Method for calculating flexural capacity of variable cross-section column

A technology of variable cross-section column and calculation method, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve the problem that the calculation results are not accurate enough, the cross-sectional area conversion of irregular concrete of corrugated plates, structural constraint effects, etc. are not considered. The force of the carapace column is not clear enough to achieve the effect of accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

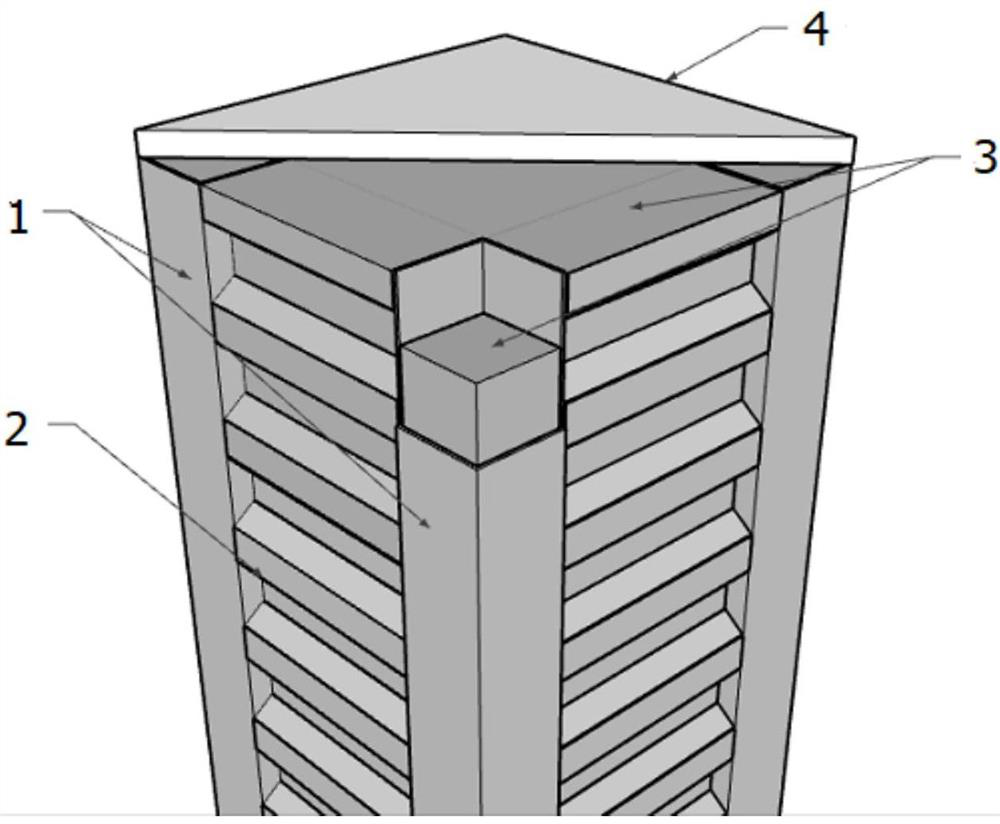

[0035] To study a calculation method for the flexural capacity of columns with variable cross-sections, the specimens are firstly designed.

