Method for repairing housing of hot blast heater in late service period

A hot blast stove and furnace skin technology, which is applied in the field of red-burning repair and furnace skin cracking in the later stage of the hot blast stove service, can solve the problems of reduced strength, difficulty in welding, cracking, etc., so as to prolong the service life and prevent deformation and cracking. , to ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] What present embodiment is repaired is the supporting of volume 1650 cubic meters blast furnace, has used 22 years iron-smelting hot blast stove, and furnace skin cracks 4mm wide crack and furnace skin burns red.

[0044] This embodiment includes the following steps in sequence:

[0045] Ⅰ Restoration of furnace skin cracks

[0046] Stop the hot blast stove, close all valves except the waste gas valve; use compressed air pipes to locally cool down the surrounding area of the running air from the outside.

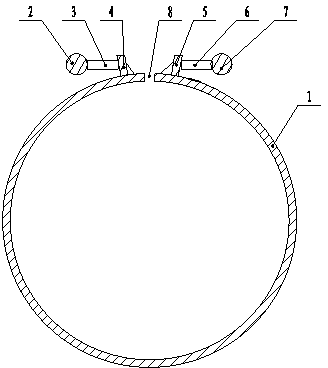

[0047] The stove skin 1 of the hot-blast stove that the present embodiment modifies cracks 4mm wide crack 8, long 1200mm, see figure 1 , weld the left support frame 4 (its structure is the original "corbel") on the outer surface of the left side of the crack 8 of the furnace skin 1 for restoring the furnace skin 1, and weld on the outer surface of the right side of the crack 8 of the furnace skin 1 For restoring the right support frame 5 of the furnace skin 1, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com