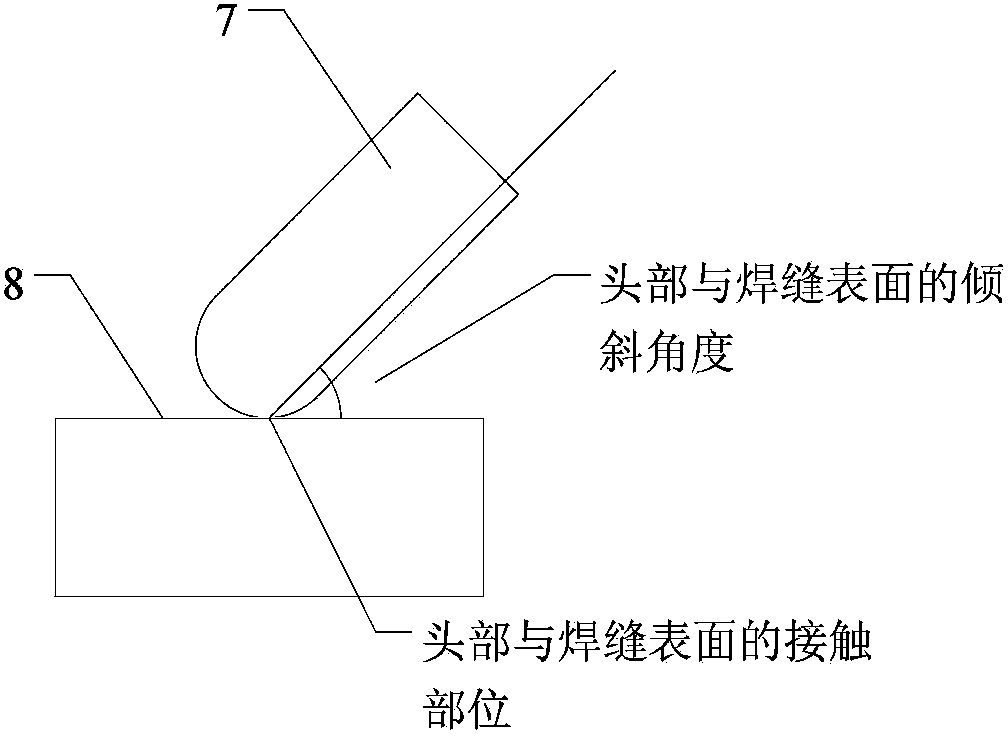

Cold-welding restoring method for tooth surface notches of presser iron-casting press roll shell

ActiveCN103406642AAvoid local overheatingReduce welding stressArc welding apparatusEngineeringMechanical engineering

The invention discloses a cold-welding restoring method for tooth surface notches of a presser iron-casting press roll shell. The press roll shell comprises a plurality of teeth, at least one tooth has at least one notch, and each of other teeth at least has two notches. The cold-welding restoring method includes for any one notch, dividing the notch into n sections continuously distributed along the length direction of the notch according to the length of the notch; for any two notches, welding the notches in turn, selecting a section on the first notch for welding, quickly hammering a welding seam of the section after welding of the section, and selecting the next section on the first notch for welding when the welding seam of the first notch is cooled to below 60 DEG C. Local overheating of welding-up areas at notches is avoided, welding stress is reduced, cracks are avoided, restored notch positions have good extension strength and rigidity, and working efficiency is guaranteed.

