Concrete with low shrinkage, good erosion and abrasion resistance and ultrahigh toughness, and preparation method thereof

An ultra-high toughness and anti-abrasion technology, applied in the field of building materials, can solve the problems of large slump loss, high amount of cementitious materials, strong destructive force, etc., to reduce self-shrinkage and drying shrinkage, improve compactness and Strength, the effect of improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the shrinkage-reducing viscosity-reducing type water reducer described in Examples 1-5 comprises the following steps:

[0043] 1) Add maleic anhydride into the reaction vessel, heat up to 55°C to melt it completely, then add diethylene glycol monobutyl ether and p-toluenesulfonic acid, heat up to 135°C, perform constant temperature esterification for 4.5 hours, and cool Purify by suction filtration afterward, obtain the diethylene glycol monobutyl ether maleic anhydride monoester monomer with shrinkage function, wherein the mass ratio of maleic anhydride, diethylene glycol monobutyl ether and p-toluenesulfonic acid is 1:0.55:0.06;

[0044] 2) Add the diethylene glycol monobutyl ether maleic anhydride monoester monomer, methacrylic acid and sodium methacrylate sulfonate prepared in step 1) into a reaction vessel filled with distilled water, heat up to 95°C, drop Add allyl polyethylene glycol and ammonium persulfate aqueous solution, react at a c...

Embodiment 1~3

[0053] A low-shrinkage anti-abrasion ultra-high toughness concrete, the preparation method of which comprises the following steps:

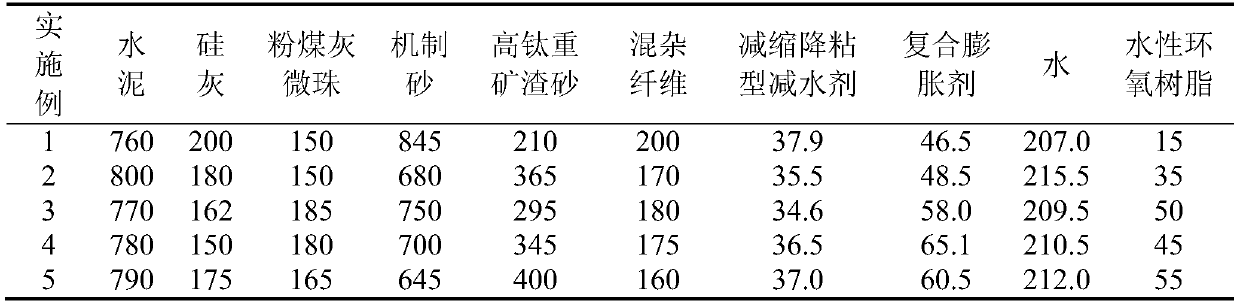

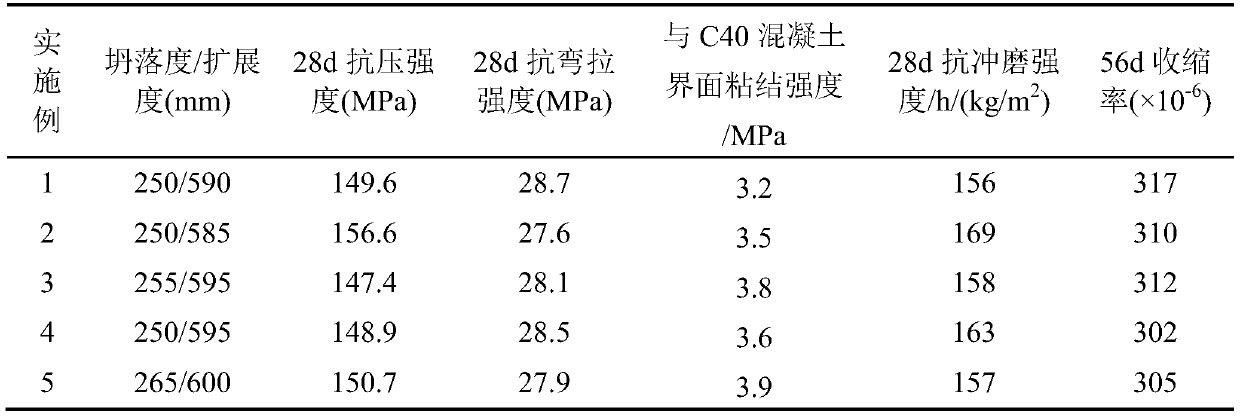

[0054] 1) take each raw material according to the proportioning described in Table 1;

[0055] 2) Put the weighed high-titanium heavy slag sand into water and soak for 1 day until saturated, then drain until the saturated surface is dry to obtain pre-wetted high-titanium heavy slag sand; machine-made sand, pre-wetted high-titanium heavy slag sand, cement , silica fume and fly ash microbeads were added to the concrete mixer for pre-mixing for 3 minutes, poured in water and viscosity-reducing superplasticizer and stirred for 4 minutes, then added composite expansion agent and stirred for 2 minutes, then evenly added mixed fibers and continued to stir for 3 minutes; Oxygen resin was stirred for 3 minutes, and finally molded, vibrated, and formed, and the surface was covered with an impermeable film. After 1 day, the mold was removed for standard mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com