Articulated concrete joint member

a joint member and concrete technology, applied in the direction of roads, paving details, roads, etc., can solve the problems of increasing the height or the lower of one peripheral edge, and eventually cracking of the unitary slab. , to achieve the effect of controlling the cracking of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It will be convenient to further describe the articulation member with respect to the accompanying drawings, which illustrate possible arrangements of the invention. Other arrangements of the articulation member are possible and consequently the particularity of the accompanying drawings is not to be understood as superceding the generality of the preceding description of the invention.

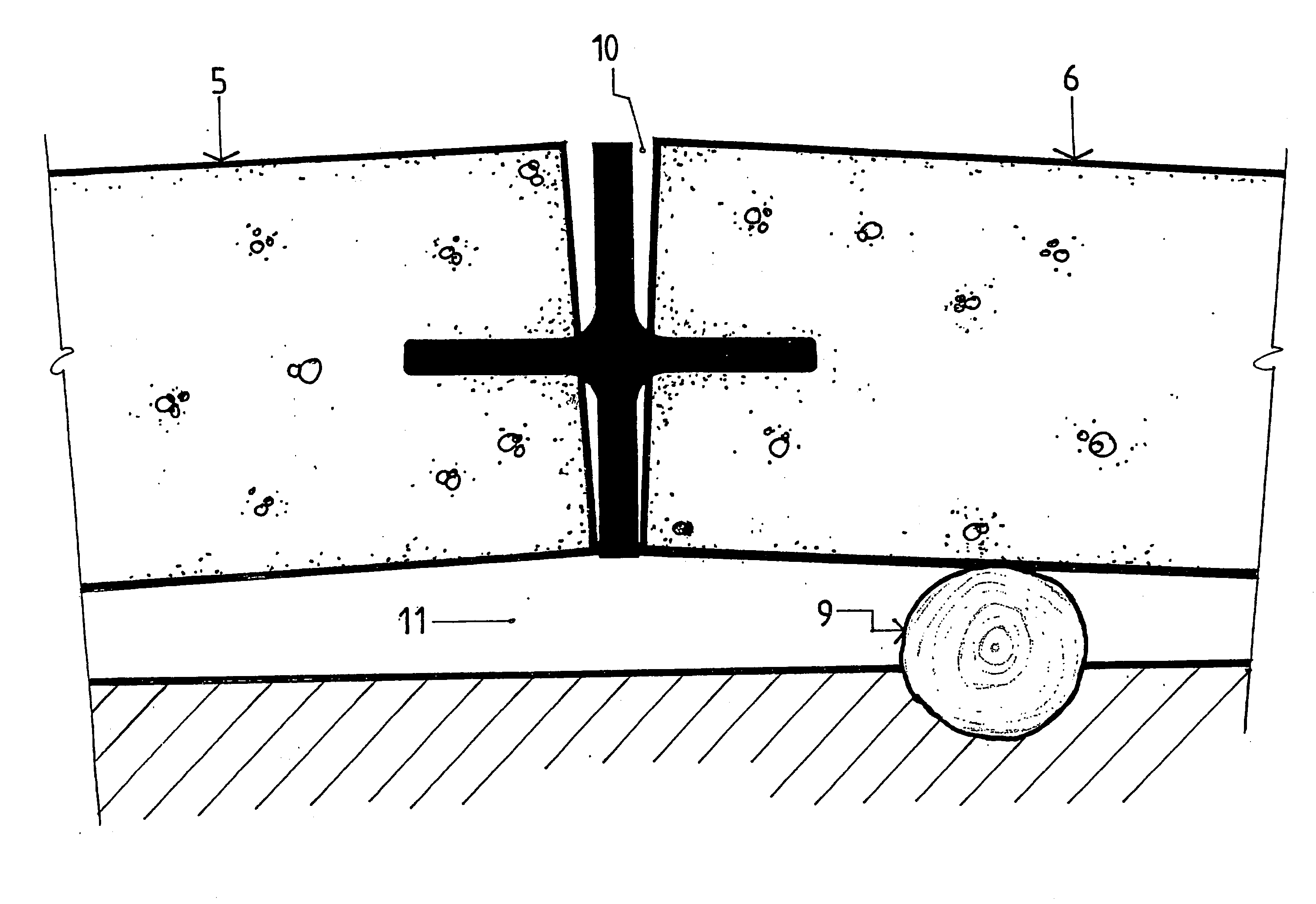

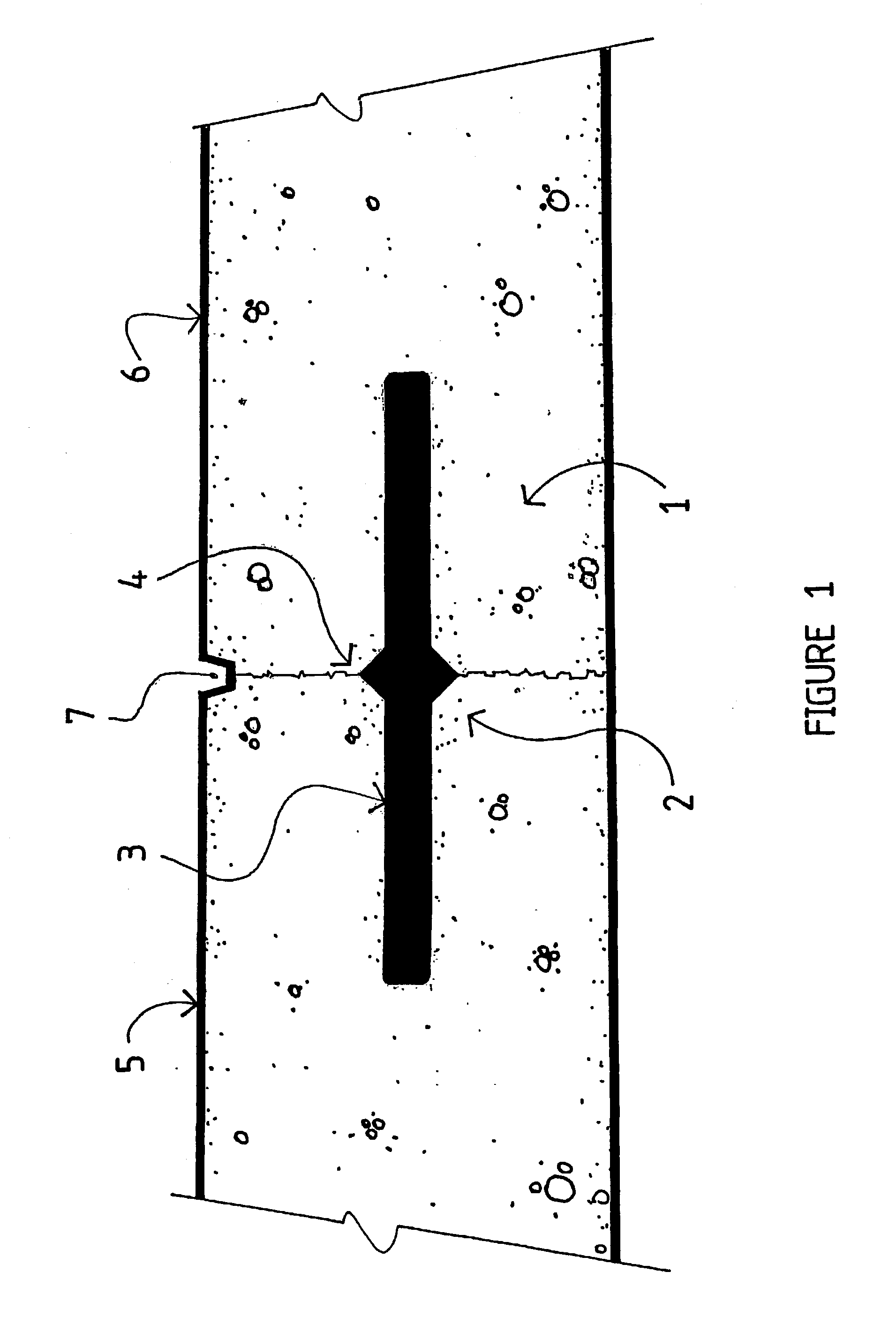

[0036] FIG. 1 is an elevation sectional view of the articulation member, according to the present invention.