Owner:GUANGXI YILAN WELDING TECH

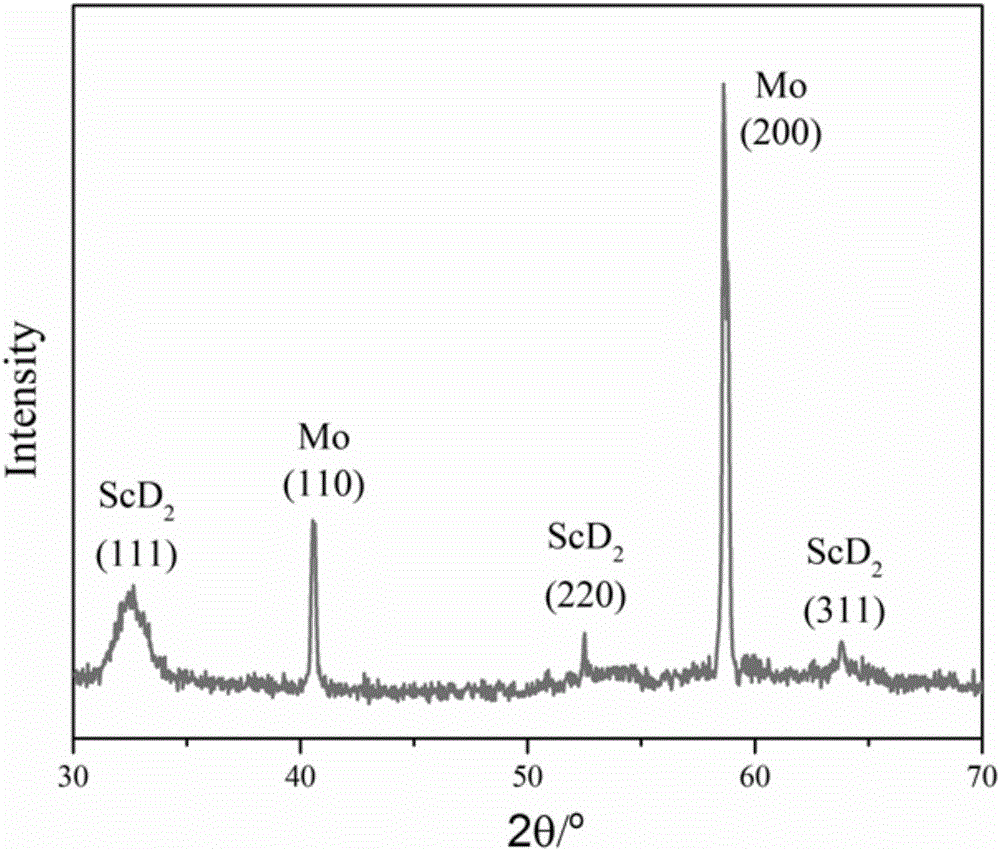

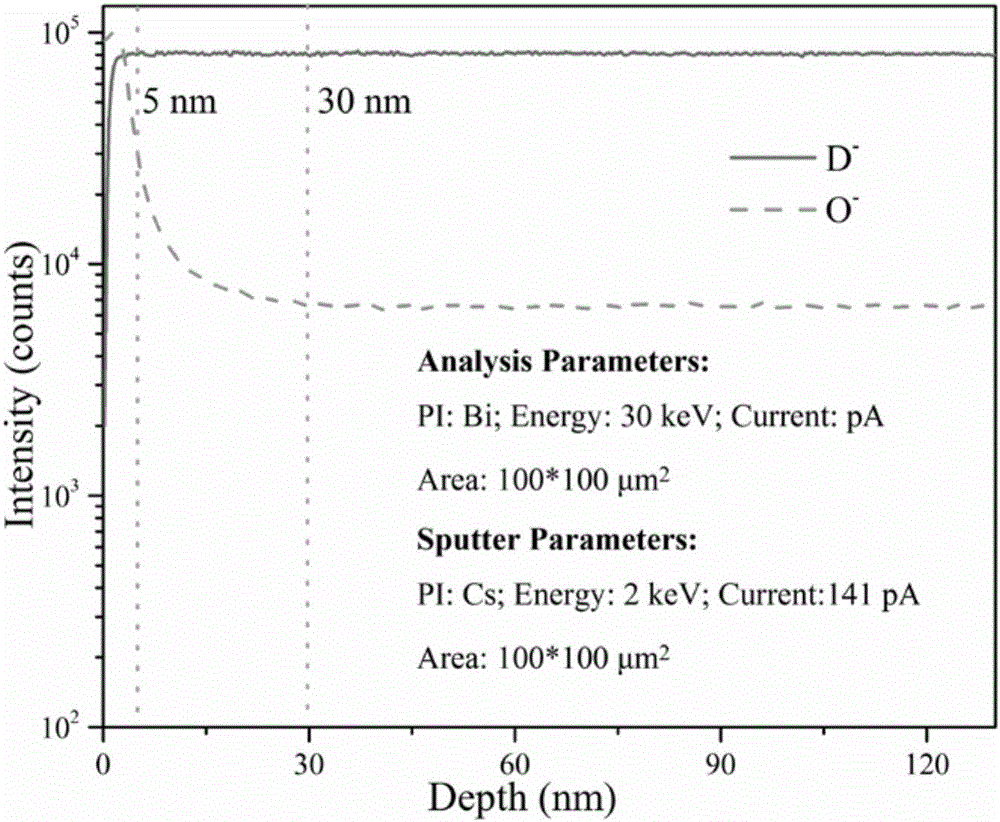

Preparation method for deuterium-containing metal film target

ActiveCN106544628AExtended service lifeHigh purityVacuum evaporation coatingSputtering coatingNeutron yieldMaterials science

The invention discloses a preparation method for a deuterium-containing metal film target. The preparation method comprises the following steps: firstly, using high-purity molybdenum or high-purity copper as a substrate material of the deuterium-containing metal film target, and performing surface pretreatment on the substrate material; secondly, mounting and placing the substrate into a physical vapor deposition (PVD) vacuum coating machine, bombarding the surface of the substrate with argon ions, removing an oxide layer on the surface of the substrate by sputtering; thirdly, setting the coating temperature of the substrate, introducing high-purity deuterium gas in a vacuum cavity, starting the coating machine, and directly preparing the deuterium-containing metal film; fourthly, turning off the coating machine, continually introducing deuterium gas into the vacuum cavity, and turning off a deuterium gas flower meter until an appropriate air pressure is reached in the cavity. By adopting the preparation method, the mechanical performance of the deuterium-containing metal film target is improved, the brittleness and occurrence of cracks are controlled effectively, and adhesive force of the target film is enhanced; meanwhile, the thickness of a dead layer on the surface is decreased, the purity of the target film is increased, the neutron yield of a neutron generator is increased, and the service life of the target is prolonged.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Method for repairing housing of hot blast heater in late service period

ActiveCN103292599AEnsure safe productionEliminate deformation problemsLinings repairAngle grinderBrick

The invention relates to a method for repairing a housing of a hot blast heater in late service period. The method includes steps of I, restoring a housing crack: welding two supports on two outer sides of the crack respectively, adopting two jacks to transversely support between the supports and parts and to jack the cracking crack back from two sides; II, welding the crack: adopting an angle grinder to clean a breach and a crevasse with an angle, bottoming an Austentic 002 stainless steel electrode in the crack and welding into a joint by a common welding electrode; III, reinforcing the housing: arranging an annular belt at the housing crack and hooping the housing; IV, drilling a manhole and scooping residual brick: drilling a circular manhole not smaller than DN600mm in a burned position of the housing and scooping the burned residual brick; V, casting a formwork: blowing the manhole by a compressed air pipe, and fastening a circular steel plate at a hole of the housing and casting; VI, roasting cast materials. By the method for repairing the housing of the hot blast heater in the late service period, the service life of the housing of the hot blast heater is prolonged.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