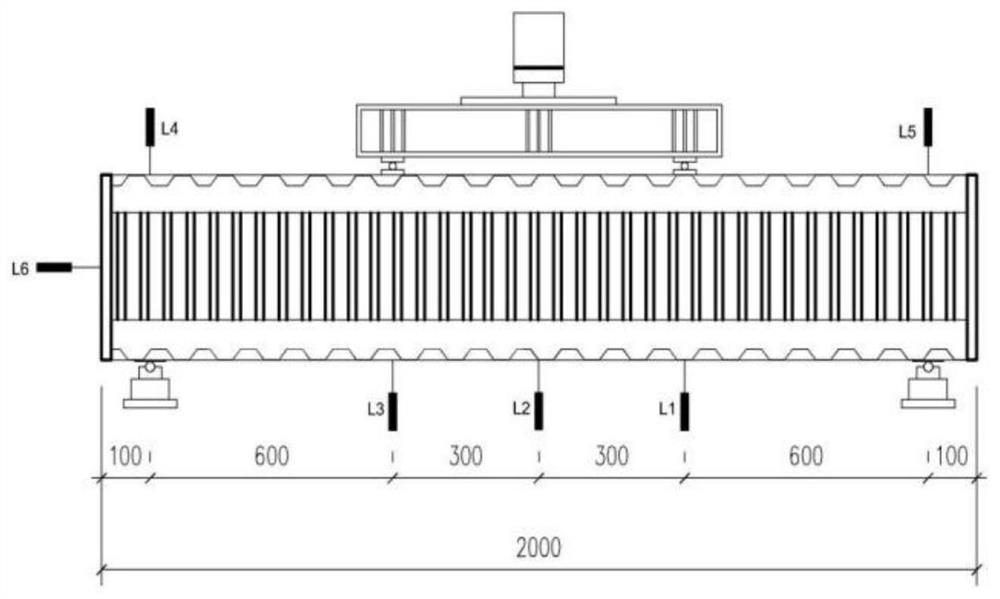

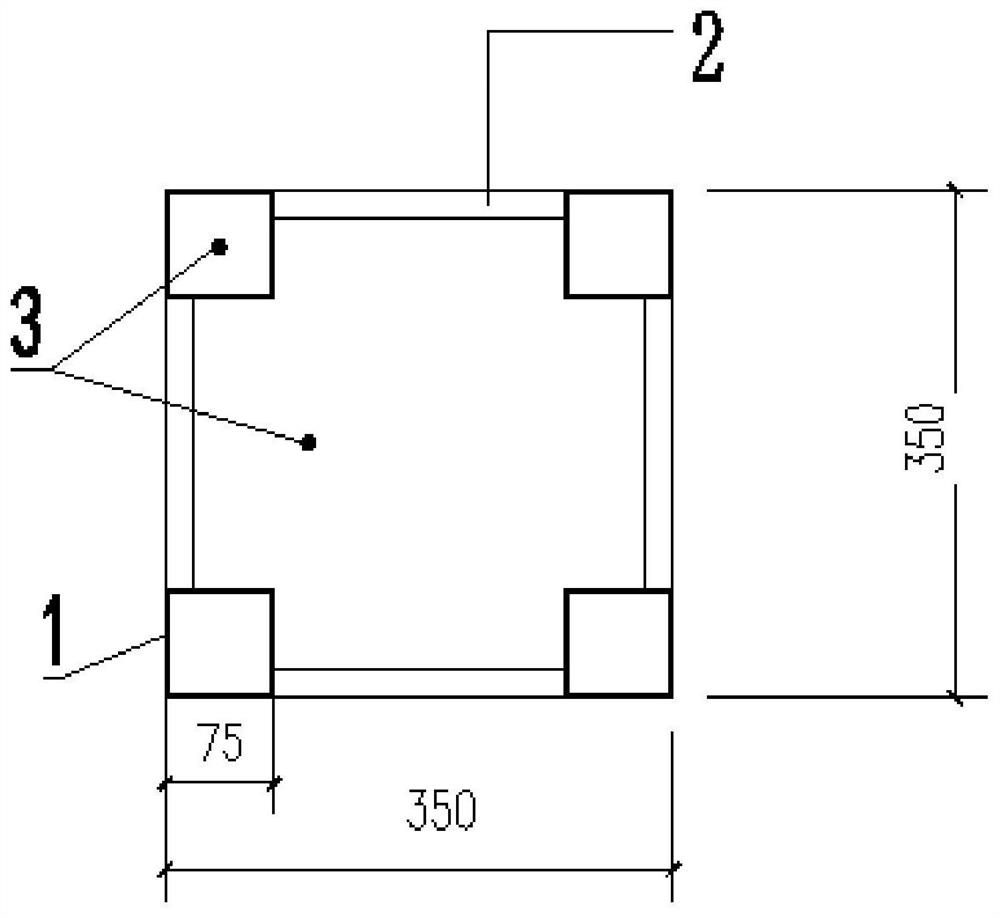

[0036] In order to study the mechanical performance of carapace columns under pure bending load, the bending bearing capacity test was carried out on two specimens of this type. In the test, the influence of the thickness of the steel pipe on the flexural stiffness and flexural capacity of the carapace column under pure flexural load was mainly considered. A total of 2 composite column specimens were designed, both subjected to pure bending load, numbered CPST1 and CPST2 respectively, the column height was uniformly taken as 2m, and the cross-sectional size was 350mm. Both the steel pipe and the corrugated plate are made of Q345 steel, and the thickness of the corrugated plate is 1mm. The strength class of concrete is C40.

[0037] The design parameters of the reference specimen CPST1 are as follows: image 3 shown. The remaining sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com