Non-autoclaved lightweight thermal insulation particle aerated concrete block and preparation method thereof

A technology of air-entrained concrete and lightweight particles, which is applied to ceramic products, other household appliances, household appliances, etc., and can solve problems such as unsatisfactory thermal insulation performance of aerated concrete blocks and complicated maintenance processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

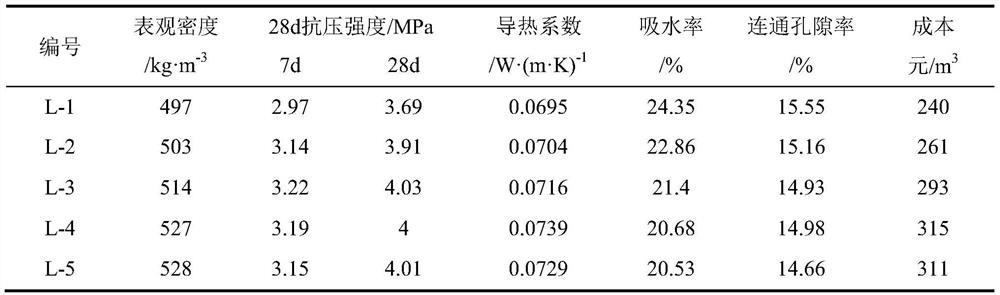

Examples

Embodiment 1

[0033] A non-autoclaved lightweight thermal insulation granular aerated concrete block, comprising the following components in parts by weight: 650g of cement, 262.5g of fly ash, 87.5g of slag micropowder, lightweight particles (ceramsite, EPS particles and active Consolidated magnesium oxide particles) 100g, hydrogen peroxide 40g, coagulation accelerator 30g, foam stabilizer 1g, water reducing agent 8g, water repellent 4g, fiber 4g, water 400g. The cement is ordinary aluminate cement; the coagulant is one or more of aluminum sulfate, sodium silicate, and sodium carbonate; the foam stabilizer is hydroxypropyl methylcellulose ether, hydroxyethyl One or more of methyl cellulose ether, hydroxyethyl cellulose ether, and methyl cellulose ether; the water reducer is an aromatic sulfonate formaldehyde condensate high-efficiency water reducer, a ketone aldehyde condensate high-efficiency water reducer One or more of water agent, polycarboxylate-based high-efficiency water reducer; the...

Embodiment 2

[0043] A non-autoclaved lightweight thermal insulation granular aerated concrete block, comprising the following components in parts by weight: 66g of cement, 262.9g of fly ash, 90g of slag micropowder, lightweight particles (ceramsite, EPS particles and activated oxidation Magnesium consolidated particles) 140g, hydrogen peroxide 41g, coagulation accelerator 32g, foam stabilizer 1.2g, water reducing agent 9g, water repellent 4.2g, fiber 4.3g, water 410g. The cement is ordinary Portland cement; the coagulant is one or more of aluminum sulfate, sodium silicate, and sodium carbonate; the foam stabilizer is hydroxypropyl methylcellulose ether, hydroxyethyl One or more of methyl cellulose ether, hydroxyethyl cellulose ether, and methyl cellulose ether; the water reducer is an aromatic sulfonate formaldehyde condensate high-efficiency water reducer, a ketone aldehyde condensate high-efficiency water reducer One or more of water agent, polycarboxylate-based high-efficiency water red...

Embodiment 3

[0053] A non-autoclaved lightweight thermal insulation granular aerated concrete block, comprising the following components in parts by weight: 670g of cement, 273.5g of fly ash, 90.25g of fine slag powder, lightweight particles (ceramsite, EPS particles and active Consolidated magnesium oxide particles) 180g, hydrogen peroxide 42g, coagulation accelerator 35g, foam stabilizer 1.35g, water reducing agent 9.6g, water repellent 4.4g, fiber 4.6g, water 420g. The cement is ordinary Portland cement or aluminate cement; the coagulant is one or more of aluminum sulfate, sodium silicate, and sodium carbonate; the foam stabilizer is hydroxypropyl methylcellulose One or more of ether, hydroxyethyl methyl cellulose ether, hydroxyethyl cellulose ether, methyl cellulose ether; the water reducer is an aromatic sulfonate formaldehyde condensate high-efficiency water reducer, ketone One or more of aldehyde condensate superplasticizers and polycarboxylate superplasticizers; the water repellent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com