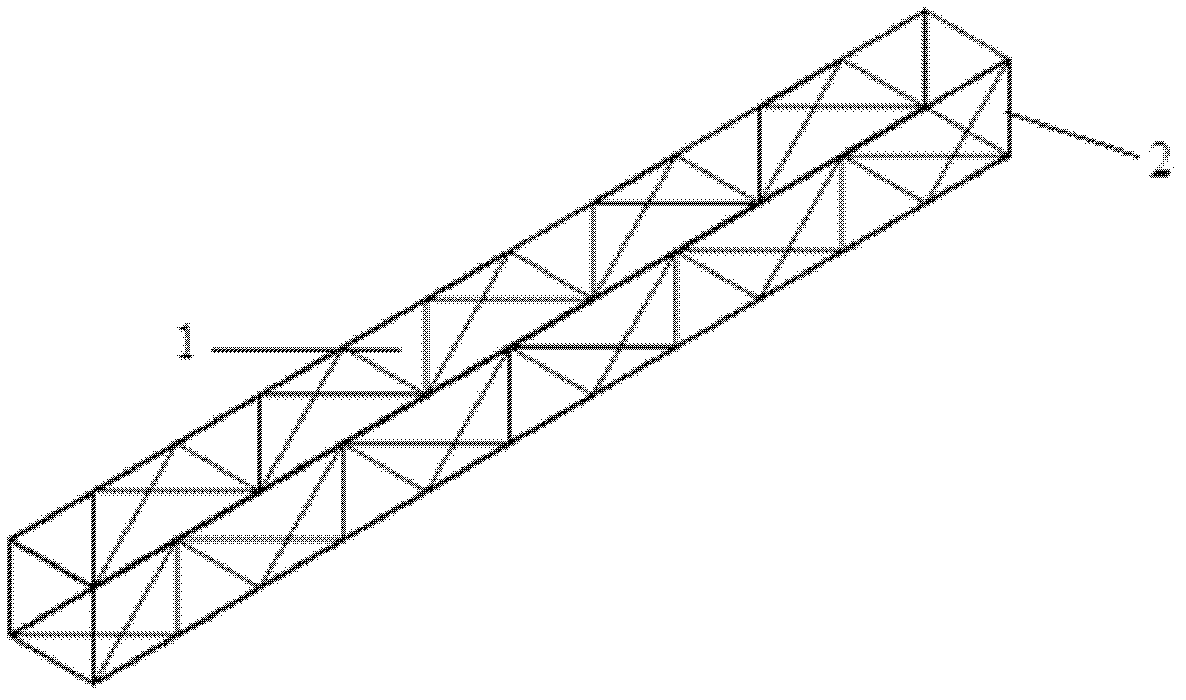

Trussed type reinforced concrete beam

The invention relates to a trussed type reinforced concrete beam, comprising a concrete beam body and a space truss arranged inside the concrete beam body, wherein the space truss is formed by combining four reinforced trusses, namely an upper reinforced truss, a lower reinforced truss, a left reinforced truss and a right reinforced truss, and the reinforced trusses are prefabricated. Compared with the prior art, the trussed type reinforced concrete beam disclosed by the invention has the advantages of convenience in construction, conservation of construction time and high overall strength.

Owner:SHANGHAI JIAO TONG UNIV

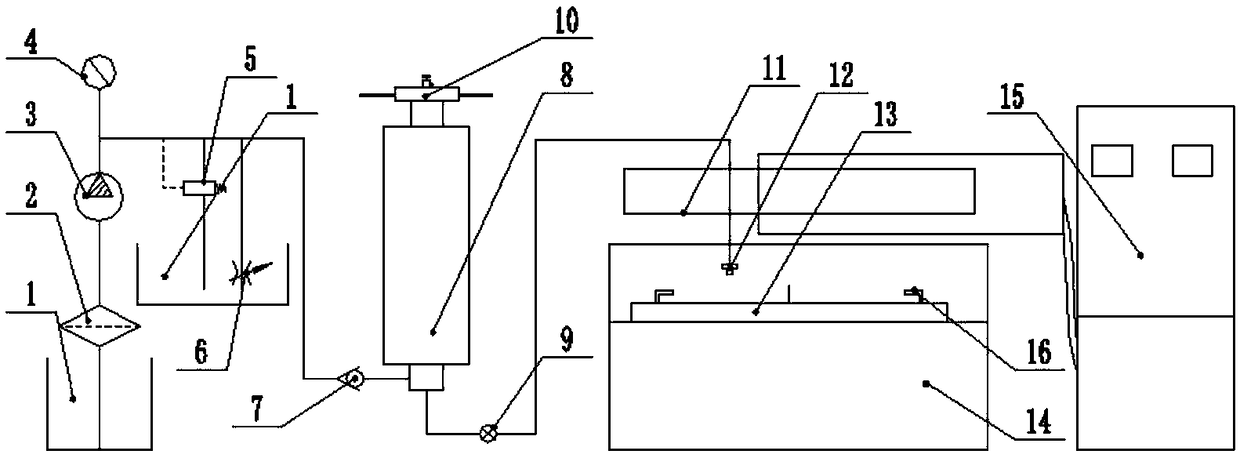

Pre-mixed abrasive water-jet shot-blasting equipment

InactiveCN109333375AImprove fatigue strengthUniform stressAbrasive machine appurtenancesAbrasive blasting machinesSpray nozzleCantilever