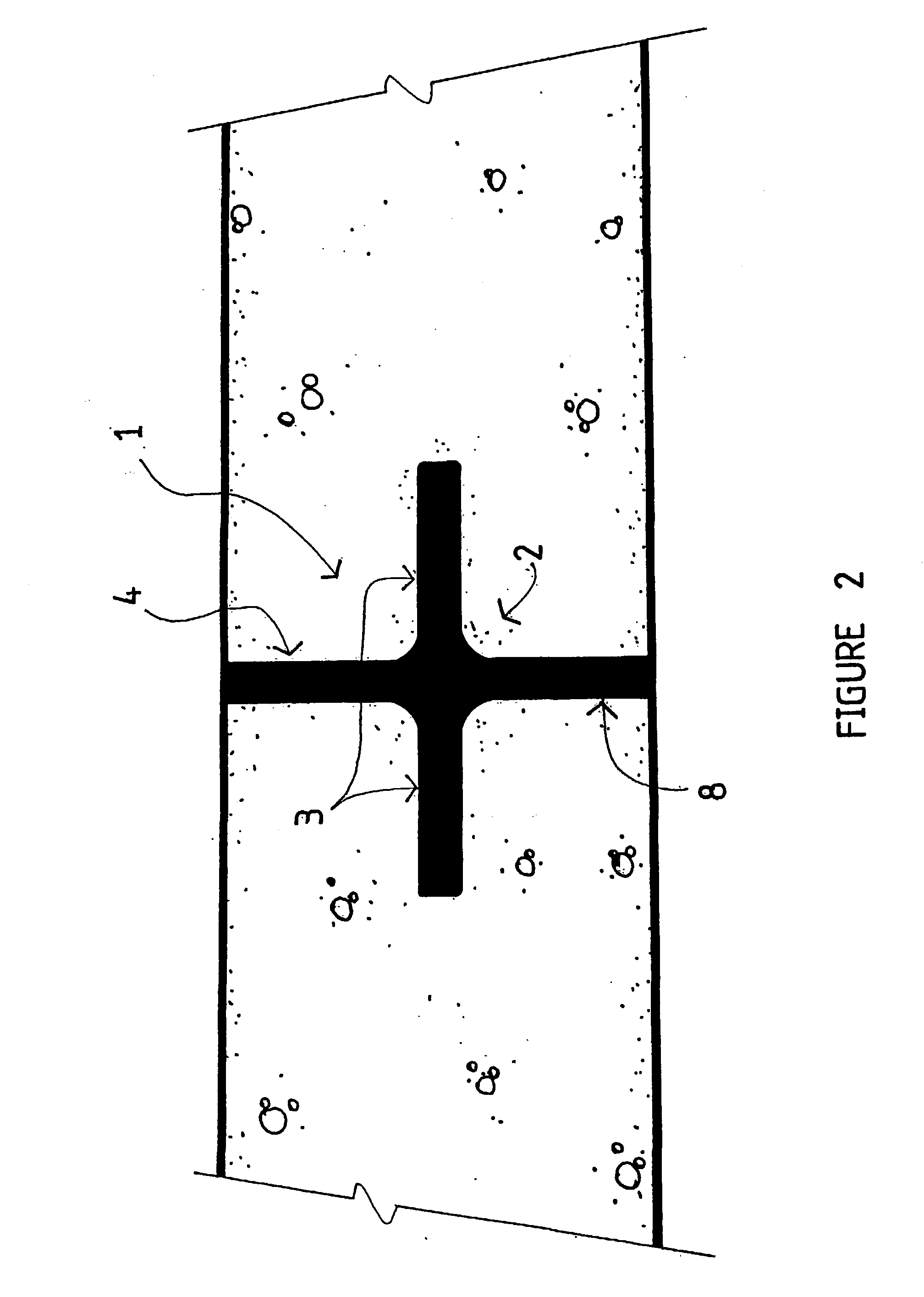

[0037] FIG. 2 is an elevation sectional view of the articulation member, according to another embodiment of the present invention.

[0038] FIG. 3 is a further elevation sectional view of the articulation member, according to the present invention.

[0039] FIG. 4 is a further elevation sectional view of the articulation member, according to another embodiment of the present invention.

[0040] FIG. 5A is an elevation view of the support means, according to one embodiment of the present invention....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific gravity | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com