The invention provides pre-mixed abrasive water-jet shot-blasting equipment. The pre-mixed abrasive water-jet shot-blasting equipment comprises a water supplying box, a water outlet of the water supplying box communicates with a water inlet of a shot material tank through a water inlet pipe, and the water inlet pipe is sequentially connected with a filter, a water pump, a safe valve, a pressure adjusting valve and a one-way valve in series from the water supplying box to the shot material tank; a plurality of shot materials are stored in the shot material tank, and a material putting opening is formed in the top end of the shot material tank and matched with an end cover for sealing; an outlet of the shot material tank communicates with the inlet end of a shot material pipe used for conveying the shot materials, and a stop valve is arranged on the shot material pipe; the outlet end of the shot material pipe penetrates through a cantilever beam from top to bottom and communicates with anozzle, and the nozzle allows the shot materials to pass through; a displacement working table is arranged below the nozzle and erected on a water return box for recovery of water and the shot materials which are sprayed by the nozzle, and a clamp used for clamping a to-be-machined workpiece is arranged on the upper surface of the displacement working table; and the cantilever beam is located above the displacement working table and can horizontally move above the displacement working table through a moving device.

Owner:ZHEJIANG UNIV OF TECH

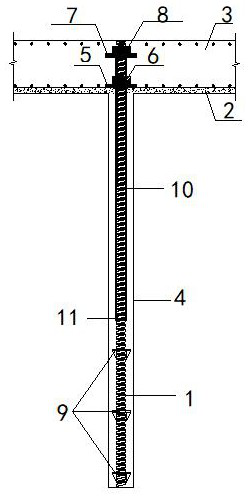

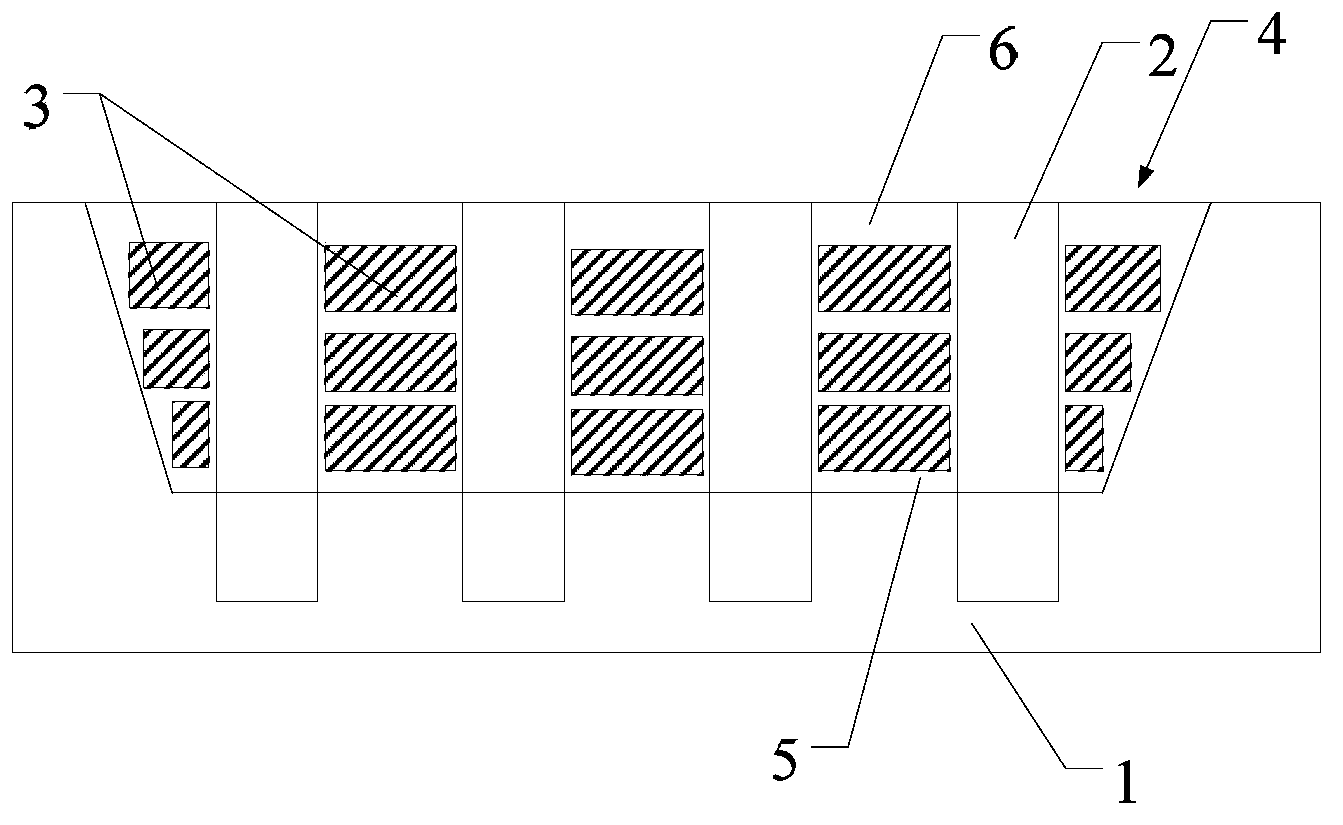

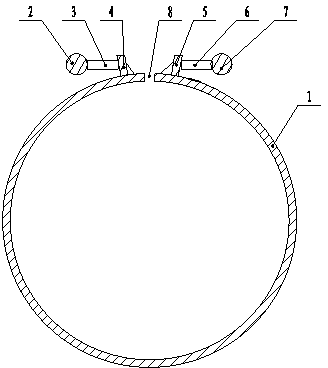

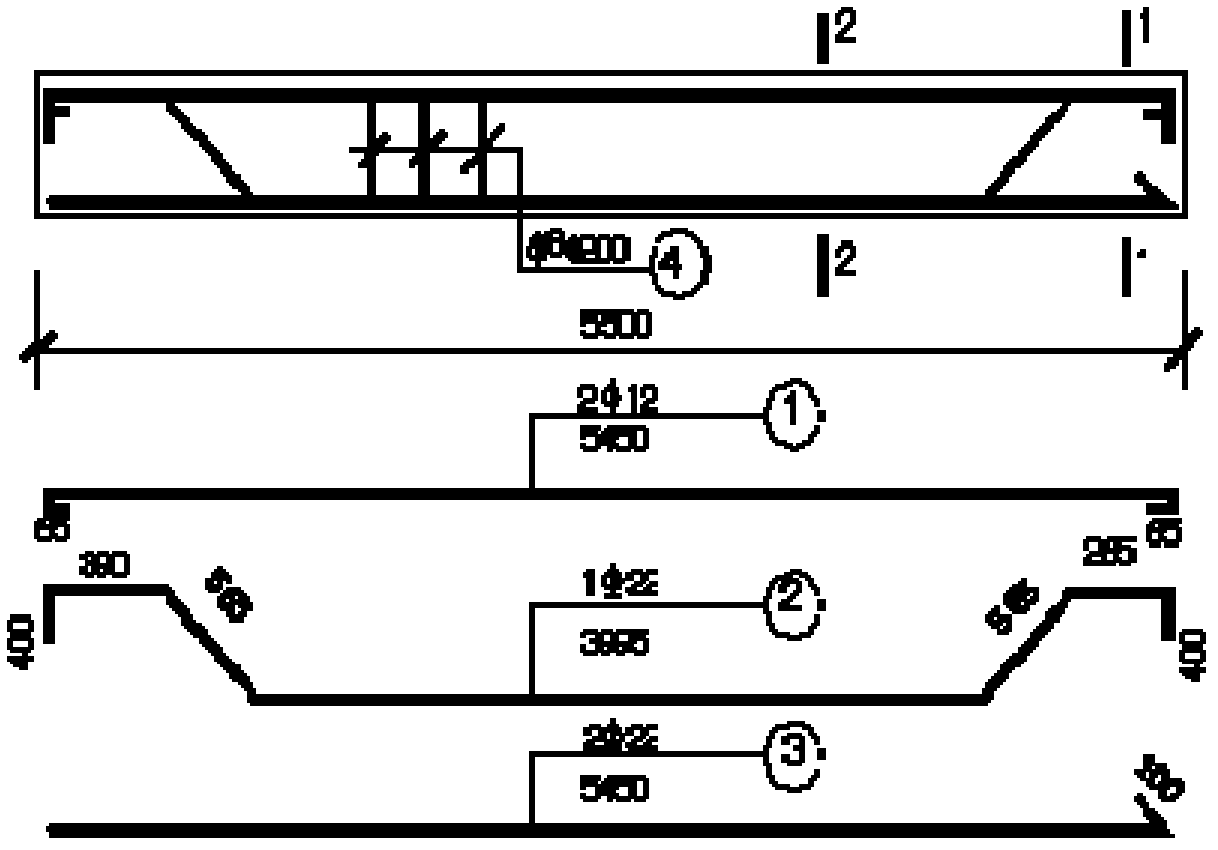

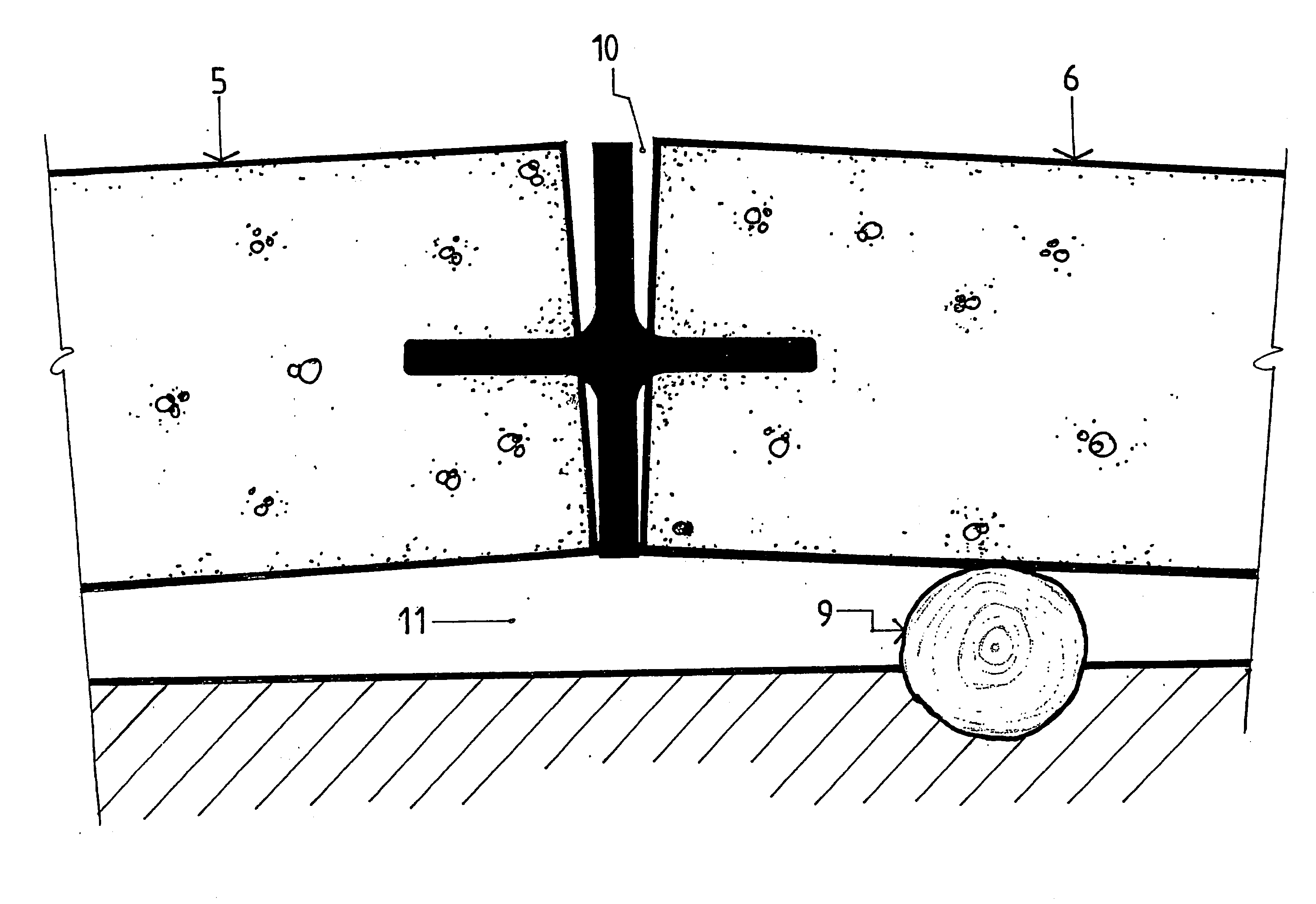

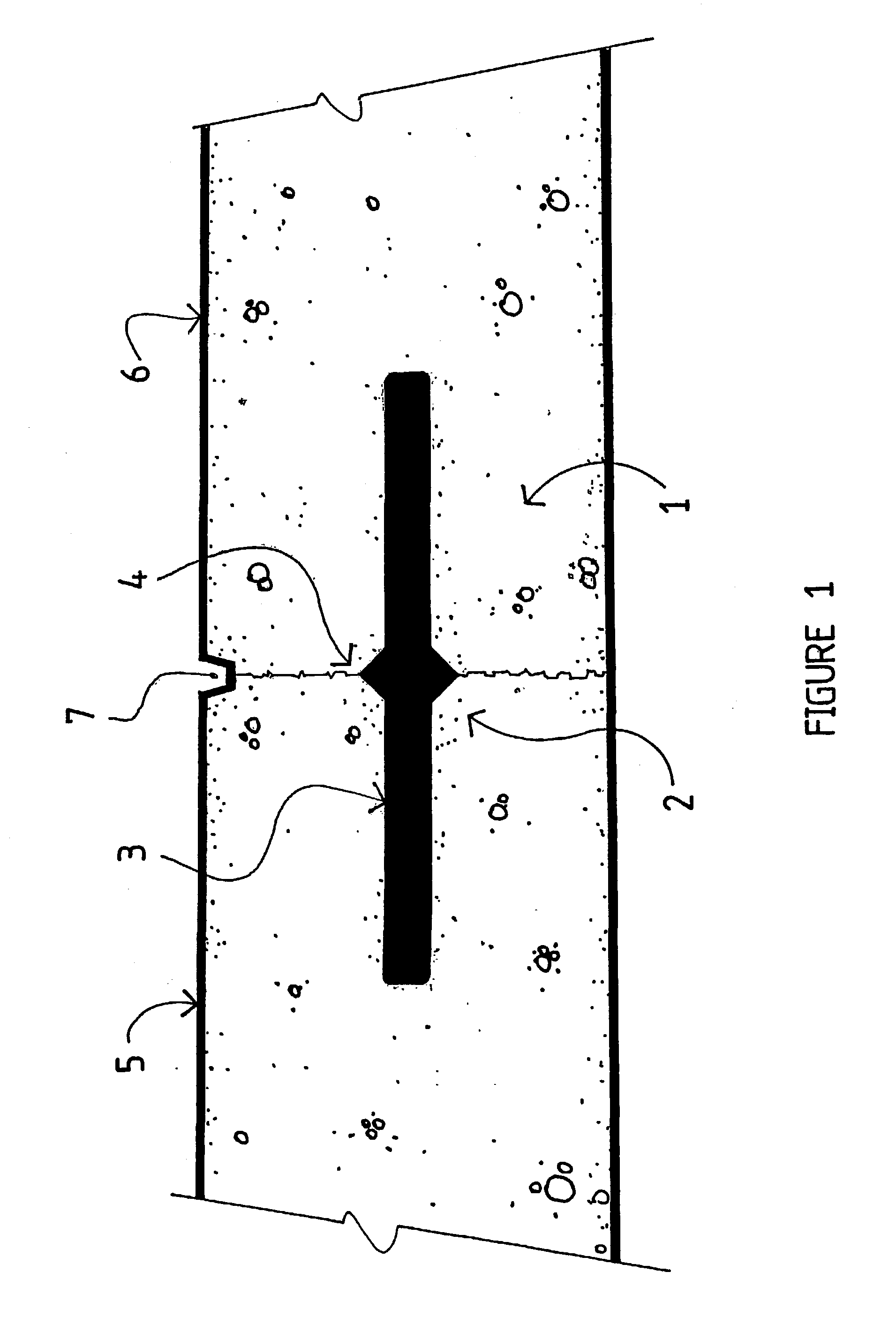

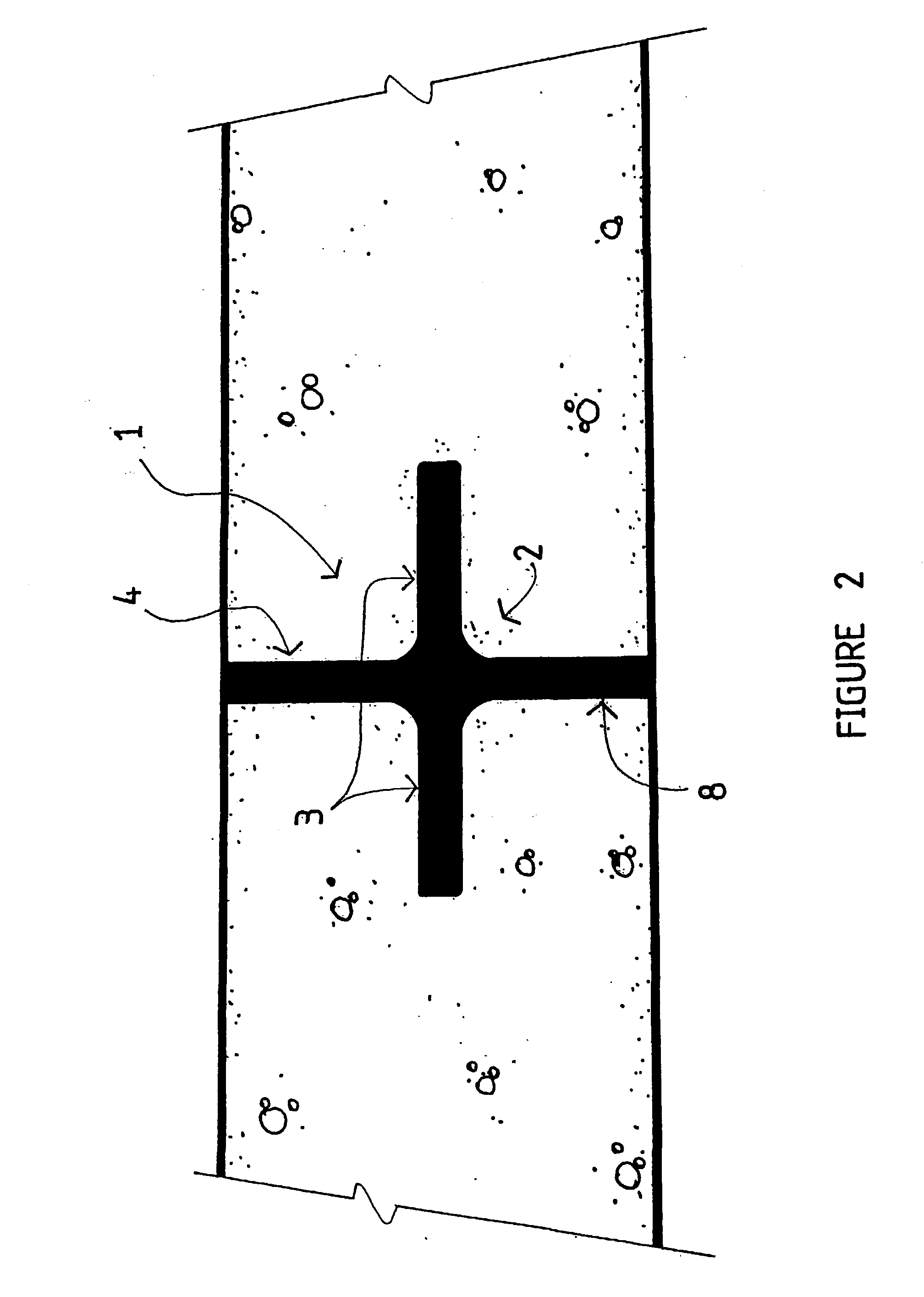

Articulated concrete joint member

InactiveUS20030190190A1Crack controlControl crackingPaving detailsJoint componentOut of plane displacement

An articulated concrete joint member (1) including a resilient core (2), the core (2) having connections means (3) attached thereto, the connection means (3) adapted to link two co-planar concrete slabs (5, 6) along an adjacent peripheral edge of each slab, wherein on application of an out-of-plane displacement to one of the co-planar concrete slabs (5, 6) the displacement is transmitted to the other slab through pivoting about the articulated joint member (1). In one embodiment, the articulated concrete joint member (1), which further includes crack propagation means (4), is fully immersed in the concrete slab so that the slab is subjected to extraneous loads, the slab cracks along predetermined lines of weakness (7).

Owner:GALLAGHER STEPHEN JAMES

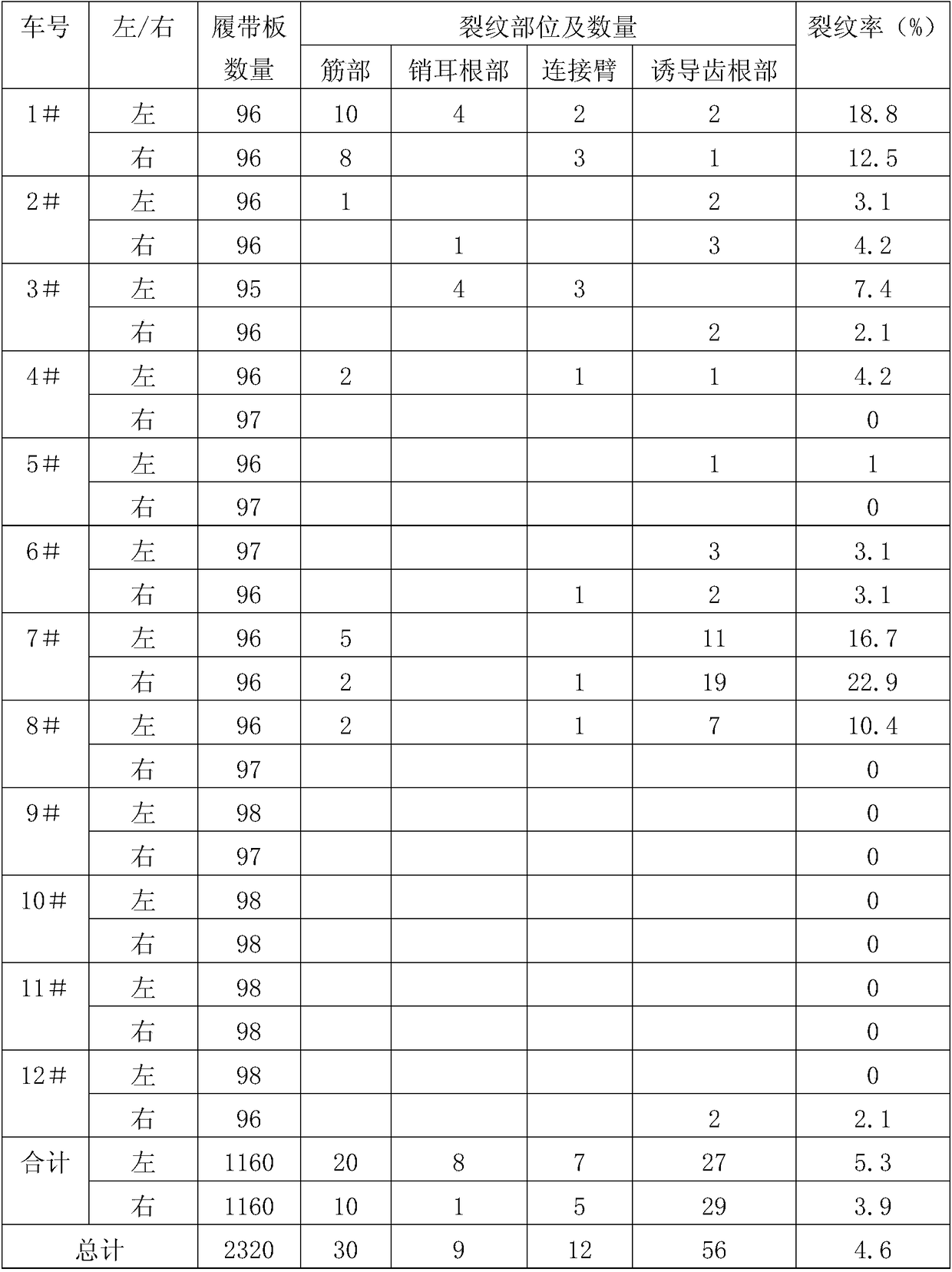

Casting process for high-manganese steel track plates

The invention relates to a casting process for high-manganese steel track plates. The casting process comprises the following specific steps: (1) a manufacturing mold is determined; (2) a sand mold and a lower core box are manufactured; (3) waste steel is smelted to prepare pour steel; 1) alloy elements of vanadium and titanium are added before smelting as nucleating agents 2) white slag is continuously prepared in the smelting reduction process; and the content of phosphorous is controlled below 0.035%; (4) pouring: the tapping temperature of the pour steel is 1590-1620 DEG C; and the bag guidance is performed once before pouring, so that the pouring temperature is 1415-1435 DEG C; and (5) unpacking: the pouring is performed by 50 minutes for unpacking. The casting process reduces the crack rate and the rupture probability of the high-manganese steel track plates, and prominently prolongs the service life.

Owner:内蒙古第一机械集团股份有限公司

Anti-crack anti-freezing cement mortar

The invention discloses anti-crack anti-freezing cement mortar. The anti-crack anti-freezing cement mortar is prepared by mixing coal ash, silicon ash, quartz sand, an early strength agent, a water reducing agent, water, fiber and a thickening agent. According to the anti-crack anti-freezing cement mortar provided by the invention, the common silicic acid serves as a main cementing material, and auxiliary materials such as the coal ash and the silicon ash are used cooperatively, so that the strength of the mortar is effectively improved; the quartz sand with different grain size are used in a matched way, and a proper amount of water-reducing agent, thickening agent and the early strength agent are added, so the porosity of the mortar is reduced and the earth strength of the mortar is improved; high-quality polyvinyl alcohol fiber and cement are added, so that high affinity and excellent alkali resistance and weather resistance are achieved, and crack caused by plastic shrinkage of the mortar and temperature change can be effectively controlled; moreover, the impact resistance, the permeation resistance and the anti-freezing property of the cement mortar are improved, and the anti-crack anti-freezing cement mortar can be widely applied to water conservancy project, roads and bridges, ports and piers and the like.

Owner:江世妹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com